coolant temperature DODGE TRUCK 1993 Service Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 1440 of 1502

•

HEATING

AND AIR

CONDITIONING

24 - 3

DIAGNOSTIC

PROCEDURES

INDEX

page

page ..

7

General Information

3

.

. 3

Heating System Output

3

Air

Conditioning System

Blower

Motor

GENERAL

INFORMATION

The reason for owner dissatisfaction must be thor

oughly understood before any attempt is made to re

pair or replace any parts. It must be determined if

the condition is the heater system, the refrigerant system, air conditioning air flow or related to the

compressor. After confirming the condition, a func

tional test is suggested using the diagnostic charts.

After the condition has been properly diagnosed and corrected, check out the complete system to assure

that it is performing satisfactorily. The following charts have been developed for quick

reference. If the step by step method used is not com pletely understood, refer to the correct section of the Service Manual for detailed explanations.

HEATING

SYSTEM

OUTPUT

WARNING:

IF

VEHICLE

HAS

BEEN

RUN

RECENTLY,

WAIT

15

MINUTES

BEFORE

REMOVING

CAP, THEN

PLACE

A RAG

OVER

THE CAP AND

TURN

IT TO

THE

FIRST

STOP.

ALLOW

PRESSURE

TO

ESCAPE

THROUGH

THE

OVERFLOW

TUBE

AND

WHEN

THE

SYSTEM

STABILIZES,

REMOVE

THE CAP

COM

PLETELY.

Check the radiator coolant level, drive belt tension,

engine vacuum line connections, radiator air flow and radiator fan operation. Start engine and bring to

normal operating temperature (refer to Group 7,

Cooling System).

Engine coolant is provided to the heater system by

2 heater hoses. With engine idling at normal operat

ing temperature, set the heater control to maximum

heat, defrost and high blower setting. Using a test

thermometer, check the air temperature coming from

the defroster outlets (refer to Temperature Reference Chart).

Should the temperature not meet the minimum

values shown, refer to Heater Diagnosis (Mechanical)

for possible causes and corrections.

(1) Remove radiator pressure cap.

(2) Drain 1 pint of coolant from the radiator.

(3) Warm the engine to operating temperature by

idling for 20 minutes, with the pressure cap off. Idle longer if working outdoors in cold temperatures. (4) With the engine idling, place a thermometer

into the coolant in the radiator filler neck.

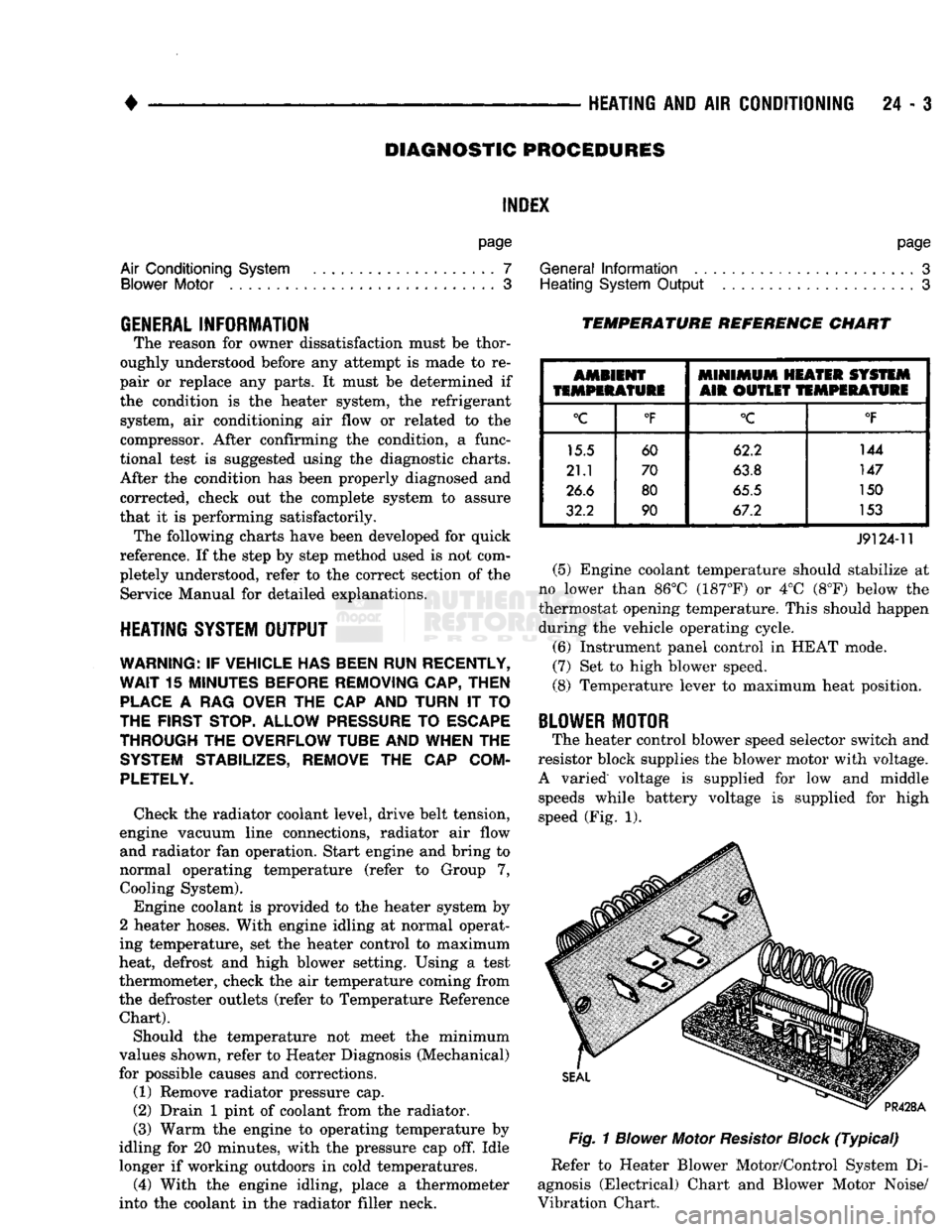

TEMPERATURE REFERENCE CHART

AMBIENT

MINIMUM

HEATER SYSTEM

TEMPERATURE

AIR OUTLET

TEMPERATURE

°C

°F

°C

°F

15.5 60 62.2 144

21.1 70

63.8 147

26.6 80

65.5 150

32.2 90 67.2 153

J9124-11

(5) Engine coolant temperature should stabilize at

no lower than 86°C (187°F) or 4°C (8°F) below the

thermostat opening temperature. This should happen during the vehicle operating cycle.

(6) Instrument panel control in HEAT mode.

(7) Set to high blower speed.

(8) Temperature lever to maximum heat position.

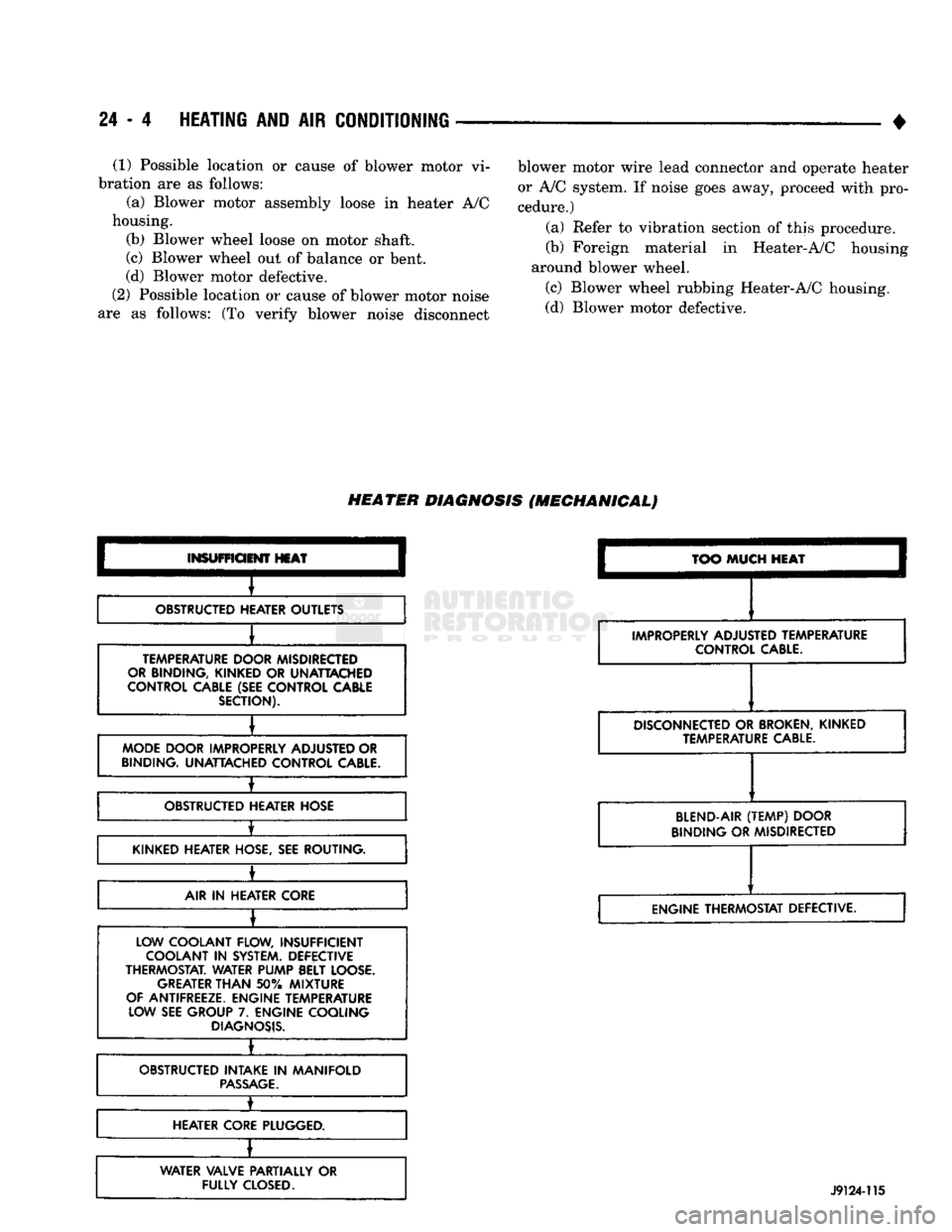

BLOWER

MOTOR

The heater control blower speed selector switch and

resistor block supplies the blower motor with voltage.

A varied voltage is supplied for low and middle speeds while battery voltage is supplied for high

speed (Fig. 1).

Fig.

1

Blower

Motor

Resistor

Block

(Typical)

Refer to Heater Blower Motor/Control System Di

agnosis (Electrical) Chart and Blower Motor Noise/

Vibration Chart.

Page 1441 of 1502

24

- 4

HEATING

AND

AIR

CONDITIONING

•

(1) Possible location or cause of blower motor vi

bration are as follows:

(a) Blower motor assembly loose in heater A/C

housing.

(b) Blower wheel loose on motor shaft.

(c) Blower wheel out of balance or bent.

(d) Blower motor defective.

(2) Possible location or cause of blower motor noise

are as follows: (To verify blower noise disconnect blower motor wire lead connector and operate heater

or A/C system. If noise goes away, proceed with pro

cedure.)

(a) Refer to vibration section of this procedure.

(b) Foreign material in Heater-A/C housing

around blower wheel.

(c) Blower wheel rubbing Heater-A/C housing.

(d) Blower motor defective.

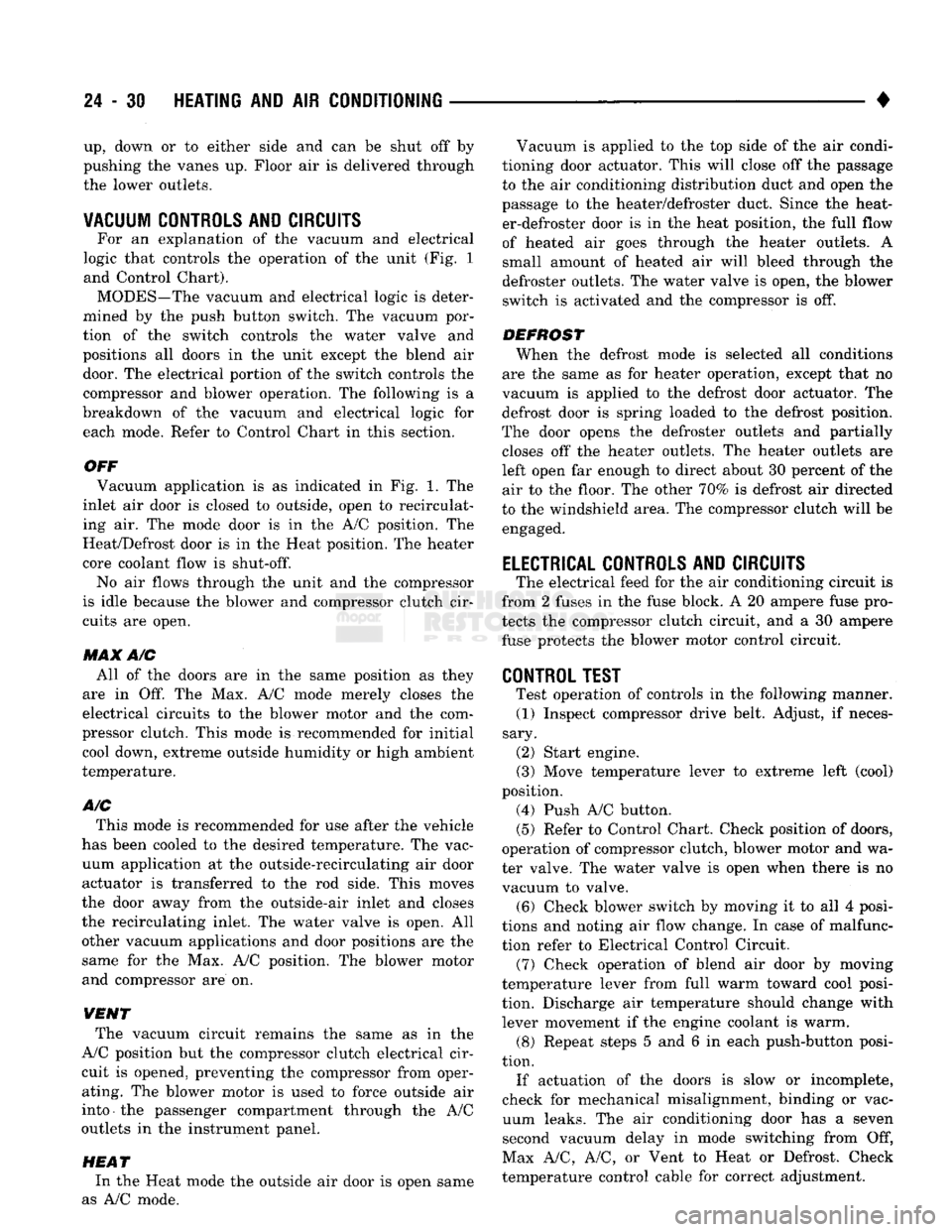

HEATER

DIAGNOSIS

(MECHANICAL)

INSUFFICIENT

HEAT

OBSTRUCTED HEATER OUTLETS

TEMPERATURE DOOR MISDIRECTED

OR BINDING, KINKED

OR

UNATTACHED

CONTROL CABLE (SEE CONTROL CABLE SECTION).

MODE DOOR IMPROPERLY ADJUSTED OR

BINDING. UNATTACHED CONTROL

CABLE.

±

OBSTRUCTED HEATER HOSE

•

KINKED HEATER HOSE, SEE ROUTING.

±

AIR

IN

HEATER CORE

LOW COOLANT FLOW, INSUFFICIENT COOLANT

IN

SYSTEM. DEFECTIVE

THERMOSTAT. WATER PUMP BELT LOOSE. GREATER

THAN

50%

MIXTURE

OF ANTIFREEZE. ENGINE TEMPERATURE LOW SEE GROUP

7.

ENGINE COOLING

DIAGNOSIS.

•

OBSTRUCTED INTAKE

IN

MANIFOLD

PASSAGE.

1_

HEATER CORE PLUGGED.

WATER VALVE PARTIALLY

OR

FULLY

CLOSED.

TOO

MUCH

HEAT

IMPROPERLY ADJUSTED TEMPERATURE CONTROL

CABLE.

DISCONNECTED

OR

BROKEN,

KINKED TEMPERATURE

CABLE.

BLEND-AIR

(TEMP)

DOOR

BINDING OR MISDIRECTED

ENGINE THERMOSTAT DEFECTIVE.

J9124-115

Page 1467 of 1502

24 - 30

HEATING

AND AIR

CONDITIONING

•

up,

down or to either side and can be shut off by

pushing the vanes up. Floor air is delivered through

the lower outlets.

VACUUM CONTROLS

AND

CIRCUITS

For an explanation of the vacuum and electrical

logic that controls the operation of the unit (Fig. 1

and Control Chart). MODES—The vacuum and electrical logic is deter

mined by the push button switch. The vacuum por

tion of the switch controls the water valve and

positions all doors in the unit except the blend air

door. The electrical portion of the switch controls the compressor and blower operation. The following is a

breakdown of the vacuum and electrical logic for each mode. Refer to Control Chart in this section.

OFF Vacuum application is as indicated in Fig. 1. The

inlet air door is closed to outside, open to recirculat

ing air. The mode door is in the A/C position. The

Heat/Defrost door is in the Heat position. The heater core coolant flow is

shut-off.

No air flows through the unit and the compressor

is idle because the blower and compressor clutch cir

cuits are open.

MAX A/C All of the doors are in the same position as they

are in Off. The Max. A/C mode merely closes the

electrical circuits to the blower motor and the com

pressor clutch. This mode is recommended for initial cool down, extreme outside humidity or high ambient

temperature.

A/C

This mode is recommended for use after the vehicle

has been cooled to the desired temperature. The vac

uum application at the outside-recirculating air door actuator is transferred to the rod side. This moves

the door away from the outside-air inlet and closes

the recirculating inlet. The water valve is open. All

other vacuum applications and door positions are the

same for the Max. A/C position. The blower motor and compressor are on.

VENT The vacuum circuit remains the same as in the

A/C position but the compressor clutch electrical cir

cuit is opened, preventing the compressor from oper ating. The blower motor is used to force outside air

into the passenger compartment through the A/C

outlets in the instrument panel.

HEAT

In the Heat mode the outside air door is open same

as A/C mode. Vacuum is applied to the top side of the air condi

tioning door actuator. This will close off the passage

to the air conditioning distribution duct and open the

passage to the heater/defroster duct. Since the heat er-defroster door is in the heat position, the full flow

of heated air goes through the heater outlets. A

small amount of heated air will bleed through the

defroster outlets. The water valve is open, the blower

switch is activated and the compressor is off.

DEFROST When the defrost mode is selected all conditions

are the same as for heater operation, except that no

vacuum is applied to the defrost door actuator. The defrost door is spring loaded to the defrost position.

The door opens the defroster outlets and partially closes off the heater outlets. The heater outlets are

left open far enough to direct about 30 percent of the

air to the floor. The other 70% is defrost air directed

to the windshield area. The compressor clutch will be engaged.

ELECTRICAL CONTROLS AND CIRCUITS

The electrical feed for the air conditioning circuit is

from 2 fuses in the fuse block. A 20 ampere fuse pro

tects the compressor clutch circuit, and a 30 ampere fuse protects the blower motor control circuit.

CONTROL TEST

Test operation of controls in the following manner.

(1) Inspect compressor drive belt. Adjust, if neces

sary. (2) Start engine. (3) Move temperature lever to extreme left (cool)

position. (4) Push A/C button.

(5)

Refer to Control Chart. Check position of doors,

operation of compressor clutch, blower motor and wa

ter valve. The water valve is open when there is no

vacuum to valve. (6) Check blower switch by moving it to all 4 posi

tions and noting air flow change. In case of malfunc

tion refer to Electrical Control Circuit. (7) Check operation of blend air door by moving

temperature lever from full warm toward cool posi

tion. Discharge air temperature should change with lever movement if the engine coolant is warm. (8) Repeat steps 5 and 6 in each push-button posi

tion. If actuation of the doors is slow or incomplete,

check for mechanical misalignment, binding or vac uum leaks. The air conditioning door has a seven

second vacuum delay in mode switching from Off,

Max A/C, A/C, or Vent to Heat or Defrost. Check

temperature control cable for correct adjustment.

Page 1487 of 1502

25-10

EMISSION

CONTROL

SYSTEMS

EXHAUST

EMISSION

CONTROLS

INDEX

page

Air Inlet—5.9L Diesel

Engine

13

Exhaust

Gas Recirculation (EGR)

Systems

10

HEATED

INLET

AIR

SYSTEM

The air filter housing mounted-heated inlet air sys

tem is no longer used on any Dodge Truck gas pow ered engine.

EXHAUST

GAS

RECIRCULATION

(EGR)

SYSTEMS

GENERAL INFORMATION The EGR system reduces oxides of nitrogen (NOx)

in the engine exhaust and helps prevent spark

knock. This is accomplished by allowing a predeter

mined amount of hot exhaust gas to recirculate and

dilute the incoming fuel/air mixture. This dilution

reduces peak flame temperature during combustion.

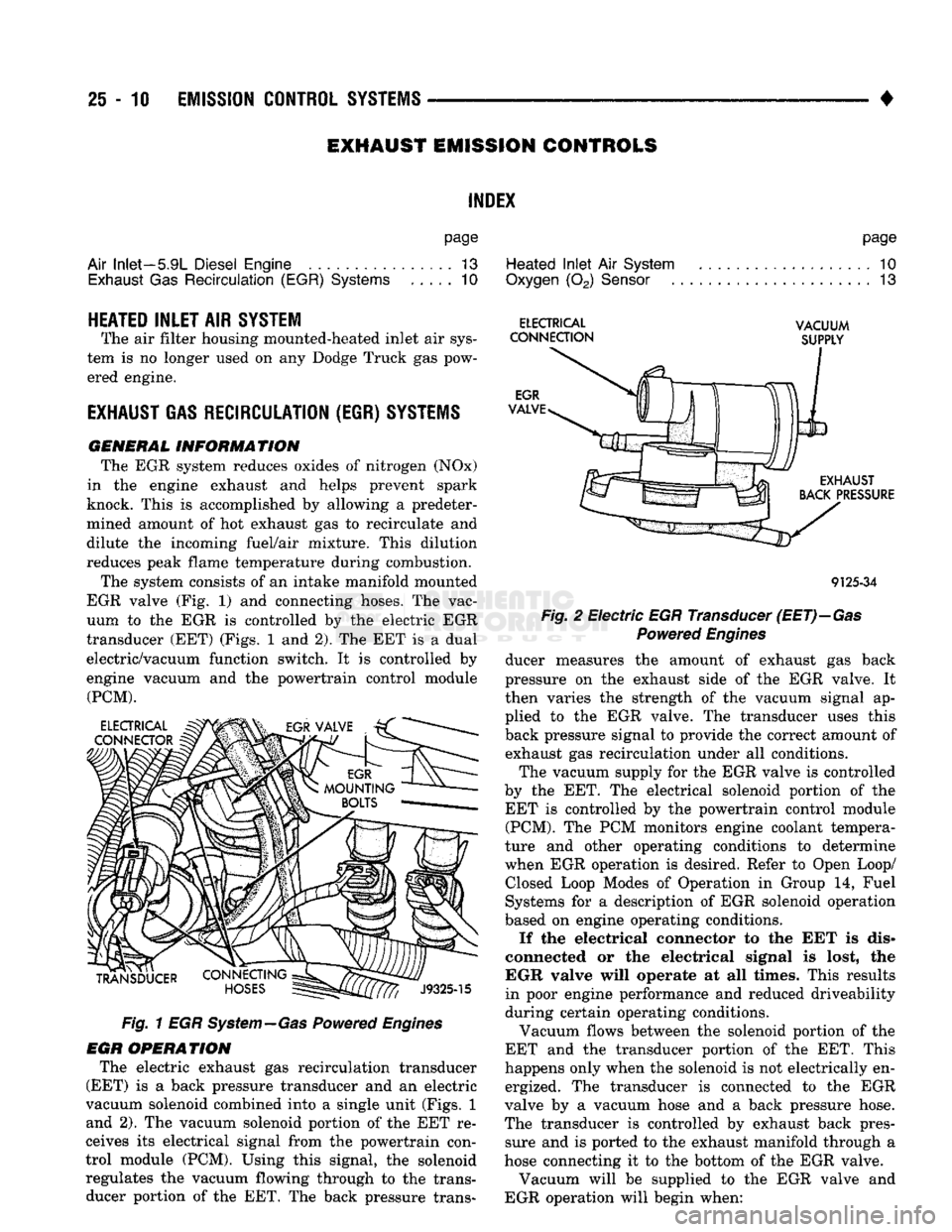

The system consists of an intake manifold mounted

EGR valve (Fig. 1) and connecting hoses. The vac

uum to the EGR is controlled by the electric EGR

transducer (EET) (Figs. 1 and 2). The EET is a dual

electric/vacuum function switch. It is controlled by

engine vacuum and the powertrain control module (PCM).

Fig. 1 EGR System—Gas Powered Engines

EGR OPERATION The electric exhaust gas recirculation transducer

(EET) is a back pressure transducer and an electric

vacuum solenoid combined into a single unit (Figs. 1 and 2). The vacuum solenoid portion of the EET re

ceives its electrical signal from the powertrain con

trol module (PCM). Using this signal, the solenoid regulates the vacuum flowing through to the trans ducer portion of the EET. The back pressure trans-

page

Heated

Inlet

Air

System

. 10

Oxygen

(02)

Sensor

13

ELECTRICAL

VACUUM

CONNECTION

SUPPLY

9125-34

Fig.

2 Electric EGR Transducer

(EET)—Gas

Powered

Engines

ducer measures the amount of exhaust gas back

pressure on the exhaust side of the EGR valve. It

then varies the strength of the vacuum signal ap

plied to the EGR valve. The transducer uses this

back pressure signal to provide the correct amount of exhaust gas recirculation under all conditions.

The vacuum supply for the EGR valve is controlled

by the EET. The electrical solenoid portion of the EET is controlled by the powertrain control module (PCM). The PCM monitors engine coolant tempera

ture and other operating conditions to determine

when EGR operation is desired. Refer to Open Loop/ Closed Loop Modes of Operation in Group 14, Fuel

Systems for a description of EGR solenoid operation

based on engine operating conditions.

If the electrical connector to the EET is dis

connected or the electrical signal is lost, the

EGR valve will operate at all times. This results

in poor engine performance and reduced driveability

during certain operating conditions.

Vacuum flows between the solenoid portion of the

EET and the transducer portion of the EET. This

happens only when the solenoid is not electrically en ergized. The transducer is connected to the EGR

valve by a vacuum hose and a back pressure hose.

The transducer is controlled by exhaust back pres sure and is ported to the exhaust manifold through a

hose connecting it to the bottom of the EGR valve.

Vacuum will be supplied to the EGR valve and

EGR operation will begin when:

Page 1494 of 1502

•

EMISSION

CONTROL SYSTEMS

25 - 17

COMPONENT REMOVAL/INSTALLATION

INDEI

page

Air

Filter/Filter

Housing—Diesel Engines

17

Air

Filter/Filter

Housing—Gas Engines

17

Air

Injection

Pump

17

Air

Injection

Pump Relief Valve

18

Check

Valve—Air

Injection

Tube

18

Coolant Temperature

Sensor

. 18

EGR

Tube—Gas Powered Engines

19

EGR

Valve

19

AIR FILTER/FILTER HOUSING-GAS ENGINES

REMOVAL/INSTALLATION Remove crankcase breather/filter hose at side of air

filter housing. Remove wingnut (Fig. 1) and remove

housing from engine. Check condition of gasket at

throttle body and replace as necessary. To replace air filter element only: Remove wingnut

and air filter housing cover (Fig. 1). Clean inside of

housing before replacing filter. Housing removal is not necessary for filter replacement.

^

WING NUT

COVER

:

GASKET

| I

MOUNTING

STUD

Fig.

1 Air

Filter

Housing—Gas

Powered

Engines—Typical

page

Electric

EGR Transducer (EET)

20

EVAP

Canister

20

EVAP

Canister Purge Solenoid

20

Fuel Tank

Filler

Tube

Cap . 21

Oxygen

(02)

Sensor

21

Powertrain Control Module (PCM)

21

Pressure

Relief/Rollover Valve

21

If housing-to-throttle body mounting stud is being

installed, tighten to 10 N»m (90 in. lbs.) torque. In stall housing to engine and tighten wingnut to 1.5

N»m (15 in. lbs.) torque.

AIR FILTER/FILTER HOUSING-DIESEL ENGINES

REMO

VAL/INSTALLA

TION Remove the hose clamp at air filter housing (Fig.

2).

Remove mounting nuts and remove air filter

housing from vehicle.

To replace air filter element only: Remove hose clamp

and hose at air filter housing inlet tube. Remove three

wingnuts and air filter housing cover (Figs. 2 and 3). Clean inside of housing before replacing filter. Housing

removal is not necessary for filter replacement.

When installing a new air filter element, push el

ement into cover. Be sure it is pushed into tabs in

back of filter housing. Install wing nuts.

If housing had been removed, install mounting

nuts and tighten to 10 N»m (95 in. lbs.) torque.

AIR INJECTION PUMP

REMOVAL (1) Remove the relief valve hose clamp (Fig. 4) and

remove hose at relief valve.

(2) Remove relief valve from air pump (two bolts)

(Fig. 4). (3) Loosen (but do not remove at this time) the

three air pump pulley mounting bolts (number 2—figure 4).

(4) Relax the automatic belt tensioner and remove

the engine accessory drive belt. Refer to Group 7, Cooling System. See Belt Removal/Installation.

(5) Remove the three air pump pulley bolts and re

move pulley from pump.

(6) Remove the two air pump mounting bolts

(number

1—figure

4) and remove pump from mount

ing bracket.

Page 1495 of 1502

25

- 18

EMISSION

CONTROL

SYSTEMS

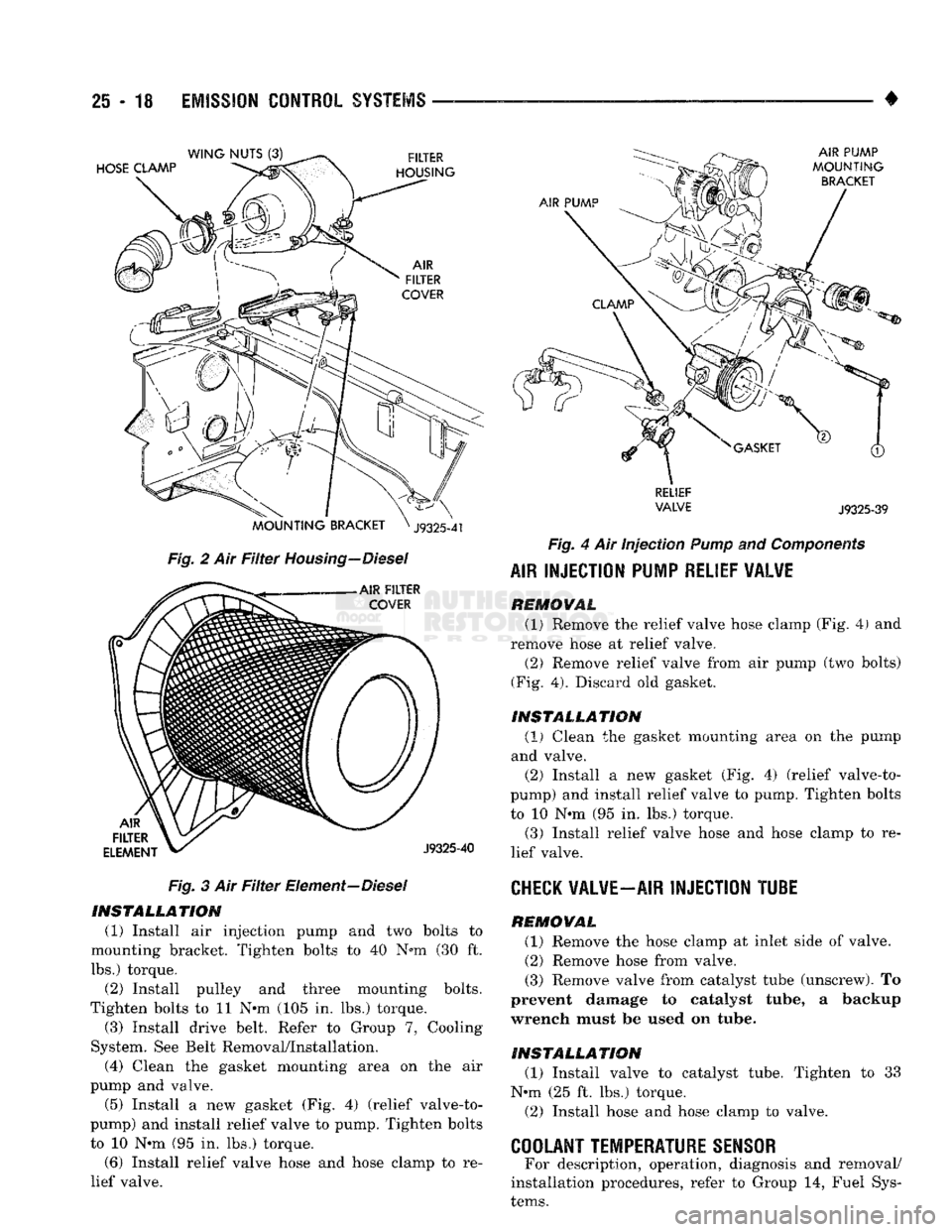

Fig. 2 Air Filter Housing—Diesel Fig. 3 Air Filter Element—Diesel INSTALLATION

(1) Install air injection pump and two bolts to

mounting bracket. Tighten bolts to 40 N*m (30 ft.

lbs.) torque. (2) Install pulley and three mounting bolts.

Tighten bolts to 11 N*m (105 in. lbs.) torque.

(3) Install drive belt. Refer to Group 7, Cooling

System. See Belt Removal/Installation.

(4) Clean the gasket mounting area on the air

pump and valve. (5) Install a new gasket (Fig. 4) (relief valve-to-

pump) and install relief valve to pump. Tighten bolts to 10 N*m (95 in. lbs.) torque.

(6) Install relief valve hose and hose clamp to re

lief valve. •

RELIEF

VALVE

J9325-39

Fig. 4 Air Injection

Pump

and

Components

AIR

INJECTION PUMP RELIEF VALVE REMOVAL

(1) Remove the relief valve hose clamp (Fig. 4) and

remove hose at relief valve.

(2) Remove relief valve from air pump (two bolts)

(Fig. 4). Discard old gasket.

INSTALLATION (1)

Clean the gasket mounting area on the pump

and valve. (2) Install a new gasket (Fig. 4) (relief valve-to-

pump) and install relief valve to pump. Tighten bolts

to 10 N*m (95 in. lbs.) torque. (3) Install relief valve hose and hose clamp to re

lief valve.

CHECK

VALVE—AIR INJECTION TUBE REMOVAL

(1) Remove the hose clamp at inlet side of valve.

(2) Remove hose from valve.

(3) Remove valve from catalyst tube (unscrew). To

prevent damage to catalyst tube, a backup

wrench must be used on tube.

INSTALLATION

(1) Install valve to catalyst tube. Tighten to 33

N«m (25 ft. lbs.) torque.

(2) Install hose and hose clamp to valve.

COOLANT TEMPERATURE SENSOR

For description, operation, diagnosis and removal/

installation procedures, refer to Group 14, Fuel Sys

tems.