fuel pump DODGE TRUCK 1993 Service Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 602 of 1502

•

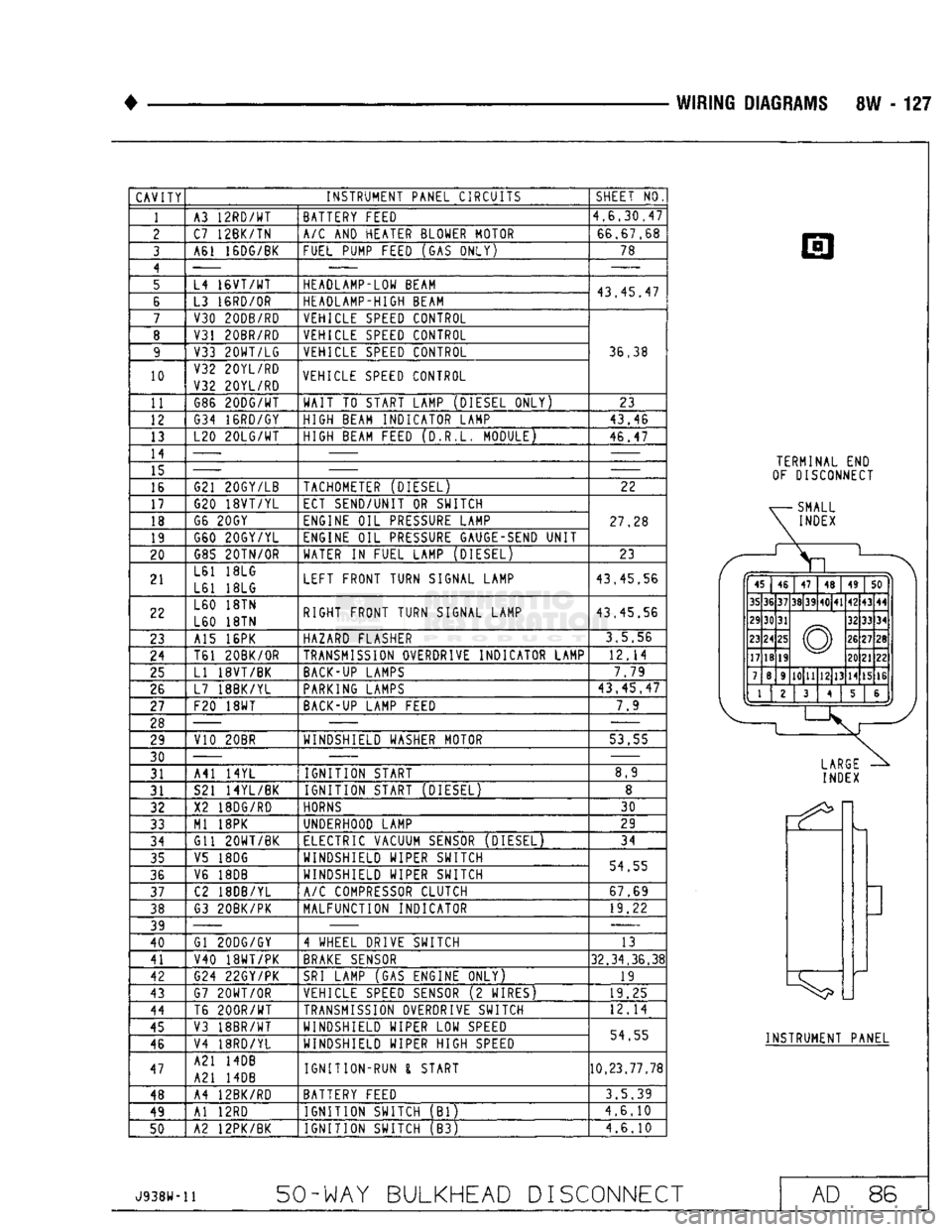

WIRING

DIAGRAMS

8W - 127

CAVITY

INSTRUMENT PANEL CIRCUITS

1

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28 29

30 31

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

A3

12RD/WT

C7 12BK/TN

A61 16DG/BK

L4

16VT/WT

L3

16RD/0R

V30 20DB/RD

V31 20BR/RD

V33

20WT/LG

V32 20YL/RD

V32 20YL/RD G86

20DG/WT

G34 16RD/GY

L20

20LG/WT

G21 20GY/LB

G20

18VT/YL

G6

20GY

G60 20GY/YL G85

20TN/0R

L61

18LG

L61

18LG

L60

18TN

L60

18TN

A15

16PK

T61 20BK/OR

LI

18VT/BK

L7 18BK/YL

F20

18WT

V10 20BR

A41

14YL

S21 14YL/BK

X2

18DG/R0

Ml

18PK

Gil

20WT/BK

V5

18DG

V6

18DB

C2 18DB/YL

G3 20BK/PK

Gl 20DG/GY

V40

18WT/PK

G24 22GY/PK

G7

20WT/0R

T6

200R/WT

V3 18BR/WT

V4 18RD/YL

A21

14DB

A21

14DB

A4 12BK/RD

Al

12RD

A2 12PK/BK BATTERY FEED

A/C

AND

HEATER BLOWER MOTOR

FUEL PUMP FEED

(GAS

ONLY)

HEADLAMP-LOW BEAM

HEADLAMP-HIGH BEAM VEHICLE

SPEED

CONTROL

VEHICLE

SPEED

CONTROL VEHICLE

SPEED

CONTROL

VEHICLE

SPEED

CONTROL

WAIT

TO

START LAMP (DIESEL ONLY)

HIGH BEAM INDICATOR LAMP

HIGH BEAM FEED (D.R.L. MODULE)

TACHOMETER (DIESEL)

ECT SEND/UNIT

OR

SWITCH

ENGINE

OIL

PRESSURE

LAMP

ENGINE

OIL

PRESSURE

GAUGE-SEND

UNIT

WATER

IN

FUEL LAMP (DIESEL)

LEFT FRONT TURN SIGNAL LAMP

RIGHT FRONT TURN SIGNAL LAMP

HAZARD FLASHER

TRANSMISSION

OVERDRIVE INDICATOR LAMP

BACK-UP

LAMPS

PARKING

LAMPS

BACK-UP

LAMP FEED

WINDSHIELD WASHER MOTOR

IGNITION START

IGNITION START (DIESEL)

HORNS

UNDERHOOD LAMP

ELECTRIC VACUUM

SENSOR

(DIESEL) WINDSHIELD WIPER SWITCH

WINDSHIELD WIPER SWITCH

A/C

COMPRESSOR CLUTCH

MALFUNCTION INDICATOR

4 WHEEL DRIVE SWITCH

BRAKE

SENSOR

SRI

LAMP

(GAS

ENGINE ONLY)

VEHICLE

SPEED

SENSOR

(2

WIRES)

TRANSMISSION

OVERDRIVE SWITCH

WINDSHIELD WIPER

LOW

SPEED

WINDSHIELD WIPER HIGH

SPEED

IGNITION-RUN

I

START

BATTERY FEED IGNITION SWITCH

(Bl)

IGNITION SWITCH

(B3)

SHEET

NO

4,6.30,47

66,67,68 78

43,45,47

36,38

23

43,46

46,47

22

27,28

23

43.45,56

43,45.56

3,5,56

12,14 7.79

43,45,47

7.9

53.55 8,9

30

29

34

54,55 67,69 19,22

13

32,34,36,38

19

19,25

12,14

54.55

10,23.77,78

3.5.39

4,6.10

4.6.10

TERMINAL

END

OF DISCONNECT

ff

p

45 46

47

48 49

50

35 36 37

38 39

40 41

42

43 44

29 30 31

© 32

33 34

23 24

25

© 26

27 28

17 18

19 ©

20 21 22

7 8 9

10 11

12 13

14 15 16

1

^

1.

2

3

4 5 &

J *j

LARGE

INDEX

INSTRUMENT PANEL

J938W-11

50-WAY BULKHEAD

DISCONNECT

AD

86

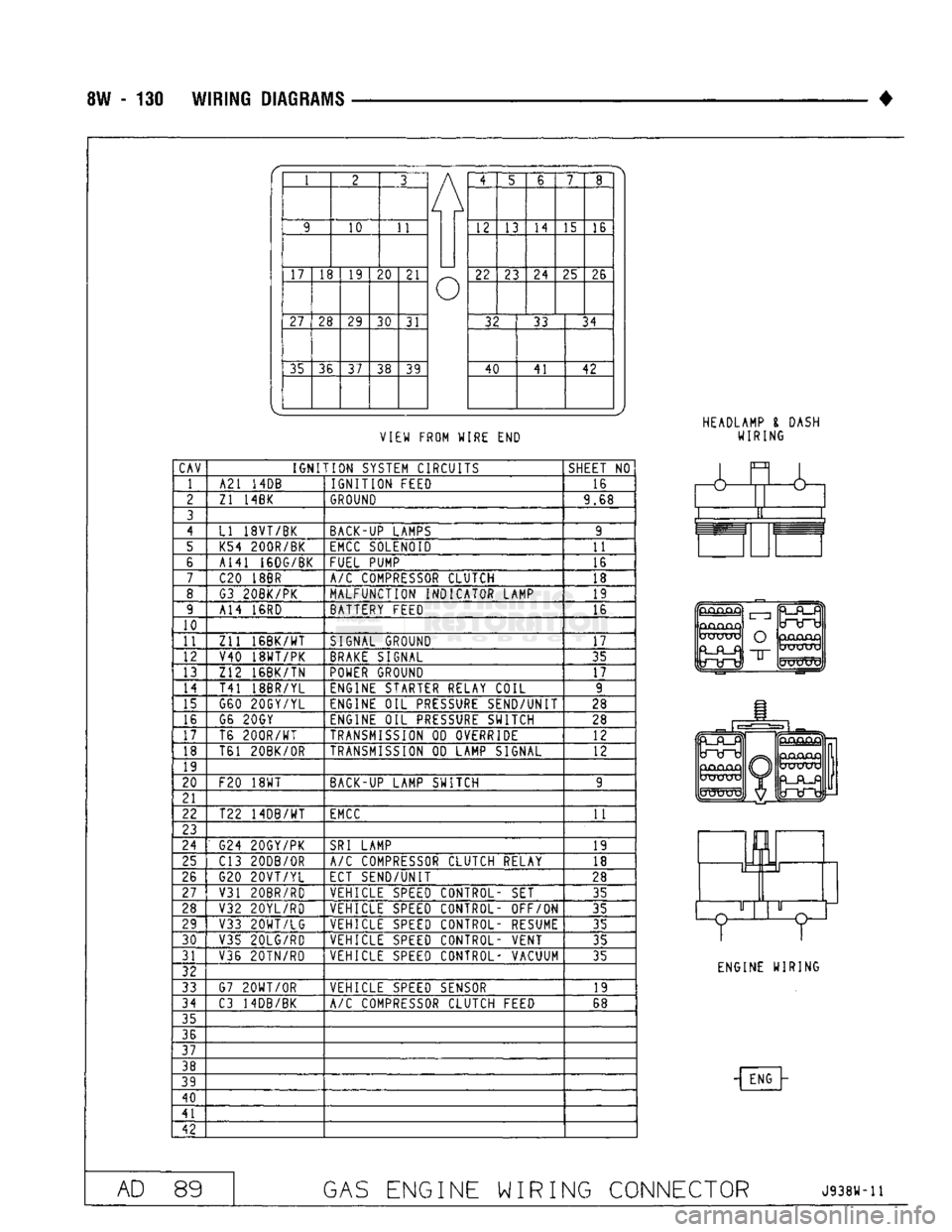

Page 605 of 1502

8W - 130

WIRING

DIAGRAMS

•

1 2 3

A 4

5 6

7

8

/

9

10

11

/

12 13

14

15 16

/

17

18

19

20

21

u

22

23

24

25 26

u

27

28 29

30

31

u

32 33

34

u

35 36

37

38 39

u

40

41 42

u

VIEW FROM WIRE

END

HEADLAMP

I

DASH

WIRING

CAV

IGNITION

SYSTEM CIRCUITS

SHEET

NO

1 A21

14DB

IGNITION

FEED 16

2

Zl 14BK

GROUND

9.68

3

4

LI 18VT/BK BACK-UP LAMPS 9

5 K54 200R/BK

EMCC

SOLENOID

11

6 A141 16DG/BK

FUEL PUMP 16

7

C20

18BR

A/C

COMPRESSOR CLUTCH 18

8 G3 20BK/PK MALFUNCTION INDICATOR LAMP 19

9 A14

16RD

BATTERY FEED 16

10

11

Zll

16BK/WT

SIGNAL GROUND

17

12 V40 18WT/PK

BRAKE

SIGNAL 35

13 Z12 16BK/TN

POWER

GROUND

17

14

T41 18BR/YL ENGINE STARTER RELAY COIL 9

15 G60 20GY/YL ENGINE

OIL

PRESSURE

SEND/UNIT 28

16 G6 20GY

ENGINE

OIL

PRESSURE

SWITCH 28

17 T6

200R/WT

TRANSMISSION

OD

OVERRIDE 12

18 T61 20BK/0R

TRANSMISSION

OD

LAMP SIGNAL

12

19

20

F20

18WT

BACK-UP LAMP SWITCH 9

21

22 T22 14DB/WT

EMCC

11

23

24

G24 20GY/PK

SRI

LAMP

19

25 C13 20DB/0R

A/C

COMPRESSOR CLUTCH RELAY

18

26 G20

20VT/YL

ECT SEND/UNIT

28

27

V31 20BR/RD VEHICLE

SPEED

CONTROL-

SET

35

28 V32 20YL/RD VEHICLE

SPEED

CONTROL- OFF/ON

35

29 V33

20WT/LG

VEHICLE

SPEED

CONTROL- RESUME 35

30

V35 20LG/RD VEHICLE

SPEED

CONTROL- VENT

35

31 V36 20TN/RD VEHICLE

SPEED

CONTROL- VACUUM

35

32

33 G7

20WT/0R

VEHICLE

SPEED

SENSOR 19

34

C3 14DB/BK

A/C

COMPRESSOR CLUTCH FEED 68

35

36

37

38

39

40

41

42

&

GjCUQjQ

UXJUXj

O

"IT

mJKXTV

ENGINE WIRING

- ENG

AD

89

GAS

ENGINE WIRING CONNECTOR

J938W-11

Page 607 of 1502

9

- 2

ENGINES

rial surrounds each mounting hole. Excess material

can easily be wiped off. Components should be

torqued in place within 15 minutes. The use of a lo cating dowel is recommended during assembly to pre

vent smearing the material off location.

ENGINE PERFORMANCE

To provide best vehicle performance and lowest ve

hicle emissions, it is most important that the tune-up

be done accurately. Use the specifications listed on

the Vehicle Emission Control Information label found on the engine compartment hood.

(1) Test cranking amperage draw (refer to Group

8B,

Battery/Starter/Generator Service for the proper

procedures).

(2) Tighten the intake manifold bolts (refer to

Group 11, Exhaust System and Intake Manifold for

the proper specifications). (3) Perform cylinder compression test:

(a) Check engine oil level and add oil, if neces

sary.

(b) Drive the vehicle until engine reaches normal

operating temperature. (c) Select a route free from traffic and other

forms of congestion, observe all traffic laws and

briskly accelerate through the gears several times. The higher engine speed may help clean out valve seat deposits which can prevent accurate compres

sion readings.

CAUTION:

DO NOT

overspeed

the

engine.

(d) Remove all spark plugs from engine. As

spark plugs are being removed, check electrodes for

abnormal firing indicators - fouled, hot, oily, etc.

Record cylinder number of spark plug for future

reference.

(e) Disconnect coil wire from distributor and se

cure to good ground to prevent a spark from start

ing a fire.

(f) Be sure throttle blades are fully open during

the compression check. (g) Insert compression gage adaptor into the

No.l spark plug hole. Crank engine until maxi

mum pressure is reached on gauge. Record this

pressure as No.l cylinder pressure.

(h) Repeat Step 3g for all remaining cylinders.

(i) Compression should not be less than 689 kPa

(100 psi) and not vary more than 172 kPa (25 psi)

from cylinder to cylinder.

(j) If cylinder(s) have abnormally low compres

sion pressures, repeat steps 3a through 3h. (k) If the same cylinder(s) repeat an abnormally

low reading, it could indicate the existence of a

problem in the cylinder.

The recommended compression pressures are

to be used only as a guide to diagnosing engine

problems. An engine should NOT be disassem bled to determine the cause of low compression

unless some malfunction is present. (4) Clean or replace spark plugs as necessary. Ad

just gap (refer to Group 8D, Ignition System for gap adjustment and torque).

(5) Test resistance of spark plug cables (refer to

Group 8D, Ignition System.

(6) Inspect the primary wire. Test coil output volt

age,

primary and secondary resistance. Replace parts as necessary (refer to Group 8D, Ignition System and

make necessary adjustment).

(7) Set ignition timing to specifications (refer to

Specification Label on engine compartment hood).

(8) Perform a combustion analysis.

(9) Test fuel pump for pressure and vacuum (refer

to Group 14, Fuel System for the proper specifica

tions).

(10) Inspect air filter element (refer to Group 0,

Lubrication and Maintenance for the proper proce

dure).

(11) Inspect crankcase ventilation system (refer to

Group 0, Lubrication and Maintenance for the proper

procedure).

(12) For emission controls refer to Group 25, Emis

sion Controls System for service procedures.

(13) Inspect and adjust accessory belt drives (refer

to Group 7, Cooling System for the proper adjust

ments).

(14) Road test vehicle as a final test.

H0NIN6

CYLINDER

BORES

Before honing, stuff plenty of clean shop towels un

der the bores and over the crankshaft to keep abra sive materials from entering the crankshaft area.

(1) Used carefully, the Cylinder Bore Sizing Hone

C-823 equipped with 220 grit stones, is the best tool

for this job. In addition to deglazing, it will reduce

taper and out-of-round as well as removing light scuffing, scoring or scratches. Usually a few strokes

will clean up a bore and maintain the required lim

its.

CAUTION:

DO NOT use rigid type

hones

to remove

cylinder

wall

glaze.

(2) Deglazing of the cylinder walls may be done if

the cylinder bore is straight and round. Use a cylin

der surfacing hone, Honing Tool C-3501, equipped

with 280 grit stones (C-3501-3810). 20-60 strokes, de

pending on the bore condition, will be sufficient to

provide a satisfactory surface. Using honing oil C-3501-3880 or a light honing oil available from ma

jor oil distributors.

CAUTION:

DO NOT use engine or

transmission

oil, mineral

spirits

or

kerosene.

Page 610 of 1502

•

ENGINES

9 - S

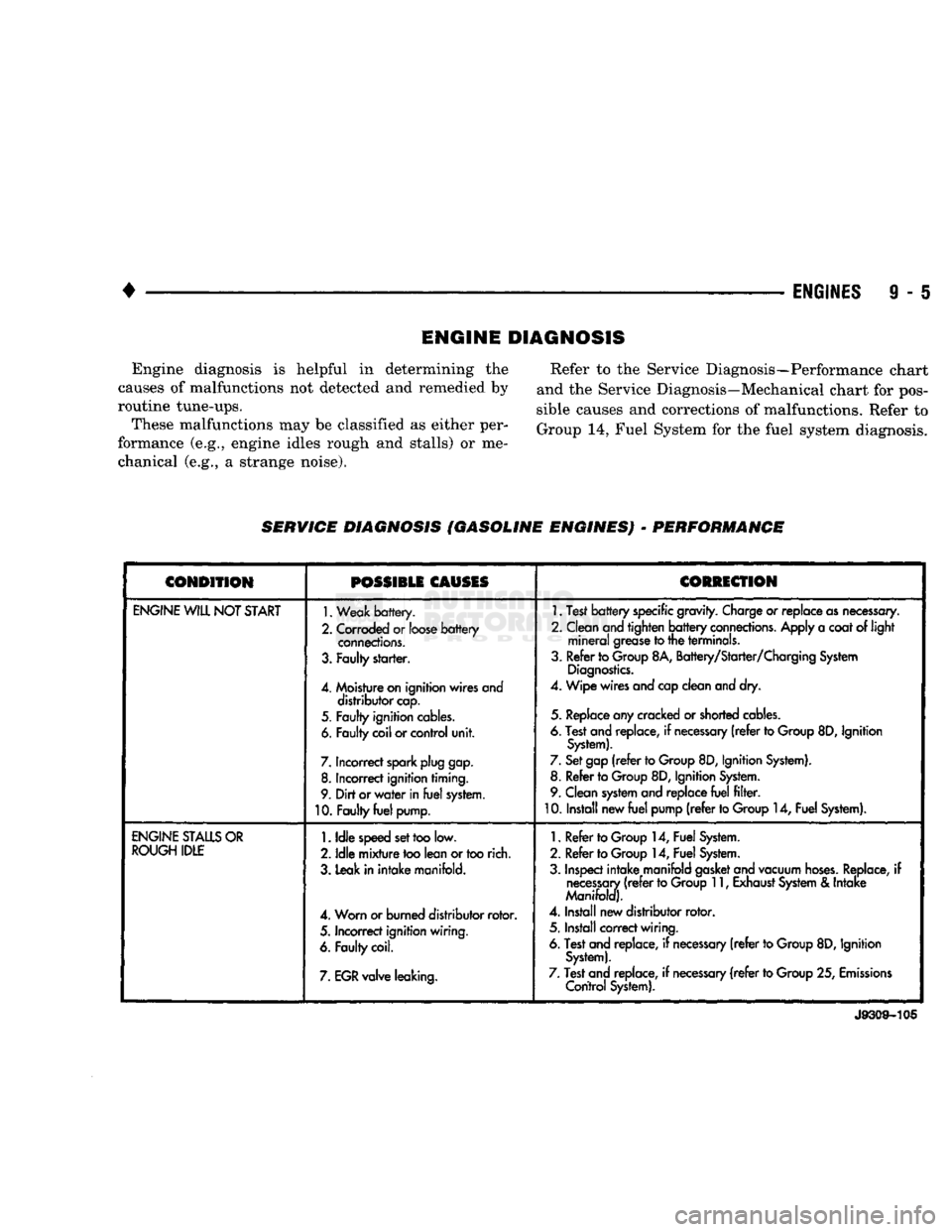

ENGINE

DIAGNOSIS

Engine diagnosis is helpful in determining the

causes of malfunctions not detected and remedied by

routine tune-ups. These malfunctions may be classified as either per

formance (e.g., engine idles rough and stalls) or me chanical (e.g., a strange noise). Refer to the Service Diagnosis—Performance chart

and the Service Diagnosis—Mechanical chart for pos

sible causes and corrections of malfunctions. Refer to

Group 14, Fuel System for the fuel system diagnosis.

SERWIGE DIAGNOSIS (GASOLINE ENGINES)

-

PERFORMANCE

CONDITION

POSSIBLE

CAUSES

CORRECTION

ENGINE

WILL

NOT

START

1.

Weak

battery.

2.

Corroded

or

loose

battery

connections.

3.

Faulty

starter.

4.

Moisture

on

ignition wires and distributor

cap.

5.

Faulty

ignition

cables.

6.

Faulty

coil

or

control

unit.

7.

Incorrect

spark

plug

gap.

8.

Incorrect

ignition timing.

9.

Dirt

or

water

in

fuel

system.

10.

Faulty

fuel

pump.

1.

Test

battery

specific

gravity.

Charge

or

replace

as

necessary.

2. Clean

and

tighten

battery

connections.

Apply

a

coat

of light

mineral

grease

to

the terminals.

3. Refer to

Group

8A, Battery/Starter/Charging

System

Diagnostics.

4. Wipe

wires

and

cap

clean

and

dry.

5.

Replace

any

cracked

or

shorted

cables.

6.

Test

and

replace,

if

necessary

(refer

to

Group

8D,

Ignition

System).

7.

Set

gap

(refer

to

Group

8D, Ignition

System).

8. Refer to

Group

8D, Ignition

System.

9. Clean

system

and

replace

fuel

filter.

10. Install new

fuel

pump

(refer

to

Group

14,

Fuel

System).

ENGINE

STALLS

OR

ROUGH

IDLE

1.

Idle

speed

set

too

low.

2.

Idle

mixture

too

lean

or

too

rich.

3. Leak in

intake

manifold.

4. Worn or burned distributor

rotor.

5.

Incorrect

ignition wiring.

6.

Faulty

coil.

7.

EGR

valve leaking.

1.

Refer to

Group

14,

Fuel

System.

2. Refer to

Group

14,

Fuel

System.

3.

Inspect

intake

manifold

gasket

and

vacuum

hoses.

Replace,

if

necessary

(refer

to

Group

11,

Exhaust

System

&

Intake

Manifold).

4.

Install new distributor

rotor.

5. Install

correct

wiring.

6.

Test

and

replace,

if

necessary

(refer

to

Group

8D,

Ignition

System).

7.

Test

and

replace,

if

necessary

(refer

to

Group

25,

Emissions

Control

System).

J9309-105

Page 611 of 1502

9

- 6

ENGINES

•

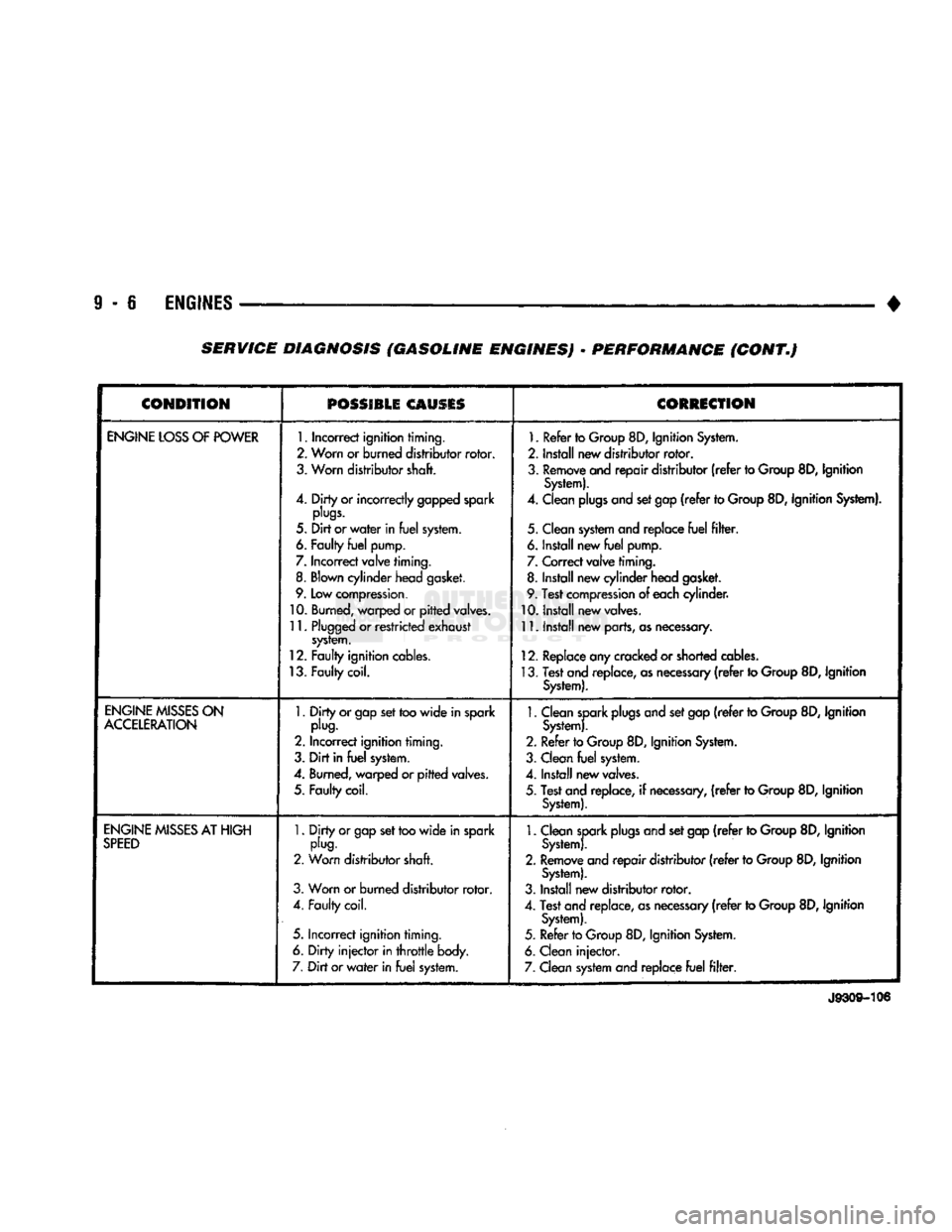

SERVICE DIAGNOSIS (GASOLINE ENGINES)

•

PERFORMANCE (CONT.)

1

CONDITION

POSSIBLE

CAUSES

^

CORRECTION

1

ENGINE

LOSS

OF

POWER

1.

Incorrect ignition timing.

2. Worn or burned distributor

rotor.

3. Worn distributor shaft.

4.

Dirty

or

incorrectly

gapped

spark

plugs.

5.

Dirt

or

water

in

fuel

system.

6.

Faulty

fuel

pump.

7.

Incorrect valve timing.

8.

Blown

cylinder head

gasket.

9.

Low

compression.

10.

Burned,

warped or

pitted

valves.

11.

Plugged

or

restricted

exhaust

system.

12. Faulty ignition

cables.

13. Faulty coil.

1.

Refer

to

Group

8D, Ignition

System.

2. install new distributor

rotor.

3.

Remove

and

repair

distributor

(refer

to

Group

8D, Ignition

System).

4.

Clean

plugs

and

set gap

(refer

to

Group

8D, Ignition

System).

5. Clean

system

and replace

fuel

filter.

6. Install new

fuel

pump.

7.

Correct

valve

timing.

8. Install new cylinder head

gasket.

9.

Test

compression

of

each

cylinder.

10.

Install new

valves.

11.

Install new

parts,

as

necessary.

12.

Replace

any cracked or

shorted

cables.

13.

Test

and

replace,

as

necessary

(refer

to

Group

8D, Ignition

System).

ENGINE

MISSES

ON

ACCELERATION

1.

Dirty

or

gap set

too

wide

in spark

plug.

2. Incorrect ignition timing.

3.

Dirt

in

fuel

system.

4.

Burned,

warped or

pitted

valves.

5. Faulty coil.

1.

Clean spark

plugs

and set gap

(refer

to

Group

8D, Ignition

System).

2. Refer to

Group

8D, Ignition

System.

3. Clean

fuel

system.

4.

Install new

valves.

5.

Test

and

replace,

if

necessary,

(refer

to

Group

8D, Ignition

System).

ENGINE

MISSES

AT HIGH

SPEED

1.

Dirty

or

gap set too

wide

in spark

plug.

2. Worn distributor shaft.

3. Worn or burned distributor

rotor.

4. Faulty

coil.

5. Incorrect ignition timing.

6.

Dirty

injector

in

throttle

body.

7.

Dirt

or

water

in

fuel

system.

1.

Clean

spark

plugs

and

set gap

(refer

to

Group

8D, Ignition

System).

2.

Remove

and

repair

distributor

(refer

to

Group

8D,

Ignition

System).

3. Install new distributor

rotor.

4.

Test

and replace,

as

necessary

(refer

to

Group

8D, Ignition

System).

5.

Refer

to

Group

8D, Ignition

System.

6.

Clean

injector.

7.

Clean

system

and replace

fuel

filter.

J9309-106

Page 613 of 1502

9

- 8

ENGINES

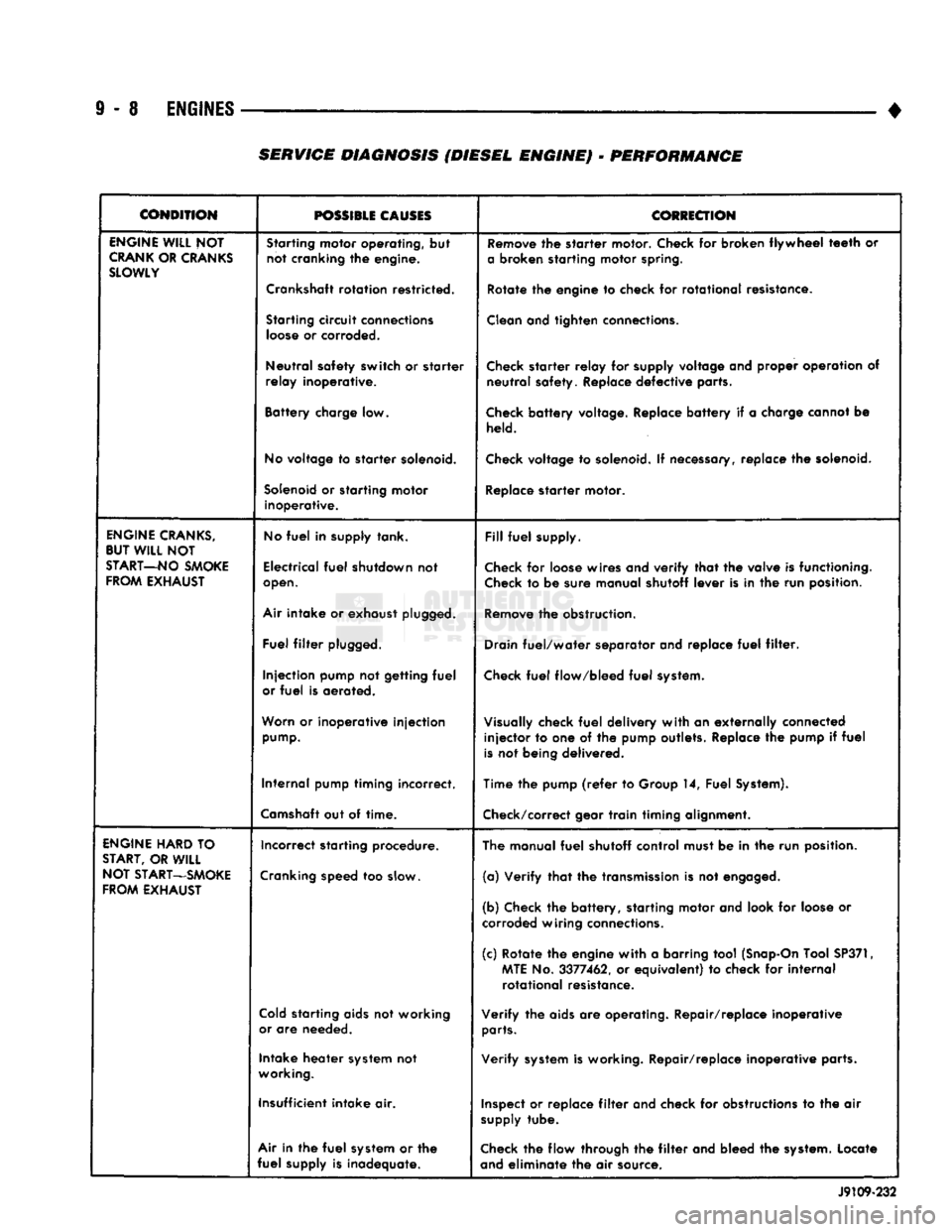

• SERVICE DIAGNOSIS (DIESEL ENGINE) - PERFORMANCE

CONDITION

POSSIBLE

CAUSES

COtiECTION

ENGINE

WILL

NOT

CRANK

OR

CRANKS

SLOWLY

Starting

motor operating, but

not cranking the engine.

Crankshaft

rotation restricted.

Starting

circuit

connections

loose

or corroded.

Neutral safety switch or starter

relay inoperative.

Battery charge low.

No

voltage to starter

solenoid.

Solenoid

or starting motor inoperative.

Remove

the starter motor. Check for broken flywheel

teeth

or

a

broken starting motor

spring.

Rotate the engine to check for rotational resistance.

Clean

and tighten

connections.

Check

starter relay for

supply

voltage and proper operation of neutral safety. Replace defective parts.

Check

battery voltage. Replace battery if a charge cannot be

held.

Check

voltage to

solenoid.

If

necessary,

replace the

solenoid.

Replace

starter motor.

ENGINE

CRANKS,

BUT

WILL

NOT

START—NO

SMOKE

FROM

EXHAUST

No

fuel

in supply tank.

Electrical

fuel

shutdown not

open.

Air

intake or exhaust

plugged.

Fuel

filter

plugged.

Injection pump not getting

fuel

or

fuel

is aerated.

Worn

or inoperative injection

pump.

Internal pump timing incorrect.

Camshaft

out of time.

Fill

fuel

supply.

Check

for

loose

wires and verify that the valve is functioning.

Check

to be sure manual shutoff lever is in the run position.

Remove

the obstruction.

Drain

fuel/water separator and replace

fuel

filter.

Check

fuel

flow/bleed

fuel

system.

Visually

check

fuel

delivery with an externally connected injector to one of the pump outlets. Replace the pump if

fuel

is

not being delivered.

Time the pump

(refer

to Group 14, Fuel

System).

Check/correct

gear train timing alignment.

ENGINE

HARD

TO

START,

OR

WILL

NOT

START—SMOKE

FROM

EXHAUST

Incorrect starting procedure.

Cranking

speed too

slow.

Cold

starting

aids

not working

or

are needed.

Intake heater

system

not

working.

Insufficient intake air.

Air

in the

fuel

system

or the

fuel

supply is inadequate. The manual

fuel

shutoff control must be in the run position.

(a) Verify that the

transmission

is not

engaged.

(b) Check the battery, starting motor and look for

loose

or

corroded

wiring

connections.

(c) Rotate the engine with a barring tool

(Snap-On

Tool

SP371,

MTE

No. 3377462, or equivalent) to check for internal rotational resistance.

Verify the

aids

are operating. Repair/replace inoperative

parts.

Verify

system

is working. Repair/replace inoperative parts.

Inspect

or replace

filter

and check for

obstructions

to the air

supply

tube.

Check

the flow through the

filter

and bleed the

system.

Locate

and

eliminate the air source. J9109-232

Page 614 of 1502

•

ENGINES

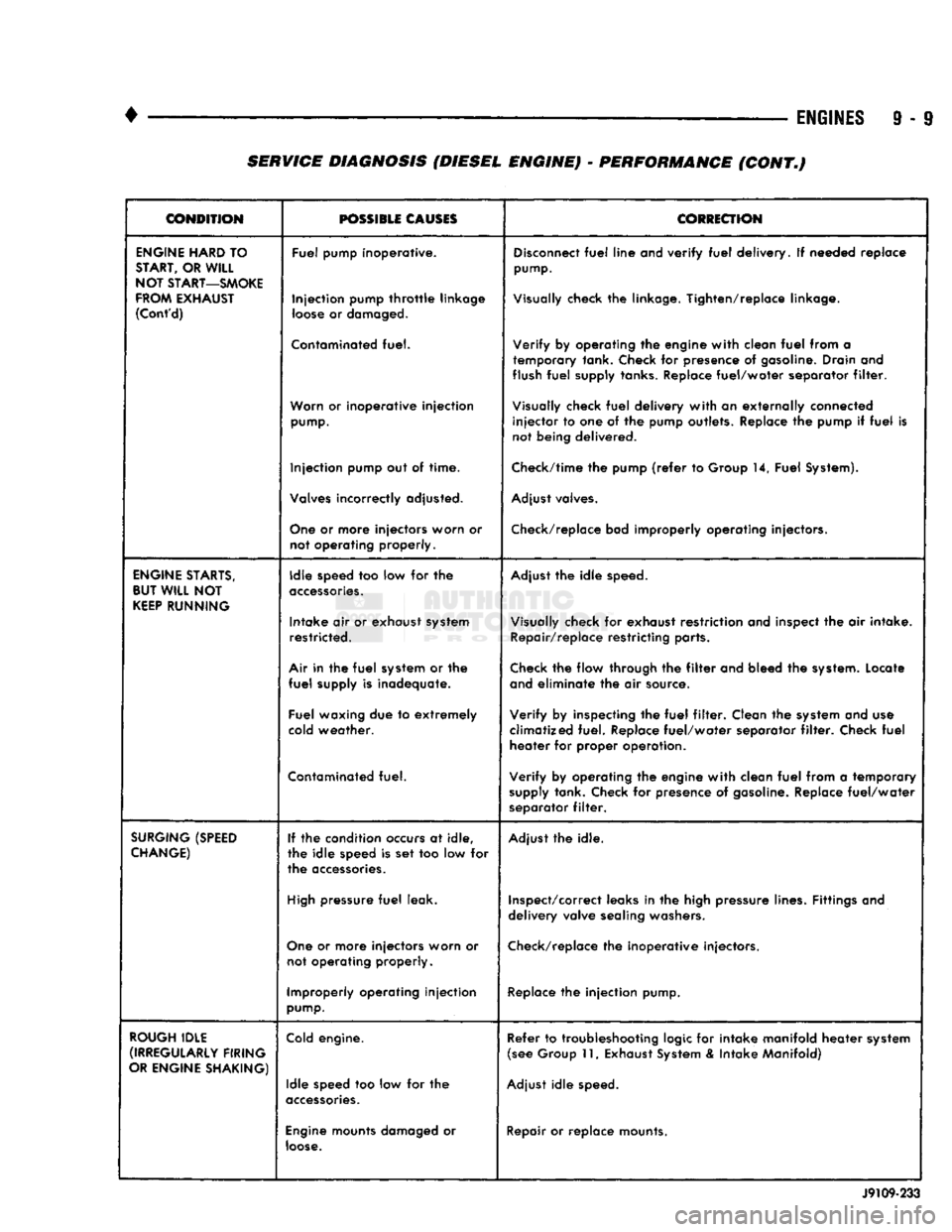

9 - 9 SERVICE DIAGNOSIS (DIESEL ENGINE) • PERFORMANCE (CONT.)

CONDITION

POSSIBLE

CAUSES

CORRECTION

ENGINE

HARD

TO

START,

OR

WILL

NOT

START—SMOKE

FROM

EXHAUST

(Cont'd)

Fuel pump Inoperative.

Injection pump

throttle

linkage

loose

or

damaged.

Contaminated

fuel.

Worn

or inoperative injection

pump.

Injection pump out of time.

Valves

incorrectly adjusted.

One

or more injectors worn or not operating properly.

Disconnect

fuel

line and verify

fuel

delivery. If needed replace

pump.

Visually

check the linkage. Tighten/replace linkage.

Verify by operating the engine with clean

fuel

from a temporary tank. Check for presence of

gasoline.

Drain and

flush

fuel

supply tanks.

Replace

fuel/water separator

filter.

Visually

check

fuel

delivery with an externally connected injector to one of the pump outlets. Replace the pump if

fuel

is

not being delivered.

Check/time

the pump

(refer

to Group 14, Fuel

System).

Adjust

valves.

Check/replace

bad improperly operating injectors.

ENGINE

STARTS,

BUT

WILL

NOT

KEEP

RUNNING

Idle speed too low for the

accessories.

Intake air or exhaust

system

restricted.

Air

in the

fuel

system

or the

fuel

supply is inadequate.

Fuel waxing due to extremely

cold

weather.

Contaminated

fuel.

Adjust

the idle

speed.

Visually

check for exhaust restriction and inspect the air intake.

Repair/replace restricting parts.

Check

the flow through the

filter

and bleed the

system.

Locate

and

eliminate the air source.

Verify by inspecting the

fuel

filter.

Clean the

system

and use

climatized fuel. Replace fuel/water separator

filter.

Check

fuel

heater for proper operation.

Verify by operating the engine with clean

fuel

from a temporary

supply

tank. Check for presence of

gasoline.

Replace fuel/water

separator

filter.

SURGING

(SPEED

CHANGE)

If the condition

occurs

at idle,

the idle speed is set too low for

the

accessories.

High

pressure

fuel

leak.

One

or more injectors worn or not operating properly.

Improperly operating injection

pump.

Adjust

the idle.

Inspect/correct

leaks in the high pressure lines. Fittings and

delivery valve

sealing

washers.

Check/replace

the inoperative injectors.

Replace

the injection pump.

ROUGH

IDLE

(IRREGULARLY

FIRING

OR

ENGINE

SHAKING)

Cold

engine.

Idle speed too low for the

accessories.

Engine

mounts

damaged

or

loose.

Refer to troubleshooting

logic

for intake manifold heater

system

(see

Group 11,

Exhaust

System

& Intake Manifold)

Adjust

idle

speed.

Repair

or replace mounts. J9109-233

Page 615 of 1502

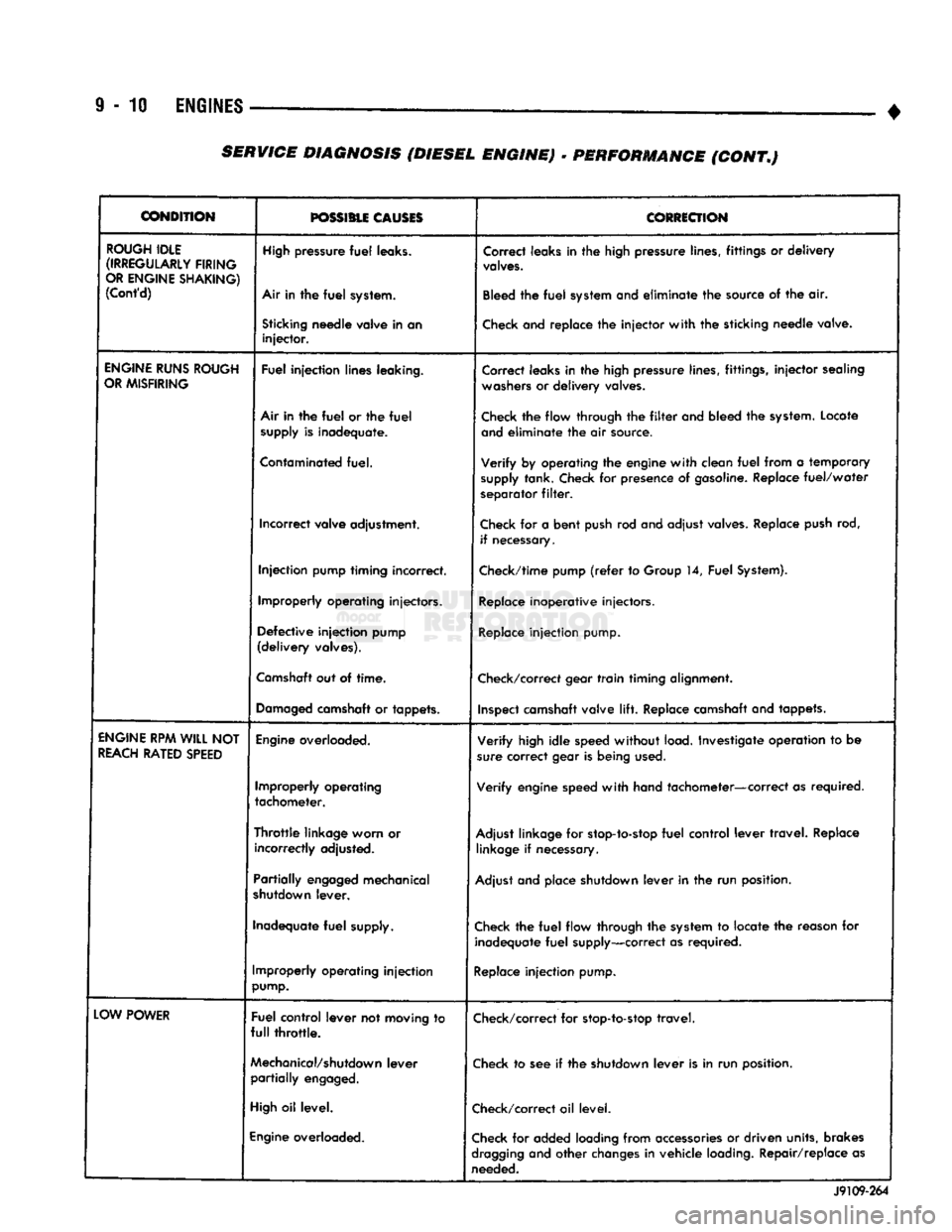

9

- 10

ENGINES

— _

•

CONDITION

possmu

CLOSES

CORRECTION

ROUGH

IDLE

(IRREGULARLY

FIRING

OR

ENGINE

SHAKING)

(Cont'd)

High

pressure

fuel

leaks.

Air In the

fuel

system.

Correct leaks in the high pressure lines, fittings or

delivery

valves.

Bleed the

fuel

system and

eliminate

the source of the air.

Sticking

needle

valve

in an

injector.

Check and replace the

injector

with

the sticking

needle

valve.

ENGINE

RUNS

ROUGH

OR

MISFIRING

Fuel

injection

lines

leaking.

Correct leaks in the high pressure lines, fittings,

injector

sealing

washers

or

delivery

valves.

Air in the

fuel

or the

fuel

supply

is

inadequate.

Check the flow through the

filter

and bleed the system. Locate

and

eliminate

the air source.

Contaminated

fuel.

Verify

by operating the engine

with

clean

fuel

from a temporary

supply

tank. Check for presence of gasoline. Replace

fuel/water

separator

filter.

Incorrect

valve

adjustment.

Check for a

bent

push rod and adjust valves. Replace push rod,

if necessary.

Injection

pump

timing

incorrect.

Check/time pump

(refer

to Group 14,

Fuel

System).

Improperly

operating

injectors.

Replace inoperative injectors.

Defective

injection

pump

(delivery

valves).

Replace

injection

pump.

Camshaft

out of

time.

Check/correct gear

train

timing alignment.

Damaged

camshaft or

tappets.

Inspect camshaft valve

lift.

Replace camshaft and tappets.

ENGINE

RPM WILL NOT

REACH

RATED

SPEED

Engine

overloaded.

Verify

high

idle

speed

without

load. Investigate operation to be

sure correct gear is being used.

Improperly

operating

tachometer.

Verify

engine speed

with

hand tachometer—correct as required.

Throttle

linkage

worn

or

incorrectly

adjusted.

Adjust linkage for stop-to-stop

fuel

control

lever

travel.

Replace

linkage if necessary.

Partially

engaged

mechanical

shutdown

lever.

Adjust and place shutdown

lever

in the run position.

Inadequate

fuel

supply. Check the

fuel

flow through the system to locate the reason for

inadequate

fuel

supply—correct as required.

Improperly

operating

injection

pump.

Replace

injection

pump.

LOW

POWER

Fuel

control

lever

not

moving

to

full

throttle.

Check/correct for stop-to-stop

travel.

Mechanical/shutdown

lever

partially

engaged.

Check to see if the shutdown

lever

is in run position.

High

oil

level.

Check/correct oil level.

Engine

overloaded.

Check for added loading from accessories or driven units, brakes

dragging

and

other

changes in vehicle loading. Repair/replace as

needed.

J9109-264

SERVICE

DIAGNOSIS (DIESEL ENGINE)

•

PERFORMANCE (CONT.)

Page 616 of 1502

•

ENGINES

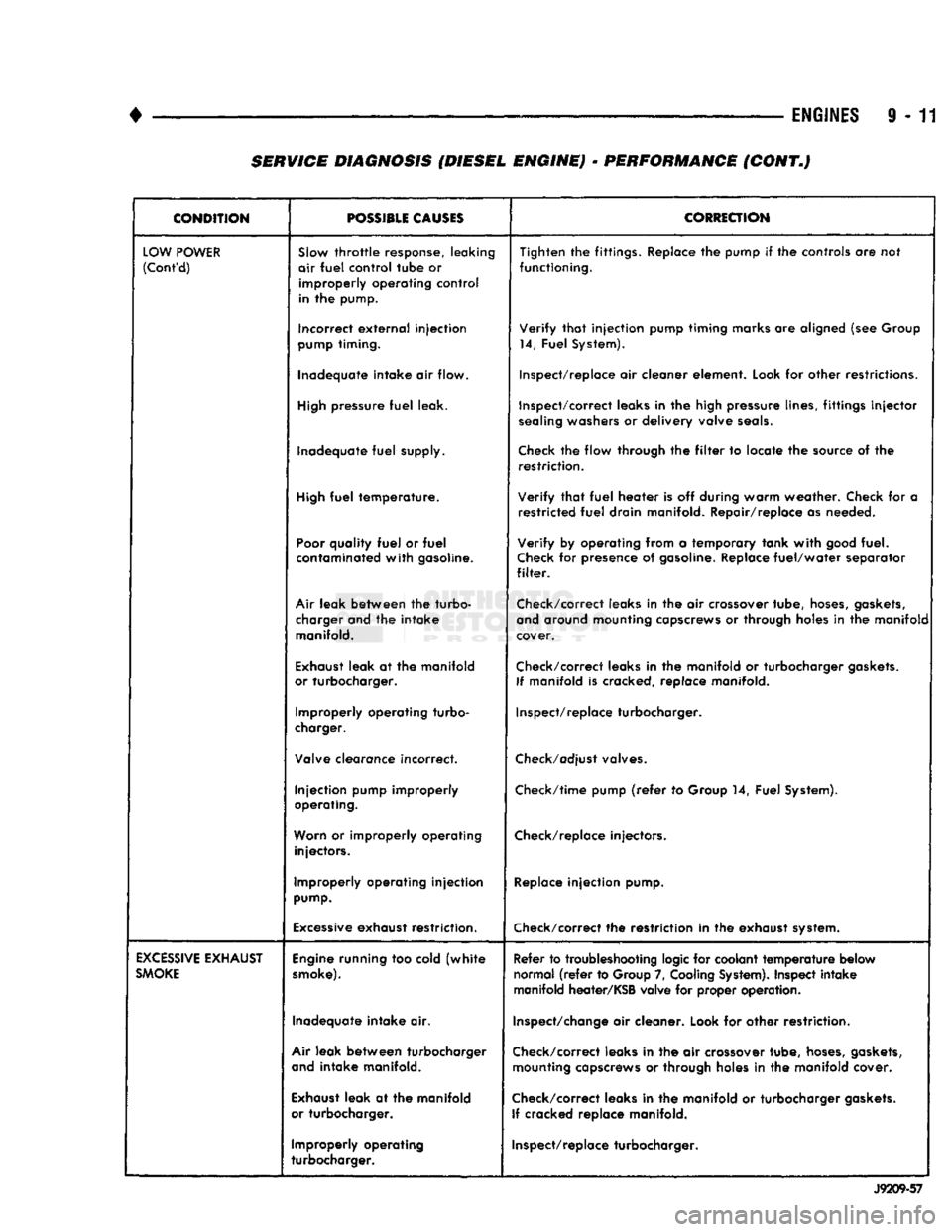

9 - 11 SERVICE DIAGNOSIS (DIESEL ENGINE) - PERFORMANCE (CONT.)

CONDITION

POSSIBLE

CAUSES

CORRECTION

LOW

POWER

(Cont'd)

SJow

throttle

response, leaking

air

fuel

control

tube

or

improperly

operating

control

in the pump. Tighten the fittings. Replace the pump if the controls are not

functioning.

Incorrect

external

injection

pump

timing. Verify

that

injection pump timing marks are aligned (see Group

14, Fuel System).

Inadequate intake air flow. Inspect/replace air cleaner element. Look for other restrictions.

High

pressure

fuel

leak. Inspect/correct leaks in the high pressure lines, fittings

injector

sealing

washers or delivery valve

seals.

Inadequate

fuel

supply.

Check

the flow through the

filter

to locate the source of the

restriction.

High

fuel

temperature. Verify

that

fuel

heater is off during warm weather. Check for a

restricted

fuel

drain manifold. Repair/replace as needed.

Poor

quality

fuel

or

fuel

contaminated

with

gasoline. Verify by operating from a temporary tank

with

good

fuel.

Check

for presence of

gasoline.

Replace

fuel/water

separator

filter.

Air

leak between the turbo- charger and the intake manifold. Check/correct leaks in the air crossover tube,

hoses,

gaskets,

and

around mounting capscrews or through holes in the manifold

cover.

Exhaust

leak at the manifold

or turbocharger. Check/correct leaks in the manifold or turbocharger

gaskets.

If manifold is cracked, replace manifold.

Improperly operating turbo-

charger. Inspect/replace turbocharger.

Valve clearance incorrect.

Check/adjust

valves.

Injection pump improperly

operating. Check/time pump

(refer

to Group 14, Fuel System).

Worn

or improperly operating injectors. Check/replace injectors.

Improperly operating injection

pump.

Replace

injection pump.

Excessive

exhaust restriction. Check/correct the restriction in the exhaust system.

EXCESSIVE

EXHAUST

SMOKE

Engine

running too cold

(white

smoke).

Refer to troubleshooting logic for coolant

temperature

below

normal

(refer

to Group 7,

Cooling

System).

Inspect intake

manifold heater/KSB valve for proper operation.

Inadequate intake air.

Inspect/change

air cleaner. Look for other restriction.

Air

leak between turbocharger

and

intake manifold. Check/correct leaks in the air crossover tube,

hoses,

gaskets,

mounting capscrews or through holes in the manifold cover.

Exhaust

leak at the manifold

or turbocharger. Check/correct leaks in the manifold or turbocharger

gaskets.

If cracked replace manifold.

Improperly operating

turbocharger. Inspect/replace turbocharger.

J9209-57

Page 617 of 1502

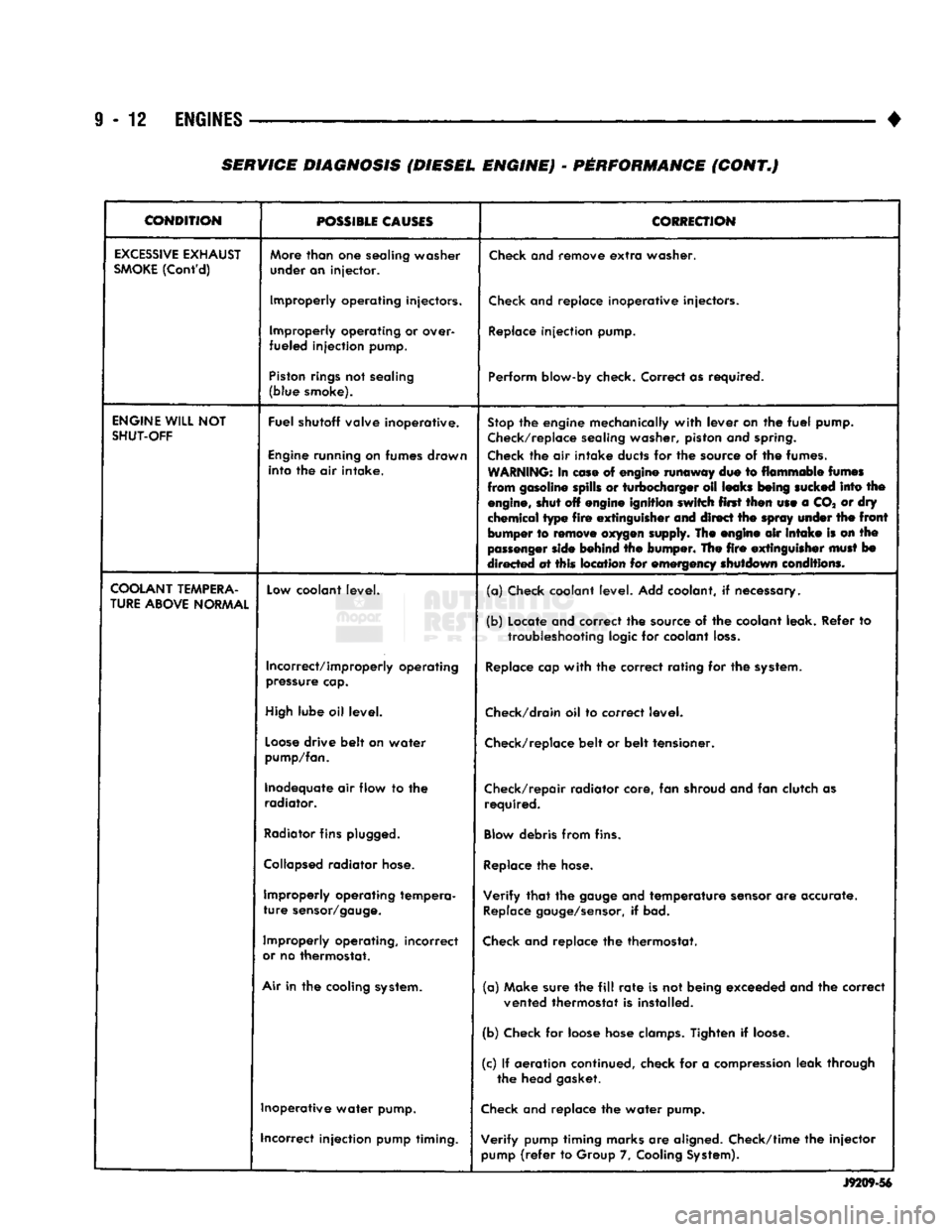

9

- 12

ENGINES

•

CONDITION

POSSIBLE

CAUSES

CORRECTION

EXCESSIVE

EXHAUST

SMOKE

(Cont'd)

More

than

one

sealing washer

under an injector.

Check

and remove

extra

washer.

Improperly operating injectors.

Check

and replace inoperative injectors.

Improperly operating or over-

fueled injection pump.

Replace

injection pump.

Piston

rings

not sealing

(blue smoke). Perform blow-by check. Correct as required.

ENGINE

WILL

NOT

SHUT-OFF

Fuel shutoff valve inoperative.

Engine

running on fumes drawn into the air intake.

Stop

the engine mechanically

with

lever on the

fuel

pump.

Check/replace

sealing washer, piston and

spring.

Check

the air intake ducts for the source of the fumes.

WARNING:

In

ease

of engine runaway due to flammable

fumes

from gasoline spills or turbocharger oil leaks

being

sucked

into the

engine,

shut off engine ignition switch first then use a CO* or dry

chemical type

fire

extinguisher

and direct the

spray

under

the

front

bumper to

remove

oxygen

supply. The engine air

intake

is on the

passenger

side

behind the bumper. The

fire

extinguisher

must

bo

directed at this location for emergency shutdown conditions.

COOLANT

TEMPERA

TURE

ABOVE

NORMAL

Low

coolant level.

(a) Check coolant level. Add coolant, if necessary.

(b) Locate and correct the source of the coolant leak. Refer to

troubleshooting

logic for coolant

loss.

Incorrect/improperly operating

pressure

cap.

Replace

cap

with

the correct rating for the

system.

High

lube oil level.

Check/drain

oil to correct level.

Loose

drive belt on water

pump/fan.

Check/replace

belt or belt tensioner.

Inadequate air flow to the radiator. Check/repair radiator core, fan shroud and fan clutch as

required.

Radiator

fins

plugged.

Blow

debris from fins.

Collapsed

radiator

hose.

Replace

the

hose.

Improperly operating tempera

ture

sensor/gauge.

Verify

that

the

gauge

and temperature

sensor

are accurate.

Replace

gauge/sensor,

if bad.

Improperly operating, incorrect

or

no thermostat.

Check

and replace the thermostat.

Air

in the cooling

system.

(a) Make sure the

fill

rate

is not being exceeded and the correct

vented thermostat is installed.

(b) Check for loose hose

clamps.

Tighten if

loose.

(c) If aeration continued, check for a

compression

leak through the head gasket.

Inoperative water pump.

Check

and replace the water pump.

incorrect injection pump timing. Verify pump timing marks are aligned. Check/time the injector

pump

(refer

to Group 7,

Cooling

System).

J9209-56

SERVICE DIAGNOSIS (DIESEL ENGINE) - PERFORMANCE (CONT.)