coolant temperature DODGE TRUCK 1993 Service Service Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 617 of 1502

9

- 12

ENGINES

•

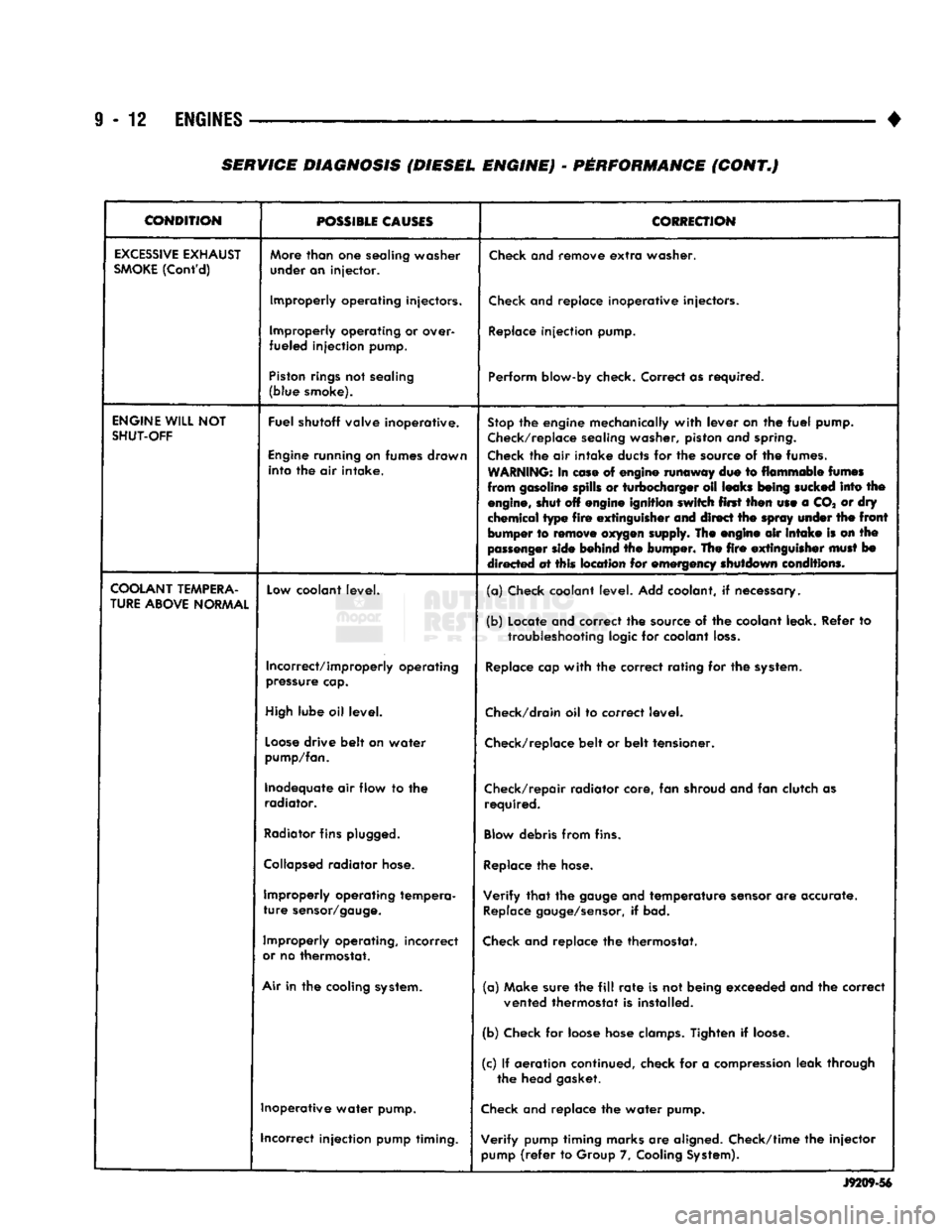

CONDITION

POSSIBLE

CAUSES

CORRECTION

EXCESSIVE

EXHAUST

SMOKE

(Cont'd)

More

than

one

sealing washer

under an injector.

Check

and remove

extra

washer.

Improperly operating injectors.

Check

and replace inoperative injectors.

Improperly operating or over-

fueled injection pump.

Replace

injection pump.

Piston

rings

not sealing

(blue smoke). Perform blow-by check. Correct as required.

ENGINE

WILL

NOT

SHUT-OFF

Fuel shutoff valve inoperative.

Engine

running on fumes drawn into the air intake.

Stop

the engine mechanically

with

lever on the

fuel

pump.

Check/replace

sealing washer, piston and

spring.

Check

the air intake ducts for the source of the fumes.

WARNING:

In

ease

of engine runaway due to flammable

fumes

from gasoline spills or turbocharger oil leaks

being

sucked

into the

engine,

shut off engine ignition switch first then use a CO* or dry

chemical type

fire

extinguisher

and direct the

spray

under

the

front

bumper to

remove

oxygen

supply. The engine air

intake

is on the

passenger

side

behind the bumper. The

fire

extinguisher

must

bo

directed at this location for emergency shutdown conditions.

COOLANT

TEMPERA

TURE

ABOVE

NORMAL

Low

coolant level.

(a) Check coolant level. Add coolant, if necessary.

(b) Locate and correct the source of the coolant leak. Refer to

troubleshooting

logic for coolant

loss.

Incorrect/improperly operating

pressure

cap.

Replace

cap

with

the correct rating for the

system.

High

lube oil level.

Check/drain

oil to correct level.

Loose

drive belt on water

pump/fan.

Check/replace

belt or belt tensioner.

Inadequate air flow to the radiator. Check/repair radiator core, fan shroud and fan clutch as

required.

Radiator

fins

plugged.

Blow

debris from fins.

Collapsed

radiator

hose.

Replace

the

hose.

Improperly operating tempera

ture

sensor/gauge.

Verify

that

the

gauge

and temperature

sensor

are accurate.

Replace

gauge/sensor,

if bad.

Improperly operating, incorrect

or

no thermostat.

Check

and replace the thermostat.

Air

in the cooling

system.

(a) Make sure the

fill

rate

is not being exceeded and the correct

vented thermostat is installed.

(b) Check for loose hose

clamps.

Tighten if

loose.

(c) If aeration continued, check for a

compression

leak through the head gasket.

Inoperative water pump.

Check

and replace the water pump.

incorrect injection pump timing. Verify pump timing marks are aligned. Check/time the injector

pump

(refer

to Group 7,

Cooling

System).

J9209-56

SERVICE DIAGNOSIS (DIESEL ENGINE) - PERFORMANCE (CONT.)

Page 618 of 1502

•

ENGINES

9 - 13

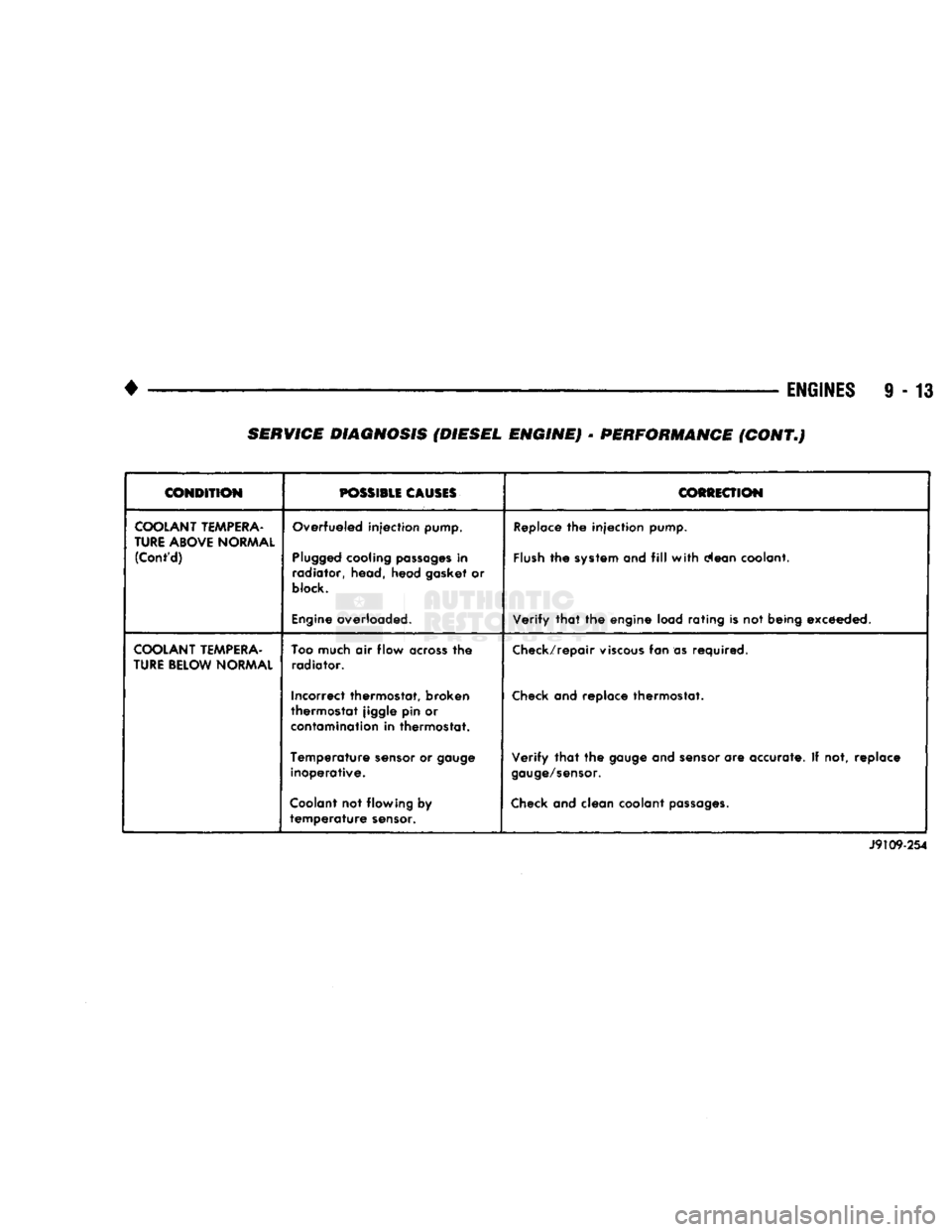

CONDITION

POSSIBLE

CAUSES

COfiiiECTION

COOLANT

TEMPERA

TURE

ABOVE

NORMAL

(Cont'd)

Overfueled injection pump.

Plugged

cooling

passages

in

radiator, head, head gasket or

block.

Engine

overloaded.

Replace

the injection

pump.

Flush

the

system

and

fill

with

clean coolant.

Verify

that

the engine load rating is not being exceeded.

COOLANT

TEMPERA

TURE

BELOW

NORMAL

Too

much air flow

across

the

radiator.

Incorrect thermostat, broken

thermostat jiggle pin or

contamination

in thermostat.

Temperature

sensor

or

gauge

inoperative.

Coolant

not flowing by

temperature

sensor.

Check/repair

viscous

fan as required.

Check

and replace thermostat.

Verify

that

the

gauge

and

sensor

are accurate. If not, replace

gauge/sensor.

Check

and clean coolant

passages.

J9109-254

SERVICE DIAGNOSIS (DIESEL ENGINE) • PERFORMANCE (CONT.)

Page 620 of 1502

•

• —

ENGINES

9 - 15

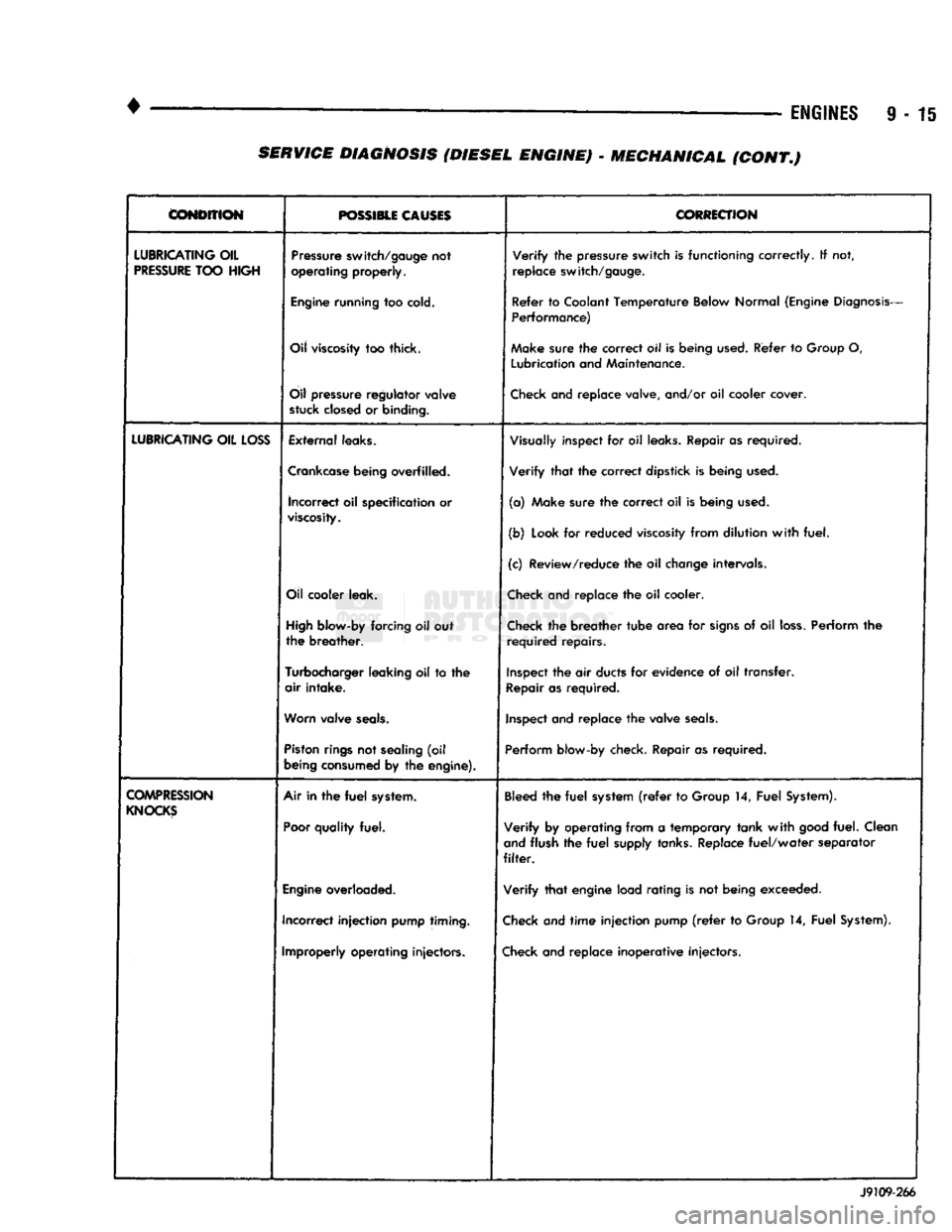

CONDITION

POSSIBLE CAUSES

CORRECTION

LUBRICATING

OIL

PRESSURE

TOO

HIGH

Pressure

switch/gauge

not

operating

properly.

Verify

the

pressure

switch

is

functioning

correctly.

If not,

replace

switch/gauge.

Engine

running

too

cold.

Refer

to

Coolant

Temperature

Below

Normal

(Engine

Diagnosis-

Performance)

Oil

viscosity

too thick. Make

sure

the

correct

oil Is

being

used.

Refer

to

Group

O,

Lubrication

and

Maintenance.

Oil

pressure

regulator

valve

stuck

closed

or

binding.

Check

and replace valve, and/or oil cooler cover.

LUBRICATING

OIL

LOSS

External

leaks.

Visually

inspect for oil

leaks.

Repair as required.

Crankcase

being

overfilled. Verify that the correct dipstick is being

used.

incorrect

oil specification or

viscosity.

(a) Make sure the correct oil is being

used.

(b)

Look

for reduced

viscosity

from dilution with fuel.

(c) Review/reduce the oil

change

intervals.

Oil

cooler

leak.

Check

and replace the oil cooler.

High

blow-by

forcing oil out

the breather.

Check

the breather tube area for

signs

of oil

loss.

Perform the

required repairs.

Turbocharger

leaking

oil to the

air intake.

Inspect

the air

ducts

for evidence of oil transfer.

Repair

as required.

Worn

valve

seals.

Inspect

and replace the valve

seals.

Piston

rings

not

sealing

(oil

being

consumed

by the

engine).

Perform

blow-by check. Repair as required.

COMPRESSION

KNOCKS

Air in the

fuel

system.

Poor

quality

fuel.

Bleed

the fuel

system

(refer

to

Group

14, Fuel

System).

Verify by operating from a temporary tank with

good

fuel. Clean

and

flush the fuel

supply

tanks.

Replace fuel/water separator

filter.

Engine

overloaded. Verify that engine load rating is not being exceeded.

Incorrect injection

pump

timing.

Check

and time injection pump

(refer

to

Group

14, Fuel

System).

Improperly

operating

injectors.

Check

and replace inoperative injectors. J9109-266 SERVICE DIAGNOSIS (DIESEL ENGINE) - MECHANICAL (CONT.)

Page 848 of 1502

•

FUEL

SYSTEM

14-29

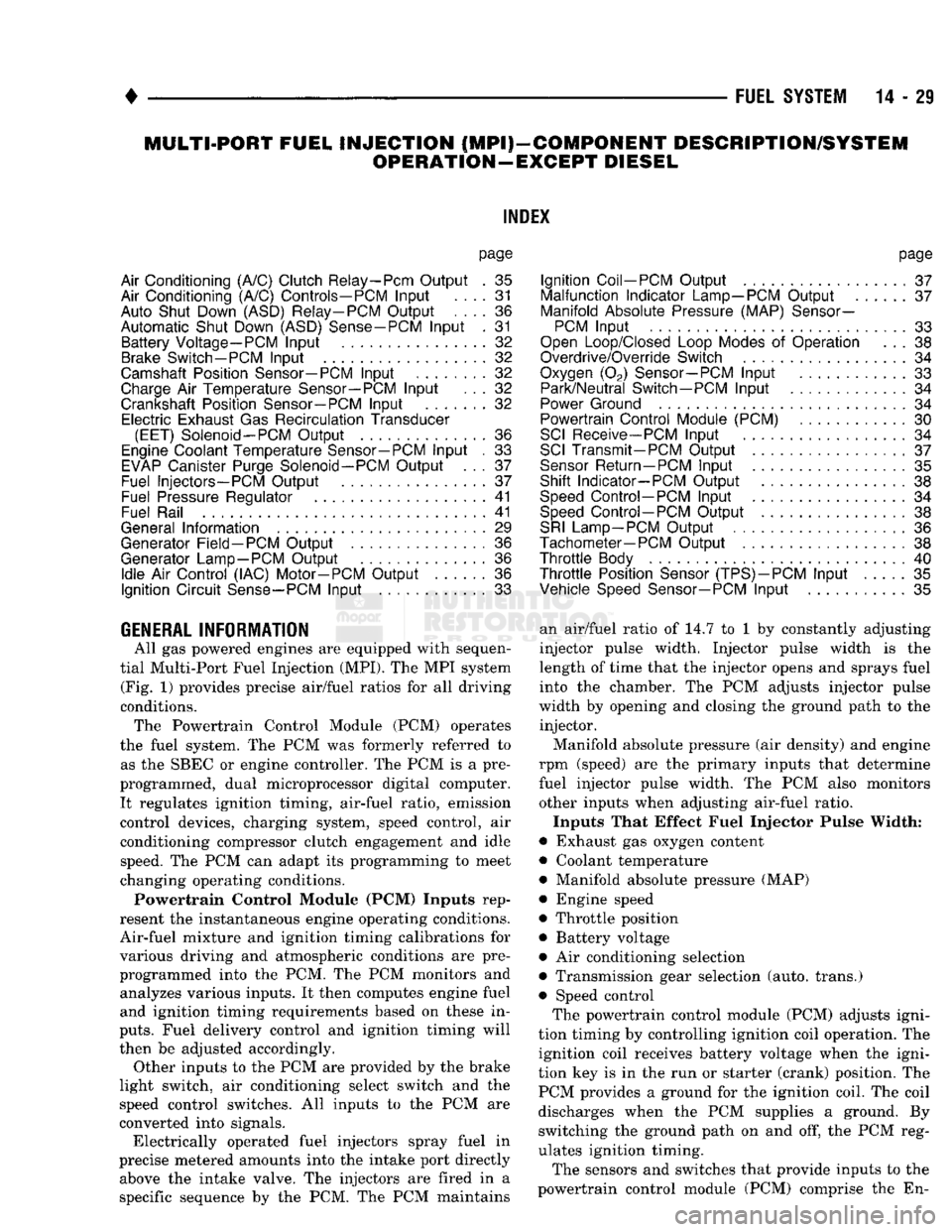

MULTI-PORT

FUEL

INJECTION

(MPI)-COMPONENT DESCRIPTION/SYSTEM

OPERATION-EXCEPT DIESEL

INDEX

page

Air

Conditioning (A/C) Clutch

Relay-Pern

Output

. 35

Air

Conditioning (A/C)

Controls—PCM

Input

.... 31

Auto

Shut

Down

(ASD)

Relay-PCM

Output

. ... 36

Automatic

Shut

Down

(ASD)

Sense-PCM

Input

. 31

Battery

Voltage-PCM

Input

32

Brake

Switch-PCM

Input

32

Camshaft

Position

Sensor—PCM

Input

32

Charge

Air

Temperature

Sensor—PCM

Input

. . . 32

Crankshaft

Position

Sensor-PCM

Input

.......

32

Electric

Exhaust

Gas Recirculation Transducer

(EET)

Solenoid-PCM

Output

...

.......

36

Engine

Coolant Temperature

Sensor—PCM

Input

. 33

EVAP

Canister

Purge

Solenoid—PCM

Output

. . . 37

Fuel

Injectors-PCM Output

37

Fuel

Pressure

Regulator

41

Fuel

Rail

41

General

Information

.......................

29

Generator

Field-PCM

Output

36

Generator

Lamp-PCM

Output

36

Idle

Air

Control

(IAC)

Motor-PCM

Output

......

36

Ignition

Circuit

Sense—PCM

Input

33

GENERAL

INFORMATION

All

gas

powered engines

are

equipped with sequen

tial Multi-Port Fuel Injection (MPI).

The MPI

system (Fig.

1)

provides precise air/fuel ratios

for all

driving

conditions. The Powertrain Control Module

(PCM)

operates

the fuel system.

The PCM was

formerly referred

to

as

the

SBEC

or

engine controller.

The PCM is a

pre

programmed, dual microprocessor digital computer. It regulates ignition timing, air-fuel ratio, emission

control devices, charging system, speed control,

air

conditioning compressor clutch engagement

and

idle speed.

The PCM can

adapt

its

programming

to

meet

changing operating conditions.

Powertrain Control Module (PCM) Inputs rep

resent

the

instantaneous engine operating conditions.

Air-fuel mixture

and

ignition timing calibrations

for

various driving

and

atmospheric conditions

are

pre

programmed into

the PCM. The PCM

monitors

and

analyzes various inputs.

It

then computes engine fuel

and ignition timing requirements based

on

these

in

puts.

Fuel delivery control

and

ignition timing will

then

be

adjusted accordingly. Other inputs

to the

PCM

are

provided

by the

brake

light switch,

air

conditioning select switch

and the

speed control switches.

All

inputs

to the PCM are

converted into signals. Electrically operated fuel injectors spray fuel

in

precise metered amounts into

the

intake port directly above

the

intake valve.

The

injectors

are

fired

in a

specific sequence

by the PCM. The PCM

maintains

page

Ignition

Coil-PCM

Output

37

Malfunction Indicator

Lamp—PCM

Output

37

Manifold

Absolute

Pressure

(MAP)

Sensor-

PCM

Input

33

Open

Loop/Closed

Loop

Modes

of

Operation

. . . 38

Overdrive/Override

Switch

34

Oxygen

(02)

Sensor—PCM

Input

33

Park/Neutral

Switch—PCM

Input

34

Power

Ground

34

Powertrain Control Module

(PCM)

30

SCI

Receive-PCM

Input

. 34

SCI

Transmit-PCM

Output

37

Sensor

Return

—PCM

Input

35

Shift Indicator-PCM Output

38

Speed

Control-PCM

Input

34

Speed

Control-PCM

Output

38

SRI

Lamp-PCM

Output

36

Tachometer—PCM

Output

38

Throttle

Body

40

Throttle

Position

Sensor

(TPS)-PCM

Input

35

Vehicle

Speed

Sensor-PCM

Input

35

an air/fuel ratio

of 14.7 to 1 by

constantly adjusting

injector pulse width. Injector pulse width

is the

length

of

time that

the

injector opens

and

sprays fuel into

the

chamber.

The PCM

adjusts injector pulse

width

by

opening

and

closing

the

ground path

to the

injector.

Manifold absolute pressure

(air

density)

and

engine

rpm (speed)

are the

primary inputs that determine

fuel injector pulse width.

The PCM

also monitors

other inputs when adjusting air-fuel ratio.

Inputs That Effect Fuel Injector Pulse Width:

• Exhaust

gas

oxygen content

• Coolant temperature

• Manifold absolute pressure (MAP)

• Engine speed

• Throttle position

• Battery voltage •

Air

conditioning selection

• Transmission gear selection (auto, trans.)

• Speed control The powertrain control module (PCM) adjusts igni

tion timing

by

controlling ignition coil operation.

The

ignition coil receives battery voltage when

the

igni

tion

key is in the run or

starter (crank) position.

The

PCM provides

a

ground

for the

ignition coil.

The

coil

discharges when

the PCM

supplies

a

ground.

By

switching

the

ground path

on and off, the PCM

reg

ulates ignition timing.

The sensors

and

switches that provide inputs

to the

powertrain control module

(PCM)

comprise

the En-

Page 849 of 1502

14

- 30

FUEL

SYSTEM

INPUTS

OUTPUTS

POWERTRAIN

CONTROL

MODULE

DRB

II

SCAN

TOOL

SPEED

CONTROL

BRAKE

SWITCH

A/C

LOW

PRESSURE

CUTOFF

SWITCH VEHICLE

SPEED

SENSOR PARK/NEUTRAL

SWITCH TORQUE CONVERTER

CLUTCH SOLENOID

MALFUNCTION

INDICATOR

LAMP

m

HEATED

i

*OXYGEN SENSOR ENGINE

COOLANT

yy

BATTERY

TEMPERATURE

SENSOR

MAP SENSOR

i—r

CHARGE

AIR

TEMPERATURE

SENSOR

AIR CHARGE

TEMPERATURE

SENSOR

DISTRIBUTOR

WITH

CAMSHAFT

r

POSITION

SENSOR

(|

TACHOMETER

A/C

CLUTCH RELAY

AUTO

SHUTDOWN

RELAY OVERDRIVE

SOLENOID

IDLE AIR

CONTROL MOTOR

SPEED

CONTROL

SHIFT

INDICATOR

LAMP

EMISSION

CONTROL SOLENOIDS

IGNITION

COIL

OVERDRIVE

OVERRIDE SWITCH

ASD

SENSE

FUEL

INJECTORS

PARK

THROTTLE

SOLENOID

GENERATOR CRANKSHAFT

POSITION FUEL

PUMP

RELAY

J9314-117

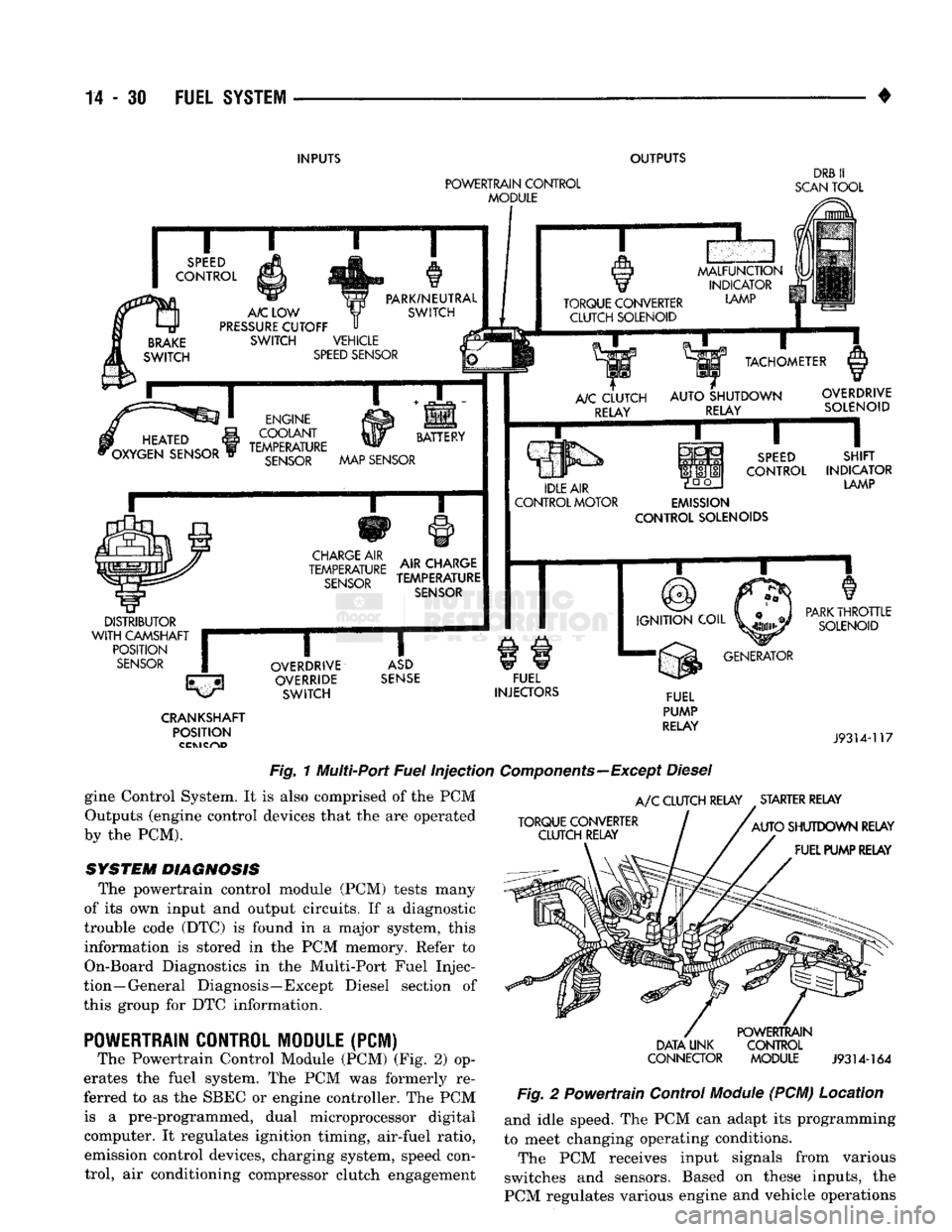

Fig.

1 Multi-Port

Fuel

Injection

Components—Except

Diesel

gine Control System. It is also comprised of the PCM Outputs (engine control devices that the are operated

by the PCM).

SYSTEM DIAGNOSIS

The powertrain control module (PCM) tests many

of its own input and output circuits. If a diagnostic

trouble code (DTC) is found in a major system, this information is stored in the PCM memory. Refer to

On-Board Diagnostics in the Multi-Port Fuel Injec

tion—General Diagnosis—Except Diesel section of

this group for DTC information.

POWERTRAIN

CONTROL MODULE (PCM)

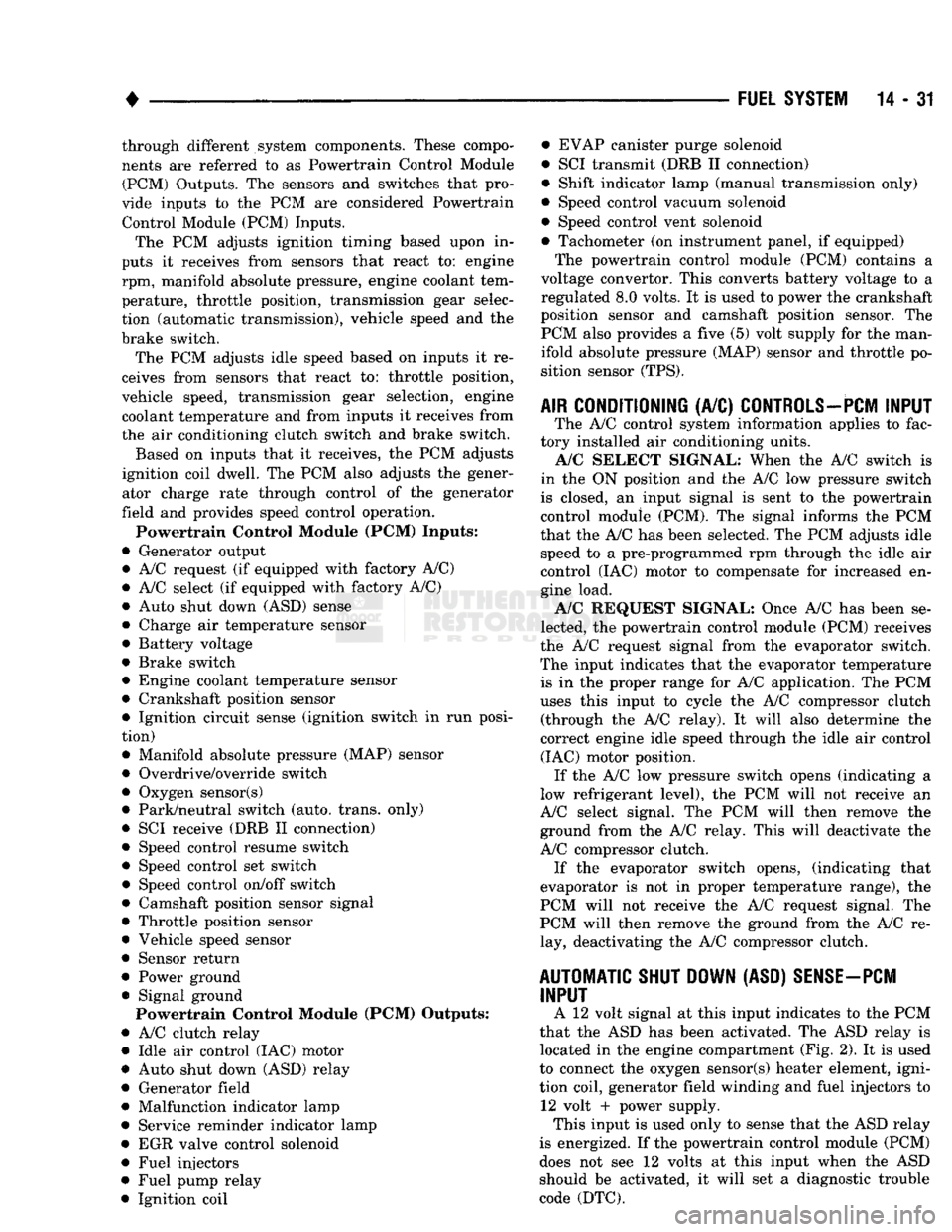

The Powertrain Control Module (PCM) (Fig. 2) op

erates the fuel system. The PCM was formerly re

ferred to as the SBEC or engine controller. The PCM is a pre-programmed, dual microprocessor digital computer. It regulates ignition timing, air-fuel ratio, emission control devices, charging system, speed control, air conditioning compressor clutch engagement

A/C

CLUTCH RELAY STARTER RELAY

TORQUE CONVERTER CLUTCH RELAY

AUTO

SHUTDOWN RELAY

FUEL PUMP RELAY

DATA UNK

CONNECTOR

POWERTRAIN

CONTROL MODULE

J9314-164

Fig.

2 Powertrain Control

Module

(PCM) Location and idle speed. The PCM can adapt its programming

to meet changing operating conditions.

The PCM receives input signals from various

switches and sensors. Based on these inputs, the

PCM regulates various engine and vehicle operations

Page 850 of 1502

•

FUEL SYSTEM

14-31 through different system components. These compo

nents are referred to as Powertrain Control Module

(PCM) Outputs. The sensors and switches that pro

vide inputs to the PCM are considered Powertrain Control Module (PCM) Inputs.

The PCM adjusts ignition timing based upon in

puts it receives from sensors that react to: engine rpm, manifold absolute pressure, engine coolant tem

perature, throttle position, transmission gear selec

tion (automatic transmission), vehicle speed and the

brake switch.

The PCM adjusts idle speed based on inputs it re

ceives from sensors that react to: throttle position,

vehicle speed, transmission gear selection, engine coolant temperature and from inputs it receives from

the air conditioning clutch switch and brake switch.

Based on inputs that it receives, the PCM adjusts

ignition coil dwell. The PCM also adjusts the gener

ator charge rate through control of the generator

field and provides speed control operation.

Powertrain Control Module (PCM) Inputs:

• Generator output • A/C request (if equipped with factory A/C)

• A/C select (if equipped with factory A/C)

• Auto shut down (ASD) sense

• Charge air temperature sensor

• Battery voltage

• Brake switch

• Engine coolant temperature sensor

• Crankshaft position sensor • Ignition circuit sense (ignition switch in run posi

tion)

• Manifold absolute pressure (MAP) sensor

• Overdrive/override switch

• Oxygen sensor(s)

• Park/neutral switch (auto, trans, only)

• SCI receive (DRB II connection) • Speed control resume switch

• Speed control set switch • Speed control on/off switch

• Camshaft position sensor signal

• Throttle position sensor

• Vehicle speed sensor

• Sensor return

• Power ground

• Signal ground Powertrain Control Module (PCM) Outputs:

• A/C clutch relay

• Idle air control (IAC) motor

• Auto shut down (ASD) relay

• Generator field

• Malfunction indicator lamp

• Service reminder indicator lamp

• EGR valve control solenoid • Fuel injectors

• Fuel pump relay

• Ignition coil • EVAP canister purge solenoid

• SCI transmit (DRB II connection)

• Shift indicator lamp (manual transmission only)

• Speed control vacuum solenoid

• Speed control vent solenoid

• Tachometer (on instrument panel, if equipped) The powertrain control module (PCM) contains a

voltage convertor. This converts battery voltage to a

regulated 8.0 volts. It is used to power the crankshaft

position sensor and camshaft position sensor. The

PCM also provides a five (5) volt supply for the man ifold absolute pressure (MAP) sensor and throttle po

sition sensor (TPS).

AIR

CONDITIONING

(A/C)

CONTROLS-PCM

INPUT

The A/C control system information applies to fac

tory installed air conditioning units. A/C SELECT SIGNAL: When the A/C switch is

in the ON position and the A/C low pressure switch

is closed, an input signal is sent to the powertrain

control module (PCM). The signal informs the PCM

that the A/C has been selected. The PCM adjusts idle speed to a pre-programmed rpm through the idle air

control (IAC) motor to compensate for increased en

gine load. A/C REQUEST SIGNAL: Once A/C has been se

lected, the powertrain control module (PCM) receives

the A/C request signal from the evaporator switch.

The input indicates that the evaporator temperature is in the proper range for A/C application. The PCM

uses this input to cycle the A/C compressor clutch (through the A/C relay). It will also determine the

correct engine idle speed through the idle air control (IAC) motor position. If the A/C low pressure switch opens (indicating a

low refrigerant level), the PCM will not receive an

A/C select signal. The PCM will then remove the ground from the A/C relay. This will deactivate the

A/C compressor clutch. If the evaporator switch opens, (indicating that

evaporator is not in proper temperature range), the

PCM will not receive the A/C request signal. The

PCM will then remove the ground from the A/C re lay, deactivating the A/C compressor clutch.

AUTOMATIC SHUT DOWN

(ASD)

SENSE-PCM INPUT

A 12 volt signal at this input indicates to the PCM

that the ASD has been activated. The ASD relay is located in the engine compartment (Fig. 2). It is used

to connect the oxygen sensor(s) heater element, igni

tion coil, generator field winding and fuel injectors to 12 volt + power supply. This input is used only to sense that the ASD relay

is energized. If the powertrain control module (PCM)

does not see 12 volts at this input when the ASD

should be activated, it will set a diagnostic trouble

code (DTC).

Page 852 of 1502

•

FUEL SYSTEM

14 - 33 Refer to Group 8D, Ignition System for more crank

shaft position sensor information. The engine will not operate if the PCM does not re

ceive a crankshaft position sensor input.

ENGINE

COOLANT TEMPERATURE SENSOR-PCM

INPUT

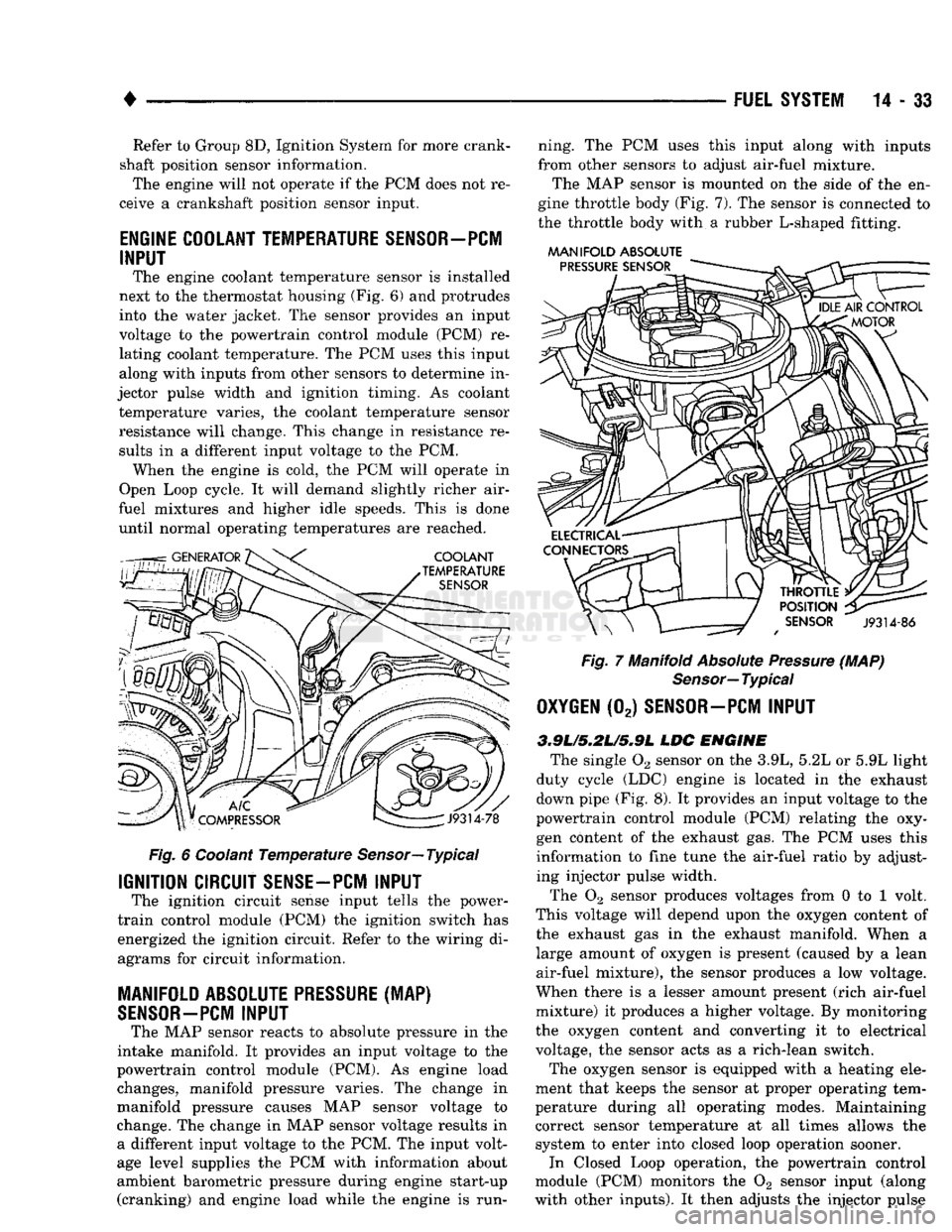

The engine coolant temperature sensor is installed

next to the thermostat housing (Fig. 6) and protrudes

into the water jacket. The sensor provides an input

voltage to the powertrain control module (PCM) re

lating coolant temperature. The PCM uses this input

along with inputs from other sensors to determine in

jector pulse width and ignition timing. As coolant temperature varies, the coolant temperature sensor

resistance will change. This change in resistance results in a different input voltage to the PCM. When the engine is cold, the PCM will operate in

Open Loop cycle. It will demand slightly richer air-

fuel mixtures and higher idle speeds. This is done until normal operating temperatures are reached.

Fig.

6 Coolant

Temperature

Sensor—

Typical

IGNITION CIRCUIT

SENSE-PCM

INPUT

The ignition circuit sense input tells the power-

train control module (PCM) the ignition switch has

energized the ignition circuit. Refer to the wiring di

agrams for circuit information.

MANIFOLD ABSOLUTE

PRESSURE

(MAP)

SENSOR-PCM

INPUT

The MAP sensor reacts to absolute pressure in the

intake manifold. It provides an input voltage to the

powertrain control module (PCM). As engine load changes, manifold pressure varies. The change in

manifold pressure causes MAP sensor voltage to

change. The change in MAP sensor voltage results in a different input voltage to the PCM. The input volt

age level supplies the PCM with information about

ambient barometric pressure during engine start-up (cranking) and engine load while the engine is run ning. The PCM uses this input along with inputs

from other sensors to adjust air-fuel mixture.

The MAP sensor is mounted on the side of the en

gine throttle body (Fig. 7). The sensor is connected to

the throttle body with a rubber L-shaped fitting.

MANIFOLD

ABSOLUTE

Fig.

7 Manifold

Absolute

Pressure

(MAP)

Sensor—

Typical

OXYGEN

(02)

SENSOR—PCM

INPUT

3.9L/5.2L/S»9L

LDC

ENGINE

The single 02 sensor on the 3.9L, 5.2L or 5.9L light

duty cycle (LDC) engine is located in the exhaust

down pipe (Fig. 8). It provides an input voltage to the

powertrain control module (PCM) relating the oxy

gen content of the exhaust gas. The PCM uses this

information to fine tune the air-fuel ratio by adjust ing injector pulse width.

The 02 sensor produces voltages from 0 to 1 volt.

This voltage will depend upon the oxygen content of

the exhaust gas in the exhaust manifold. When a large amount of oxygen is present (caused by a lean

air-fuel mixture), the sensor produces a low voltage.

When there is a lesser amount present (rich air-fuel

mixture) it produces a higher voltage. By monitoring

the oxygen content and converting it to electrical

voltage, the sensor acts as a rich-lean switch.

The oxygen sensor is equipped with a heating ele

ment that keeps the sensor at proper operating tem

perature during all operating modes. Maintaining

correct sensor temperature at all times allows the system to enter into closed loop operation sooner. In Closed Loop operation, the powertrain control

module (PCM) monitors the 02 sensor input (along

with other inputs). It then adjusts the injector pulse

Page 857 of 1502

14 - 38

FUEL SYSTEM

•

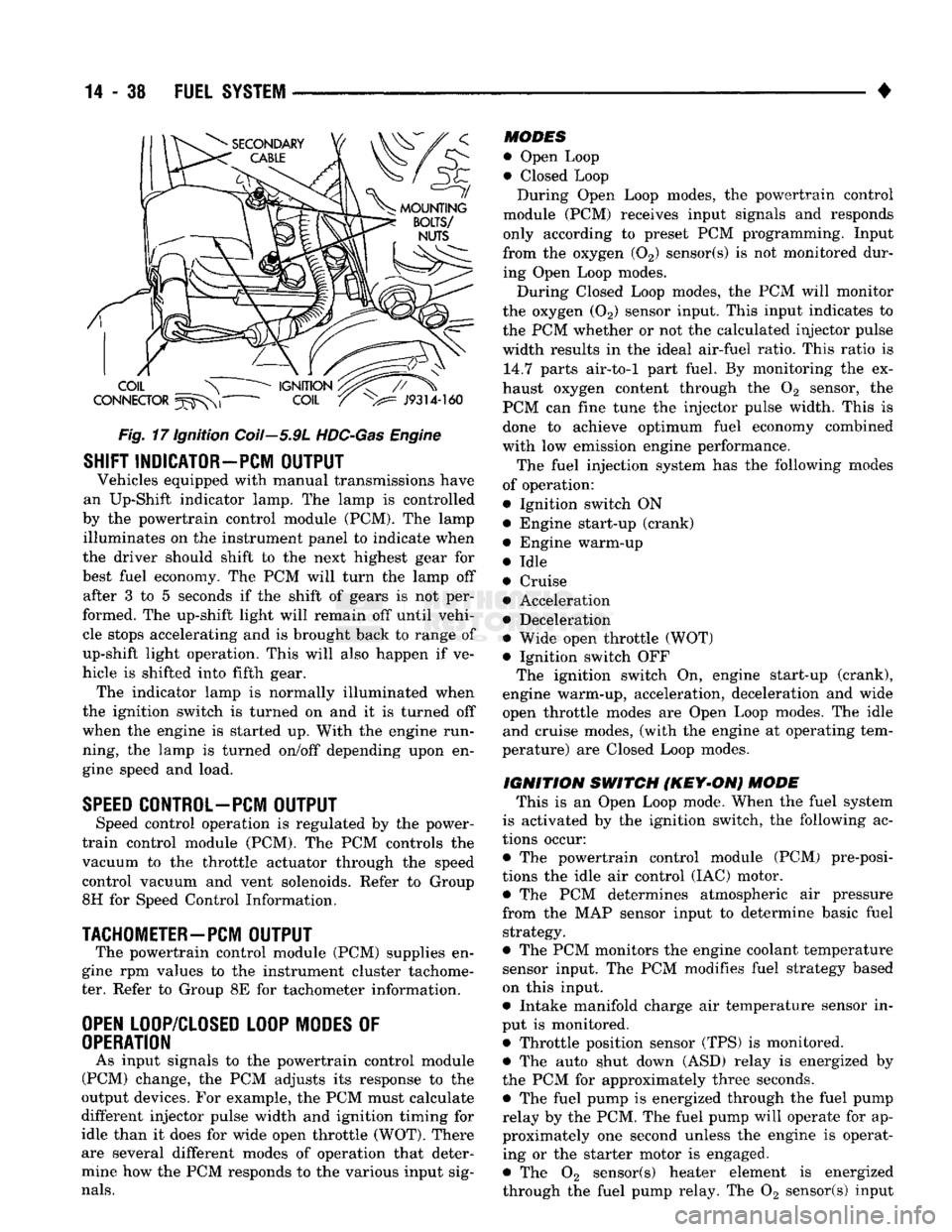

Fig.

17 Ignition Coil—5.9L

HDC-Gas

Engine

SHIFT INDICATOR-PCM

OUTPUT

Vehicles equipped with manual transmissions have

an Up-Shift indicator lamp. The lamp is controlled

by the powertrain control module (PCM). The lamp illuminates on the instrument panel to indicate when

the driver should shift to the next highest gear for

best fuel economy. The PCM will turn the lamp off after 3 to 5 seconds if the shift of gears is not per

formed. The up-shift light will remain off until vehi cle stops accelerating and is brought back to range of

up-shift light operation. This will also happen if ve

hicle is shifted into fifth gear. The indicator lamp is normally illuminated when

the ignition switch is turned on and it is turned off

when the engine is started up. With the engine run

ning, the lamp is turned on/off depending upon en

gine speed and load.

SPEED

CONTROL-PCM

OUTPUT

Speed control operation is regulated by the power-

train control module (PCM). The PCM controls the

vacuum to the throttle actuator through the speed

control vacuum and vent solenoids. Refer to Group

8H for Speed Control Information.

TACHOMETER—PCM

OUTPUT

The powertrain control module (PCM) supplies en

gine rpm values to the instrument cluster tachome ter. Refer to Group 8E for tachometer information.

OPEN

LOOP/CLOSED LOOP MODES

OF

OPERATION

As input signals to the powertrain control module

(PCM) change, the PCM adjusts its response to the

output devices. For example, the PCM must calculate

different injector pulse width and ignition timing for

idle than it does for wide open throttle (WOT). There

are several different modes of operation that deter

mine how the PCM responds to the various input sig

nals.

MODES

• Open Loop

• Closed Loop During Open Loop modes, the powertrain control

module (PCM) receives input signals and responds

only according to preset PCM programming. Input

from the oxygen (02) sensor(s) is not monitored dur

ing Open Loop modes.

During Closed Loop modes, the PCM will monitor

the oxygen (02) sensor input. This input indicates to

the PCM whether or not the calculated injector pulse width results in the ideal air-fuel ratio. This ratio is 14.7 parts air-to-1 part fuel. By monitoring the ex

haust oxygen content through the 02 sensor, the

PCM can fine tune the injector pulse width. This is done to achieve optimum fuel economy combined

with low emission engine performance.

The fuel injection system has the following modes

of operation:

• Ignition switch ON • Engine start-up (crank)

• Engine warm-up

• Idle

• Cruise • Acceleration

• Deceleration

• Wide open throttle (WOT)

• Ignition switch OFF The ignition switch On, engine start-up (crank),

engine warm-up, acceleration, deceleration and wide

open throttle modes are Open Loop modes. The idle and cruise modes, (with the engine at operating tem

perature) are Closed Loop modes.

IGNITION

SWITCH

(KEY-ON)

MODE

This is an Open Loop mode. When the fuel system

is activated by the ignition switch, the following ac

tions occur:

• The powertrain control module (PCM) pre-posi-

tions the idle air control (IAC) motor. • The PCM determines atmospheric air pressure

from the MAP sensor input to determine basic fuel strategy.

• The PCM monitors the engine coolant temperature sensor input. The PCM modifies fuel strategy based

on this input.

• Intake manifold charge air temperature sensor in

put is monitored.

• Throttle position sensor (TPS) is monitored. • The auto shut down (ASD) relay is energized by

the PCM for approximately three seconds. • The fuel pump is energized through the fuel pump

relay by the PCM. The fuel pump will operate for ap

proximately one second unless the engine is operat ing or the starter motor is engaged.

• The 02 sensor(s) heater element is energized

through the fuel pump relay. The 02 sensor(s) input

Page 858 of 1502

•

FUEL SYSTEM

14 - 39 is not used by the PCM to calibrate air-fuel ratio

during this mode of operation,

• The up-shift indicator light is illuminated (manual

transmission only).

ENGINE

START-UP

MODE

This is an Open Loop mode. The following actions

occur when the starter motor is engaged.

The powertrain control module (PCM) receives in

puts from:

• Battery voltage

• Engine coolant temperature sensor • Crankshaft position sensor

• Intake manifold charge air temperature sensor • Manifold absolute pressure (MAP) sensor

• Throttle position sensor (TPS)

• Starter motor relay • Camshaft position sensor signal The PCM monitors the crankshaft position sensor.

If the PCM does not receive a crankshaft position sensor signal within 3 seconds of cranking the en

gine,

it will shut down the fuel injection system.

The fuel pump is activated by the PCM through

the fuel pump relay.

Voltage is applied to the fuel injectors with the

PCM. The PCM will then control the injection se quence and injector pulse width by turning the

ground circuit to each individual injector on and off.

The PCM determines the proper ignition timing ac

cording to input received from the crankshaft posi

tion sensor.

ENGINE

WARM-UP

MODE This is an Open Loop mode. During engine warm-

up,

the powertrain control module (PCM) receives in

puts from:

• Battery voltage • Crankshaft position sensor

• Engine coolant temperature sensor

• Intake manifold charge air temperature sensor • Manifold absolute pressure (MAP) sensor

• Throttle position sensor (TPS) • Camshaft position sensor signal (in the distributor)

• Park/Neutral switch (gear indicator signal—auto,

trans,

only)

• Air conditioning select signal (if equipped)

• Air conditioning request signal (if equipped) Based on these inputs the following occurs:

• Voltage is applied to the fuel injectors with the

powertrain control module (PCM). The PCM will

then control the injection sequence and injector pulse

width by turning the ground circuit to each individ ual injector on and off.

• The PCM adjusts engine idle speed through the

idle air control (IAC) motor and adjusts ignition tim

ing. • The PCM operates the A/C compressor clutch

through the clutch relay. This is done if A/C has

been selected by the vehicle operator and requested by the A/C thermostat.

• If the vehicle has a manual transmission, the up

shift light is operated by the PCM.

« When engine has reached operating temperature,

the PCM will begin monitoring 02 sensor(s) input.

The system will then leave the warm-up mode and go into closed loop operation.

IDLE

MODE

When the engine is at operating temperature, this

is a Closed Loop mode. At idle speed, the powertrain control module (PCM) receives inputs from:

Air conditioning select signal (if equipped)

• Air conditioning request signal (if equipped)

• Battery voltage

• Crankshaft position sensor

• Engine coolant temperature sensor • Intake manifold charge air temperature sensor

• Manifold absolute pressure (MAP) sensor

• Throttle position sensor (TPS)

• Camshaft position sensor signal (in the distributor)

® Battery voltage

• Park/Neutral switch (gear indicator signal—Auto,

trans,

only) • Oxygen sensor

Based on these inputs, the following occurs:

• Voltage is applied to the fuel injectors with the

powertrain control module (PCM). The PCM will

then control injection sequence and injector pulse

width by turning the ground circuit to each individ ual injector on and off.

• The PCM monitors the 02 sensor(s) input and ad

justs air-fuel ratio by varying injector pulse width. It also adjusts engine idle speed through the idle air

control (IAC) motor. • The PCM adjusts ignition timing by increasing and decreasing spark advance.

• The PCM operates the A/C compressor clutch

through the clutch relay. This happens if A/C has

been selected by the vehicle operator and requested

by the A/C thermostat.

CRUISE

MODE

When the engine is at operating temperature, this

is a Closed Loop mode. At cruising speed, the power-

train control module (PCM) receives inputs from:

• Air conditioning select signal (if equipped)

• Air conditioning request signal (if equipped)

• Battery voltage • Engine coolant temperature sensor

• Crankshaft position sensor

• Intake manifold charge air temperature sensor • Manifold absolute pressure (MAP) sensor

• Throttle position sensor (TPS)

• Camshaft position sensor signal (in the distributor)

Page 859 of 1502

14

- 40

FUEL

SYSTEM

• • Park/Neutral switch (gear indicator signal—auto,

trans,

only)

• Oxygen (02) sensor(s) Based on these inputs, the following occurs:

• Voltage is applied to the fuel injectors with the

PCM. The PCM will then adjust the injector pulse

width by turning the ground circuit to each individ

ual injector on and off.

• The PCM monitors the 02 sensor(s) input and ad

justs air-fuel ratio. It also adjusts engine idle speed through the idle air control (IAC) motor.

• The PCM adjusts ignition timing by turning the

ground path to the coil on and off.

• The PCM operates the A/C compressor clutch

through the clutch relay. This happens if A/C has

been selected by the vehicle operator and requested

by the A/C thermostat.

ACCELERATION MODE

This is an Open Loop mode. The powertrain control

module (PCM) recognizes an abrupt increase in

throttle position or MAP pressure as a demand for

increased engine output and vehicle acceleration.

The PCM increases injector pulse width in response

to increased throttle opening.

DECELERATION MODE

When the engine is at operating temperature, this

is an Open Loop mode. During hard deceleration, the

powertrain control module (PCM) receives the follow ing inputs.

• Air conditioning select signal (if equipped)

• Air conditioning request signal (if equipped)

• Battery voltage

• Engine coolant temperature sensor

• Crankshaft position sensor

• Intake manifold charge air temperature sensor

• Manifold absolute pressure (MAP) sensor

• Throttle position sensor (TPS)

• Camshaft position sensor signal (in the distributor)

• Park/Neutral switch (gear indicator signal —auto,

trans,

only)

If the vehicle is under hard deceleration with the

proper rpm and closed throttle conditions, the PCM

will ignore the oxygen sensor input signal. The PCM

will enter a fuel cut-off strategy in which it will not supply battery voltage to the injectors. If a hard de

celeration does not exist, the PCM will determine the

proper injector pulse width and continue injection.

Based on the above inputs, the PCM will adjust en

gine idle speed through the idle air control (IAC) mo

tor. The PCM adjusts ignition timing by turning the

ground path to the coil on and off.

The PCM opens the ground circuit to the A/C

clutch relay to disengage the A/C compressor clutch.

This is done until the vehicle is no longer under de

celeration (if the A/C system is operating).

WIDE OPEN

THROTTLE

MODE

This is an Open Loop mode. During wide open

throttle operation, the powertrain control module (PCM) receives the following inputs.

• Battery voltage

• Crankshaft position sensor

• Engine coolant temperature sensor

• Intake manifold charge air temperature sensor

• Manifold absolute pressure (MAP) sensor

• Throttle position sensor (TPS) • Camshaft position sensor signal (in the distributor) During wide open throttle conditions, the following

occurs:

• Voltage is applied to the fuel injectors with the

powertrain control module (PCM). The PCM will

then control the injection sequence and injector pulse

width by turning the ground circuit to each individ ual injector on and off. The PCM ignores the oxygen sensor input signal and provides a predetermined amount of additional fuel. This is done by adjusting

injector pulse width.

• The PCM adjusts ignition timing by turning the

ground path to the coil on and off.

• The PCM opens the ground circuit to the A/C

clutch relay to disengage the A/C compressor clutch.

This will be done for approximately 15 seconds (if the air conditioning system is operating).

If the vehicle has a manual transmission, the up

shift light is operated by the PCM.

IGNITION

SWITCH

OFF

MODE

When ignition switch is turned to OFF position,

the PCM stops operating the injectors, ignition coil,

ASD relay and fuel pump relay.

THROTTLE

BODY

Filtered air from the air cleaner enters the intake

manifold through the throttle body (Fig. 18). Fuel does not enter the intake manifold through the throt

tle body. Fuel is sprayed into the manifold by the fuel injectors. The throttle body is mounted on the

intake manifold. It contains an air control passage (Fig. 19) controlled by an idle air control (IAC) mo

tor. The air control passage is used to supply air for idle conditions. A throttle valve (plate) is used to supply air for above idle conditions. The throttle position sensor (TPS), idle air control

(IAC) motor and manifold absolute pressure sensor

(MAP) are attached to the throttle body. The acceler

ator pedal cable, speed control cable and transmis

sion control cable (when equipped) are connected to

the throttle arm. A (factory adjusted) set screw is used to mechani

cally limit the position of the throttle body throttle

plate. Never attempt to adjust the engine idle speed using this screw. All idle speed functions are

controlled by the PCM.