fuel pump DODGE TRUCK 1993 Service Owner's Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 618 of 1502

•

ENGINES

9 - 13

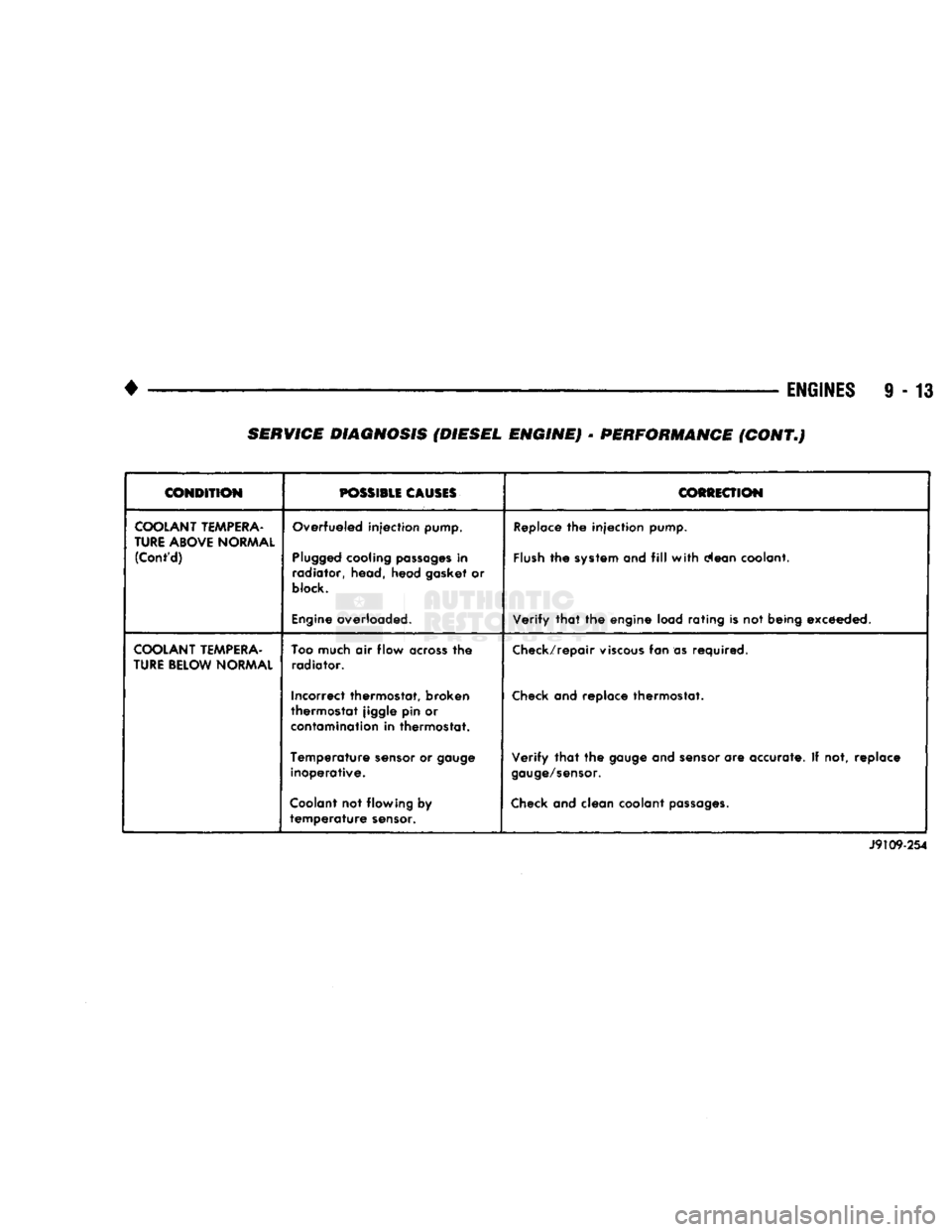

CONDITION

POSSIBLE

CAUSES

COfiiiECTION

COOLANT

TEMPERA

TURE

ABOVE

NORMAL

(Cont'd)

Overfueled injection pump.

Plugged

cooling

passages

in

radiator, head, head gasket or

block.

Engine

overloaded.

Replace

the injection

pump.

Flush

the

system

and

fill

with

clean coolant.

Verify

that

the engine load rating is not being exceeded.

COOLANT

TEMPERA

TURE

BELOW

NORMAL

Too

much air flow

across

the

radiator.

Incorrect thermostat, broken

thermostat jiggle pin or

contamination

in thermostat.

Temperature

sensor

or

gauge

inoperative.

Coolant

not flowing by

temperature

sensor.

Check/repair

viscous

fan as required.

Check

and replace thermostat.

Verify

that

the

gauge

and

sensor

are accurate. If not, replace

gauge/sensor.

Check

and clean coolant

passages.

J9109-254

SERVICE DIAGNOSIS (DIESEL ENGINE) • PERFORMANCE (CONT.)

Page 620 of 1502

•

• —

ENGINES

9 - 15

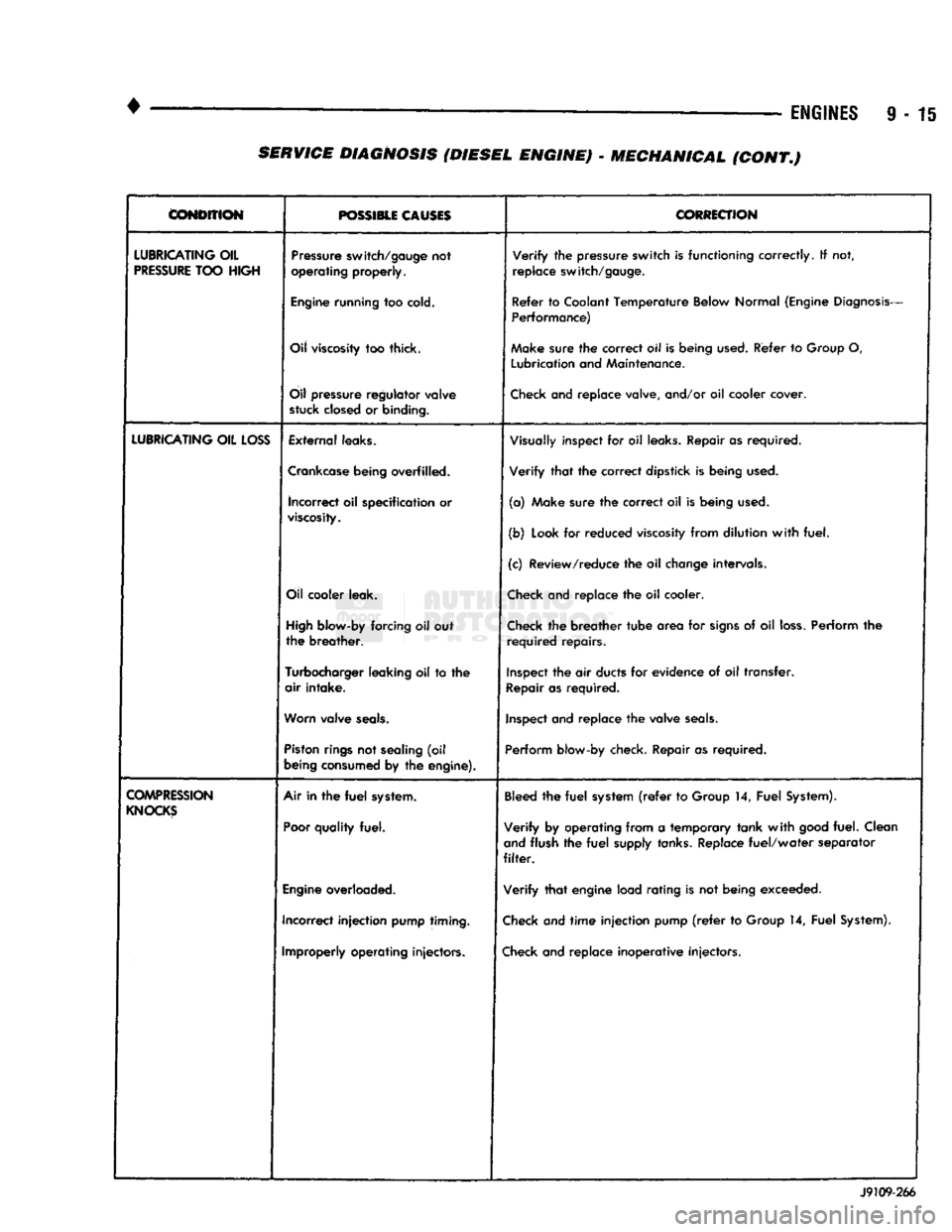

CONDITION

POSSIBLE CAUSES

CORRECTION

LUBRICATING

OIL

PRESSURE

TOO

HIGH

Pressure

switch/gauge

not

operating

properly.

Verify

the

pressure

switch

is

functioning

correctly.

If not,

replace

switch/gauge.

Engine

running

too

cold.

Refer

to

Coolant

Temperature

Below

Normal

(Engine

Diagnosis-

Performance)

Oil

viscosity

too thick. Make

sure

the

correct

oil Is

being

used.

Refer

to

Group

O,

Lubrication

and

Maintenance.

Oil

pressure

regulator

valve

stuck

closed

or

binding.

Check

and replace valve, and/or oil cooler cover.

LUBRICATING

OIL

LOSS

External

leaks.

Visually

inspect for oil

leaks.

Repair as required.

Crankcase

being

overfilled. Verify that the correct dipstick is being

used.

incorrect

oil specification or

viscosity.

(a) Make sure the correct oil is being

used.

(b)

Look

for reduced

viscosity

from dilution with fuel.

(c) Review/reduce the oil

change

intervals.

Oil

cooler

leak.

Check

and replace the oil cooler.

High

blow-by

forcing oil out

the breather.

Check

the breather tube area for

signs

of oil

loss.

Perform the

required repairs.

Turbocharger

leaking

oil to the

air intake.

Inspect

the air

ducts

for evidence of oil transfer.

Repair

as required.

Worn

valve

seals.

Inspect

and replace the valve

seals.

Piston

rings

not

sealing

(oil

being

consumed

by the

engine).

Perform

blow-by check. Repair as required.

COMPRESSION

KNOCKS

Air in the

fuel

system.

Poor

quality

fuel.

Bleed

the fuel

system

(refer

to

Group

14, Fuel

System).

Verify by operating from a temporary tank with

good

fuel. Clean

and

flush the fuel

supply

tanks.

Replace fuel/water separator

filter.

Engine

overloaded. Verify that engine load rating is not being exceeded.

Incorrect injection

pump

timing.

Check

and time injection pump

(refer

to

Group

14, Fuel

System).

Improperly

operating

injectors.

Check

and replace inoperative injectors. J9109-266 SERVICE DIAGNOSIS (DIESEL ENGINE) - MECHANICAL (CONT.)

Page 622 of 1502

•

3.9L ENGINE

9 - 17

3.9L

ENGINE SERVICE PROCEDURES

INDEX

page

Camshaft

31

Crankshaft

38

Crankshaft Main Bearings

39

Crankshaft Rear

Oil

Seals

. 40

Cylinder Block

41

Cylinder Head Cover

. , 21

Cylinder Heads

. 22

Distributor

33

Engine

Assembly .........................

20

Engine

Front Mounts

17

Engine

Rear Mount

18

Front Crankshaft

Oil

Seal Replacement ........

31

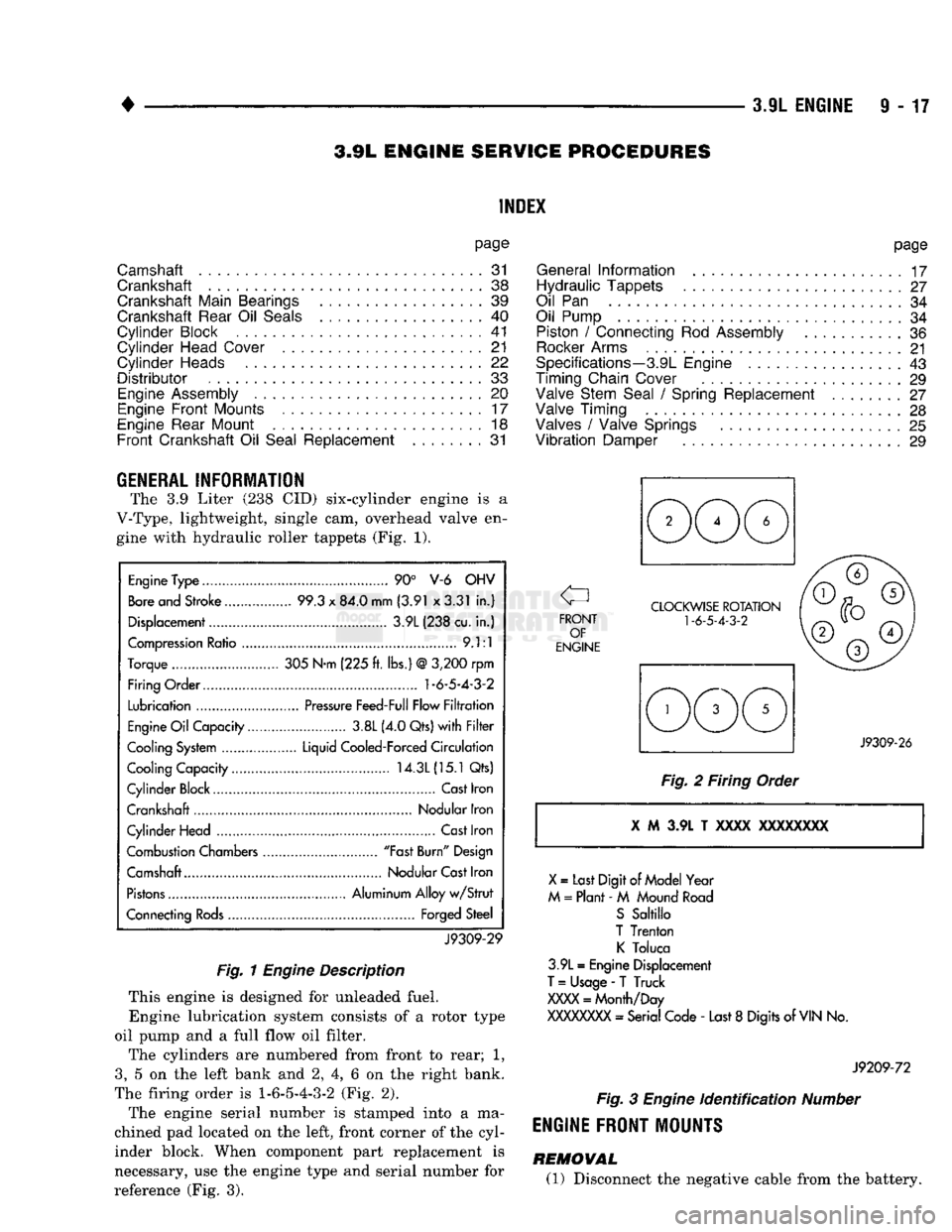

GENERAL INFORMATION

The 3.9 Liter (238 CID) six-cylinder engine is a

V-Type, lightweight, single cam, overhead valve en gine with hydraulic roller tappets (Fig. 1).

Engine

Type

90° V-6 OHV

Bore

and Stroke 99.3

x

84.0 mm (3.91 x3.31

in.)

Displacement 3.9L (238 cu.

in.)

Compression

Ratio

9.1:1

Torque 305 N-m (225

ft.

lbs.)

@

3,200

rpm

Firing Order.... 1-6-5-4-3-2

Lubrication

Pressure

Feed-Full Flow

Filtration

Engine

Oil

Capacity 3.8L (4.0 Qts)

with Filter

Cooling

System

Liquid Cooled-Forced

Circulation

Cooling Capacity 14.3L

(15.1

Qts)

Cylinder Block Cast Iron

Crankshaft Nodular Iron

Cylinder Head

Cast

Iron

Combustion Chambers "Fast

Burn"

Design

Camshaft Nodular

Cast

Iron

Pistons

Aluminum Alloy

w/Strut

Connecting

Rods

Forged Steel

J9309-29

Fig.

1

Engine

Description

This engine is designed for unleaded fuel. Engine lubrication system consists of a rotor type

oil pump and a full flow oil filter.

The cylinders are numbered from front to rear; 1,

3,

5 on the left bank and 2, 4, 6 on the right bank.

The firing order is

1-6-5-4-3-2

(Fig. 2).

The engine serial number is stamped into a ma

chined pad located on the left, front corner of the cyl

inder block. When component part replacement is

necessary, use the engine type and serial number for

reference (Fig. 3).

page

General

Information

17

Hydraulic Tappets

27

Oil

Pan 34

Oil Pump

34

Piston

/

Connecting

Rod

Assembly

36

Rocker

Arms

21

Specifications—3.9L Engine

43

Timing Chain Cover

29

Valve Stem Seal

/

Spring Replacement ........

27

Valve Timing

28

Valves

/

Valve Springs

25

Vibration

Damper

29

J9309-26

Fig.

2 Firing Order i M 3.9L T xxxx

XXXXXXXX

X

=

Last Digit

of

Model Year

M

=

Plant -

M

Mound

Road

S

Sabillo

T Trenton

K

Toluca

3.9L

=

Engine Displacement

T

=

Usage

-

T Truck

XXXX

=

Month/Day

XXXXXXXX

- Serial Code -

Last

8

Digits of

VIN

No.

J9209-72

Fig.

3

Engine

identification

Number

ENGINE FRONT MOUNTS

REMOVAL (1) Disconnect the negative cable from the battery.

Page 634 of 1502

•

3.9L

ENGINE

I - 21

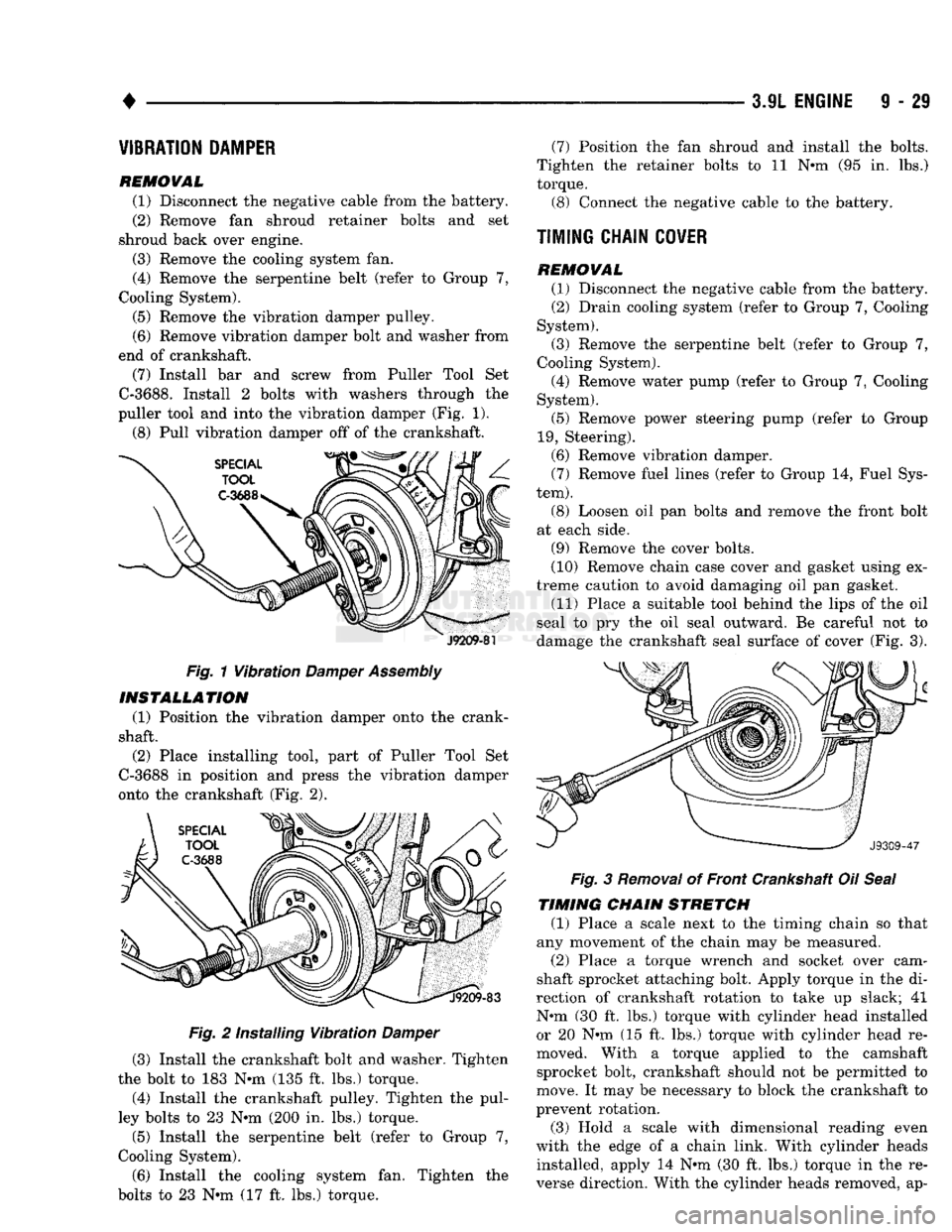

VIBRATION

DAMPER

REMOVAL

(1) Disconnect the negative cable from the battery,

(2) Remove fan shroud retainer bolts and set

shroud back over engine.

(3) Remove the cooling system fan.

(4) Remove the serpentine belt (refer to Group 7,

Cooling System).

(5) Remove the vibration damper pulley.

(6) Remove vibration damper bolt and washer from

end of crankshaft.

(7) Install bar and screw from Puller Tool Set

C-3688.

Install 2 bolts with washers through the

puller tool and into the vibration damper (Fig. 1).

(8) Pull vibration damper off of the crankshaft.

J9209-81

Fig. 1 Vibration

Damper

Assembly INSTALLATION

(1) Position the vibration damper onto the crank

shaft.

(2) Place installing tool, part of Puller Tool Set

C-3688 in position and press the vibration damper

onto the crankshaft (Fig. 2).

Fig. 2 Installing Vibration Damper

(3) Install the crankshaft bolt and washer. Tighten

the bolt to 183 N*m (135 ft. lbs.) torque.

(4) Install the crankshaft pulley. Tighten the pul

ley bolts to 23 N*m (200 in. lbs.) torque.

(5) Install the serpentine belt (refer to Group 7,

Cooling System).

(6) Install the cooling system fan. Tighten the

bolts to 23 N*m (17 ft. lbs.) torque. (7) Position the fan shroud and install the bolts.

Tighten the retainer bolts to 11 N*m (95 in. lbs.)

torque.

(3)

Connect the negative cable to the battery.

TIMING CHAIN

COVER

REMOVAL (1)

Disconnect the negative cable from the battery.

(2)

Drain cooling system (refer to Group 7, Cooling

System).

(3)

Remove the serpentine belt (refer to Group 7,

Cooling System).

(4)

Remove water pump (refer to Group 7, Cooling

System).

(5)

Remove power steering pump (refer to Group

19,

Steering).

(6)

Remove vibration damper. (7) Remove fuel lines (refer to Group 14, Fuel Sys

tem).

(8) Loosen oil pan bolts and remove the front bolt

at each side.

(9)

Remove the cover bolts.

(10)

Remove chain case cover and gasket using ex

treme caution to avoid damaging oil pan gasket.

(11)

Place a suitable tool behind the lips of the oil

seal to pry the oil seal outward. Be careful not to

damage the crankshaft seal surface of cover (Fig. 3). Fig. 3 Removal of Front Crankshaft Oil Seal

TIMING CHAIN STRETCH

(1) Place a scale next to the timing chain so that

any movement of the chain may be measured.

(2)

Place a torque wrench and socket over cam

shaft sprocket attaching bolt. Apply torque in the di

rection of crankshaft rotation to take up slack; 41

N#m (30 ft. lbs.) torque with cylinder head installed or 20 N»m (15 ft. lbs.) torque with cylinder head re

moved. With a torque applied to the camshaft sprocket bolt, crankshaft should not be permitted to

move. It may be necessary to block the crankshaft to

prevent rotation.

(3)

Hold a scale with dimensional reading even

with the edge of a chain link. With cylinder heads installed, apply 14 N*m (30 ft. lbs.) torque in the re

verse direction. With the cylinder heads removed, ap-

Page 636 of 1502

•

3.9L

ENGINE

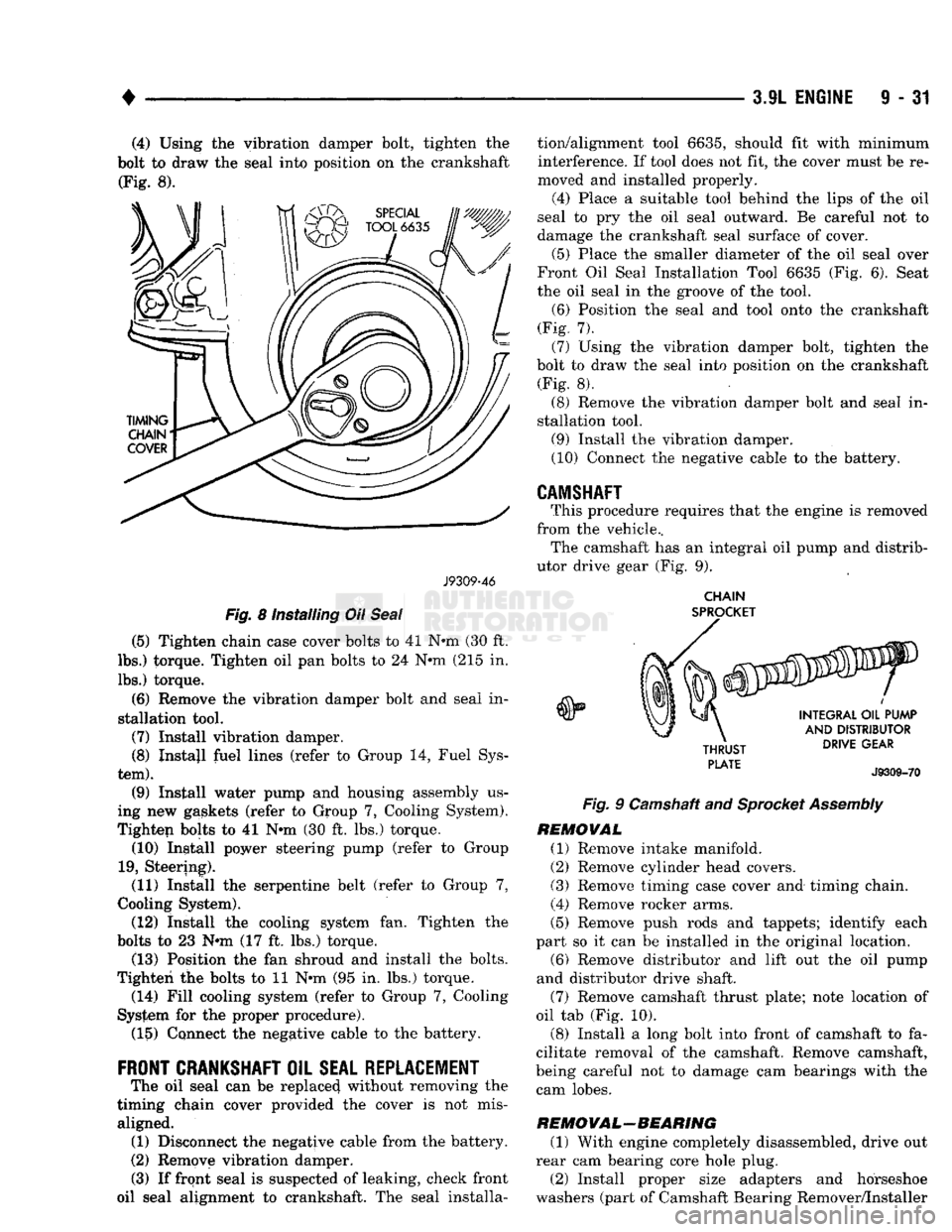

9 - 31 (4) Using the vibration damper bolt, tighten the

bolt to draw the seal into position on the crankshaft (Fig. 8).

J9309-46

Fig.

8 installing Oil

Seal

(5) Tighten chain case cover bolts to 41 N-m (30 ft.

lbs.) torque. Tighten oil pan bolts to 24 N*m (215 in.

lbs.) torque.

(6) Remove the vibration damper bolt and seal in

stallation tool.

(7) Install vibration damper. (8) Instajl fuel lines (refer to Group 14, Fuel Sys

tem).

(9) Install water pump and housing assembly us

ing new gaskets (refer to Group 7, Cooling System).

Tighten bolts to 41 N-m (30 ft. lbs.) torque. (10) Install power steering pump (refer to Group

19,

Steering). (11) Install the serpentine belt (refer to Group 7,

Cooling System). (12) Install the cooling system fan. Tighten the

bolts to 23 N-m (17 ft. lbs.) torque. (13) Position the fan shroud and install the bolts.

Tighten the bolts to 11 N-m (95 in. lbs.) torque. (14) Fill cooling system (refer to Group 7, Cooling

System for the proper procedure). (15) Connect the negative cable to the battery.

FRONT

CRANKSHAFT

OIL

SEAL REPLACEMENT

The oil seal can be replaced without removing the

timing chain cover provided the cover is not mis aligned. (1) Disconnect the negative cable from the battery.

(2) Remove vibration damper.

(3) If front seal is suspected of leaking, check front

oil seal alignment to crankshaft. The seal installa tion/alignment tool 6635, should fit with minimum

interference. If tool does not fit, the cover must be re

moved and installed properly.

(4)

Place a suitable tool behind the lips of the oil

seal to pry the oil seal outward. Be careful not to

damage the crankshaft seal surface of cover.

(5) Place the smaller diameter of the oil seal over

Front Oil Seal Installation Tool 6635 (Fig. 6). Seat

the oil seal in the groove of the tool.

(6) Position the seal and tool onto the crankshaft

(Fig. 7). (7) Using the vibration damper bolt, tighten the

bolt to draw the seal into position on the crankshaft (Fig. 8).

(8) Remove the vibration damper bolt and seal in

stallation tool. (9) Install the vibration damper.

(10) Connect the negative cable to the battery.

CAMSHAFT

This procedure requires that the engine is removed

from the vehicle.. The camshaft has an integral oil pump and distrib

utor drive gear (Fig. 9).

CHAIN

SPROCKET

Fig.

9 Camshaft and

Sprocket

Assembly

REMOVAL

(1) Remove intake manifold.

(2) Remove cylinder head covers. (3) Remove timing case cover and timing chain.

(4) Remove rocker arms.

(5) Remove push rods and tappets; identify each

part so it can be installed in the original location. (6) Remove distributor and lift out the oil pump

and distributor drive shaft.

(7) Remove camshaft thrust plate; note location of

oil tab (Fig. 10).

(8) Install a long bolt into front of camshaft to fa

cilitate removal of the camshaft. Remove camshaft,

being careful not to damage cam bearings with the cam lobes.

RE

MO

VAL-BEA RING

(1) With engine completely disassembled, drive out

rear cam bearing core hole plug.

(2) Install proper size adapters and horseshoe

washers (part of Camshaft Bearing Remover/Installer

Page 652 of 1502

5.2L

ENGINE

9 - 47

S.2L ENGINE

SERVICE

PROCEDURES

INDEX

page

Camshaft

. , . 61

Crankshaft

68

Crankshaft Main Bearings

69

Crankshaft Rear

Oil

Seals

...... ........

70

Cylinder Block ...........................

71

Cylinder Head Cover

. . . . 51

Cylinder Heads

52

Distributor

62

Engine

Assembly

. 50

Engine

Front Mounts

47

Engine

Rear Mount ...............

48

Front Crankshaft

Oil

Seal Replacement

. . 61

GENERAL

INFORMATION

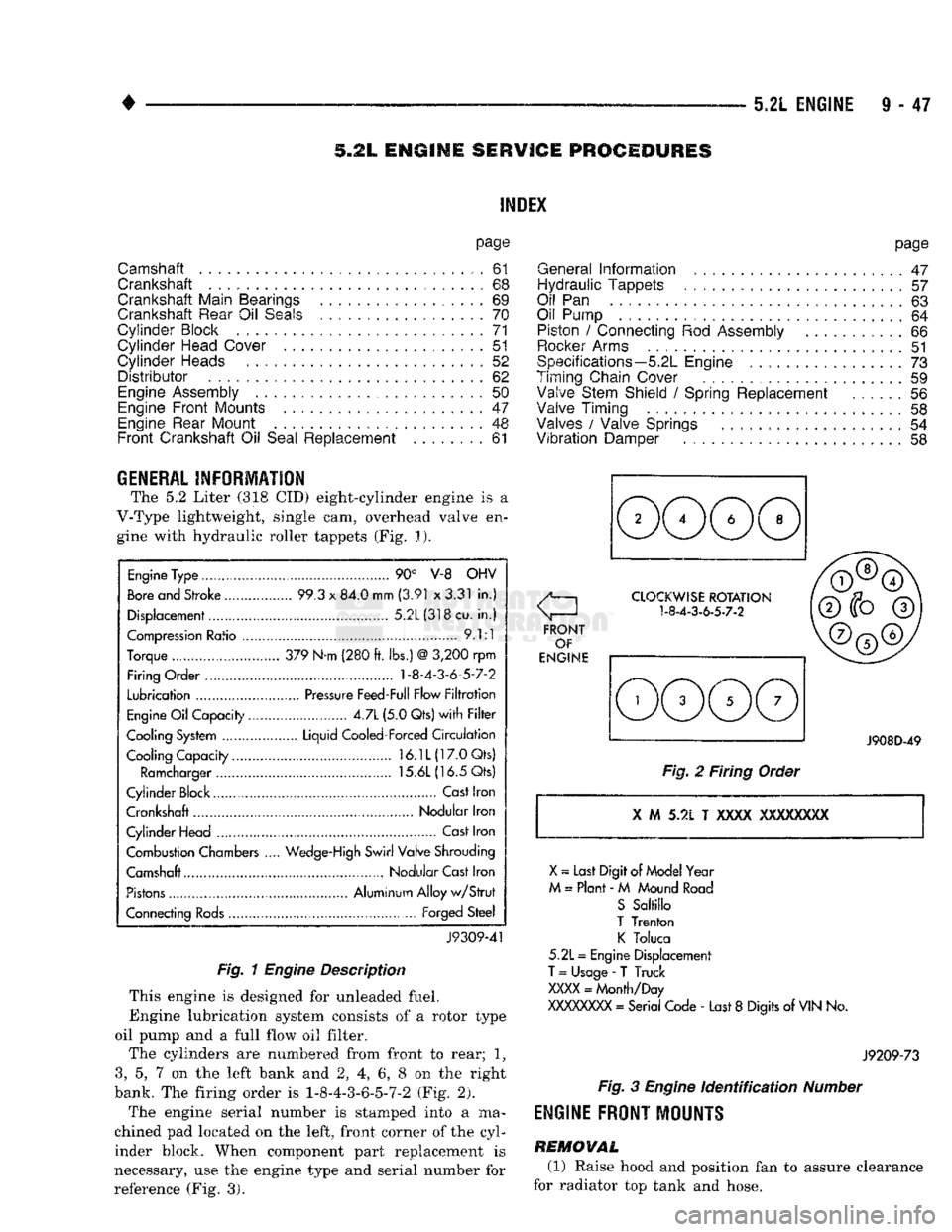

The 5.2 Liter (318 CID) eight-cylinder engine is a

V-Type lightweight, single cam, overhead valve en gine with hydraulic roller tappets (Fig. J).

Engine

Type ....

90° V-8 OHV

Bore

and Stroke .....

99.3

x

84.0 mm

(3.91

x

3.31

in.)

Displacement................

5.2L(318cu.

in.)

Compression

Ratio ....... .

9.1:1

Torque .. 379 N-m (280

ft.

lbs.)

@

3,200

rpm

Firing Order .... 1-8-4-3-6-5-7-2

Lubrication

.......

Pressure

Feed-Full Flow

Filtration

Engine

Oil

Capacity......

4.7L

(5.0 Qts)

with Filter

Cooling System ...... Liquid Cooled-Forced

Circulation

Cooling Capacity..........

16.1L(17.0Qts)

Ramcharger

15.6L

(16.5 Qts)

Cylinder Block

,

Cast

Iron

Crankshaft Nodular Iron

Cylinder Head ..............

Cast

Iron

Combustion Chambers

..

Wedge-High

Swirl Valve Shrouding

Camshaft Nodular Cast Iron

Pistons

Aluminum Alloy

w/Strut

Connecting

Rods...........

Forged

Steel

J9309-41

Fig. 1

Engine

Description

This engine is designed for unleaded fuel.

Engine lubrication system consists of a rotor type

oil pump and a full flow oil filter.

The cylinders are numbered from front to rear; 1?

3,

5, 7 on the left bank and 2, 4, 6, 8 on the right

bank. The firing order is 1-8-4-3-6-5-7-2 (Fig. 2).

The engine serial number is stamped into a ma

chined pad located on the left, front corner of the cyl

inder block. When component part replacement is

necessary, use the engine type and serial number for

reference (Fig. 3).

page

General

Information

.......................

47

Hydraulic Tappets

57

Oil

Pan . 63

Oil Pump

. 64

Piston

/

Connecting

Rod

Assembly

66

Rocker

Arms

51

Specifications—5.2L Engine

73

Timing Chain Cover ................

59

Valve Stem Shield

/

Spring Replacement

56

Valve Timing

. 58

Valves

/

Valve Springs

54

Vibration

Damper

. . 58

J908D-49

Fig.

2 Firing Order

X

M 5.2L T

XXXX

XXXXXXXX

X

~

Last Digit of

Model

Year

M

=

Plant

- M

Mound

Road

S

Saltillo

T

Trenton

K

Toluca

5.2L

=

Engine Displacement

T

=

Usage

-

T Truck

XXXX

=

Month/Day

XXXXXXXX

=

Serial Code

-

Last

8

Digits

of

VIN

No.

J9209-73

Fig.

3

Engine

Identification

Number

ENGINE

FRONT

MOUNTS

REMOVAL

(1) Raise hood and position fan to assure clearance

for radiator top tank and hose.

Page 664 of 1502

•

5.2L

ENGINE

9 - 59

INSTALLATION

(1) Position the vibration damper onto the crank

shaft. (2) Place installing tool, part of Puller Tool Set

C-3688 in position and press the vibration damper

onto the crankshaft (Fig. 2).

Fig.

2 Installing

Vibration

Damper

(3) Install the crankshaft bolt and washer. Tighten

the bolt to 183 N*m (135 ft. lbs.) torque.

(4) Install the crankshaft pulley. Tighten the pul

ley bolts to 23 Nin (200 in. lbs.) torque.

(5) Install the serpentine belt (refer to Group 7,

Cooling System).

(6) Install the cooling system fan. Tighten the

bolts to 23 N*m (17 ft. lbs.) torque.

(7) Position the fan shroud and install the bolts.

Tighten the retainer bolts to 11 N»m (95 in. lbs.)

torque.

(8) Connect the negative cable to the battery.

TIMING

CHAIN

COVER

REMOVAL (1) Disconnect the negative cable from the battery.

(2) Drain cooling system (refer to Group 7, Cooling

System).

(3) Remove the serpentine belt (refer to Group 7,

Cooling System).

(4) Remove water pump (refer to Group 7, Cooling

System).

(5) Remove power steering pump (refer to Group

19,

Steering). (6) Remove vibration damper.

(7) Remove fuel lines (refer to Group 14, Fuel Sys

tem).

(8) Loosen oil pan bolts and remove the front bolt

at each side.

(9) Remove the cover bolts.

(10) Remove chain case cover and gasket using ex

treme caution to avoid damaging oil pan gasket.

(11) Place a suitable tool behind the lips of the oil

seal to pry the oil seal outward. Be careful not to

damage the crankshaft seal surface of cover (Fig. 3).

Fig.

3

Removal

of Front Crankshaft Oil

Seal

TIMING

CHAIN

STRETCH

(1) Place a scale next to the timing chain so that

any movement of the chain may be measured.

(2) Place a torque wrench and socket over cam

shaft sprocket attaching bolt. Apply torque in the di

rection of crankshaft rotation to take up slack; 41

N»m (30 ft. lbs.) torque with cylinder head installed

or 20 N»m (15 ft. lbs.) torque with cylinder head re

moved. With a torque applied to the camshaft sprocket bolt, crankshaft should not be permitted to

move. It may be necessary to block the crankshaft to

prevent rotation.

(3) Hold a scale with dimensional reading even

with the edge of a chain link. With cylinder heads installed, apply 14 Nnn (30 ft. lbs.) torque in the re

verse direction. With the cylinder heads removed, ap

ply 20 N»m (15 ft. lbs.) torque in the reverse direction. Note the amount of chain movement (Fig.

4).

Fig.

4

Measuring

Timing

Chain

Wear and Stretch

(4) Install a new timing chain, if its movement ex

ceeds 3.175 mm (1/8 inch). (5) If chain is not satisfactory, remove camshaft

sprocket attaching bolt and remove timing chain

with crankshaft and camshaft sprockets.

(6) Place both camshaft sprocket and crankshaft

sprocket on the bench with timing marks on exact

imaginary center line through both camshaft and

crankshaft bores.

(7) Place timing chain around both sprockets.

Page 665 of 1502

9

- 60 5.2L

ENGINE

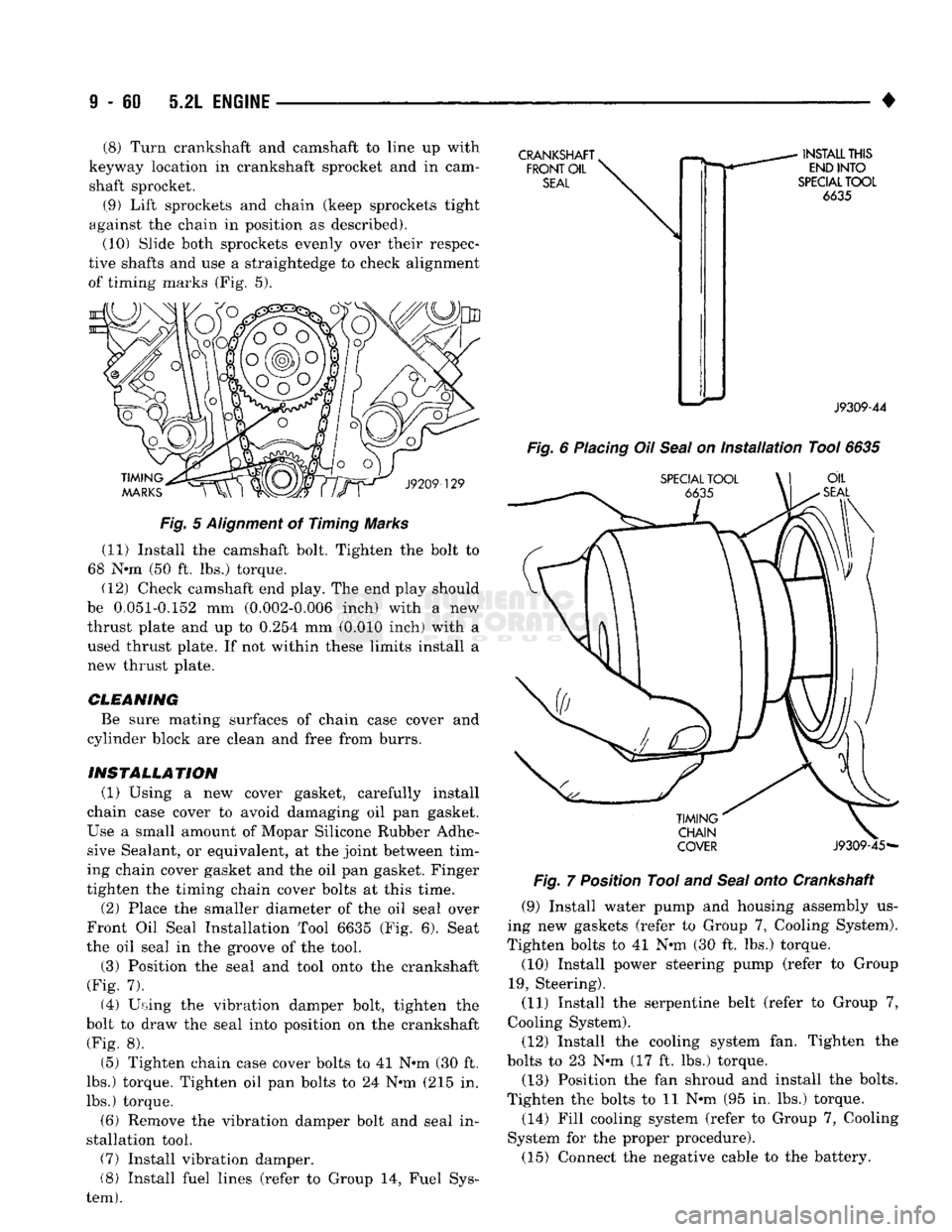

(8) Turn crankshaft and camshaft to line up with

keyway location in crankshaft sprocket and in cam shaft sprocket.

(9) Lift sprockets and chain (keep sprockets tight

against the chain in position as described). (10) Slide both sprockets evenly over their respec

tive shafts and use a straightedge to check alignment

of timing marks (Fig. 5).

TIMING

MARKS

J9209-129

Fig.

5

Alignment

of Timing Marks (11) Install the camshaft bolt. Tighten the bolt to

68 Nnn (50 ft. lbs.) torque. (12) Check camshaft end play. The end play should

be 0.051-0.152 mm (0.002-0.006 inch) with a new

thrust plate and up to 0.254 mm (0.010 inch) with a used thrust plate. If not within these limits install a

new thrust plate.

CLEANING Be sure mating surfaces of chain case cover and

cylinder block are clean and free from burrs.

INSTALLATION (1) Using a new cover gasket, carefully install

chain case cover to avoid damaging oil pan gasket.

Use a small amount of Mopar Silicone Rubber Adhe sive Sealant, or equivalent, at the joint between tim

ing chain cover gasket and the oil pan gasket. Finger

tighten the timing chain cover bolts at this time.

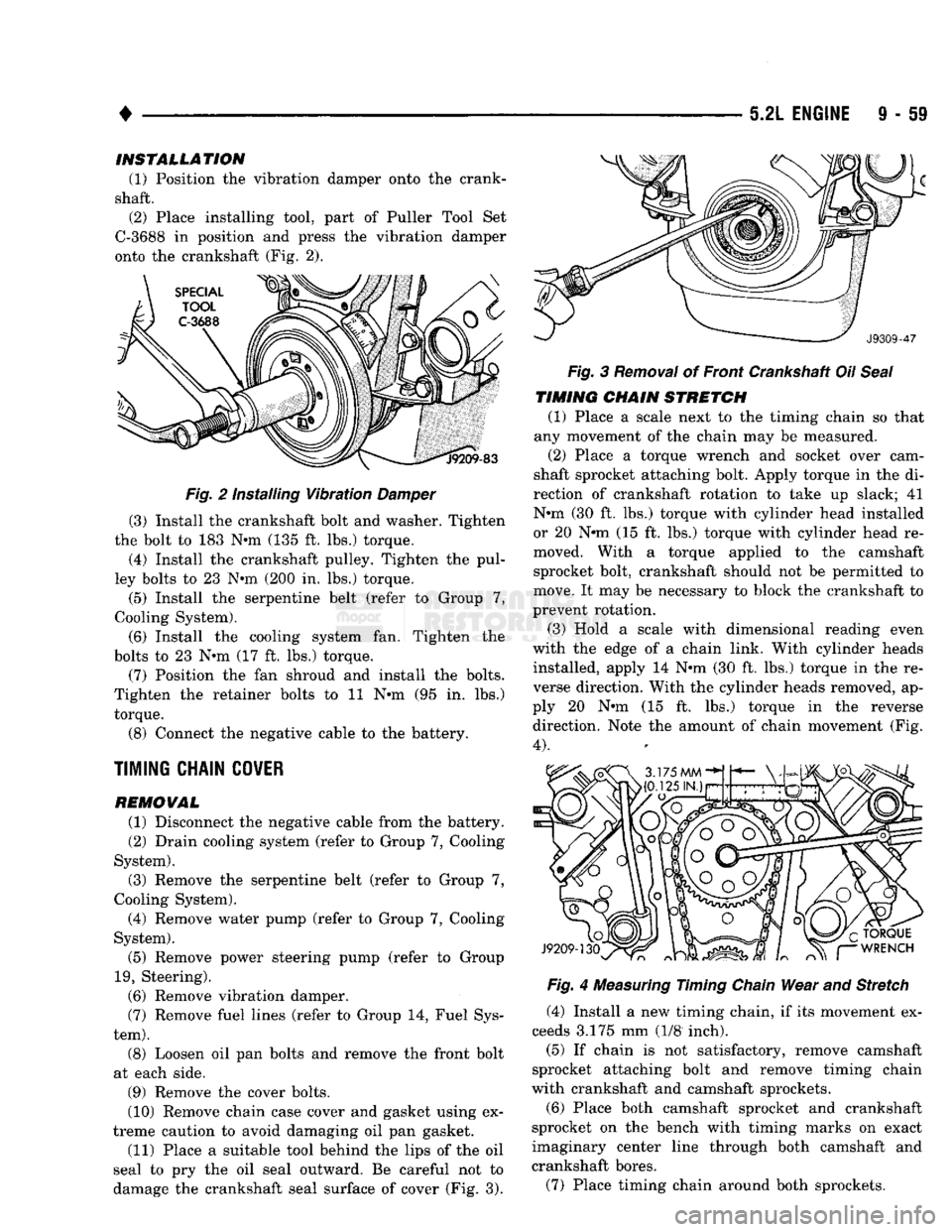

(2) Place the smaller diameter of the oil seal over

Front Oil Seal Installation Tool 6635 (Fig. 6). Seat

the oil seal in the groove of the tool.

(3) Position the seal and tool onto the crankshaft

(Fig. 7). (4) Using the vibration damper bolt, tighten the

bolt to draw the seal into position on the crankshaft (Fig. 8).

(5) Tighten chain case cover bolts to 41 Nnn (30 ft.

lbs.) torque. Tighten oil pan bolts to 24 Nnn (215 in.

lbs.) torque.

(6) Remove the vibration damper bolt and seal in

stallation tool. (7) Install vibration damper.

(8) Install fuel lines (refer to Group 14, Fuel Sys

tem).

CRANKSHAFT

k

FRONT

OIL

SEAL

INSTALL

THIS

END

INTO

SPECIAL

TOOL

6635

J9309-44

Fig.

6

Placing

Oil

Seal

on

Installation

Tool

6635

SPECIAL

TOOL

\ | OIL

SEAL

TIMING

CHAIN

COVER

J9309-45*-

Fig.

7 Position Tool and

Seal

onto Crankshaft

(9) Install water pump and housing assembly us

ing new gaskets (refer to Group 7, Cooling System).

Tighten bolts to 41 Nnn (30 ft. lbs.) torque.

(10) Install power steering pump (refer to Group

19,

Steering).

(11) Install the serpentine belt (refer to Group 7,

Cooling System).

(12) Install the cooling system fan. Tighten the

bolts to 23 Nnn (17 ft. lbs.) torque. (13) Position the fan shroud and install the bolts.

Tighten the bolts to 11 Nnn (95 in. lbs.) torque.

(14) Fill cooling system (refer to Group 7, Cooling

System for the proper procedure).

(15) Connect the negative cable to the battery.

Page 682 of 1502

5.9L

ENGINE SERVICE PROCEDURES

INDEX

page

Camshaft

91

Crankshaft

98

Crankshaft Main Bearings

99

Crankshaft Rear

Oil

Seals

100

Cylinder

Block

101

Cylinder

Head Cover

81

Cylinder

Heads

82

Distributor

92

Engine Assembly

80

Engine

Front

Mounts

77

Engine Rear Mount

78

Front

Crankshaft

Oil

Seal Replacement

91

page

General

Information

77

Hydraulic

Tappets

87

Oil

Pan 93

Oil Pump

. 94

Piston

/

Connecting

Rod

Assembly

96

Rocker Arms

81

Specifications—5.9L

Engine

103

Timing

Chain Cover

89

Valve Stem Shield

/

Spring Replacement

86

Valve

Timing

. 88

Valves

/

Valve Springs

84

Vibration

Damper

88

GENERAL

INFORMATION

The 5.9 Liter (360 CID) eight-cylinder engine is a

V-Type lightweight, single cam, overhead valve en

gine with hydraulic roller tappets (Fig. 1).

Engine Type .90° V-8 OHV

Bore and Stroke 101.6 x 90.9

mm

(4.00 x 3.58 in.)

Displacement 5.9L (360 cu. in.)

Compression Ratio 9.1:1

Torque 441 N-m (325 ft. lbs.) @ 3,200 rpm (Heavy Duty). 448 N-m (330 ft. lbs.)

@

2,800 rpm

Firing Order

1-8-4-3-6-5-7-2

Lubrication ...... Pressure Feed - Full Flow Filtration

Engine Oil Capacity .4.7L (5.0 Qts) w/filter

Cooling System . .

.

Liquid Cooled - Forced Circulation Cooling Capacity ..... . . 14.7L (15.5 Qts)

Ramcharger (4WD) 14.2L (15.0 Qts)

Cylinder Block Cast Iron Crankshaft

-

Nodular Iron

Cylinder Head • . Cast Iron Combustion Chambers Wedge-High Swirl Valve

Shrouding

Camshaft Nodular Cast Iron Pistons Cast Aluminum Alloy

Connecting Rods Forged Steel

J9309-99

Fig. 1

Engine

Description

This engine is designed for unleaded fuel.

Engine lubrication system consists of a rotor type

oil pump and a full flow oil filter.

The cylinders are numbered from front to rear; 1,

3,

5, 7 on the left bank and 2, 4, 6, 8 on the right

bank. The firing order is

1-8-4-3-6-5-7-2

(Fig. 2).

The engine serial number is stamped into a ma

chined pad located on the left, front corner of the cyl

inder block. When component part replacement is

necessary, use the engine type and serial number for

reference (Fig. 3).

o

FRONT OF

ENGINE CLOCKWISE ROTATION

1-8-4-3-6-5-7-2

J908D-49

Fig. 2 Firing Order

X

M 5.9L T

XXXX

XXXXXXXX

X

= Last Digit of Model Year

M = Plant - M Mound Road S Saltillo

T Trenton K Toluca

5.9L = Engine Displacement

T

= Usage -

T

Truck

XXXX

= Month/Day

XXXXXXXX

= Serial Code - Last 8 Digits of

VIN

No.

J9209-74

Fig.

3

Engine

identification

Number

ENGINE

FRONT MOUNTS

REMOVAL (1) Raise hood and position fan to assure clearance

for radiator top tank and hose.

Page 694 of 1502

•

5.9L

ENGINE

9 - 89

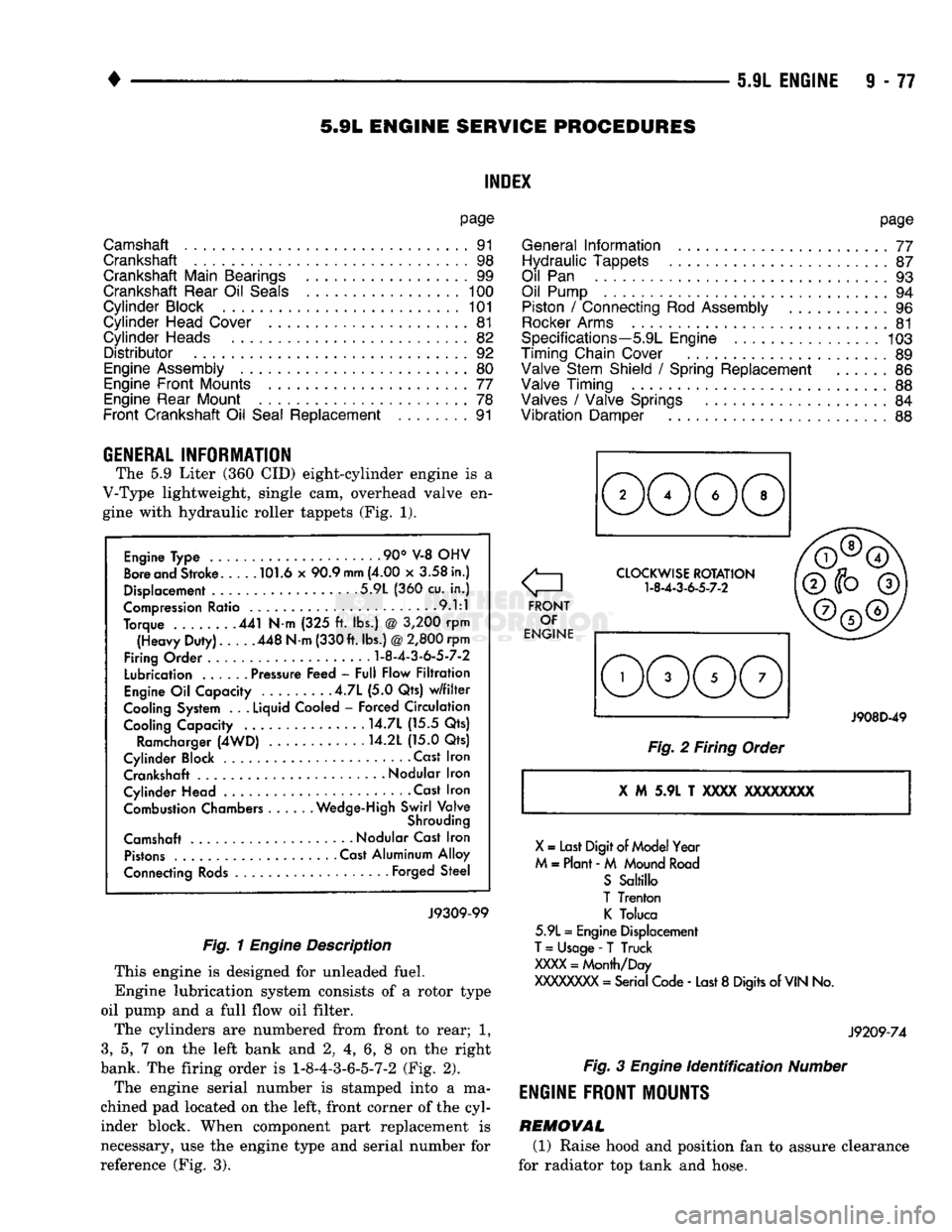

(2) Place installing tool, part of Puller Tool Set

C-3688 in position and press the vibration damper

onto the crankshaft (Fig. 2).

Fig. 2 Installing Vibration Damper (3) Install the crankshaft bolt and washer. Tighten

the bolt to 183 N-m (135 ft. lbs.) torque.

(4) Install the crankshaft pulley. Tighten the pul

ley bolts to 23 N-m (200 In. lbs.) torque.

(5) Install the serpentine belt (refer to Group 7,

Cooling System). (6) Install the cooling system fan. Tighten the

bolts to 23 N-m (17 ft. lbs.) torque.

(7) Position the fan shroud and install the bolts.

Tighten the retainer bolts to 11 N-m (95 in. lbs.)

torque.

(8) Connect the negative cable to the battery.

TIMING CHAIN COWER

REMOVAL

(1) Disconnect the negative cable from the battery.

(2) Drain cooling system (refer to Group 7, Cooling

System).

(3) Remove the serpentine belt (refer to Group 7,

Cooling System). (4) Remove water pump (refer to Group 7, Cooling

System).

(5) Remove power steering pump (refer to Group

19,

Steering). (6) Remove vibration damper.

(7) Remove fuel lines (refer to Group 14, Fuel Sys

tem).

(8) Loosen oil pan bolts and remove the front bolt

at each side. (9) Remove the cover bolts.

(10) Remove chain case cover and gasket using ex

treme caution to avoid damaging oil pan gasket.

(11) Place a suitable tool behind the lips of the oil

seal to pry the oil seal outward. Be careful not to

damage the crankshaft seal surface of cover (Fig. 3).

TIMING

CHAIN

STRETCH

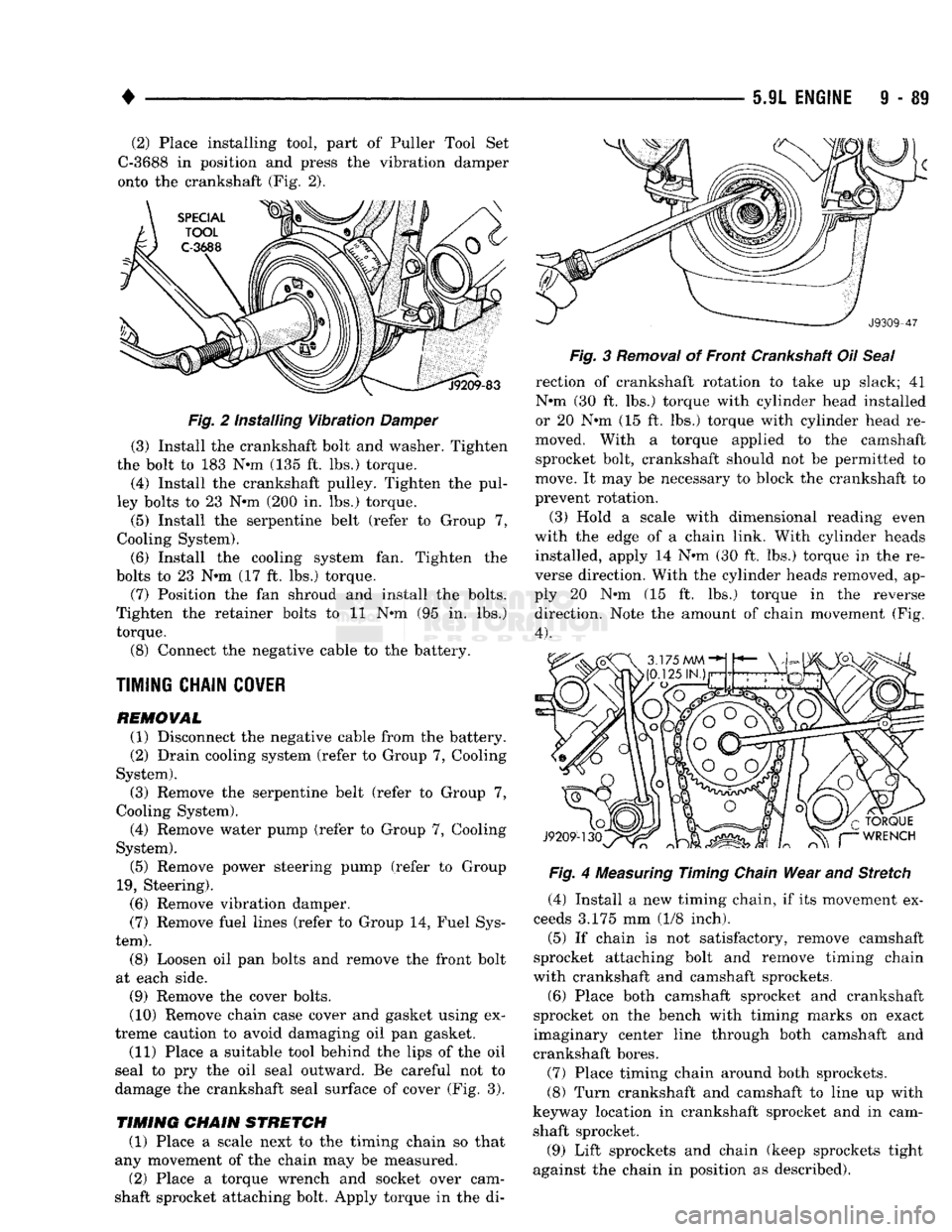

(1) Place a scale next to the timing chain so that

any movement of the chain may be measured.

(2) Place a torque wrench and socket over cam

shaft sprocket attaching bolt. Apply torque in the di- Fig. 3 Removal of Front Crankshaft Oil Seal

rection of crankshaft rotation to take up slack; 41

N-m (30 ft, lbs.) torque with cylinder head installed

or 20 N-m (15 ft. lbs.) torque with cylinder head re

moved. With a torque applied to the camshaft sprocket bolt, crankshaft should not be permitted to

move. It may be necessary to block the crankshaft to

prevent rotation.

(3) Hold a scale with dimensional reading even

with the edge of a chain link. With cylinder heads installed, apply 14 N-m (30 ft. lbs.) torque In the re

verse direction. With the cylinder heads removed, ap

ply 20 N-m (15 ft. lbs.) torque In the reverse direction. Note the amount of chain movement (Fig.

4).

Fig. 4 Measuring Timing Chain Wear and Stretch

(4) Install a new timing chain, if its movement ex

ceeds 3.175 mm (1/8 inch). (5) If chain is not satisfactory, remove camshaft

sprocket attaching bolt and remove timing chain

with crankshaft and camshaft sprockets,

(6) Place both camshaft sprocket and crankshaft

sprocket on the bench with timing marks on exact

imaginary center line through both camshaft and

crankshaft bores.

(7) Place timing chain around both sprockets.

(8) Turn crankshaft and camshaft to line up with

keyway location in crankshaft sprocket and in cam

shaft sprocket.

(9) Lift sprockets and chain (keep sprockets tight

against the chain in position as described).