oil temperature DODGE TRUCK 1993 Service Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 309 of 1502

7 - 38

COOLING

SYSTEM

•

WARNING:

DO NOT

ATTEMPT

TO

BEND

OR

STRAIGHTEN

FAN

BLADES

IF

NOT WITHIN

SPECI

FICATIONS.

(4) Inspect fan assembly for cracks, bends, loose

rivets or broken welds. Replace fan if any damage is

found.

CAUTION; If the fan

blade assembly

is

replaced

be

cause

of

mechanical damage,

the fan

pulley

and

viscous

fan

drive should also

be

inspected.

These

components

could have been damaged

due to ex

cessive

vibration.

INSTALLATION

(1) Install fan blade assembly to viscous fan drive.

Tighten mounting bolts.

(2) Position the fan shroud and fan blade/viscous

fan drive to the vehicle as an assembly.

(3) Install viscous fan drive assembly on fan hub

shaft. Tighten mounting nut to 57 N*m (42 ft. lbs.)

torque.

(4) Install fan shroud bolts.

(5) Install battery cable to battery.

VISCOUS

FAN

DRIVE

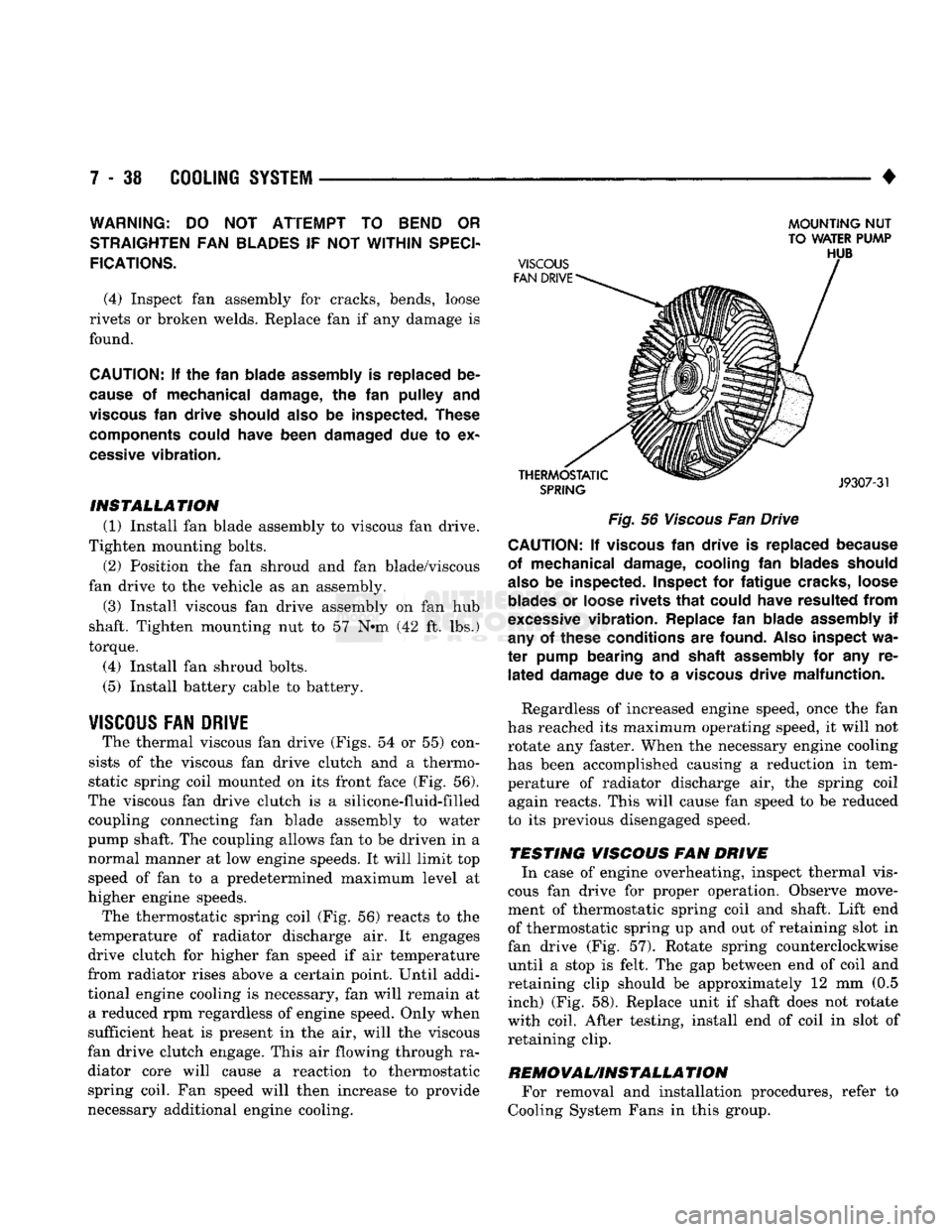

The thermal viscous fan drive (Figs. 54 or 55) con

sists of the viscous fan drive clutch and a thermo

static spring coil mounted on its front face (Fig. 56).

The viscous fan drive clutch is a silicone-fluid-filled coupling connecting fan blade assembly to water

pump shaft. The coupling allows fan to be driven in a normal manner at low engine speeds. It will limit top

speed of fan to a predetermined maximum level at

higher engine speeds.

The thermostatic spring coil (Fig. 56) reacts to the

temperature of radiator discharge air. It engages drive clutch for higher fan speed if air temperature

from radiator rises above a certain point. Until addi

tional engine cooling is necessary, fan will remain at a reduced rpm regardless of engine speed. Only when

sufficient heat is present in the air, will the viscous

fan drive clutch engage. This air flowing through ra diator core will cause a reaction to thermostatic spring coil. Fan speed will then increase to provide

necessary additional engine cooling.

MOUNTING

NUT

TO WATER PUMP

Fig.

56

Viscous

Fan Drive CAUTION; If

viscous

fan

drive

is

replaced because

of mechanical damage, cooling

fan

blades should

also

be

inspected. Inspect

for

fatigue cracks, loose

blades

or

loose rivets

that

could have resulted

from

excessive

vibration. Replace

fan

blade assembly

if

any

of

these conditions

are

found.

Also

inspect

wa

ter

pump bearing

and

shaft assembly

for any re

lated

damage

due to a

viscous

drive malfunction.

Regardless of increased engine speed, once the fan

has reached its maximum operating speed, it will not

rotate any faster. When the necessary engine cooling

has been accomplished causing a reduction in tem perature of radiator discharge air, the spring coil again reacts. This will cause fan speed to be reduced

to its previous disengaged speed.

TESTING VISCOUS FAN DRIVE In case of engine overheating, inspect thermal vis

cous fan drive for proper operation. Observe move

ment of thermostatic spring coil and shaft. Lift end

of thermostatic spring up and out of retaining slot in

fan drive (Fig. 57). Rotate spring counterclockwise until a stop is felt. The gap between end of coil and

retaining clip should be approximately 12 mm (0.5 inch) (Fig. 58). Replace unit if shaft does not rotate

with coil. After testing, install end of coil in slot of retaining clip.

REMOVAUINSTALLA

TION For removal and installation procedures, refer to

Cooling System Fans in this group.

Page 327 of 1502

8A

- 6

ELECTRICAL

•

Fig.

10

Load

50%

Cold

Crank

Rating Note Voltage

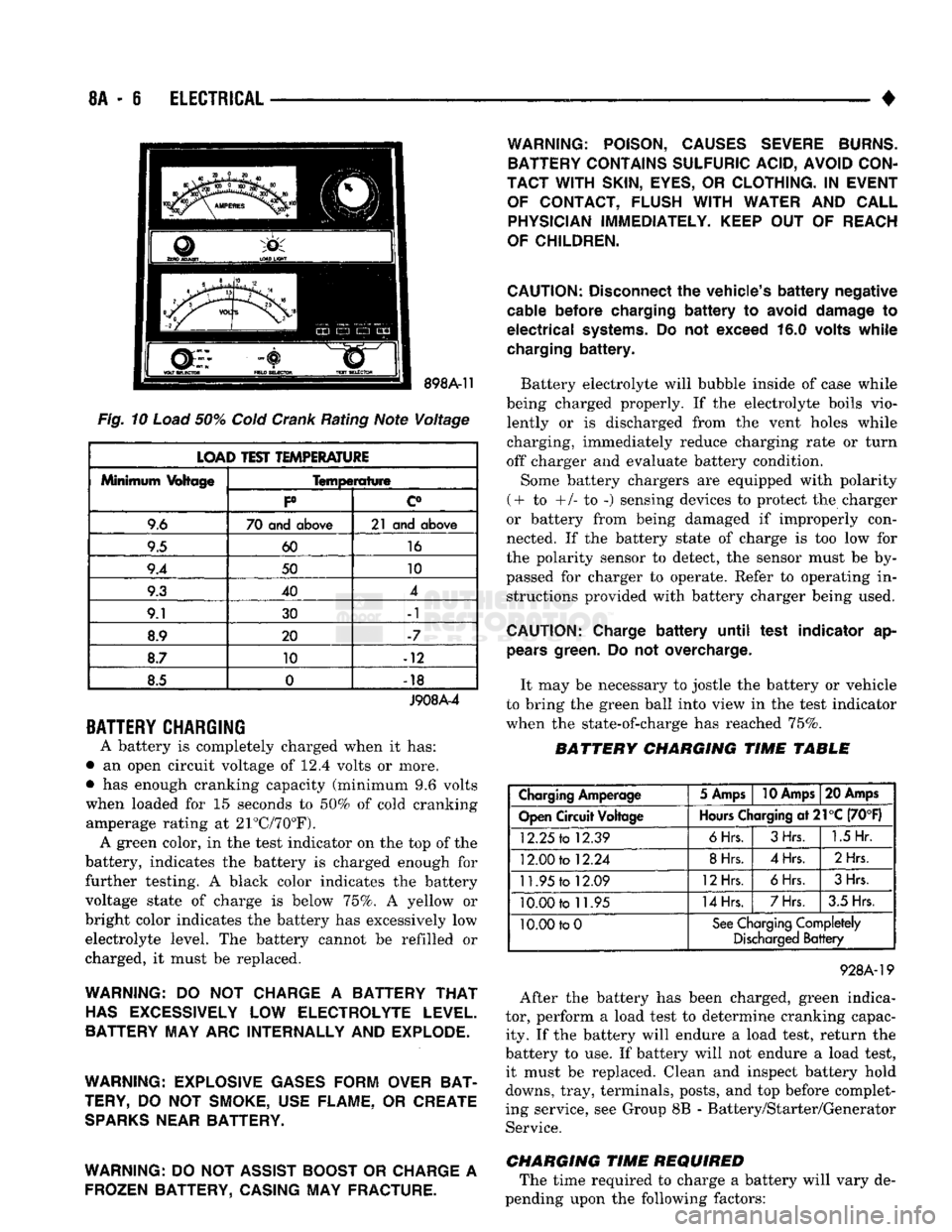

LOAD TEST TEMPERATURE

Minimum

Voltage

Temperature

Minimum

Voltage

P c°

9.6 70 and

above

21 and

above

9.5 60

16

9.4 50 10

9.3 40 4

9.1 30 -1

8.9 20 -7

8.7 10 -12

8.5 0

•

18

J908A-4

BATTERY

CHARGING

A battery is completely charged when it has:

• an open circuit voltage of 12.4 volts or more.

• has enough cranking capacity (minimum 9.6 volts

when loaded for 15 seconds to 50% of cold cranking amperage rating at 21°C/70°F). A green color, in the test indicator on the top of the

battery, indicates the battery is charged enough for

further testing. A black color indicates the battery

voltage state of charge is below 75%. A yellow or

bright color indicates the battery has excessively low electrolyte level. The battery cannot be refilled or

charged, it must be replaced.

WARNING:

DO NOT

CHARGE

A

BATTERY

THAT

HAS

EXCESSIVELY

LOW

ELECTROLYTE LEVEL.

BATTERY MAY ARC INTERNALLY AND EXPLODE.

WARNING: EXPLOSIVE GASES FORM OVER BAT

TERY,

DO NOT

SMOKE, USE FLAME,

OR

CREATE

SPARKS

NEAR BATTERY.

WARNING:

DO

NOT ASSIST BOOST

OR

CHARGE

A

FROZEN BATTERY, CASING MAY FRACTURE. WARNING: POISON, CAUSES SEVERE BURNS.

BATTERY CONTAINS SULFURIC ACID, AVOID CON

TACT WITH

SKIN,

EYES,

OR

CLOTHING.

IN

EVENT OF CONTACT, FLUSH

WITH

WATER

AND

CALL PHYSICIAN IMMEDIATELY. KEEP

OUT OF

REACH

OF CHILDREN.

CAUTION:

Disconnect

the

vehicle's

battery

negative

cable

before

charging

battery to

avoid

damage

to

electrical

systems.

Do not

exceed

16.0

volts

while

charging

battery.

Battery electrolyte will bubble inside of case while

being charged properly. If the electrolyte boils vio lently or is discharged from the vent holes while

charging, immediately reduce charging rate or turn

off charger and evaluate battery condition.

Some battery chargers are equipped with polarity

(+ to +/- to -) sensing devices to protect the charger

or battery from being damaged if improperly con

nected. If the battery state of charge is too low for

the polarity sensor to detect, the sensor must be by

passed for charger to operate. Refer to operating in structions provided with battery charger being used.

CAUTION:

Charge

battery

until

test

indicator

ap

pears

green.

Do not

overcharge.

It may be necessary to jostle the battery or vehicle

to bring the green ball into view in the test indicator

when the state-of-charge has reached 75%.

BATTERY CHARGING TIME TABLE

Charging

Amperage

5 Amps

10 Amps

20 Amps

Open

Circuit

Voltage

Hours

Charging

at21°C

(70°F)

12.25

to

12.39

6Hrs.

3Hrs.

1.5

Hr.

12.00

to

12.24

8Hrs.

4Hrs.

2Hrs

11.95

to

12.09

12Hrs.

6Hrs.

3Hrs.

10.00

to

11.95

14Hrs.

7Hrs.

3.5 Hrs.

10.00 to

0

See

Charging

Completely

Discharged

Battery

928A-19

After the battery has been charged, green indica

tor, perform a load test to determine cranking capac ity. If the battery will endure a load test, return the

battery to use. If battery will not endure a load test, it must be replaced. Clean and inspect battery hold

downs, tray, terminals, posts, and top before complet

ing service, see Group 8B - Battery/Starter/Generator Service.

CHARGING TIME REQUIRED The time required to charge a battery will vary de

pending upon the following factors:

Page 339 of 1502

8A

- 18

ELECTRICAL

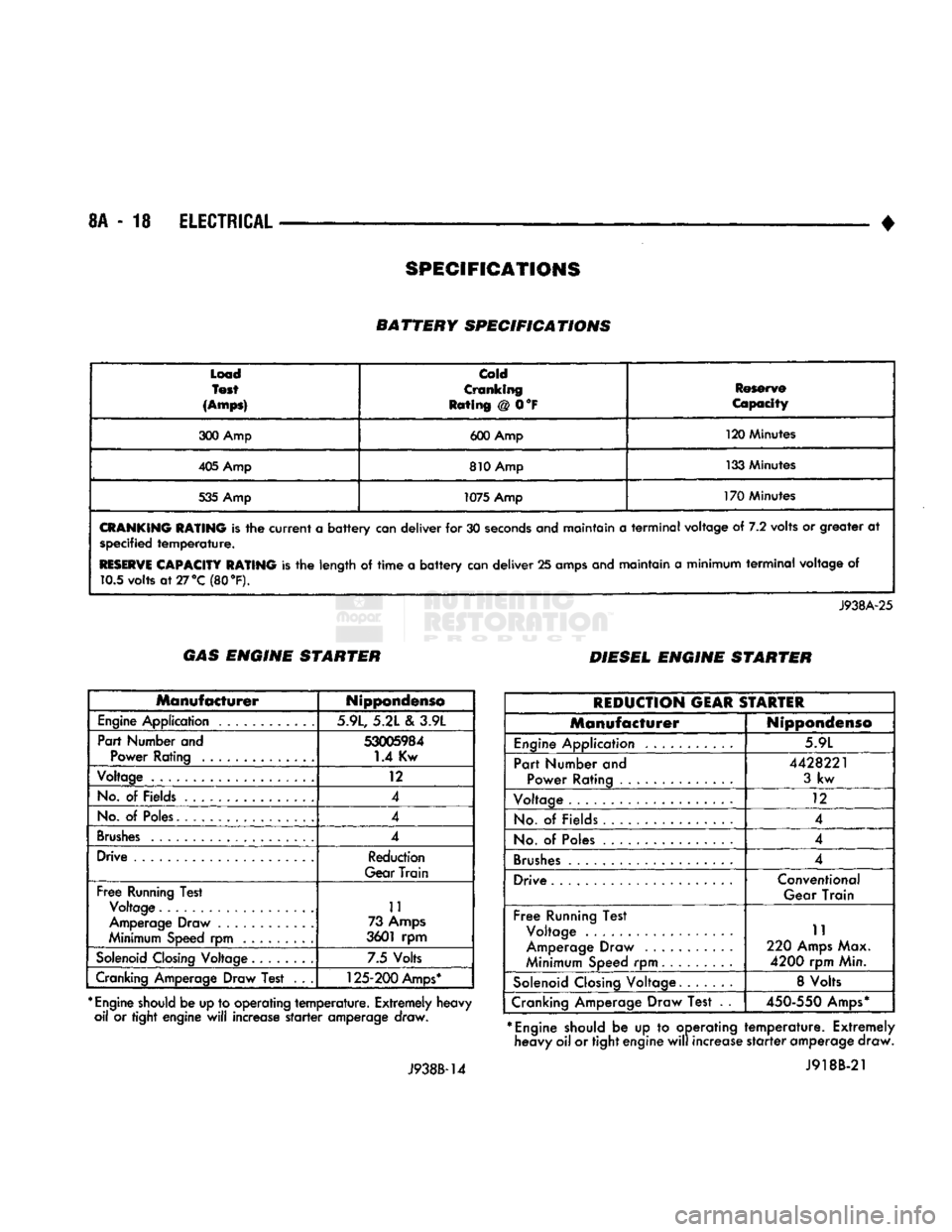

• BATTERY SPECIFICATIONS

Load

Test

(Amps)

Cold

Cranking

Rating @ 0°F Reserve

Capacity

300 Amp 600 Amp 120 Minutes

405 Amp 810 Amp 133 Minutes

535 Amp 1075 Amp 170 Minutes

CRANKING

RATING

is the

current

a

battery

can deliver for 30

seconds

and maintain a

terminal

voltage of 7.2 volts or greater at specified

temperature.

RESERVE

CAPACITY RATING

is the length of

time

a

battery

can deliver 25 amps and maintain a minimum

terminal

voltage of 10.5 volts

at27°C

(80 °F).

J938A-25 GAS ENGINE STARTER

DIESEL ENGINE STARTER

Manufacturer

Nippondenso

Engine

Application 5.9L, 5.21 e\ 3.9L

Part Number and

53005984

Power Rating 1.4 Kw

Voltage 12

No.

of Fields 4

No.

of

Poles.

4

Brushes

4

Drive Reduction

Gear Train

Free

Running Test Voltage 11

Amperage Draw ............ 73

Amps

Minimum Speed rpm 3601 rpm

Solenoid

Closing

Voltage 7.5 Volts

Cranking Amperage Draw Test . . .

125-200

Amps*

*

Engine

should

be up to operating

temperature.

Extremely heavy oil or tight engine

will

increase

starter

amperage draw.

J938B-14

REDUCTION

GEAR

STARTER

Manufacturer

Nippondenso

Engine

Application 5.9L

Part Number and Power Rating ..............

4428221

3

kw

Voltage 12

No.

of Fields 4

No.

of

Poles

4

Brushes

.................... 4

Drive Conventional

Gear Train

Free

Running Test Voltage .

Amperage Draw

Minimum Speed rpm 11

220

Amps

Max.

4200

rpm Min.

Solenoid

Closing

Voltage. 8 Volts

Cranking Amperage Draw Test . .

450-550

Amps*

*

Engine

should be up to operating heavy oil or tight engine

will

increase

temperature.

Extremely

starter

amperage draw. J918B-21

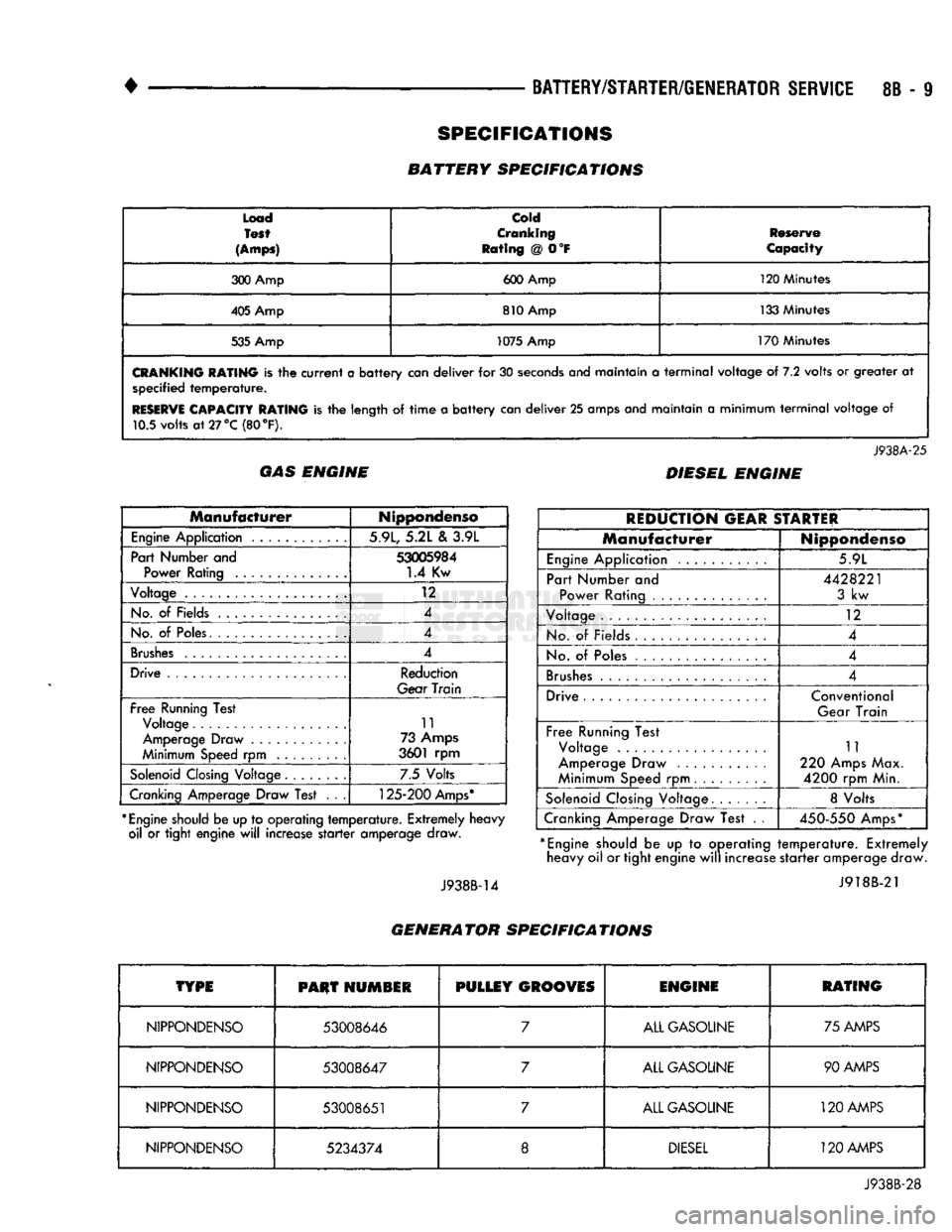

SPECIFICATIONS

Page 350 of 1502

•

BATTERY/STARTER/GENERATOR

SERVICE

8B - 9

Load

Test

(Amps)

cold

Cranking

Rating

@ 0°F

Reserve

Capacity

300 Amp 600 Amp 120 Minutes

405 Amp 810 Amp 133 Minutes

535 Amp 1075 Amp

170 Minutes

CRANKING

RATING

is the

current

a

battery

can

deliver

for 30

seconds

anej

maintain

a

terminal

voltage

of 7.2

volts

or

greater

at

specified

temperature.

RESERVE

CAPACITY RATING

is the

length

of

time

a

battery

can

deliver

25

amps and maintain

a

minimum

terminal

voltage

of

10.5 volts

at

27 °C (80

°F).

J938A-25

GAS ENGINE DIESEL ENGINE

Manufacturer

Nippondenso

Engine

Application 5.9L, 5.2L

&

3.9L

Part Number and

53005984

Power Rating

1.4

Kw

Voltage

12

No.

of

Fields 4

No.

of

Poles. 4

Brushes

4

Drive Reduction

Gear

Train

Free

Running Test Voltage 11

Amperage Draw 73 Amps

Minimum Speed

rpm

3601

rpm

Solenoid

Closing Voltage 7.5 Volts

Cranking Amperage Draw Test

. . .

125-200

Amps*

*

Engine

should be up to operating

temperature.

Extremely heavy oil

or

tight engine

will

increase

starter

amperage draw.

J938B-14

REDUCTION

GEAR

STARTER

Manufacturer

Nippondenso

Engine

Application 5.9L

Part Number

and

Power Rating

4428221

3

kw

Voltage

12

No.

of

Fields

4

No.

of

Poles 4

Brushes

4

Drive Conventional

Gear Train

Free

Running Test Voltage

Amperage Draw

Minimum Speed

rpm

11

220 Amps Max.

4200

rpm Min.

Solenoid

Closing Voltage 8 Volts

Cranking Amperage Draw Test

. .

450-550

Amps*

*

Engine

should

be up to

operating

temperature.

Extremely heavy oil or tight engine

will

increase

starter

amperage draw.

J918B-21

GENERATOR SPECIFICATIONS

TYPE

PHUT

HUMSIR

PULLEY

GROOVES

ENGINE

RATING

NIPPONDENSO

53008646

7

ALL GASOLINE 75 AMPS

NIPPONDENSO

53008647

7

ALL GASOLINE 90 AMPS

NIPPONDENSO

53008651

7

ALL GASOLINE

120

AMPS

NIPPONDENSO

5234374

8

DIESEL

120 AMPS

J938B-28

SPECIFICATIONS

BATTERY SPECIFICATIONS

Page 352 of 1502

•

IGNITION

SYSTEMS

8D

- 1

CONTENTS

page page

COMPONENT IDENTIFICATION/SYSTEM DIAGNOSTICS/SERVICE PROCEDURES

7

OPERATION

1

IGNITION SWITCH

25

COMPONENT REMOVAL/INSTALLATION

..... 18

SPECIFICATIONS

28

COMPONENT

IDENTIFICATION/SYSTEM OPERATION

INDEX

page

Automatic

Shut Down (ASD) Relay

1

Camshaft Position Sensor

2

Crankshaft Position Sensor

2

Distributors

3

Engine Coolant

Temperature

Sensor

...........

4

General

Information

1

page

Ignition

Coil

3

Intake

Manifold Charge

Air

Temperature

Sensor

. . 4

Manifold Absolute Pressure (MAP) Sensor

4

Powertrain

Control

Module (PCM)

. 5

Throttle

Position Sensor

5

GENERAL

INFORMATION

Throughout this group, references

are

made

to

par

ticular vehicle models

by

alphabetical designation

or

by

the

particular vehicle nameplate.

A

chart showing a breakdown

of

alphabetical designations

is

included

in

the

Introduction group

at the

beginning

of

this

manual. 5.9L

gas

powered engines will

be

referred

to as ei

ther: LDC (Light Duty Cycle),

or

HDC (Heavy Duty Cycle). This section

of the

group, Component Identifica

tion/System Operation, will discuss ignition system operation

and

will identify ignition system compo

nents.

For diagnostic procedures

and

adjustments, refer

to

the Diagnostics/Service Procedures section

of

this

group.

For removal

and

installation

of

ignition system

components, refer

to the

Component Removal/Instal

lation section

of

this group. For other useful information, refer

to

On-Board

Di

agnostics

in the

General Diagnosis sections

of

Group

14,

Fuel System

in

this manual. For operation

of the DRB II

Diagnostic Scan Tool,

refer

to the

appropriate Powertrain Diagnostic Proce

dures service manual.

An Ignition specifications section

is

included

at the

end

of

this group.

A

general Maintenance Schedule (mileage intervals)

for

ignition related items

can be

found

in

Group

0,

Lubrication and Maintenance. This

schedule

can

also

be

found

in the

Owners Manual.

IGNITION

SYSTEMS

The ignition systems used

on all

engines

are

basi

cally identical. Similarities

and

differences between

the systems will

be

discussed.

A sequential multi-port fuel injection system

is

used

on all gas

powered engines.

The ignition system

is

controlled

by the

powertrain

control module (PCM)

on all

engines.

The

PCM

was

formerly referred

to as the

SBEC

or

engine control ler.

The ignition system consists

of:

• Spark Plugs

• Ignition Coil

• Secondary Ignition Cables

• Ignition distributor. Contains rotor

and

camshaft

position sensor • Powertrain Control Module (PCM)

• Crankshaft Position Sensor

AUTOMATIC SHUT DOWN (ASD) RELAY

The automatic shut down (ASD) relay

is

located

in

the engine compartment (Fig.

1). As one of its

func

tions,

the ASD

relay will supply battery voltage

to

the ignition coil.

The

ground circuit

for the

ASD

re

lay

is

controlled

by the

powertrain control module (PCM).

The PCM

regulates

ASD

relay operation

by

switching

the

ground circuit on-and-off.

IGNITION

SYSTEMS

Page 355 of 1502

8D

- 4

IGNITION

SYSTEMS

•

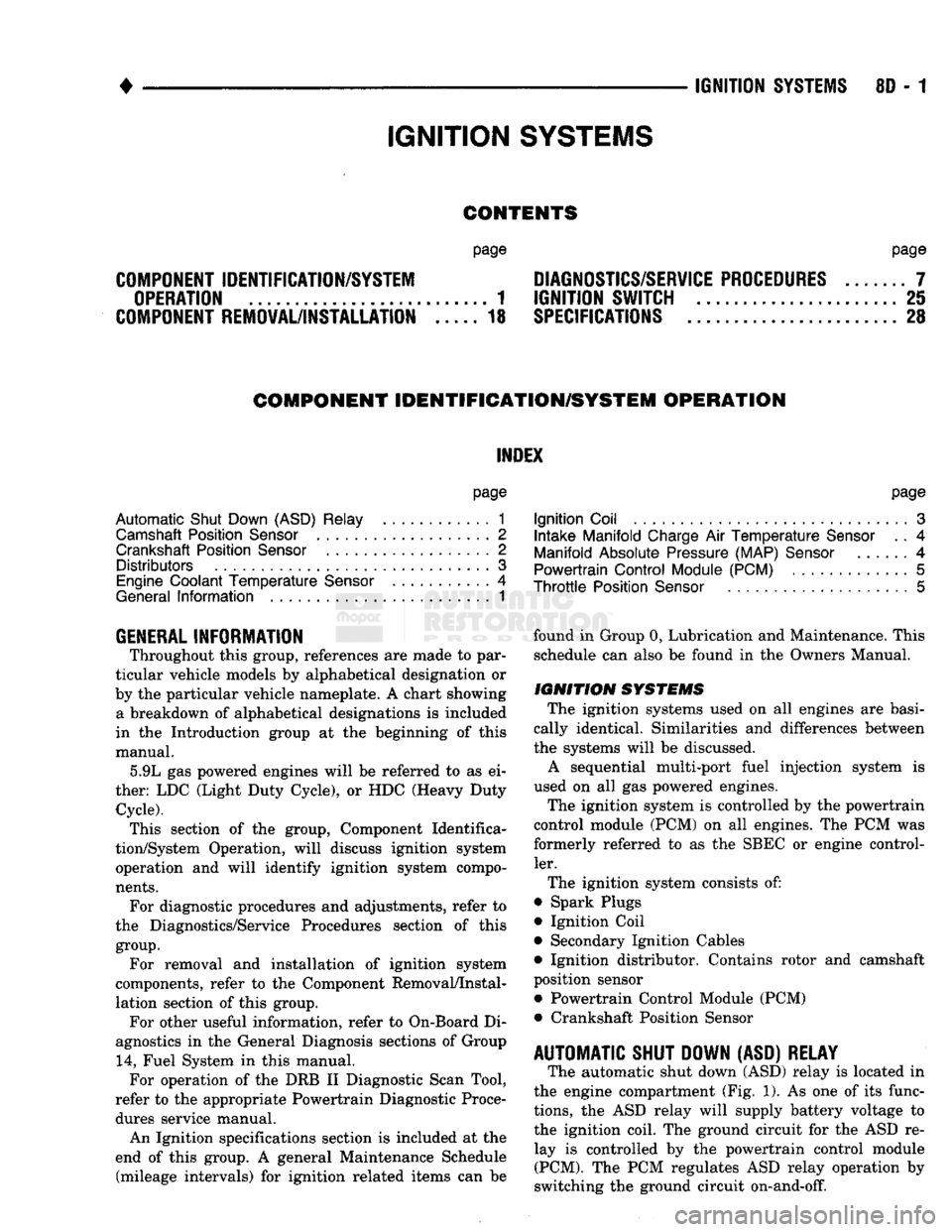

Fig. 6 ignition Coil—3.9L/5.2L/5.9L

LDC-Gas

Engines Fig. 7 Ignition Coil—5.9L

HDC-Gas

Engine

• 5.9L HDC-Gas Engines: The coil is mounted to a

bracket that is bolted to the automatic belt tensioner mounting bracket (Fig. 7).

For component testing, refer to the Diagnostics/Ser

vice Procedures section of this group.

For removal and installation of this component, re

fer to the Component Removal/Installation section of

this group.

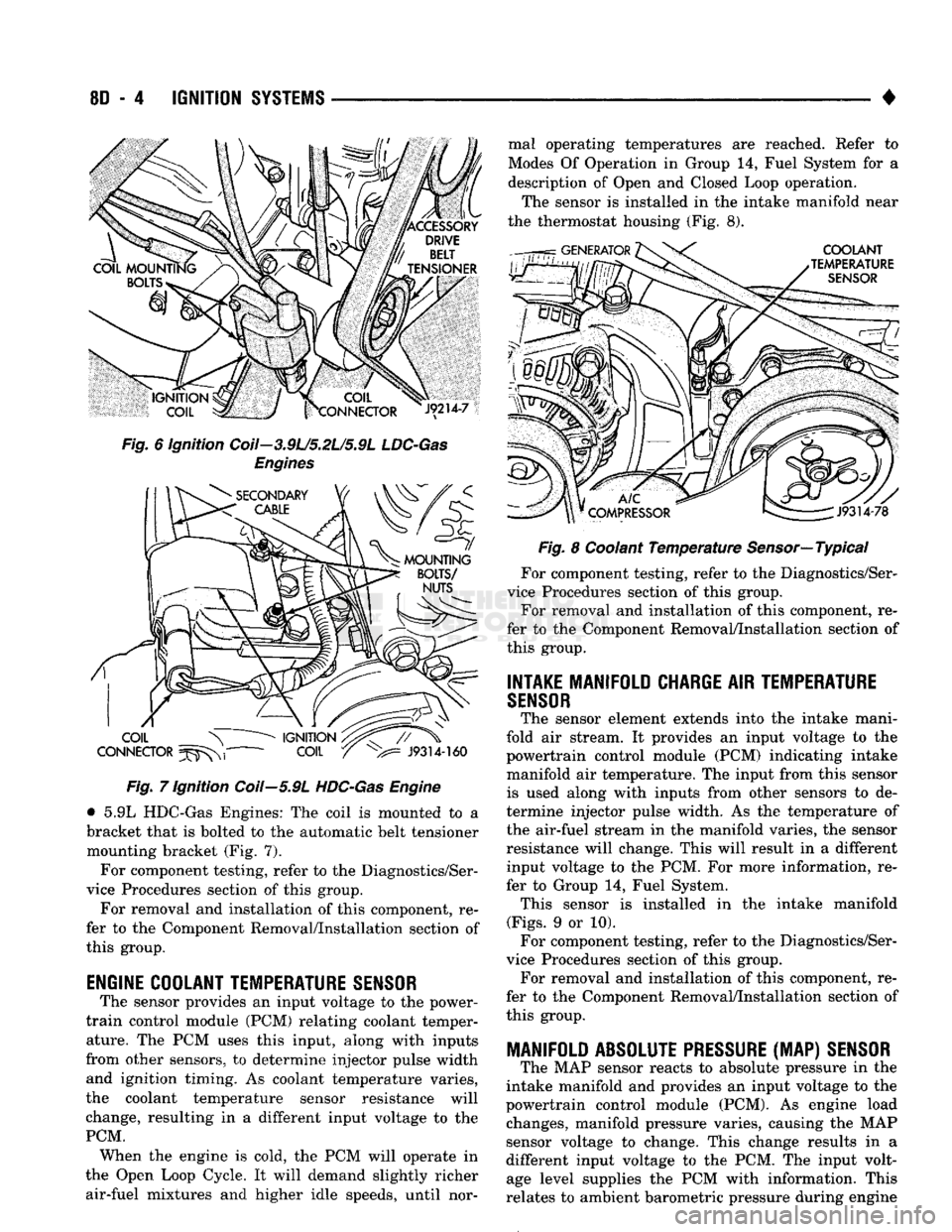

ENGINE COOLANT TEMPERATURE

SENSOR

The sensor provides an input voltage to the power-

train control module (PCM) relating coolant temper ature. The PCM uses this input, along with inputs

from other sensors, to determine injector pulse width and ignition timing. As coolant temperature varies,

the coolant temperature sensor resistance will

change, resulting in a different input voltage to the

PCM. When the engine is cold, the PCM will operate in

the Open Loop Cycle. It will demand slightly richer air-fuel mixtures and higher idle speeds, until nor mal operating temperatures are reached. Refer to

Modes Of Operation in Group 14, Fuel System for a

description of Open and Closed Loop operation.

The sensor is installed in the intake manifold near

the thermostat housing (Fig. 8).

Fig. 8 Coolant Temperature Sensor—Typical

For component testing, refer to the Diagnostics/Ser

vice Procedures section of this group. For removal and installation of this component, re

fer to the Component Removal/Installation section of

this group.

INTAKE MANIFOLD CHARGE

AIR

TEMPERATURE

SENSOR

The sensor element extends into the intake mani

fold air stream. It provides an input voltage to the

powertrain control module (PCM) indicating intake

manifold air temperature. The input from this sensor is used along with inputs from other sensors to de

termine injector pulse width. As the temperature of

the air-fuel stream in the manifold varies, the sensor

resistance will change. This will result in a different input voltage to the PCM. For more information, re

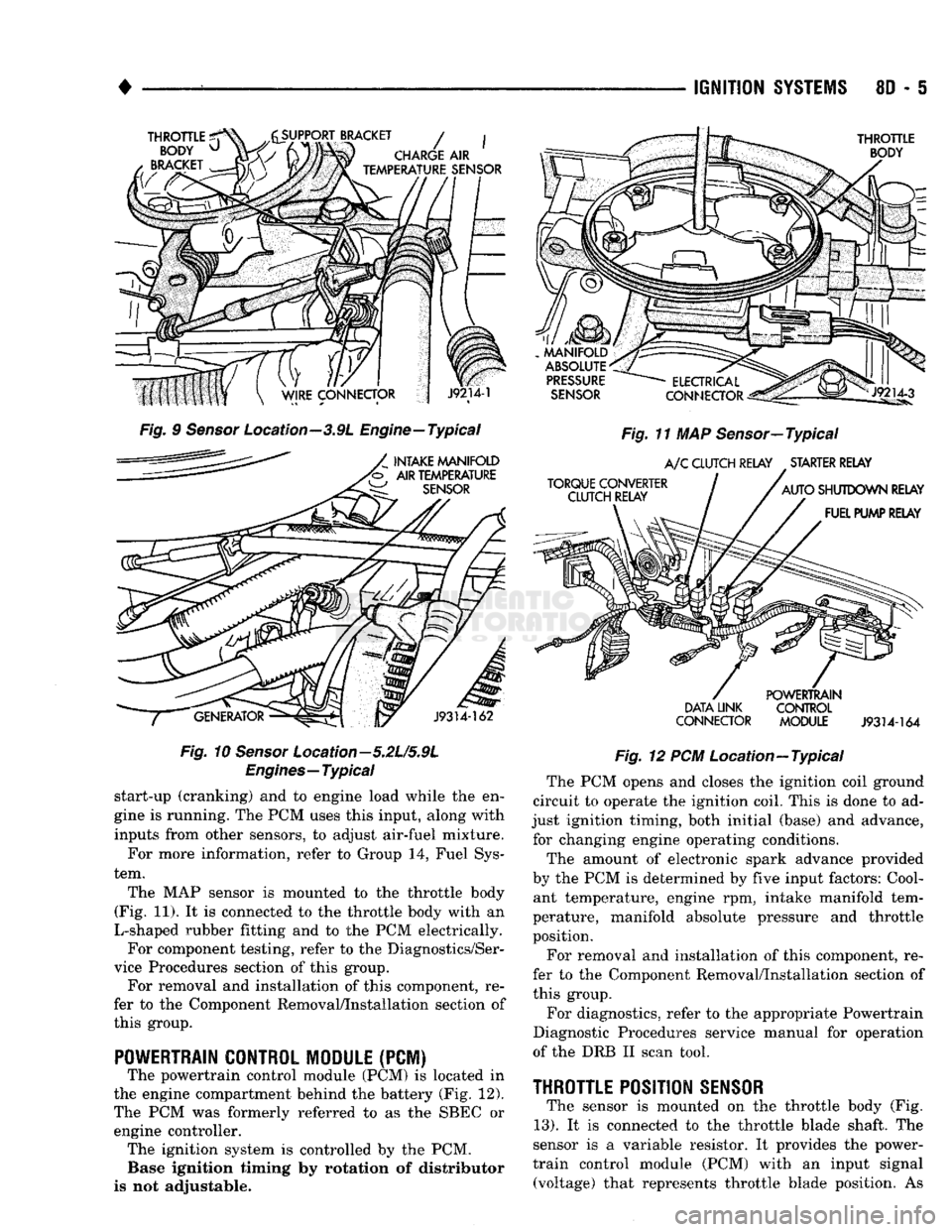

fer to Group 14, Fuel System. This sensor is installed in the intake manifold

(Figs.

9 or 10). For component testing, refer to the Diagnostics/Ser

vice Procedures section of this group. For removal and installation of this component, re

fer to the Component Removal/Installation section of

this group.

MANIFOLD ABSOLUTE

PRESSURE

(MAP)

SENSOR

The MAP sensor reacts to absolute pressure in the

intake manifold and provides an input voltage to the

powertrain control module (PCM). As engine load changes, manifold pressure varies, causing the MAP

sensor voltage to change. This change results in a

different input voltage to the PCM. The input volt age level supplies the PCM with information. This

relates to ambient barometric pressure during engine

Page 356 of 1502

•

IGNITION

SYSTEMS

8D - 5

THROTTLE

^

BODY

u

BRACKET

y^SUPPORT

BRACKET

/ |

CHARGE

AIR

ijmmmmk

TEMPERATURE

SENSOR

THROTTLE

BODY

Fig.

9

Sensor

Location—3.9L Engine—Typical

INTAKE MANIFOLD

'b AIR TEMPERATURE

SENSOR

J9314-162

Fig.

10

Sensor

Location—5.2L/5.9L

Engines—Typical

start-up (cranking) and to engine load while the en

gine is running. The PCM uses this input, along with

inputs from other sensors, to adjust air-fuel mixture.

For more information, refer to Group 14, Fuel Sys

tem.

The MAP sensor is mounted to the throttle body

(Fig. 11). It is connected to the throttle body with an

L-shaped rubber fitting and to the PCM electrically. For component testing, refer to the Diagnostics/Ser

vice Procedures section of this group. For removal and installation of this component, re

fer to the Component Removal/Installation section of

this group.

POWERTRAIN CONTROL MODULE

(PCM) The powertrain control module (PCM) is located in

the engine compartment behind the battery (Fig. 12).

The PCM was formerly referred to as the SBEC or engine controller. The ignition system is controlled by the PCM. Base ignition timing by rotation of distributor

is not adjustable.

MANIFOLD

ABSOLUTE

PRESSURE

SENSOR

TORQUE CONVERTER CLUTCH RELAY

ELECTRICAL

Jlp^

CONNECTOR

^gis!—

Fig.

11 MAP Sensor—Typical

A/C

CLUTCH RELAY STARTER RELAY

AUTO

SHUTDOWN RELAY FUEL PUMP RELAY

DATA LINK

CONNECTOR POWERTRAIN

CONTROL

MODULE

J9314-164

Fig.

12 PCM Location—Typical The PCM opens and closes the ignition coil ground

circuit to operate the ignition coil. This is done to ad

just ignition timing, both initial (base) and advance, for changing engine operating conditions.

The amount of electronic spark advance provided

by the PCM is determined by five input factors: Cool ant temperature, engine rpm, intake manifold tem

perature, manifold absolute pressure and throttle

position.

For removal and installation of this component, re

fer to the Component Removal/Installation section of

this group.

For diagnostics, refer to the appropriate Powertrain

Diagnostic Procedures service manual for operation

of the DRB II scan tool.

THROTTLE

POSITION

SENSOR

The sensor is mounted on the throttle body (Fig.

13).

It is connected to the throttle blade shaft. The

sensor is a variable resistor. It provides the power-

train control module (PCM) with an input signal (voltage) that represents throttle blade position. As

Page 358 of 1502

•

IGNITION

SYSTEMS

80 - 7

DIAGNOSTICS/SERW1CE

PROCEDURES

INDEX

page

Automatic Shut Down (ASD) Relay

7

Camshaft Position

Sensor

Test

...............

7

Crankshaft Position

Sensor

Test

8

Distributor

Cap

8

Distributor

Rotor

8

Engine

Coolant Temperature

Sensor

Test

10

General

Information

7

Ignition

Coil

8

Ignition

Secondary

Circuit

Diagnosis

10

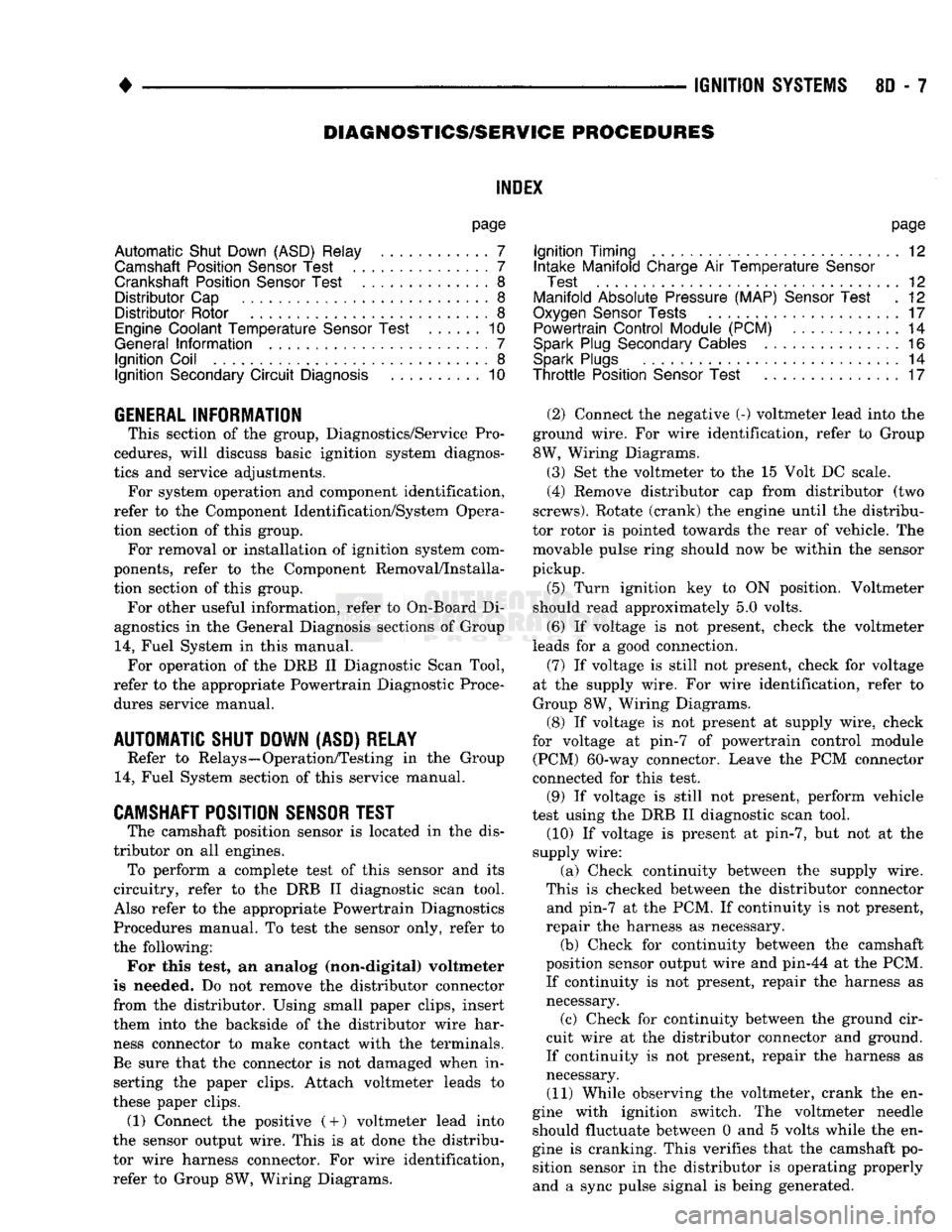

GENERAL

INFORMATION

This section

of the

group, Diagnostics/Service Pro

cedures, will discuss basic ignition system diagnos

tics

and

service adjustments. For system operation

and

component identification,

refer

to the

Component Identification/System Opera

tion section

of

this group. For removal

or

installation

of

ignition system com

ponents, refer

to the

Component Removal/Installa

tion section

of

this group. For other useful information, refer

to

On-Board

Di

agnostics

in the

General Diagnosis sections

of

Group

14,

Fuel System

in

this manual. For operation

of the DRB II

Diagnostic Scan Tool,

refer

to the

appropriate Powertrain Diagnostic Proce

dures service manual.

AUTOMATIC SHUT DOWN

(ASD)

RELAY

Refer

to

Relays—Operation/Testing

in the

Group

14,

Fuel System section

of

this service manual.

CAMSHAFT POSITION SENSOR TEST

The camshaft position sensor

is

located

in the

dis

tributor

on all

engines. To perform

a

complete test

of

this sensor

and its

circuitry, refer

to the DRB II

diagnostic scan tool.

Also refer

to the

appropriate Powertrain Diagnostics

Procedures manual.

To

test

the

sensor only, refer

to

the following: For this test,

an

analog (non-digital) voltmeter

is needed.

Do not

remove

the

distributor connector from

the

distributor. Using small paper clips, insert

them into

the

backside

of the

distributor wire har ness connector

to

make contact with

the

terminals.

Be sure that

the

connector

is not

damaged when

in

serting

the

paper clips. Attach voltmeter leads

to

these paper clips. (1) Connect

the

positive (

+

)

voltmeter lead into

the sensor output wire. This

is at

done

the

distribu tor wire harness connector.

For

wire identification,

refer

to

Group

8W,

Wiring Diagrams.

page

Ignition

Timing

12

Intake Manifold Charge

Air

Temperature

Sensor

Test

12

Manifold Absolute Pressure (MAP)

Sensor

Test

. 12

Oxygen

Sensor

Tests

17

Powertrain Control Module (PCM)

............

14

Spark

Plug Secondary Cables

16

Spark

Plugs

............................

14

Throttle

Position

Sensor

Test

17

(2) Connect

the

negative

(-)

voltmeter lead into

the

ground wire.

For

wire identification, refer

to

Group

8W, Wiring Diagrams.

(3)

Set the

voltmeter

to the 15

Volt

DC

scale. (4) Remove distributor

cap

from distributor

(two

screws). Rotate (crank)

the

engine until

the

distribu

tor rotor

is

pointed towards

the

rear

of

vehicle.

The

movable pulse ring should

now be

within

the

sensor

pickup.

(5) Turn ignition

key to ON

position. Voltmeter

should read approximately

5.0

volts.

(6)

If

voltage

is not

present, check

the

voltmeter

leads

for a

good connection.

(7)

If

voltage

is

still

not

present, check

for

voltage

at

the

supply wire.

For

wire identification, refer

to

Group

8W,

Wiring Diagrams.

(8)

If

voltage

is not

present

at

supply wire, check

for voltage

at

pin-7

of

powertrain control module (PCM) 60-way connector. Leave

the PCM

connector

connected

for

this test. (9)

If

voltage

is

still

not

present, perform vehicle

test using

the DRB II

diagnostic scan tool. (10)

If

voltage

is

present

at

pin-7,

but not at the

supply wire: (a) Check continuity between

the

supply wire.

This

is

checked between

the

distributor connector and pin-7

at the PCM. If

continuity

is not

present,

repair

the

harness

as

necessary. (b) Check

for

continuity between

the

camshaft

position sensor output wire

and

pin-44

at the PCM.

If continuity

is not

present, repair

the

harness

as

necessary. (c) Check

for

continuity between

the

ground cir

cuit wire

at the

distributor connector

and

ground.

If continuity

is not

present, repair

the

harness

as

necessary. (11) While observing

the

voltmeter, crank

the en

gine with ignition switch.

The

voltmeter needle should fluctuate between

0 and 5

volts while

the en

gine

is

cranking. This verifies that

the

camshaft

po

sition sensor

in the

distributor

is

operating properly

and

a

sync pulse signal

is

being generated.

Page 361 of 1502

8D

- 10

IGNITION

SYSTEMS

• Arcing at the tower will carbonize the cable boot,

which if it is connected to a new ignition coil, will cause the coil to fail. If the secondary coil cable shows any signs of dam

age,

it should be replaced with a new cable and new

terminal. Carbon tracking on the old cable can cause

arcing and the failure of a new ignition coil.

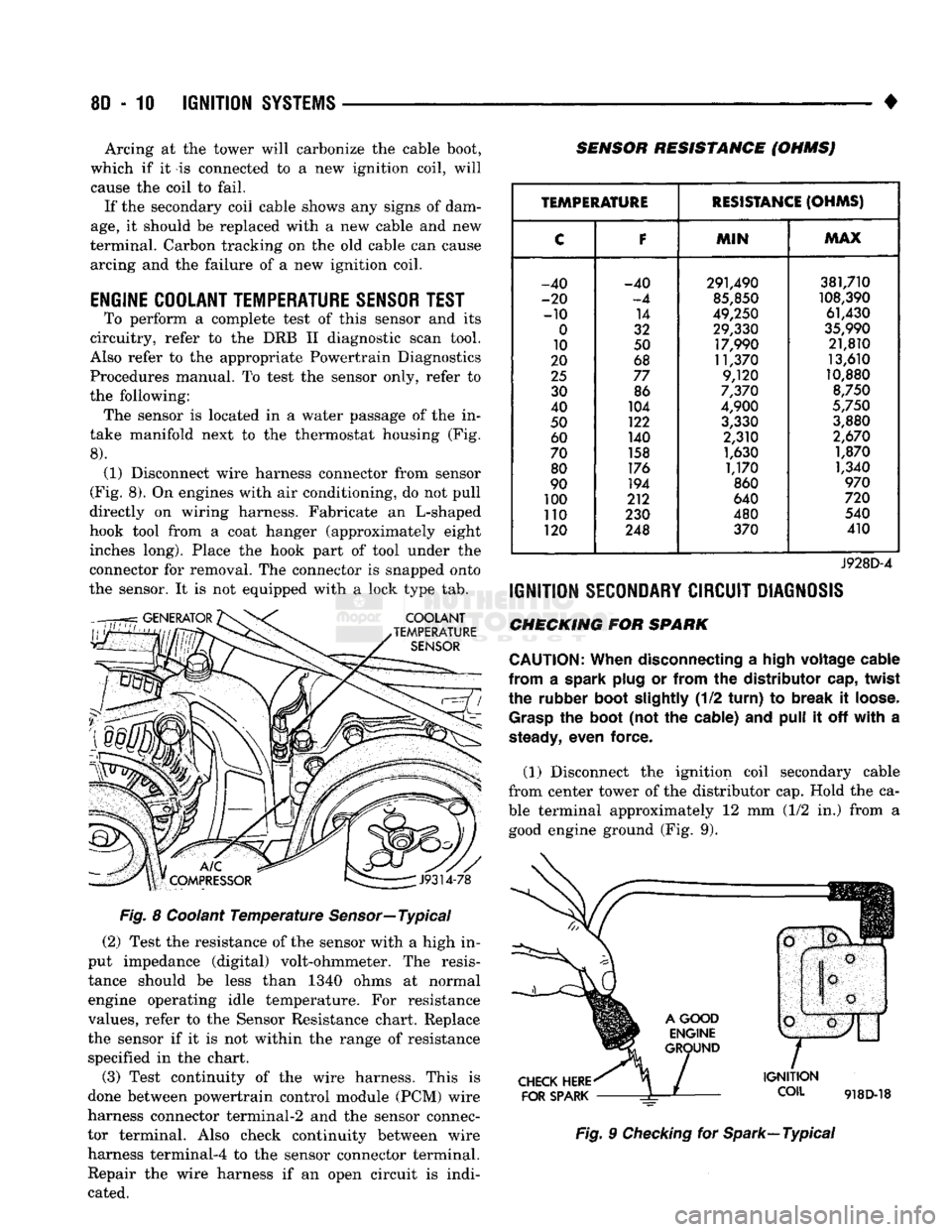

ENGINE

COOLANT

TEMPERATURE

SENSOR

TEST

To perform a complete test of this sensor and its

circuitry, refer to the DRB II diagnostic scan tool.

Also refer to the appropriate Powertrain Diagnostics

Procedures manual. To test the sensor only, refer to

the following: The sensor is located in a water passage of the in

take manifold next to the thermostat housing (Fig.

8).

(1) Disconnect wire harness connector from sensor

(Fig. 8). On engines with air conditioning, do not pull

directly on wiring harness. Fabricate an L-shaped

hook tool from a coat hanger (approximately eight inches long). Place the hook part of tool under the

connector for removal. The connector is snapped onto

the sensor. It is not equipped with a lock type tab.

COOLANT

TEMPERATURE

SENSOR

SENSOR RESISTANCE (OHMSJ

V

J9314-78

Fig. 8 Coolant Temperature Sensor—Typical (2) Test the resistance of the sensor with a high in

put impedance (digital) volt-ohmmeter. The resis tance should be less than 1340 ohms at normal

engine operating idle temperature. For resistance

values, refer to the Sensor Resistance chart. Replace

the sensor if it is not within the range of resistance specified in the chart.

(3) Test continuity of the wire harness. This is

done between powertrain control module (PCM) wire

harness connector terminal-2 and the sensor connec

tor terminal. Also check continuity between wire harness terminal-4 to the sensor connector terminal. Repair the wire harness if an open circuit is indi

cated.

TEMPERATURE

RESISTANCE

(OHMS)

C

F

MIN

MAX

-40 -40 291,490 381,710

-20

-4

85,850

108,390

-10 14

49,250 61,430

0

32 29,330

35,990

10 50 17,990 21,810

20 68 11,370 13,610

25

77 9,120 10,880

30 86

7,370

8,750

40 104

4,900

5,750

50 122

3,330 3,880

60 140 2,310

2,670

70 158

1,630 1,870

80 176

1,170 1,340

90 194

860

970

100 212 640

720

110 230 480 540

120 248 370 410

J928D-4

IGNITION

SECONDARY

CIRCUIT

DIAGNOSIS

CHECKING FOR SPARK

CAUTION:

When

disconnecting a

high

voltage

cable

from

a spark

plug

or

from

the

distributor

cap,

twist

the rubber

boot

slightly

(1/2

turn)

to

break

it

loose.

Grasp

the

boot

(not the cable) and

pull

it off

with

a

steady,

even force.

(1) Disconnect the ignition coil secondary cable

from center tower of the distributor cap. Hold the ca

ble terminal approximately 12 mm (1/2 in.) from a good engine ground (Fig. 9).

CHECK

HERE

FOR

SPARK

IGNITION

COIL

918D-18

Fig. 9 Checking for Spark—Typical

Page 363 of 1502

8D

- 12

IGNITION

SYSTEMS

•

XX

oooooooooo

,0000000000

\2141

3%

lOOOOOOOOOO

OOOOOOOOOO

si

20

fcji^OQOOOOOOJ

«r

~

• • -

•

- - #

•oooooooooo.

CONNECTOR

TERMINAL

SIDE

SHOWN

J908D-42

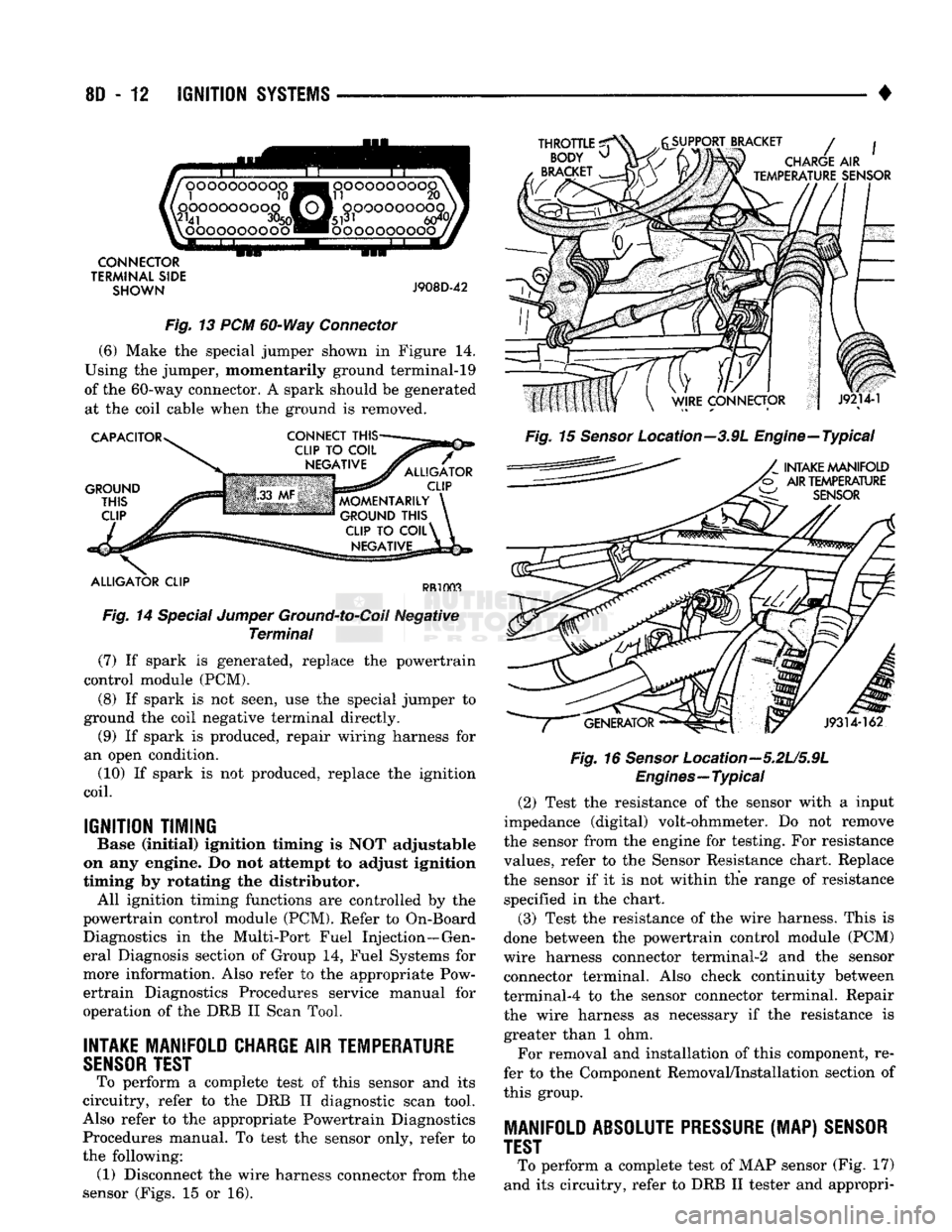

Fig. 13 PCM 60-Way Connector

(6) Make the special jumper shown in Figure 14.

Using the jumper, momentarily ground terminal-19

of the 60-way connector. A spark should be generated at the coil cable when the ground is removed.

CAPACITOR

GROUND

THIS

CLIP

CONNECT

THIS-

ALLIGATOR

CLIP

MOMENTARILY

GROUND

THIS

CLIP

TO

COIL^

NEGATIVE

ALLIGATOR

CLIP

PR1003

Fig. 14 Special Jumper Ground-to-Coil Negative Terminal (7) If spark is generated, replace the powertrain

control module (PCM).

(8) If spark is not seen, use the special jumper to

ground the coil negative terminal directly. (9) If spark is produced, repair wiring harness for

an open condition. (10) If spark is not produced, replace the ignition

coil.

IGNITION TIMING

Base (Initial) ignition timing Is NOT adjustable

on any engine. Do not attempt to adjust Ignition

timing by rotating the distributor. All ignition timing functions are controlled by the

powertrain control module (PCM). Refer to On-Board Diagnostics in the Multi-Port Fuel Injection—Gen

eral Diagnosis section of Group 14, Fuel Systems for

more information. Also refer to the appropriate Pow ertrain Diagnostics Procedures service manual for

operation of the DRB II Scan Tool.

INTAKE

MANIFOLD

CHARGE

AIR

TEMPERATURE

SENSOR

TEST

To perform a complete test of this sensor and its

circuitry, refer to the DRB II diagnostic scan tool.

Also refer to the appropriate Powertrain Diagnostics Procedures manual. To test the sensor only, refer to

the following: (1) Disconnect the wire harness connector from the

sensor (Figs. 15 or 16).

THROTTLE

^

BODY

^

BRACKET

SUPPORT BRACKET

/

CHARGE

AIR

TEMPERATURE

SENSOR

Fig. 15 Sensor Location--3.9L Engine—Typical

INTAKE

MANIFOLD

AIR

TEMPERATURE

W

SENSOR

J9314-162

Fig. 16

Sensor

Location—5.2U5.9L

Engines—Typical

(2) Test the resistance of the sensor with a input

impedance (digital) volt-ohmmeter. Do not remove

the sensor from the engine for testing. For resistance

values, refer to the Sensor Resistance chart. Replace

the sensor if it is not within the range of resistance specified in the chart.

(3) Test the resistance of the wire harness. This is

done between the powertrain control module (PCM)

wire harness connector terminal-2 and the sensor connector terminal. Also check continuity between

terminal-4 to the sensor connector terminal. Repair

the wire harness as necessary if the resistance is greater than 1 ohm.

For removal and installation of this component, re

fer to the Component Removal/Installation section of

this group.

MANIFOLD

ABSOLUTE PRESSURE

(MAP)

SENSOR

TEST

To perform a complete test of MAP sensor (Fig. 17)

and its circuitry, refer to DRB II tester and appropri-