DODGE TOWN AND COUNTRY 2004 Service Manual

TOWN AND COUNTRY 2004

DODGE

DODGE

https://www.carmanualsonline.info/img/12/56919/w960_56919-0.png

DODGE TOWN AND COUNTRY 2004 Service Manual

Trending: maintenance schedule, spark plugs, key fob, jump start, fuses, battery location, water pump

Page 1861 of 2585

Page 1862 of 2585

TRANSMISSION/TRANSAXLE

TABLE OF CONTENTS

page page

T850 MANUAL TRANSAXLE ................1

40TE AUTOMATIC TRANSAXLE .............2441TE AUTOMATIC TRANSAXLE

............166

T850 MANUAL TRANSAXLE

TABLE OF CONTENTS

page page

INPUT SHAFT DESCRIPTION ..........................1

DISASSEMBLY ..........................1

ASSEMBLY .............................5 INTERMEDIATE SHAFT

DESCRIPTION ..........................9

DISASSEMBLY .........................10

ASSEMBLY ............................17

INPUT SHAFT

DESCRIPTION

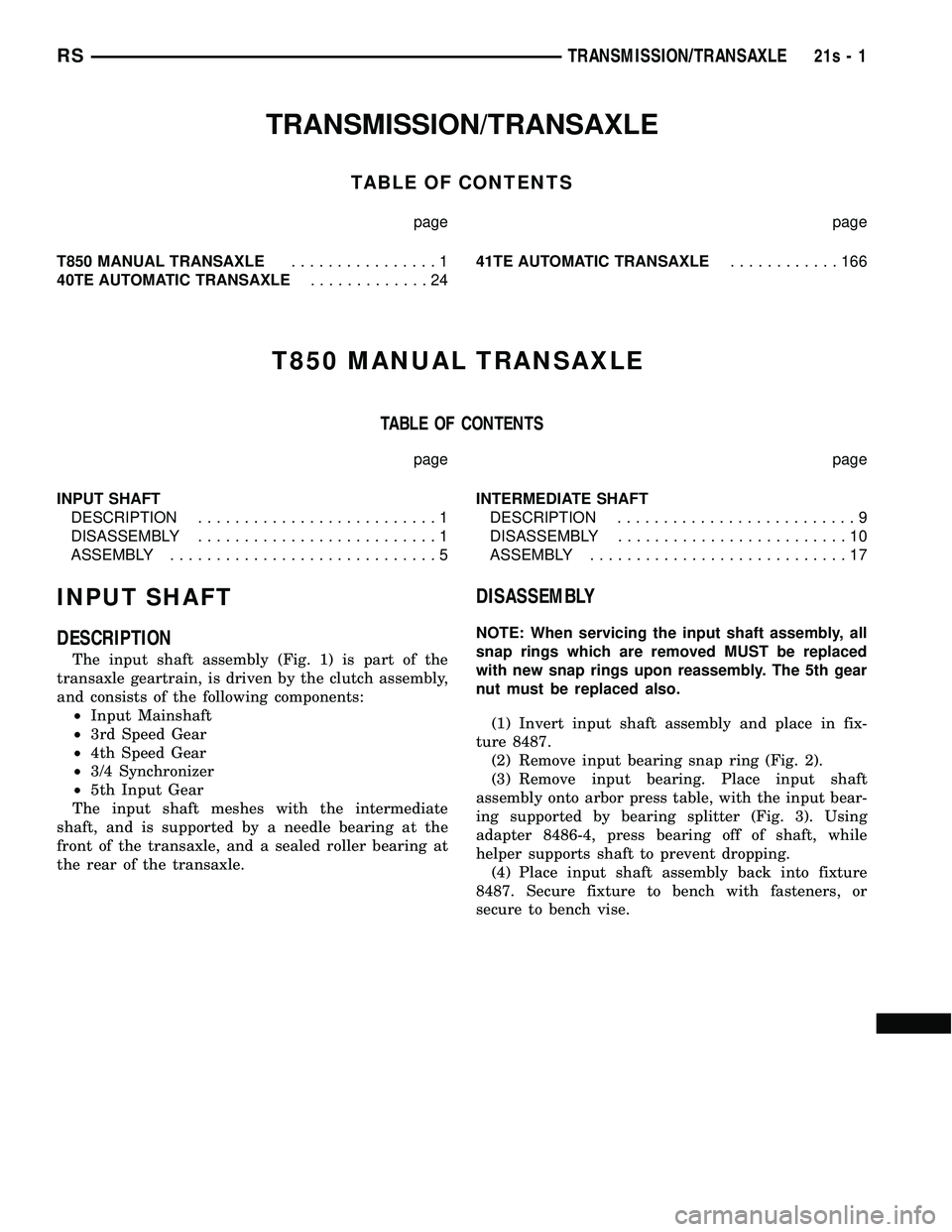

The input shaft assembly (Fig. 1) is part of the

transaxle geartrain, is driven by the clutch assembly,

and consists of the following components: ² Input Mainshaft

² 3rd Speed Gear

² 4th Speed Gear

² 3/4 Synchronizer

² 5th Input Gear

The input shaft meshes with the intermediate

shaft, and is supported by a needle bearing at the

front of the transaxle, and a sealed roller bearing at

the rear of the transaxle.

DISASSEMBLY

NOTE: When servicing the input shaft assembly, all

snap rings which are removed MUST be replaced

with new snap rings upon reassembly. The 5th gear

nut must be replaced also.

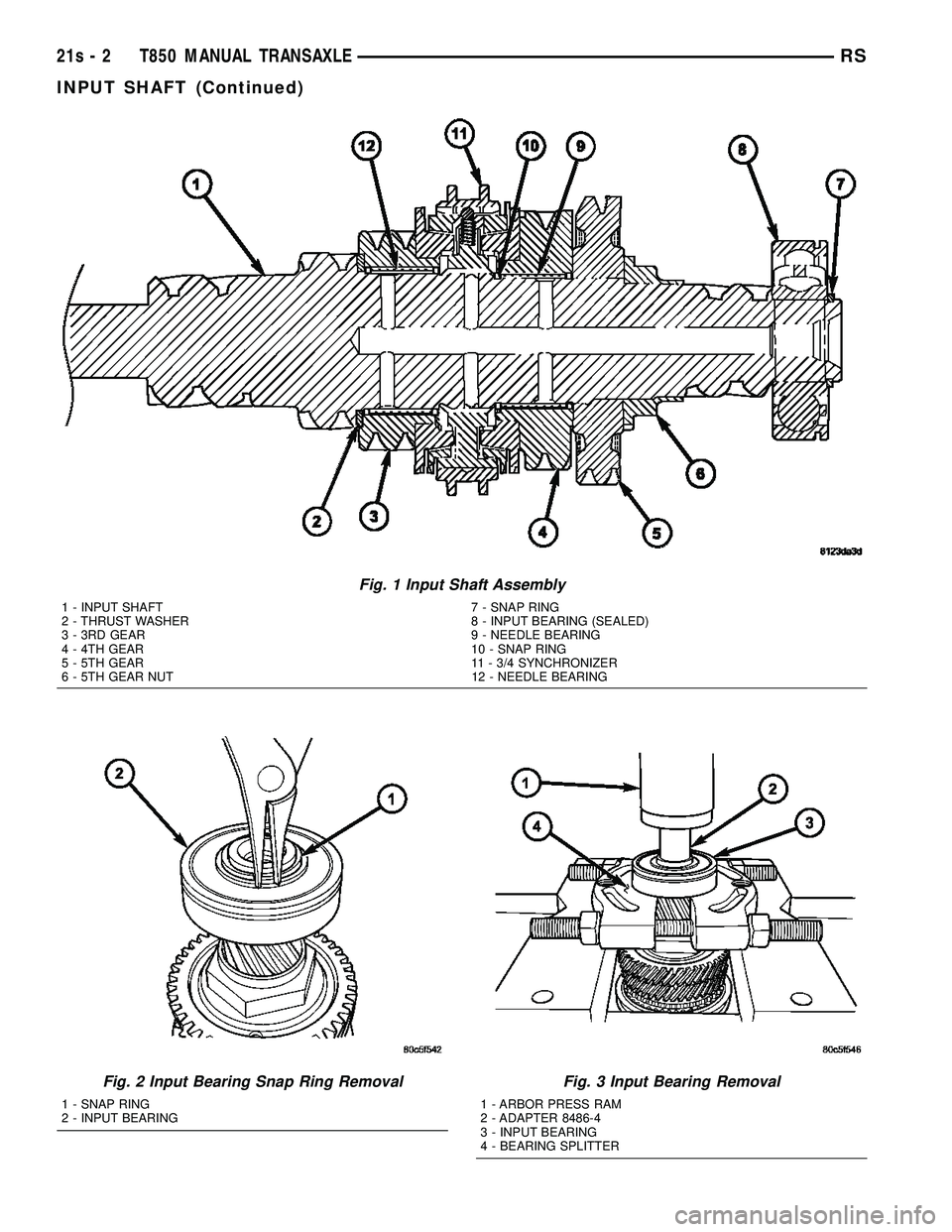

(1) Invert input shaft assembly and place in fix-

ture 8487. (2) Remove input bearing snap ring (Fig. 2).

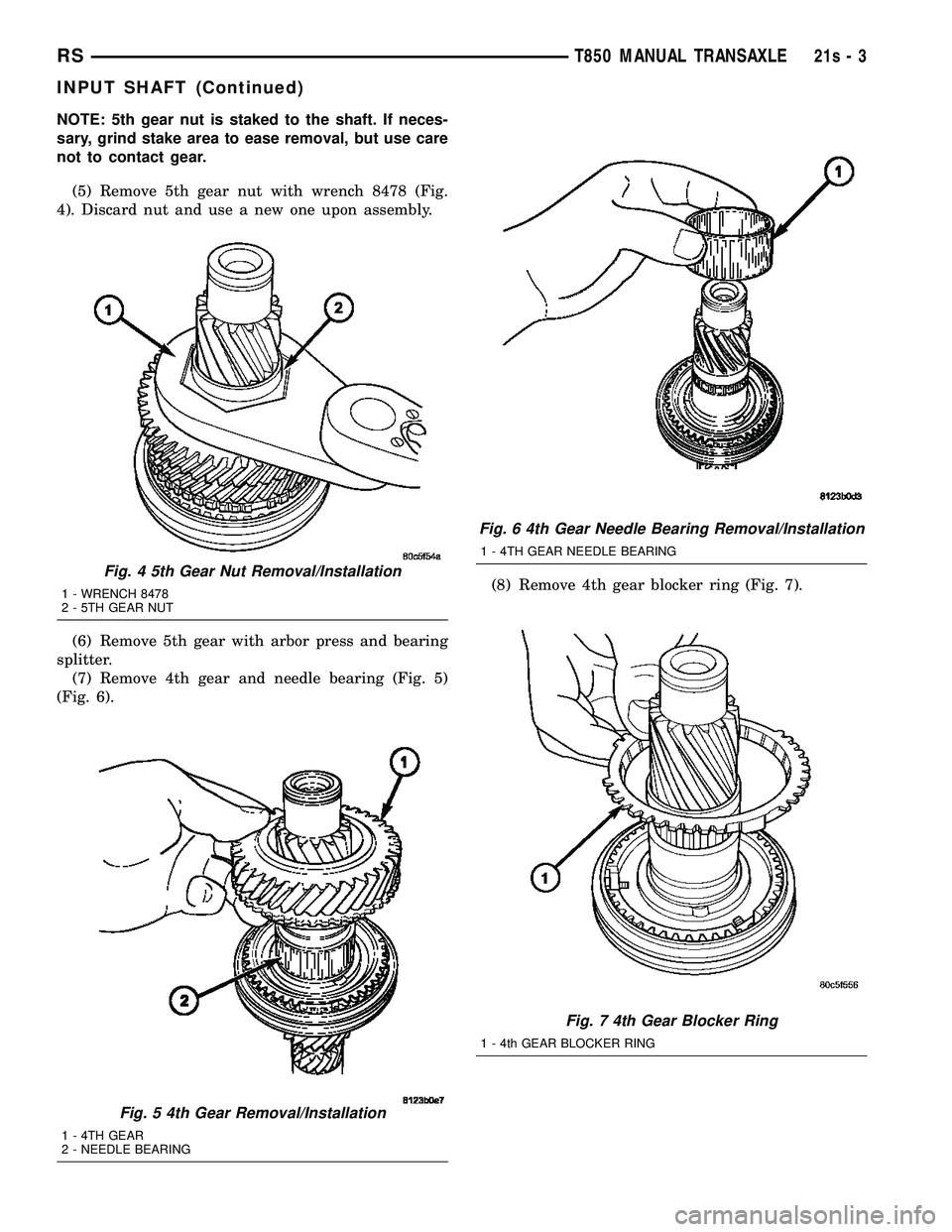

(3) Remove input bearing. Place input shaft

assembly onto arbor press table, with the input bear-

ing supported by bearing splitter (Fig. 3). Using

adapter 8486-4, press bearing off of shaft, while

helper supports shaft to prevent dropping. (4) Place input shaft assembly back into fixture

8487. Secure fixture to bench with fasteners, or

secure to bench vise.

RS TRANSMISSION/TRANSAXLE21s-1

Page 1863 of 2585

Fig. 1 Input Shaft Assembly

1 - INPUT SHAFT 7 - SNAP RING

2 - THRUST WASHER 8 - INPUT BEARING (SEALED)

3 - 3RD GEAR 9 - NEEDLE BEARING

4 - 4TH GEAR 10 - SNAP RING

5 - 5TH GEAR 11 - 3/4 SYNCHRONIZER

6 - 5TH GEAR NUT 12 - NEEDLE BEARING

Fig. 2 Input Bearing Snap Ring Removal

1 - SNAP RING

2 - INPUT BEARING

Fig. 3 Input Bearing Removal

1 - ARBOR PRESS RAM

2 - ADAPTER 8486-4

3 - INPUT BEARING

4 - BEARING SPLITTER

21s - 2 T850 MANUAL TRANSAXLERS

INPUT SHAFT (Continued)

Page 1864 of 2585

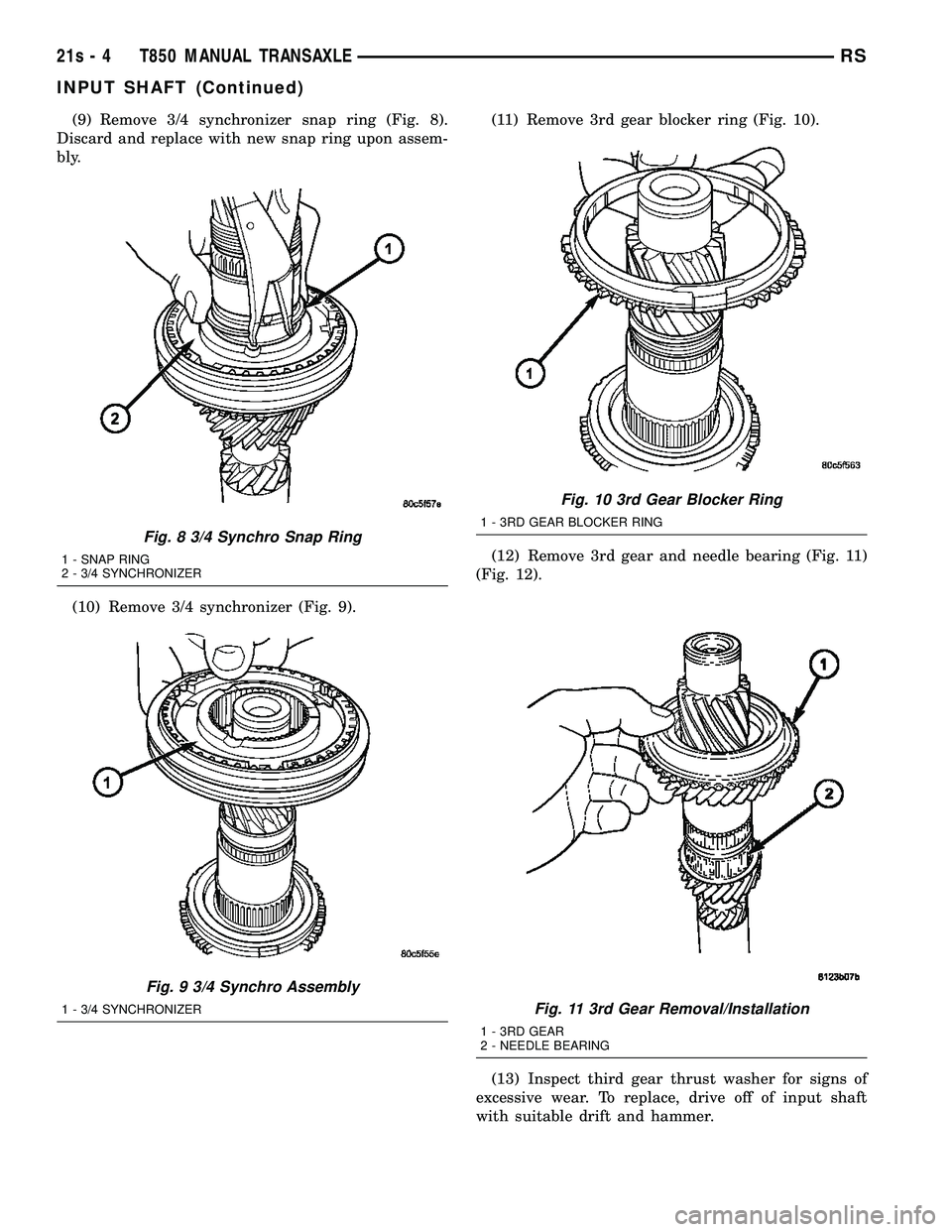

NOTE: 5th gear nut is staked to the shaft. If neces-

sary, grind stake area to ease removal, but use care

not to contact gear.(5) Remove 5th gear nut with wrench 8478 (Fig.

4). Discard nut and use a new one upon assembly.

(6) Remove 5th gear with arbor press and bearing

splitter. (7) Remove 4th gear and needle bearing (Fig. 5)

(Fig. 6). (8) Remove 4th gear blocker ring (Fig. 7).

Fig. 4 5th Gear Nut Removal/Installation

1 - WRENCH 8478

2 - 5TH GEAR NUT

Fig. 5 4th Gear Removal/Installation

1 - 4TH GEAR

2 - NEEDLE BEARING

Fig. 6 4th Gear Needle Bearing Removal/Installation

1 - 4TH GEAR NEEDLE BEARING

Fig. 7 4th Gear Blocker Ring

1 - 4th GEAR BLOCKER RING

RS

T850 MANUAL TRANSAXLE21s-3

INPUT SHAFT (Continued)

Page 1865 of 2585

(9) Remove 3/4 synchronizer snap ring (Fig. 8).

Discard and replace with new snap ring upon assem-

bly.

(10) Remove 3/4 synchronizer (Fig. 9). (11) Remove 3rd gear blocker ring (Fig. 10).

(12) Remove 3rd gear and needle bearing (Fig. 11)

(Fig. 12).

(13) Inspect third gear thrust washer for signs of

excessive wear. To replace, drive off of input shaft

with suitable drift and hammer.

Fig. 8 3/4 Synchro Snap Ring

1 - SNAP RING

2 - 3/4 SYNCHRONIZER

Fig. 9 3/4 Synchro Assembly

1 - 3/4 SYNCHRONIZER

Fig. 10 3rd Gear Blocker Ring

1 - 3RD GEAR BLOCKER RING

Fig. 11 3rd Gear Removal/Installation

1 - 3RD GEAR

2 - NEEDLE BEARING

21s - 4 T850 MANUAL TRANSAXLERS

INPUT SHAFT (Continued)

Page 1866 of 2585

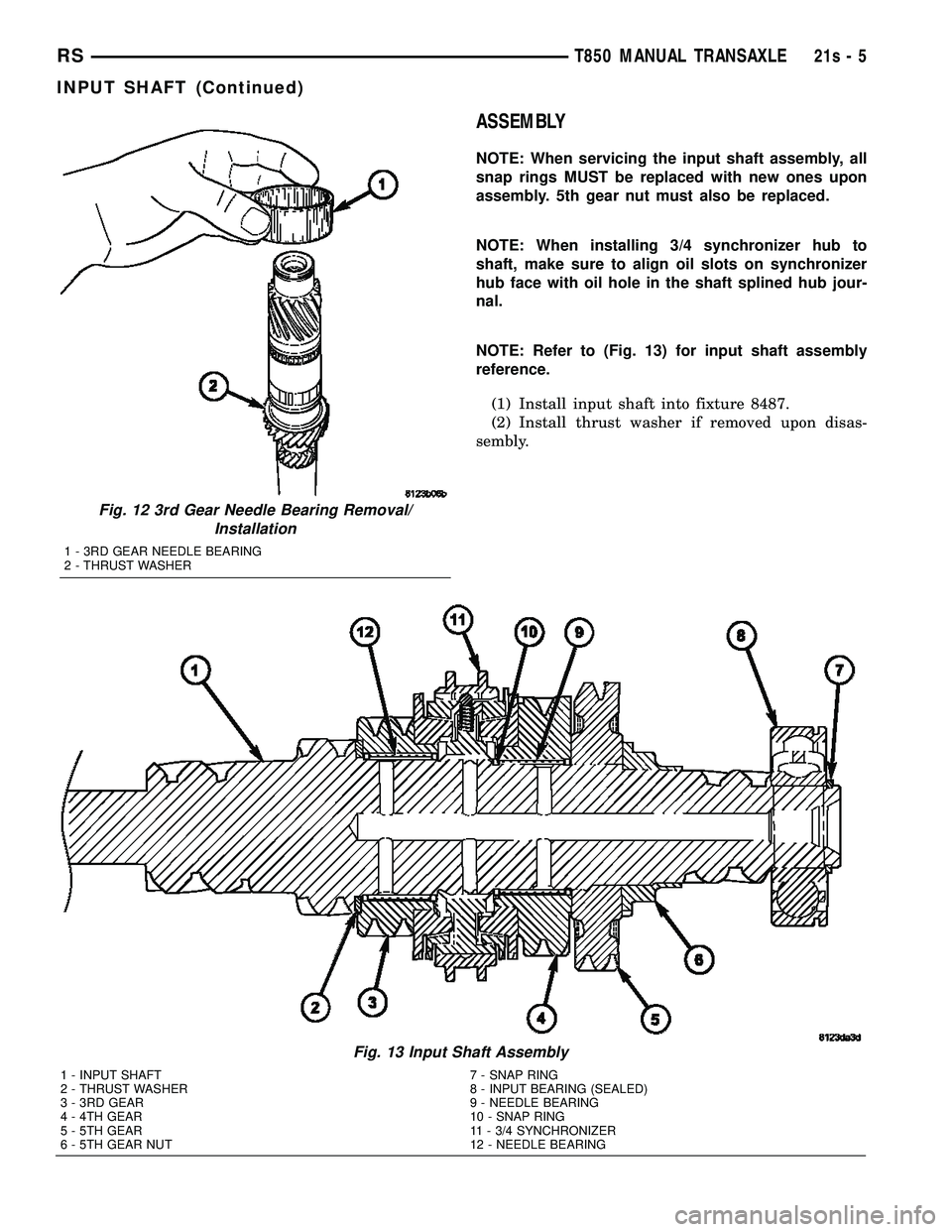

ASSEMBLY

NOTE: When servicing the input shaft assembly, all

snap rings MUST be replaced with new ones upon

assembly. 5th gear nut must also be replaced.

NOTE: When installing 3/4 synchronizer hub to

shaft, make sure to align oil slots on synchronizer

hub face with oil hole in the shaft splined hub jour-

nal.

NOTE: Refer to (Fig. 13) for input shaft assembly

reference.(1) Install input shaft into fixture 8487.

(2) Install thrust washer if removed upon disas-

sembly.

Fig. 12 3rd Gear Needle Bearing Removal/ Installation

1 - 3RD GEAR NEEDLE BEARING

2 - THRUST WASHER

Fig. 13 Input Shaft Assembly

1 - INPUT SHAFT 7 - SNAP RING

2 - THRUST WASHER 8 - INPUT BEARING (SEALED)

3 - 3RD GEAR 9 - NEEDLE BEARING

4 - 4TH GEAR 10 - SNAP RING

5 - 5TH GEAR 11 - 3/4 SYNCHRONIZER

6 - 5TH GEAR NUT 12 - NEEDLE BEARING

RS T850 MANUAL TRANSAXLE21s-5

INPUT SHAFT (Continued)

Page 1867 of 2585

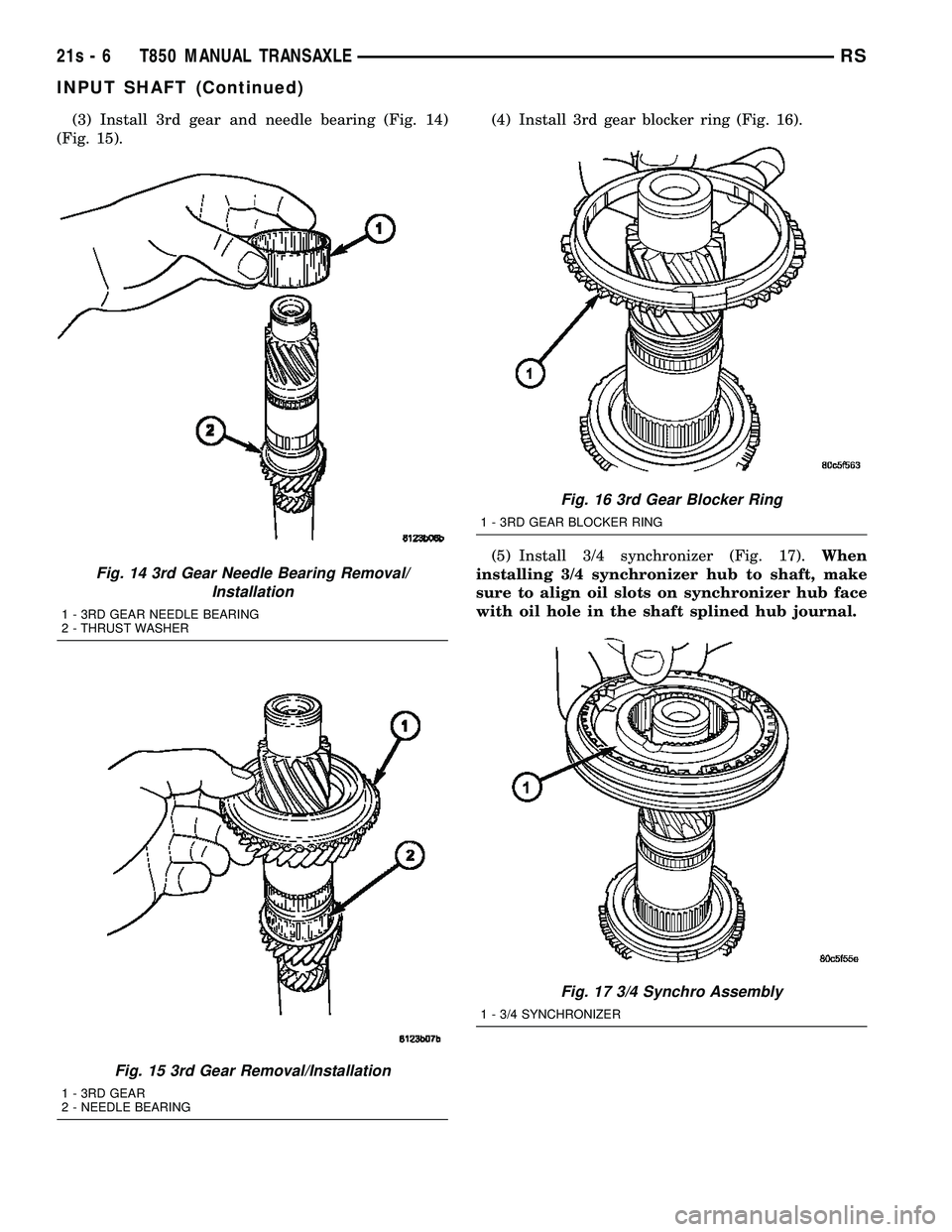

(3) Install 3rd gear and needle bearing (Fig. 14)

(Fig. 15). (4) Install 3rd gear blocker ring (Fig. 16).

(5) Install 3/4 synchronizer (Fig. 17).

When

installing 3/4 synchronizer hub to shaft, make

sure to align oil slots on synchronizer hub face

with oil hole in the shaft splined hub journal.

Fig. 14 3rd Gear Needle Bearing Removal/ Installation

1 - 3RD GEAR NEEDLE BEARING

2 - THRUST WASHER

Fig. 15 3rd Gear Removal/Installation

1 - 3RD GEAR

2 - NEEDLE BEARING

Fig. 16 3rd Gear Blocker Ring

1 - 3RD GEAR BLOCKER RING

Fig. 17 3/4 Synchro Assembly

1 - 3/4 SYNCHRONIZER

21s - 6 T850 MANUAL TRANSAXLERS

INPUT SHAFT (Continued)

Page 1868 of 2585

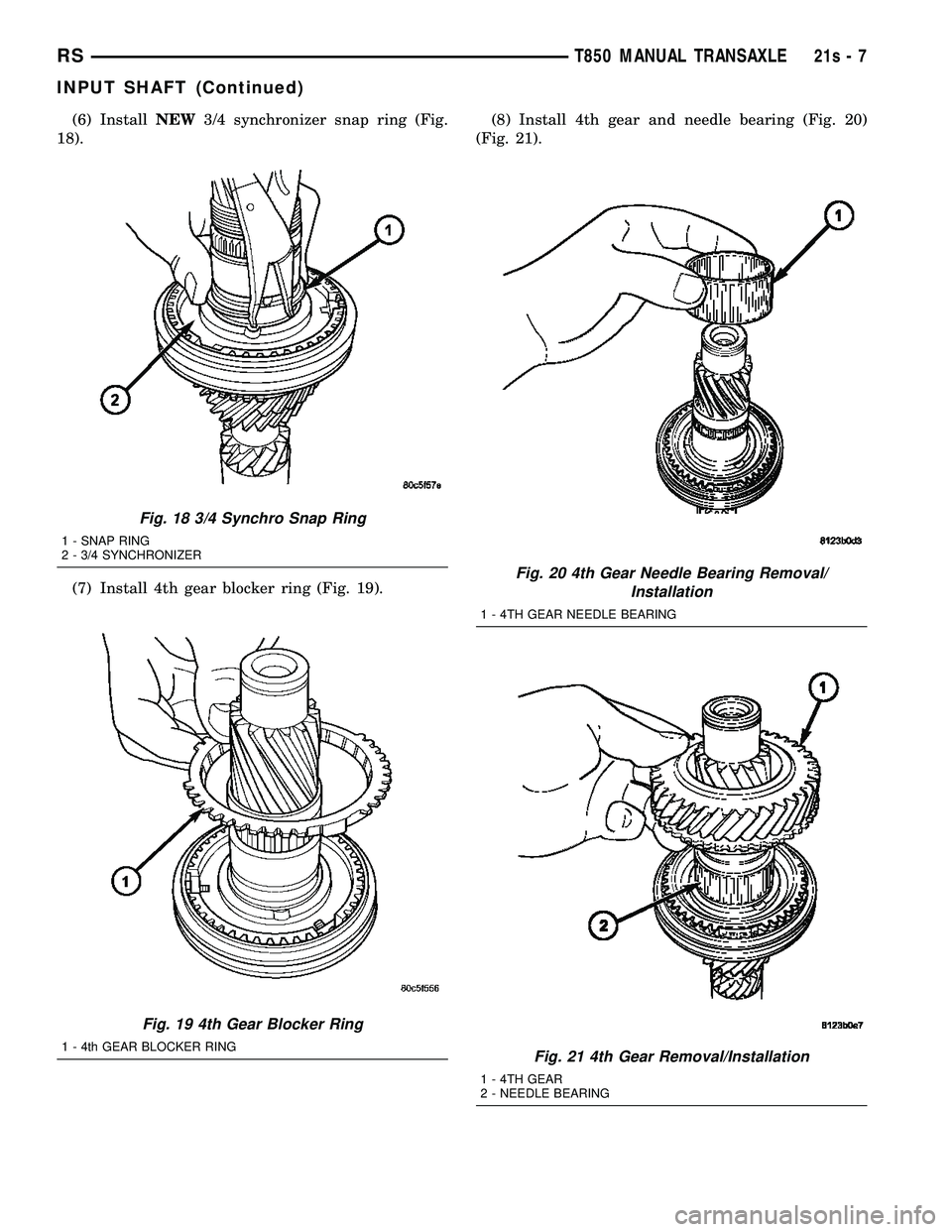

(6) InstallNEW3/4 synchronizer snap ring (Fig.

18).

(7) Install 4th gear blocker ring (Fig. 19). (8) Install 4th gear and needle bearing (Fig. 20)

(Fig. 21).

Fig. 18 3/4 Synchro Snap Ring

1 - SNAP RING

2 - 3/4 SYNCHRONIZER

Fig. 19 4th Gear Blocker Ring

1 - 4th GEAR BLOCKER RING

Fig. 20 4th Gear Needle Bearing Removal/ Installation

1 - 4TH GEAR NEEDLE BEARING

Fig. 21 4th Gear Removal/Installation

1 - 4TH GEAR

2 - NEEDLE BEARING

RS T850 MANUAL TRANSAXLE21s-7

INPUT SHAFT (Continued)

Page 1869 of 2585

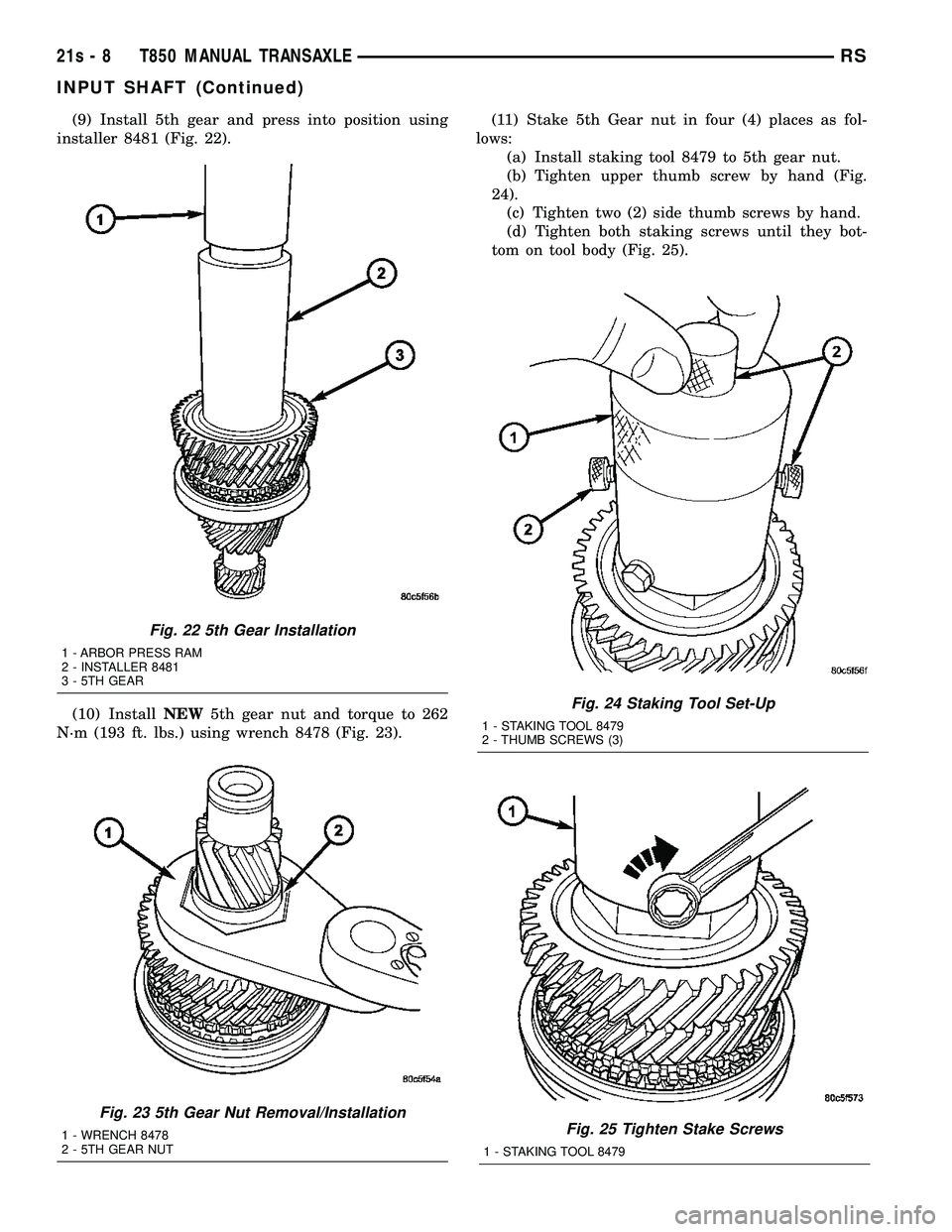

(9) Install 5th gear and press into position using

installer 8481 (Fig. 22).

(10) Install NEW5th gear nut and torque to 262

N´m (193 ft. lbs.) using wrench 8478 (Fig. 23). (11) Stake 5th Gear nut in four (4) places as fol-

lows: (a) Install staking tool 8479 to 5th gear nut.

(b) Tighten upper thumb screw by hand (Fig.

24). (c) Tighten two (2) side thumb screws by hand.

(d) Tighten both staking screws until they bot-

tom on tool body (Fig. 25).

Fig. 24 Staking Tool Set-Up

1 - STAKING TOOL 8479

2 - THUMB SCREWS (3)

Fig. 25 Tighten Stake Screws

1 - STAKING TOOL 8479

Fig. 22 5th Gear Installation

1 - ARBOR PRESS RAM

2 - INSTALLER 8481

3 - 5TH GEAR

Fig. 23 5th Gear Nut Removal/Installation

1 - WRENCH 8478

2 - 5TH GEAR NUT

21s - 8 T850 MANUAL TRANSAXLERS

INPUT SHAFT (Continued)

Page 1870 of 2585

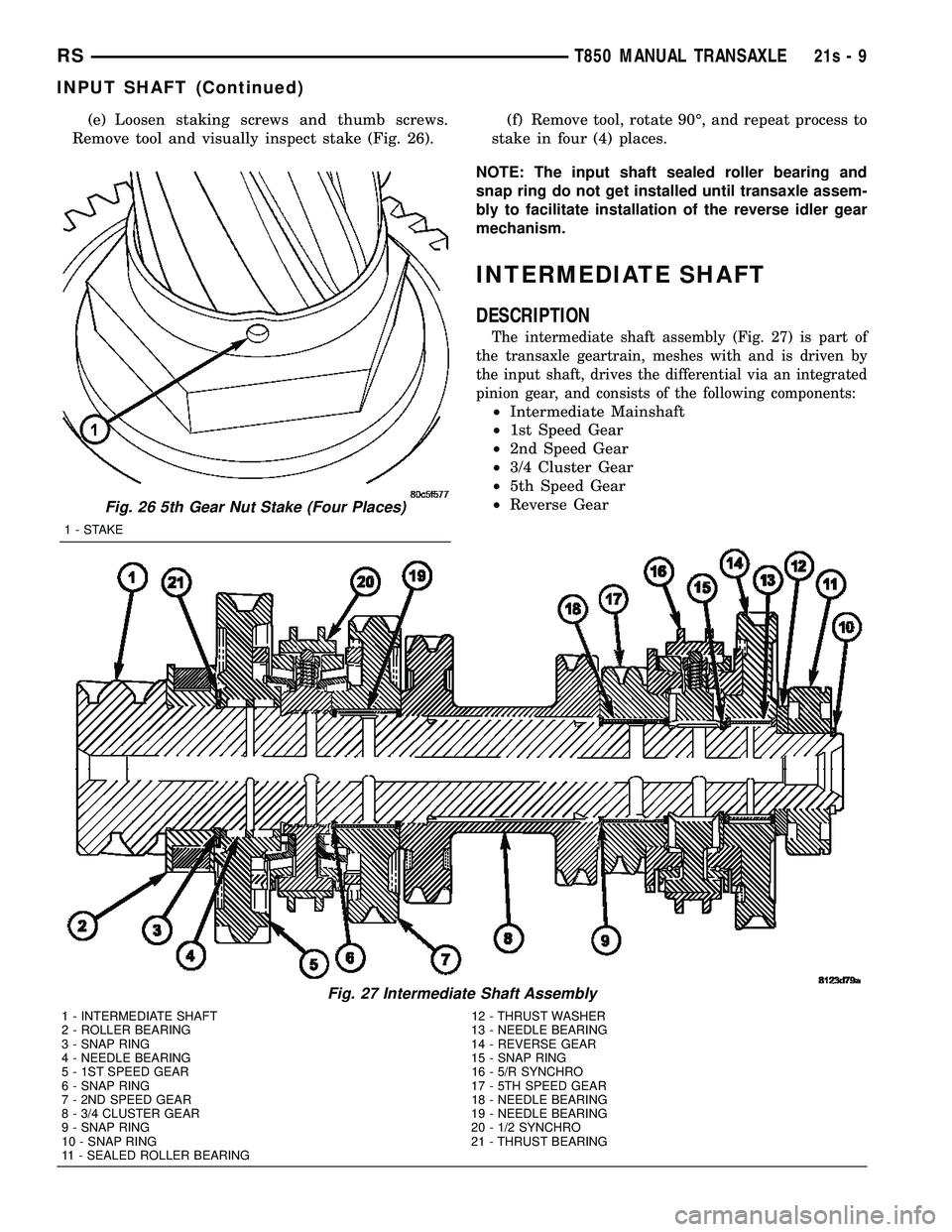

(e) Loosen staking screws and thumb screws.

Remove tool and visually inspect stake (Fig. 26). (f) Remove tool, rotate 90É, and repeat process to

stake in four (4) places.

NOTE: The input shaft sealed roller bearing and

snap ring do not get installed until transaxle assem-

bly to facilitate installation of the reverse idler gear

mechanism.

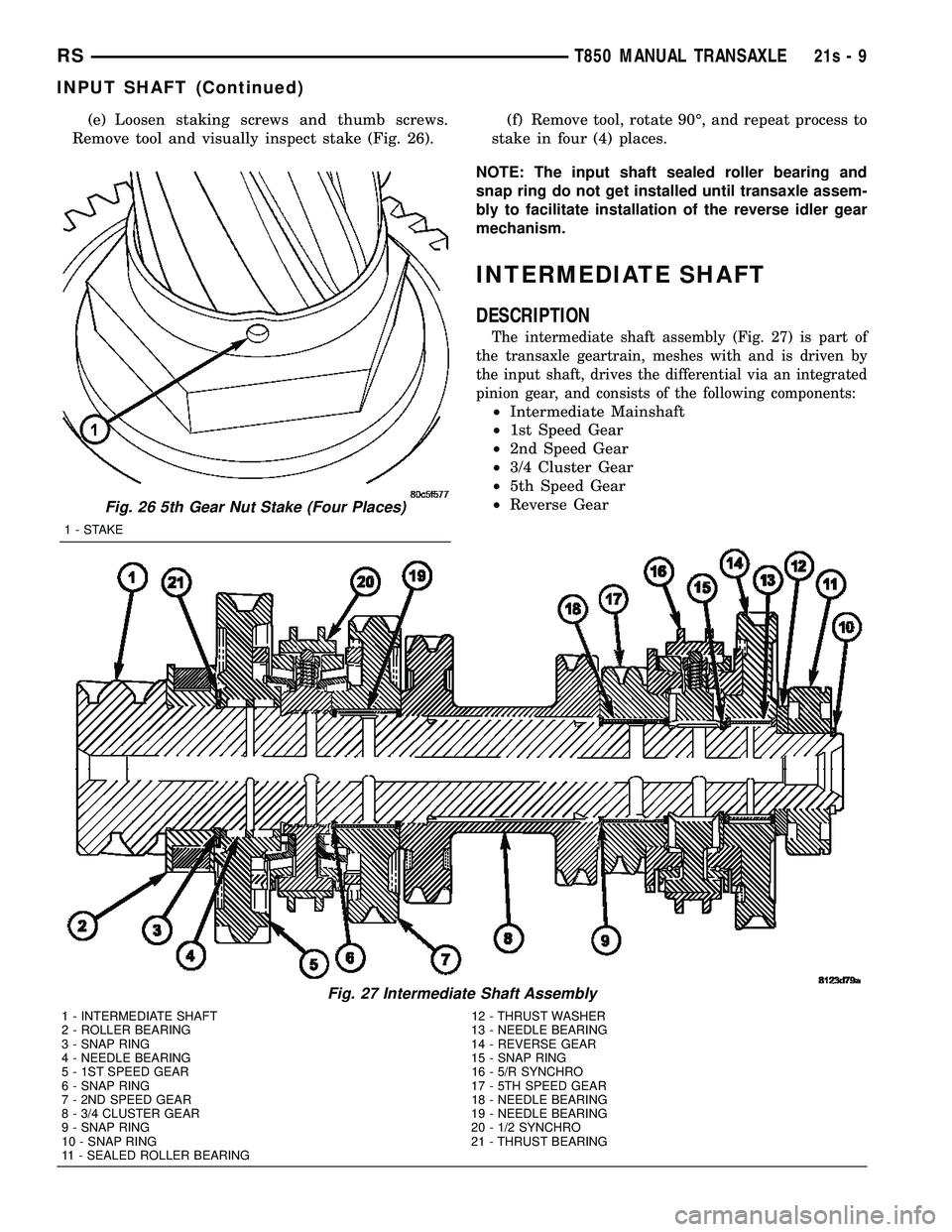

INTERMEDIATE SHAFT

DESCRIPTION

The intermediate shaft assembly (Fig. 27) is part of

the transaxle geartrain, meshes with and is driven by

the input shaft, drives the differential via an integrated

pinion gear, and consists of the following components:

² Intermediate Mainshaft

² 1st Speed Gear

² 2nd Speed Gear

² 3/4 Cluster Gear

² 5th Speed Gear

² Reverse Gear

Fig. 26 5th Gear Nut Stake (Four Places)

1-STAKE

Fig. 27 Intermediate Shaft Assembly

1 - INTERMEDIATE SHAFT 12 - THRUST WASHER

2 - ROLLER BEARING 13 - NEEDLE BEARING

3 - SNAP RING 14 - REVERSE GEAR

4 - NEEDLE BEARING 15 - SNAP RING

5 - 1ST SPEED GEAR 16 - 5/R SYNCHRO

6 - SNAP RING 17 - 5TH SPEED GEAR

7 - 2ND SPEED GEAR 18 - NEEDLE BEARING

8 - 3/4 CLUSTER GEAR 19 - NEEDLE BEARING

9 - SNAP RING 20 - 1/2 SYNCHRO

10 - SNAP RING 21 - THRUST BEARING

11 - SEALED ROLLER BEARING

RS T850 MANUAL TRANSAXLE21s-9

INPUT SHAFT (Continued)

Trending: headlamp, automatic transmission, oil, height adjustment, drain bolt, roof rack, wiring