mileage DODGE TRUCK 1993 Service Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 978 of 1502

•

STEERING

19 - 17

STEERING

LINKAGE

SERVICE

INFORMATION

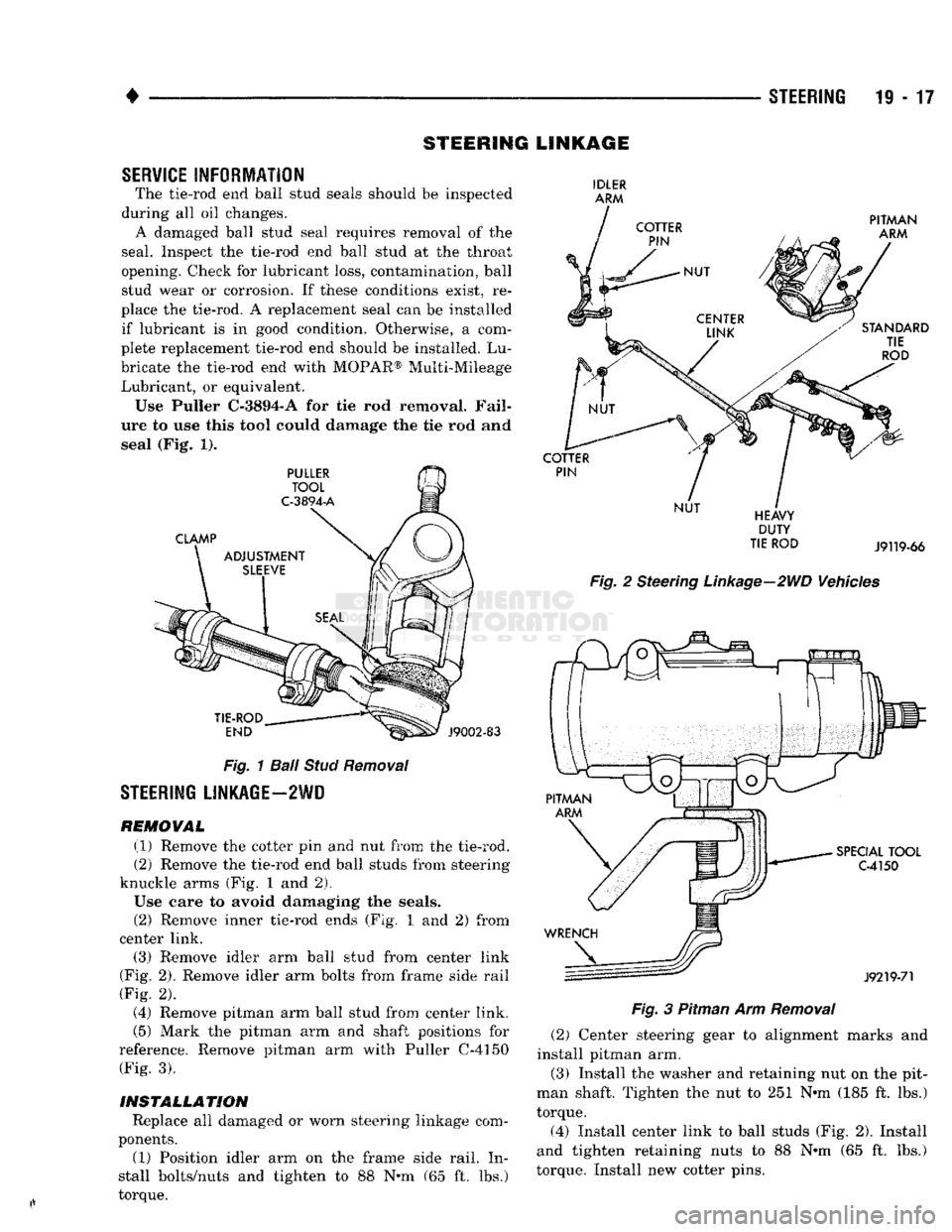

The tie-rod end ball stud seals should be inspected

during all oil changes. A damaged ball stud seal requires removal of the

seal. Inspect the tie-rod end ball stud at the throat

opening. Check for lubricant loss, contamination, ball

stud wear or corrosion. If these conditions exist, re

place the tie-rod. A replacement seal can be installed if lubricant is in good condition. Otherwise, a com

plete replacement tie-rod end should be installed. Lu

bricate the tie-rod end with MOPAR® Multi-Mileage Lubricant, or equivalent. Use Puller C-3894-A for tie rod removal. Fail

ure to use this tool could damage the tie rod and seal (Fig. 1).

Fig.

1

Ball

Stud

Removal

STEERING

LINKAGE—2WD

REMOWAL (1) Remove the cotter pin and nut from the tie-rod.

(2) Remove the tie-rod end ball studs from steering

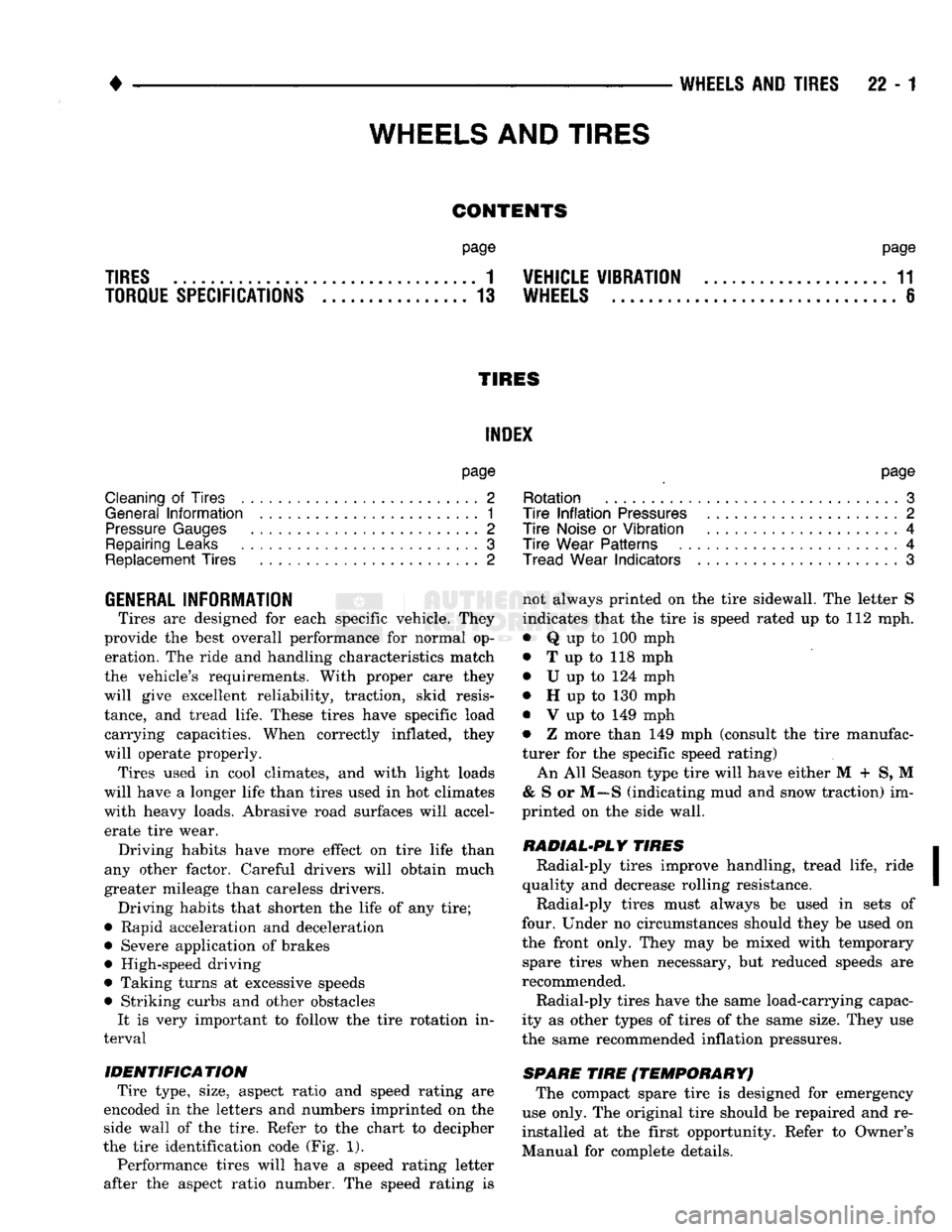

knuckle arms (Fig. 1 and 2),

Use care to avoid damaging the seals. (2) Remove inner tie-rod ends (Fig. 1 and 2) from

center link. (3) Remove idler arm ball stud from center link

(Fig. 2). Remove idler arm bolts from frame side rail

(Fig. 2). (4) Remove pitman arm ball stud from center link.

(5) Mark the pitman arm and shaft positions for

reference. Remove pitman arm with Puller C-4150 (Fig. 3).

INSTALLATION

Replace all damaged or worn steering linkage com

ponents.

(1) Position idler arm on the frame side rail. In

stall bolts/nuts and tighten to 88 N-m (65 ft. lbs.)

torque.

IDLER

ARM

DUTY

TIE

ROD

J9119-66

Fig.

2 Steering

Linkage—2WD

Vehicles

Fig.

3 Pitman Arm

Removal

(2) Center steering gear to alignment marks and

install pitman arm.

(3) Install the washer and retaining nut on the pit

man shaft. Tighten the nut to 251 N-m (185 ft. lbs.)

torque. (4) Install center link to ball studs (Fig. 2). Install

and tighten retaining nuts to 88 N-m (65 ft. lbs.)

torque. Install new cotter pins.

Page 1370 of 1502

•

WHEELS

AND

TIRES

22 - 1

CONTENTS

page page

TIRES

1

VEHICLE VIBRATION

11

TORQUE SPECIFICATIONS

13

WHEELS

6

TIRES INDEX

page

Cleaning

of

Tires

2

General

Information

1

Pressure

Gauges

. 2

Repairing Leaks

3

Replacement Tires

2

GENERAL

INFORMATION

Tires are designed for each specific vehicle. They

provide the best overall performance for normal op eration. The ride and handling characteristics match

the vehicle's requirements. With proper care they

will give excellent reliability, traction, skid resis

tance, and tread life. These tires have specific load carrying capacities. When correctly inflated, they

will operate properly.

Tires used in cool climates, and with light loads

will have a longer life than tires used in hot climates

with heavy loads. Abrasive road surfaces will accel erate tire wear.

Driving habits have more effect on tire life than

any other factor. Careful drivers will obtain much

greater mileage than careless drivers.

Driving habits that shorten the life of any tire;

• Rapid acceleration and deceleration

• Severe application of brakes • High-speed driving

• Taking turns at excessive speeds

• Striking curbs and other obstacles It is very important to follow the tire rotation in

terval

IDENTIFICATION Tire type, size, aspect ratio and speed rating are

encoded in the letters and numbers imprinted on the

side wall of the tire. Refer to the chart to decipher

the tire identification code (Fig. 1). Performance tires will have a speed rating letter

after the aspect ratio number. The speed rating is

page

Rotation

. 3

Tire

Inflation

Pressures

2

Tire

Noise

or

Vibration

4

Tire

Wear

Patterns

4

Tread Wear

Indicators

3

not always printed on the tire side wall. The letter S

indicates that the tire is speed rated up to 112 mph.

• Q up to 100 mph

• T up to 118 mph

• U up to 124 mph

• H up to 130 mph

• V up to 149 mph

• Z more than 149 mph (consult the tire manufac

turer for the specific speed rating)

An All Season type tire will have either M + S, M

& S or M—S (indicating mud and snow traction) im

printed on the side wall.

RADIAL-PLY TIRES Radial-ply tires improve handling, tread life, ride

quality and decrease rolling resistance. Radial-ply tires must always be used in sets of

four. Under no circumstances should they be used on

the front only. They may be mixed with temporary spare tires when necessary, but reduced speeds are

recommended.

Radial-ply tires have the same load-carrying capac

ity as other types of tires of the same size. They use

the same recommended inflation pressures.

SPARE TIRE (TEMPORARY) The compact spare tire is designed for emergency

use only. The original tire should be repaired and re

installed at the first opportunity. Refer to Owner's

Manual for complete details.

WHEELS

AND

TIRES

Page 1478 of 1502

•

EMISSION

CONTROL

SYSTEMS

25

- 1

CONTENTS

page page

AIR INJECTION

SYSTEM-o

9L

HDC-GAS EVAPORATIVE EMISSION CONTROLS

6

ENGINE

15

EXHAUST EMISSION CONTROLS

10

COMPONENT

REMOVAL/INSTALLATION

17

GENERAL INFORMATION

1

GENERAL

INFORMATION

Throughout this group, references are made

to

par

ticular vehicle models

by

alphabetical designation

or

by the particular vehicle nameplate.

A

chart showing a breakdown

of

alphabetical designations

is

included

in

the

Introduction section

at

the

beginning

of

this

manual.

The 5.9L (V-8) gas powered engine will

be

referred

to

in

this group

as

either the: LDC (Light Duty Cy cle)

or

HDC (Heavy Duty Cycle) engine.

The

HDC

engine can

be

easily identified

by

the

use

of

an en

gine mounted

air

injection pump. The 3.9L/5.2L/5.9L

LDC engine will not use

an

air

injection pump.

Maintenance requirements for LDC and HDC emis

sion systems differ because

of

different load

and

op

erating conditions. This section will cover emission control systems

for

the 3.9L (V-6), 5.2L (V-8), 5.9L LDC (V-8), 5.9L HDC (V-8) and 5.9L (in-line six cylinder) diesel engines.

SERVICE

REMINDER INDICATOR

(SRI)

LIGHT

The instrument panel mounted SRI light was for

merly referred

to as the

emission maintenance

re

minder (EMR) light.

It is

used with 5.9L HDC-gas

powered engines only.

It is

not

used with diesel

en

gines.

The SRI system

is

incorporated into the powertrain

control module (PCM)

(the

PCM

was

formerly

re

ferred

to as the

engine controller

or

SBEC).

The

PCM records

the

vehicles mileage and stores

it

into

memory every

8

miles. At that time, the PCM checks

for the 60,000 and 82,500 mileage trip points. When

the current mileage matches one

of

the above men

tioned trip points,

the

SRI light

is

activated.

The following parts are

to

be replaced

at

either the

indicated mileage

or

when the SRI light remains

on

when the key

is in

the ON position. After performing

the required maintenance,

the

SRI light must

be

re set

to

turn the light

off.

96,000

km

(60,000 miles):

• Replace EGR Valve

• Clean EGR passage • Replace PCV Valve

132,000

km

(82,500 miles):

• Replace Oxygen Sensor

Refer

to

Group

0,

Lubrication and Maintenance

for

all required maintenance schedules.

Failure

to

perform

the

required maintenance

and

only reset the SRI light may be

a

violation of federal

law. Only after performing

the

required mainte

nance, should the SRI light

be

reset.

RESETTING

SRI

LIGHT

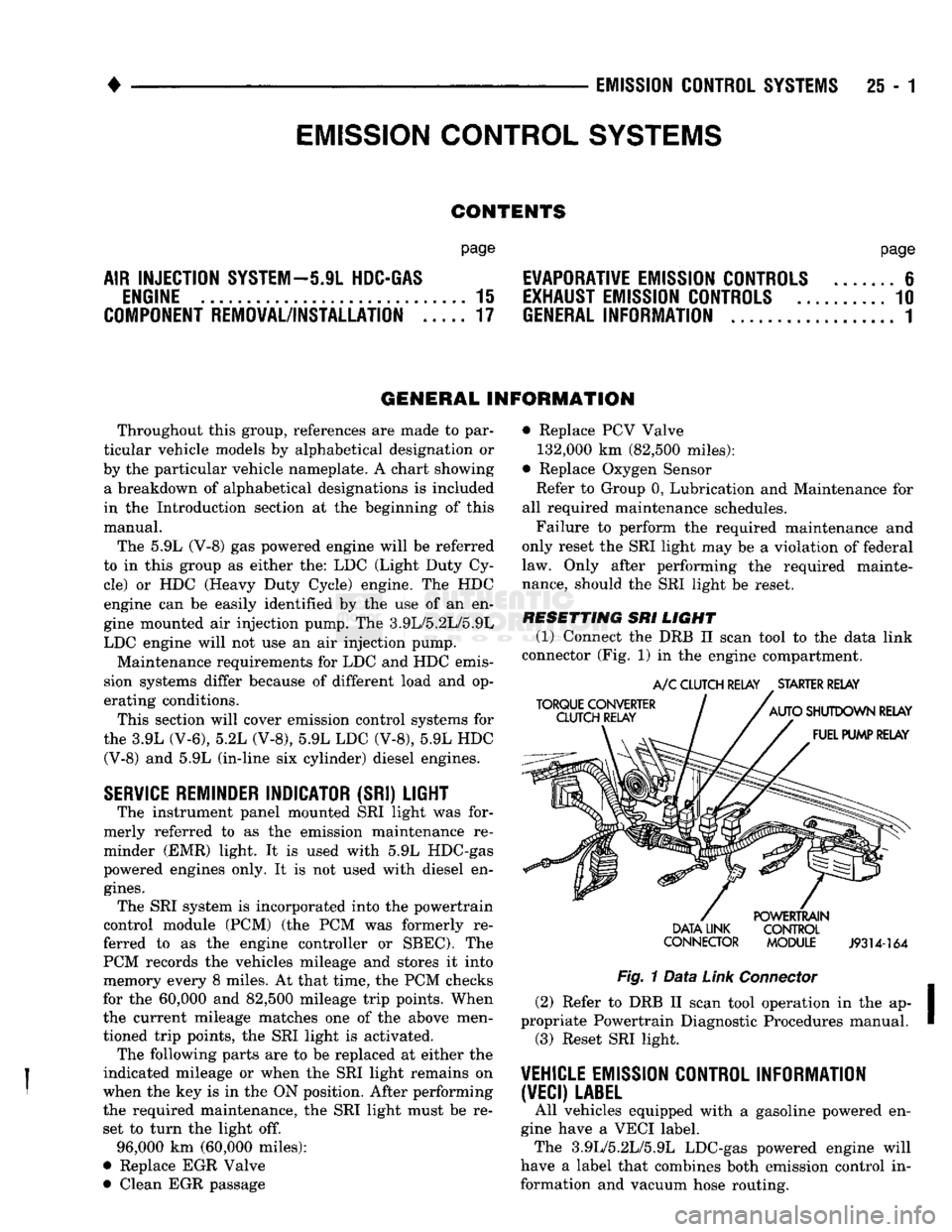

(1) Connect

the

DRB

II

scan tool

to

the

data link

connector (Fig.

1)

in

the engine compartment.

TORQUE CONVERTER

CLUTCH RELAY

A/C

CLUTCH RELAY

.

STARTER RELAY

AUTO

SHUTDOWN RELAY FUEL PUMP RELAY DATA LINK

CONNECTOR POWERTRAIN

CONTROL

MODULE

J9314-164

Fig.

1

Data

Link

Connector

(2) Refer

to

DRB

II

scan tool operation

in

the ap

propriate Powertrain Diagnostic Procedures manual. (3) Reset SRI light.

VEHICLE

EMISSION CONTROL INFORMATION

(VECI)

LABEL

All vehicles equipped with

a

gasoline powered

en

gine have

a

VECI label. The 3.9L/5.2L/5.9L LDC-gas powered engine will

have

a

label that combines both emission control

in

formation and vacuum hose routing.

EMISSION CONTROL

SYSTEMS