torque DODGE TRUCK 1993 Service Service Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 107 of 1502

2

- 54

FRONT SUSPENSION

AND

AXLE

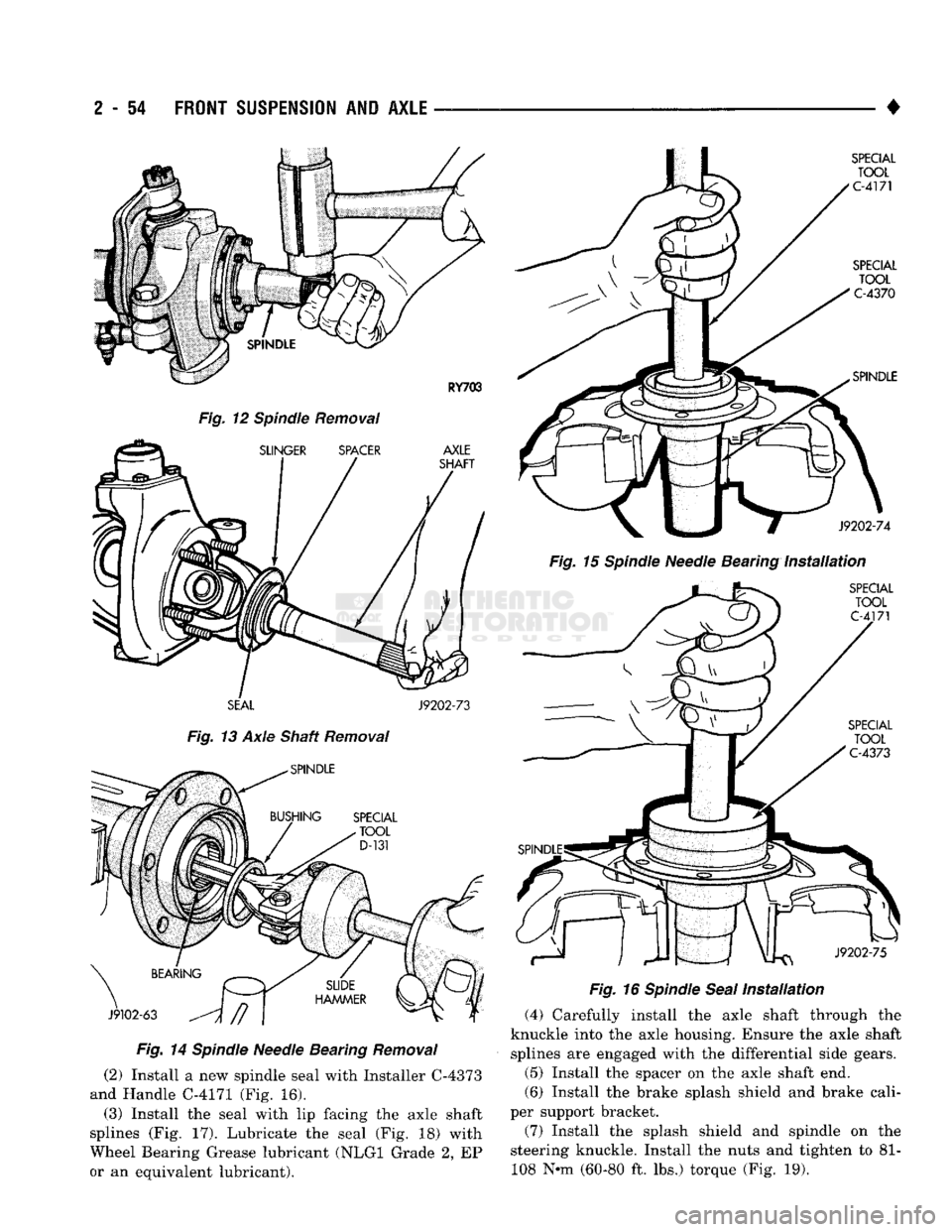

Fig.

12 Spindle Removal

SEAL

J9202-73

Fig.

13 Axle Shaft Removal

Fig.

14

Spindle

Needle Bearing

Removal

(2) Install a new spindle seal with Installer C-4373

and Handle C-4171 (Fig. 16).

(3) Install the seal with lip facing the axle shaft

splines (Fig. 17). Lubricate the seal (Fig. 18) with

Wheel Bearing Grease lubricant (NLGI Grade 2, EP

or an equivalent lubricant). •

Fig.

15

Spindle

Needle Bearing

Installation

Fig.

16

Spindle

Seal

Installation

(4) Carefully install the axle shaft through the

knuckle into the axle housing. Ensure the axle shaft splines are engaged with the differential side gears.

(5) Install the spacer on the axle shaft end.

(6) Install the brake splash shield and brake cali

per support bracket.

(7) Install the splash shield and spindle on the

steering knuckle. Install the nuts and tighten to 81- 108 N-m (60-80 ft. lbs.) torque (Fig. 19).

Page 108 of 1502

•

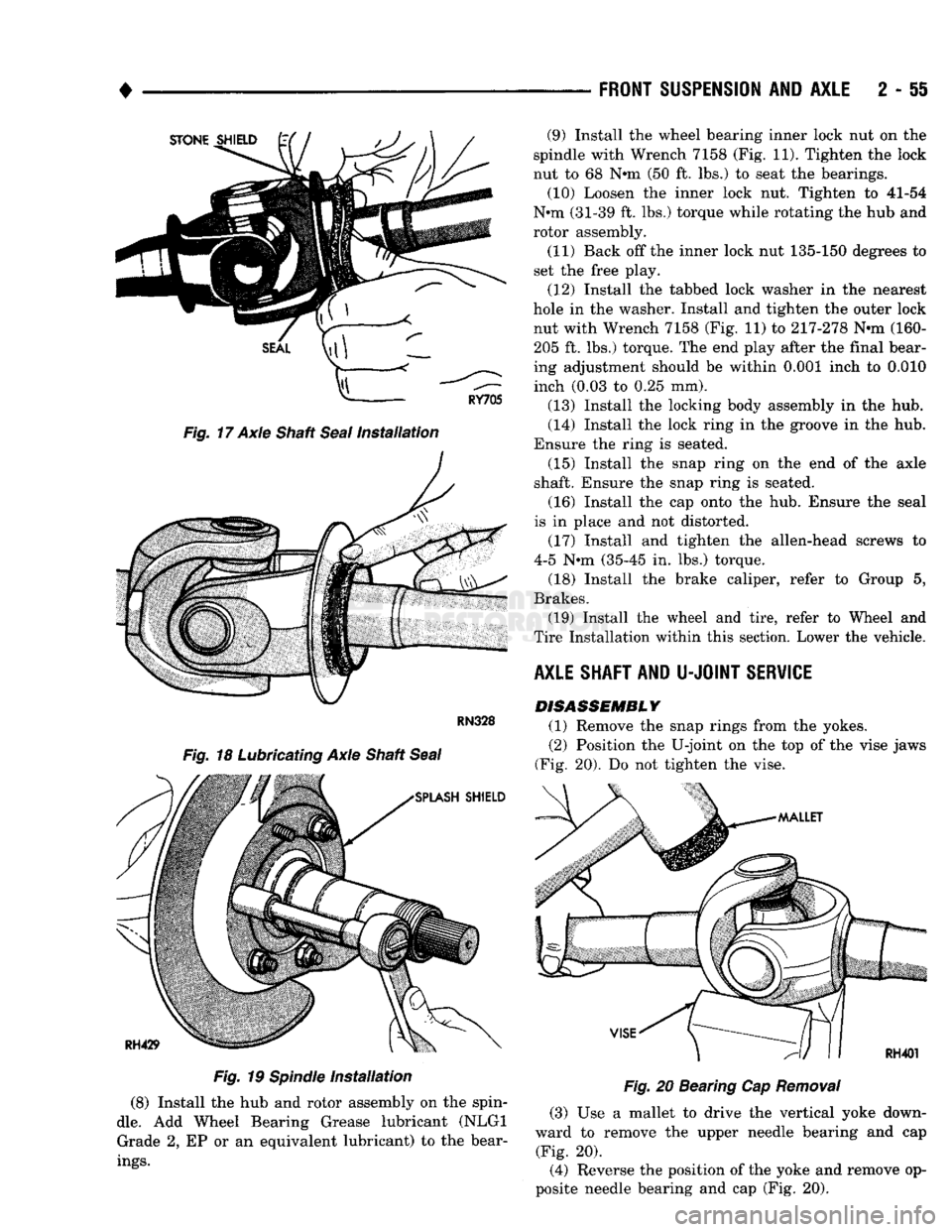

Fig.

17 Axle Shaft

Seal

Installation

Fig.

19

Spindle

Installation

(8) Install the hub and rotor assembly on the spin

dle.

Add Wheel Bearing Grease lubricant (NLGI Grade 2, EP or an equivalent lubricant) to the bear

ings.

FRONT

SUSPENSION

AND

AXLE

2 - 51

Fig.

20 Bearing Cap

Removal

(3) Use a mallet to drive the vertical yoke down

ward to remove the upper needle bearing and cap (Fig. 20).

(4) Reverse the position of the yoke and remove op

posite needle bearing and cap (Fig. 20). (9) Install the wheel bearing inner lock nut on the

spindle with Wrench 7158 (Fig. 11). Tighten the lock

nut to 68 N*m (50 ft. lbs.) to seat the bearings. (10) Loosen the inner lock nut. Tighten to 41-54

N*m (31-39 ft. lbs.) torque while rotating the hub and

rotor assembly.

(11) Back off the inner lock nut 135-150 degrees to

set the free play.

(12) Install the tabbed lock washer in the nearest

hole in the washer. Install and tighten the outer lock nut with Wrench 7158 (Fig. 11) to 217-278 N-m (160-205 ft. lbs.) torque. The end play after the final bear

ing adjustment should be within 0.001 inch to 0.010 inch (0.03 to 0.25 mm).

(13) Install the locking body assembly in the hub.

(14) Install the lock ring in the groove in the hub.

Ensure the ring is seated. (15) Install the snap ring on the end of the axle

shaft. Ensure the snap ring is seated.

(16) Install the cap onto the hub. Ensure the seal

is in place and not distorted.

(17) Install and tighten the allen-head screws to

4-5 N-m (35-45 in. lbs.) torque.

(18) Install the brake caliper, refer to Group 5,

Brakes. (19) Install the wheel and tire, refer to Wheel and

Tire Installation within this section. Lower the vehicle.

AXLE SHAFT AND

U-JOINT

SERVICE DISASSEMBLY

(1) Remove the snap rings from the yokes.

(2) Position the U-joint on the top of the vise jaws

(Fig. 20). Do not tighten the vise.

Page 110 of 1502

•

FRONT

SUSPENSION

AND

AXLE

2 - 57

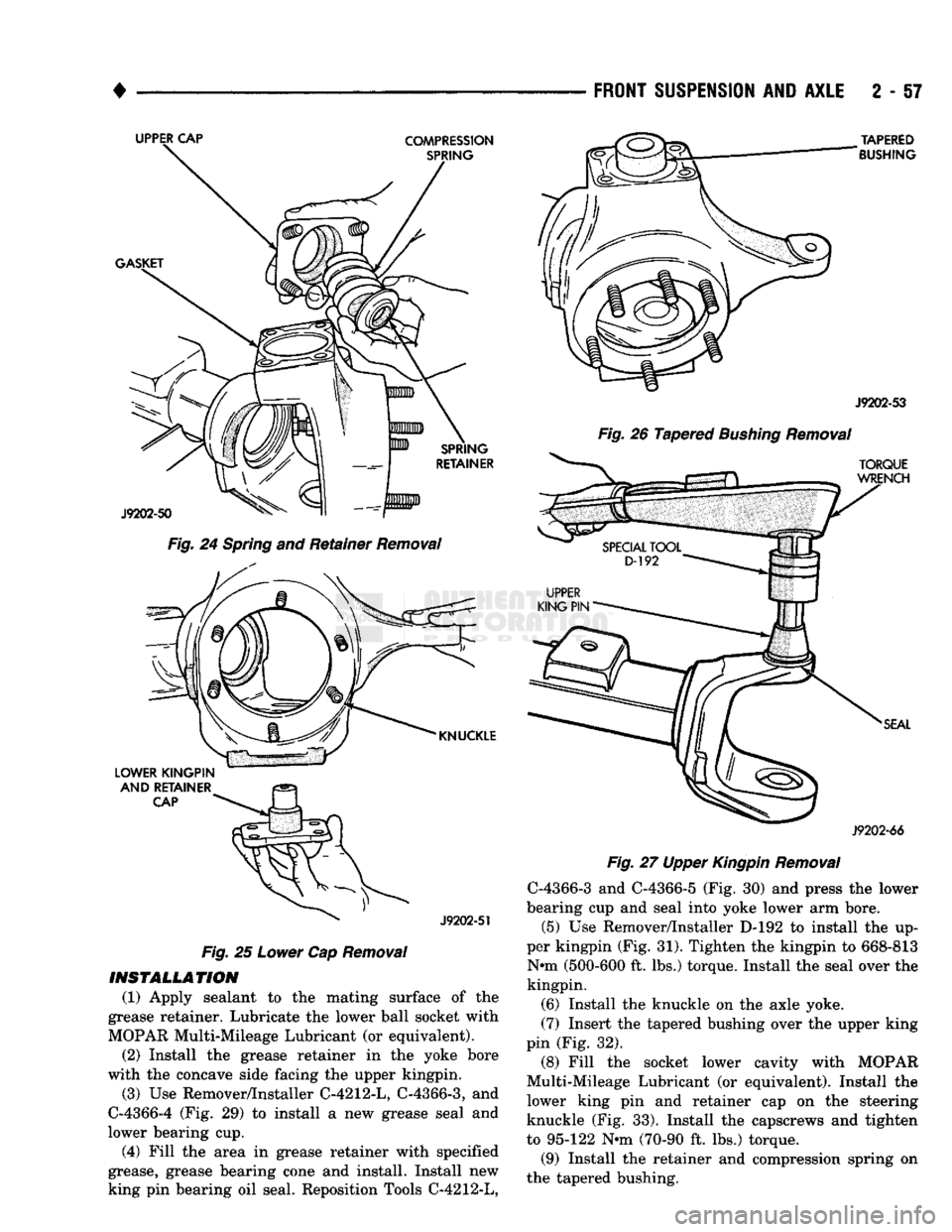

Fig.

24

Spring

and Retainer

Removal

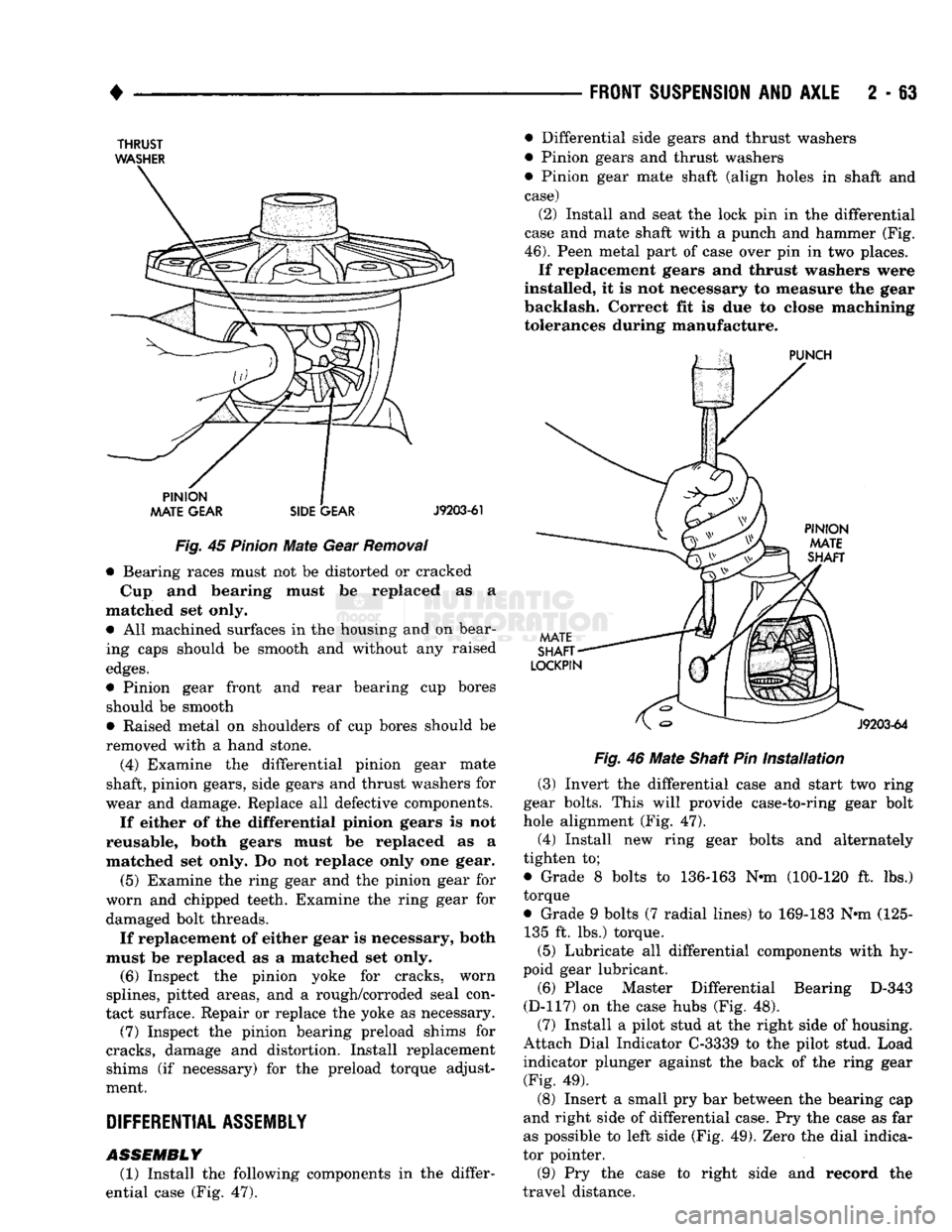

LOWER KINGPIN

AND

RETAINER

CAP

^

J9202-51

Fig.

25

Lower

Cap

Removal

INSTALLATION (1) Apply sealant to the mating surface of the

grease retainer. Lubricate the lower ball socket with

MOPAR Multi-Mileage Lubricant (or equivalent).

(2) Install the grease retainer in the yoke bore

with the concave side facing the upper kingpin.

(3) Use Remover/Installer C-4212-L, C-4366-3, and

C-4366-4 (Fig. 29) to install a new grease seal and

lower bearing cup.

(4) Fill the area in grease retainer with specified

grease, grease bearing cone and install. Install new

king pin bearing oil seal. Reposition Tools C-4212-L,

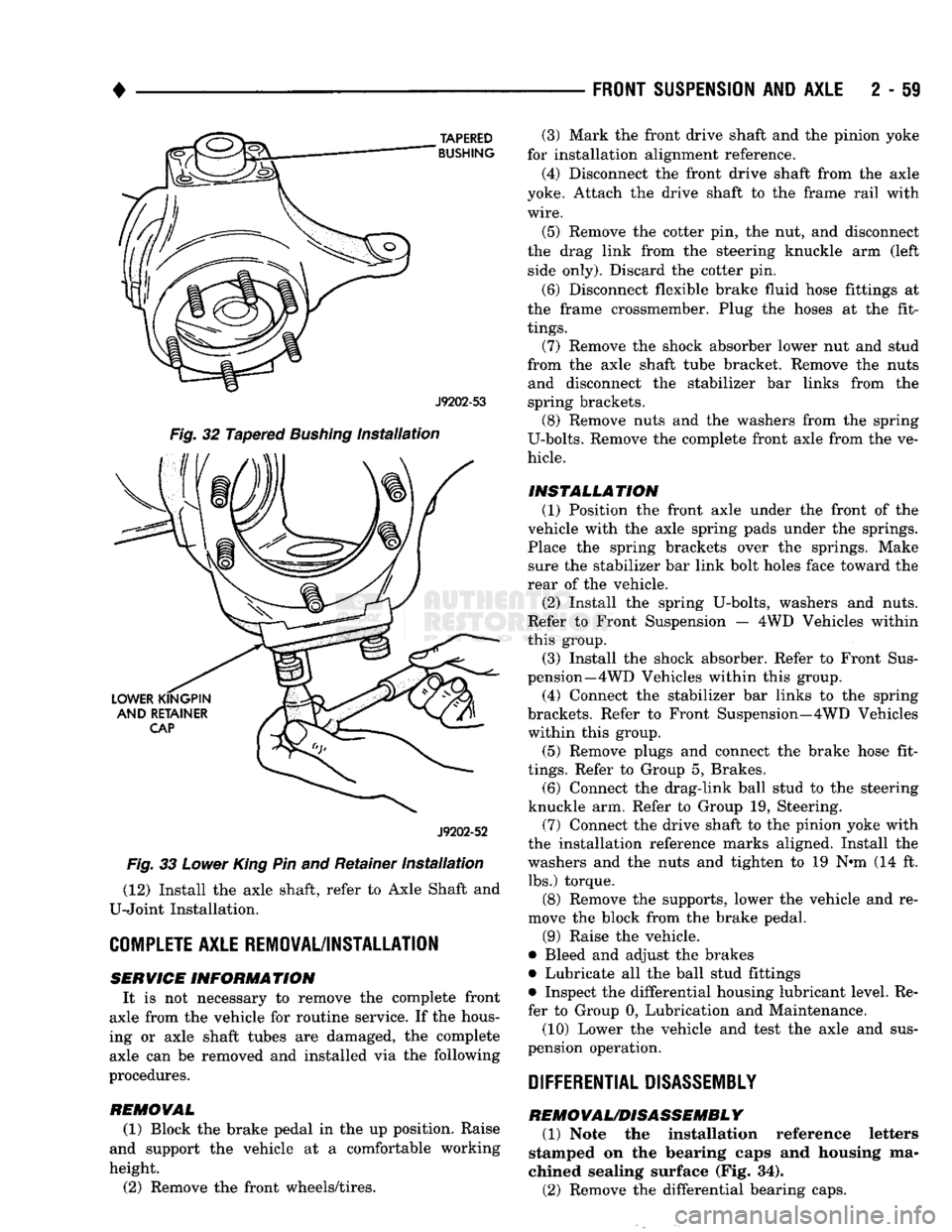

TAPERED

BUSHING

J9202-53

Fig.

26 Tapered

Bushing

Removal

J9202-66

Fig.

27 Upper

Kingpin

Removal

C-4366-3 and C-4366-5 (Fig. 30) and press the lower

bearing cup and seal into yoke lower arm bore.

(5) Use Remover/Installer D-192 to install the up

per kingpin (Fig. 31). Tighten the kingpin to 668-813 N-m (500-600 ft. lbs.) torque. Install the seal over the

kingpin.

(6) Install the knuckle on the axle yoke.

(7) Insert the tapered bushing over the upper king

pin (Fig. 32).

(8) Fill the socket lower cavity with MOPAR

Multi-Mileage Lubricant (or equivalent). Install the

lower king pin and retainer cap on the steering

knuckle (Fig. 33). Install the capscrews and tighten

to 95-122 N-m (70-90 ft. lbs.) torque.

(9) Install the retainer and compression spring on

the tapered bushing.

Page 111 of 1502

2

- 58

FRONT

SUSPENSION

AND

AXLE

•

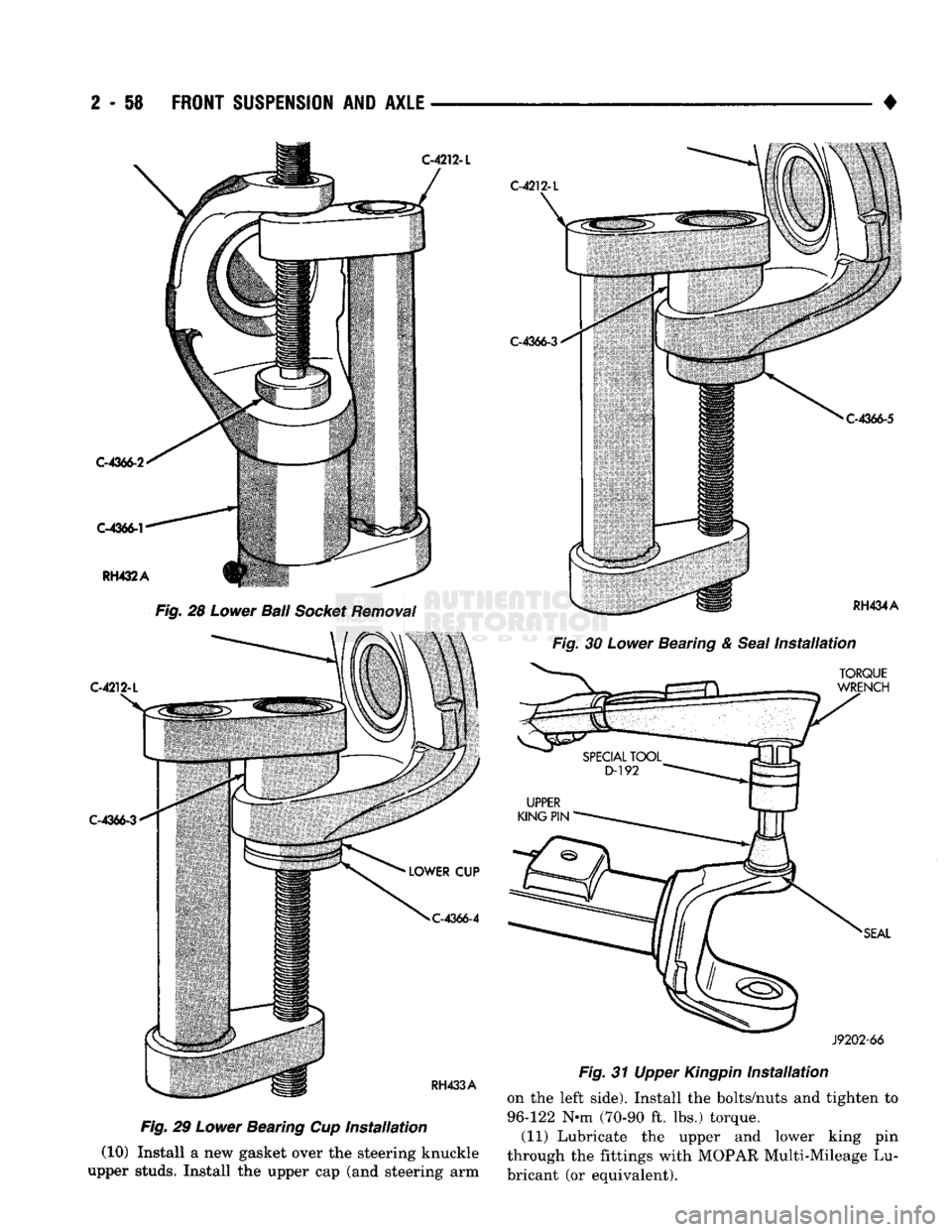

C-4366-2

C-4366-1

RH432A

C-4212-L

Fig.

28

Lower

Ball

Socket

Removal

C-4212-L

C-4366-3

C-4366-4

RH433A

Fig.

29

Lower

Bearing Cup Installation

(10) Install a new gasket over the steering knuckle

upper studs. Install the upper cap (and steering arm

C-4212-L

C-4366-3

RH434A

Fig.

30

Lower

Bearing &

Seal

Installation

TORQUE

WRENCH

SEAL

J9202-66

Fig.

31 Upper

Kingpin

Installation

on the left side). Install the bolts/nuts and tighten to

96-122 N*m (70-90 ft. lbs.) torque. (11) Lubricate the upper and lower king pin

through the fittings with MOPAR Multi-Mileage Lu

bricant (or equivalent).

Page 112 of 1502

•

TAPERED

BUSHING

J9202-53

Fig.

32 Tapered

Bushing

Installation

J9202-52

Fig.

33

Lower

King

Pin and Retainer

Installation

(12) Install the axle shaft, refer to Axle Shaft and

U-Joint Installation.

COMPLETE

AXLE REMOVAL/INSTALLATION SERVICE

INFORMATION

It is not necessary to remove the complete front

axle from the vehicle for routine service. If the hous

ing or axle shaft tubes are damaged, the complete axle can be removed and installed via the following

procedures.

REMOVAL

(1) Block the brake pedal in the up position. Raise

and support the vehicle at a comfortable working

height.

(2) Remove the front wheels/tires.

FRONT SUSPENSION

AND

AXLE

2 - 59

(3) Mark the front drive shaft and the pinion yoke

for installation alignment reference.

(4) Disconnect the front drive shaft from the axle

yoke. Attach the drive shaft to the frame rail with

wire.

(5) Remove the cotter pin, the nut, and disconnect

the drag link from the steering knuckle arm (left side only). Discard the cotter pin.

(6) Disconnect flexible brake fluid hose fittings at

the frame crossmember. Plug the hoses at the fit

tings.

(7) Remove the shock absorber lower nut and stud

from the axle shaft tube bracket. Remove the nuts and disconnect the stabilizer bar links from the

spring brackets. (8) Remove nuts and the washers from the spring

U-bolts. Remove the complete front axle from the ve

hicle.

INSTALLATION (1) Position the front axle under the front of the

vehicle with the axle spring pads under the springs.

Place the spring brackets over the springs. Make sure the stabilizer bar link bolt holes face toward the

rear of the vehicle.

(2) Install the spring U-bolts, washers and nuts.

Refer to Front Suspension — 4WD Vehicles within

this group. (3) Install the shock absorber. Refer to Front Sus

pension—4 WD Vehicles within this group.

(4) Connect the stabilizer bar links to the spring

brackets. Refer to Front Suspension—4WD Vehicles within this group.

(5) Remove plugs and connect the brake hose fit

tings.

Refer to Group 5, Brakes. (6) Connect the drag-link ball stud to the steering

knuckle arm. Refer to Group 19, Steering. (7) Connect the drive shaft to the pinion yoke with

the installation reference marks aligned. Install the

washers and the nuts and tighten to 19 N-m (14 ft. lbs.) torque.

(8) Remove the supports, lower the vehicle and re

move the block from the brake pedal.

(9) Raise the vehicle.

• Bleed and adjust the brakes

• Lubricate all the ball stud fittings

• Inspect the differential housing lubricant level. Re

fer to Group 0, Lubrication and Maintenance.

(10) Lower the vehicle and test the axle and sus

pension operation.

DIFFERENTIAL DISASSEMBLY

REMOVAL/DISASSEMBLY

(1) Note the installation reference letters

stamped on the bearing caps and housing ma

chined sealing surface (Fig. 34).

(2) Remove the differential bearing caps.

Page 116 of 1502

•

FRONT SUSPENSION

AND

AXLE

2 - 63

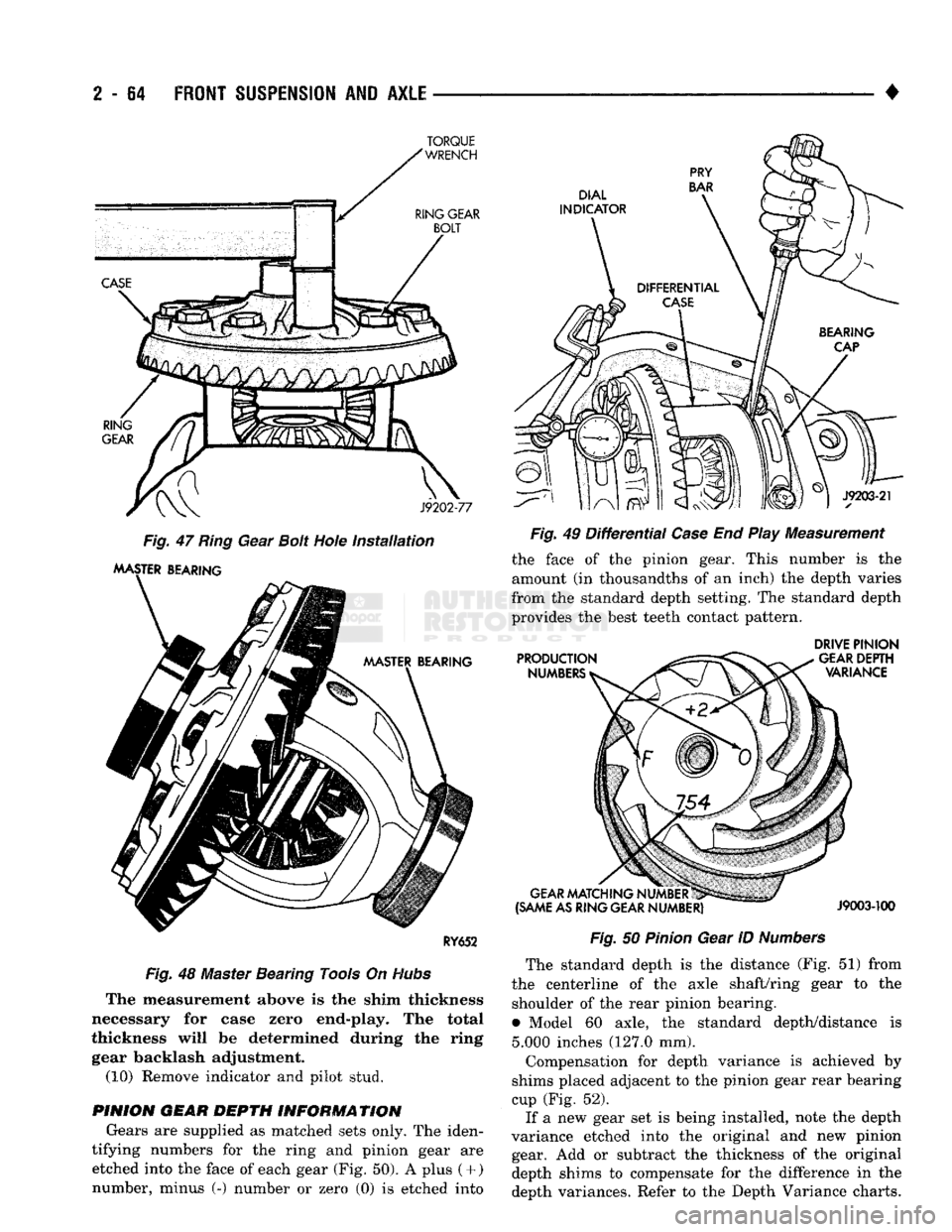

THRUST

WASHER

Fig.

45

Pinion

Mate

Gear

Removal

• Bearing races must not be distorted or cracked

Cup and bearing must be replaced as a

matched set only. • All machined surfaces in the housing and on bear

ing caps should be smooth and without any raised

edges.

• Pinion gear front and rear bearing cup bores should be smooth

• Raised metal on shoulders of cup bores should be

removed with a hand stone.

(4) Examine the differential pinion gear mate

shaft, pinion gears, side gears and thrust washers for

wear and damage. Replace all defective components.

If either of the differential pinion gears is not

reusable, both gears must be replaced as a

matched set only. Do not replace only one gear.

(5) Examine the ring gear and the pinion gear for

worn and chipped teeth. Examine the ring gear for damaged bolt threads.

If replacement of either gear is necessary, both

must be replaced as a matched set only. (6) Inspect the pinion yoke for cracks, worn

splines, pitted areas, and a rough/corroded seal con

tact surface. Repair or replace the yoke as necessary. (7) Inspect the pinion bearing preload shims for

cracks, damage and distortion. Install replacement shims (if necessary) for the preload torque adjust

ment.

DIFFERENTIAL

ASSEMBLY

ASSEMBLY

(1) Install the following components in the differ

ential case (Fig. 47). • Differential side gears and thrust washers

• Pinion gears and thrust washers

• Pinion gear mate shaft (align holes in shaft and

case) (2) Install and seat the lock pin in the differential

case and mate shaft with a punch and hammer (Fig.

46).

Peen metal part of case over pin in two places. If replacement gears and thrust washers were

installed, it is not necessary to measure the gear

backlash. Correct fit is due to close machining tolerances during manufacture.

Fig.

46

Mate

Shaft Pin

Installation

(3) Invert the differential case and start two ring

gear bolts. This will provide case-to-ring gear bolt

hole alignment (Fig. 47). (4) Install new ring gear bolts and alternately

tighten to;

• Grade 8 bolts to 136-163 N*m (100-120 ft. lbs.)

torque

• Grade 9 bolts (7 radial lines) to 169-183 N*m (125- 135 ft. lbs.) torque.

(5) Lubricate all differential components with hy

poid gear lubricant. (6) Place Master Differential Bearing D-343

(D-117) on the case hubs (Fig. 48). (7) Install a pilot stud at the right side of housing.

Attach Dial Indicator C-3339 to the pilot stud. Load indicator plunger against the back of the ring gear (Fig. 49).

(8) Insert a small pry bar between the bearing cap

and right side of differential case. Pry the case as far

as possible to left side (Fig. 49). Zero the dial indica

tor pointer.

(9) Pry the case to right side and record the

travel distance.

Page 117 of 1502

2

- 64

FRONT

SUSPENSION

AND

AXLE

—

Fig.

47 Ring Gear Bolt Hole

installation

MASTER BEARING

RY652

Fig.

48 Master Bearing Tools On

Hubs

The measurement above is the shim thickness

necessary for case zero end-play. The total

thickness will be determined during the ring gear backlash adjustment. (10) Remove indicator and pilot stud.

PINION GEAR DEPTH INFORMATION Gears are supplied as matched sets only. The iden

tifying numbers for the ring and pinion gear are etched into the face of each gear (Fig. 50). A plus

(

+ )

number, minus (-) number or zero (0) is etched into •

Fig.

49

Differential

Case

End Play Measurement the face of the pinion gear. This number is the

amount (in thousandths of an inch) the depth varies

from the standard depth setting. The standard depth

provides the best teeth contact pattern.

DRIVE

PINION

Fig.

50

Pinion

Gear ID

Numbers

The standard depth is the distance (Fig. 51) from

the centerline of the axle shaft/ring gear to the shoulder of the rear pinion bearing.

• Model 60 axle, the standard depth/distance is

5.000

inches (127.0 mm).

Compensation for depth variance is achieved by

shims placed adjacent to the pinion gear rear bearing

cup (Fig. 52). If a new gear set is being installed, note the depth

variance etched into the original and new pinion gear. Add or subtract the thickness of the original

depth shims to compensate for the difference in the

depth variances. Refer to the Depth Variance charts.

TORQUE

Page 120 of 1502

•

FRONT

SUSPENSION

AND

AXLE

2 - 67

SPECIAL

TOOL

D-111

PRESS

DRIVE

PINION GEAR SHAFT

REAR

BEARING' INSTALLATION

TOOL

SPECIAL

TOOL

C-4171

J9203-65

DRIVE

PINION GEAR OIL

SUNGER

J9302-68

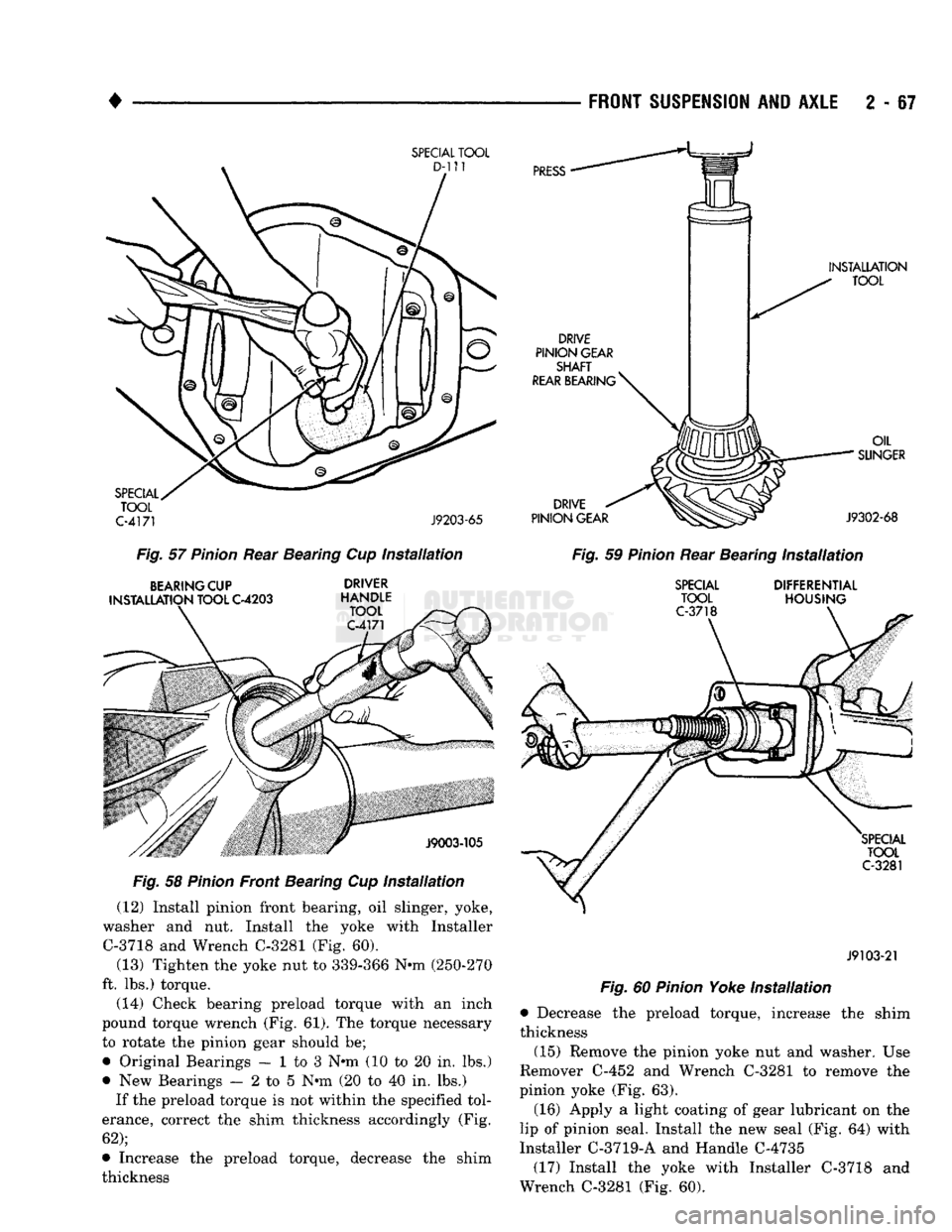

Fig.

57

Pinion

Rear Bearing Cup

Installation

Fig.

59

Pinion

Rear Bearing

Installation

BEARING

CUP

INSTALLATION TOOL

C-4203

DRIVER

HANDLE TOOL

C-4171

SPECIAL

TOOL

C-3718

DIFFERENTIAL

HOUSING

SPECIAL

TOOL

C-3281

Fig.

58

Pinion

Front Bearing Cup

Installation

(12) Install pinion front bearing, oil slinger, yoke,

washer and nut. Install the yoke with Installer C-3718 and Wrench C-3281 (Fig. 60).

(13) Tighten the yoke nut to 339-366 N-m (250-270

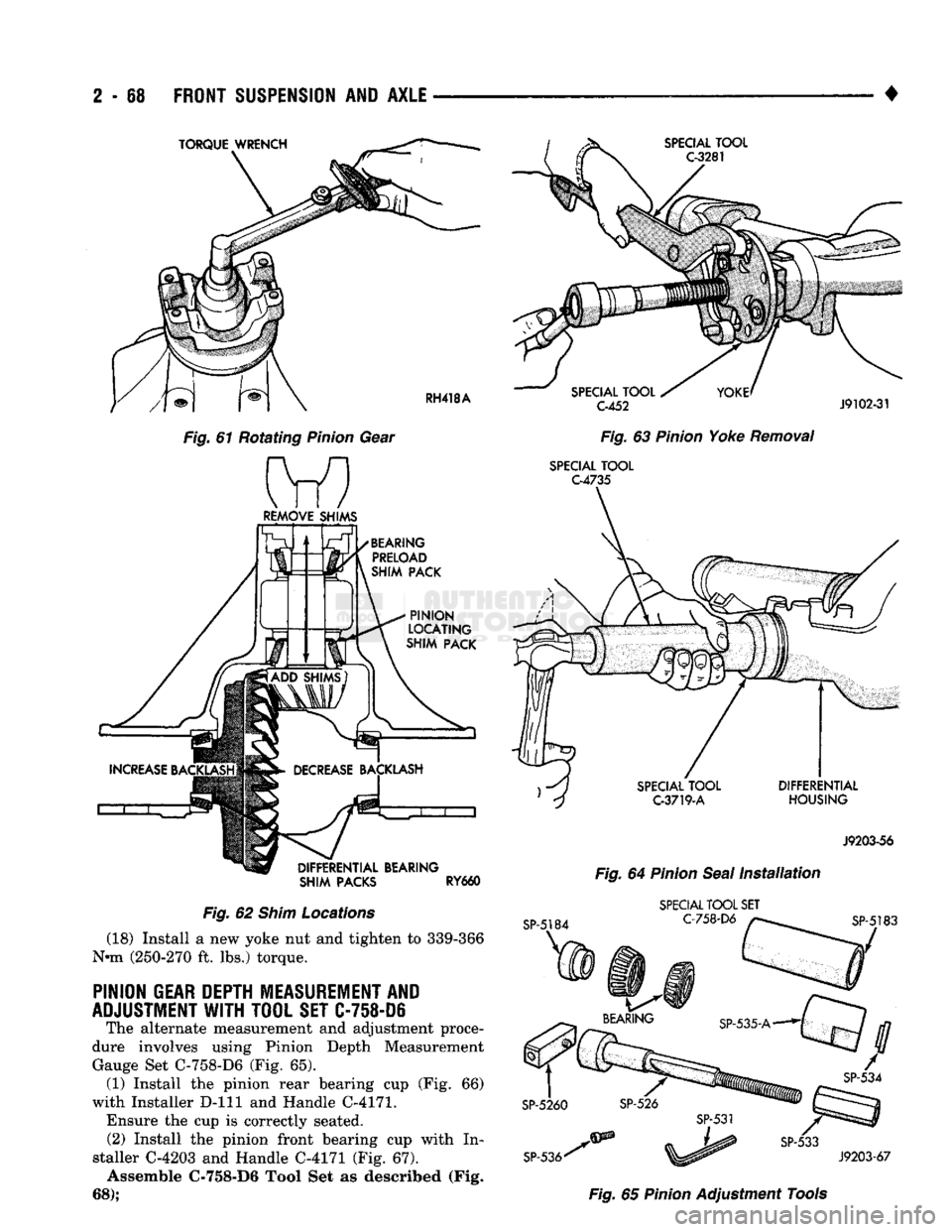

ft. lbs.) torque. (14) Check bearing preload torque with an inch

pound torque wrench (Fig. 61). The torque necessary

to rotate the pinion gear should be;

• Original Bearings — 1 to 3 N*m (10 to 20 in. lbs.)

• New Bearings — 2 to 5 N-m (20 to 40 in. lbs.) If the preload torque is not within the specified tol

erance, correct the shim thickness accordingly (Fig.

62);

• Increase the preload torque, decrease the shim

thickness

J9103-21

Fig.

60

Pinion

Yoke

Installation

• Decrease the preload torque, increase the shim

thickness (15) Remove the pinion yoke nut and washer. Use

Remover C-452 and Wrench C-3281 to remove the

pinion yoke (Fig. 63).

(16) Apply a light coating of gear lubricant on the

lip of pinion seal. Install the new seal (Fig. 64) with

Installer C-3719-A and Handle C-4735

(17) Install the yoke with Installer C-3718 and

Wrench C-3281 (Fig. 60).

Page 121 of 1502

2

- 88

FRONT

SUSPENSION

AND

AXLE

•

TORQUE WRENCH SPECIAL TOOL

C-3281

RH418A

Fig.

61 Rotating

Pinion

Gear Ml

REMOVE SHIMS

BEARING PRELOAD

SHIM

PACK

PINION

LOCATING

SHIM

PACK

DIFFERENTIAL

BEARING

SHIM PACKS

RY660

Fig.

62

Shim

Locations

(18) Install a new yoke nut and tighten to 339-366

N-m (250-270 ft. lbs.) torque.

PINION

GEAR

DEPTH

MEASUREMENT

AND

ADJUSTMENT

WITH

TOOL

SET

C-758-D6

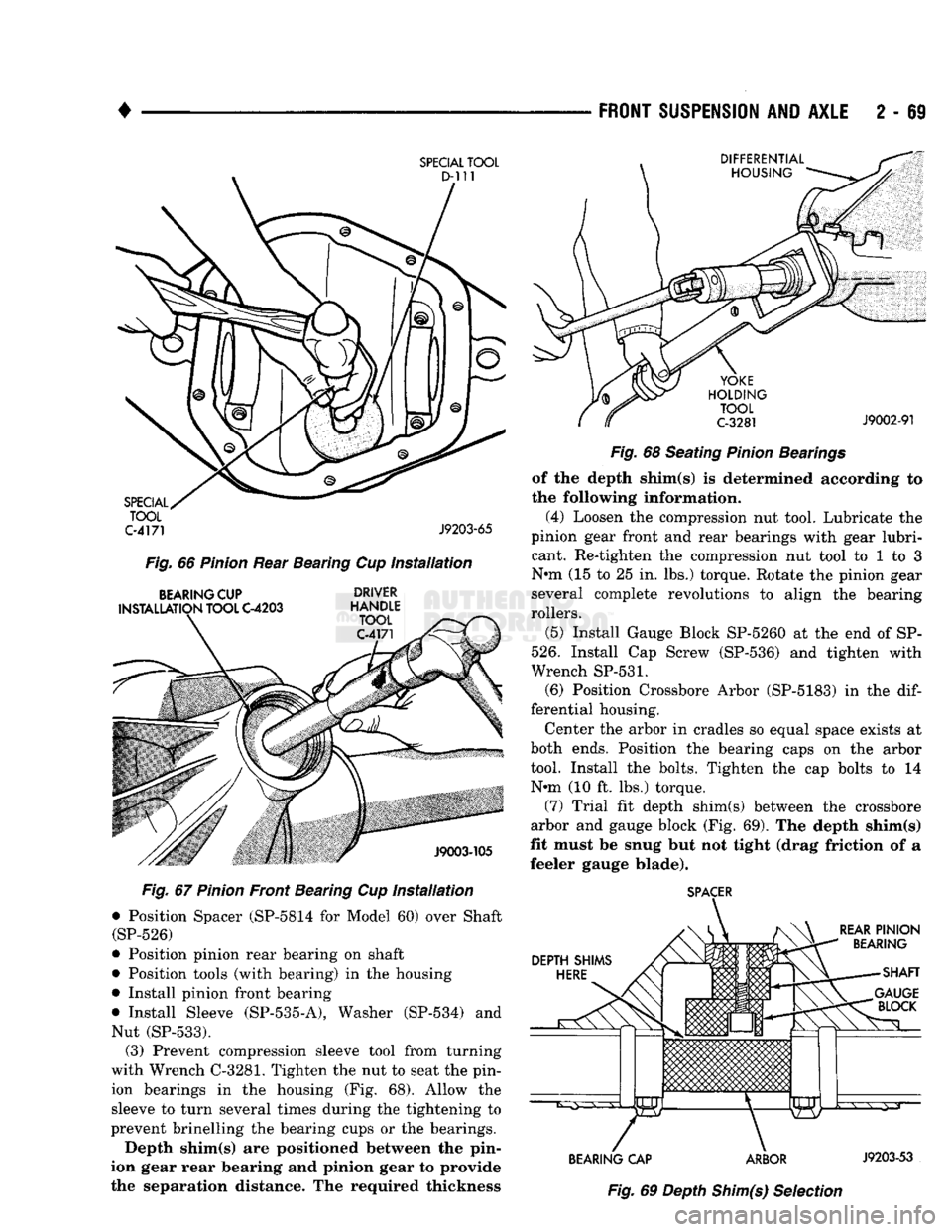

The alternate measurement and adjustment proce

dure involves using Pinion Depth Measurement Gauge Set C-758-D6 (Fig. 65). (1) Install the pinion rear bearing cup (Fig. 66)

with Installer D-lll and Handle C-4171.

Ensure the cup is correctly seated. (2) Install the pinion front bearing cup with In

staller C-4203 and Handle C-4171 (Fig. 67). Assemble C-758-D6 Tool Set as described (Fig.

68);

SPECIAL

TOOL

C-452

J9102-31

Fig.

63

Pinion

Yoke

Removal

SPECIAL

TOOL C4735

SP-5184 C-3719-A

DIFFERENTIAL

HOUSING

J9203-56

Fig.

64

Pinion

Seal

Installation

SPECIAL

TOOL

SET C-758-D6

J9203-67

Fig.

65

Pinion

Adjustment Tools

Page 122 of 1502

•

.

C-4171 J9203-65

Fig.

66

Pinion

Rear Bearing Cup

Installation

BEARING

CUP DRIVER

INSTALLATION

TOOL

C-4203

HANDLE

Fig.

67

Pinion

Front Bearing Cup

Installation

•

Position Spacer (SP-5814 for Model 60) over Shaft

(SP-526)

•

Position pinion rear bearing on shaft

•

Position tools (with bearing) in the housing

•

Install pinion front bearing

•

Install Sleeve

(SP-535-A),

Washer (SP-534) and

Nut

(SP-533).

(3) Prevent compression sleeve tool from turning

with Wrench C-3281. Tighten the nut to seat the pin ion bearings in the housing (Fig. 68). Allow the

sleeve to turn several times during the tightening to

prevent brinelling the bearing cups or the bearings.

Depth shim(s) are positioned between the pin

ion gear rear bearing and pinion gear to provide

the separation distance. The required thickness

FRONT SUSPENSION

AND

AXLE

2 - 69

Fig.

68 Seating

Pinion

Bearings

of the depth shim(s) is determined according to

the following information.

(4) Loosen the compression nut tool. Lubricate the

pinion gear front and rear bearings with gear lubri cant. Re-tighten the compression nut tool to 1 to 3

Nnn (15 to 25 in. lbs.) torque. Rotate the pinion gear several complete revolutions to align the bearing

rollers.

(5) Install Gauge Block SP-5260 at the end of SP-

526.

Install Cap Screw (SP-536) and tighten with

Wrench

SP-531.

(6) Position Crossbore Arbor (SP-5183) in the

dif

ferential housing.

Center the arbor in cradles so equal space exists at

both ends. Position the bearing caps on the arbor

tool. Install the bolts. Tighten the cap bolts to 14 Nnn (10 ft. lbs.) torque.

(7) Trial fit depth shim(s) between the crossbore

arbor and gauge block (Fig. 69). The depth shim(s)

fit must be snug but not tight (drag friction of a

feeler gauge blade).

SPACER

BEARING CAP ARBOR

J9203-53

Fig.

69 Depth

Shim(s)

Selection

SPECIAL

TOOL