width DODGE TRUCK 1993 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 9 of 1502

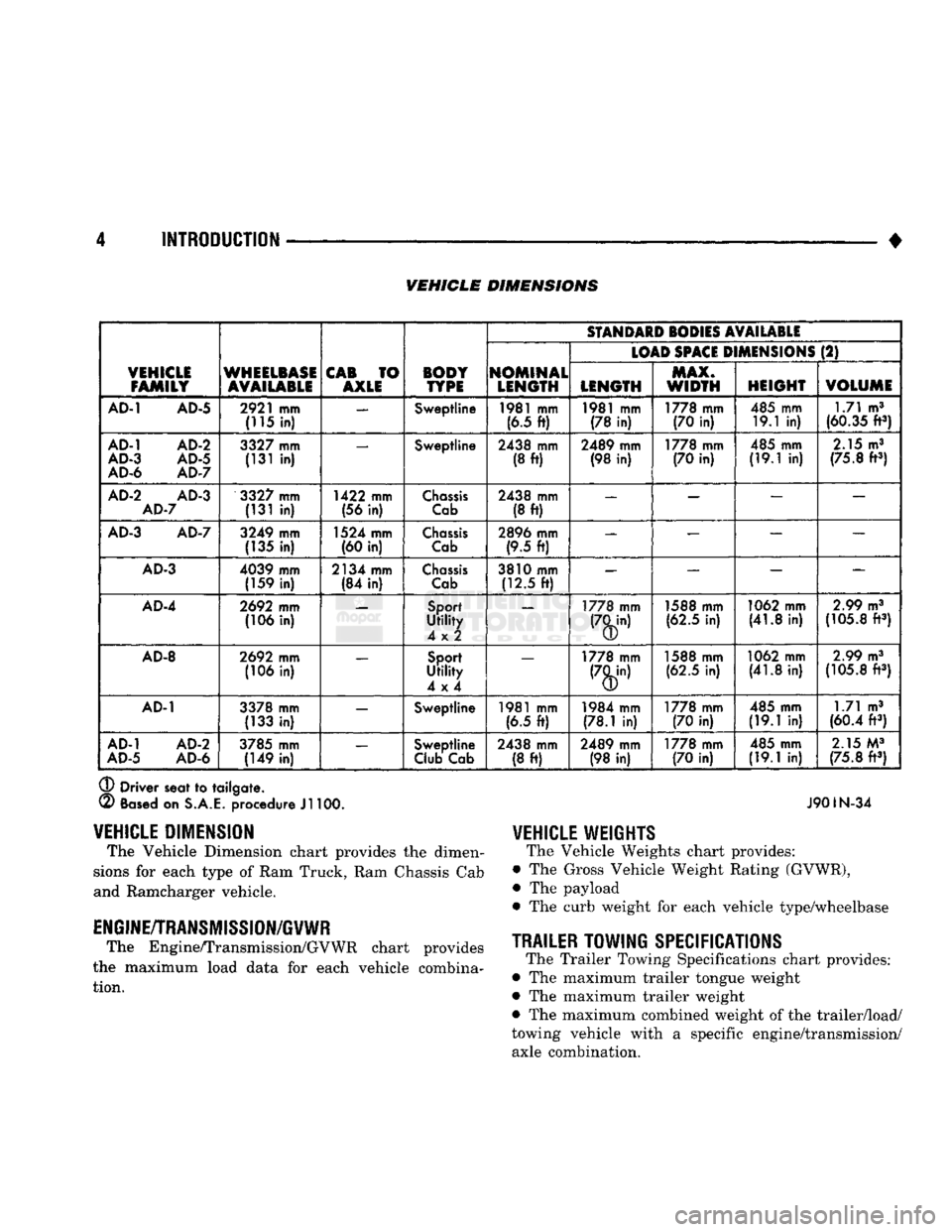

4 INTRODUCTION

• VEHICLE DIMENSIONS

VEHICLE

FAMILY

WHEELBASE

AVAILABLE

CAB

TO

AXLE BODY

TYPE

SfANDAID

SODIES

AVAILABLE

VEHICLE

FAMILY

WHEELBASE

AVAILABLE

CAB

TO

AXLE BODY

TYPE

NOMINAL

LENGTH

(LOAD

SPACE

D

MENSIONS

(2)

VEHICLE

FAMILY

WHEELBASE

AVAILABLE

CAB

TO

AXLE BODY

TYPE

NOMINAL

LENGTH LENGTH MAX.

WIDTH

HEIGHT

VOLUME

AD-1

AD-5

2921

mm

(115

in) —

Sweptline

1981

mm

(6.5

ft)

1981

mm

(78

in)

1778 mm

(70

in)

485 mm

19.1

in) 1.71 m3

(60.35

ft3)

AD-1

AD-2

AD-3

AD-5

AD-6

AD-7

3327

mm

(131

in) —

Sweptline

2438 mm

(8

ft)

2489 mm

(98

in)

1778 mm

(70

in)

485 mm

(19.1

in)

2.15

m3

(75.8

ft3)

AD-2

AD-3

AD-7

3327

mm

(131

in)

1422 mm

(56

in)

Chassis

Cab

2438 mm

(8

ft)

—

— — —

AD-3

AD-7

3249 mm

(135

in)

1524 mm

(60

in)

Chassis

Cab

2896 mm

(9.5

ft) —

— — —

AD-3

4039 mm

(159

in)

2134 mm

(84

in)

Chassis

Cab

3810 mm

(12.5

ft)

—

— —

AD-4

2692

mm

(106

in)

Sport

Utility

4x2

—

1778 mm 1588 mm

(62.5

in)

1062 mm

(41.8

in)

2.99

m3

(105.8

ft3)

AD-8

2692

mm

(106

in)

Sport

Utility

4x4

—

1778 mm 1588 mm

(62.5

in)

1062 mm

(41.8

in)

2.99

m3

(105.8

ft3)

AD-1

3378 mm

(133

in) —

Sweptline

1981

mm

(6.5

ft)

1984 mm

(78.1

in)

1778 mm

(70

in)

485 mm

(19.1

in) 1.71 m3

(60.4

ft3)

AD-1

AD-2

AD-5

AD-6

3785 mm

(149

in) —

Sweptline

Club

Cab 2438 mm

(8

ft)

2489 mm

(98

in)

1778 mm

(70

in)

485 mm

(19.1

in)

2.15

M3

(75.8

ft3)

®

Driver seat

to

tailgate.

(2)

Based

on

S.A.E.

procedure

Jl

100. J901N-34

VEHICLE

WEIGHTS

The Vehicle Weights chart provides:

• The Gross Vehicle Weight Rating (GVWR),

• The payload

• The curb weight

for

each vehicle type/wheelbase

TRAILER

TOWING

SPECIFICATIONS

The Trailer Towing Specifications chart provides:

• The maximum trailer tongue weight

• The maximum trailer weight

• The maximum combined weight of the trailer/load/

towing vehicle with

a

specific engine/transmission/ axle combination.

VEHICLE

DIMENSION

The Vehicle Dimension chart provides

the

dimen

sions

for

each type

of

Ram Truck, Ram Chassis Cab

and Ramcharger vehicle.

ENGINE/TRANSMISSION/GVWR

The Engine/Transmission/GVWR chart provides

the maximum load data

for

each vehicle combina tion.

Page 234 of 1502

BRAKES

5 - 47

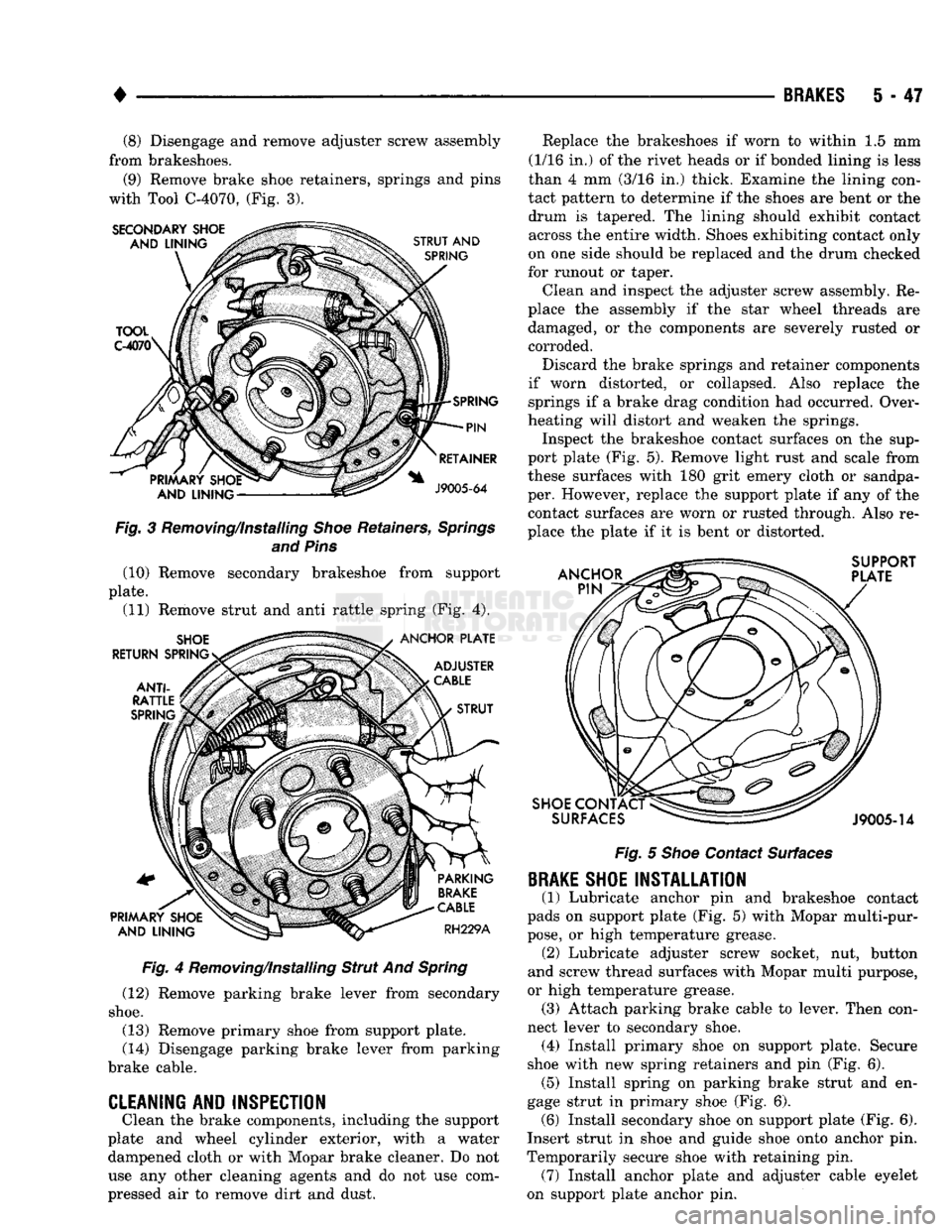

(8) Disengage and remove adjuster screw assembly

from brakeshoes.

(9) Remove brake shoe retainers, springs and pins

with Tool C-4070, (Fig. 3). Fig. 3 Removing/Installing Shoe Retainers, Springs

and Pins (10) Remove secondary brakeshoe from support

plate. (11) Remove strut and anti rattle spring (Fig. 4).

Fig. 4 Removing/Installing Strut And Spring

(12) Remove parking brake lever from secondary

shoe.

(13) Remove primary shoe from support plate.

(14) Disengage parking brake lever from parking

brake cable.

CLEANING AND INSPECTION

Clean the brake components, including the support

plate and wheel cylinder exterior, with a water dampened cloth or with Mopar brake cleaner. Do not

use any other cleaning agents and do not use com

pressed air to remove dirt and dust. Replace the brakeshoes if worn to within 1.5 mm

(1/16 in.) of the rivet heads or if bonded lining is less

than 4 mm (3/16 in.) thick. Examine the lining con

tact pattern to determine if the shoes are bent or the drum is tapered. The lining should exhibit contact across the entire width. Shoes exhibiting contact only

on one side should be replaced and the drum checked

for runout or taper.

Clean and inspect the adjuster screw assembly. Re

place the assembly if the star wheel threads are damaged, or the components are severely rusted or corroded.

Discard the brake springs and retainer components

if worn distorted, or collapsed. Also replace the springs if a brake drag condition had occurred. Over

heating will distort and weaken the springs. Inspect the brakeshoe contact surfaces on the sup

port plate (Fig. 5). Remove light rust and scale from

these surfaces with 180 grit emery cloth or sandpa

per. However, replace the support plate if any of the contact surfaces are worn or rusted through. Also re

place the plate if it is bent or distorted.

Fig. 5 Shoe Contact Surfaces

BRAKE

SHOE INSTALLATION

(1) Lubricate anchor pin and brakeshoe contact

pads on support plate (Fig. 5) with Mopar multi-pur

pose,

or high temperature grease. (2) Lubricate adjuster screw socket, nut, button

and screw thread surfaces with Mopar multi purpose,

or high temperature grease. (3) Attach parking brake cable to lever. Then con

nect lever to secondary shoe. (4) Install primary shoe on support plate. Secure

shoe with new spring retainers and pin (Fig. 6). (5) Install spring on parking brake strut and en

gage strut in primary shoe (Fig. 6). (6) Install secondary shoe on support plate (Fig. 6).

Insert strut in shoe and guide shoe onto anchor pin.

Temporarily secure shoe with retaining pin. (7) Install anchor plate and adjuster cable eyelet

on support plate anchor pin.

Page 239 of 1502

5

- 52

BRAKES

•

BRAKE

DRUM

REMOVAL

(1) Raise and support vehicle.

(2) Remove wheel and tire assembly.

(3) Remove axle shaft nuts, washers and cones.

Strike axle shaft in center with copper or dead blow

hammer to loosen retaining cones.

(4) Remove axle shaft.

(5) Remove outer hub nut.

(6)

Straighten and remove lock washer.

(7) Remove inner nut and bearing.

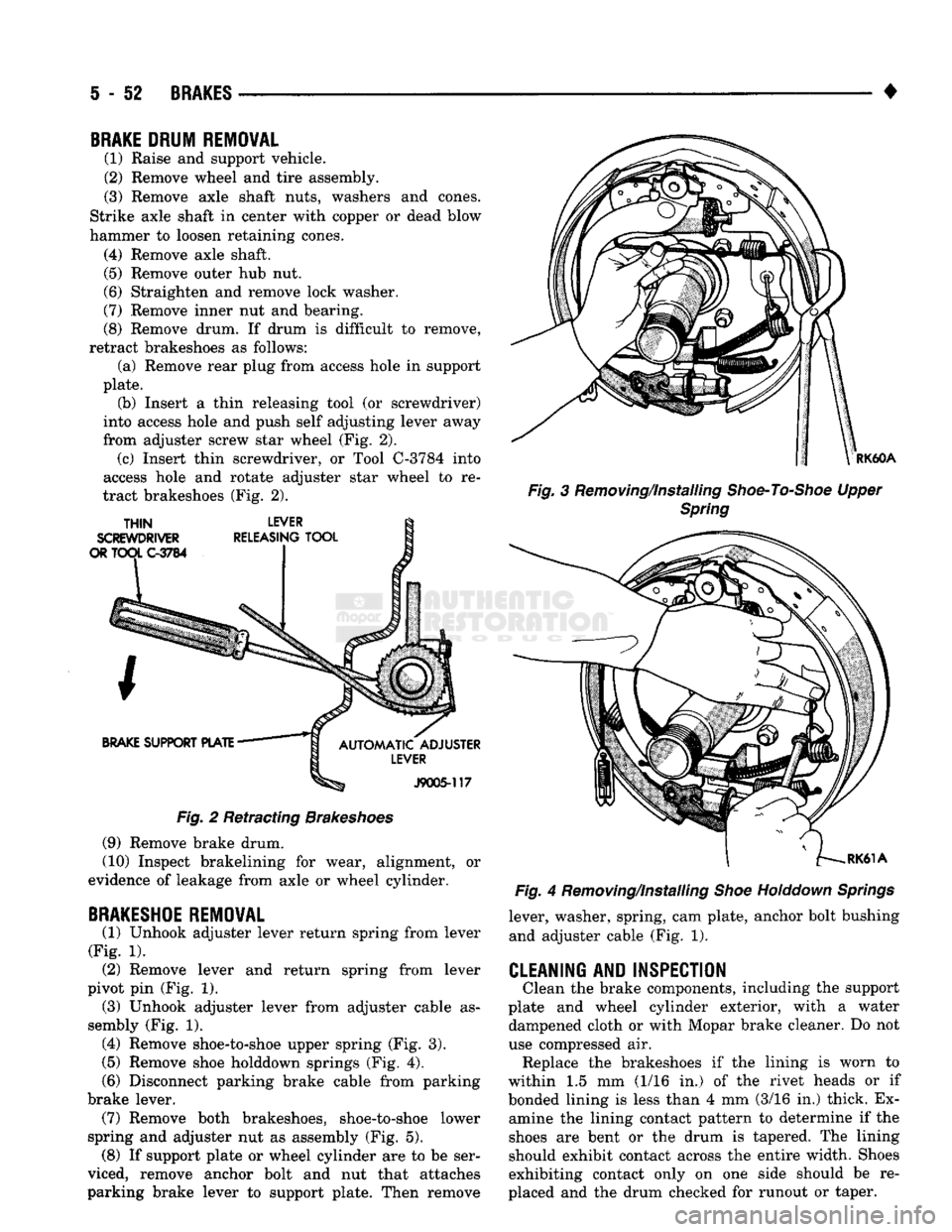

(8) Remove drum. If drum is difficult to remove,

retract brakeshoes as follows: (a) Remove rear plug from access hole in support

plate. (b) Insert a thin releasing tool (or screwdriver)

into access hole and push self adjusting lever away

from adjuster screw star wheel (Fig. 2). (c) Insert thin screwdriver, or Tool C-3784 into

access hole and rotate adjuster star wheel to re

tract brakeshoes (Fig. 2).

Fig.

2 Retracting

Brakeshoes

(9) Remove brake drum.

(10) Inspect brakelining for wear, alignment, or

evidence of leakage from axle or wheel cylinder.

BRAKESHOE

REMOVAL

(1) Unhook adjuster lever return spring from lever

(Fig. 1). (2) Remove lever and return spring from lever

pivot pin (Fig. 1). (3) Unhook adjuster lever from adjuster cable as

sembly (Fig. 1). (4) Remove shoe-to-shoe upper spring (Fig. 3).

(5)

Remove shoe holddown springs (Fig. 4).

(6)

Disconnect parking brake cable from parking

brake lever. (7) Remove both brakeshoes, shoe-to-shoe lower

spring and adjuster nut as assembly (Fig. 5). (8) If support plate or wheel cylinder are to be ser

viced, remove anchor bolt and nut that attaches

parking brake lever to support plate. Then remove

RK60A

Fig.

3 Removing/Installing

Shoe-To-Shoe

Upper

Spring

Fig.

4 Removing/Installing

Shoe

Holddown

Springs

lever, washer, spring, cam plate, anchor bolt bushing and adjuster cable (Fig. 1).

CLEANING AND INSPECTION

Clean the brake components, including the support

plate and wheel cylinder exterior, with a water dampened cloth or with Mopar brake cleaner. Do not

use compressed air. Replace the brakeshoes if the lining is worn to

within 1.5 mm (1/16 in.) of the rivet heads or if

bonded lining is less than 4 mm (3/16 in.) thick. Ex amine the lining contact pattern to determine if the

shoes are bent or the drum is tapered. The lining

should exhibit contact across the entire width. Shoes

exhibiting contact only on one side should be re

placed and the drum checked for runout or taper.

Page 316 of 1502

•

COOLING

SYSTEM

7 - 45 (3) Rotate socket/wrench counterclockwise. Install

belt over tensioner pulley. Let tensioner rotate back into place. Remove wrench. Be sure belt is properly

seated on all pulleys.

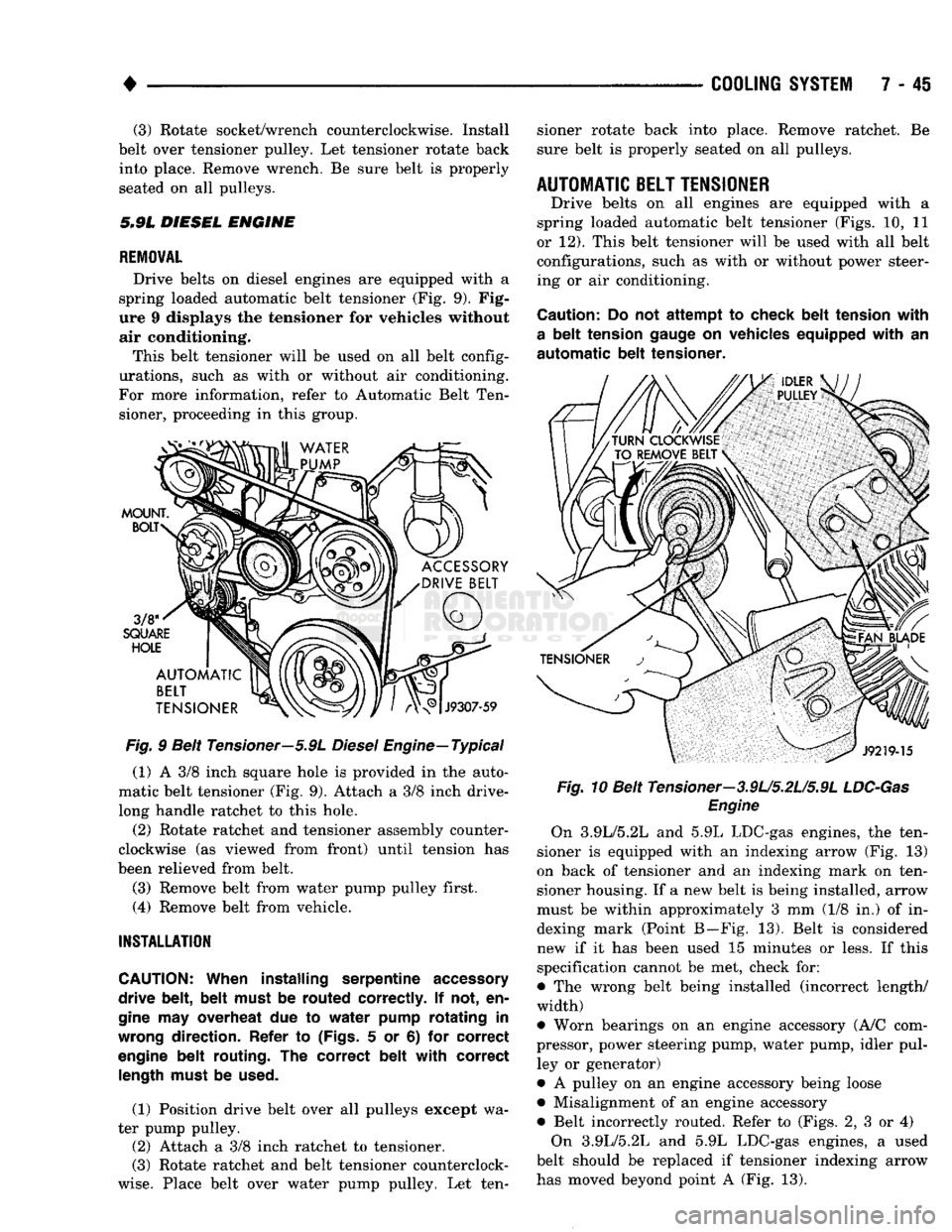

5«9L

DIESEL ENGINE

REMOVAL

Drive belts on diesel engines are equipped with a

spring loaded automatic belt tensioner (Fig. 9). Fig

ure 9 displays the tensioner for vehicles without air conditioning.

This belt tensioner will be used on all belt config

urations, such as with or without air conditioning.

For more information, refer to Automatic Belt Ten sioner, proceeding in this group.

Fig.

9 Belt Tensioner—5.9L

Diesel

Engine—Typical

(1) A 3/8 inch square hole is provided in the auto

matic belt tensioner (Fig. 9). Attach a 3/8 inch drive-

long handle ratchet to this hole.

(2) Rotate ratchet and tensioner assembly counter

clockwise (as viewed from front) until tension has

been relieved from belt.

(3) Remove belt from water pump pulley first.

(4) Remove belt from vehicle.

INSTALLATION

CAUTION:

When installing serpentine

accessory

drive belt, belt must

be

routed correctly.

If not, en

gine

may

overheat

due to

water pump rotating

in

wrong

direction. Refer

to

(Figs.

5 or 6) for

correct

engine

belt routing.

The

correct belt with correct

length

must

be

used.

(1) Position drive belt over all pulleys except wa

ter pump pulley. (2) Attach a 3/8 inch ratchet to tensioner.

(3) Rotate ratchet and belt tensioner counterclock

wise.

Place belt over water pump pulley. Let ten sioner rotate back into place. Remove ratchet. Be

sure belt is properly seated on all pulleys.

AUTOMATIC

BELT

TENSIONER

Drive belts on all engines are equipped with a

spring loaded automatic belt tensioner (Figs. 10, 11

or 12). This belt tensioner will be used with all belt configurations, such as with or without power steer

ing or air conditioning.

Caution:

Do not

attempt

to

check belt tension with

a

belt tension

gauge

on

vehicles equipped with

an

automatic

belt tensioner. Fig.

10 Belt Tensioner—3.9U5.2U5.9L

LDC-Gas

Engine

On 3.9L/5.2L and 5.9L LDC-gas engines, the ten

sioner is equipped with an indexing arrow (Fig. 13)

on back of tensioner and an indexing mark on ten

sioner housing. If a new belt is being installed, arrow

must be within approximately 3 mm (1/8 in.) of in dexing mark (Point B—Fig. 13). Belt is considered

new if it has been used 15 minutes or less. If this

specification cannot be met, check for:

• The wrong belt being installed (incorrect length/

width)

• Worn bearings on an engine accessory (A/C com

pressor, power steering pump, water pump, idler pul ley or generator)

• A pulley on an engine accessory being loose

• Misalignment of an engine accessory

• Belt incorrectly routed. Refer to (Figs. 2, 3 or 4) On 3.9L/5.2L and 5.9L LDC-gas engines, a used

belt should be replaced if tensioner indexing arrow

has moved beyond point A (Fig. 13).

Page 355 of 1502

8D

- 4

IGNITION

SYSTEMS

•

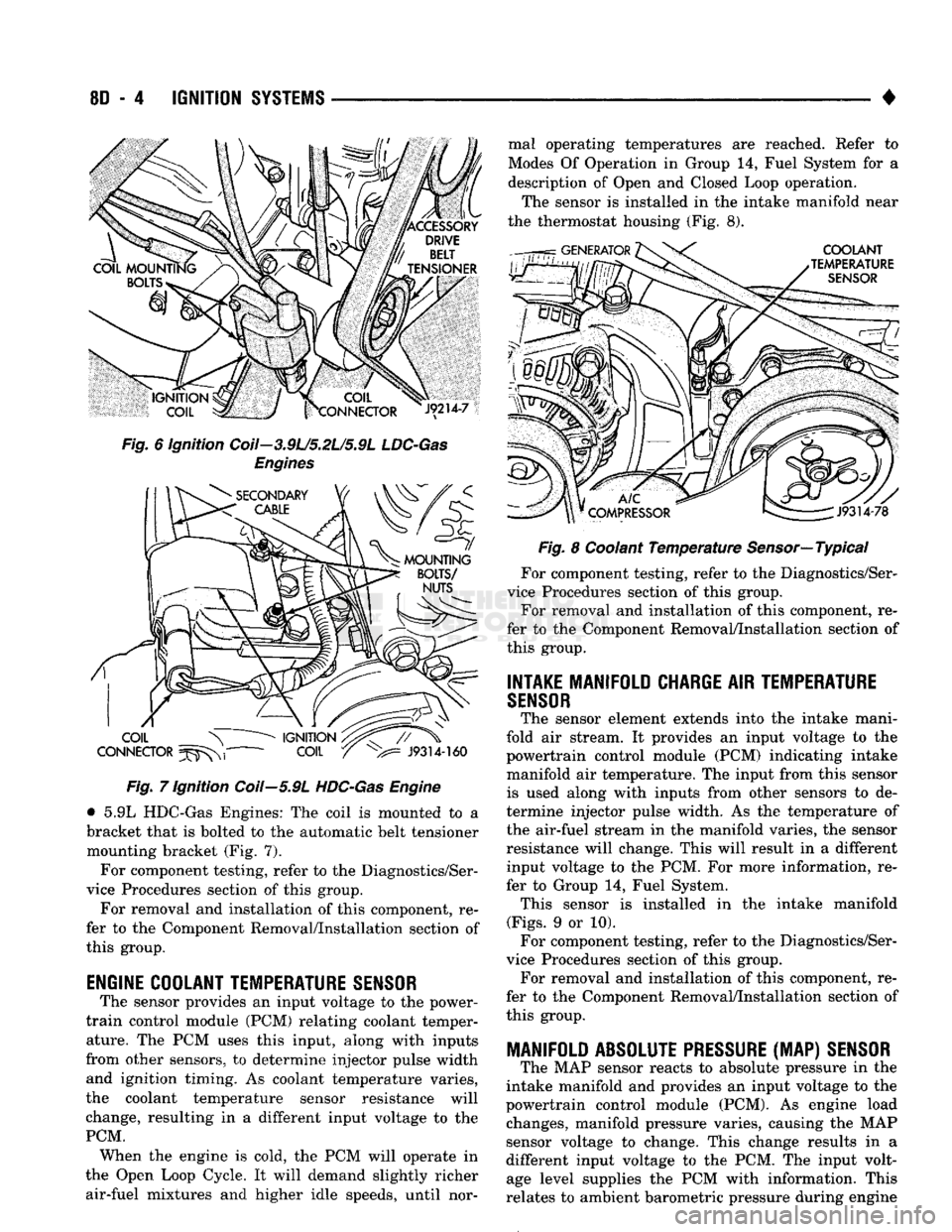

Fig. 6 ignition Coil—3.9L/5.2L/5.9L

LDC-Gas

Engines Fig. 7 Ignition Coil—5.9L

HDC-Gas

Engine

• 5.9L HDC-Gas Engines: The coil is mounted to a

bracket that is bolted to the automatic belt tensioner mounting bracket (Fig. 7).

For component testing, refer to the Diagnostics/Ser

vice Procedures section of this group.

For removal and installation of this component, re

fer to the Component Removal/Installation section of

this group.

ENGINE COOLANT TEMPERATURE

SENSOR

The sensor provides an input voltage to the power-

train control module (PCM) relating coolant temper ature. The PCM uses this input, along with inputs

from other sensors, to determine injector pulse width and ignition timing. As coolant temperature varies,

the coolant temperature sensor resistance will

change, resulting in a different input voltage to the

PCM. When the engine is cold, the PCM will operate in

the Open Loop Cycle. It will demand slightly richer air-fuel mixtures and higher idle speeds, until nor mal operating temperatures are reached. Refer to

Modes Of Operation in Group 14, Fuel System for a

description of Open and Closed Loop operation.

The sensor is installed in the intake manifold near

the thermostat housing (Fig. 8).

Fig. 8 Coolant Temperature Sensor—Typical

For component testing, refer to the Diagnostics/Ser

vice Procedures section of this group. For removal and installation of this component, re

fer to the Component Removal/Installation section of

this group.

INTAKE MANIFOLD CHARGE

AIR

TEMPERATURE

SENSOR

The sensor element extends into the intake mani

fold air stream. It provides an input voltage to the

powertrain control module (PCM) indicating intake

manifold air temperature. The input from this sensor is used along with inputs from other sensors to de

termine injector pulse width. As the temperature of

the air-fuel stream in the manifold varies, the sensor

resistance will change. This will result in a different input voltage to the PCM. For more information, re

fer to Group 14, Fuel System. This sensor is installed in the intake manifold

(Figs.

9 or 10). For component testing, refer to the Diagnostics/Ser

vice Procedures section of this group. For removal and installation of this component, re

fer to the Component Removal/Installation section of

this group.

MANIFOLD ABSOLUTE

PRESSURE

(MAP)

SENSOR

The MAP sensor reacts to absolute pressure in the

intake manifold and provides an input voltage to the

powertrain control module (PCM). As engine load changes, manifold pressure varies, causing the MAP

sensor voltage to change. This change results in a

different input voltage to the PCM. The input volt age level supplies the PCM with information. This

relates to ambient barometric pressure during engine

Page 357 of 1502

8D

- 6

IGNITION

SYSTEMS

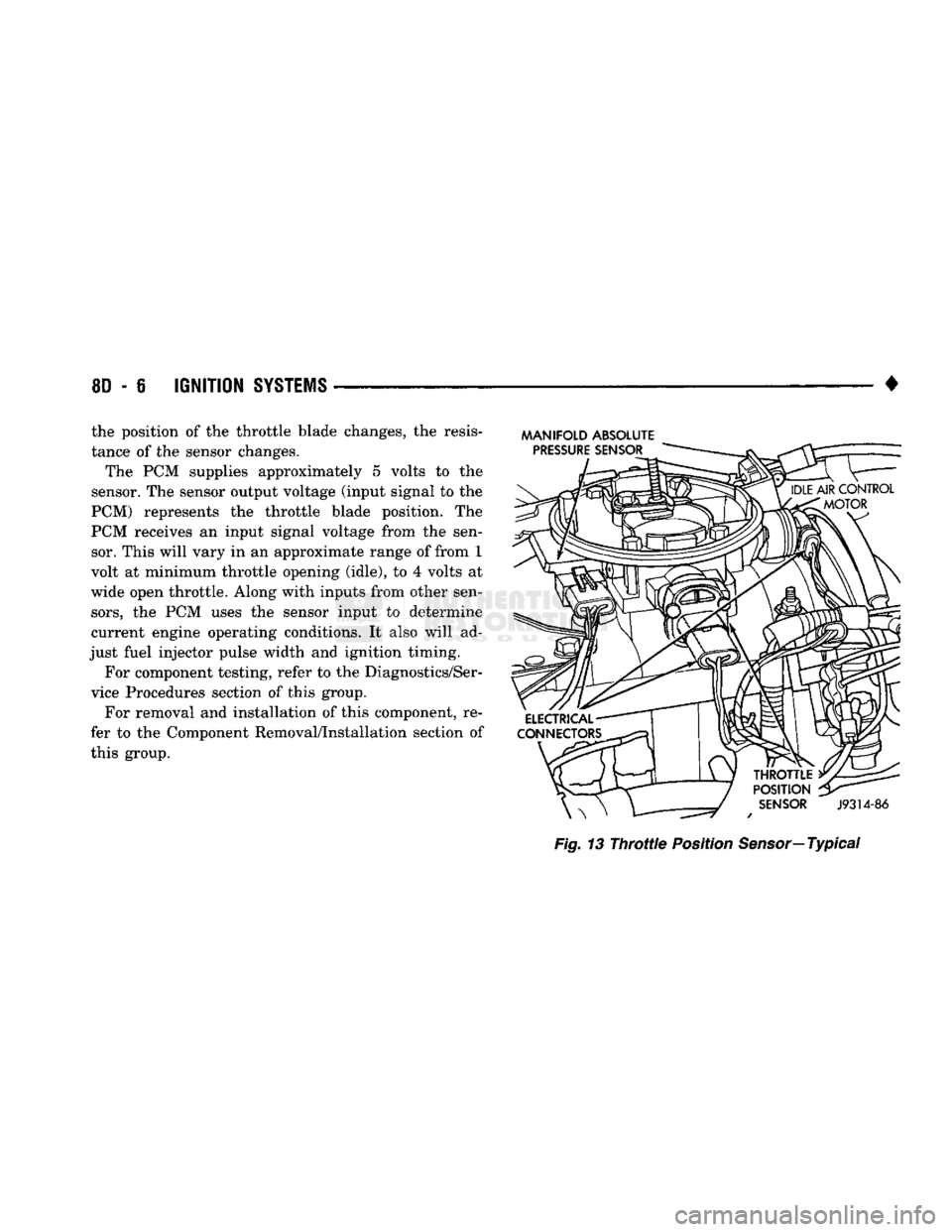

• the position of the throttle blade changes, the resis

tance of the sensor changes.

The PCM supplies approximately 5 volts to the

sensor. The sensor output voltage (input signal to the

PCM) represents the throttle blade position. The

PCM receives an input signal voltage from the sen sor. This will vary in an approximate range of from 1

volt at minimum throttle opening (idle), to 4 volts at

wide open throttle. Along with inputs from other sen

sors,

the PCM uses the sensor input to determine

current engine operating conditions. It also will ad

just fuel injector pulse width and ignition timing.

For component testing, refer to the Diagnostics/Ser

vice Procedures section of this group.

For removal and installation of this component, re

fer to the Component Removal/Installation section of

this group.

MANIFOLD ABSOLUTE

Fig.

13

Throttle

Position

Sensor—

Typical

Page 387 of 1502

8E

- 6

INSTRUMENT PANEL

AND

GAUGES

•

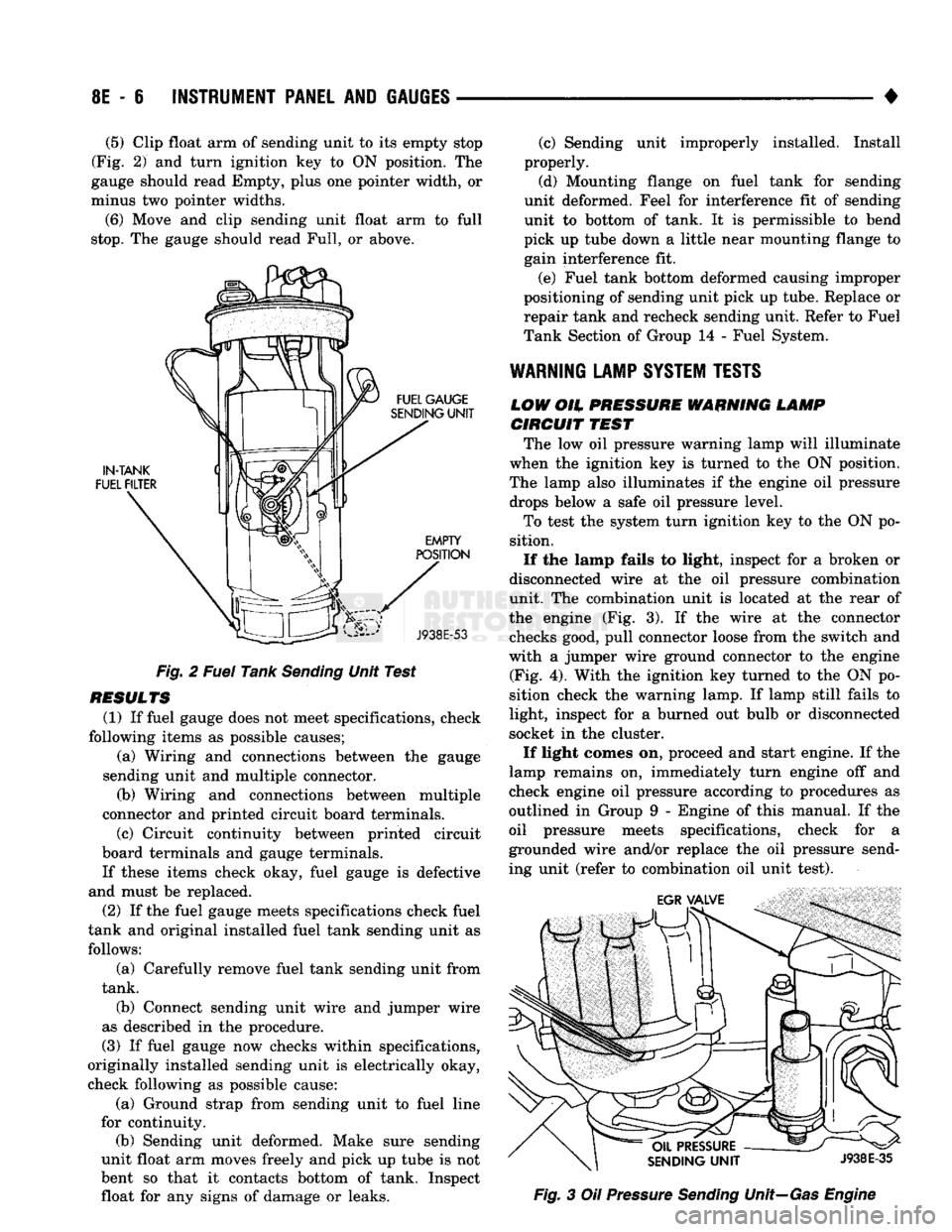

(5)

Clip float arm of sending unit to its empty stop

(Fig. 2) and turn ignition key to ON position. The

gauge should read Empty, plus one pointer width, or

minus two pointer widths.

(6) Move and clip sending unit float arm to full

stop.

The gauge should read Full, or above.

Fig. 2 Fuel Tank Sending Unit Test

RESULTS (1) If fuel gauge does not meet specifications, check

following items as possible causes; (a) Wiring and connections between the gauge

sending unit and multiple connector. (b) Wiring and connections between multiple

connector and printed circuit board terminals.

(c) Circuit continuity between printed circuit

board terminals and gauge terminals.

If these items check okay, fuel gauge is defective

and must be replaced.

(2) If the fuel gauge meets specifications check fuel

tank and original installed fuel tank sending unit as follows:

(a) Carefully remove fuel tank sending unit from

tank.

(b) Connect sending unit wire and jumper wire

as described in the procedure.

(3) If fuel gauge now checks within specifications,

originally installed sending unit is electrically okay,

check following as possible cause:

(a) Ground strap from sending unit to fuel line

for continuity. (b) Sending unit deformed. Make sure sending

unit float arm moves freely and pick up tube is not

bent so that it contacts bottom of tank. Inspect float for any signs of damage or leaks. (c) Sending unit improperly installed. Install

properly.

(d) Mounting flange on fuel tank for sending

unit deformed. Feel for interference fit of sending

unit to bottom of tank. It is permissible to bend

pick up tube down a little near mounting flange to gain interference fit.

(e) Fuel tank bottom deformed causing improper

positioning of sending unit pick up tube. Replace or

repair tank and recheck sending unit. Refer to Fuel

Tank Section of Group 14 - Fuel System.

WARNING

LAMP

SYSTEM

TESTS

LOW

OH.

PRESSURE WARNING LAMP CIRCUIT

TEST

The low oil pressure warning lamp will illuminate

when the ignition key is turned to the ON position.

The lamp also illuminates if the engine oil pressure drops below a safe oil pressure level.

To test the system turn ignition key to the ON po

sition.

If the lamp fails to light, inspect for a broken or

disconnected wire at the oil pressure combination

unit. The combination unit is located at the rear of

the engine (Fig. 3). If the wire at the connector checks good, pull connector loose from the switch and

with a jumper wire ground connector to the engine (Fig. 4). With the ignition key turned to the ON po

sition check the warning lamp. If lamp still fails to

light, inspect for a burned out bulb or disconnected

socket in the cluster.

If light comes on, proceed and start engine. If the

lamp remains on, immediately turn engine off and

check engine oil pressure according to procedures as

outlined in Group 9 - Engine of this manual. If the

oil pressure meets specifications, check for a

grounded wire and/or replace the oil pressure send

ing unit (refer to combination oil unit test). Fig. 3 Oil Pressure Sending Unit—Gas Engine

Page 606 of 1502

•

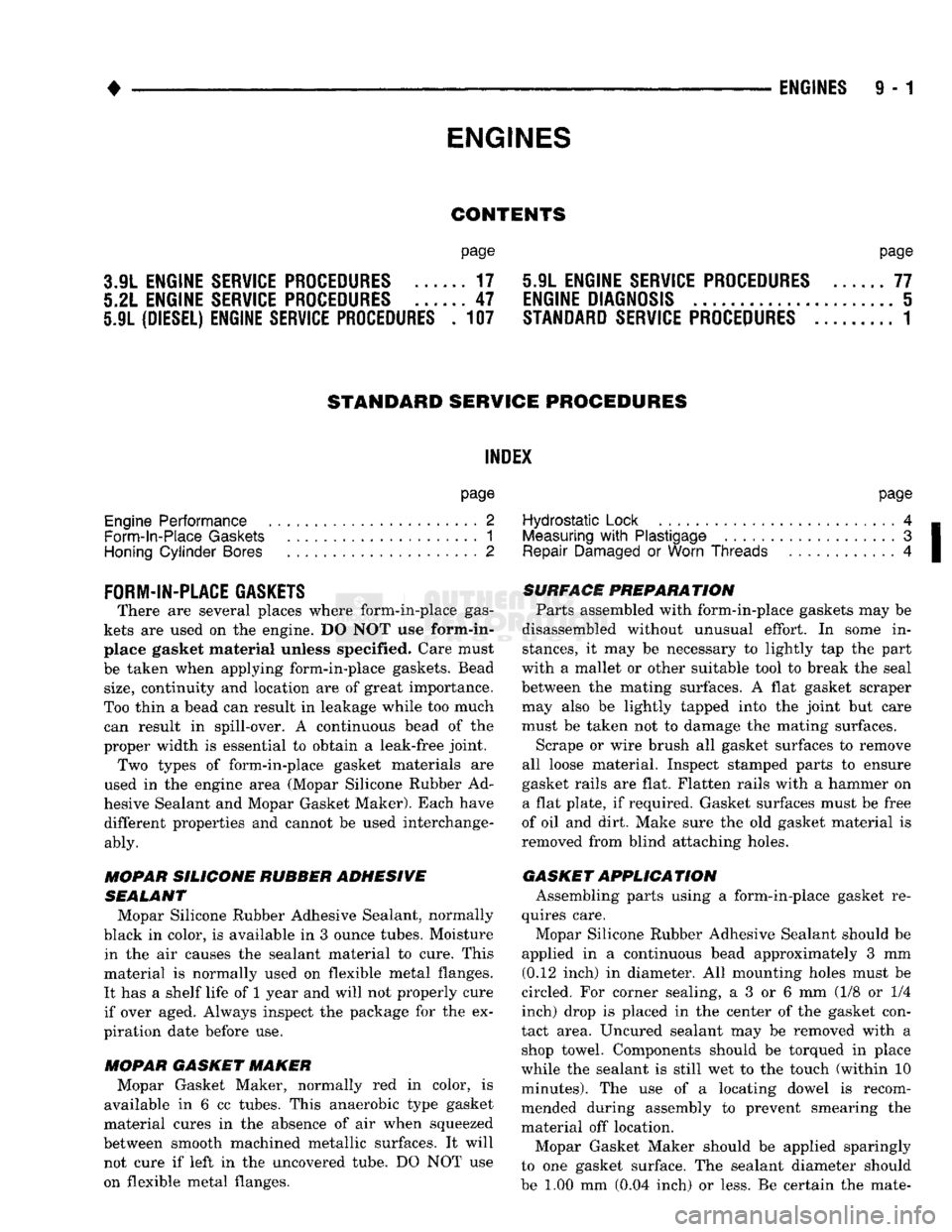

ENGINES ENGINES

9 - 1

CONTENTS

page page

3.9L

ENGINE SERVICE PROCEDURES

17 5.9L

ENGINE SERVICE PROCEDURES

77

5.2L

ENGINE SERVICE PROCEDURES

47

ENGINE DIAGNOSIS

5

5.9L

(DIESEL) ENGINE SERVICE PROCEDURES

. 107

STANDARD SERVICE PROCEDURES

1

STANDARD SERVICE PROCEDURES INDEX

page

Engine

Performance 2

Form-ln-Place

Gaskets

1

Honing

Cylinder

Bores

2

FORM-IN-PLACE GASKETS

There are several places where form-in-place gas

kets are used on the engine. DO NOT use form-in-

place gasket material unless specified. Care must

be taken when applying form-in-place gaskets. Bead

size,

continuity and location are of great importance.

Too thin a bead can result in leakage while too much can result in spill-over. A continuous bead of the

proper width is essential to obtain a leak-free joint. Two types of form-in-place gasket materials are

used in the engine area (Mopar Silicone Rubber Ad

hesive Sealant and Mopar Gasket Maker). Each have different properties and cannot be used interchange ably.

MOPAR SILICONE RUBBER ADHESIWE

SEALANT

Mopar Silicone Rubber Adhesive Sealant, normally

black in color, is available in 3 ounce tubes. Moisture in the air causes the sealant material to cure. This

material is normally used on flexible metal flanges.

It has a shelf life of 1 year and will not properly cure

if over aged. Always inspect the package for the ex

piration date before use.

MOPAR

GASKET MAKER Mopar Gasket Maker, normally red in color, is

available in 6 cc tubes. This anaerobic type gasket

material cures in the absence of air when squeezed

between smooth machined metallic surfaces. It will not cure if left in the uncovered tube. DO NOT use on flexible metal flanges.

page

Hydrostatic

Lock

4

Measuring

with

Plastigage 3

Repair

Damaged

or Worn

Threads

. 4

SURFACE PREPARA

TION

Parts assembled with form-in-place gaskets may be

disassembled without unusual effort. In some in

stances, it may be necessary to lightly tap the part

with a mallet or other suitable tool to break the seal

between the mating surfaces. A flat gasket scraper may also be lightly tapped into the joint but care

must be taken not to damage the mating surfaces.

Scrape or wire brush all gasket surfaces to remove

all loose material. Inspect stamped parts to ensure

gasket rails are flat. Flatten rails with a hammer on a flat plate, if required. Gasket surfaces must be free

of oil and dirt. Make sure the old gasket material is

removed from blind attaching holes.

GASKET

APPLICATION

Assembling parts using a form-in-place gasket re

quires care.

Mopar Silicone Rubber Adhesive Sealant should be

applied in a continuous bead approximately 3 mm (0.12 inch) in diameter. All mounting holes must be

circled. For corner sealing, a 3 or 6 mm (1/8 or 1/4

inch) drop is placed in the center of the gasket con

tact area. Uncured sealant may be removed with a shop towel. Components should be torqued in place

while the sealant is still wet to the touch (within 10

minutes). The use of a locating dowel is recom

mended during assembly to prevent smearing the

material off location.

Mopar Gasket Maker should be applied sparingly

to one gasket surface. The sealant diameter should

be 1.Q0 mm (0.04 inch) or less. Be certain the mate-

Page 608 of 1502

•

ENGINES

9 - 3

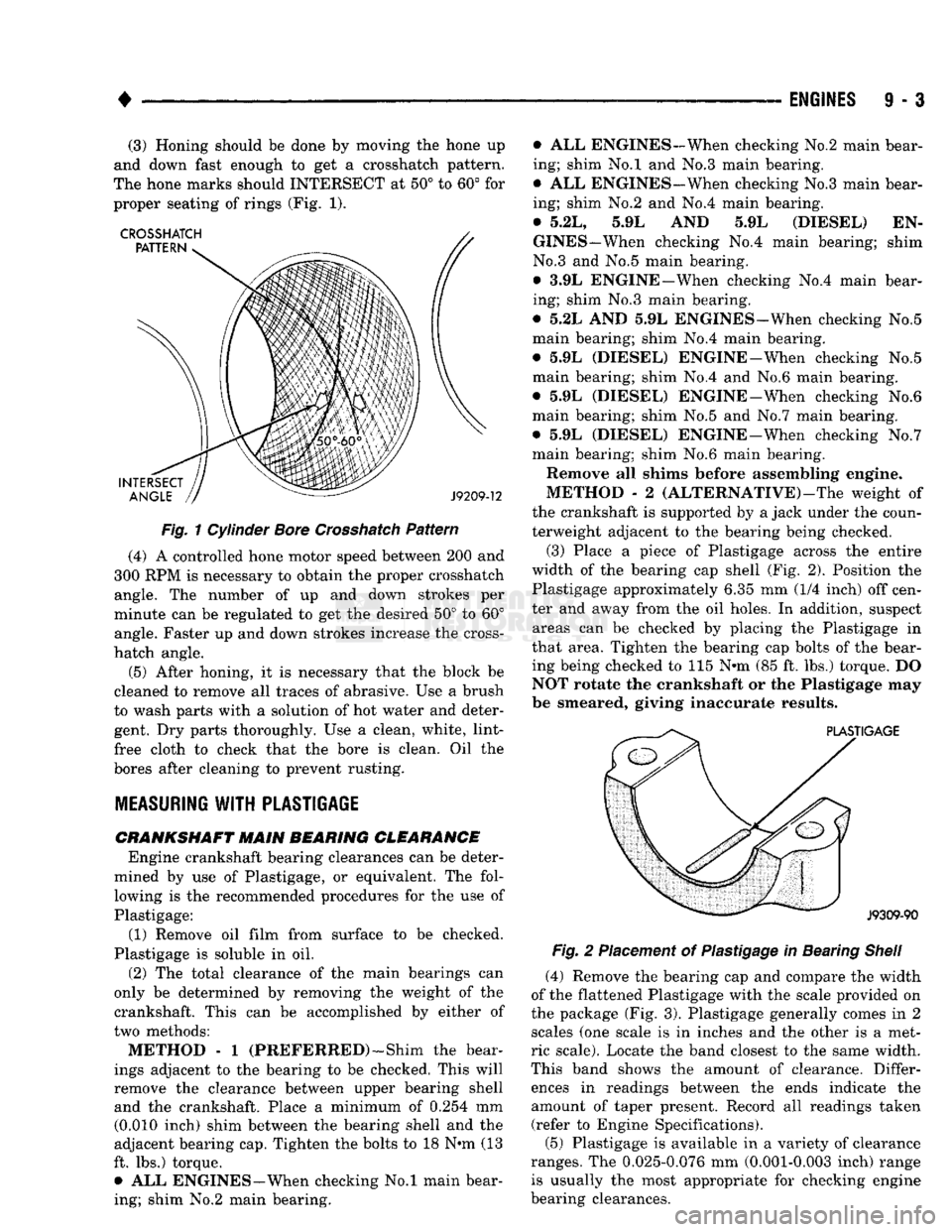

(3) Honing

should be

done

by moving the

hone

up

and down

fast

enough

to get a Crosshatch pattern.

The hone

marks should

INTERSECT

at 50° to 60° for

proper seating

of

rings (Fig.

1).

Fig.

1

Cylinder

Bore

Crosshatch

Pattern

(4)

A

controlled hone motor speed between

200 and

300

RPM is

necessary

to

obtain

the

proper Crosshatch angle.

The

number

of up and

down strokes

per

minute

can be

regulated

to get the

desired

50° to 60°

angle. Faster

up and

down strokes increase

the

cross-

hatch angle.

(5) After honing,

it is

necessary that

the

block

be

cleaned

to

remove

all

traces

of

abrasive.

Use a

brush

to wash parts with

a

solution

of hot

water

and

deter gent.

Dry

parts thoroughly.

Use a

clean, white, lint-

free cloth

to

check that

the

bore

is

clean.

Oil the

bores after cleaning

to

prevent rusting.

MEASURING

WITH

PLASTIGAGE

CRANKSHAFT

MAIN BEARING CLEARANCE Engine crankshaft bearing clearances

can be

deter

mined

by use of

Plastigage,

or

equivalent.

The

fol lowing

is the

recommended procedures

for the use of

Plastigage:

(1) Remove

oil

film from surface

to be

checked.

Plastigage

is

soluble

in oil.

(2)

The

total clearance

of the

main bearings

can

only

be

determined

by

removing

the

weight

of the

crankshaft. This

can be

accomplished

by

either

of

two methods:

METHOD - 1

(PREFERRED)—Shim

the

bear

ings adjacent

to the

bearing

to be

checked. This will

remove

the

clearance between upper bearing shell and

the

crankshaft. Place

a

minimum

of

0.254

mm

(0.010 inch) shim between

the

bearing shell

and the

adjacent bearing cap. Tighten

the

bolts

to 18 N*m (13

ft.

lbs.)

torque. •

ALL

ENGINES—When checking

No.l

main bear

ing; shim

No.2

main bearing. •

ALL

ENGINES-When checking

No.2

main bear

ing; shim

No.l and No.3

main bearing.

•

ALL

ENGINES-When checking No.3 main bear

ing; shim

No.2 and No.4

main bearing.

•

5.2L, 5.9L AND 5.9L

(DIESEL)

EN

GINES—When checking

No.4

main bearing; shim

No.3

and No.5

main bearing.

•

3.9L

ENGINE—When checking

No.4

main bear

ing; shim

No.3

main bearing.

•

5.2L AND 5.9L

ENGINES—When checking

No.5

main bearing; shim

No.4

main bearing.

•

5.9L

(DIESEL) ENGINE-When checking

No.5

main bearing; shim

No.4 and No.6

main bearing.

•

5.9L

(DIESEL) ENGINE-When checking

No.6

main bearing; shim

No.5 and No.7

main bearing.

•

5.9L

(DIESEL) ENGINE-When checking

No.7

main bearing; shim

No.6

main bearing.

Remove

all

shims before assembling engine.

METHOD

- 2

(ALTERNATIVE)—The weight

of

the crankshaft

is

supported

by a

jack under

the

coun

terweight adjacent

to the

bearing being checked.

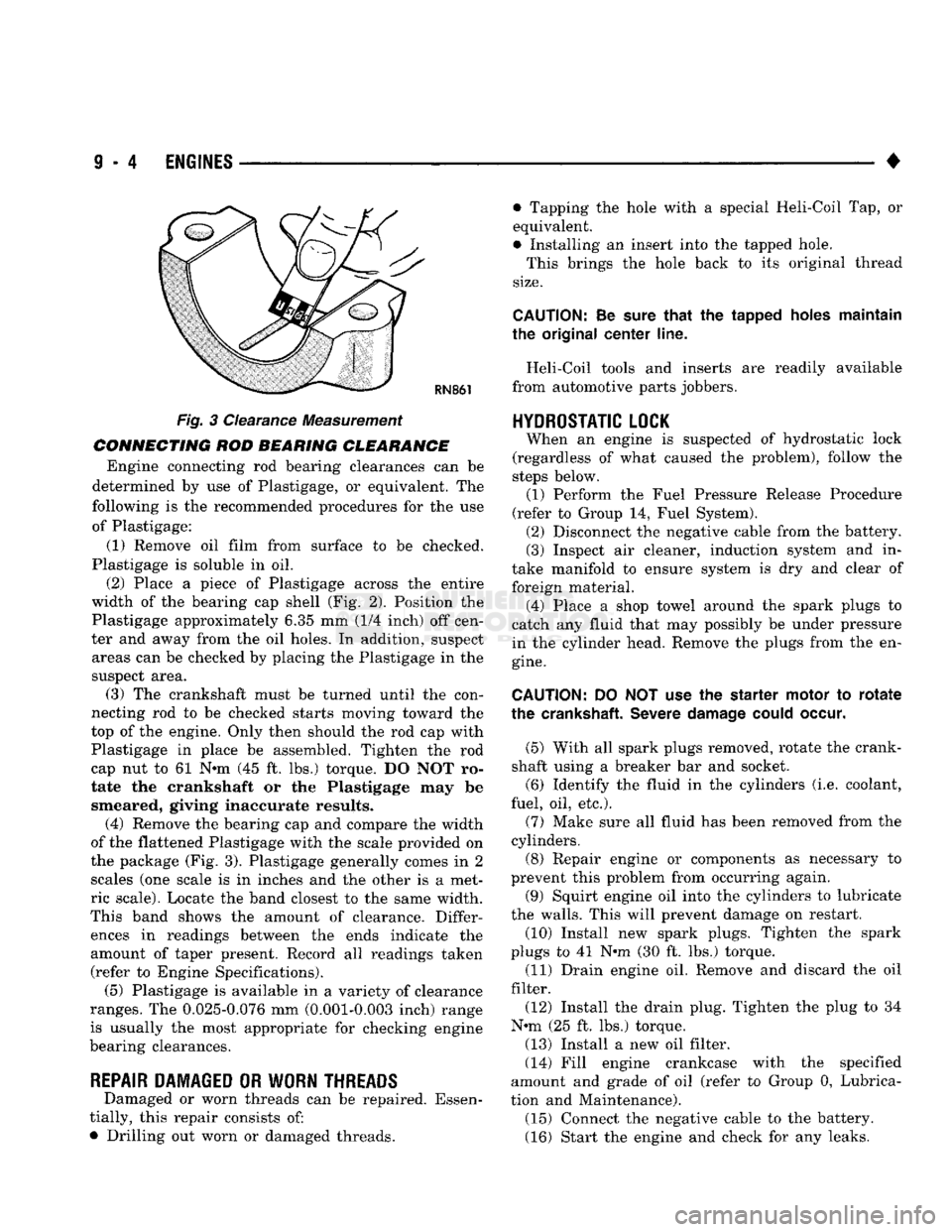

(3) Place

a

piece

of

Plastigage across

the

entire

width

of the

bearing

cap

shell

(Fig. 2).

Position

the

Plastigage approximately

6.35 mm (1/4

inch)

off

cen

ter

and

away from

the oil

holes.

In

addition, suspect areas

can be

checked

by

placing

the

Plastigage

in

that area. Tighten

the

bearing

cap

bolts

of the

bear

ing being checked

to 115 N»m (85 ft. lbs.)

torque.

DO

NOT rotate

the

crankshaft

or the

Plastigage

may

be smeared, giving inaccurate results.

Fig.

2

Placement

of

Plastigage

in

Bearing

Shell

(4) Remove

the

bearing

cap and

compare

the

width

of

the

flattened Plastigage with

the

scale provided

on

the package

(Fig. 3).

Plastigage generally comes

in 2

scales

(one

scale

is in

inches

and the

other

is a

met

ric scale). Locate

the

band closest

to the

same width.

This band shows

the

amount

of

clearance. Differ ences

in

readings between

the

ends indicate

the

amount

of

taper present. Record

all

readings taken (refer

to

Engine Specifications).

(5) Plastigage

is

available

in a

variety

of

clearance

ranges.

The

0.025-0.076

mm

(0.001-0.003 inch) range is usually

the

most appropriate

for

checking engine

bearing clearances.

Page 609 of 1502

9

- 4 ENGINES

•

RN861

Fig. 3 Clearance Measurement

CONNECTING ROD BEARING CLEARANCE Engine connecting rod bearing clearances can be

determined by use of Plastigage, or equivalent. The

following is the recommended procedures for the use of Plastigage:

(1) Remove oil film from surface to be checked.

Plastigage is soluble in oil.

(2) Place a piece of Plastigage across the entire

width of the bearing cap shell (Fig. 2). Position the

Plastigage approximately 6.35 mm (1/4 inch) off cen

ter and away from the oil holes. In addition, suspect areas can be checked by placing the Plastigage in the

suspect area. (3) The crankshaft must be turned until the con

necting rod to be checked starts moving toward the

top of the engine. Only then should the rod cap with

Plastigage in place be assembled. Tighten the rod

cap nut to 61 Nnn (45 ft. lbs.) torque. DO NOT ro

tate the crankshaft or the Plastigage may be smeared, giving inaccurate results. (4) Remove the bearing cap and compare the width

of the flattened Plastigage with the scale provided on

the package (Fig. 3). Plastigage generally comes in 2 scales (one scale is in inches and the other is a met

ric scale). Locate the band closest to the same width.

This band shows the amount of clearance. Differ ences in readings between the ends indicate the

amount of taper present. Record all readings taken (refer to Engine Specifications). (5) Plastigage is available in a variety of clearance

ranges. The 0.025-0.076 mm (0.001-0.003 inch) range

is usually the most appropriate for checking engine

bearing clearances.

REPAIR DAMAGED OR WORN THREADS Damaged or worn threads can be repaired. Essen

tially, this repair consists of:

• Drilling out worn or damaged threads. • Tapping the hole with a special Heli-Coil Tap, or

equivalent.

• Installing an insert into the tapped hole.

This brings the hole back to its original thread

size.

CAUTION:

Be

sure

that

the tapped holes maintain

the original

center

line.

Heli-Coil tools and inserts are readily available

from automotive parts jobbers.

HYDROSTATIC

LOCK

When an engine is suspected of hydrostatic lock

(regardless of what caused the problem), follow the

steps below. (1) Perform the Fuel Pressure Release Procedure

(refer to Group 14, Fuel System). (2) Disconnect the negative cable from the battery.

(3) Inspect air cleaner, induction system and in

take manifold to ensure system is dry and clear of

foreign material. (4) Place a shop towel around the spark plugs to

catch any fluid that may possibly be under pressure

in the cylinder head. Remove the plugs from the en

gine.

CAUTION:

DO NOT use the starter motor to

rotate

the

crankshaft.

Severe

damage

could

occur.

(5) With all spark plugs removed, rotate the crank

shaft using a breaker bar and socket.

(6) Identify the fluid in the cylinders (i.e. coolant,

fuel, oil, etc.).

(7) Make sure all fluid has been removed from the

cylinders. (8) Repair engine or components as necessary to

prevent this problem from occurring again.

(9) Squirt engine oil into the cylinders to lubricate

the walls. This will prevent damage on restart.

(10) Install new spark plugs. Tighten the spark

plugs to 41 N#m (30 ft. lbs.) torque. (11) Drain engine oil. Remove and discard the oil

filter.

(12) Install the drain plug. Tighten the plug to 34

N-m (25 ft. lbs.) torque.

(13) Install a new oil filter.

(14) Fill engine crankcase with the specified

amount and grade of oil (refer to Group 0, Lubrica

tion and Maintenance). (15) Connect the negative cable to the battery.

(16) Start the engine and check for any leaks.