mileage DODGE TRUCK 1993 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 218 of 1502

•

BRAKES

5 - 31 board lining. Also check condition of the caliper pis

ton dust boot. If leakage is evident or if the boot is

cut, torn, or damaged in any way, it will be necessary to overhaul the caliper.

Remove the O-ring from the caliper adapter and clean

the slide surfaces of the adapter and the machined ways on the caliper with a wire brush and sandpaper.

DISC

BRAKESHOE

INSTALLATION

(1) Install inboard brakeshoe in adapter (Fig. 8).

(2) If new brakeshoes are being installed, remove

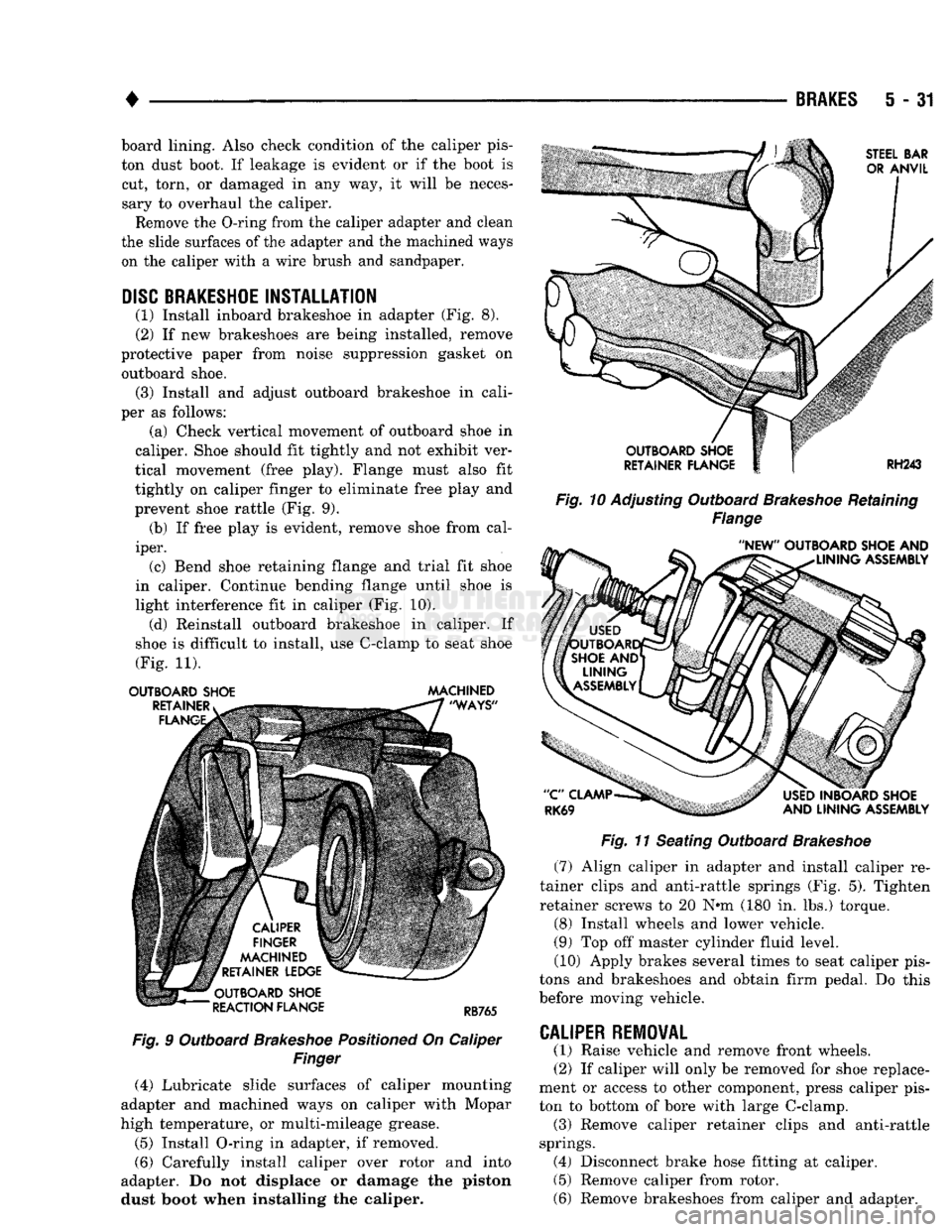

protective paper from noise suppression gasket on outboard shoe. (3) Install and adjust outboard brakeshoe in cali

per as follows: (a) Check vertical movement of outboard shoe in

caliper. Shoe should fit tightly and not exhibit ver

tical movement (free play). Flange must also fit

tightly on caliper finger to eliminate free play and

prevent shoe rattle (Fig. 9). (b) If free play is evident, remove shoe from cal

iper. (c) Bend shoe retaining flange and trial fit shoe

in caliper. Continue bending flange until shoe is

light interference fit in caliper (Fig. 10). (d) Reinstall outboard brakeshoe in caliper. If

shoe is difficult to install, use C-clamp to seat shoe

(Fig. 11).

OUTBOARD SHOE MACHINED

Fig.

9 Outboard

Brakeshoe

Positioned

On Caliper

Finger

(4) Lubricate slide surfaces of caliper mounting

adapter and machined ways on caliper with Mopar

high temperature, or multi-mileage grease.

(5) Install O-ring in adapter, if removed.

(6) Carefully install caliper over rotor and into

adapter. Do not displace or damage the piston dust boot when installing the caliper.

Fig. 10

Adjusting Outboard

Brakeshoe

Retaining

Flange

Fig.

11 Seating Outboard

Brakeshoe

(7) Align caliper in adapter and install caliper re

tainer clips and anti-rattle springs (Fig. 5). Tighten

retainer screws to 20 N«m (180 in. lbs.) torque.

(8) Install wheels and lower vehicle.

(9) Top off master cylinder fluid level. (10) Apply brakes several times to seat caliper pis

tons and brakeshoes and obtain firm pedal. Do this

before moving vehicle.

CALIPER

REMOVAL

(1) Raise vehicle and remove front wheels.

(2) If caliper will only be removed for shoe replace

ment or access to other component, press caliper pis

ton to bottom of bore with large C-clamp. (3) Remove caliper retainer clips and anti-rattle

springs. (4) Disconnect brake hose fitting at caliper. (5) Remove caliper from rotor.

(6) Remove brakeshoes from caliper and adapter.

Page 220 of 1502

•

BRAKES

5

- 33

BLEEDER

CALIPER

INBOARD

ANTI-RATTLE

PISTON

SPRING

RH242A

Fig.

15

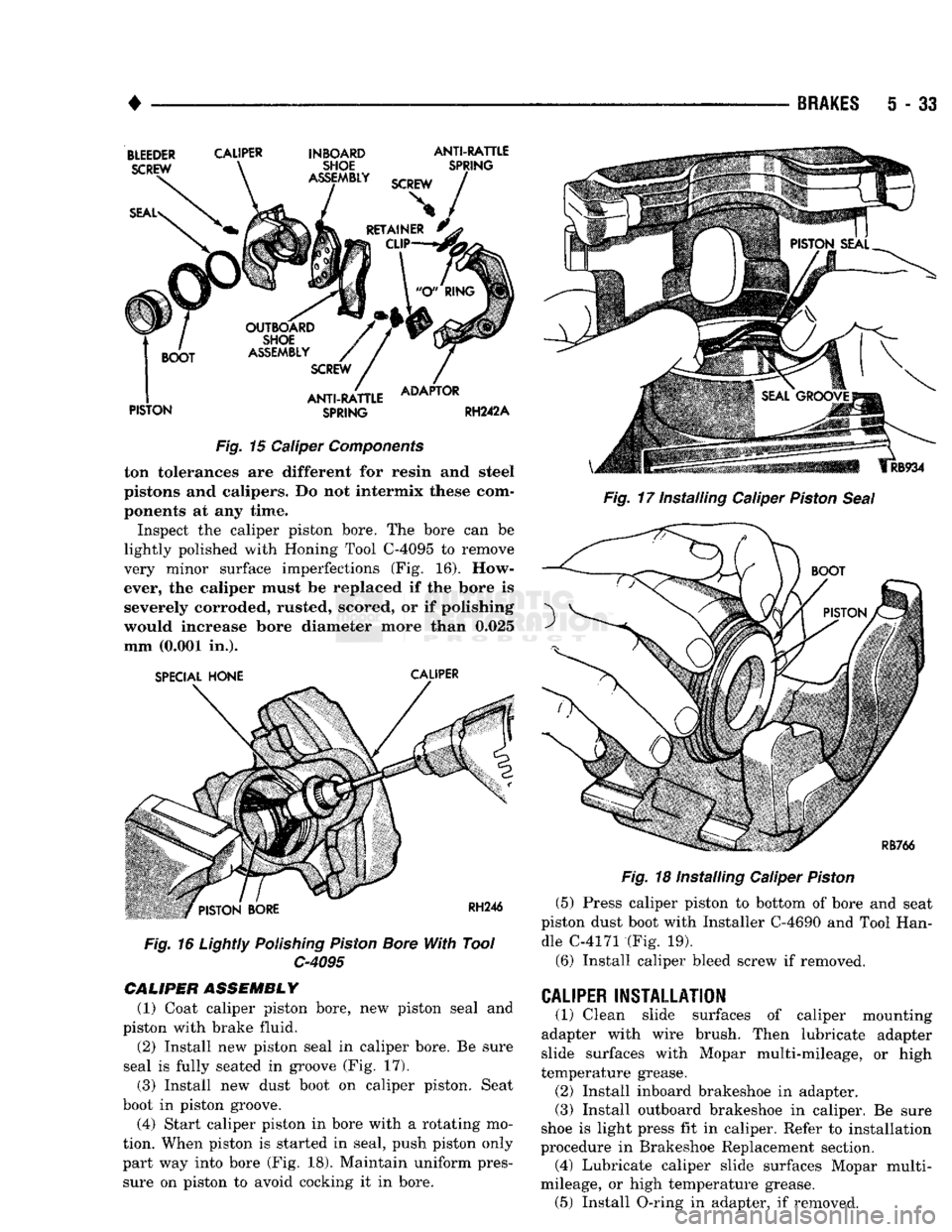

Caliper Components ton tolerances

are

different

for

resin

and

steel

pistons

and

calipers.

Do not

intermix these com

ponents

at any

time. Inspect

the

caliper piston bore.

The

bore

can be

lightly polished with Honing Tool C-4095

to

remove

very minor surface imperfections

(Fig. 16).

How

ever,

the

caliper must

be

replaced

if the

bore

is

severely corroded, rusted, scored,

or if

polishing

would increase bore diameter more than 0.025

mm (0.001

in.).

Fig. 16 Lightly Polishing Piston Bore With Tool

C-4095

CALIPER ASSEMBLY (1) Coat caliper piston bore,

new

piston seal

and

piston with brake fluid.

(2) Install

new

piston seal

in

caliper bore.

Be

sure

seal

is

fully seated

in

groove

(Fig. 17).

(3) Install

new

dust boot

on

caliper piston. Seat

boot

in

piston groove.

(4) Start caliper piston

in

bore with

a

rotating

mo

tion. When piston

is

started

in

seal, push piston only

part

way

into bore

(Fig. 18).

Maintain uniform pres sure

on

piston

to

avoid cocking

it in

bore.

Fig.

17 Installing Caliper

Piston

Seal

Fig.

18 Installing Caliper

Piston

(5) Press caliper piston

to

bottom

of

bore

and

seat

piston dust boot with Installer C-4690

and

Tool Han dle C-4171

(Fig. 19).

(6) Install caliper bleed screw

if

removed.

CALIPER

INSTALLATION

(1) Clean slide surfaces

of

caliper mounting

adapter with wire brush. Then lubricate adapter

slide surfaces with Mopar multi-mileage,

or

high

temperature grease.

(2) Install inboard brakeshoe

in

adapter.

(3) Install outboard brakeshoe

in

caliper.

Be

sure

shoe

is

light press

fit in

caliper. Refer

to

installation

procedure

in

Brakeshoe Replacement section. (4) Lubricate caliper slide surfaces Mopar multi-

mileage,

or

high temperature grease. (5) Install O-ring

in

adapter,

if

removed.

Page 226 of 1502

BRAKES

5 - 39

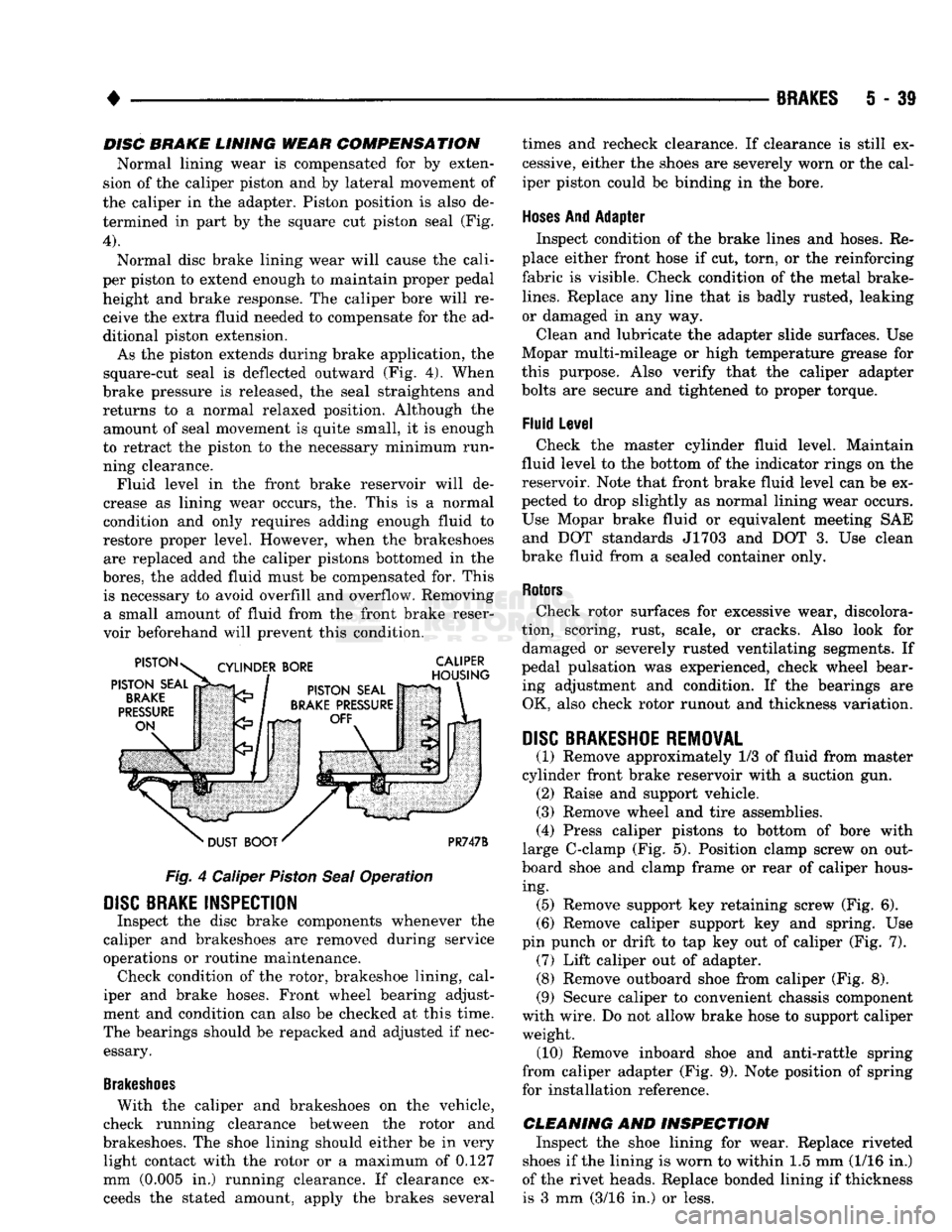

DISC BRAKE LINING WEAR COMPENSATION

Normal lining wear is compensated for by exten

sion of the caliper piston and by lateral movement of

the caliper in the adapter. Piston position is also de termined in part by the square cut piston seal (Fig.

4).

Normal disc brake lining wear will cause the cali

per piston to extend enough to maintain proper pedal height and brake response. The caliper bore will receive the extra fluid needed to compensate for the ad

ditional piston extension.

As the piston extends during brake application, the

square-cut seal is deflected outward (Fig. 4). When

brake pressure is released, the seal straightens and returns to a normal relaxed position. Although the amount of seal movement is quite small, it is enough

to retract the piston to the necessary minimum run ning clearance. Fluid level in the front brake reservoir will de

crease as lining wear occurs, the. This is a normal

condition and only requires adding enough fluid to

restore proper level. However, when the brakeshoes are replaced and the caliper pistons bottomed in the

bores,

the added fluid must be compensated for. This is necessary to avoid overfill and overflow. Removing a small amount of fluid from the front brake reser

voir beforehand will prevent this condition.

Fig.

4 Caliper

Piston

Seal

Operation

DISC

BRAKE INSPECTION

Inspect the disc brake components whenever the

caliper and brakeshoes are removed during service

operations or routine maintenance. Check condition of the rotor, brakeshoe lining, cal

iper and brake hoses. Front wheel bearing adjust

ment and condition can also be checked at this time.

The bearings should be repacked and adjusted if nec essary.

Brakeshoes

With the caliper and brakeshoes on the vehicle,

check running clearance between the rotor and

brakeshoes. The shoe lining should either be in very light contact with the rotor or a maximum of 0.127

mm (0.005 in.) running clearance. If clearance exceeds the stated amount, apply the brakes several times and recheck clearance. If clearance is still ex

cessive, either the shoes are severely worn or the cal

iper piston could be binding in the bore.

Hoses

And Adapter Inspect condition of the brake lines and hoses. Re

place either front hose if cut, torn, or the reinforcing

fabric is visible. Check condition of the metal brake-

lines.

Replace any line that is badly rusted, leaking

or damaged in any way.

Clean and lubricate the adapter slide surfaces. Use

Mopar multi-mileage or high temperature grease for

this purpose. Also verify that the caliper adapter

bolts are secure and tightened to proper torque.

Fluid Level Check the master cylinder fluid level. Maintain

fluid level to the bottom of the indicator rings on the

reservoir. Note that front brake fluid level can be ex

pected to drop slightly as normal lining wear occurs.

Use Mopar brake fluid or equivalent meeting SAE and DOT standards J1703 and DOT 3. Use clean

brake fluid from a sealed container only.

Rotors

Check rotor surfaces for excessive wear, discolora

tion, scoring, rust, scale, or cracks. Also look for damaged or severely rusted ventilating segments. If

pedal pulsation was experienced, check wheel bear ing adjustment and condition. If the bearings are OK, also check rotor runout and thickness variation.

DISC

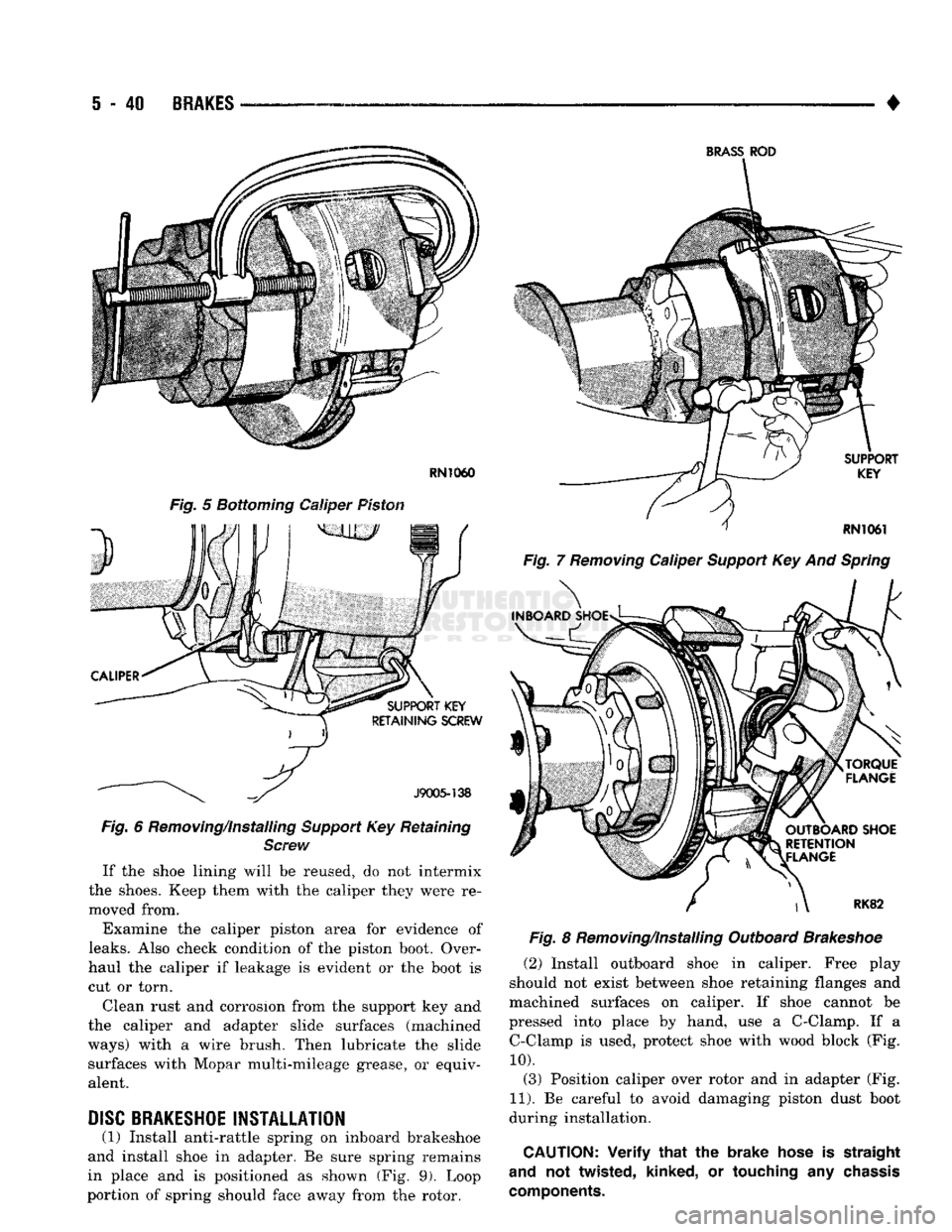

BRAKESHOE REMOVAL

(1) Remove approximately 1/3 of fluid from master

cylinder front brake reservoir with a suction gun. (2) Raise and support vehicle.

(3) Remove wheel and tire assemblies.

(4) Press caliper pistons to bottom of bore with

large C-clamp (Fig. 5). Position clamp screw on out

board shoe and clamp frame or rear of caliper hous ing. (5) Remove support key retaining screw (Fig. 6).

(6) Remove caliper support key and spring. Use

pin punch or drift to tap key out of caliper (Fig. 7). (7) Lift caliper out of adapter. (8) Remove outboard shoe from caliper (Fig. 8).

(9) Secure caliper to convenient chassis component

with wire. Do not allow brake hose to support caliper weight. (10) Remove inboard shoe and anti-rattle spring

from caliper adapter (Fig. 9). Note position of spring

for installation reference.

CLEANING AND INSPECTION Inspect the shoe lining for wear. Replace riveted

shoes if the lining is worn to within 1.5 mm (1/16 in.)

of the rivet heads. Replace bonded lining if thickness is 3 mm (3/16 in.) or less.

Page 227 of 1502

5

- 40

BRAKES

•

Fig.

6 Removing/Installing

Support

Key Retaining

Screw

If the shoe lining will be reused, do not intermix

the shoes. Keep them with the caliper they were re moved from.

Examine the caliper piston area for evidence of

leaks.

Also check condition of the piston boot. Over

haul the caliper if leakage is evident or the boot is

cut or torn.

Clean rust and corrosion from the support key and

the caliper and adapter slide surfaces (machined

ways) with a wire brush. Then lubricate the slide surfaces with Mopar multi-mileage grease, or equiv

alent.

DISC

BRAKESHOE

INSTALLATION

(1) Install anti-rattle spring on inboard brakeshoe

and install shoe in adapter. Be sure spring remains

in place and is positioned as shown (Fig. 9). Loop

portion of spring should face away from the rotor.

BRASS

ROD

Fig.

7

Removing

Caliper

Support

Key And

Spring

Fig.

8 Removing/Installing Outboard

Brakeshoe

(2) Install outboard shoe in caliper. Free play

should not exist between shoe retaining flanges and

machined surfaces on caliper. If shoe cannot be

pressed into place by hand, use a C-Clamp. If a C-Clamp is used, protect shoe with wood block (Fig.

10).

(3) Position caliper over rotor and in adapter (Fig.

11).

Be careful to avoid damaging piston dust boot

during installation.

CAUTION:

Verify

that

the brake

hose

is straight

and

not twisted, kinked, or

touching

any

chassis

components.

Page 270 of 1502

•

CLUTCH

6-17

CLUTCH PEDAL INSTALLATION

(1) Lubricate pedal shaft, pedal shaft bore and all

bushings with Mopar Multi Mileage grease. (2) Insert pedal pin into cylinder push rod. Then

position clutch pedal in support. (3) Slide pedal shaft through clutch pedal bore and

bushings. (4) Install bolt that retains pedal shaft in support.

(5) Secure push rod to pedal pin with wave washer,

flat washer and retaining ring.

FLYWHEEL SERVICE

Inspect the flywheel whenever the clutch disc,

cover and housing are removed for service. Check

condition of the flywheel face, hub, ring gear teeth,

and flywheel bolts. Minor scratches, burrs, or glazing on the flywheel

face can be scuff sanded with 180 grit emery cloth. However, the flywheel should be replaced if the disc

contact surface is severely scored, heat checked,

cracked, or obviously worn. Cleanup of minor flywheel scoring should be per

formed with surface grinding equipment. Remove

only enough material to reduce scoring (approximate

ly 0.001 - 0.003 in.). Heavy stock removal is not rec

ommended. Replace the flywheel if scoring is severe

and deeper than 0.076 mm (0.003 in.). Excessive

stock removal can result in flywheel cracking or

warpage after installation; it can also weaken the flywheel and interfere with proper clutch release. Check flywheel runout if misalignment is sus

pected. Runout should not exceed 0.08 mm (0.003

in.).

Measure runout at the outer edge of the fly

wheel face with a dial indicator. Mount the dial in

dicator on a stud installed in place of one of the

flywheel attaching bolts. Clean the crankshaft flange before mounting the

flywheel. Dirt and grease on the flange surface may cock the flywheel causing excessive runout. Check condition of the flywheel hub and attaching

bolts.

Replace the flywheel if the hub exhibits cracks in the area of the attaching bolt holes. Install new attaching bolts whenever the flywheel

is replaced and use Mopar Lock N' Seal, or Loctite

242 on replacement bolt threads.

Recommended flywheel bolt torques are:

• 75 N»m (55 ft. lbs.) for gas engine flywheels

• 137 N*m (101 ft. lbs.) for diesel flywheels Inspect the teeth on the starter ring gear. If the

teeth are worn or damaged, the flywheel should

be replaced as an assembly. This is the recom mended and preferred method of repair.

In cases where a new flywheel is not readily avail

able,

a replacement ring gear can be installed. How

ever, the following precautions must be observed to

avoid damaging the flywheel and replacement gear.

(a) Mark position of the old gear for alignment

reference on the flywheel. Use a scriber for this

purpose.

(b) Wear protective goggles or approved safety

glasses. Also wear heat resistent gloves when han

dling a heated ring gear. (c) Remove the old gear by cutting most of the

way through it (at one point) with an abrasive cut off wheel. Then complete removal with a cold chisel

or punch. (d) The ring gear is a shrink fit on the flywheel.

This means the gear must be expanded by heating in order to install it. The method of heating and expanding the gear is extremely important. Ev

ery surface of the gear must be heated at the same

time to produce uniform expansion. An oven or

similar enclosed heating device must be used. Tem

perature required for uniform expansion is 325-350° F.

CAUTION:

Never

use an

oxy/acetylene torch

to re

move

the old

gear,

or to

heat

and

expand

a new

gear.

The

high temperature

of the

torch flame

will

cause

localized heating

and

damage

the

flywheel.

In

addition,

using

the

torch

to

heat

a

replacement gear

will

cause uneven heating

and

expansion.

The

torch

flame

will

also

anneal

the

gear

teeth

resulting

in

rapid wear

and

damage

after

installation.

(e) The heated gear must be installed evenly to

avoid misalignment or distortion. A shop press and

suitable press plates should be used to install the

gear if at all possible.

(f) Be sure to wear eye and hand protection.

Heat resistent gloves and safety goggles are needed

for personal safety. Also use metal tongs, vise

grips,

or similar tools to position the gear as necessary for installation.

(g) Allow the flywheel and ring gear to cool

down before installation. Set the assembly on a

workbench and let it cool in normal shop air.

CAUTION:

Do not

use water,

or

compressed

air to

cool

the

flywheel.

The

rapid cooling produced

by

water

or

compressed

air can

distort,

or

crack

the

gear

and

flywheel.

Page 277 of 1502

7 - 6

COOLING

SYSTEM

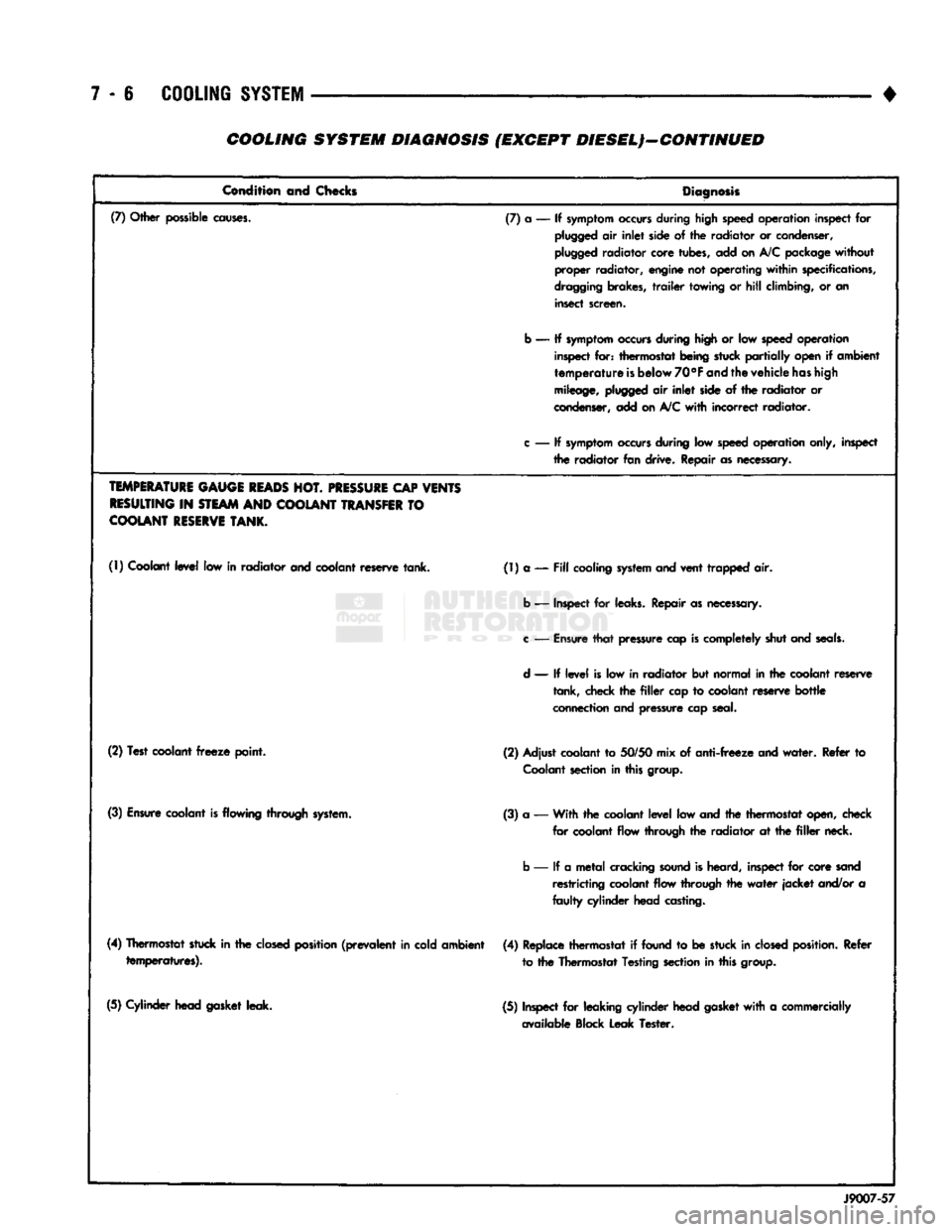

• COOLING SYSTEM DIAGNOSIS (EXCEPT DIESEL)—CONTINUED

Condition and Checks

Diagnosis

(7) Other possible

causes.

(7) a — If

symptom

occurs

during high speed operation inspect for

plugged

air

inlet

side of the radiator or condenser,

plugged

radiator core tubes, add on A/C package

without

proper radiator, engine not operating

within

specifications,

dragging

brakes,

trailer

towing or

hill

climbing, or an insect screen.

b — If

symptom

occurs

during high or low

speed

operation inspect for: thermostat being stuck

partially

open if ambient

temperature

is

below

70°F

and

the vehicle

has

high

mileage,

plugged

air

inlet

side of the radiator or

condenser, add on

A/C

with

incorrect radiator.

c

— If

symptom

occurs

during low

speed

operation only, inspect the radiator fan drive. Repair as necessary.

TEMPERATURE

GAUGE

READS

HOT.

PRESSURE

CAP

VENTS

RESULTING

IN

STEAM

AND

COOLANT

TRANSFER

TO

COOLANT

RESERVE

TANK.

(1) Coolant

level

low in radiator and coolant reserve tank. (1) a —

Fill

cooling

system

and vent trapped air.

b — Inspect for leaks. Repair as necessary.

c

—

Ensure

that

pressure cap

is

completely shut and

seals.

d

— If

level

is low in radiator but normal in the coolant reserve tank, check the

filler

cap to coolant reserve

bottle

connection and pressure cap seal.

(2) Test coolant

freeze

point. (2) Adjust coolant to

50/50

mix of

anti-freeze

and

water.

Refer to

Coolant

section in this group.

(3)

Ensure

coolant

is

flowing through system. (3) a — With the coolant

level

low and the thermostat open, check

for coolant flow through the radiator at the

filler

neck.

b — If a

metal

cracking

sound

is heard, inspect for core sand restricting coolant flow through the

water

jacket

and/or a

faulty

cylinder head casting.

(4) Thermostat stuck in the

closed

position

(prevalent

in cold ambient temperatures). (4) Replace thermostat if found to be stuck in

closed

position.

Refer

to the Thermostat Testing section in this group.

(5) Cylinder head gasket leak. (5) Inspect for leaking cylinder head gasket

with

a commercially

available Block Leak Tester.

J9007-57

Page 282 of 1502

•

COOLING

SYSTEM

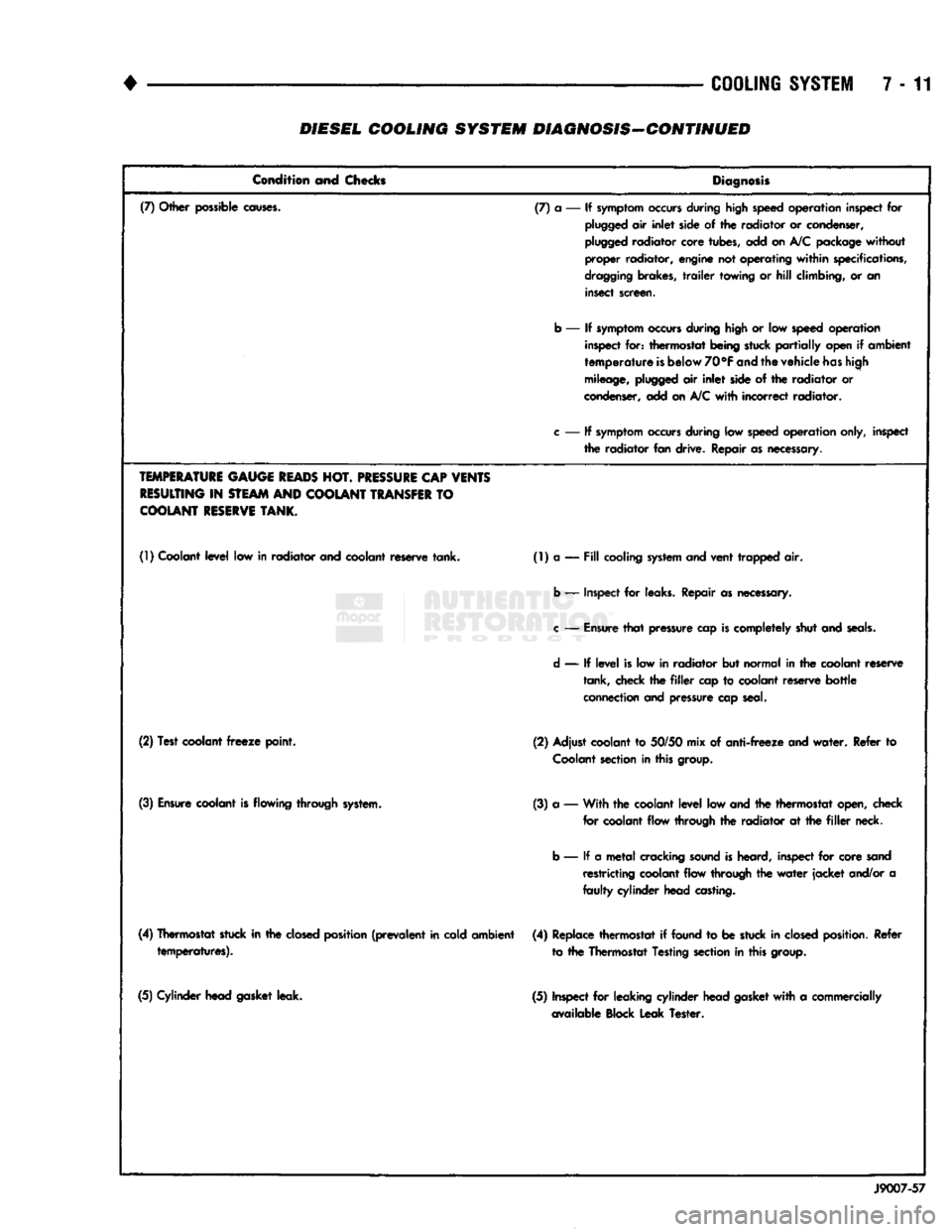

7-11 DIESEL COOLING SYSTEM DIAGNOSIS-CONTINUED

Condition and Chocks

Diagnosis

(7) Other possible

causes.

(7) a — If

symptom

occurs

during high speed operation inspect for

plugged

air

inlet

side of the radiator or condenser,

plugged

radiator core tubes, add on

A/C

package without

proper radiator, engine not operating

within

specifications,

dragging

brakes,

trailer

towing or

hill

climbing, or an insect screen.

b — If

symptom

occurs

during

high

or low speed operation inspect for: thermostat being stuck

partially

open if ambient

temperature

is

below 70°F

and

the vehicle

has

high

mileage,

plugged

air

inlet

side of the radiator or

condenser, add on

A/C

with

incorrect radiator.

c

— If

symptom

occurs

during low

speed

operation only, inspect the radiator fan drive. Repair

as

necessary.

TEMPERATURE

GAUGE

READS

HOT.

PRESSURE

CAP VENTS

RESULTING

IN

STEAM

AND COOLANT

TRANSFER

TO

COOLANT

RESERVE

TANK.

(1)

Coolant

level

low in radiator and coolant reserve tank. (1) a —

Fill

cooling

system

and vent trapped air.

b — Inspect for leaks. Repair as necessary.

c

—

Ensure

that

pressure cap

is

completely shut and

seals.

d

— If

level

is low in radiator but normal in the coolant reserve tank, check the

filler

cap to coolant reserve

bottle

connection and pressure cap seal.

(2) Test coolant

freeze

point. (2) Adjust coolant to 50/50 mix of

anti-freeze

and

water.

Refer to

Coolant

section

in this group.

(3)

Ensure

coolant

is

flowing through system. (3) a — With the coolant

level

low and the thermostat open, check

for coolant flow through the radiator at the

filler

neck.

b — If a

metal

cracking

sound

is

heard, inspect for core sand restricting coolant flow through the

water

jacket

and/or a

faulty

cylinder head casting.

(4) Thermostat stuck in the

closed

position (prevalent in cold ambient temperatures). (4) Replace thermostat if found to be stuck in

closed

position. Refer

to the Thermostat Testing section in this group.

(5) Cylinder head gasket leak. (5) Inspect for leaking cylinder head

gasket

with

a commercially

available Block Leak Tester.

J9007-57

Page 352 of 1502

•

IGNITION

SYSTEMS

8D

- 1

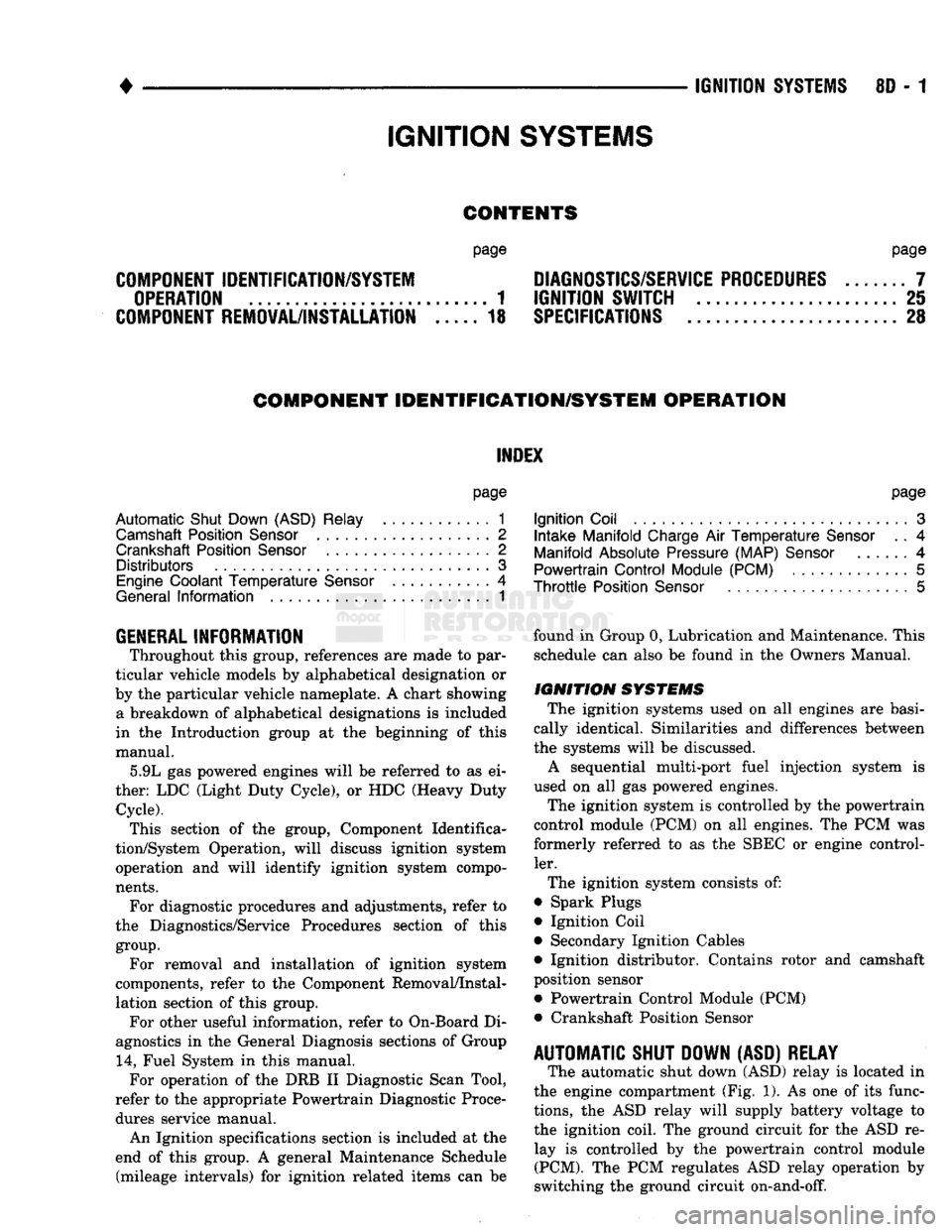

CONTENTS

page page

COMPONENT IDENTIFICATION/SYSTEM DIAGNOSTICS/SERVICE PROCEDURES

7

OPERATION

1

IGNITION SWITCH

25

COMPONENT REMOVAL/INSTALLATION

..... 18

SPECIFICATIONS

28

COMPONENT

IDENTIFICATION/SYSTEM OPERATION

INDEX

page

Automatic

Shut Down (ASD) Relay

1

Camshaft Position Sensor

2

Crankshaft Position Sensor

2

Distributors

3

Engine Coolant

Temperature

Sensor

...........

4

General

Information

1

page

Ignition

Coil

3

Intake

Manifold Charge

Air

Temperature

Sensor

. . 4

Manifold Absolute Pressure (MAP) Sensor

4

Powertrain

Control

Module (PCM)

. 5

Throttle

Position Sensor

5

GENERAL

INFORMATION

Throughout this group, references

are

made

to

par

ticular vehicle models

by

alphabetical designation

or

by

the

particular vehicle nameplate.

A

chart showing a breakdown

of

alphabetical designations

is

included

in

the

Introduction group

at the

beginning

of

this

manual. 5.9L

gas

powered engines will

be

referred

to as ei

ther: LDC (Light Duty Cycle),

or

HDC (Heavy Duty Cycle). This section

of the

group, Component Identifica

tion/System Operation, will discuss ignition system operation

and

will identify ignition system compo

nents.

For diagnostic procedures

and

adjustments, refer

to

the Diagnostics/Service Procedures section

of

this

group.

For removal

and

installation

of

ignition system

components, refer

to the

Component Removal/Instal

lation section

of

this group. For other useful information, refer

to

On-Board

Di

agnostics

in the

General Diagnosis sections

of

Group

14,

Fuel System

in

this manual. For operation

of the DRB II

Diagnostic Scan Tool,

refer

to the

appropriate Powertrain Diagnostic Proce

dures service manual.

An Ignition specifications section

is

included

at the

end

of

this group.

A

general Maintenance Schedule (mileage intervals)

for

ignition related items

can be

found

in

Group

0,

Lubrication and Maintenance. This

schedule

can

also

be

found

in the

Owners Manual.

IGNITION

SYSTEMS

The ignition systems used

on all

engines

are

basi

cally identical. Similarities

and

differences between

the systems will

be

discussed.

A sequential multi-port fuel injection system

is

used

on all gas

powered engines.

The ignition system

is

controlled

by the

powertrain

control module (PCM)

on all

engines.

The

PCM

was

formerly referred

to as the

SBEC

or

engine control ler.

The ignition system consists

of:

• Spark Plugs

• Ignition Coil

• Secondary Ignition Cables

• Ignition distributor. Contains rotor

and

camshaft

position sensor • Powertrain Control Module (PCM)

• Crankshaft Position Sensor

AUTOMATIC SHUT DOWN (ASD) RELAY

The automatic shut down (ASD) relay

is

located

in

the engine compartment (Fig.

1). As one of its

func

tions,

the ASD

relay will supply battery voltage

to

the ignition coil.

The

ground circuit

for the

ASD

re

lay

is

controlled

by the

powertrain control module (PCM).

The PCM

regulates

ASD

relay operation

by

switching

the

ground circuit on-and-off.

IGNITION

SYSTEMS

Page 365 of 1502

8D

- 14

IGNITION SYSTEMS

• (5) Test the MAP sensor ground circuit at sensor

connector terminal-A (Fig. 19) and PCM connector

terminal-4. Repair the wire harness if necessary.

(6) Test the MAP sensor ground circuit at the

PCM connector between terminal-4 and terminal-11

with an ohmmeter. If the ohmmeter indicates an

open circuit, inspect for a defective sensor ground

connection. Refer to Group 8W, Wiring for location of

this connection. If the ground connection is good, re

place the PCM. If terminal-4 has a short circuit to 12 volts +, correct this condition before replacing the

PCM.

POWERTRAIN

CONTROL MODULE {PCM)

The PCM (formerly called the SBEC or engine -con

troller) is located in the engine compartment (Fig.

20). DATA UNK CONTROL

CONNECTOR MODULE

J9314-164

Fig.

20 PCM Location The ignition system is controlled by the PCM.

For removal and installation of this component, re

fer to the Component Removal/Installation section of

this group.

For diagnostics, refer to the appropriate Powertrain

Diagnostic Procedures service manual for operation

of the DRB II scan tool.

SPARK

PLUGS

For spark plug removal, cleaning, gap adjustment

and installation, refer to the Component Removal/In

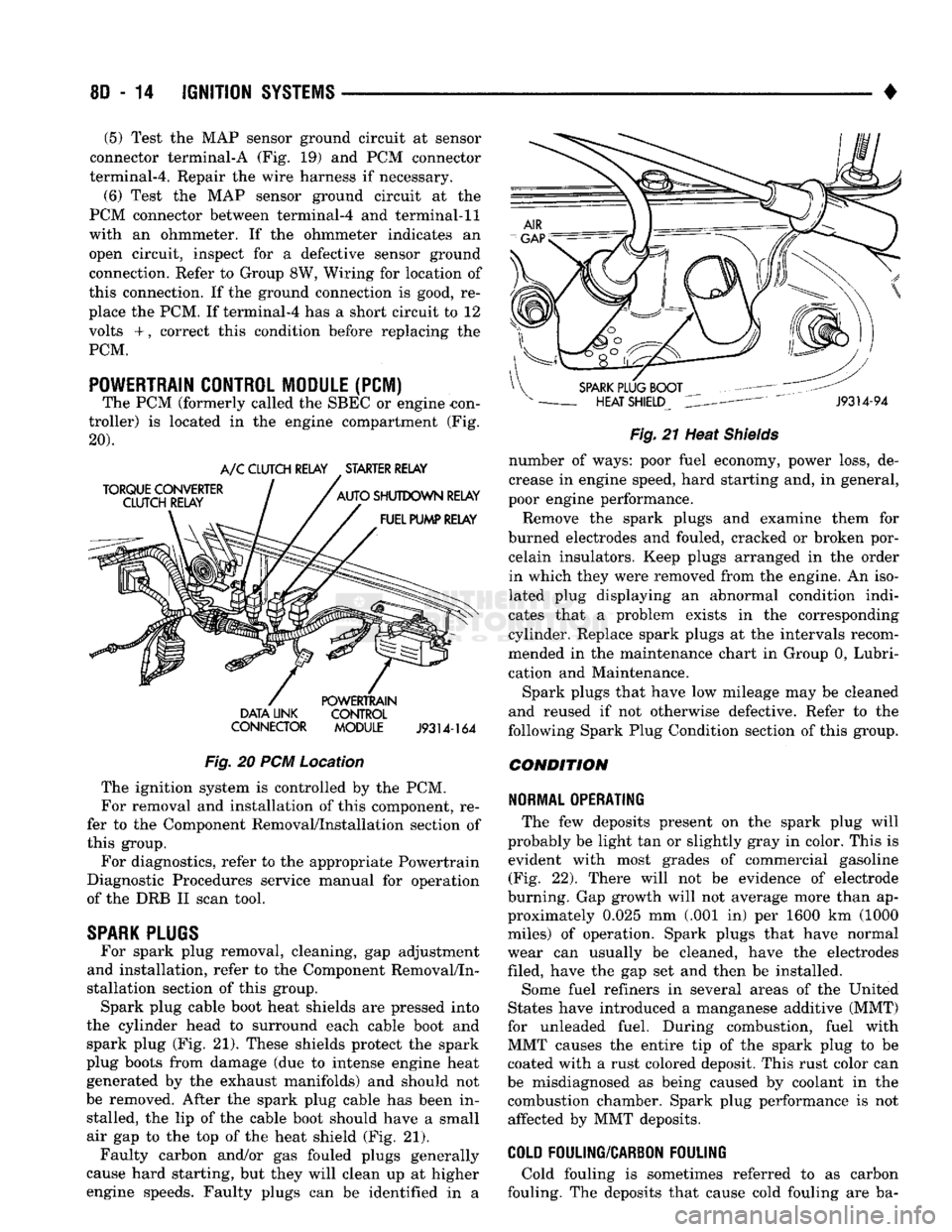

stallation section of this group. Spark plug cable boot heat shields are pressed into

the cylinder head to surround each cable boot and

spark plug (Fig. 21). These shields protect the spark

plug boots from damage (due to intense engine heat

generated by the exhaust manifolds) and should not

be removed. After the spark plug cable has been in stalled, the lip of the cable boot should have a small

air gap to the top of the heat shield (Fig. 21). Faulty carbon and/or gas fouled plugs generally

cause hard starting, but they will clean up at higher

engine speeds. Faulty plugs can be identified in a

Fig.

21 Heat

Shields

number of ways: poor fuel economy, power loss, de

crease in engine speed, hard starting and, in general,

poor engine performance.

Remove the spark plugs and examine them for

burned electrodes and fouled, cracked or broken por celain insulators. Keep plugs arranged in the order

in which they were removed from the engine. An iso

lated plug displaying an abnormal condition indi

cates that a problem exists in the corresponding

cylinder. Replace spark plugs at the intervals recom

mended in the maintenance chart in Group 0, Lubri

cation and Maintenance.

Spark plugs that have low mileage may be cleaned

and reused if not otherwise defective. Refer to the

following Spark Plug Condition section of this group.

CONDITION

NORMAL OPERATING

The few deposits present on the spark plug will

probably be light tan or slightly gray in color. This is evident with most grades of commercial gasoline (Fig. 22). There will not be evidence of electrode

burning. Gap growth will not average more than ap proximately 0.025 mm (.001 in) per 1600 km (1000

miles) of operation. Spark plugs that have normal

wear can usually be cleaned, have the electrodes filed, have the gap set and then be installed.

Some fuel refiners in several areas of the United

States have introduced a manganese additive (MMT)

for unleaded fuel. During combustion, fuel with

MMT causes the entire tip of the spark plug to be coated with a rust colored deposit. This rust color can

be misdiagnosed as being caused by coolant in the combustion chamber. Spark plug performance is not affected by MMT deposits.

COLD

FOULING/CARBON FOULING

Cold fouling is sometimes referred to as carbon

fouling. The deposits that cause cold fouling are ba-

Page 464 of 1502

•

POWER

WINDOWS

8S - 3

FROM PIN

SIDE

OF

SWITCH

MASTER

WINDOW

LIFT

SWITCH

SWITCH

POSITION CONTINUITY

BETWEEN

OFF

PINS

1 & 2

PINS

2 & 3

PINS

2 &4

PINS

2 & 6

DRIVER'S

MP

PINS

3 & 5

PINS

2 & 6

PASSENGER'S

PINS

1 & 5

PINS

2 &4

DRIVER'S

PINS

5 & 6

PINS

2 & 3

TOWN

PASSENGER'S

PINS

1 & 2

PINS

4 & 5 898S-11

Fig.

1 Master Window

Lift

Switch

Continuity

(b) Likewise, motor connected to DOWN direc

tion rotation, no movement will be observed if win

dow is already in full down position.

PIN IDENTIFICATION SHOWN

FROM

PIN

SIDE

OF

SWITCH

SWITCH CONTINUITY

POSITION

BETWEEN

PINS

1 & 4

OFF

PINS

2 & 5

PINS

3 & 4

UP

PINS

2 & 5

PINS

2 & 3

DOWN

PINS

1 & 4

898S-12

Fig.

2

Passenger's Door

Mounted

Switch

Continuity

(4) Reverse battery leads (opposite to steps 1 and

2) and window should now move. If window does not

move, remove motor. Refer to Service Procedures for

motor removal from vehicle for bench test.

If window moved completely up or down, motor

should be reversed one more time (reverse leads from

step 4) to complete a full window travel inspection.

SERVICE

PROCEDURES

GEAR

AND PINION

REPLACEMENT

AND

LUBRICATION

If gear and pinion assembly are replaced in gear

box, lubrication of gear box, gear pinion and seal is necessary. In the event there is no lubricant in gear box, fill

with MOPAR, multi-mileage lubricant or equivalent. Apply a liberal amount of lubricant to inside area of seal and sealing surface at center area of gear and

pinion coupling. Also lubricate center housing shaft and worm gear.

REGULATOR

AND

MOTOR

ASSEMBLY

REMOVAL To repair or inspect the entire electric window reg

ulator, remove from door as follows: (1) Remove remote control handle (Fig. 3).

(2) Remove power window/lock switch by inserting

a standard blade screwdriver into notch on forward

end of switch housing. Push screwdriver to depress

locking tab. Pull bezel out and forward to remove

from door panel.

(3) Remove screws at bottom front and rear of trim

panel.

(4) Remove screw behind remote handle.

(5)

Using a device such as a trim stick, pry trim

panel away from door around perimeter and remove

trim panel. (6) Roll door watershield away from bottom of door

to reveal inside panel access opening. (7) Remove speaker if equipped.

(8) Lower glass to full down position.

(9) Disconnect wiring connectors from motor.