oil temperature DODGE TRUCK 1993 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 158 of 1502

•

REAR

SUSPENSION

AND

AXLE

3 - 31

LUBRICANT

Hypoid gear lubricant, as defined by MIL-L-2105-B

and API GL 5 is the specified lube. MOPAR Hypoid

Gear Lubricant conforms with both of these specifica

tions and is highly recommended.

CAUTION:

If a

rear

axle

is

submerged

in

water,

the

axle

lubricant

must

be

replaced

immediately,

DRAIN

AND

REFILL

(1) Drive the vehicle until the gear lubricant

reaches normal operating temperature. (2) Raise and support the vehicle. (3) Remove the lubricant fill hole plug from the

differential housing cover. (4) Remove the differential housing cover. Allow

the lubricant to completely drain from the housing and axle shaft tubes. (5) Flush the differential and the housing cavity

with a flushing oil to remove residual lubricant and

foreign matter. Do not use water,

steam,

kerosene

or

gasoline for

flushing,

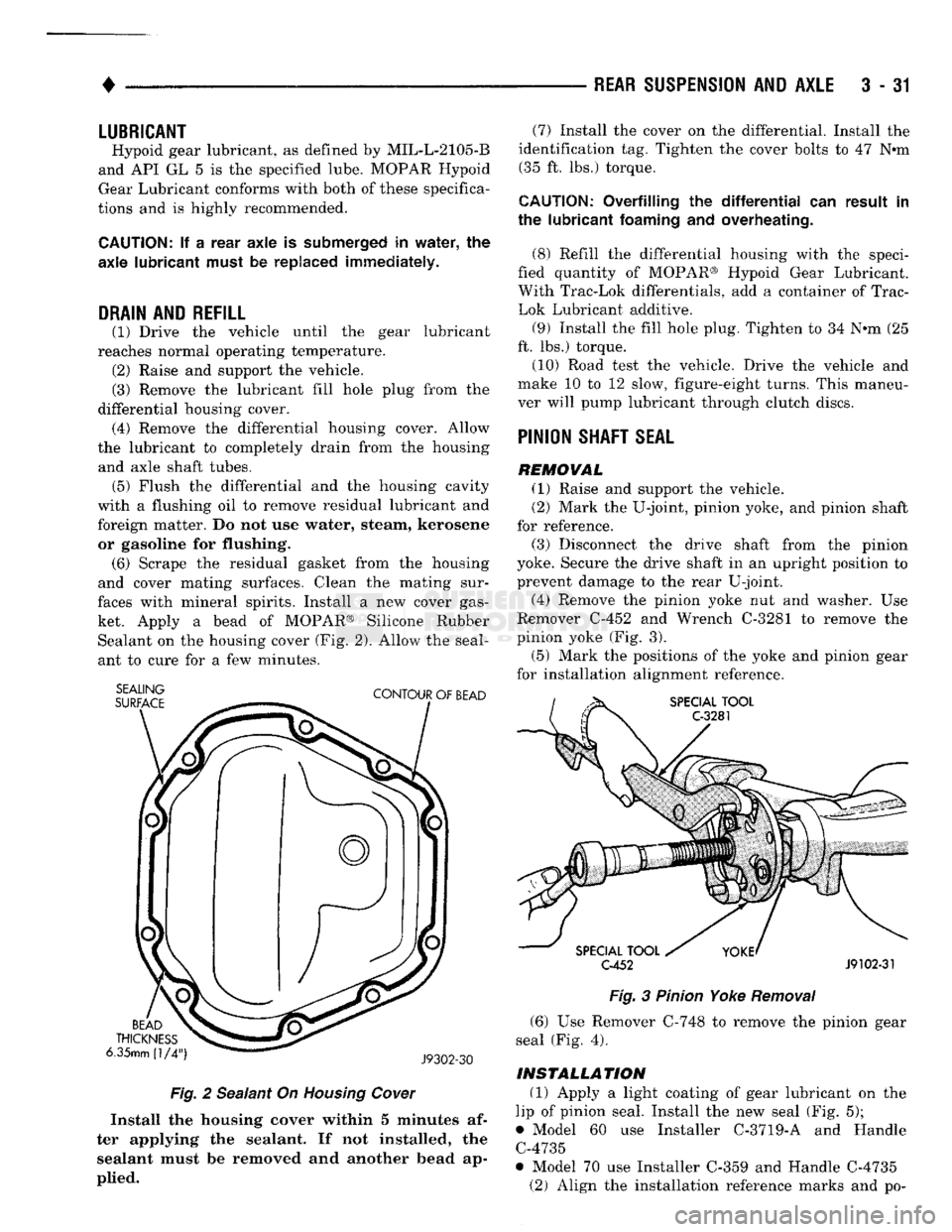

(6) Scrape the residual gasket from the housing

and cover mating surfaces. Clean the mating sur

faces with mineral spirits. Install a new cover gas

ket. Apply a bead of MOPAR® Silicone Rubber Sealant on the housing cover (Fig. 2). Allow the seal

ant to cure for a few minutes.

SEALING

SURFACE

CONTOUR

OF

BEAD

BEAD

THICKNESS

6.35mm

(1/4")

J9302-30

Fig.

2 Sealant On Housing Cower

Install

the

housing

cover

within 5

minutes

af

ter

applying

the

sealant.

If not

installed,

the

sealant

must be

removed

and another

bead

ap

plied.

(7) Install the cover on the differential. Install the

identification tag. Tighten the cover bolts to 47 Nem (35 ft. lbs.) torque.

CAUTION:

Overfilling

the differential" can

result

in

the

lubricant

foaming

and

overheating.

(8) Refill the differential housing with the speci

fied quantity of MOPAR® Hypoid Gear Lubricant.

With Trac-Lok differentials, add a container of Trac-

Lok Lubricant additive.

(9) Install the fill hole plug. Tighten to 34 N-m (25

ft. lbs.) torque.

(10) Road test the vehicle. Drive the vehicle and

make 10 to 12 slow, figure-eight turns. This maneu

ver will pump lubricant through clutch discs.

PINION

SHAFT

SEAL

REMOVAL

(1) Raise and support the vehicle.

(2) Mark the U-joint, pinion yoke, and pinion shaft

for reference.

(3) Disconnect the drive shaft from the pinion

yoke. Secure the drive shaft in an upright position to

prevent damage to the rear U-joint.

(4) Remove the pinion yoke nut and washer. Use

Remover C-452 and Wrench C-3281 to remove the

pinion yoke (Fig. 3).

(5) Mark the positions of the yoke and pinion gear

for installation alignment reference.

SPECIAL

TOOL

C-3281

SPECIAL

TOOL

C-452

J9102-31

Fig.

3 Pinion Yoke

Removal

(6) Use Remover C-748 to remove the pinion gear

seal (Fig. 4).

INSTALLATION

(1) Apply a light coating of gear lubricant on the

lip of pinion seal. Install the new seal (Fig. 5);

• Model 60 use Installer C-3719-A and Handle C-4735

• Model 70 use Installer C-359 and Handle C-4735 (2) Align the installation reference marks and po-

Page 273 of 1502

7 - 2

COOLING

SYSTEM

•

NOTE: HEATER

COOLANT FLOW

CIRCUIT

IS

ALWAYS

OPEN

EXCEPT

WHEN

IN MAX. A/C

OR

OFF

MODES

HEATER

INTAKE MANIFOLD

COOLANT FLOW "METERED" FROM REAR

TO

FRONT

AND

BELOW EXHAUST HEAT

CROSSOVER

SHUT

OFF

VALVE

A/C

ONLY COOLANT FLOW

-

PUMP

TO

CYLINDER

BLOCK,

UP

THROUGH

CYLINDER

HEADS

TO

INTAKE MANIFOLD WATER BOX

TO

RADIATOR

—

TO PUMP

•BYPASS

THERMOSTAT CLOSED-HIGH FLOW

THERMOSTAT OPEN

-

LOW FLOW

CYLINDER

HEAD

RR07B52

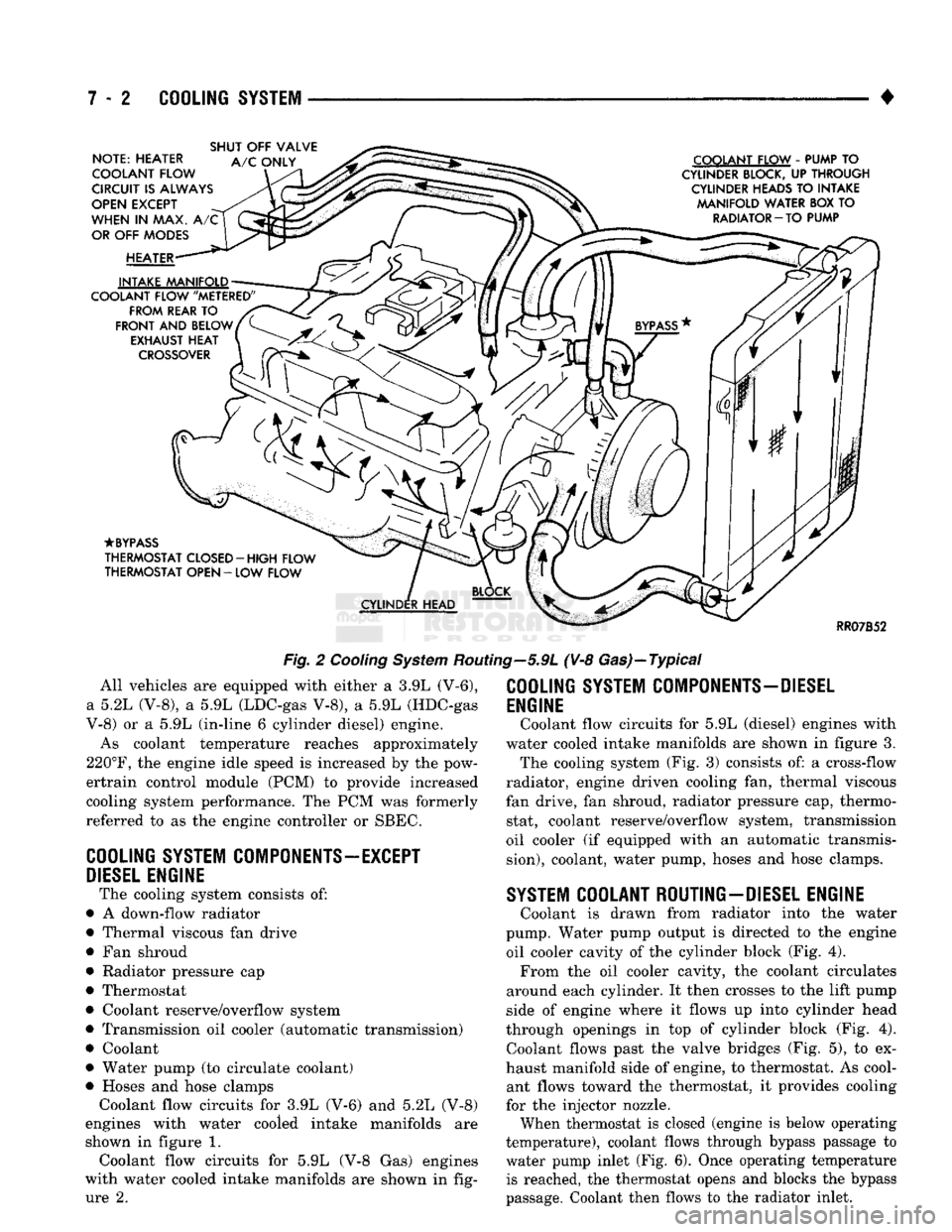

Fig.

2

Cooling

System

Routing—5.9L (V-8 Gas)—Typical All vehicles are equipped with either a 3.9L (V-6),

a 5.2L (V-8), a 5.9L (LDC-gas V-8), a 5.9L (HDC-gas

V-8) or a 5.9L (in-line 6 cylinder diesel) engine.

As coolant temperature reaches approximately

220°F,

the engine idle speed is increased by the pow-

ertrain control module (PCM) to provide increased

cooling system performance. The PCM was formerly

referred to as the engine controller or SBEC.

COOLING

SYSTEM

COMPONENTS—EXCEPT

DIESEL

ENGINE

The cooling system consists of:

• A down-flow radiator

• Thermal viscous fan drive

• Fan shroud

• Radiator pressure cap

• Thermostat

• Coolant reserve/overflow system

• Transmission oil cooler (automatic transmission)

• Coolant

• Water pump (to circulate coolant)

• Hoses and hose clamps Coolant flow circuits for 3.9L (V-6) and 5.2L (V-8)

engines with water cooled intake manifolds are

shown in figure 1. Coolant flow circuits for 5.9L (V-8 Gas) engines

with water cooled intake manifolds are shown in fig ure 2.

COOLING

SYSTEM

COMPONENTS-DIESEL

ENGINE

Coolant flow circuits for 5.9L (diesel) engines with

water cooled intake manifolds are shown in figure 3. The cooling system (Fig. 3) consists of: a cross-flow

radiator, engine driven cooling fan, thermal viscous

fan drive, fan shroud, radiator pressure cap, thermo stat, coolant reserve/overflow system, transmission

oil cooler (if equipped with an automatic transmis

sion),

coolant, water pump, hoses and hose clamps.

SYSTEM

COOLANT ROUTING-DIESEL ENGINE

Coolant is drawn from radiator into the water

pump. Water pump output is directed to the engine oil cooler cavity of the cylinder block (Fig. 4). From the oil cooler cavity, the coolant circulates

around each cylinder. It then crosses to the lift pump

side of engine where it flows up into cylinder head

through openings in top of cylinder block (Fig. 4). Coolant flows past the valve bridges (Fig. 5), to ex

haust manifold side of engine, to thermostat. As cool ant flows toward the thermostat, it provides cooling

for the injector nozzle.

When thermostat is closed (engine is below operating

temperature), coolant flows through bypass passage to

water pump inlet (Fig. 6). Once operating temperature is reached, the thermostat opens and blocks the bypass

passage. Coolant then flows to the radiator inlet.

Page 276 of 1502

•

COOLING

SYSTEM

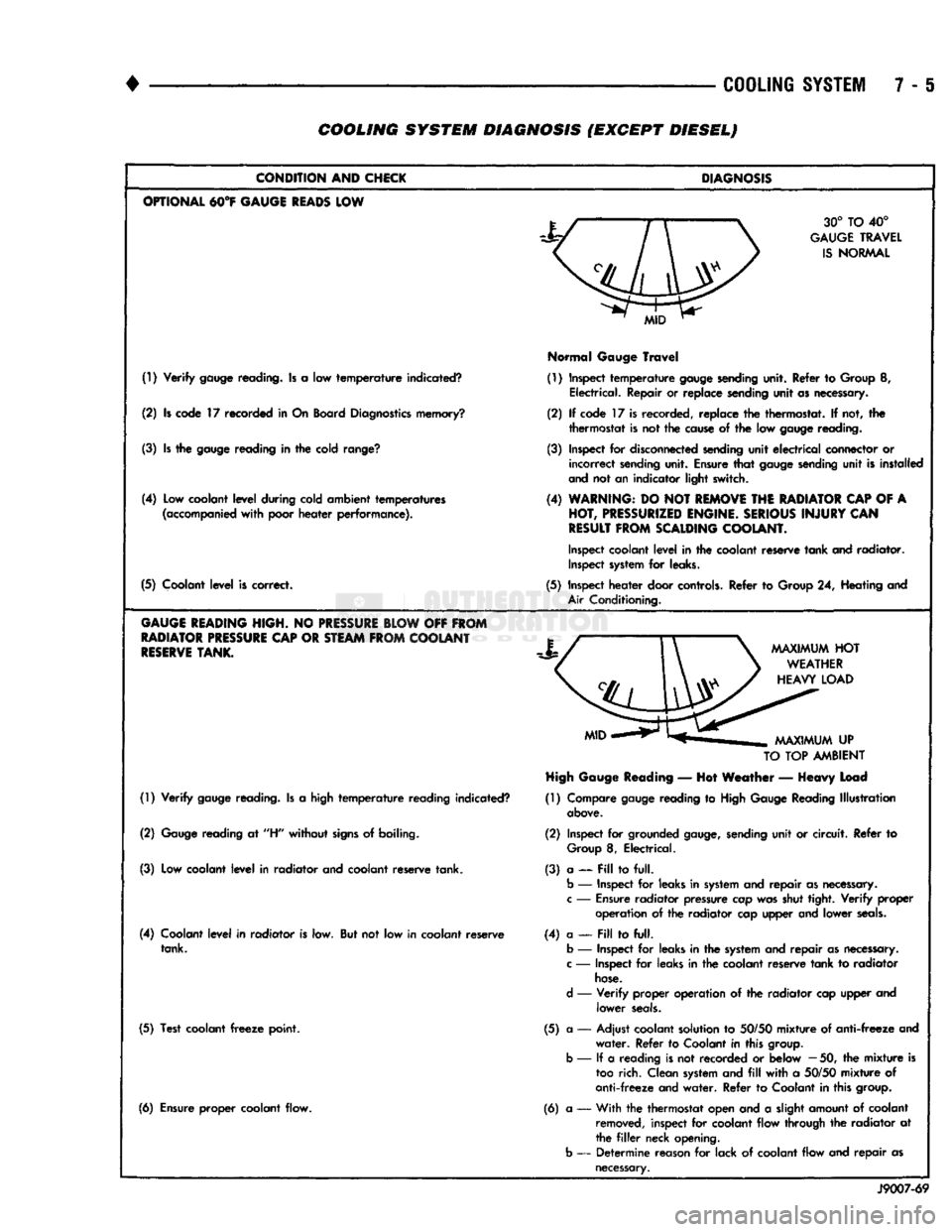

7 - 6 COOLING SYSTEM DIAGNOSIS (EXCEPT DIESEL)

CONDITION

AND

CHICK

OPTIONAL

M°¥

GAUGE

READS

LOW

(!) Verify

gauge

reading. Is a low temperature indicated?

(2) Is code 17 recorded in On Board

Diagnostics

memory?

(3) Is the

gauge

reading in the cold

range?

(4) Low coolant level during cold ambient temperatures

(accompanied

with poor heater performance).

(5) Coolant level is correct.

GAUGE

HEADING

HIGH.

NO

PRESSURE

BLOW

OFF

FROM

RADIATOR

PRESSURE

CAP

OR

STEAM

FROM

COOLANT

RESERVE

TANK.

(1) Verify

gauge

reading. Is a high temperature reading indicated?

(2)

Gauge

reading at

"H"

without

signs

of boiling.

(3) Low coolant level in radiator and coolant reserve tank.

(4) Coolant level in radiator is low. But not low in coolant reserve tank.

(5) Test coolant

freeze

point.

(6) Ensure proper coolant flow.

DIAGNOSIS

30° TO 40°

GAUGE

TRAVEL

IS

NORMAL

Normal

Gauge

Travel

(1) Inspect temperature

gauge

sending

unit. Refer to Group 8, Electrical. Repair or replace sending unit as necessary.

(2) If code 17 is recorded, replace the thermostat. If not, the thermostat is not the

cause

of the low

gauge

reading.

(3) Inspect for

disconnected

sending

unit electrical connector or incorrect

sending

unit. Ensure that

gauge

sending

unit is installed

and

not an indicator light switch.

(4)

WARNING:

DO NOT

REMOVE

THE

RADIATOR

CAP

OF A

HOT,

PRESSURIZED

ENGINE.

SERIOUS

INJURY

CAN

RESULT

FROM

SCALDING

COOLANT.

Inspect

coolant level in the coolant reserve tank and radiator.

Inspect

system

for leaks.

(5) Inspect heater door

controls.

Refer to Group 24, Heating and

Air

Conditioning.

TO

TOP

AMBIENT

High

Gauge

Reading

— Hot Weather — Heavy Load

(1) Compare

gauge

reading to

High

Gauge

Reading Illustration

above.

(2) Inspect for grounded

gauge,

sending

unit or circuit. Refer to

Group

8, Electrical.

(3) a — Pill to full.

b

— Inspect for leaks in

system

and repair as

necessary,

c

—

Ensure

radiator pressure cap was shut tight. Verify

proper

operation of the radiator cap upper and lower

seals.

(4) a —

Fill

to full,

b

— Inspect for leaks in the

system

and repair as

necessary,

c

— Inspect for leaks in the coolant reserve tank to radiator

hose.

d

— Verify proper operation of the radiator cap upper and lower

seals.

(5) a — Adjust coolant solution to

50/50

mixture of anti-freeze and water. Refer to Coolant in this

group,

b

— If a reading is not recorded or below

—

50, the mixture is

too

rich. Clean

system

and

fill

with a

50/50

mixture of

anti-freeze and water. Refer to Coolant in this

group.

(6) a •— With the thermostat open and a slight amount of coolant

removed,

inspect for coolant flow through the radiator at

the

filler

neck opening,

b

— Determine reason for lack of coolant flow and repair as

necessary.

J9007-69

Page 278 of 1502

•

COOLING

SYSTEM

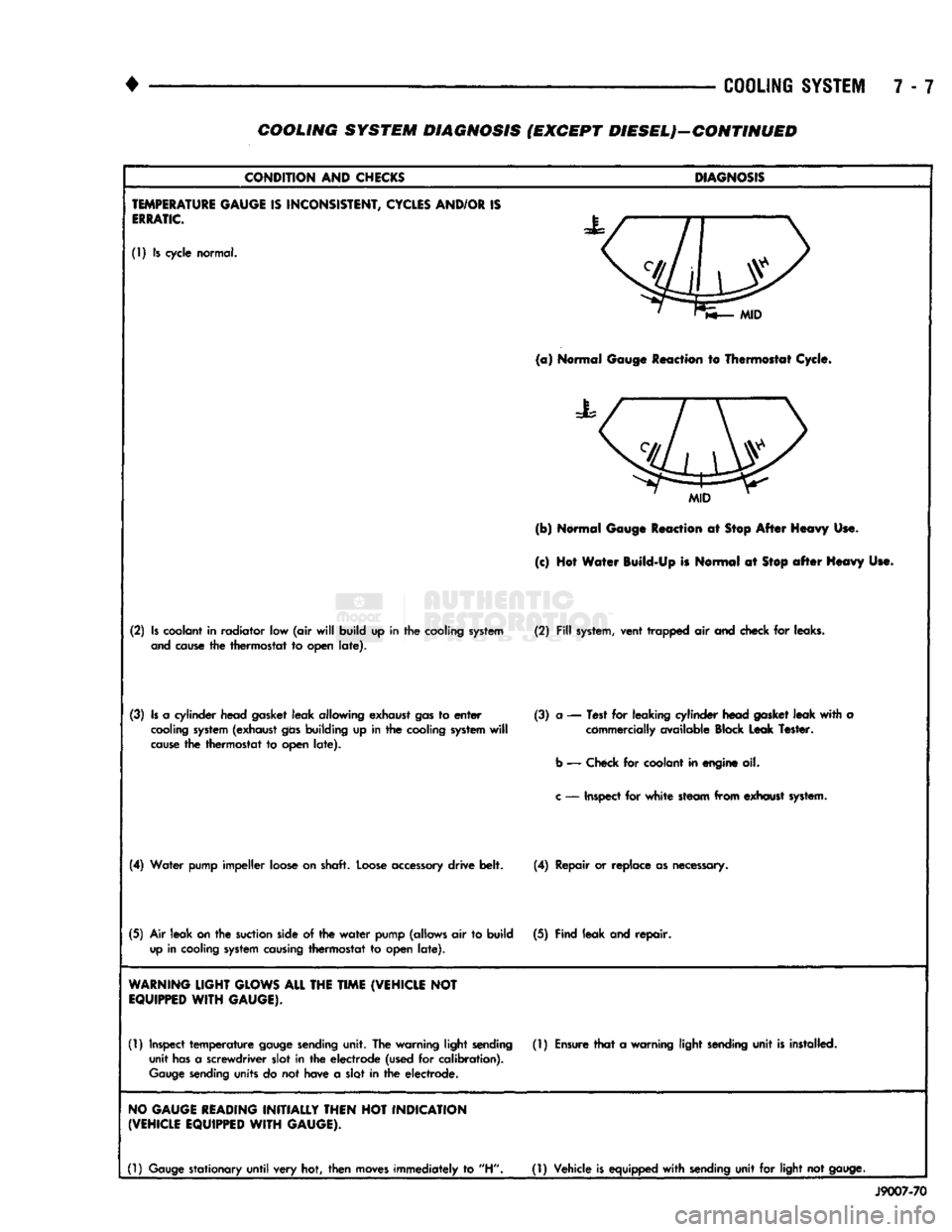

7 - 7 COOLING SYSTEM DIAGNOSIS (EXCEPT DIESELJ-GONTINUED

CONDITION

AND

CHECKS

DIAGNOSIS

TEMPERATURE

GAUGE

IS

INCONSISTENT,

CYCLES

AND/OR

IS

ERRATIC.

(1) Is cycle normal.

MID

(a)

Normal Gauge Reaction to Thermostat Cycle.

MID

(b) Normal Gauge Reaction at Stop After Heavy Use.

(c) Hot Water Build-Up is Normal at

Stop

after

Heavy Use.

(2)

Is

coolant in radiator low (air

will

build up in the cooling

system

(2)

Fill

system,

vent trapped air and check for leaks,

and

cause

the thermostat to open

late).

(3)

Is

a cylinder head gasket leak allowing exhaust

gas

to

enter

(3) a — Test for leaking cylinder head

gasket

leak

with

a

cooling

system

(exhaust

gas

building up in the cooling

system

will

commercially available Block Leak Tester,

cause

the thermostat to open

late).

b

— Check for coolant in engine oil.

c

— Inspect for

white

steam from exhaust

system.

(4)

Water pump impeller loose on shaft.

Loose

accessory

drive belt. (4) Repair or replace as necessary.

(5)

Air leak

on

the

suction

side of the

water

pump (allows air to build (5) Find leak and repair,

up

in cooling

system

causing

thermostat to open

late).

WARNING

LIGHT

GLOWS

ALL

THE

TIME

(VEHICLE

NOT

EQUIPPED

WITH

GAUGE).

(1) Inspect

temperature

gauge

sending

unit. The warning light

sending

(1)

Ensure

that

a warning light

sending

unit

is

installed, unit

has

a screwdriver slot in the electrode (used for calibration).

Gauge

sending

units do not have a slot in the electrode.

NO

GAUGE

READING

INITIALLY

THEN

HOT

INDICATION

(VEHICLE

EQUIPPED

WITH

GAUGE).

(1)

Gauge

stationary

until

very hot, then

moves

immediately to "H"

(1)

Vehicle

is

equipped

with

sending

unit for light not

gauge.

J9007-70

Page 281 of 1502

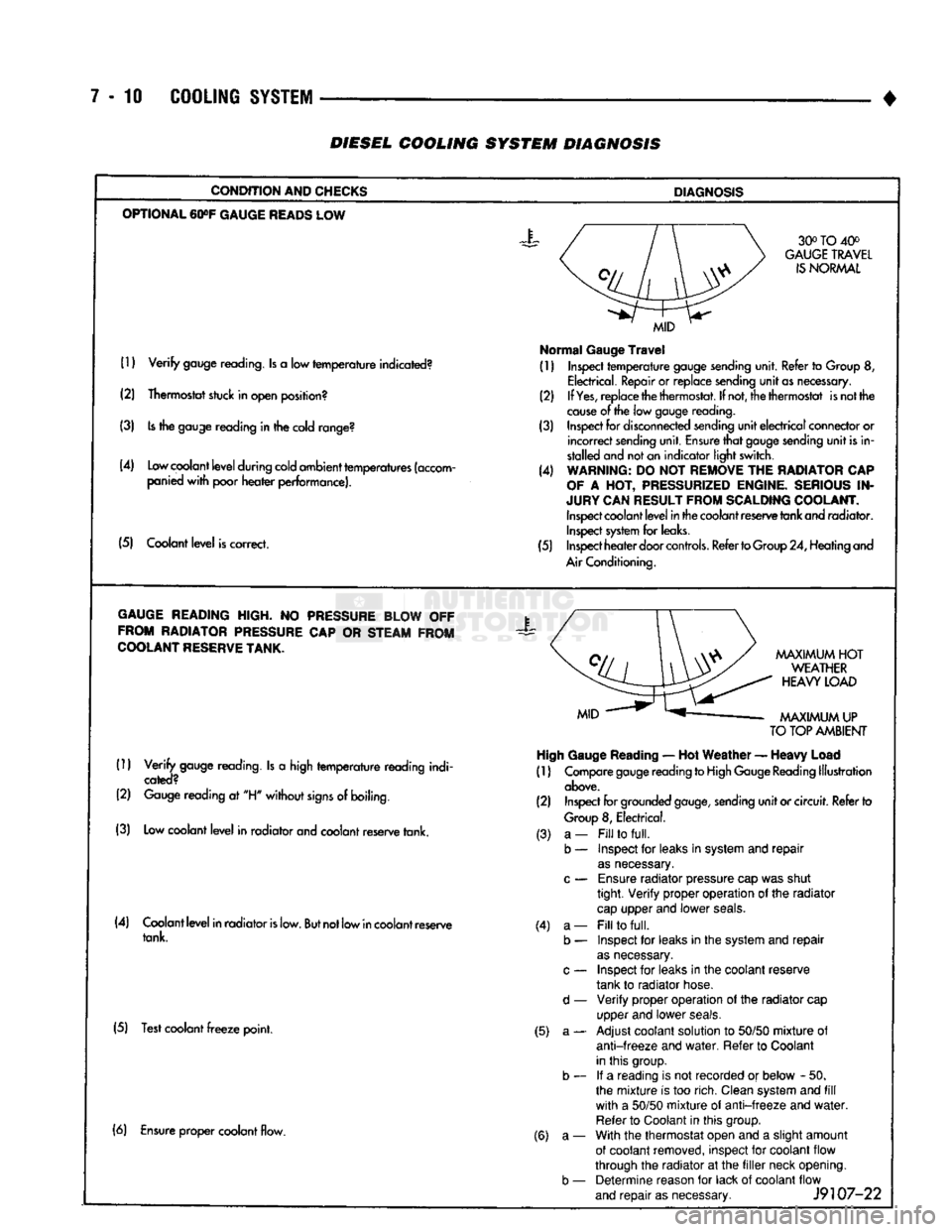

7-10 COOLING SYSTEM

•

DIESEL

COOLING SYSTEM

DIAGNOSIS

CONDITION AND CHECKS

DIAGNOSIS

OPTIONAL

60»F

GAUGE

READS

LOW 30° TO 40°

GAUGE

TRAVEL

IS

NORMAL

(1)

Verify

gauge reading. Is a low

temperature

indicated?

(2) Thermostat stuck in open position?

(3) Is the gauge reading in the cold range?

(4) Low coolant

level

during cold ambient temperatures (accom panied

with

poor

heater

performance).

(5) Coolant

level

is correct.

MID

Normal

Gauge

Travel

(1) Inspect

temperature

gauge sending unit. Refer to Group 8,

Electrical. Repair or replace sending

unit

as necessary.

(2) If

Yes,

replace the thermostat. If not, the thermostat is not the

cause

of the low gauge

reading.

(3) Inspect for disconnected sending

unit

electrical

connector or

incorrect

sending unit. Ensure

that

gauge sending

unit

is in

stalled and not an indicator light switch.

(4) WARNING: DO NOT REMOVE THE RADIATOR CAP

OF

A HOT, PRESSURIZED ENGINE. SERIOUS IN

JURY CAN RESULT FROM SCALDING COOLANT. Inspect coolant

level

in the coolant reserve tank and radiator. Inspect system for leaks.

(5) Inspect

heater

door

controls.

Refer to Group 24, Heating and

Air Conditioning.

GAUGE

READING HIGH. NO PRESSURE BLOW OFF FROM RADIATOR PRESSURE CAP OR STEAM FROM

COOLANT

RESERVE

TANK.

X

(1)

Verify

gauge reading. Is a high

temperature

reading indi

cated?

(2) Gauge reading at "H"

without

signs

of boiling.

(3) Low coolant

level

in radiator and coolant reserve tank.

MAXIMUM

HOT

WEATHER

HEAVY

LOAD

MAXIMUM

UP

TO

TOP AMBIENT High Gauge

Reading

— Hot

Weather

—

Heavy

Load

(1) Compare gauge reading to High Gauge Reading Illustration

above.

(2) Inspect for grounded

gauge,

sending

unit

or circuit. Refer to

Group

8, Electrical.

(4) Coolant

level

in radiator

is

low.

But

not low in coolant reserve tank.

(5) Test coolant

freeze

point. (3) a-

b — (4) a-

b —

d —

(5) a- (6) Ensure proper coolant flow.

(6) a-

b —

Fill

to

full.

Inspect for leaks in system and

repair

as

necessary.

Ensure

radiator pressure cap was shut

tight.

Verify

proper operation of the radiator

cap

upper and lower

seals.

Fill

to

full.

Inspect for leaks in the system and

repair

as

necessary.

Inspect for leaks in the coolant reserve

tank to radiator hose.

Verify

proper operation of the radiator cap

upper and lower

seals.

Adjust coolant solution to

50/50

mixture

of

anti-freeze

and

water.

Refer to Coolant

in this group. If a reading is not recorded or below - 50.

the

mixture

is too rich. Clean system and

fill

with

a

50/50

mixture

of

anti-freeze

and

water.

Refer to Coolant in this group.

With the thermostat open and a slight amount

of coolant removed, inspect for coolant flow

through the radiator at the

filler

neck opening. Determine reason for lack of coolant flow

and

repair

as necessary.

J9107-22

Page 283 of 1502

7

- 12

COOLING

SYSTEM

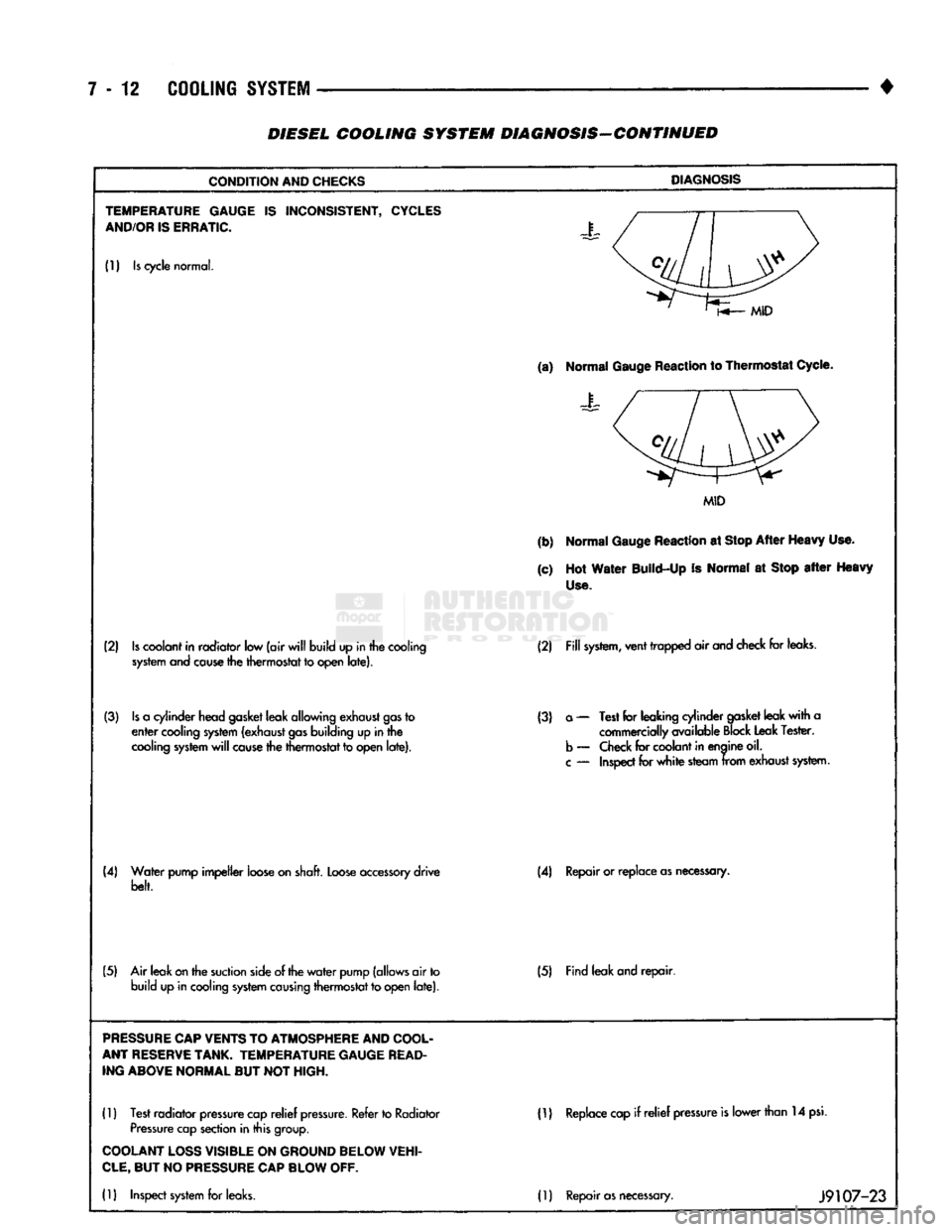

• DIESEL COOLING SYSTEM DIAGNOSIS-CONTINUED

CONDITION

AND

CHECKS

DIAGNOSIS

TEMPERATURE GAUGE

IS

INCONSISTENT,

CYCLES

AND/OR

IS

ERRATIC.

J

(1)

Is

cycle

normal.

(a)

Normal

Gauge

Reaction

to Thermostat

Cycle.

Normal

Gauge

Reaction

to Thermostat

Cycle.

MID

(b)

Normal

Gauge

Reaction

at

Stop

After

Heavy

Use.

(c)

Hot

Water

Build-Up

Is

Normal

at

Stop

after

Heavy

Use.

(2)

Is

coolant

in

radiator

low

(air

will

build

up in

the

cooling

system and cause

the

thermostat

to

open

late). (2)

Fill

system,

vent

trapped

air

and

check

for

leaks.

(3)

Is

a

cylinder

head

gasket

leak

allowing

exhaust

gas

to

enter

cooling

system

(exhaust

gas

building

up in

the

cooling

system

will

cause

the

thermostat

to

open

late).

(3)

a

—

Test

for

leaking

cylinder

gasket

leak

with

a

commercially

available

Block

Leak

Tester,

b

—

Check

for

coolant

in

enaine

oil.

c

—

Inspect

for

white

steam

from

exhaust

system.

(4)

Water

pump

impeller

loose

on

shaft.

Loose

accessory

drive

belt. (4)

Repair or

replace

as

necessary.

(5)

Air

leak

on

the

suction

side

of the

water

pump

(allows

air

to

build

up in

cooling

system causing

thermostat

to

open

late). (5)

Find

leak

and

repair.

PRESSURE

CAP

VENTS

TO

ATMOSPHERE

AND

COOL

ANT

RESERVE

TANK.

TEMPERATURE GAUGE

READ

ING ABOVE NORMAL

BUT NOT

HIGH.

(1)

Test

radiator

pressure

cap

relief

pressure.

Refer

to

Radiator

Pressure

cap

section

in

this

group.

ID

Replace

cap

if relief

pressure

is

lower

than

14

psi.

COOLANT

LOSS

VISIBLE

ON

GROUND BELOW VEHI

CLE,

BUT NO

PRESSURE

CAP

BLOW

OFF.

(1)

Inspect

system

for

leaks.

(1)

Repair

as

necessary.

J9107-23

Page 298 of 1502

•

COOLING

SYSTEM

7 - 27 down to -67.7°C (-90°F). A higher percentage will

freeze at a warmer temperature. Also, a higher per centage of antifreeze can cause the engine to over

heat because specific heat of antifreeze is lower than

that of water.

CAUTION:

Richer

antifreeze

mixtures

cannot

be

measured

with

normal

field

equipment

and can

cause

problems

associated

with 100

percent

ethyl

ene-glycol.

COOLANT SELECTION-ADDITIVES The presence of aluminum components in the cool

ing system requires strict corrosion protection. Main

tain coolant at specified level with a mixture of ethylene-glycol based antifreeze and water. Only use an antifreeze containing ALUGARD 340-2

™

such as

Mopar Antifreeze. If coolant becomes contaminated

or looses color, drain and flush cooling system and

fill with correctly mixed solution.

A 0.25 percent emulsifiable oil is added to the ra

diator at the factory to prevent solder corrosion.

CAUTION:

Do not use

coolant

additives

that are

claimed

to

improve

engine

cooling.

COOLANT SERVICE-EXCEPT DIESEL It is recommended that the cooling system be

drained and flushed at 84,000 kilometers (52,500

miles) or 3 years, whichever occurs first. Then every

two years or 48,000 kilometers (30,000 miles), which ever occurs first.

COOLANT SERVICE-DIESEL ENGINE It is recommended that the cooling system be

drained and flushed every 24 months or 38,600 kilo meters (24,000 miles), whichever occurs first.

COOLANT LEVEL CHECK-ROUTINE Do not remove radiator cap for routine coolant

level inspections. The coolant level can be checked at the coolant reserve/overflow tank.

The coolant reserve/overflow system provides a

quick visual method for determining the coolant

level without removing the radiator pressure cap.

With engine idling and at normal operating temper ature, observe coolant level in coolant reserve/over

flow tank. The coolant level should be between the MIN and MAX (diesel engine) or ADD and FULL (gas engines) marks.

ADDING ADDITIONAL COOLANT-ROUTINE Do not remove the radiator cap to add coolant

to the system. When adding coolant to maintain the correct level, do so at the coolant reserve/overflow

tank with a 50/50 mixture of ethylene-glycol anti

freeze (containing Alugard 340-2 ™) and water. Re move the radiator cap only for testing or when

refilling the system after service. Removing cap un necessarily can cause loss of coolant and allow air to

enter system. This produces corrosion.

COOLANT LEVEL CHECK-SERVICE The cooling system is closed and designed to main

tain coolant level to the top of the radiator.

WARNING:

DO

NOT OPEN RADIATOR DRAINCOCK

WITH

ENGINE RUNNING

OR

WHILE ENGINE

IS HOT

AND COOLING

SYSTEM

IS

UNDER

PRESSURE.

When vehicle servicing requires a coolant level

check in the radiator, drain several ounces of coolant

from the radiator drain cock. Do this while observing

the coolant reserve/overflow system tank. The cool ant level in the reserve/overflow tank should drop

slightly. If not, inspect for a leak between radiator and coolant reserve/overflow system connection. Re

move radiator cap. The coolant level should be to the

top of the radiator. If not and if coolant level in re serve/overflow tank is at the ADD (gas engines) or

MIN (5.9L diesel engine) mark, check for:

• An air leak in the coolant reserve/overflow tank

• An air leak in the radiator filler neck

• Leak in the pressure cap seal to the radiator filler

neck

LOW COOLANT LEVEL-AERATION If the coolant level in the radiator drops below the

top of the radiator core tubes, air will enter the sys

tem. Low coolant level can cause the thermostat pellet

to be suspended in air instead of coolant. This will cause the thermostat to open later, which in turn causes higher coolant temperature. Air trapped in

cooling system also reduces the amount of coolant

circulating in the heater core. This may result in low

heat output.

DEAERATION As the engine operates, air trapped in the cooling

system gathers under the radiator cap. The next time

engine is operated, thermal expansion of coolant will

push trapped air past radiator cap into coolant re serve/overflow tank. Here it escapes to atmosphere in

the tank. When engine cools down the coolant, it will

be drawn from reserve/overflow tank into radiator to replace removed air.

DRAINING

COOLING

SYSTEM

WARNING:

DO NOT

REMOVE

THE

CYLINDER BLOCK DRAIN PLUGS

OR

LOOSEN THE RADIATOR

DRAIN PLUG

WITH

SYSTEM

HOT AND

UNDER

PRESSURE.

SERIOUS BURNS

FROM

COOLANT

CAN OCCUR.

Page 299 of 1502

7 - 28

COOLING SYSTEM

DO NOT WASTE reusable coolant. If the solution

is clean, drain the coolant into a clean container for

reuse.

(1) Start the engine and place the heater control

temperature selector in the Full On position. Engine vacuum is needed to actuate the heater controls.

(2) Turn the ignition off. (3) Do not remove radiator cap when draining cool

ant from reserve/overflow tank. Open radiator drain

plug and when tank is empty, remove radiator cap. If

the coolant reserve/overflow tank does not drain, re fer to the Testing Cooling System for Leaks section

in this group. The coolant need not be removed from

tank unless the system is being refilled with fresh mixture.

(4) On vehicles equipped with gas powered en

gines,

remove the cylinder block drain plugs. These are located on the sides of the block towards the

front of engine, just above the oil pan (Fig. 36).

Fig.

36 Drain Plugs—Gas Powered

Engines—Typical

(5) Remove radiator pressure cap.

REFILLING

THE

COOLING SYSTEM

Clean cooling system prior to refilling. Refer to

Cooling System Cleaning section of this group. (1) Install the cylinder block drain plugs (Fig. 36).

(2)

Close radiator drain plug.

(3) Fill the cooling system with a 50/50 mixture of

water and antifreeze. (4) Fill coolant reserve/overflow tank to the MAX

(5.9L diesel engine) or FULL (gas engines) mark. (5) Start and operate engine until thermostat

opens. Upper radiator hose should be warm to touch. (6) If necessary, add 50/50 water and antifreeze

mixture to the coolant reserve/overflow tank to main

tain coolant level. This level should be between the MAX and MIN (5.9L diesel engine) or ADD and FULL (gas engines) marks. The level in the reserve/ overflow tank may drop below the MIN (or ADD)

mark after three or four warm-up and cool-down cy

cles.

COOLING SYSTEM CLEANING/REVERSE FLUSHING

CLEMMING Drain cooling system and refill with water. Run

engine with radiator cap installed until upper radia

tor hose is hot. Stop engine and drain water from system. If water is dirty, fill system with water, run

engine and drain system. Repeat until water drains

clean.

REVERSE

FLUSHING

Reverse flushing of cooling system is the forcing of

water through the cooling system. This is done using air pressure in the opposite direction of normal cool

ant flow. It is usually only necessary with very dirty

systems with evidence of partial plugging.

REVERSE

FLUSHING

RADIATOR Disconnect radiator hoses from radiator inlet and

outlet. Attach a section of radiator hose to radiator

bottom outlet fitting and insert flushing gun. Con

nect a water supply hose and air supply hose to flushing gun.

CAUTION:

Internal

radiator

pressure must

not'ex

ceed 138 kPa (20 psi) as damage to

radiator

may re

sult

Allow radiator to fill with water. When radiator is

filled, apply air in short blasts. Allow radiator to re

fill between blasts. Continue this reverse flushing

until clean water flows out through rear of radiator cooling tube passages. Have radiator cleaned more extensively by a radiator repair shop.

REVERSE

FLUSHING

ENGINE-EXCEPT DIESEL Drain cooling system. Remove thermostat housing

and thermostat. Install thermostat housing. Discon

nect radiator upper hose from radiator and attach

flushing gun to hose. Disconnect radiator lower hose

from water pump and attach a lead-away hose to wa

ter pump inlet fitting.

CAUTION;

On vehicles equipped

with

a

heater

water

control

valve, be sure

heater

control

valve is closed

(heat

off). This

will

prevent

coolant

flow

with

scale

and

other

deposits

from

entering

heater

core.

Connect water supply hose and air supply hose to

flushing gun. Allow engine to fill with water. When engine is filled, apply air in short blasts, allowing system to fill between air blasts. Continue until

clean water flows through the lead away hose.

Page 302 of 1502

•

COOLING

SYSTEM

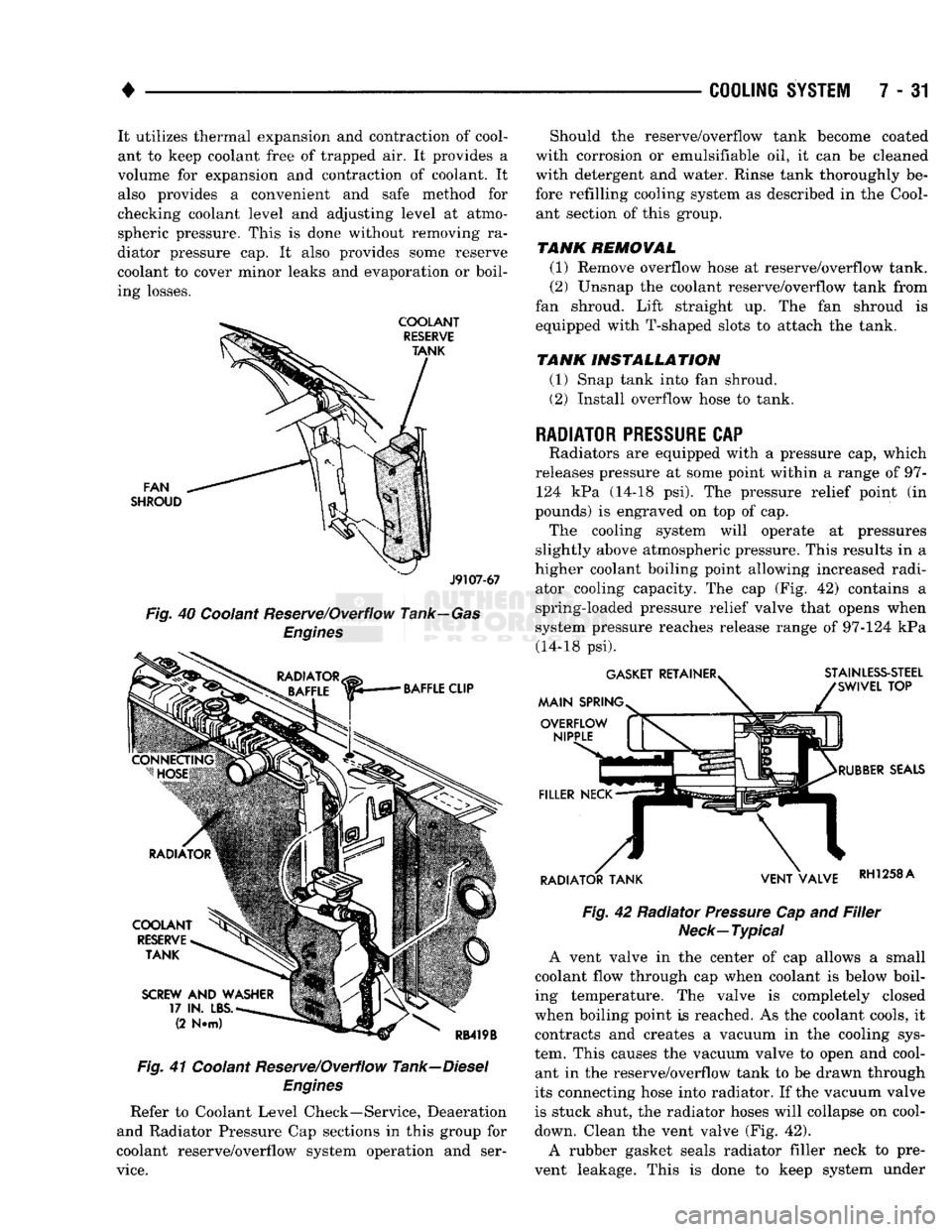

7 - 31 It utilizes thermal expansion and contraction of cool

ant to keep coolant free of trapped air. It provides a

volume for expansion and contraction of coolant. It

also provides a convenient and safe method for

checking coolant level and adjusting level at atmo

spheric pressure. This is done without removing ra

diator pressure cap. It also provides some reserve

coolant to cover minor leaks and evaporation or boil

ing losses.

FAN

SHROUD

J9107-67

Fig.

40 Coolant Reserve/Overflow Tank—Gas

Engines

Fig.

41 Coolant Reserve/Overflow Tank—Diesel

Engines

Refer to Coolant Level Check—Service, Deaeration

and Radiator Pressure Cap sections in this group for

coolant reserve/overflow system operation and ser

vice.

Should the reserve/overflow tank become coated

with corrosion or emulsifiable oil, it can be cleaned

with detergent and water. Rinse tank thoroughly be

fore refilling cooling system as described in the Cool ant section of this group.

TANK REMOVAL

(1) Remove overflow hose at reserve/overflow tank.

(2) Unsnap the coolant reserve/overflow tank from

fan shroud. Lift straight up. The fan shroud is

equipped with T-shaped slots to attach the tank.

TANK INSTALLATION

(1) Snap tank into fan shroud.

(2) Install overflow hose to tank.

RADIATOR

PRESSURE

CAP

Radiators are equipped with a pressure cap, which

releases pressure at some point within a range of 97- 124 kPa (14-18 psi). The pressure relief point (in

pounds) is engraved on top of cap. The cooling system will operate at pressures

slightly above atmospheric pressure. This results in a

higher coolant boiling point allowing increased radi ator cooling capacity. The cap (Fig. 42) contains a

spring-loaded pressure relief valve that opens when

system pressure reaches release range of 97-124 kPa (14-18 psi).

Fig.

42 Radiator

Pressure

Cap and

Filler

Neck—Typical

A vent valve in the center of cap allows a small

coolant flow through cap when coolant is below boil

ing temperature. The valve is completely closed

when boiling point is reached. As the coolant cools, it contracts and creates a vacuum in the cooling sys

tem. This causes the vacuum valve to open and cool ant in the reserve/overflow tank to be drawn through

its connecting hose into radiator. If the vacuum valve

is stuck shut, the radiator hoses will collapse on cool-

down. Clean the vent valve (Fig. 42).

A rubber gasket seals radiator filler neck to pre

vent leakage. This is done to keep system under

Page 304 of 1502

•

COOLING

SYSTEM

7 - 33 The radiator supplies sufficient heat transfer to

cool the engine and automatic transmission (if equipped).

RADIATOR COOLANT FLOW CHECK

Use the following procedure to determine if coolant

is flowing through the cooling system.

(1) Idle engine until operating temperature is

reached. If the upper radiator hose is warm to the

touch, the thermostat is opening and coolant is flow ing to the radiator.

WARNING:

HOT,

PRESSURIZED COOLANT

CAN

CAUSE

INJURY

BY

SCALDING. USING

A

RAG

TO

COVER

THE

RADIATOR

PRESSURE

CAP,

OPEN RADIATOR

CAP

SLOWLY

TO THE

FIRST STOP.

THIS

WILL

ALLOW

ANY

BUILT-UP

PRESSURE

TO

VENT

TO

THE

RESERVE/OVERFLOW TANK. AFTER

PRESSURE

BUILD-UP

HAS

BEEN RELEASED,

RE

MOVE

CAP

FROM FILLER NECK.

(2) Drain a small amount of coolant from the radi

ator until the ends of the radiator tubes are visible

through the filler neck. Idle the engine at normal op

erating temperature. If coolant is flowing past the

exposed tubes, the coolant is circulating.

RADIATOR REMOVAL-EXCEPT DIESEL

(1) Disconnect negative battery cable from battery.

WARNING;

DO NOT

REMOVE

THE

CYLINDER BLOCK DRAIN PLUGS

OR

LOOSEN

THE

RADIATOR

DRAINCOCK

WITH

THE

SYSTEM

HOT AND

UNDER

PRESSURE.

SERIOUS BURNS FROM COOLANT

CAN OCCUR.

(2) Drain the cooling system. Refer to Draining

Cooling System.

(3) Disconnect throttle cable from clip at radiator

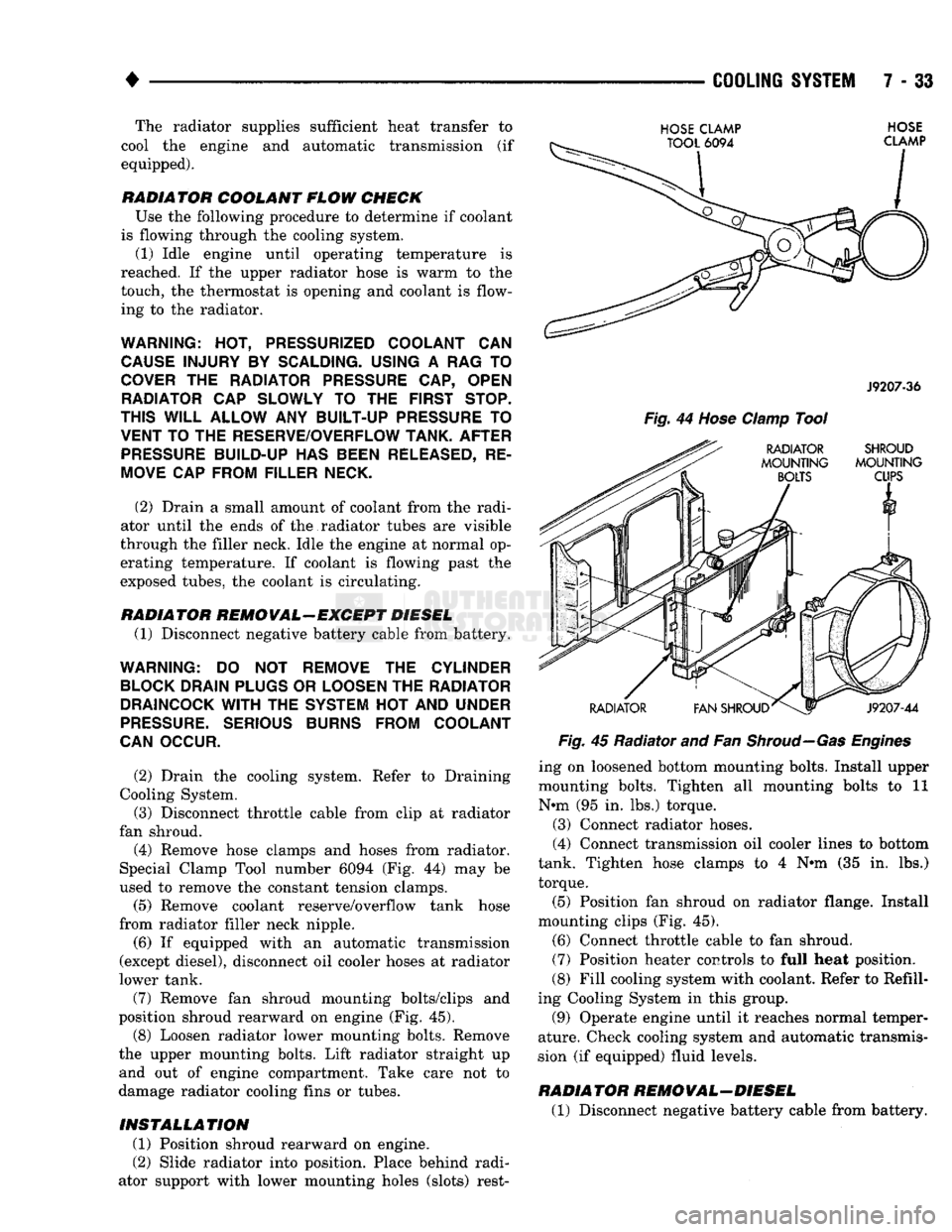

fan shroud. (4) Remove hose clamps and hoses from radiator.

Special Clamp Tool number 6094 (Fig. 44) may be

used to remove the constant tension clamps.

(5) Remove coolant reserve/overflow tank hose

from radiator filler neck nipple.

(6) If equipped with an automatic transmission

(except diesel), disconnect oil cooler hoses at radiator

lower tank.

(7) Remove fan shroud mounting bolts/clips and

position shroud rearward on engine (Fig. 45). (8) Loosen radiator lower mounting bolts. Remove

the upper mounting bolts. Lift radiator straight up and out of engine compartment. Take care not to

damage radiator cooling fins or tubes.

INSTALLATION

(1) Position shroud rearward on engine.

(2) Slide radiator into position. Place behind radi

ator support with lower mounting holes (slots) rest-

HOSE

CLAMP

TOOL

6094

HOSE

CLAMP

J9207-36

Fig.

44

Hose

Clamp

Tool

RADIATOR SHROUD

MOUNTING MOUNTING

BOLTS

CUPS

RADIATOR

V1

FAN SHROUD^

J9207-44

Fig.

45 Radiator and Fan

Shroud—Gas Engines

ing on loosened bottom mounting bolts. Install upper

mounting bolts. Tighten all mounting bolts to 11

N*m (95 in. lbs.) torque.

(3) Connect radiator hoses.

(4) Connect transmission oil cooler lines to bottom

tank. Tighten hose clamps to 4 N#m (35 in. lbs.)

torque.

(5) Position fan shroud on radiator flange. Install

mounting clips (Fig. 45).

(6) Connect throttle cable to fan shroud.

(7) Position heater controls to full heat position.

(8) Fill cooling system with coolant. Refer to Refill

ing Cooling System in this group.

(9) Operate engine until it reaches normal temper

ature. Check cooling system and automatic transmis

sion (if equipped) fluid levels.

RADIATOR REMOVAL-DIESEL

(1) Disconnect negative battery cable from battery.