wheel bolt torque DODGE TRUCK 1993 Service Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 1006 of 1502

1

.

NW4500

MANUAL

TRANSMISSION 21 - 5 making transmission removal/installation easier.

Cylinder does not have to be removed completely. (28) Remove bolts attaching transmission to clutch

housing.

(29) Move transmission rearward until drive pin

ion clears clutch disc and release bearing. (30) Lower transmission and remove it from under

vehicle.

(31) If transmission will be overhauled, thoroughly

clean transmission exterior with solvent or steam

gun.

TRANSMISSION INSTALLATION-4-WHEEL DRIVE (1) Apply light coat of Mopar high temperature

bearing grease to contact surfaces of following com

ponents: • drive gear splines and pilot bearing hub • release bearing slide surface of front retainer

• pilot bearing

• release bearing bore

• release fork

• release fork ball stud

• propeller shaft slip yoke (2) Fill transmission with recommended lubricant.

Correct level is to bottom edge of fill plug hole. (3) Mount transmission on jack and position trans

mission under vehicle. Secure transmission to jack

with safety chains. (4) Raise transmission until drive gear is centered

in release bearing and clutch disc hub. (5) Move transmission forward and start drive gear

in release bearing and clutch disc. (6) Work transmission forward until seated against

clutch housing. Do not allow transmission to remain

unsupported after drive gear has entered clutch disc. (7) Install and tighten transmission-to-clutch hous

ing bolts to 108 N*m (80 ft. lbs.) torque. (8) Connect speed sensor and backup light switch

wires.

(9) Position transmission harness wires in clips on

shift cover. (10) Tighten slave cylinder attaching nuts and in

stall slave cylinder shield, if equipped.

(11) Install transmission mount on transmission or

rear crossmember. (12) Install rear crossmember.

(13) Remove transmission jack and engine support

fixture.

(14) Install transfer case on transmission jack. Se

cure transfer case to jack with safety chains. (15) Install new gasket on transmission adapter, or

coat adapter sealing surface with Mopar Gasket

Maker, or silicone adhesive sealer.

(16) Raise jack and align transfer case input gear

with transmission mainshaft.

(17) Move transfer case forward and seat it on

adapter.

(18) Install and tighten transfer case attaching

nuts to 47 N«m (35 ft. lbs.) torque.

(19) Connect transfer case shift lever to range le

ver on transfer case. (20) Align and connect propeller shafts. Tighten

U-joint clamp strap bolts to 19 N*m (170 in. lbs.)

torque.

(21) Check lubricant levels in transmission and

transfer case. Add lubricant if necessary.

(22) Install transfer case skid plate and crossmem

ber. Tighten attaching bolts/nuts to 41 N»m (30 ft. lbs.) torque.

(23) Install exhaust system components.

(24) Lower vehicle.

(25) Install transmission shift lever, boot and be

zel.

(26) Connect battery negative cable.

Page 1044 of 1502

•

NV4500

TRANSMISSION OVERHAUL

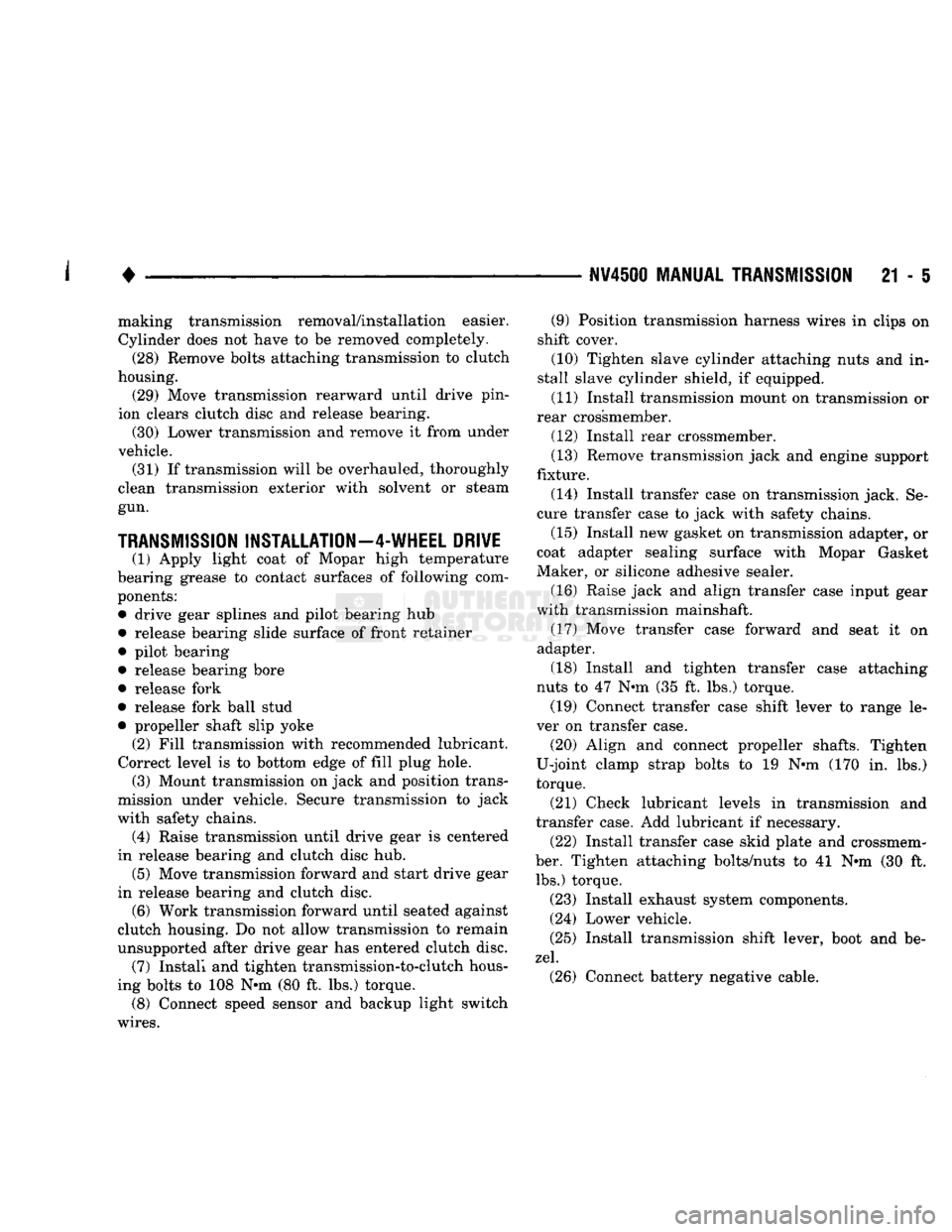

21 • 43 (5) Align and install shift cover (Fig. 163). If cover

will not seat, it is either not aligned on gear case

dowels, or shift forks are not aligned with sleeves and shift lug.

SHIFT

Fig.

163 Installing Shift

Cover

Assembly

(6) Apply Mopar Lock N' Seal or Loctite 242 to

threads of shift cover bolts. (7) Install and tighten shift cover bolts to 30 Nnn

(265 in. lbs.) torque.

(8) Install backup light switch and vent in shift

cover. Apply sealer to switch threads before installa

tion and tighten switch to 30 Nnn (265 in. lbs.).

(9) On 2-wheel drive models, install and index

speedometer adapter in extension housing. (10) Install and tighten drain plug to 40 Nnn (30

ft. lbs.) torque.

(11) Fill transmission to bottom edge of fill plug

hole with Castrol Syntorq gear lubricant.

(12) Install and tighten fill plug to 40 N-m (30 ft.

lbs.) torque.

SHIFT

COVER SERVICE

The only serviceable shift cover components are:

• fifth-reverse shift fork pads

• reverse inhibitor

• vent components • backup light switch

• expansion plugs

• shift lever components The shift cover, shift forks, shift rails and detent

components are not serviced individually. The cover

must be replaced as an assembly if the cover, or any shift components are worn or damaged.

Shift

Cover

Inspection

Inspect the cover and shift components whenever

the cover is removed from the gear case. Or, when ever diagnosis indicates inspection is necessary.

Check the forks for wear, distortion, cracks, or be

ing loose on the shift rails. Also check fit of the shift rails in the cover. Replace the cover assembly if the

rails are loose in the cover bores.

Inspect and replace the pads on the fifth-reverse

shift fork if worn. The reverse inhibitor should also

be replaced if worn, or faulty. The expansion plugs at

the rear of the cover can be replaced if loose or leak ing.

A gasket is not used between the shift cover

and gear case. Use Mopar Gasket Maker, or Loc

tite 518 to seal the cover.

Procedures for the serviceable components in the

shift cover as follows:

Fifth-Reverse

Shift

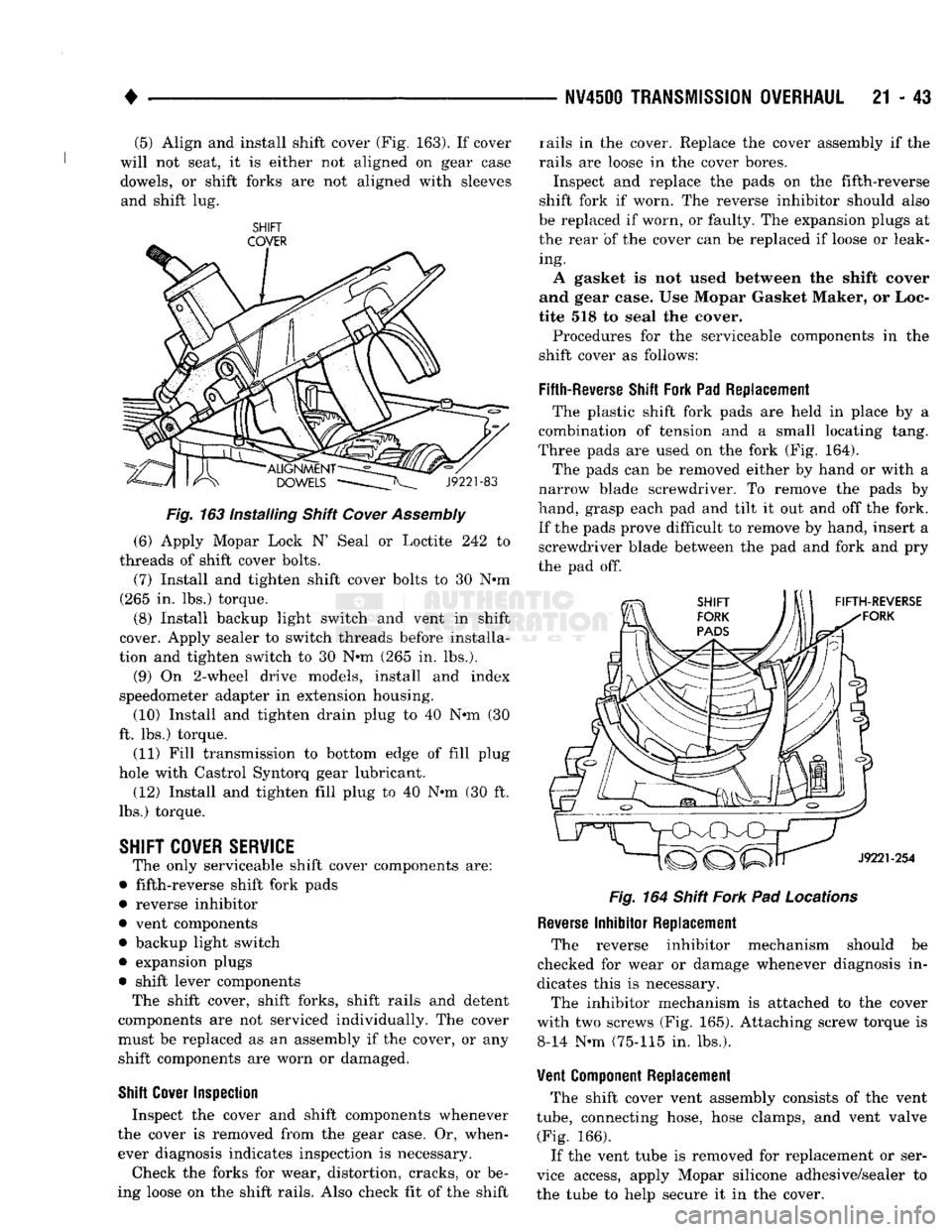

Fork Pad Replacement The plastic shift fork pads are held in place by a

combination of tension and a small locating tang.

Three pads are used on the fork (Fig. 164).

The pads can be removed either by hand or with a

narrow blade screwdriver. To remove the pads by

hand, grasp each pad and tilt it out and off the fork.

If the pads prove difficult to remove by hand, insert a screwdriver blade between the pad and fork and pry

the pad off.

Fig.

164 Shift

Fork

Pad

Locations

Reverse

Inhibitor Replacement The reverse inhibitor mechanism should be

checked for wear or damage whenever diagnosis in

dicates this is necessary.

The inhibitor mechanism is attached to the cover

with two screws (Fig. 165). Attaching screw torque is 8-14 N-m (75-115 in. lbs.).

Vent

Component

Replacement The shift cover vent assembly consists of the vent

tube,

connecting hose, hose clamps, and vent valve (Fig. 166).

If the vent tube is removed for replacement or ser

vice access, apply Mopar silicone adhesive/sealer to

the tube to help secure it in the cover.

Page 1052 of 1502

•

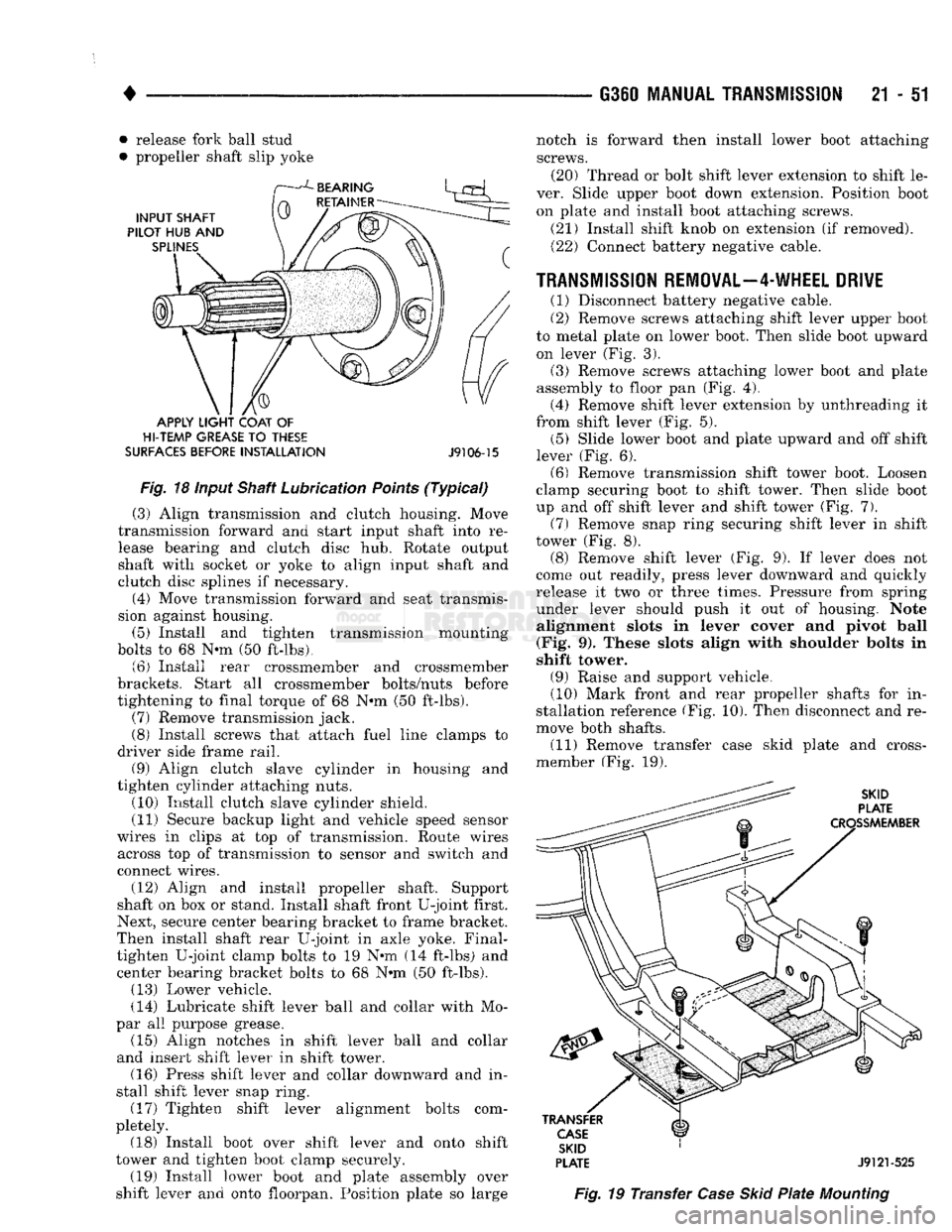

• release fork ball stud

• propeller shaft slip yoke

APPLY

LIGHT

COAT

OF

HI-TEMP

GREASE

TO

THESE

SURFACES

BEFORE

INSTALLATION

J9106-15

Fig.

18 input Shaft Lubrication

Points

(Typical)

(3) Align transmission and clutch housing. Move

transmission forward and start input shaft into re lease bearing and clutch disc hub. Rotate output

shaft with socket or yoke to align input shaft and

clutch disc splines if necessary.

(4) Move transmission forward and seat transmis

sion against housing. (5) Install and tighten transmission mounting

bolts to 68 N-m (50 ft-lbs). (6) Install rear crossmember and crossmember

brackets. Start all crossmember bolts/nuts before

tightening to final torque of 68 N»m (50 ft-lbs). (7) Remove transmission jack.

(8) Install screws that attach fuel line clamps to

driver side frame rail. (9) Align clutch slave cylinder in housing and

tighten cylinder attaching nuts. (10) Install clutch slave cylinder shield.

(11) Secure backup light and vehicle speed sensor

wires in clips at top of transmission. Route wires across top of transmission to sensor and switch and

connect wires.

(12) Align and install propeller shaft. Support

shaft on box or stand. Install shaft front U-joint first.

Next, secure center bearing bracket to frame bracket.

Then install shaft rear U-joint in axle yoke. Final- tighten U-joint clamp bolts to 19 N@m (14 ft-lbs) and center bearing bracket bolts to 68 N»m (50 ft-lbs). (13) Lower vehicle.

(14) Lubricate shift lever ball and collar with Mo

par all purpose grease. (15) Align notches in shift lever ball and collar

and insert shift lever in shift tower. (16) Press shift lever and collar downward and in

stall shift lever snap ring. (17) Tighten shift lever alignment bolts com

pletely. (18) Install boot over shift lever and onto shift

tower and tighten boot clamp securely. (19) Install lower boot and plate assembly over

shift lever and onto floorpan. Position plate so large G360

MANUAL TRANSMISSION

21 - 51

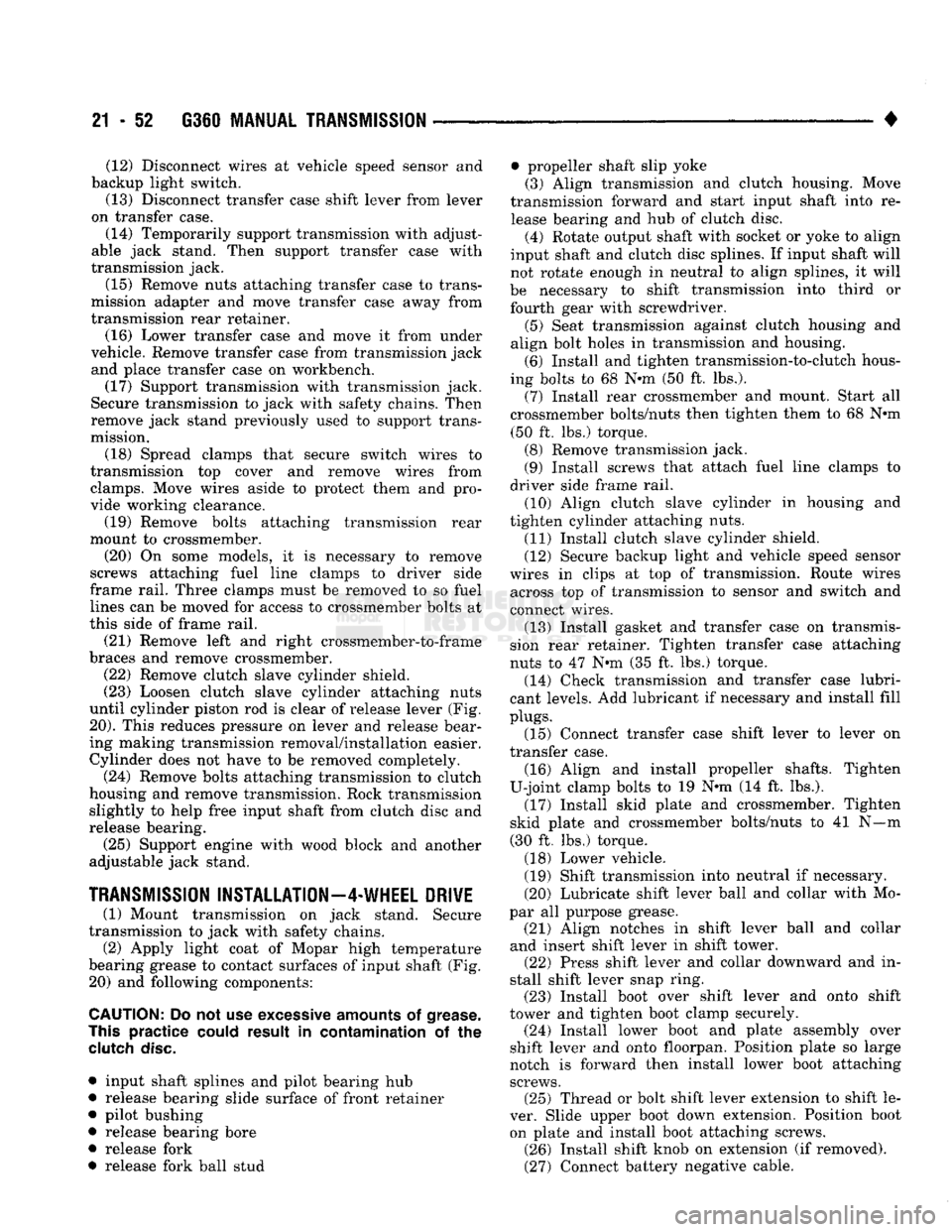

SKID

PLATE

J9121-525

Fig.

19 Transfer

Case

Skid

Plate

Mounting

notch is forward then install lower boot attaching

screws. (20) Thread or bolt shift lever extension to shift le

ver. Slide upper boot down extension. Position boot on plate and install boot attaching screws.

(21) Install shift knob on extension (if removed). (22) Connect battery negative cable.

TRANSMISSION REMOVAL—4-WHEEL DRIVE

(1) Disconnect battery negative cable.

(2) Remove screws attaching shift lever upper boot

to metal plate on lower boot. Then slide boot upward on lever (Fig. 3).

(3) Remove screws attaching lower boot and plate

assembly to floor pan (Fig. 4). (4) Remove shift lever extension by unthreading it

from shift lever (Fig. 5). (5) Slide lower boot and plate upward and off shift

lever (Fig. 6). (6) Remove transmission shift tower boot. Loosen

clamp securing boot to shift tower. Then slide boot

up and off shift lever and shift tower (Fig. 7).

(7)

Remove snap ring securing shift lever in shift

tower (Fig. 8). (8) Remove shift lever (Fig. 9). If lever does not

come out readily, press lever downward and quickly

release it two or three times. Pressure from spring under lever should push it out of housing. Note alignment slots in lever cover and pivot ball

(Fig. 9). These slots align with shoulder bolts in

shift tower.

(9) Raise and support vehicle.

(10) Mark front and rear propeller shafts for in

stallation reference (Fig. 10). Then disconnect and re

move both shafts. (11) Remove transfer case skid plate and cross-

member (Fig. 19).

Page 1053 of 1502

21 - 52 G360

MANUAL

TRANSMISSION

• (12) Disconnect wires at vehicle speed sensor and

backup light switch.

(13) Disconnect transfer case shift lever from lever

on transfer case.

(14) Temporarily support transmission with adjust

able jack stand. Then support transfer case with

transmission jack.

(15) Remove nuts attaching transfer case to trans

mission adapter and move transfer case away from

transmission rear retainer.

(16) Lower transfer case and move it from under

vehicle. Remove transfer case from transmission jack and place transfer case on workbench.

(17) Support transmission with transmission jack.

Secure transmission to jack with safety chains. Then

remove jack stand previously used to support trans

mission.

(18) Spread clamps that secure switch wires to

transmission top cover and remove wires from clamps. Move wires aside to protect them and pro

vide working clearance.

(19) Remove bolts attaching transmission rear

mount to crossmember.

(20) On some models, it is necessary to remove

screws attaching fuel line clamps to driver side

frame rail. Three clamps must be removed to so fuel lines can be moved for access to crossmember bolts at

this side of frame rail.

(21) Remove left and right crossmember-to-frame

braces and remove crossmember.

(22) Remove clutch slave cylinder shield.

(23) Loosen clutch slave cylinder attaching nuts

until cylinder piston rod is clear of release lever (Fig.

20).

This reduces pressure on lever and release bear

ing making transmission removal/installation easier. Cylinder does not have to be removed completely.

(24) Remove bolts attaching transmission to clutch

housing and remove transmission. Rock transmission slightly to help free input shaft from clutch disc and

release bearing.

(25) Support engine with wood block and another

adjustable jack stand.

TRANSMISSION

INSTALLATION—4-WHEEL

DRIVE

(1) Mount transmission on jack stand. Secure

transmission to jack with safety chains.

(2) Apply light coat of Mopar high temperature

bearing grease to contact surfaces of input shaft (Fig. 20) and following components:

CAUTION:

Do not use

excessive

amounts

of

grease.

This

practice

could

result in contamination of the

clutch

disc.

• input shaft splines and pilot bearing hub

• release bearing slide surface of front retainer

• pilot bushing

• release bearing bore

• release fork

• release fork ball stud • propeller shaft slip yoke

(3) Align transmission and clutch housing. Move

transmission forward and start input shaft into re lease bearing and hub of clutch disc. (4) Rotate output shaft with socket or yoke to align

input shaft and clutch disc splines. If input shaft will

not rotate enough in neutral to align splines, it will

be necessary to shift transmission into third or fourth gear with screwdriver. (5) Seat transmission against clutch housing and

align bolt holes in transmission and housing. (6) Install and tighten transmission-to-clutch hous

ing bolts to 68 N-m (50 ft. lbs.). (7) Install rear crossmember and mount. Start all

crossmember bolts/nuts then tighten them to 68 N*m (50 ft. lbs.) torque. (8) Remove transmission jack.

(9) Install screws that attach fuel line clamps to

driver side frame rail. (10) Align clutch slave cylinder in housing and

tighten cylinder attaching nuts. (11) Install clutch slave cylinder shield.

(12) Secure backup light and vehicle speed sensor

wires in clips at top of transmission. Route wires across top of transmission to sensor and switch and

connect wires.

(13) Install gasket and transfer case on transmis

sion rear retainer. Tighten transfer case attaching

nuts to 47 N-m (35 ft. lbs.) torque. (14) Check transmission and transfer case lubri

cant levels. Add lubricant if necessary and install fill

plugs.

(15) Connect transfer case shift lever to lever on

transfer case.

(16) Align and install propeller shafts. Tighten

U-joint clamp bolts to 19 N-m (14 ft. lbs.). (17) Install skid plate and crossmember. Tighten

skid plate and crossmember bolts/nuts to 41 N—m

(30 ft. lbs.) torque.

(18) Lower vehicle.

(19) Shift transmission into neutral if necessary.

(20) Lubricate shift lever ball and collar with Mo

par all purpose grease. (21) Align notches in shift lever ball and collar

and insert shift lever in shift tower. (22) Press shift lever and collar downward and in

stall shift lever snap ring. (23) Install boot over shift lever and onto shift

tower and tighten boot clamp securely. (24) Install lower boot and plate assembly over

shift lever and onto floorpan. Position plate so large

notch is forward then install lower boot attaching screws. (25) Thread or bolt shift lever extension to shift le

ver. Slide upper boot down extension. Position boot on plate and install boot attaching screws. (26) Install shift knob on extension (if removed).

(27) Connect battery negative cable.

Page 1054 of 1502

•

G360

TRANSMISSION OVERHAUL

21 - 53

G360

TRANSMISSION

OVERHAUL

INDEX

page

Transmission

Assembly

and

Adjustment

.......

63

Transmission

Cleaning

and

Inspection

59

TRANSMISSION

DISASSEMBLY

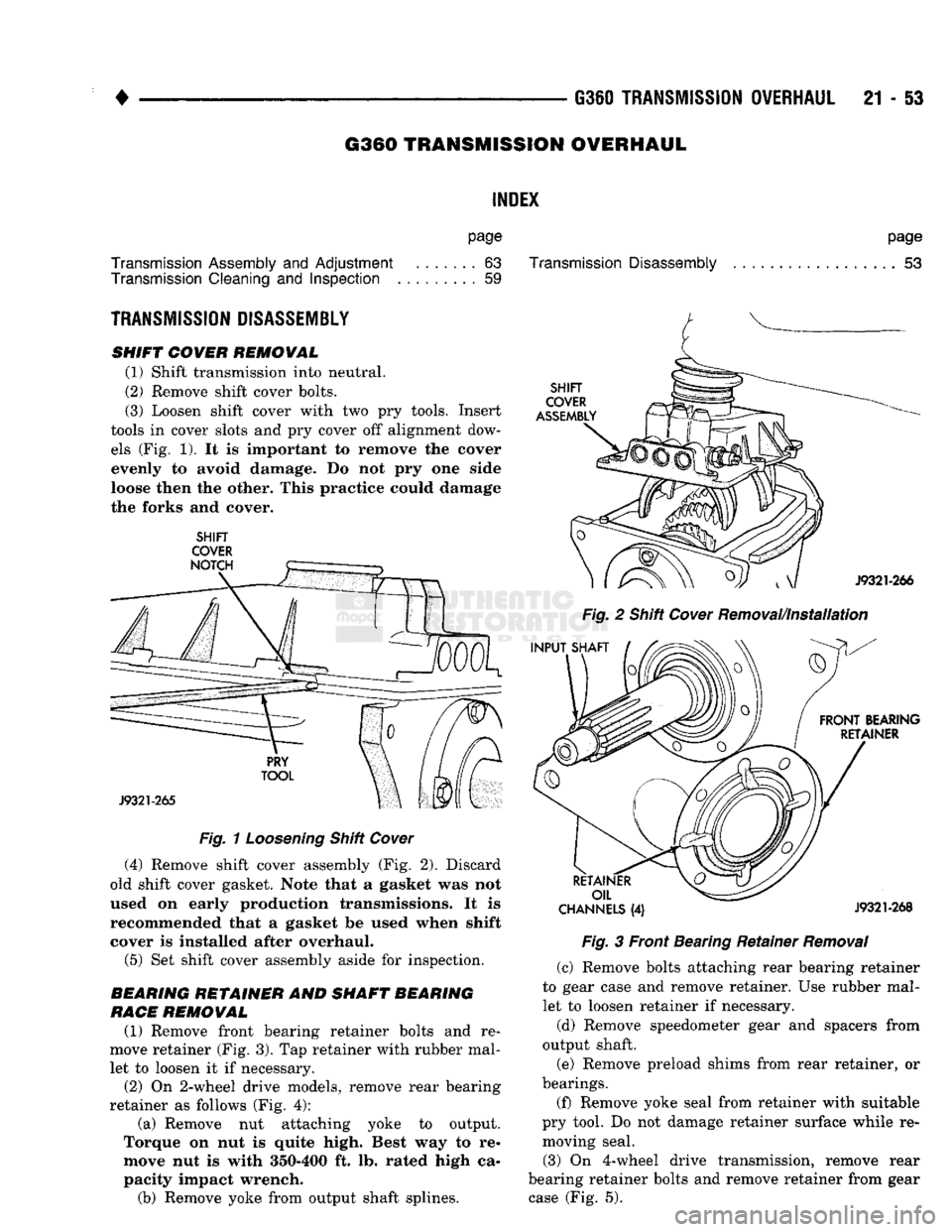

SHIFT COVER REMOVAL (1) Shift transmission into neutral.

(2) Remove shift cover bolts.

(3) Loosen shift cover with

two pry

tools. Insert

tools

in

cover slots

and pry

cover

off

alignment dow els

(Fig. 1). It is

important

to

remove

the

cover evenly

to

avoid damage.

Do not pry one

side

loose then

the

other. This practice could damage the forks

and

cover.

SHIFT

COVER

Fig.

1

Loosening

Shift

Cover

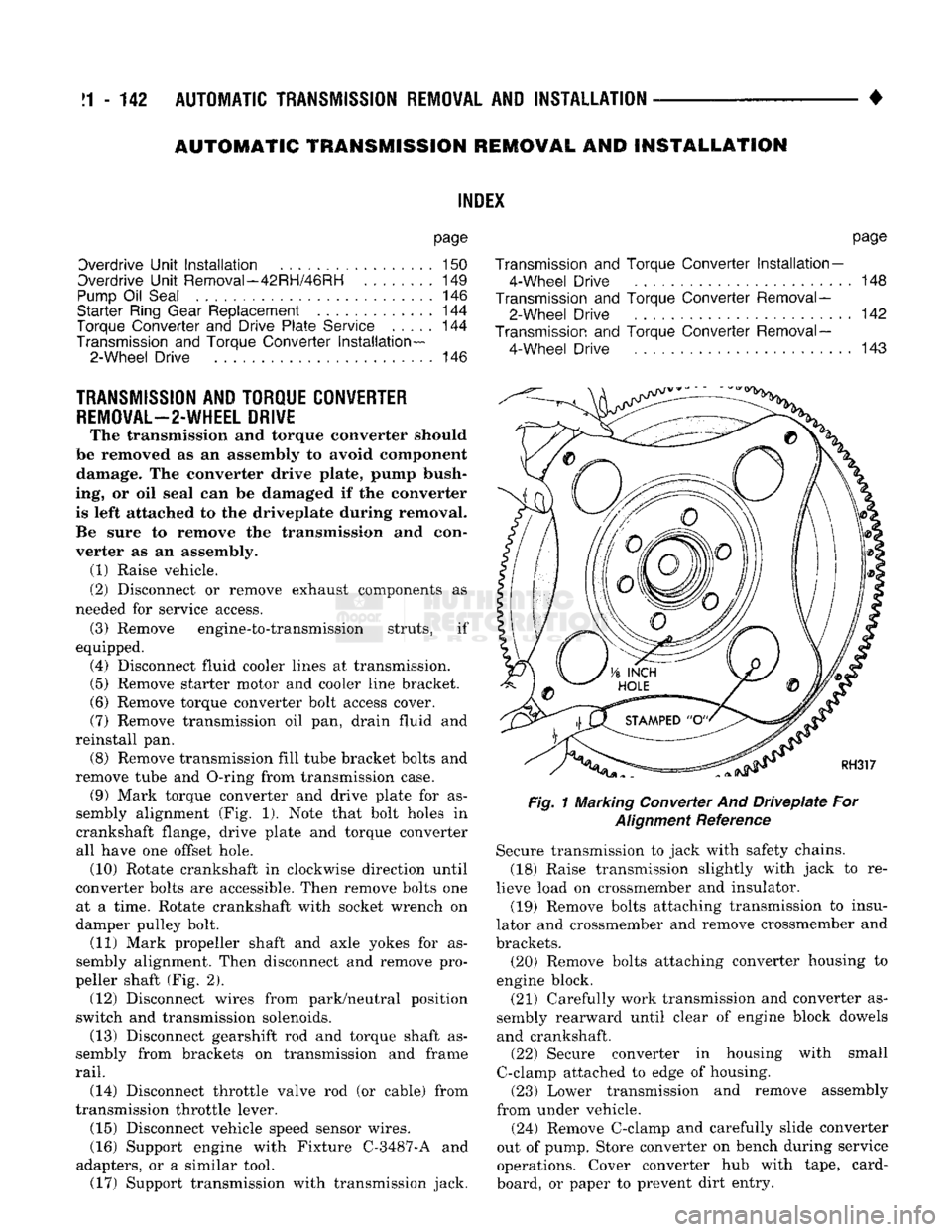

(4) Remove shift cover assembly

(Fig. 2).

Discard

old shift cover gasket. Note that

a

gasket

was not

used

on

early production transmissions.

It is

recommended that

a

gasket

be

used when shift

cover

is

installed after overhaul. (5)

Set

shift cover assembly aside

for

inspection.

REARING

RETAINER

AND

SHAFT BEARING

RACE

REMOVAL (1) Remove front bearing retainer bolts

and re

move retainer

(Fig. 3). Tap

retainer with rubber mal let

to

loosen

it if

necessary.

(2)

On

2-wheel drive models, remove rear bearing

retainer

as

follows

(Fig. 4):

(a) Remove

nut

attaching yoke

to

output.

Torque

on nut is

quite high. Best

way to re

move

nut is

with 350-400

ft. lb.

rated high

ca

pacity impact wrench.

(b) Remove yoke from output shaft splines.

page

Transmission

Disassembly

53

Fig.

2

Shift

Cover

Removal/Installation

CHANNELS

(4)

J9321-268

Fig.

3

Front Bearing Retainer

Removal

(c) Remove bolts attaching rear bearing retainer

to gear case

and

remove retainer.

Use

rubber mal let

to

loosen retainer

if

necessary.

(d) Remove speedometer gear

and

spacers from

output shaft.

(e) Remove preload shims from rear retainer,

or

bearings.

(f) Remove yoke seal from retainer with suitable

pry tool.

Do not

damage retainer surface while

re

moving seal.

(3)

On

4-wheel drive transmission, remove rear

bearing retainer bolts

and

remove retainer from gear case

(Fig. 5).

Page 1072 of 1502

•

G360

TRANSMISSION OVERHAUL

21 - 71

DEPTH

GAUGE

REAR

RETAINER COUNTERSHAFT

BEARING SHIM

BORE

J9321-332

Fig.

68

Measuring

Depth Of Countershaft Bearing

Shim

Bore

(in Rear

Retainer)

(5) Select preload shims for shaft bearings as fol

lows:

Subtract height of bearing from depth of shim

bore.

Then add extra shim thickness of 0.15 - 0.20 mm ( 0.006 - 0.008 in.) for correct preload.

(6) Assemble and install shim packs in rear re

tainer (Fig. 69). Use petroleum jelly to hold shim

packs in place during installation. Position thin shims at rear of pack where they will seat in

rear retainer shim bore.

TRANSMISSION FINAL ASSEMBLY (1) Apply Mopar Gasket Maker, or Loctite 518 to

rear retainer flange surface. OUTPUT

SHAFT

BEARING SHIMS

COUNTERSHAFT BEARING SHIMS REAR

RETAINER

J9321-325

Fig.

69 Preload

Shim

Location (2) On 2-wheel drive transmissions, install new

output shaft seal in retainer. Then install speedome

ter gear and spacers on output shaft (Fig. 70).

(3) Install rear retainer on gear case. Do not dis

place preload shims when installing retainer. (4) Apply Mopar or Loctite thread locker to rear

retainer bolts. Then install and tighten bolts to 22-30 N-m (16-22 ft. lbs.) torque.

(5) On 2-wheel drive transmissions, lube propeller

shaft yoke seal surface with petroleum jelly or en

gine oil and install yoke. Then install and tighten

new yoke nut to 380 N*m (280 ft. lbs.) torque.

(6) Apply coat of Mopar Perfect Seal, or similar

sealer to new shift cover gasket. Then position gas

ket on gear case. (Although early production trans- REAR

BEARING

RETAINER

SPEEDOMETER GEAR YOKE

NUT

YOKE

SPACERS

Fig.

70 Two

Wheel

Drive Rear Bearing Retainer And Speedometer Gear

J9321-271

Page 1143 of 1502

!1

- 142

AUTOMATIC TRANSMISSION REMOVAL

AND

INSTALLATION

• AUTOMATIC TRANSMISSION REMOWAL AND INSTALLATION

INDEX

page

Dverdrlve

Unit

Installation

150

Overdrive

Unit

Removal-42RH/46RH

........ 149

Pump

Oil

Seal

146

Starter

Ring Gear Replacement

144

Torque Converter

and

Drive

Plate

Service

..... 144

Transmission

and

Torque Converter

Installation—

2-Wheel Drive

146

page

Transmission

and

Torque Converter

Installation—

4-Wheel Drive

. . .' 148

Transmission

and

Torque Converter Removal— 2-Wheel Drive

142

Transmission

and

Torque Converter Removal

—

4-Wheel Drive

143

TRANSMISSION

AND

TORQUE CONVERTER REMOVAL—2-WHEEL DRIVE The

transmission and torque converter should

be removed as an assembly to avoid component damage. The converter drive plate, pump bush

ing, or oil seal can be damaged if the converter

is left attached to the driveplate during removal. Be sure to remove the transmission and con

verter as an assembly.

(1) Raise vehicle.

(2) Disconnect or remove exhaust components as

needed for service access.

(3) Remove engine-to-transmission struts, if

equipped. (4) Disconnect fluid cooler lines at transmission.

(5) Remove starter motor and cooler line bracket.

(6) Remove torque converter bolt access cover.

(7) Remove transmission oil pan, drain fluid and

reinstall pan. (8) Remove transmission fill tube bracket bolts and

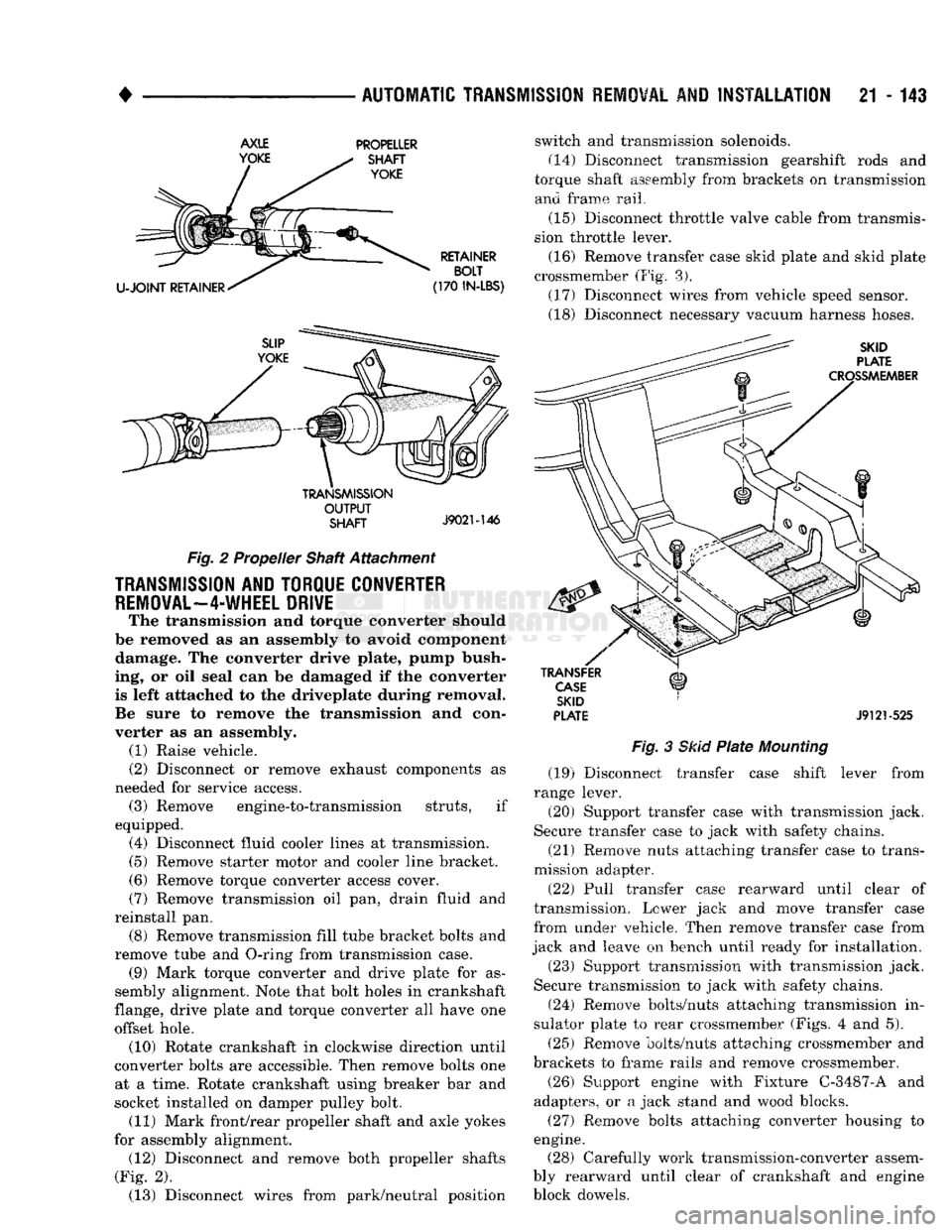

remove tube and O-ring from transmission case. (9) Mark torque converter and drive plate for as

sembly alignment (Fig. 1). Note that bolt holes in

crankshaft flange, drive plate and torque converter

all have one offset hole. (10) Rotate crankshaft in clockwise direction until

converter bolts are accessible. Then remove bolts one at a time. Rotate crankshaft with socket wrench on

damper pulley bolt. (11) Mark propeller shaft and axle yokes for as

sembly alignment. Then disconnect and remove pro

peller shaft (Fig. 2). (12) Disconnect wires from park/neutral position

switch and transmission solenoids. (13) Disconnect gearshift rod and torque shaft as

sembly from brackets on transmission and frame

rail.

(14) Disconnect throttle valve rod (or cable) from

transmission throttle lever. (15) Disconnect vehicle speed sensor wires.

(16) Support engine with Fixture C-3487-A and

adapters, or a similar tool. (17) Support transmission with transmission jack.

Fig.

1 Marking Converter And

Driveplate

For

Alignment

Reference Secure transmission to jack with safety chains.

(18) Raise transmission slightly with jack to re

lieve load on crossmember and insulator. (19) Remove bolts attaching transmission to insu

lator and crossmember and remove crossmember and

brackets. (20) Remove bolts attaching converter housing to

engine block.

(21) Carefully work transmission and converter as

sembly rearward until clear of engine block dowels and crankshaft. (22) Secure converter in housing with small

C-clamp attached to edge of housing. (23) Lower transmission and remove assembly

from under vehicle.

(24) Remove C-clamp and carefully slide converter

out of pump. Store converter on bench during service

operations. Cover converter hub with tape, card

board, or paper to prevent dirt entry.

Page 1144 of 1502

•

AUTOMATIC TRANSMISSION REMOVAL

AND

INSTALLATION

21 - 143

AXLE

YOKE PROPELLER

SHAFT

YOKE

U-JOINT

RETAINER RETAINER

BOLT

(170

IN-LBS)

TRANSMISSION

OUTPUT

SHAFT

J9021-146

Fig.

2 Propeller Shaft Attachment

TRANSMISSION

AND TORQUE CONVERTER

REMOVAL—4-WHEEL

DRIVE

The transmission and torque converter should

be removed as an assembly to avoid component damage. The converter drive plate, pump bush

ing, or oil seal can be damaged if the converter

is left attached to the driveplate during removal.

Be sure to remove the transmission and con

verter as an assembly. (1) Raise vehicle.

(2) Disconnect or remove exhaust components as

needed for service access. (3) Remove engine-to-transmission struts, if

equipped. (4) Disconnect fluid cooler lines at transmission. (5) Remove starter motor and cooler line bracket.

(6) Remove torque converter access cover.

(7) Remove transmission oil pan, drain fluid and

reinstall pan. (8) Remove transmission fill tube bracket bolts and

remove tube and O-ring from transmission case. (9) Mark torque converter and drive plate for as

sembly alignment. Note that bolt holes in crankshaft

flange, drive plate and torque converter all have one

offset hole. (10) Rotate crankshaft in clockwise direction until

converter bolts are accessible. Then remove bolts one at a time. Rotate crankshaft using breaker bar and

socket installed on damper pulley bolt. (11) Mark front/rear propeller shaft and axle yokes

for assembly alignment. (12) Disconnect and remove both propeller shafts

(Fig. 2). (13) Disconnect wires from park/neutral position switch and transmission solenoids.

(14)

Disconnect transmission gearshift rods and

torque shaft assembly from brackets on transmission and frame rail.

(15) Disconnect throttle valve cable from transmis

sion throttle lever.

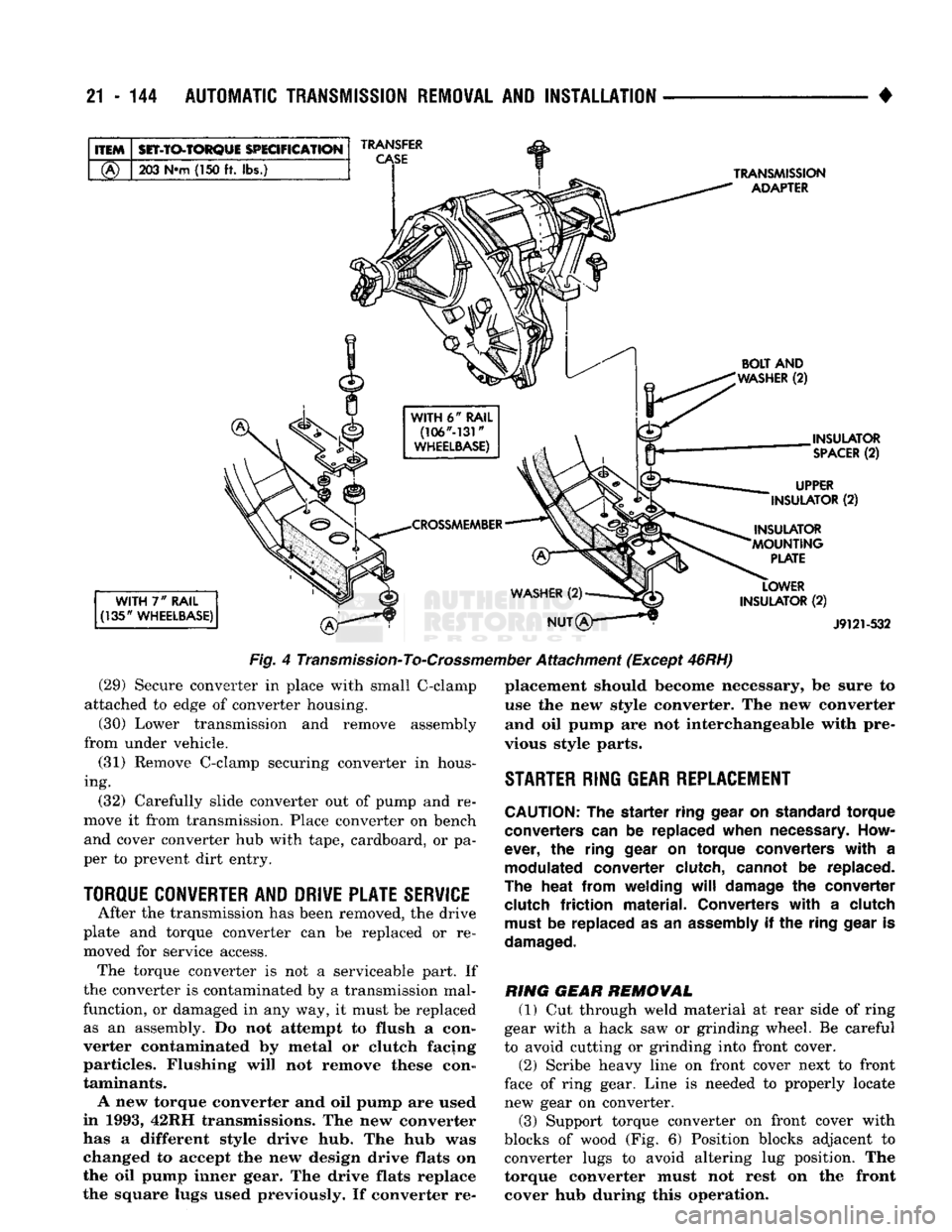

(16) Remove transfer case skid plate and skid plate

crossmember (Fig. 3). (17) Disconnect wires from vehicle speed sensor.

(18) Disconnect necessary vacuum harness hoses.

SKID

PLATE

CROSSMEMBER

TRANSFER

CASE

SKID

PLATE

J9121-525

Fig.

3

Skid

Plate

Mounting

(19) Disconnect transfer case shift lever from

range lever.

(20) Support transfer case with transmission jack.

Secure transfer case to jack with safety chains.

(21) Remove nuts attaching transfer case to trans

mission adapter.

(22) Pull transfer case rearward until clear of

transmission. Lower jack and move transfer case

from under vehicle. Then remove transfer case from

jack and leave on bench until ready for installation.

(23) Support transmission with transmission jack.

Secure transmission to jack with safety chains.

(24) Remove bolts/nuts attaching transmission in

sulator plate to rear crossmember (Figs. 4 and 5).

(25) Remove bolts/nuts attaching crossmember and

brackets to frame rails and remove crossmember.

(26) Support engine with Fixture C-3487-A and

adapters, or a jack stand and wood blocks.

(27) Remove bolts attaching converter housing to

engine. (28) Carefully work transmission-converter assem

bly rearward until clear of crankshaft and engine

block dowels.

Page 1145 of 1502

21-144

AUTOMATIC TRANSMISSION REMOVAL

AND

INSTALLATION

TRANSMISSION

ADAPTER

BOLT AND

;

WASHER

(2)

INSULATOR

SPACER

(2)

UPPER

INSULATOR

(2)

INSULATOR

MOUNTING PLATE

WITH

7"

RAIL

(135

"

WHEELBASE) LOWER

INSULATOR

(2)

J9121-532

Fig.

4

Transmission-To-Crossmember

Attachment (Except 46RH)

(29)

Secure converter in place with small C-clamp

attached to edge of converter housing.

(30)

Lower transmission and remove assembly

from under vehicle.

(31)

Remove C-clamp securing converter in hous

ing.

(32)

Carefully slide converter out of pump and re

move it from transmission. Place converter on bench and cover converter hub with tape, cardboard, or pa

per to prevent dirt entry.

TORQUE CONVERTER

AND

DRIVE PLATE SERVICE

After the transmission has been removed, the drive

plate and torque converter can be replaced or re

moved for service access.

The torque converter is not a serviceable part. If

the converter is contaminated by a transmission mal

function, or damaged in any way, it must be replaced as an assembly. Do not attempt to flush a con

verter contaminated by metal or clutch facing

particles. Flushing will not remove these con

taminants.

A new torque converter and oil pump are used

in 1993, 42RH transmissions. The new converter

has a different style drive hub. The hub was changed to accept the new design drive flats on

the oil pump inner gear. The drive flats replace

the square lugs used previously. If converter re placement should become necessary, be sure to

use the new style converter. The new converter and oil pump are not interchangeable with pre

vious style parts.

STARTER

RING GEAR

REPLACEMENT

CAUTION:

The

starter

ring

gear

on

standard

torque

converters

can be

replaced when necessary. How

ever,

the

ring gear

on

torque converters with

a

modulated converter clutch, cannot

be

replaced.

The heat from

welding

will

damage

the

converter

clutch friction material. Converters with

a

clutch

must

be

replaced

as an

assembly

if the

ring gear

is

damaged.

RING GEAR REMOWAL

(1) Cut through weld material at rear side of ring

gear with a hack saw or grinding wheel. Be careful

to avoid cutting or grinding into front cover. (2) Scribe heavy line on front cover next to front

face of ring gear. Line is needed to properly locate new gear on converter. (3) Support torque converter on front cover with

blocks of wood (Fig. 6) Position blocks adjacent to converter lugs to avoid altering lug position. The

torque converter must not rest on the front cover hub during this operation.

Page 1149 of 1502

21 - 148

AUTOMATIC TRANSMISSION REMOVAL

AND

INSTALLATION

•

ITEM

TORQUE

A

27-54

N-m

(20-40

ft. lbs.)

B

9-14

N-m

(80-120

in.

lbs.)

C

3-6 N-m

(30-50

in. lbs.)

D

47-88

N-m

(35-65

ft. lbs.)

E

14-20 N-m

(125-175

in. lbs.)

PLATE

FILL

TUBE

BRACKET

TRANSMISSION

DIPSTICK

DAMPER

WEIGHT

STRUT

DUST

COVER

J9321-232

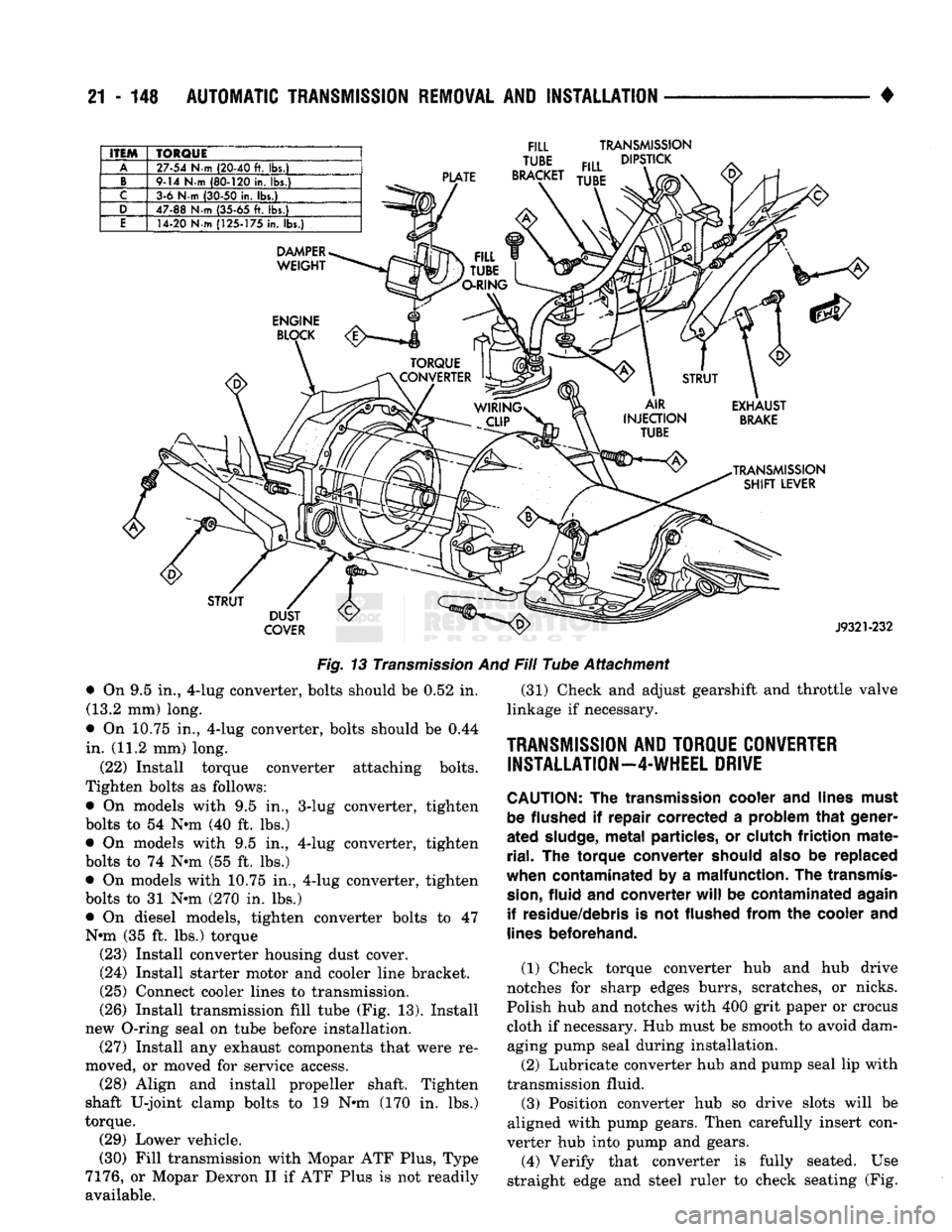

Fig. 13 Transmission And Fill Tube Attachment

3-lug converter, tighten

4-lug converter, tighten • On 9.5 in., 4-lug converter, bolts should be 0.52 in.

(13.2 mm) long.

• On 10.75 in., 4-lug converter, bolts should be 0.44

in. (11.2 mm) long. (22) Install torque converter attaching bolts.

Tighten bolts as follows:

• On models with 9.5 in.,

bolts to 54 Nnn (40 ft. lbs.) • On models with 9.5 in.,

bolts to 74 Nnn (55 ft. lbs.) • On models with 10.75 in., 4-lug converter, tighten

bolts to 31 Nnn (270 in. lbs.)

• On diesel models, tighten converter bolts to 47

Nnn (35 ft. lbs.) torque (23) Install converter housing dust cover. (24) Install starter motor and cooler line bracket.

(25) Connect cooler lines to transmission.

(26) Install transmission fill tube (Fig. 13). Install

new O-ring seal on tube before installation. (27) Install any exhaust components that were re

moved, or moved for service access. (28) Align and install propeller shaft. Tighten

shaft U-joint clamp bolts to 19 Nnn (170 in. lbs.)

torque. (29) Lower vehicle.

(30) Fill transmission with Mopar ATF Plus, Type

7176,

or Mopar Dexron II if ATF Plus is not readily

available. (31) Check and adjust gearshift and throttle valve

linkage if necessary.

TRANSMISSION

AND

TORQUE CONVERTER INSTALLATION—4-WHEEL DRIVE

CAUTION:

The

transmission cooler

and

lines must be flushed

if

repair

corrected

a

problem that gener

ated

sludge,

metal particles,

or

clutch friction mate rial.

The

torque

converter

should

also

be replaced

when contaminated

by a

malfunction.

The

transmis

sion,

fluid

and

converter

will

be

contaminated again if residue/debris

is not

flushed from

the

cooler

and

lines

beforehand.

(1) Check torque converter hub and hub drive

notches for sharp edges burrs, scratches, or nicks.

Polish hub and notches with 400 grit paper or crocus

cloth if necessary. Hub must be smooth to avoid dam aging pump seal during installation.

(2) Lubricate converter hub and pump seal lip with

transmission fluid.

(3) Position converter hub so drive slots will be

aligned with pump gears. Then carefully insert con

verter hub into pump and gears.

(4) Verify that converter is fully seated. Use

straight edge and steel ruler to check seating (Fig.