sensor DODGE TRUCK 1993 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 901 of 1502

14 - 82

FUEL 'SYSTEM

—. — ~—— — «

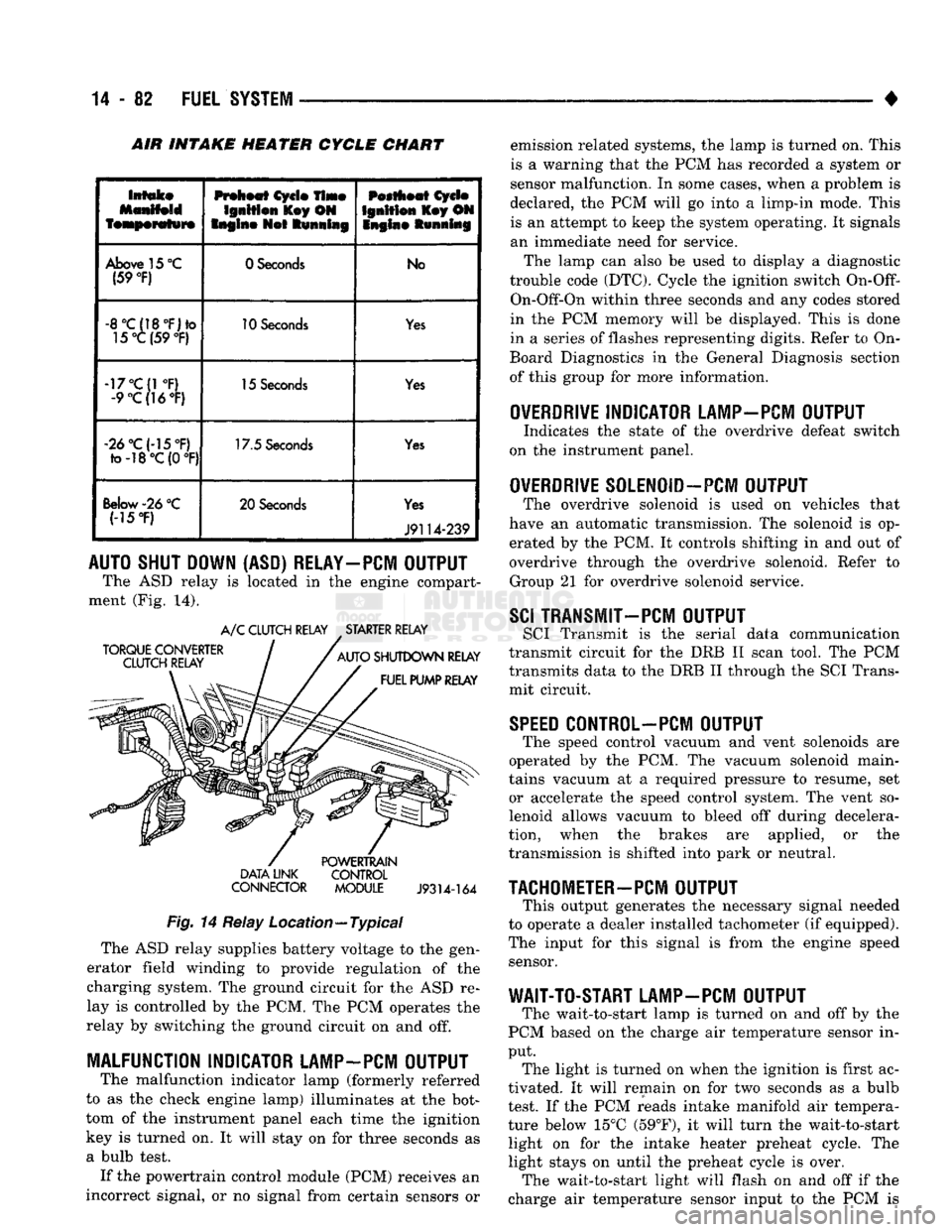

INTAKE HEATER CYCLE CHART

Intake

featperafwre

Preheat

Cycle

Time

Ignition

l£ey ON

Engine

Not

Running

Pestheat

Cycle

Ignition

Key ON

Snglne Running

Above

15

°C

(59

°F)

0 Seconds

No

-8°C(18°F)to

15°C (59

°F)

10

Seconds

Yes

-17°C(1

°F)

-9

°C(]6°F)

15

Seconds

Yes

«2d°C(-15°F)

to-18°C(0

°F) 17.5

Seconds

Yes

Below-26

°C (-15

*F)

20 Seconds

Yes

J9114-239

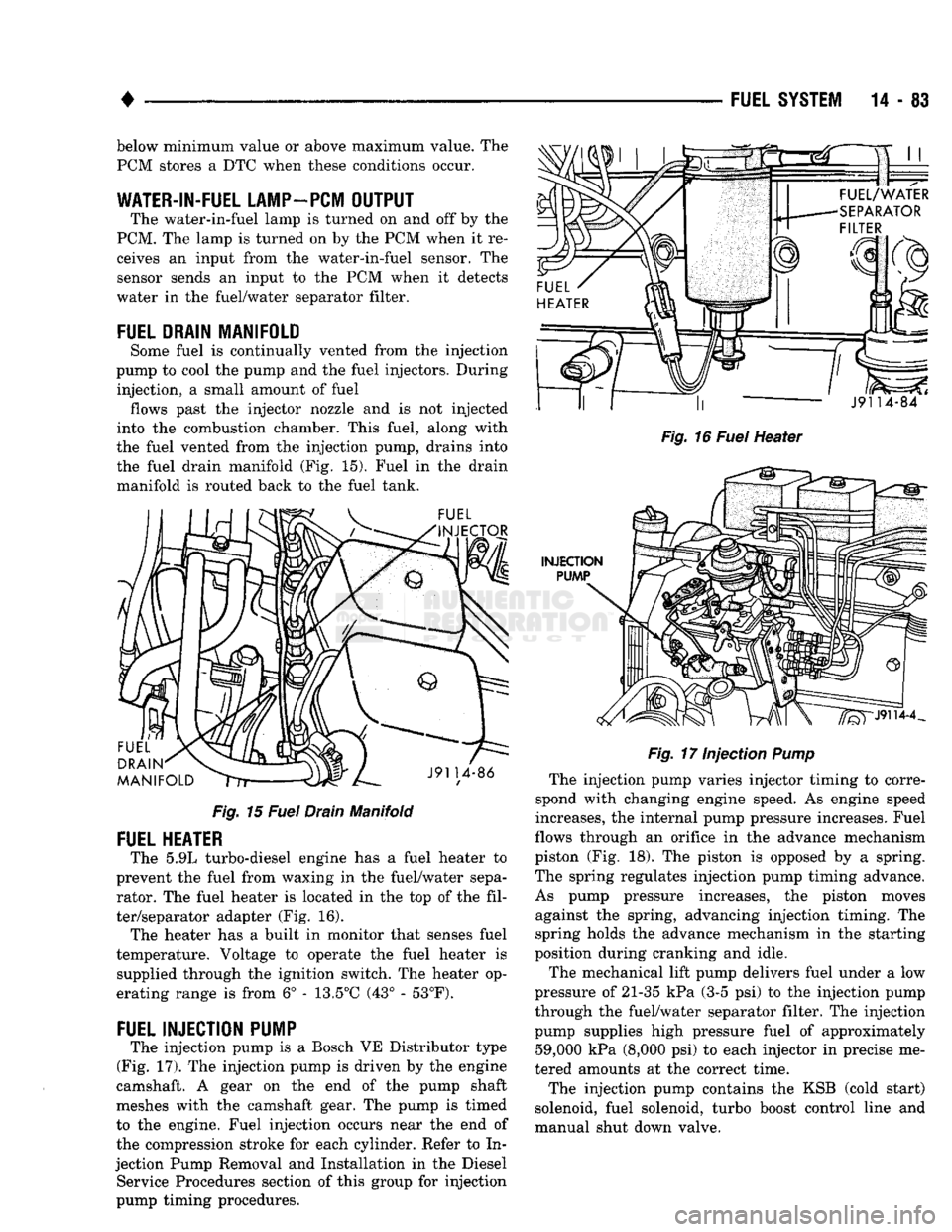

AUTO SHUT DOWN (ASD) RELAY-PCM OUTPUT

The ASD relay is located in the engine compart

ment (Fig. 14).

TORQUE CONVERTER

CLUTCH RELAY A/C CLUTCH RELAY STARTER RELAY

AUTO SHUTDOWN RELAY FUEL PUMP RELAY DATA LINK

CONNECTOR

POWERTRAIN

CONTROL MODULE

J9314-164

Fig.

14 Relay Location—Typical The ASD relay supplies battery voltage to the gen

erator field winding to provide regulation of the

charging system. The ground circuit for the ASD re

lay is controlled by the PCM. The PCM operates the

relay by switching the ground circuit on and off.

MALFUNCTION INDICATOR LAMP-PCM OUTPUT

The malfunction indicator lamp (formerly referred

to as the check engine lamp) illuminates at the bot

tom of the instrument panel each time the ignition

key is turned on. It will stay on for three seconds as

a bulb test. If the powertrain control module (PCM) receives an

incorrect signal, or no signal from certain sensors or emission related systems, the lamp is turned on. This

is a warning that the PCM has recorded a system or

sensor malfunction. In some cases, when a problem is

declared, the PCM will go into a limp-in mode. This is an attempt to keep the system operating. It signals

an immediate need for service.

The lamp can also be used to display a diagnostic

trouble code (DTC). Cycle the ignition switch

On-Off-

On-Off-On within three seconds and any codes stored

in the PCM memory will be displayed. This is done

in a series of flashes representing digits. Refer to On-

Board Diagnostics in the General Diagnosis section

of this group for more information.

OVERDRIVE

INDICATOR LAMP-PCM OUTPUT

Indicates the state of the overdrive defeat switch

on the instrument panel.

OVERDRIVE

S0LEN0ID-PCM OUTPUT

The overdrive solenoid is used on vehicles that

have an automatic transmission. The solenoid is op erated by the PCM. It controls shifting in and out of

overdrive through the overdrive solenoid. Refer to Group 21 for overdrive solenoid service.

SCI

TRANSMIT—PCM OUTPUT

SCI Transmit is the serial data communication

transmit circuit for the DRB II scan tool. The PCM

transmits data to the DRB II through the SCI Trans

mit circuit.

SPEED

C0NTR0L-PCM OUTPUT

The speed control vacuum and vent solenoids are

operated by the PCM. The vacuum solenoid main

tains vacuum at a required pressure to resume, set or accelerate the speed control system. The vent so

lenoid allows vacuum to bleed off during decelera

tion, when the brakes are applied, or the

transmission is shifted into park or neutral.

TACHOMETER-PCM

OUTPUT

This output generates the necessary signal needed

to operate a dealer installed tachometer (if equipped).

The input for this signal is from the engine speed sensor.

WAIT-TO-START LAMP-PCM OUTPUT

The wait-to-start lamp is turned on and off by the

PCM based on the charge air temperature sensor in

put. The light is turned on when the ignition is first ac

tivated. It will remain on for two seconds as a bulb

test. If the PCM reads intake manifold air tempera

ture below 15°C (59°F), it will turn the wait-to-start light on for the intake heater preheat cycle. The

light stays on until the preheat cycle is over. The wait-to-start light will flash on and off if the

charge air temperature sensor input to the PCM is

Page 902 of 1502

•

FUEL SYSTEM

14 - 83 below minimum value or above maximum value. The

PCM stores a DTC when these conditions occur.

WATER-IN-FUEL LAMP-PCM

OUTPUT

The water-in-fuel lamp is turned on and off by the

PCM. The lamp is turned on by the PCM when it re ceives an input from the water-in-fuel sensor. The sensor sends an input to the PCM when it detects

water in the fuel/water separator filter.

FUEL DRAIN MANIFOLD

Some fuel is continually vented from the injection

pump to cool the pump and the fuel injectors. During injection, a small amount of fuel flows past the injector nozzle and is not injected

into the combustion chamber. This fuel, along with

the fuel vented from the injection pump, drains into

the fuel drain manifold (Fig. 15). Fuel in the drain manifold is routed back to the fuel tank.

Fig.

15

Fuel

Drain Manifold

FUEL

HEATER

The 5.9L turbo-diesel engine has a fuel heater to

prevent the fuel from waxing in the fuel/water sepa rator. The fuel heater is located in the top of the fil

ter/separator adapter (Fig. 16). The heater has a built in monitor that senses fuel

temperature. Voltage to operate the fuel heater is supplied through the ignition switch. The heater op

erating range is from 6° - 13.5°C (43° - 53°F).

FUEL

INJECTION PUiVSP

The injection pump is a Bosch VE Distributor type

(Fig. 17). The injection pump is driven by the engine

camshaft. A gear on the end of the pump shaft

meshes with the camshaft gear. The pump is timed

to the engine. Fuel injection occurs near the end of the compression stroke for each cylinder. Refer to In

jection Pump Removal and Installation in the Diesel Service Procedures section of this group for injection

pump timing procedures.

Fig.

16

Fuel

Heater

Fig.

17 Injection

Pump

The injection pump varies injector timing to corre

spond with changing engine speed. As engine speed

increases, the internal pump pressure increases. Fuel

flows through an orifice in the advance mechanism

piston (Fig. 18). The piston is opposed by a spring.

The spring regulates injection pump timing advance.

As pump pressure increases, the piston moves against the spring, advancing injection timing. The

spring holds the advance mechanism in the starting

position during cranking and idle.

The mechanical lift pump delivers fuel under a low

pressure of 21-35 kPa (3-5 psi) to the injection pump

through the fuel/water separator filter. The injection

pump supplies high pressure fuel of approximately 59,000 kPa (8,000 psi) to each injector in precise me

tered amounts at the correct time.

The injection pump contains the KSB (cold start)

solenoid, fuel solenoid, turbo boost control line and

manual shut down valve.

Page 904 of 1502

•

FUEL SYSTEM

14-85 to pass through it, but prevents moisture (water)

from doing so. Moisture collects at the bottom of the

separator filter.

WARNING:

EXTINGUISH

ALL

SMOKING

MATERI

ALS

BEFORE

DRAINING

THE

FUEL/WATER

SEPA

RATOR

FILTER.

There is a drain at the bottom of the separator fil

ter (Fig. 16). Place a drain pan under the drain tube.

With the engine not running, push up on the drain

to remove the water from the separator filter. Hold

the drain open until all water and contaminants

have been removed and clean fuel exits the drain. Dispose of mixture in drain pan according to applica

ble regulations.

Refer to the maintenance schedules in Group 0 in

this manual for the recommended fuel/water separa

tor filter replacement intervals.

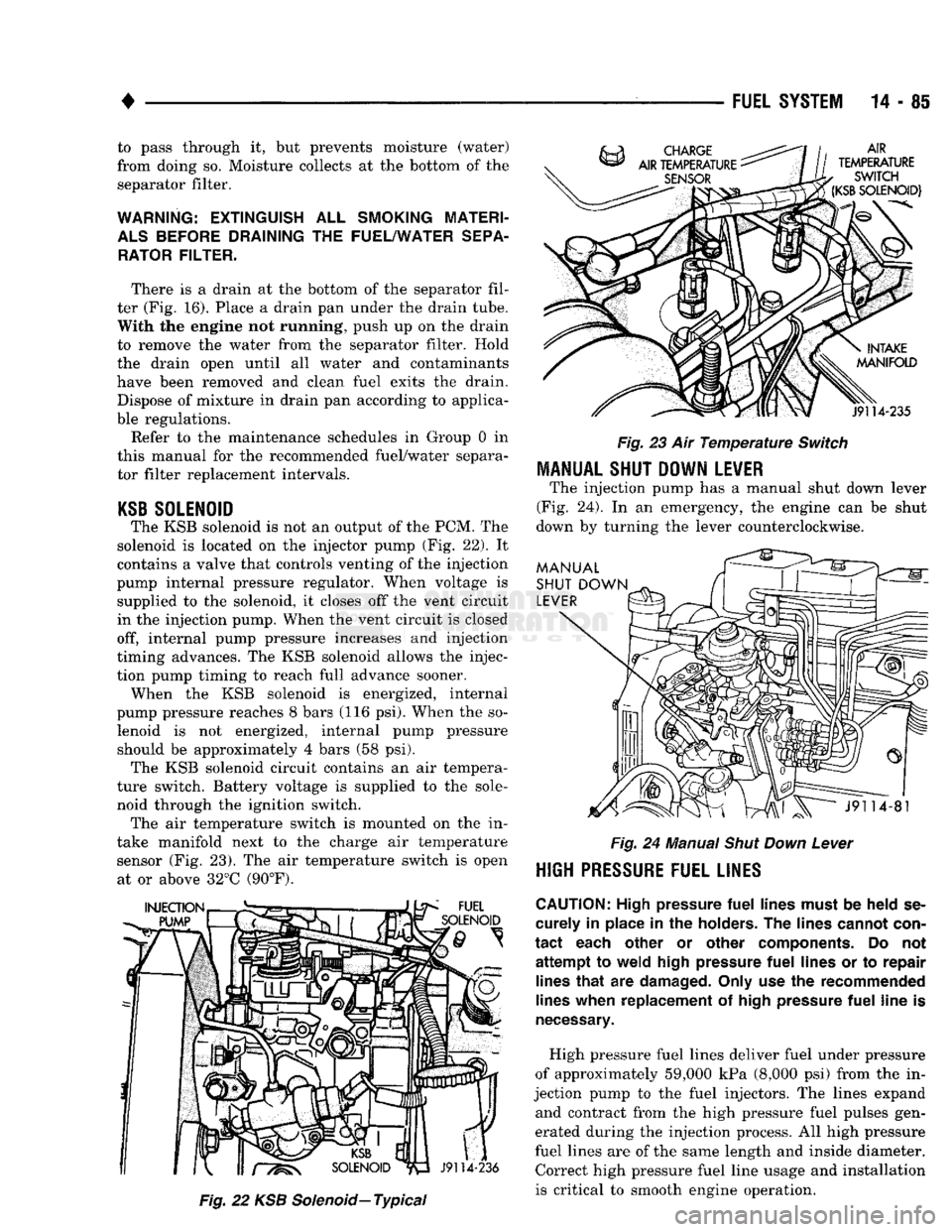

KSB

SOLENOID

The KSB solenoid is not an output of the PCM. The

solenoid is located on the injector pump (Fig. 22). It

contains a valve that controls venting of the injection

pump internal pressure regulator. When voltage is supplied to the solenoid, it closes off the vent circuit

in the injection pump. When the vent circuit is closed

off, internal pump pressure increases and injection

timing advances. The KSB solenoid allows the injec

tion pump timing to reach full advance sooner. When the KSB solenoid is energized, internal

pump pressure reaches 8 bars (116 psi). When the so lenoid is not energized, internal pump pressure should be approximately 4 bars (58 psi). The KSB solenoid circuit contains an air tempera

ture switch. Battery voltage is supplied to the sole

noid through the ignition switch. The air temperature switch is mounted on the in

take manifold next to the charge air temperature sensor (Fig. 23). The air temperature switch is open at or above 32°C (90°F).

Fig.

22 KSB

Solenoid—

Typical

Fig.

23 Air

Temperature

Switch

MANUAL SHUT DOWN LEVER

The injection pump has a manual shut down lever

(Fig. 24). In an emergency, the engine can be shut

down by turning the lever counterclockwise.

Fig.

24 Manual

Shut

Down

Lever

HIGH

PRESSURE FUEL LINES

CAUTION:

High pressure

fuel

lines must

be

held

se

curely

in

place

in the

holders.

The

lines cannot con

tact

each other

or

other components.

Do not

attempt

to

weld high pressure

fuel

lines

or to

repair lines

that

are

damaged. Only use

the

recommended

lines when replacement

of

high pressure

fuel

line

is

necessary.

High pressure fuel lines deliver fuel under pressure

of approximately 59,000 kPa (8,000 psi) from the in

jection pump to the fuel injectors. The lines expand and contract from the high pressure fuel pulses gen

erated during the injection process. All high pressure

fuel lines are of the same length and inside diameter. Correct high pressure fuel line usage and installation

is critical to smooth engine operation.

Page 905 of 1502

14-86

FUEL

SYSTEM

WARNING:

USE

EXTREME CAUTION WHEN

IN

SPECTING

FOR

HIGH

PRESSURE

FUEL

LEAKS.

IN

SPECT

FOR

HIGH

PRESSURE

FUEL

LEAKS

WITH

A

SHEET

OF

CARDBOARD. HIGH FUEL INJECTION

PRESSURE

CAN

CAUSE PERSONAL INJURY

IF

CONTACT

IS

MADE

WITH

THE

SKIN.

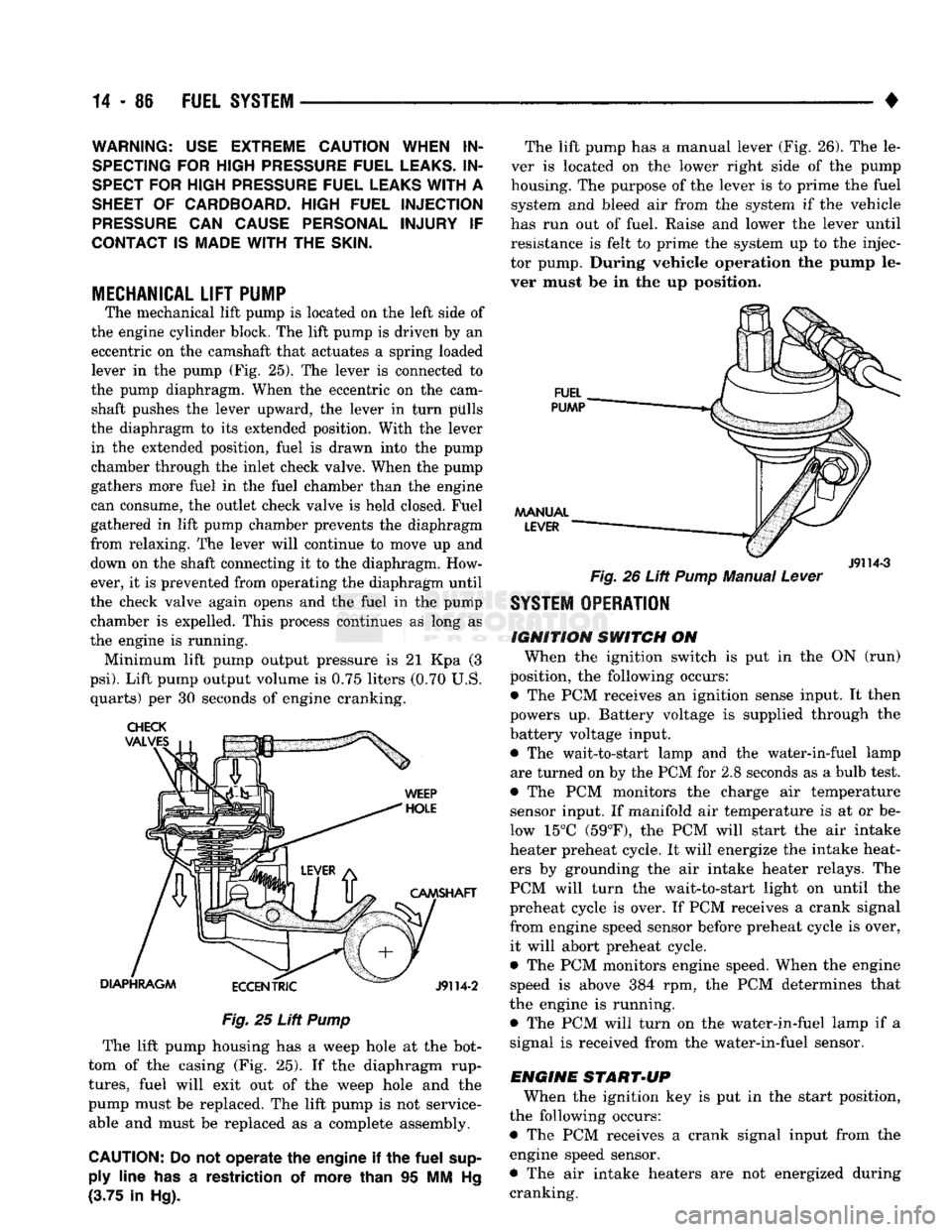

MECHANICAL

LIFT

PUMP

The mechanical lift pump

is

located

on the

left side

of

the engine cylinder block.

The

lift pump

is

driven

by an

eccentric

on the

camshaft that actuates

a

spring loaded lever

in the

pump

(Fig. 25). The

lever

is

connected

to

the pump diaphragm. When

the

eccentric

on the

cam shaft pushes

the

lever upward,

the

lever

in

turn pulls

the diaphragm

to its

extended position. With

the

lever in

the

extended position, fuel

is

drawn into

the

pump

chamber through

the

inlet check valve. When

the

pump

gathers more fuel

in the

fuel chamber than

the

engine

can consume,

the

outlet check valve

is

held closed. Fuel

gathered

in

lift pump chamber prevents

the

diaphragm

from relaxing.

The

lever will continue

to

move

up and

down

on the

shaft connecting

it to the

diaphragm. How ever,

it is

prevented from operating

the

diaphragm until

the check valve again opens

and the

fuel

in the

pump chamber

is

expelled. This process continues

as

long

as

the engine

is

running. Minimum lift pump output pressure

is 21 Kpa (3

psi).

Lift pump output volume

is 0.75

liters

(0.70 U.S.

quarts)

per 30

seconds

of

engine cranking.

Fig.

25 Lift

Pump

The lift pump housing

has a

weep hole

at the

bot

tom

of the

casing

(Fig. 25). If the

diaphragm rup

tures,

fuel will exit

out of the

weep hole

and the

pump must

be

replaced.

The

lift pump

is not

service able

and

must

be

replaced

as a

complete assembly.

CAUTION:

Do not

operate

the

engine

if the

fuel

sup

ply

line

has a

restriction

of

more than

95 MM Hg

(3.75

in Hg).

The lift pump

has a

manual lever

(Fig. 26). The le

ver

is

located

on the

lower right side

of the

pump

housing.

The

purpose

of the

lever

is to

prime

the

fuel system

and

bleed

air

from

the

system

if the

vehicle

has

run out of

fuel. Raise

and

lower

the

lever until

resistance

is

felt

to

prime

the

system

up to the

injec

tor pump. During vehicle operation

the

pump

le

ver must

be in the up

position.

FUEL

PUMP

MANUAL

JKT /

LEVER

——-—•

.

LJ*y^"^^

J9114-3

Fig.

26 Lift

Pump

Manual

Lever

SYSTEM

OPERATION

IGNITION

SWITCH

ON

When

the

ignition switch

is put in the ON (run)

position,

the

following occurs: •

The PCM

receives

an

ignition sense input.

It

then

powers

up.

Battery voltage

is

supplied through

the

battery voltage input. •

The

wait-to-start lamp

and the

water-in-fuel lamp are turned

on by the PCM for 2.8

seconds

as a

bulb test.

•

The PCM

monitors

the

charge

air

temperature

sensor input.

If

manifold

air

temperature

is at or be

low

15°C

(59°F),

the PCM

will start

the air

intake

heater preheat cycle.

It

will energize

the

intake heat

ers

by

grounding

the air

intake heater relays.

The

PCM will turn

the

wait-to-start light

on

until

the

preheat cycle

is

over.

If PCM

receives

a

crank signal

from engine speed sensor before preheat cycle

is

over, it will abort preheat cycle.

•

The PCM

monitors engine speed. When

the

engine speed

is

above

384 rpm, the PCM

determines that

the engine

is

running.

•

The PCM

will turn

on the

water-in-fuel lamp

if a

signal

is

received from

the

water-in-fuel sensor.

ENGINE

START-UP

When

the

ignition

key is put in the

start position,

the following occurs: •

The PCM

receives

a

crank signal input from

the

engine speed sensor.

•

The air

intake heaters

are not

energized during cranking.

Page 906 of 1502

•

FUEL

SYSTEM

14 - 87

ENGINE

WARM-UP

• The PCM may start the air intake heater post-heat

cycle depending on intake air temperature. If manifold air temperature was at or below 15°C (59°F) when the

ignition switch was turned on, the cycle is started.

• If intake manifold air temperature is below 32°C

(90°F),

the KSB solenoid will be energized through

the air temperature switch. The solenoid remains en ergized until the air temperature switch opens. The

switch opens when intake manifold air temperature

is above 32°C (90°F).

• If the coolant temperature is below 16°C (60° F),

the transmission will not be allowed to enter over drive (automatic transmission).

• The PCM will turn on the water-in-fuel lamp if a signal is received from the water-in-fuel sensor.

CRUISE

OR

IDLE

• The PCM monitors intake manifold air tempera

ture through the charge temperature sensor input. • If intake manifold air temperature is below 32°C

(90°F),

the KSB solenoid will be energized through

the air temperature switch. The solenoid remains en ergized until the air temperature switch opens. The switch opens when intake manifold air temperature

is above 32°C (90°F).

• The air intake heater post-heat cycle will be com

pleted, if it is not already over.

• The vehicle speed sensor, engine speed sensor and

throttle position sensor inputs are used to control

transmission overdrive operation.

• If the coolant temperature is below 16° C (60° F),

the transmission will not be allowed to enter over drive (automatic transmission).

• If the transmission thermo-switch is open, the

transmission will not be allowed to enter into over

drive (automatic transmission). If the switch opens

when the vehicle is in overdrive, the transmission

will be downshifted. The transmission thermo-switch opens at 134°C (273°F).

• The thermo-switch will close once the transmission

fluid temperature drops to 116°C (240°F). • The PCM will turn on the water-in-fuel lamp if a signal is received from the water-in-fuel sensor.

ACCELERATION

• The vehicle speed sensor, engine speed sensor and

throttle position sensor inputs are used to control

transmission overdrive operation.

• If the coolant temperature is below 16° C (60° F),

the transmission will not be allowed to enter over

drive (automatic transmission).

• If intake manifold air temperature is below 32°C

(90°F),

the KSB solenoid will be energized through

the air temperature switch. The solenoid remains en ergized until the air temperature switch opens. The

switch opens when intake manifold air temperature

is above 32°C (90°F). • If the transmission thermo-switch is open, the

transmission will not be allowed to enter into over

drive (automatic transmission). If the switch opens

when the vehicle is in overdrive, the transmission

will be downshifted. The transmission thermo-switch opens at 134°C (273°F). The thermo-switch will close

once the transmission fluid temperature drops to 116°C (240°F).

• The PCM will turn on the water-in-fuel lamp if a

signal is received from the water-in-fuel sensor.

• If the speed control system resume/accelerate func

tion is being used, the PCM will only allow the vehi

cle to accelerate at a predetermined rate. If a speed

control has been set and the resume/accelerate but

ton is momentarily pushed in, the PCM will increase

vehicle speed by two miles per hour.

• If the brakes are applied, the PCM will disable the

speed control.

DECELERATION

• The vehicle speed sensor, engine speed sensor and

throttle position sensor inputs are used to control

transmission overdrive operation.

• If the coolant temperature is below 16° C (60° F),

the transmission will not be allowed to enter over drive (automatic transmission).

• If the transmission thermo-switch is open, the trans

mission will not be allowed to enter into overdrive (au

tomatic transmission). If the switch opens when the

vehicle is in overdrive, the transmission will be down shifted. The transmission thermo-switch opens at 134°C (273°F). The thermo-switch will close once the transmis

sion fluid temperature drops to 116°C (240°F).

• The PCM will turn on the water-in-fuel lamp if a

signal is received from the water-in-fuel sensor.

• If intake manifold air temperature is below 32°C

(90°F),

the KSB solenoid will be energized through

the air temperature switch. The solenoid remains en ergized until the air temperature switch opens. The

switch opens when intake manifold air temperature

is above 32°C (90°F).

• If the speed control system coast/set function is be

ing used, the PCM will only allow the vehicle to de celerate at a predetermined rate. If the coast/set

switch is pushed while the system is operating, the

PCM will set speed control to the rate the vehicle is

traveling at when the switch is released. • If the brakes are applied, the PCM will disable the speed control.

IGNITION SWITCH

OFF

• When the ignition switch is turned to the off posi

tion, the PCM still receives battery voltage through

the battery input. Battery voltage is needed to keep

PCM memory alive. The PCM memory stores diag nostic trouble code (DTC) messages and the mini

mum TPS value from the previous key-on.

Page 907 of 1502

DIESEL FUEL INJECTION—GENERAL DIAGNOSIS

INDEX

page

Air

in

Fuel System

90

Air Intake Heater

. 90

Diagnostic

Trouble Code (DTC)

. 95

DRB

II

Scan

Tool

95

Engine

Speed

Sensor

91

Fuel Heater

91

Fuel

Injection

Pump

91

Fuel Injectors

92

Fuel Supply Restrictions

92

page

Fuel/Water Separator

Filter 92

High

Pressure Fuel Line Restrictions

93

KSB

Solenoid

. 93

Mechanical

Lift

Pump

93

On-Board

Diagnostics (OBD)

94

System

Schematics—5.9L Diesel Engine

....... 95

Throttle

Position

Sensor

Test

94

Visual

Inspection

88

VISUAL

INSPECTION

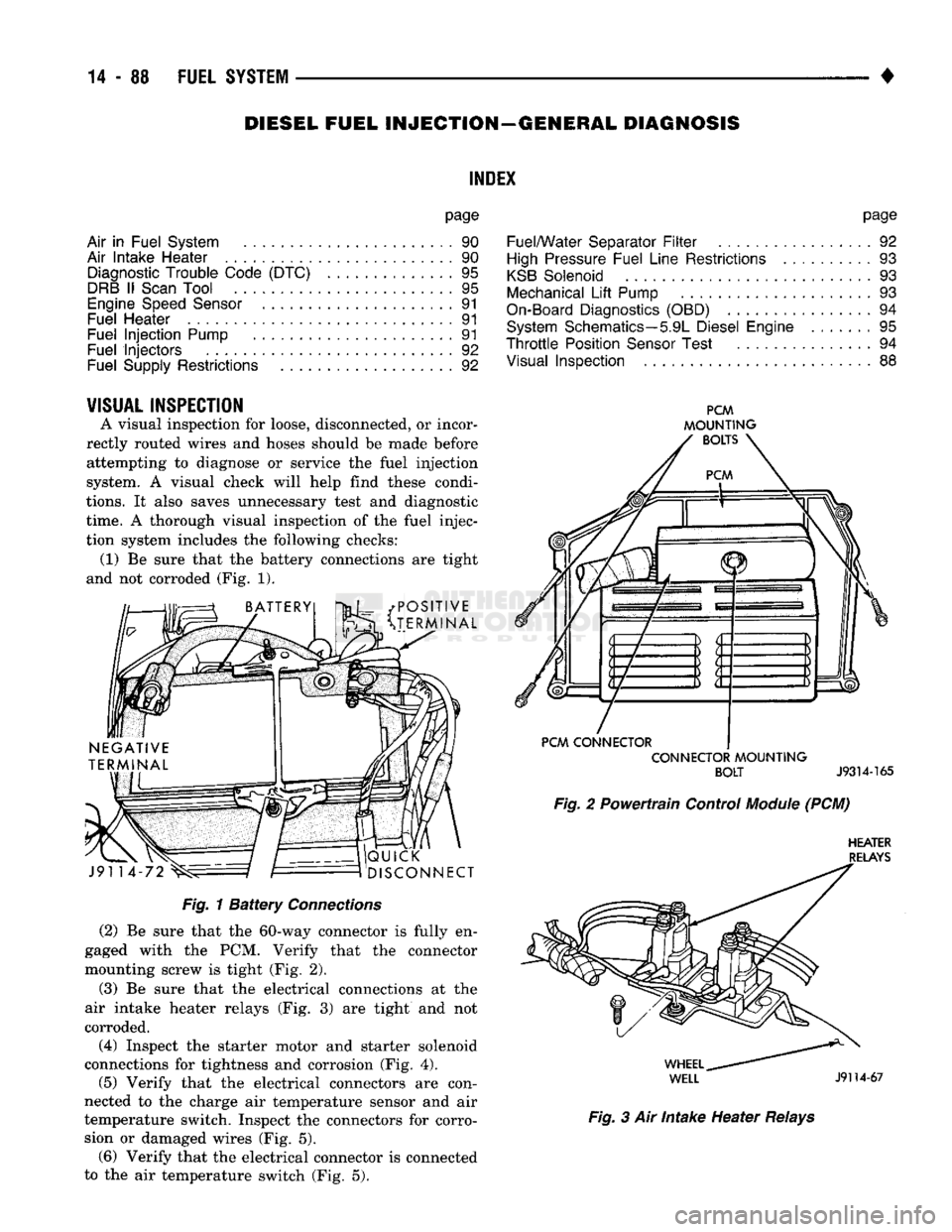

A visual inspection for loose, disconnected, or incor

rectly routed wires and hoses should be made before attempting to diagnose or service the fuel injection

system. A visual check will help find these condi

tions.

It also saves unnecessary test and diagnostic

time.

A thorough visual inspection of the fuel injec

tion system includes the following checks: (1) Be sure that the battery connections are tight

and not corroded (Fig. 1).

• POSITIVE

v^3t

^TERMINAL J91 14

QUICK

DISCONNECT

PCM

MOUNTING

BOLTS

PCM

CONNECTOR CONNECTOR

MOUNTING

BOLT

J9314-165

Fig.

2 Powertrain Control

Module

(PCM)

HEATER

RELAYS

Fig.

1

Battery

Connections

(2)

Be sure that the 60-way connector is fully en

gaged with the PCM. Verify that the connector

mounting screw is tight (Fig. 2).

(3)

Be sure that the electrical connections at the

air intake heater relays (Fig. 3) are tight and not

corroded.

(4)

Inspect the starter motor and starter solenoid

connections for tightness and corrosion (Fig. 4).

(5)

Verify that the electrical connectors are con

nected to the charge air temperature sensor and air

temperature switch. Inspect the connectors for corro sion or damaged wires (Fig. 5). (6) Verify that the electrical connector is connected

to the air temperature switch (Fig. 5).

WHEEL

^

WELL

J9114-67

Fig.

3 Air Intake Heater

Relays

Page 908 of 1502

FUEL

SYSTEM

14-89

Fig.

4 Starter Motor Connections—Typical

Fig.

5

Charge

Air

Temperature

Sensor

and Air

Temperature

Switch

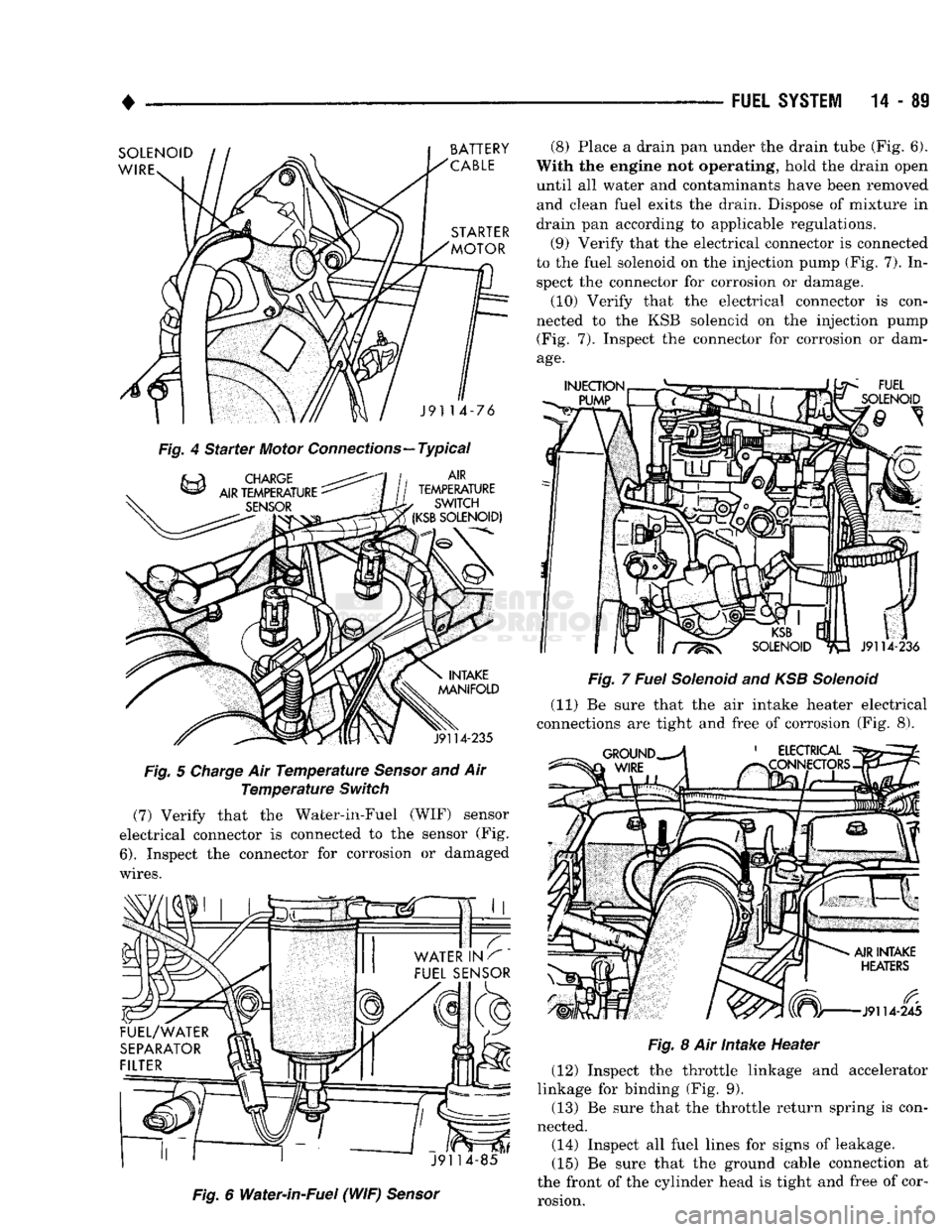

(7) Verify that the Water-in-Fuel (WIF) sensor

electrical connector is connected to the sensor (Fig.

6).

Inspect the connector for corrosion or damaged

wires.

Fig.

6 Water-in-Fuel (WIF)

Sensor

(8) Place a drain pan under the drain tube (Fig. 6).

With the engine not operating, hold the drain open

until all water and contaminants have been removed and clean fuel exits the drain. Dispose of mixture in

drain pan according to applicable regulations.

(9) Verify that the electrical connector is connected

to the fuel solenoid on the injection pump (Fig. 7). In spect the connector for corrosion or damage.

(10) Verify that the electrical connector is con

nected to the KSB solenoid on the injection pump (Fig. 7). Inspect the connector for corrosion or dam

age.

Fig.

8 Air Intake Heater

(12) Inspect the throttle linkage and accelerator

linkage for binding (Fig. 9).

(13) Be sure that the throttle return spring is con

nected. (14) Inspect all fuel lines for signs of leakage.

(15) Be sure that the ground cable connection at

the front of the cylinder head is tight and free of cor rosion.

Page 910 of 1502

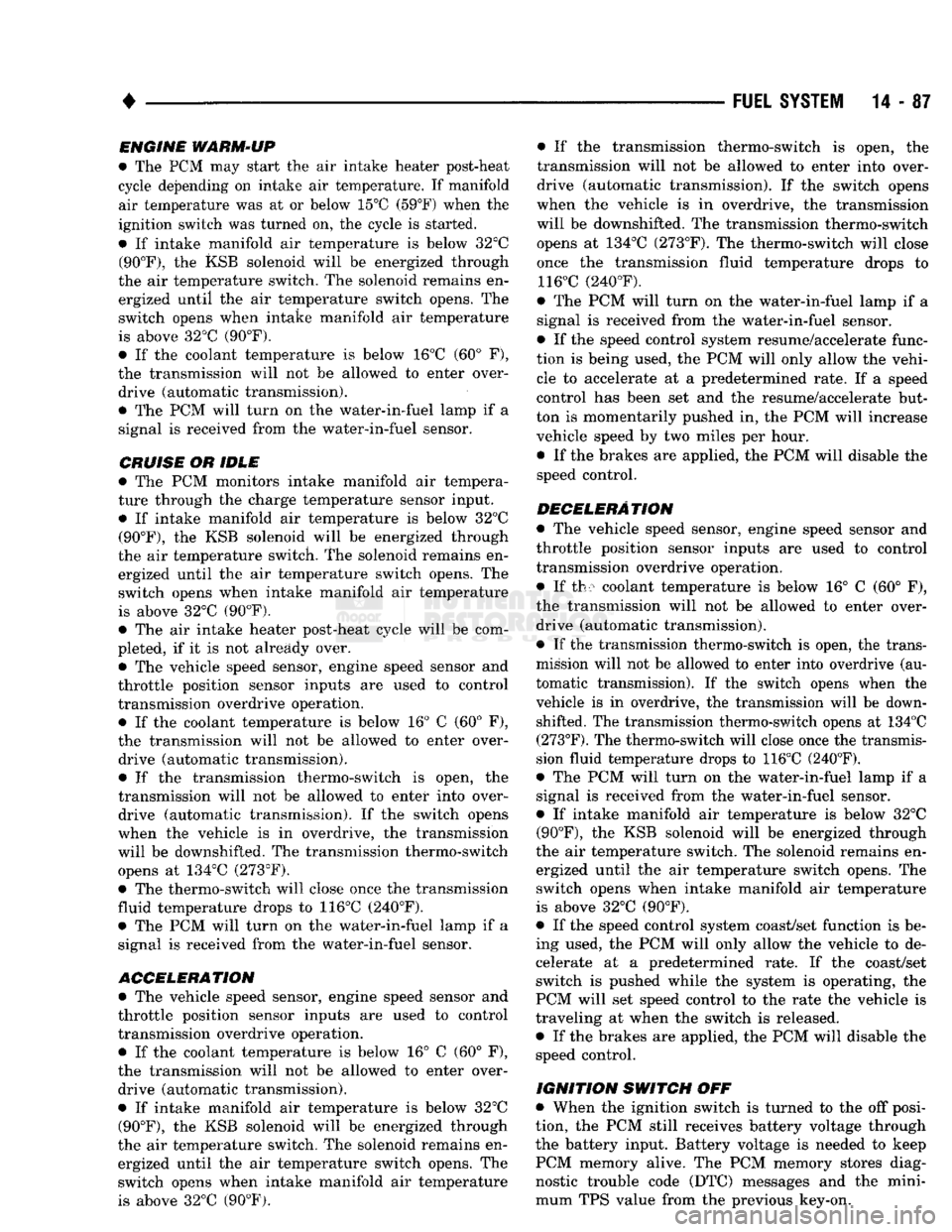

(3) Check for battery voltage at both intake air

heater terminals. The heaters will only be ener gized for 10 to 20 seconds. Refer to the Preheat Cycle Time Interval Chart.

PREHEAT

CYCLE

TIME

INTERVAL

SENSOR

MOUNTING

BOLTS

Intake

Manifold

temperature

Preheat

Cycle

Time

Ignition

Key ON

Engine

Net

Running

Pestheat

Cycle

Ignition

Key ON Ingin©

Running

Above 15 °C (59

°F)

0 Seconds

No

-8°C{18°F)*o 15°C(59

°F)

10 Seconds

Yes

-17°C{1 °F) •9°C(16°F) 15 Seconds

Yes

-26°C(-15°F) fo-18°C (0

°F)

17.5 Seconds

Yes

Below

-26

°C

(15T) 20 Seconds

Yes

J9114-239

AIR INTAKE HEATER TEST (1) Disconnect negative battery cable.

(2) Note wire positions on heater terminals for as

sembly. Disconnect wires from heater.

(3) Use an ohmmeter to test resistance from each

heater terminal to ground. The resistance should be

zero (0). If the resistance is not to specifications, in spect for corroded or dirty connections. Clean or re

pair the connections and retest before replacing

heaters.

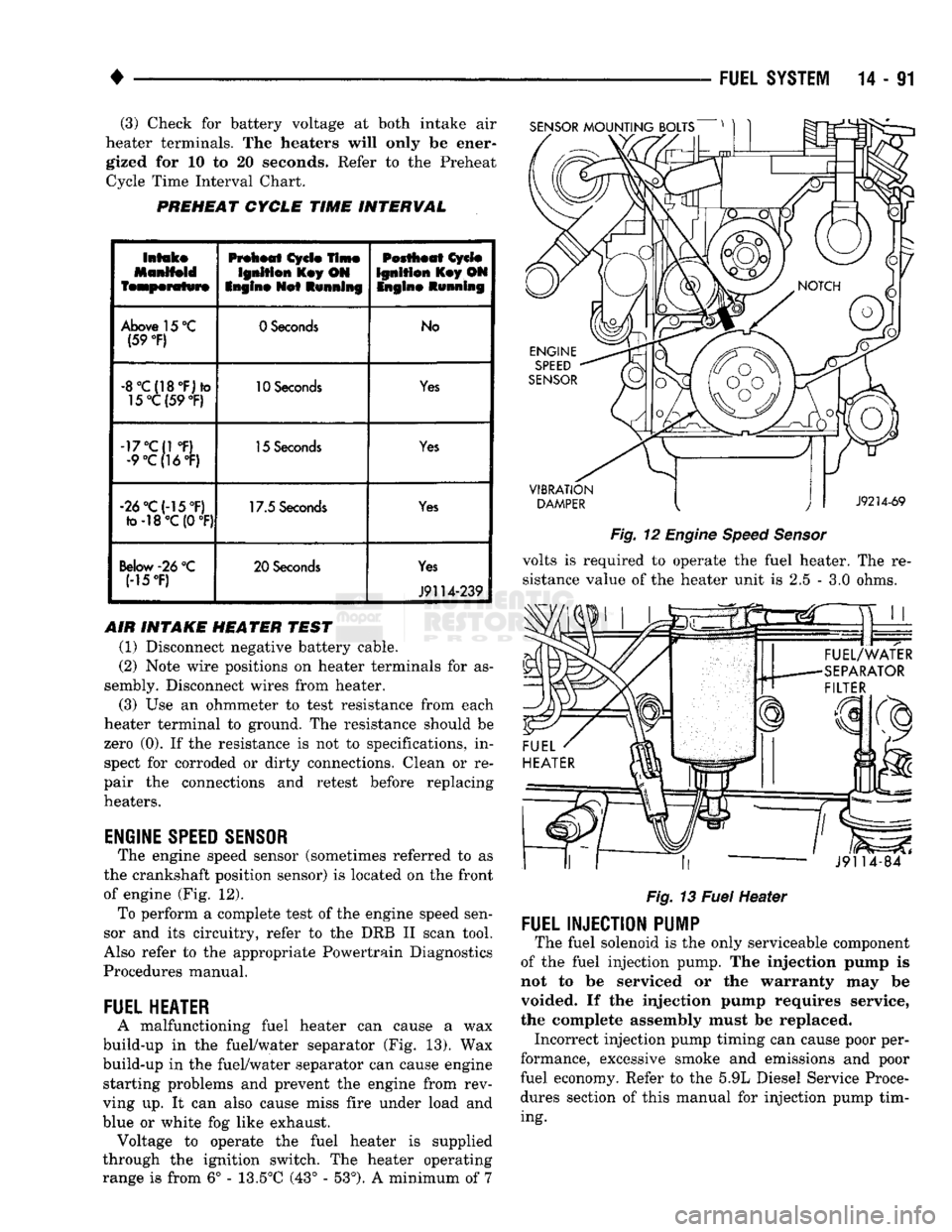

ENGINE

SPEED

SENSOR

The engine speed sensor (sometimes referred to as

the crankshaft position sensor) is located on the front

of engine (Fig. 12). To perform a complete test of the engine speed sen

sor and its circuitry, refer to the DRB II scan tool.

Also refer to the appropriate Powertrain Diagnostics

Procedures manual.

FUEL

HEATER

A malfunctioning fuel heater can cause a wax

build-up in the fuel/water separator (Fig. 13). Wax

build-up in the fuel/water separator can cause engine starting problems and prevent the engine from rev

ving up. It can also cause miss fire under load and

blue or white fog like exhaust. Voltage to operate the fuel heater is supplied

through the ignition switch. The heater operating

range is from 6° - 13.5°C (43° - 53°). A minimum of 7

VIBRATION

DAMPER

J9214-69

Fig.

12

Engine

Speed

Sensor

volts is required to operate the fuel heater. The re

sistance value of the heater unit is 2.5 - 3.0 ohms.

««.

* rr ,,

J9114-84

Fig.

13

Fuel

Heater

FUEL

INJECTION

PUMP

The fuel solenoid is the only serviceable component

of the fuel injection pump. The injection pump is

not to be serviced or the warranty may be

voided. If the injection pump requires service,

the complete assembly must be replaced. Incorrect injection pump timing can cause poor per

formance, excessive smoke and emissions and poor

fuel economy. Refer to the 5.9L Diesel Service Proce

dures section of this manual for injection pump tim

ing.

Page 913 of 1502

14

- 94

FUEL

SYSTEM

•

THROTTLE POSITION

SENSOR

TEST

CAUTION;

Before checking

the

TPS,

the

throttle

linkage must

be

checked

for

correct

adjustment.

The

throttle

lever must

contact

the low idle

speed screw.

The

throttle

lever must reach breakover when

the

throttle

is

wide

open. Refer

to the

Accelerator Pedal and

Throttle

Cable section

of

Group

14,

Fuel Systems.

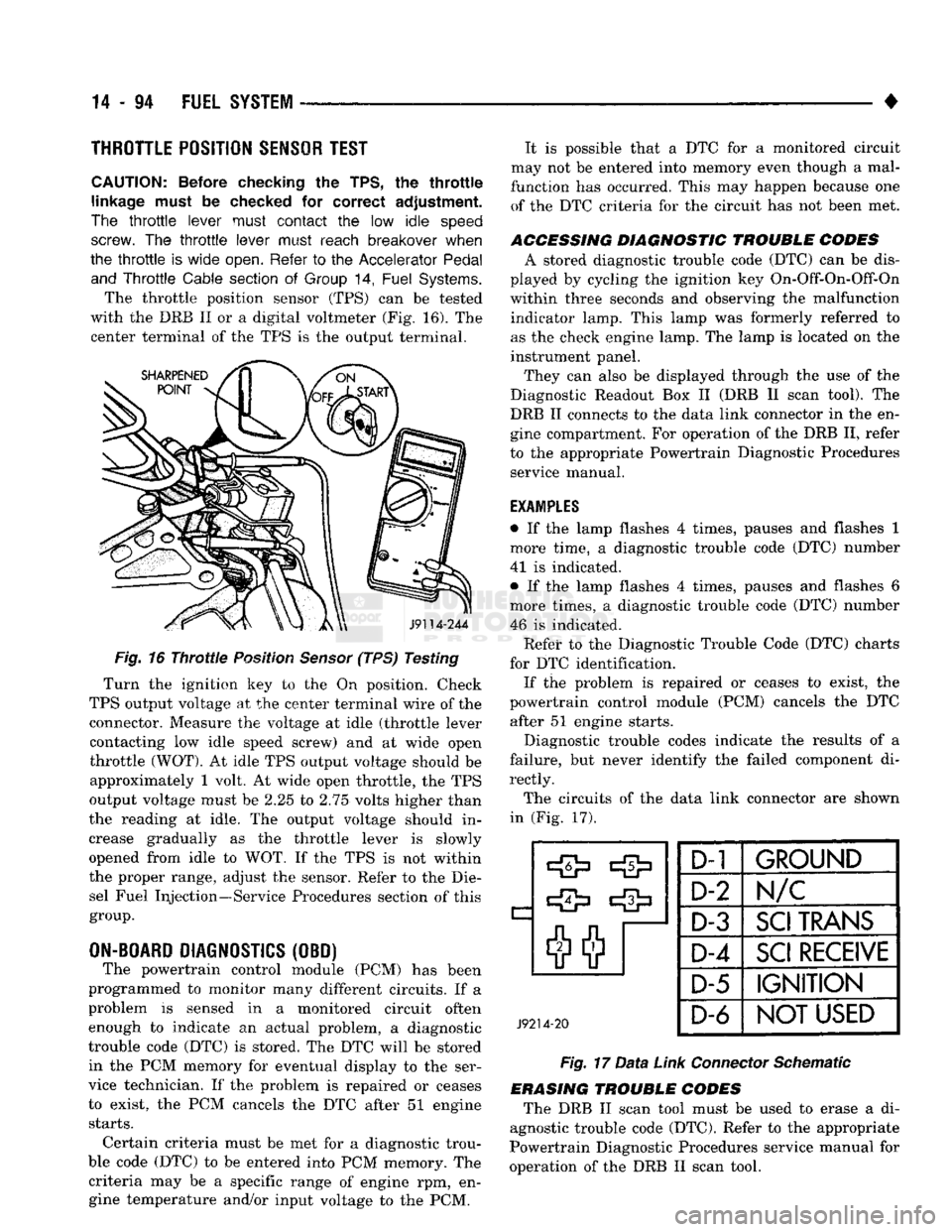

The throttle position sensor (TPS) can be tested

with the DRB II or a digital voltmeter (Fig. 16). The center terminal of the TPS is the output terminal.

J9114-244

Fig.

16

Throttle

Position

Sensor

(TPS) Testing

Turn the ignition key to the On position. Check

TPS output voltage at the center terminal wire of the connector. Measure the voltage at idle (throttle lever contacting low idle speed screw) and at wide open

throttle

(WOT).

At idle TPS output voltage should be approximately 1 volt. At wide open throttle, the TPS

output voltage must be 2.25 to 2.75 volts higher than

the reading at idle. The output voltage should in

crease gradually as the throttle lever is slowly

opened from idle to WOT. If the TPS is not within

the proper range, adjust the sensor. Refer to the Die sel Fuel Injection—Service Procedures section of this

group.

ON-BOARD

DIAGNOSTICS

(OBD) The powertrain control module (PCM) has been

programmed to monitor many different circuits. If a

problem is sensed in a monitored circuit often enough to indicate an actual problem, a diagnostic

trouble code (DTC) is stored. The DTC will be stored in the PCM memory for eventual display to the ser

vice technician. If the problem is repaired or ceases

to exist, the PCM cancels the DTC after 51 engine

starts.

Certain criteria must be met for a diagnostic trou

ble code (DTC) to be entered into PCM memory. The criteria may be a specific range of engine rpm, engine temperature and/or input voltage to the PCM. It is possible that a DTC for a monitored circuit

may not be entered into memory even though a mal

function has occurred. This may happen because one of the DTC criteria for the circuit has not been met.

ACCESSING DIAGNOSTIC TROUBLE CODES A stored diagnostic trouble code (DTC) can be dis

played by cycling the ignition key On-Off-On-Off-On

within three seconds and observing the malfunction indicator lamp. This lamp was formerly referred to

as the check engine lamp. The lamp is located on the

instrument panel.

They can also be displayed through the use of the

Diagnostic Readout Box II (DRB II scan tool). The

DRB II connects to the data link connector in the en

gine compartment. For operation of the DRB II, refer

to the appropriate Powertrain Diagnostic Procedures service manual.

EXAMPLES

• If the lamp flashes 4 times, pauses and flashes 1

more time, a diagnostic trouble code (DTC) number

41 is indicated.

• If the lamp flashes 4 times, pauses and flashes 6

more times, a diagnostic trouble code (DTC) number 46 is indicated. Refet* to the Diagnostic Trouble Code (DTC) charts

for DTC identification. If the problem is repaired or ceases to exist, the

powertrain control module (PCM) cancels the DTC after 51 engine starts.

Diagnostic trouble codes indicate the results of a

failure, but never identify the failed component di

rectly.

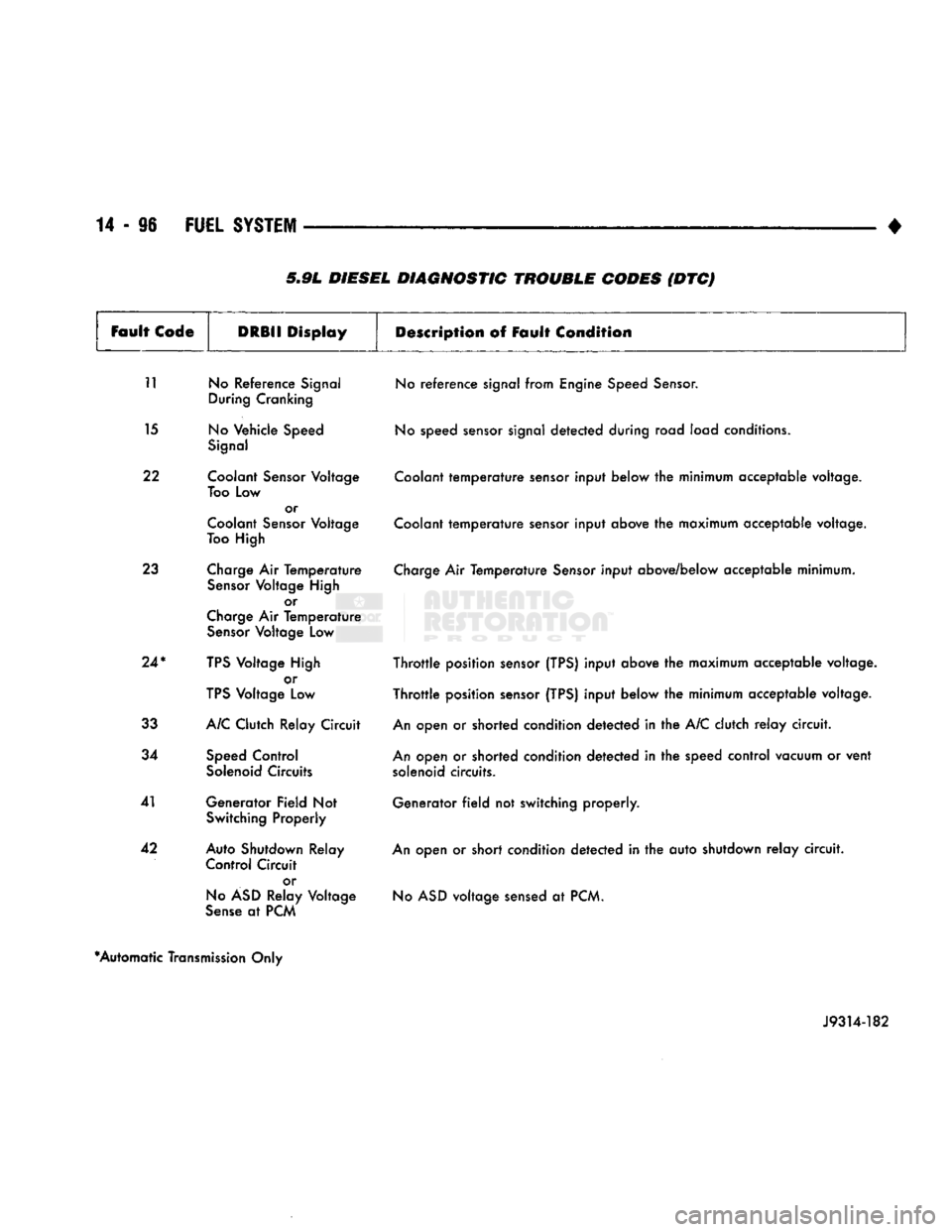

The circuits of the data link connector are shown

in (Fig. 17).

J9214-20

D-1

1

GROUND

D-2

N/C

D-3

SCI

TRANS

D-4

SCI

RECEIVE

D-5 IGNITION

D-6

NOT USED

Fig.

17

Data

Link

Connector

Schematic

ERASING TROUBLE CODES The DRB II scan tool must be used to erase a di

agnostic trouble code (DTC). Refer to the appropriate

Powertrain Diagnostic Procedures service manual for

operation of the DRB II scan tool.

Page 915 of 1502

5.9L DIESEL DIAGNOSTIC TROUBLE CODES (DTC)

Fault

Code

DRBII

Display

Description

of Fault

Condition

11 No Reference Signal During Cranking

15 No Vehicle Speed Signal

22 Coolant Sensor Voltage Too Low or

Coolant Sensor Voltage

Too High

23 Charge Air Temperature Sensor Voltage High or

Charge Air Temperature Sensor Voltage Low

24*

TPS Voltage High or

TPS Voltage Low

33 A/C Clutch Relay Circuit

34 Speed Control Solenoid Circuits

41 Generator Field Not Switching Properly

42 Auto Shutdown Relay Control Circuit

or

No ASD Relay Voltage

Sense at PCM No reference signal from Engine Speed Sensor.

No speed sensor signal detected during road load conditions.

Coolant temperature sensor input below the minimum acceptable voltage.

Coolant temperature sensor input above the maximum acceptable voltage.

Charge Air Temperature Sensor input above/below acceptable minimum.

Throttle position sensor (TPS) input above the maximum acceptable voltage.

Throttle position sensor (TPS) input below the minimum acceptable voltage.

An open or shorted condition detected in the A/C clutch relay circuit.

An open or shorted condition detected in the speed control vacuum or vent solenoid circuits.

Generator field not switching properly.

An open or short condition detected in the auto shutdown relay circuit. No ASD voltage sensed at PCM.

*Automatic Transmission Only

J9314-182