wheel bolt torque DODGE TRUCK 1993 Service Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 221 of 1502

5

- 34

BRAKES

•

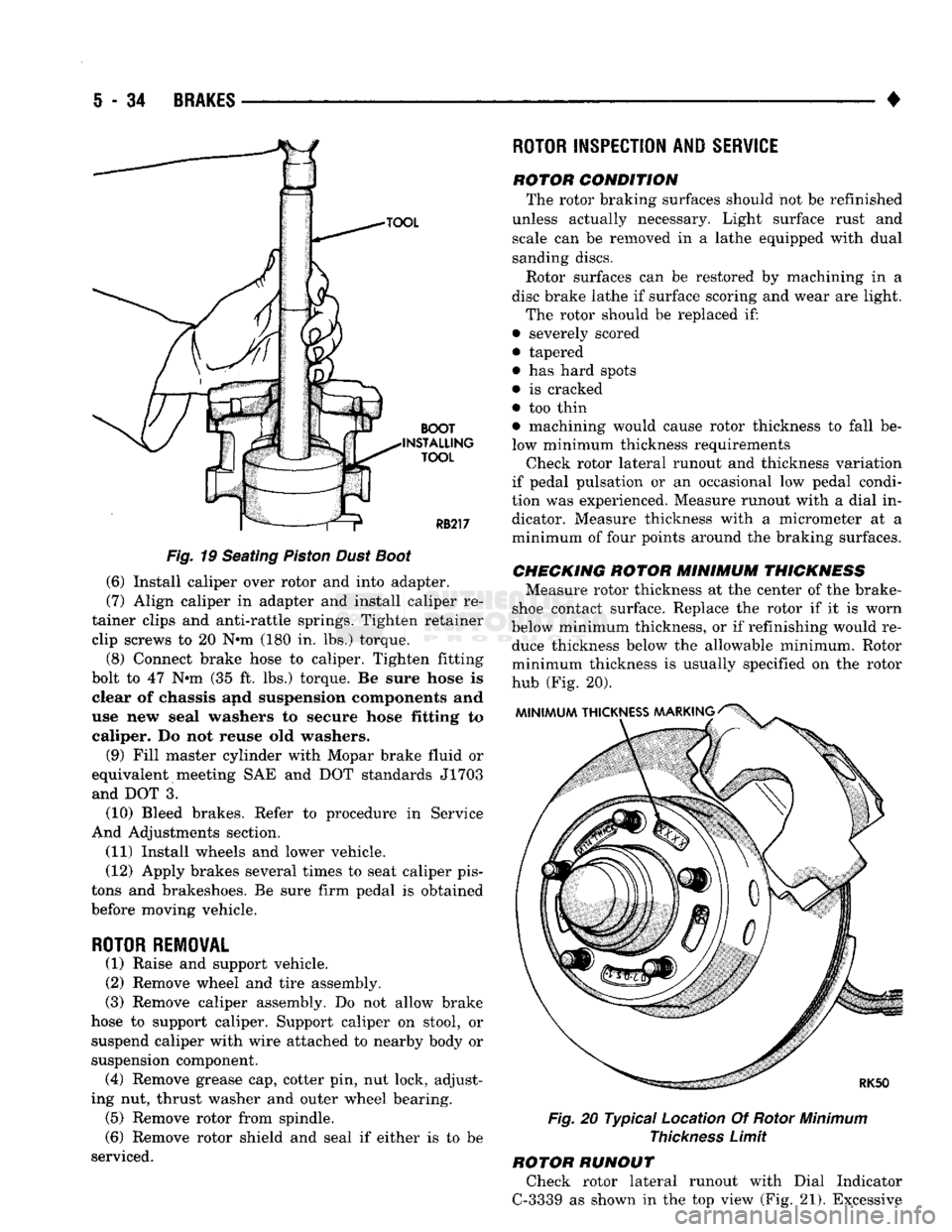

boot

>TALLir TOOL

Fig.

19 Seating

Piston

Dust

Boot

(6) Install caliper over rotor and into adapter.

(7) Align caliper in adapter and install caliper re

tainer clips and anti-rattle springs. Tighten retainer clip screws to 20 N*m (180 in. lbs.) torque.

(8) Connect brake hose to caliper. Tighten fitting

bolt to 47 N»m (35 ft. lbs.) torque. Be sure hose is clear of chassis and suspension components and

use new seal washers to secure hose fitting to caliper. Do not reuse old washers.

(9) Fill master cylinder with Mopar brake fluid or

equivalent meeting SAE and DOT standards J1703 and DOT 3.

(10) Bleed brakes. Refer to procedure in Service

And Adjustments section.

(11) Install wheels and lower vehicle.

(12) Apply brakes several times to seat caliper pis

tons and brakeshoes. Be sure firm pedal is obtained

before moving vehicle.

ROTOR REMOVAL

(1) Raise and support vehicle.

(2) Remove wheel and tire assembly.

(3) Remove caliper assembly. Do not allow brake

hose to support caliper. Support caliper on stool, or suspend caliper with wire attached to nearby body or

suspension component. (4) Remove grease cap, cotter pin, nut lock, adjust

ing nut, thrust washer and outer wheel bearing. (5) Remove rotor from spindle.

(6) Remove rotor shield and seal if either is to be

serviced.

ROTOR

INSPECTION AND

SERVICE

rotor condition The rotor braking surfaces should not be refinished

unless actually necessary. Light surface rust and scale can be removed in a lathe equipped with dual

sanding discs.

Rotor surfaces can be restored by machining in a

disc brake lathe if surface scoring and wear are light.

The rotor should be replaced if:

• severely scored

• tapered

• has hard spots

• is cracked

• too thin • machining would cause rotor thickness to fall be

low minimum thickness requirements Check rotor lateral runout and thickness variation

if pedal pulsation or an occasional low pedal condi

tion was experienced. Measure runout with a dial in dicator. Measure thickness with a micrometer at a

minimum of four points around the braking surfaces.

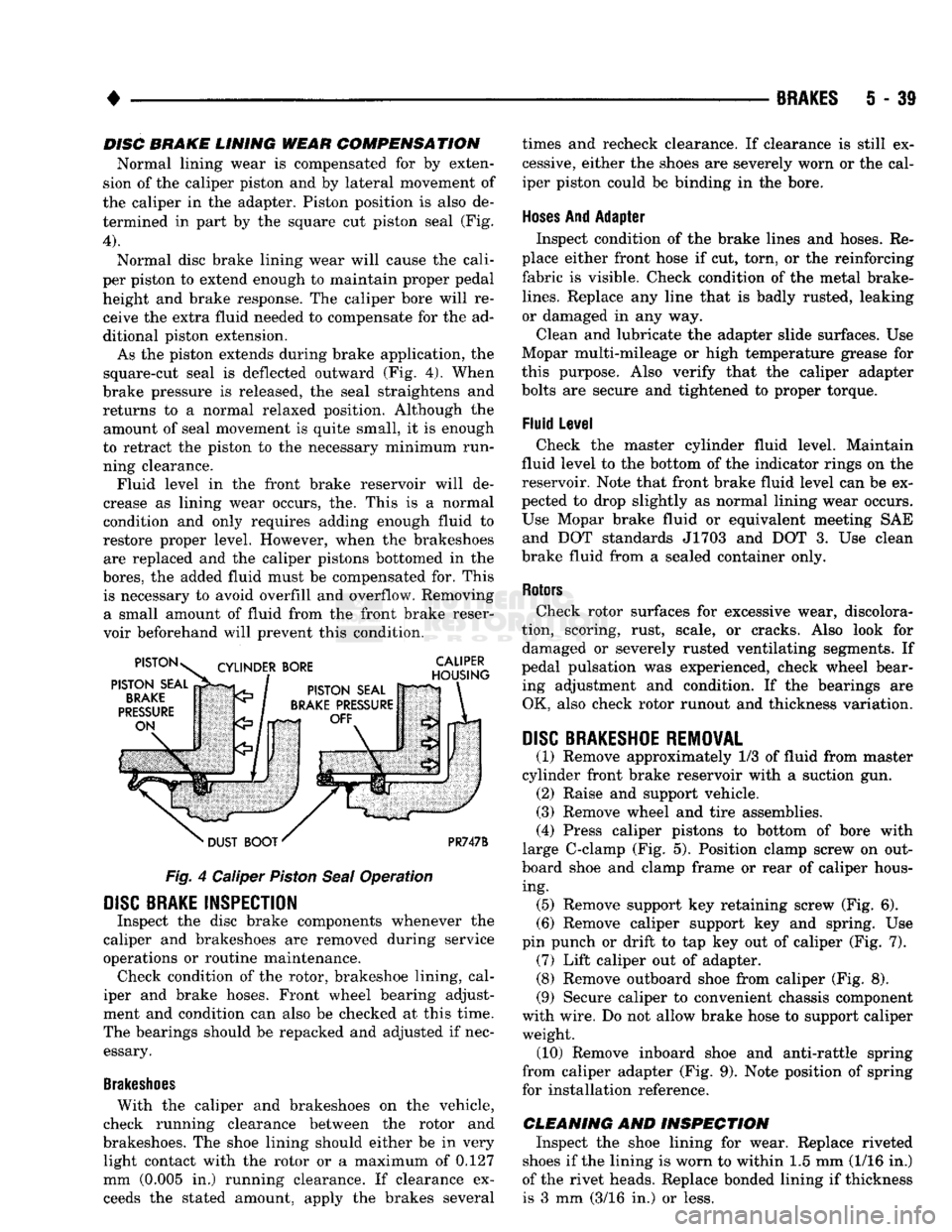

CHECKING

ROTOR

MINIMUM

THICKNESS

Measure rotor thickness at the center of the brake-

shoe contact surface. Replace the rotor if it is worn

below minimum thickness, or if refinishing would re duce thickness below the allowable minimum. Rotor

minimum thickness is usually specified on the rotor

hub (Fig. 20).

Fig.

20 Typical Location Of Rotor

Minimum

Thickness

Limit

ROTOR RUNOUT Check rotor lateral runout with Dial Indicator

C-3339 as shown in the top view (Fig. 21). Excessive

Page 226 of 1502

BRAKES

5 - 39

DISC BRAKE LINING WEAR COMPENSATION

Normal lining wear is compensated for by exten

sion of the caliper piston and by lateral movement of

the caliper in the adapter. Piston position is also de termined in part by the square cut piston seal (Fig.

4).

Normal disc brake lining wear will cause the cali

per piston to extend enough to maintain proper pedal height and brake response. The caliper bore will receive the extra fluid needed to compensate for the ad

ditional piston extension.

As the piston extends during brake application, the

square-cut seal is deflected outward (Fig. 4). When

brake pressure is released, the seal straightens and returns to a normal relaxed position. Although the amount of seal movement is quite small, it is enough

to retract the piston to the necessary minimum run ning clearance. Fluid level in the front brake reservoir will de

crease as lining wear occurs, the. This is a normal

condition and only requires adding enough fluid to

restore proper level. However, when the brakeshoes are replaced and the caliper pistons bottomed in the

bores,

the added fluid must be compensated for. This is necessary to avoid overfill and overflow. Removing a small amount of fluid from the front brake reser

voir beforehand will prevent this condition.

Fig.

4 Caliper

Piston

Seal

Operation

DISC

BRAKE INSPECTION

Inspect the disc brake components whenever the

caliper and brakeshoes are removed during service

operations or routine maintenance. Check condition of the rotor, brakeshoe lining, cal

iper and brake hoses. Front wheel bearing adjust

ment and condition can also be checked at this time.

The bearings should be repacked and adjusted if nec essary.

Brakeshoes

With the caliper and brakeshoes on the vehicle,

check running clearance between the rotor and

brakeshoes. The shoe lining should either be in very light contact with the rotor or a maximum of 0.127

mm (0.005 in.) running clearance. If clearance exceeds the stated amount, apply the brakes several times and recheck clearance. If clearance is still ex

cessive, either the shoes are severely worn or the cal

iper piston could be binding in the bore.

Hoses

And Adapter Inspect condition of the brake lines and hoses. Re

place either front hose if cut, torn, or the reinforcing

fabric is visible. Check condition of the metal brake-

lines.

Replace any line that is badly rusted, leaking

or damaged in any way.

Clean and lubricate the adapter slide surfaces. Use

Mopar multi-mileage or high temperature grease for

this purpose. Also verify that the caliper adapter

bolts are secure and tightened to proper torque.

Fluid Level Check the master cylinder fluid level. Maintain

fluid level to the bottom of the indicator rings on the

reservoir. Note that front brake fluid level can be ex

pected to drop slightly as normal lining wear occurs.

Use Mopar brake fluid or equivalent meeting SAE and DOT standards J1703 and DOT 3. Use clean

brake fluid from a sealed container only.

Rotors

Check rotor surfaces for excessive wear, discolora

tion, scoring, rust, scale, or cracks. Also look for damaged or severely rusted ventilating segments. If

pedal pulsation was experienced, check wheel bear ing adjustment and condition. If the bearings are OK, also check rotor runout and thickness variation.

DISC

BRAKESHOE REMOVAL

(1) Remove approximately 1/3 of fluid from master

cylinder front brake reservoir with a suction gun. (2) Raise and support vehicle.

(3) Remove wheel and tire assemblies.

(4) Press caliper pistons to bottom of bore with

large C-clamp (Fig. 5). Position clamp screw on out

board shoe and clamp frame or rear of caliper hous ing. (5) Remove support key retaining screw (Fig. 6).

(6) Remove caliper support key and spring. Use

pin punch or drift to tap key out of caliper (Fig. 7). (7) Lift caliper out of adapter. (8) Remove outboard shoe from caliper (Fig. 8).

(9) Secure caliper to convenient chassis component

with wire. Do not allow brake hose to support caliper weight. (10) Remove inboard shoe and anti-rattle spring

from caliper adapter (Fig. 9). Note position of spring

for installation reference.

CLEANING AND INSPECTION Inspect the shoe lining for wear. Replace riveted

shoes if the lining is worn to within 1.5 mm (1/16 in.)

of the rivet heads. Replace bonded lining if thickness is 3 mm (3/16 in.) or less.

Page 251 of 1502

5

- 64

BRAKES

•

Fig.

10

Checking

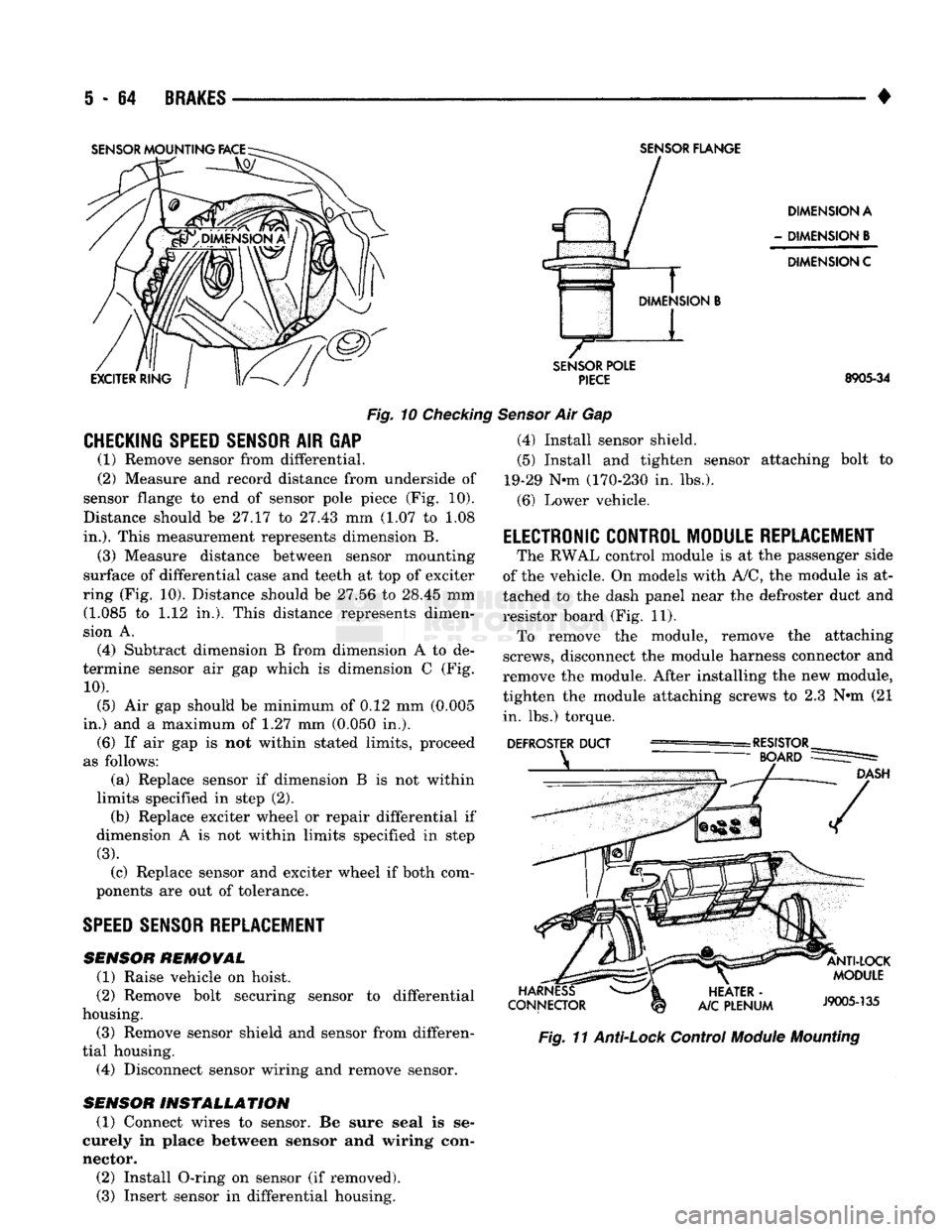

CHECKING SPEED SENSOR

AIR GAP (1) Remove sensor from differential.

(2) Measure and record distance from underside of

sensor flange to end of sensor pole piece (Fig. 10).

Distance should be 27.17 to 27.43 mm (1.07 to 1.08

in.).

This measurement represents dimension B.

(3) Measure distance between sensor mounting

surface of differential case and teeth at top of exciter

ring (Fig. 10). Distance should be 27.56 to 28.45 mm (1.085 to 1.12 in,). This distance represents dimen

sion A.

(4) Subtract dimension B from dimension A to de

termine sensor air gap which is dimension C (Fig.

10).

(5) Air gap should be minimum of 0.12 mm (0.005

in.) and a maximum of 1.27 mm (0.050 in.). (6) If air gap is not within stated limits, proceed

as follows: (a) Replace sensor if dimension B is not within

limits specified in step (2). (b) Replace exciter wheel or repair differential if

dimension A is not within limits specified in step

(3).

(c) Replace sensor and exciter wheel if both com

ponents are out of tolerance.

SPEED

SENSOR REPLACEMENT

SENSOR

REMOVAL

(1) Raise vehicle on hoist.

(2) Remove bolt securing sensor to differential

housing.

(3) Remove sensor shield and sensor from differen

tial housing. (4) Disconnect sensor wiring and remove sensor.

SENSOR

INSTALLATION

(1) Connect wires to sensor. Be sure seal is se

curely in place between sensor and wiring con

nector. (2) Install O-ring on sensor (if removed). (3) Insert sensor in differential housing.

SENSOR

FLANGE

DIMENSION A

-

DIMENSION

B

DIMENSION C

SENSOR

POLE

PIECE

8905-34

Sensor

Air Gap (4) Install sensor shield.

(5) Install and tighten sensor attaching bolt to

19-29 Nnn (170-230 in. lbs.).

(6) Lower vehicle.

ELECTRONIC CONTROL MODULE REPLACEMENT

The RWAL control module is at the passenger side

of the vehicle. On models with A/C, the module is at

tached to the dash panel near the defroster duct and

resistor board (Fig. 11). To remove the module, remove the attaching

screws, disconnect the module harness connector and

remove the module. After installing the new module,

tighten the module attaching screws to 2.3 N»m (21 in. lbs.) torque.

Fig.

11

Anti-Lock

Control

Module

Mounting

Page 252 of 1502

•

SPECIFICATIONS

BRAKES

5 - 65

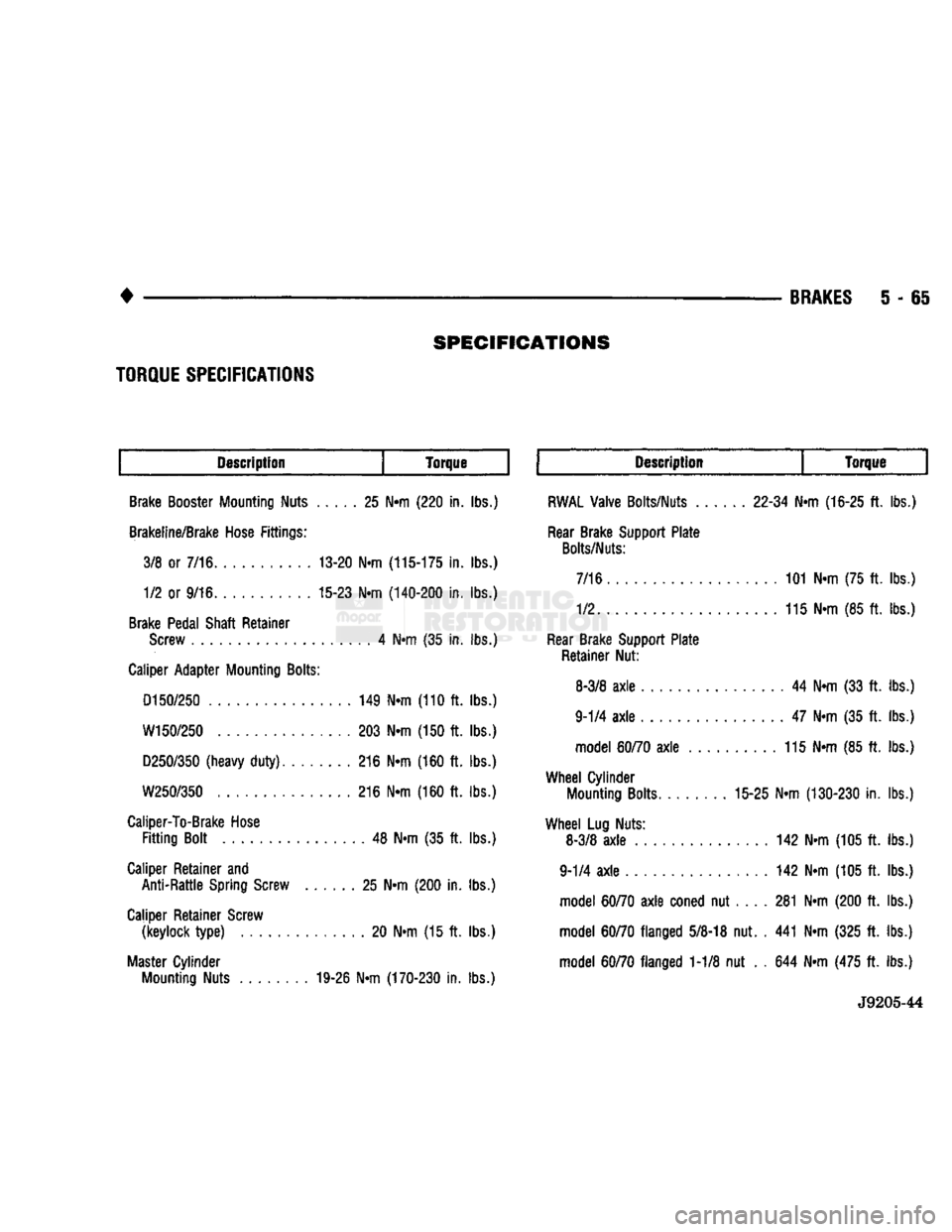

Description

Torque Description

Torque

Brake Booster Mounting Nuts 25 N«m (220 in. lbs.)

Brakeline/Brake Hose Fittings: 3/8 or 7/16 13-20 Nrn

(115-175

in. lbs.) 1/2 or 9/16 15-23 N«m

(140-200

in. lbs.)

Brake Pedal Shaft Retainer Screw 4 Ntn (35 in. lbs.)

Caliper Adapter Mounting

Bolts:

D150/250

149 N«m (110 ft. lbs.)

W150/250

203 N«m (150 ft. lbs.)

D250/350

(heavy

duty)

216 Nrn (160 ft. lbs.)

W250/350

216 N»m (160 ft. lbs.)

Caliper-To-Brake Hose

Fitting

Bolt 48 N«m (35 ft. lbs.)

Caliper Retainer and Anti-Rattle Spring Screw 25 N«m (200 in. lbs.)

Caliper Retainer Screw (keylock

type)

20 N«m (15 ft. lbs.)

Master Cylinder Mounting Nuts 19-26 N«m

(170-230

in. lbs.)

RWAL

Valve Bolts/Nuts

22-34

Nrn

(16-25

ft. lbs.)

Rear Brake Support Plate

Bolts/Nuts:

7/16 101 N»m (75 ft. lbs.)

1/2 115 N«m (85 ft. lbs.)

Rear Brake Support Plate Retainer Nut:

8-3/8

axle

44 N«m (33 ft. lbs.)

9-1/4

axle

47 N-m (35 ft. lbs.) model

60/70

axle

115 N-m (85 ft. lbs.)

Wheel

Cylinder Mounting Bolts 15-25 N«m

(130-230

in. lbs.)

Wheel

Lug Nuts: 8-3/8

axle

142 N»m (105 ft. lbs.)

9-1/4

axle

142 Nrn (105 ft. lbs.) model

60/70

axle

coned nut 281 N«m (200 ft. lbs.)

model

60/70

flanged

5/8-18

nut. . 441 Nrn (325 ft. lbs.)

model

60/70

flanged 1-1/8 nut . . 644 Nrn (475 ft. lbs.)

J9205-44

TORQUE

SPECIFICATIONS

Page 255 of 1502

6

- 2

CLUTCH

•

CLUTCH DIAGNOSIS

INDEX

page

Clutch Problem

Causes

, 2

General

Diagnosis

Information

2

GENERAL

DIAGNOSIS INFORMATION

Unless the cause of a clutch problem is obvious, a

road test and component inspection will be required

for accurate diagnosis. A road test will help determine the type of fault

while component inspection will identify the problem component. During a road test, drive the vehicle at normal

speeds. Shift the transmission through all gear

ranges and observe clutch action. If chatter, grab, slip, or improper release is experi

enced, remove and inspect the clutch components.

However, if the problem is noise or hard shifting,

further diagnosis is needed. The transmission or an

other driveline component may actually be at fault. Careful observation during a road test will help

narrow the problem area.

CLUTCH PROBLEM

CAUSES

CONTAMINATION Fluid contamination is one of the more common

causes of clutch malfunctions. Oil, water, or clutch

fluid on the clutch contact surfaces will result in

faulty operation. The usual result is chatter, slip, or

grab.

During inspection, note if any components are con

taminated with oil, hydraulic fluid, or water/road splash.

Oil contamination indicates a leak at either the

rear main seal or transmission input shaft.

Oil leakage produces a residue of oil on the hous

ing interior and on the clutch cover and flywheel.

Heat buildup caused by slippage between the cover,

disc and flywheel, can sometimes bake the oil residue

onto the components. The glaze-like residue ranges

in color from amber to black.

Road splash contamination means dirt and water

are entering the clutch housing due to loose bolts,

housing cracks, vent openings, or through the slave

cylinder opening. Driving through deep water pud

dles can force water/road splash into the housing

through such openings.

An additional problem caused by water contamina

tion and especially by steam cleaning, involves

clutch disc sticking and poor release. Water and steam vapors can be absorbed by the

clutch facing material. If the vehicle sits idle for long

page

Inspection

and

Diagnosis

Charts 5

periods after water contamination, the force exerted

by the pressure plate may cause the disc to bond it self to the flywheel or pressure plate.

Frequently, the only remedy for the above condi

tion is component replacement. To avoid this prob

lem, a vehicle should be driven as soon as possible to

heat and dry the clutch components.

Clutch fluid leaks are from a loose or damaged

slave cylinder line or connection. However, clutch

fluid leaks will usually be noted and corrected before severe contamination occurs.

CLUTCH MISALIGNMENT

Clutch components must be in proper alignment

with the crankshaft and transmission input shaft.

Misalignment caused by excessive runout or warpage of any clutch component will cause grab, chatter and improper clutch release.

Flywheel

Runout

Common causes of runout are heat warping, im

proper machining, mounting the flywheel on a dirty crankshaft flange, incorrect bolt tightening, or im

proper seating on the crankshaft flange shoulder.

Very light scratches or surface roughness on the

flywheel face can be cleaned up by scuff sanding with 180 grit emery cloth. However, if the surface is

warped or severely scored, replace the flywheel.

Do not machine the flywheel. The flywheel

face is manufactured with a unique surface con

tour. Machining would negate this feature and could result in unsatisfactory operation.

Clean the crankshaft flange before mounting the

flywheel. Dirt and grease on the flange surface may cock the flywheel causing runout.

Use new bolts when remounting a flywheel and se

cure the bolts with Mopar Lock And Seal, or Loctite

242.

Tighten flywheel bolts to specified torque only.

Overtightening could distort the flywheel hub caus

ing runout.

Clutch

Cover

And Disc

Runout

Check the clutch disc before installation. Axial

(face) runout of a new disc should not exceed 0.5 mm

(0.020 in.). Measure runout about 6 mm (1/4 in.)

from the outer edge of the disc facing. Obtain an other disc if runout is excessive.

Page 256 of 1502

•

CLUTCH

6 - 3 Check condition of the clutch before installation. A

warped cover or diaphragm spring will cause grab and incomplete release or engagement.

Be careful when handling the cover and disc. Im

pact can distort the cover, diaphragm spring, release

fingers and the hub of the clutch disc.

Use an alignment tool when positioning the disc on

the flywheel. The tool prevents accidental misalign ment which could result in cover distortion and disc

damage.

A frequent cause of clutch cover distortion (and

consequent misalignment) is improper bolt tighten

ing. To avoid warping the cover, tighten the bolts al

ternately (in a diagonal pattern) and evenly (2-3

threads at a time) to specified torque.

Clutch

Housing

Misalignment And Runout Clutch housing alignment is important to proper

operation. The housing bore maintains alignment be

tween the crankshaft and transmission input shaft.

Misalignment can cause noise, incomplete clutch

release and chatter. It can also result in premature

wear of the pilot bearing, cover release fingers and

clutch disc. In severe cases, misalignment can also cause premature wear of the transmission input

shaft and bearing.

Housing face misalignment is generally caused by

incorrect seating on the engine or transmission, loose

housing bolts, missing alignment dowels or housing damage. Infrequently, misalignment may also be

caused by housing mounting surfaces that are not

parallel. If housing misalignment is suspected, housing bore

and face runout can be checked with a dial indicator

as described in the following two procedures:

MEASURING

CLUTCH HOUSING BORE

RUNOUT

(1) Remove the clutch housing and strut.

(2) Remove the clutch cover and disc.

(3) Replace one of the flywheel bolts with a 7/16-20

threaded rod that is 10 in. (25.4 cm) long (Fig. 1).

The rod will be used to mount the dial indicator.

(4) Remove the release fork from the clutch hous

ing. (5) Reinstall the clutch housing. Tighten the hous

ing bolts nearest the alignment dowels first. (6) Mount the dial indicator on the threaded rod

and position the indicator plunger on the surface of

the clutch housing bore (Fig. 2).

(7) Rotate the crankshaft until the indicator

plunger is at the top center of the housing bore. Zero the indicator at this point.

(8) Rotate the crankshaft and record the indicator

readings at eight points (45° apart) around the bore (Fig. 3). Repeat the measurement at least twice for

accuracy. (9) Subtract each reading from the one 180° oppo

site to determine magnitude and direction of runout.

Refer to Figure 3 and following example.

Bore runout example: 0.000 - (-0.007) = 0.007 in. + 0.002 - (-0.010) = 0.012 in.

+ 0.004 - (-0.005) = 0.009 in.

-0.001 -

(

+ 0.001) = -0.002 in. (= 0.002 inch)

In the above example, the largest difference is

0.012 in. and is called the total indicator reading

(TIR).

This means that the housing bore is offset

from the crankshaft centerline by 0.006 in. (which is 1/2 of 0.012 in.).

On gas engines, the acceptable maximum TIR for

housing bore runout is 0.010 inch. If measured TIR is more than 0.010 in. (as in the example), bore runout

will have to be corrected with offset dowels. Offset dowels are available in 0.007, 0.014 and 0.021 in.

sizes for this purpose (Fig. 4). Refer to Correcting

Housing Bore Runout for dowel installation.

On diesel engines, the acceptable maximum

TIR for housing bore runout is 0.015 inch. How

ever, unlike gas engines, offset dowels are not available to correct runout on diesel engines. If

bore runout exceeds the stated maximum on a diesel engine, it may be necessary to replace ei

ther the clutch housing, or transmission adapter

plate.

CORRECTING CLUTCH HOUSING BORE

RUNOUT

(GAS

ENGINE

ONLY)

On gas engine vehicles, clutch housing bore runout

is corrected with offset dowels. However, if bore

runout exceeds 0.015 in. TIR on a diesel equipped model, the clutch housing, or transmission adapter

plate may have to be replaced. Offset dowels are not available for diesel models.

The dial indicator reads positive when the plunger

moves inward (toward indicator) and negative when it moves outward (away from indicator). As a result,

the lowest or most negative reading determines the

direction of housing bore offset (runout).

In the sample readings shown in Figure 3 and in

step (7) above, the bore is offset toward the 0.010

inch reading. To correct this, remove the housing and

original dowels. Then install the new offset dowels in

the direction needed to center the bore with the crankshaft centerline.

In the example, TIR was 0.012 inch. The dowels

needed for correction would have an offset of 0.007

in. (Fig. 4).

Install the dowels with the slotted side facing out

so they can be turned with a screwdriver. Then in

stall the housing, remount the dial indicator and

check bore runout again. Rotate the dowels until the

TIR is less than 0.010 in. if necessary.

If a TIR of 0.053 in. or greater is encountered, it

may be necessary to replace the clutch housing.

Page 258 of 1502

•

CLUTCH

6 - 5

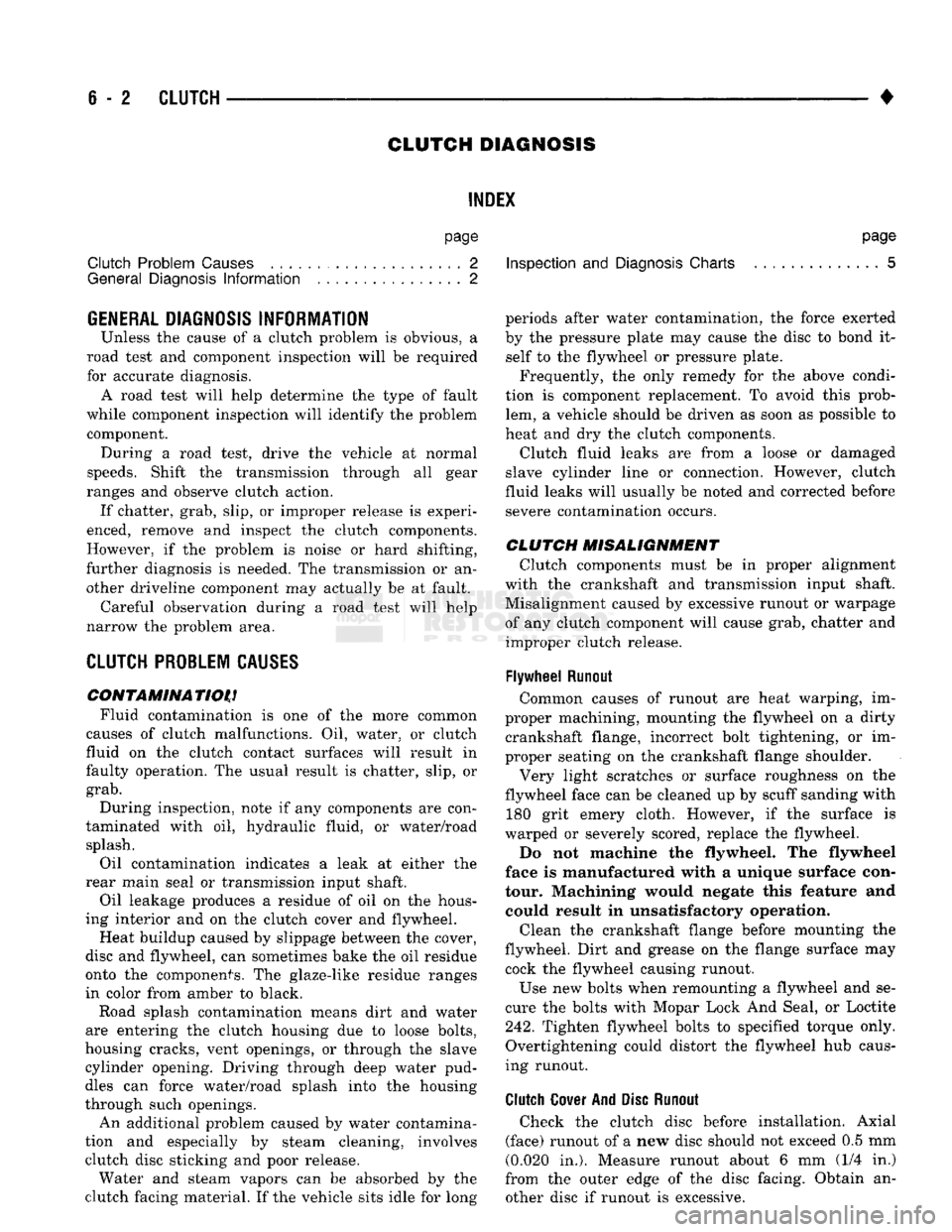

INDICATOR

PLUNGER

DIAL INDICATOR

CLUTCH

HOUSING

FACE

INDICATOR MOUNTING

„

STUD OR ROD

J9006-29

Fig.

5

Measuring

Clutch

Housing

Face

Runout

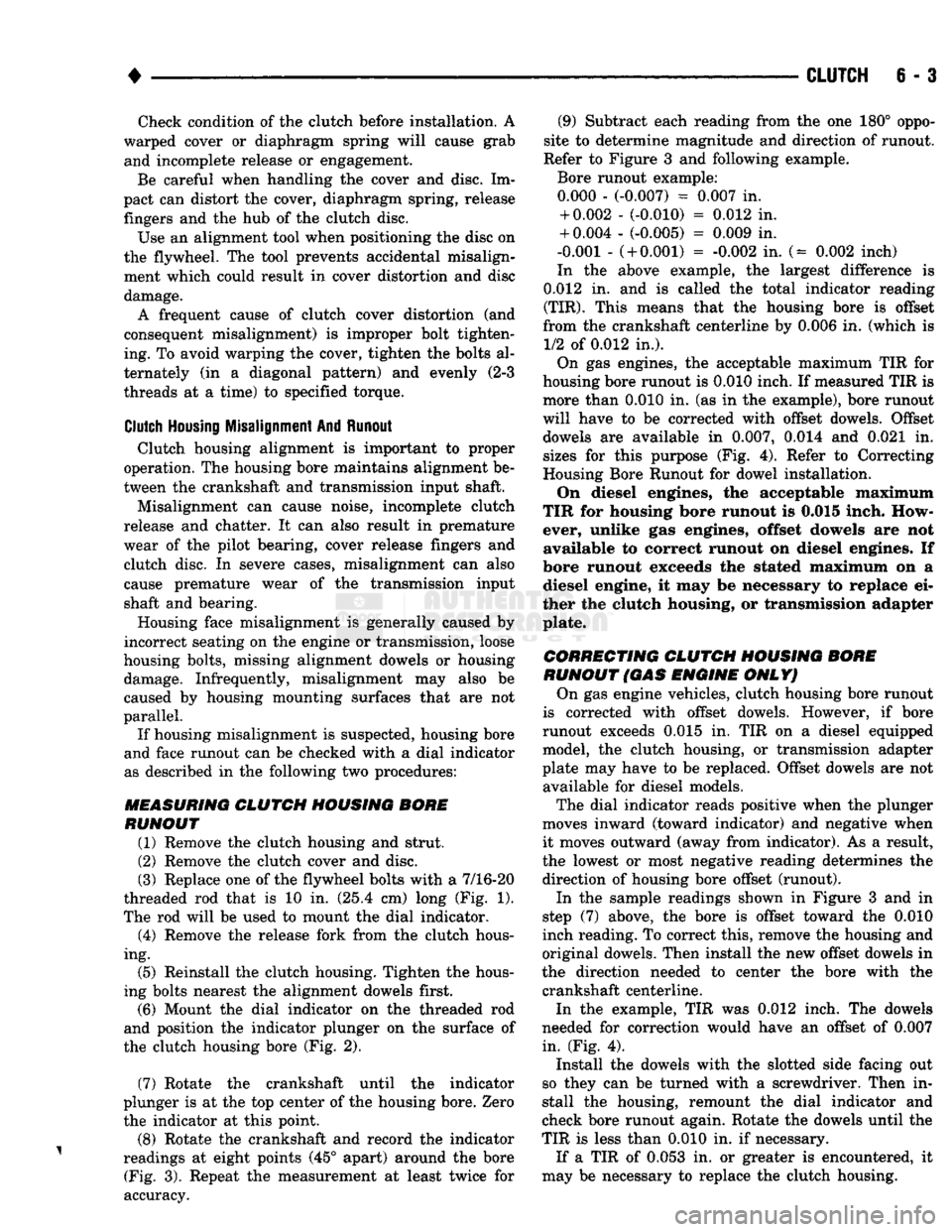

+

.009 CLUTCH

HOUSING

FACE

CIRCLE

(AT RIM

OF BORE)

,004

(SAMPLE

READINGS)

J9006-30

Fig.

6

Housing

Face Measurement

Points

And

Sample

Readings

INSTALLATION

METHODS

AND

PARTS

USAGE

Distortion of clutch components during installation

and the use of non-standard components are addi

tional causes of clutch malfunction.

Improper clutch cover bolt tightening can distort

the cover. The usual result is clutch grab, chatter

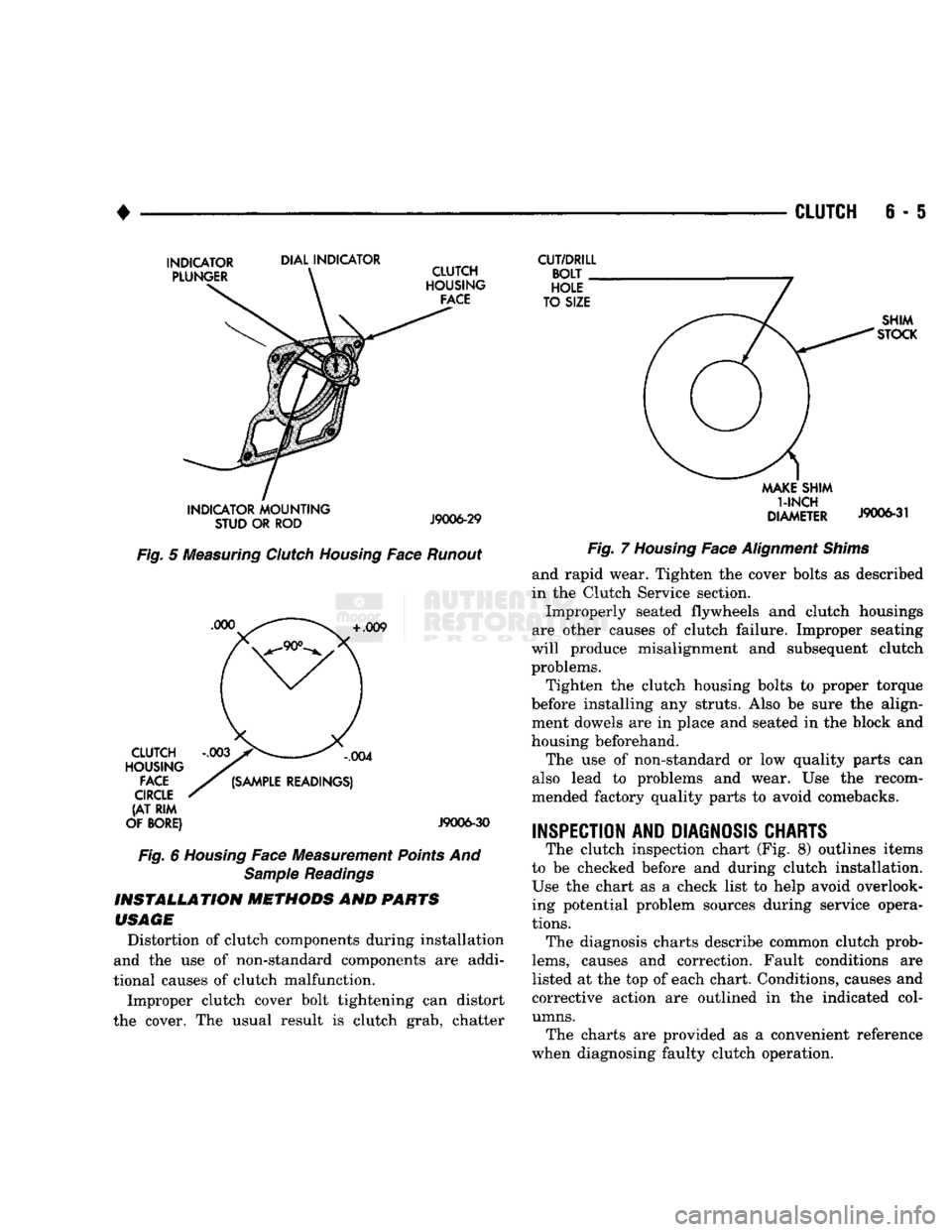

CUT/DRILL

BOLT

HOLE

TO SIZE SHIM

STOCK

MAKE

SHIM

1-INCH

DIAMETER

J9006-31

Fig.

7

Housing

Face

Alignment

Shims

and rapid wear. Tighten the cover bolts as described

in the Clutch Service section.

Improperly seated flywheels and clutch housings

are other causes of clutch failure. Improper seating

will produce misalignment and subsequent clutch problems.

Tighten the clutch housing bolts to proper torque

before installing any struts. Also be sure the align ment dowels are in place and seated in the block and

housing beforehand.

The use of non-standard or low quality parts can

also lead to problems and wear. Use the recom

mended factory quality parts to avoid comebacks.

INSPECTION AND DIAGNOSIS CHARTS

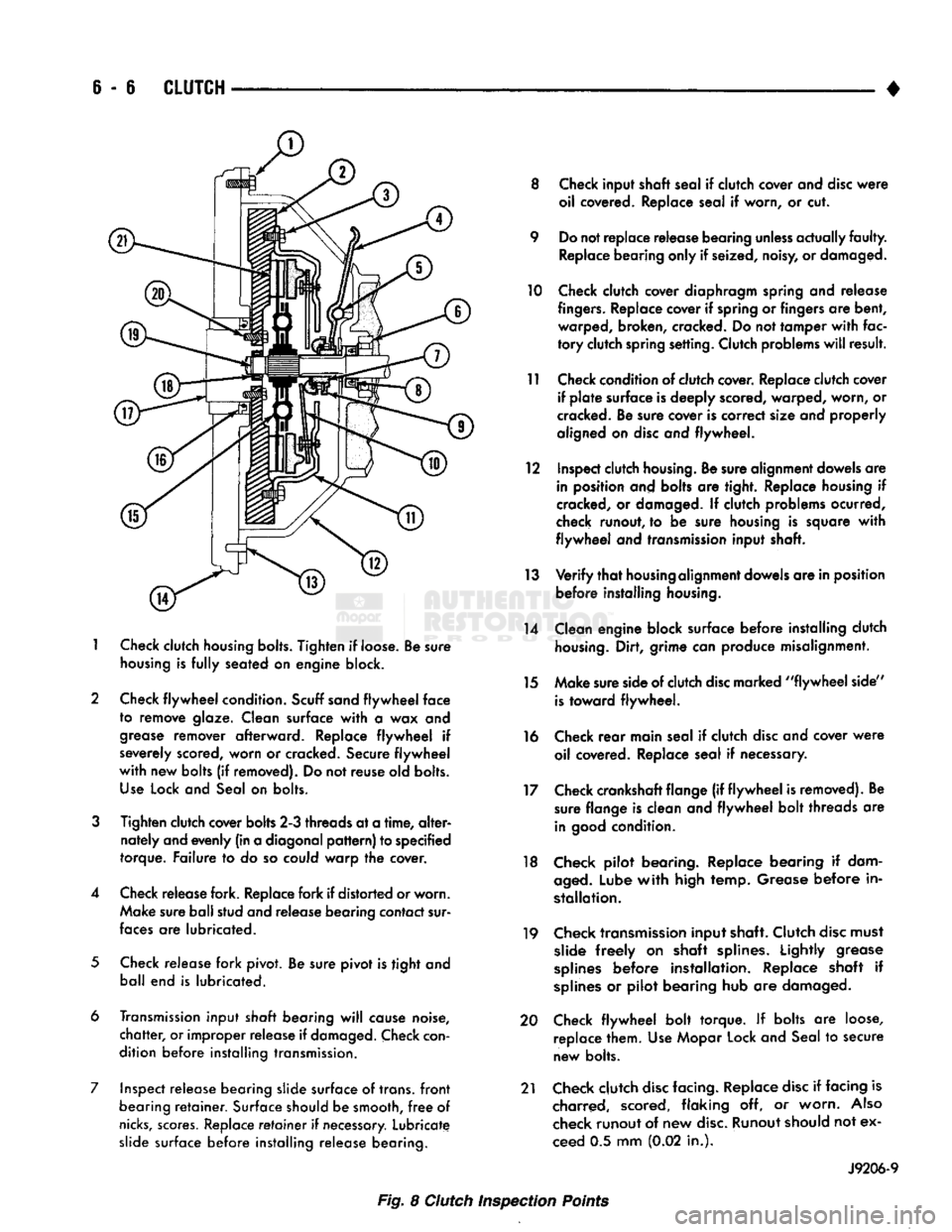

The clutch inspection chart (Fig. 8) outlines items

to be checked before and during clutch installation. Use the chart as a check list to help avoid overlooking potential problem sources during service opera

tions.

The diagnosis charts describe common clutch prob

lems,

causes and correction. Fault conditions are

listed at the top of each chart. Conditions, causes and

corrective action are outlined in the indicated col

umns.

The charts are provided as a convenient reference

when diagnosing faulty clutch operation.

Page 259 of 1502

6 - 6

CLUTCH

1

Check

clutch

housing bolts.

Tighten

if loose. Be sure

housing

is

fully

seated on engine block.

2 Check

flywheel

condition.

Scuff sand

flywheel

face

to remove glaze. Clean surface

with

a wax and

grease

remover afterward. Replace

flywheel

if

severely scored, worn or cracked. Secure

flywheel

with

new bolts (if removed). Do not reuse old bolts.

Use

Lock and Seal on bolts.

3

Tighten clutch cover bolts 2-3 threads at a

time,

alter

nately and evenly (in a diagonal

pattern)

to specified

torque. Failure to do so could warp the cover.

4 Check release fork. Replace fork if distorted or worn. Make sure ball stud and release bearing contact sur

faces

are lubricated.

5

Check release fork pivot. Be sure pivot is tight and ball end is lubricated.

6 Transmission input

shaft

bearing

will

cause noise,

chatter,

or improper release if

damaged.

Check

con

dition before installing transmission.

7 Inspect release bearing slide surface of trans,

front

bearing

retainer.

Surface should be smooth,

free

of

nicks,

scores.

Replace

retainer

if

necessary.

Lubricate slide surface before installing release bearing. 8 Check input shaft seal if clutch cover and

disc

were

oil covered. Replace seal if worn, or cut.

9 Do not replace release bearing

unless

actually

faulty.

Replace bearing only if seized, noisy, or damaged.

10 Check clutch cover diaphragm spring and release

fingers.

Replace cover if spring or fingers are bent, warped, broken, cracked. Do not tamper

with

fac

tory

clutch spring setting. Clutch problems

will

result.

11 Check condition of clutch cover. Replace clutch cover if

plate

surface is deeply scored, warped, worn, or

cracked. Be sure cover is correct size and properly

aligned on

disc

and flywheel.

12 Inspect clutch

housing.

Be sure alignment dowels are in position and bolts are tight. Replace housing if

cracked, or damaged. If clutch problems ocurred,

check runout, to be sure housing is square

with

flywheel

and transmission input shaft.

13

Verify

that

housing

alignment dowels are in position before installing

housing.

14 Clean engine block surface before installing clutch

housing.

Dirt, grime can produce misalignment.

15 Make sure side of clutch

disc

marked

"flywheel

side"

is

toward flywheel.

16 Check

rear

main seal if clutch

disc

and cover

were

oil covered. Replace seal if necessary.

17 Check crankshaft flange (if

flywheel

is removed). Be sure flange is clean and

flywheel

bolt threads are

in

good

condition.

18 Check pilot bearing. Replace bearing if dam

aged.

Lube

with

high temp. Grease before in

stallation.

19 Check transmission input shaft. Clutch

disc

must slide

freely

on shaft splines. Lightly grease

splines

before installation. Replace shaft if

splines

or pilot bearing hub are damaged.

20 Check

flywheel

bolt torque. If bolts are loose, replace them. Use Mopar Lock and Seal to secure

new bolts.

21 Check clutch

disc

facing. Replace

disc

if facing is charred, scored, flaking off, or worn.

Also

check runout of new

disc.

Runout should not ex

ceed 0.5 mm (0.02 in.).

J9206-9

Fig. 8 Clutch Inspection Points

Page 263 of 1502

6-10

CLUTCH

•

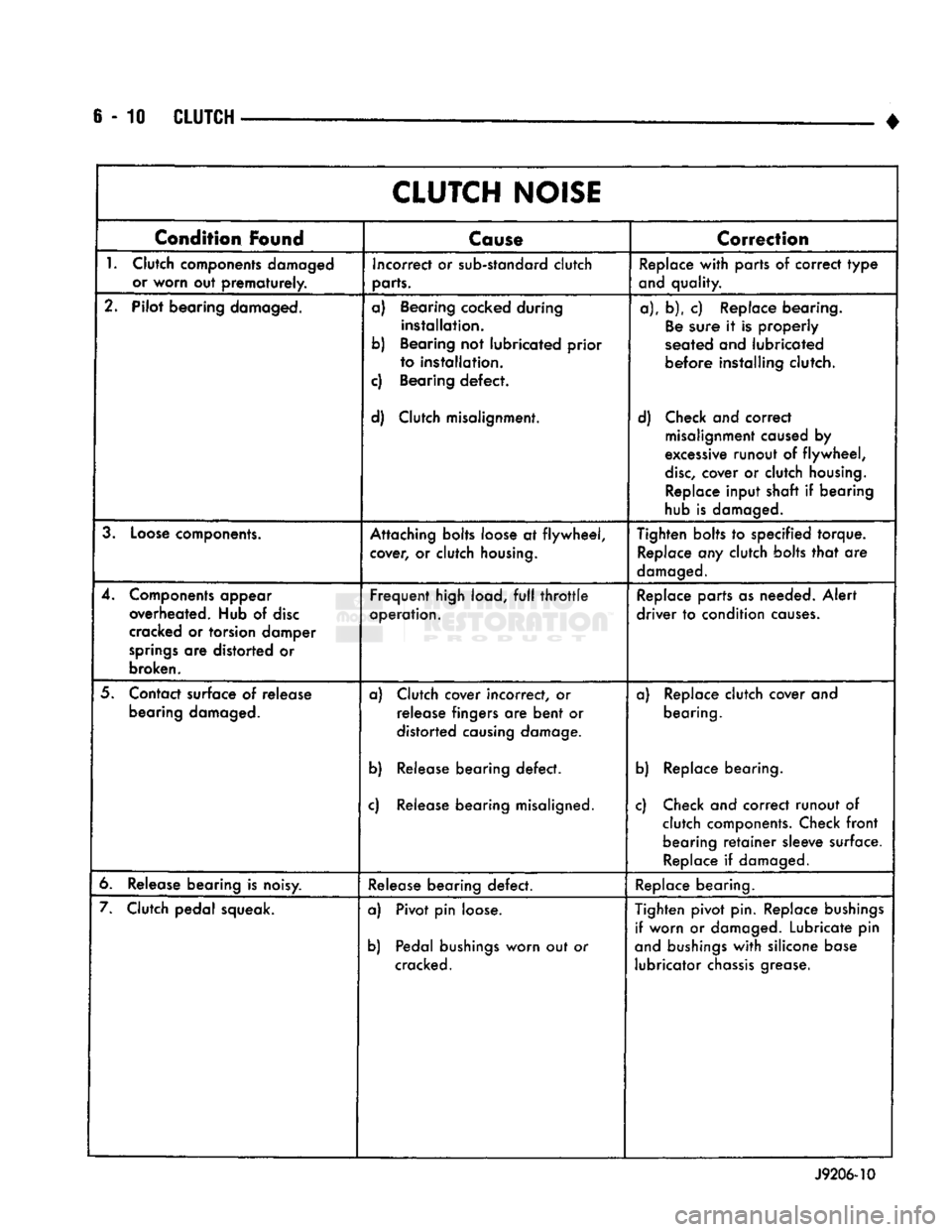

CLUTCH

NOISE

Condition

Found

Cause

Correction

1.

Clutch components damaged or worn out

prematurely.

Incorrect or sub-standard clutch

parts. Replace

with

parts of correct

type

and quality.

2. Pilot bearing damaged. a) Bearing cocked during

installation.

b) Bearing not lubricated prior to installation.

c) Bearing

defect.

d) Clutch misalignment. a), b), c) Replace bearing.

Be

sure it is properly

seated and lubricated

before

installing clutch.

d) Check and correct misalignment caused by

excessive runout of

flywheel,

disc,

cover or clutch

housing.

Replace input shaft if bearing

hub is damaged.

3.

Loose

components. Attaching bolts loose at

flywheel,

cover, or clutch

housing.

Tighten bolts to specified torque.

Replace any clutch bolts

that

are

damaged.

4. Components appear overheated. Hub of

disc

cracked or torsion damper

springs

are distorted or

broken.

Frequent

high load,

full

throttle

operation. Replace parts as needed.

Alert

driver

to condition

causes.

5. Contact surface of release bearing damaged. a) Clutch cover incorrect, or

release fingers are

bent

or

distorted causing damage.

b) Release bearing

defect.

c) Release bearing misaligned. a) Replace clutch cover and

bearing.

b) Replace bearing.

c) Check and correct runout of clutch components. Check

front

bearing

retainer

sleeve surface. Replace if damaged.

6. Release bearing is noisy. Release bearing

defect.

Replace bearing.

7. Clutch pedal squeak. a) Pivot pin loose.

b) Pedal

bushings

worn out or

cracked. Tighten pivot pin. Replace

bushings

if worn or damaged. Lubricate pin

and

bushings

with

silicone base lubricator

chassis

grease.

J9206-10

Page 265 of 1502

6-12

CLUTCH

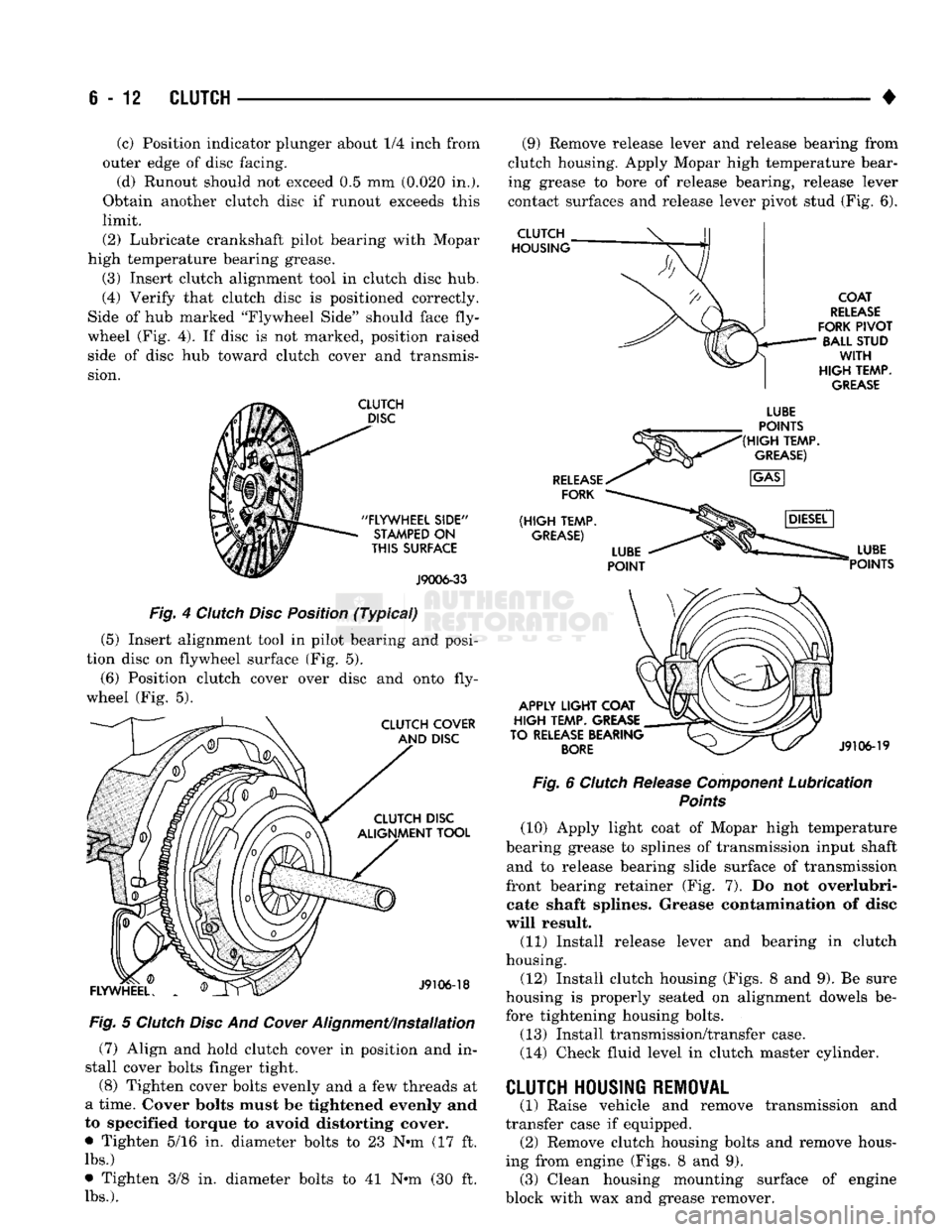

(c) Position indicator plunger about 1/4 inch from

outer edge of disc facing.

(d) Runout should not exceed 0.5 mm (0.020 in.).

Obtain another clutch disc if runout exceeds this

limit.

(2) Lubricate crankshaft pilot bearing with Mopar

high temperature bearing grease.

(3) Insert clutch alignment tool in clutch disc hub,

(4) Verify that clutch disc is positioned correctly.

Side of hub marked "Flywheel Side" should face fly

wheel (Fig. 4). If disc is not marked, position raised side of disc hub toward clutch cover and transmis

sion.

CLUTCH

DISC

"FLYWHEEL

SIDE"

STAMPED

ON

THIS

SURFACE

J9006-33

Fig. 4 Clutch Disc Position (Typical)

(5) Insert alignment tool in pilot bearing and posi

tion disc on flywheel surface (Fig. 5).

(6) Position clutch cover over disc and onto fly

wheel (Fig. 5).

CLUTCH COVER AND DISC CLUTCH DISC

ALIGNMENT TOOL

FLYWHEEL.

J9106-18

Fig. 5 Clutch Disc And

Cower

Alignment/installation (7) Align and hold clutch cover in position and in

stall cover bolts finger tight.

(8) Tighten cover bolts evenly and a few threads at

a time. Cover bolts must be tightened evenly and

to specified torque to avoid distorting cover.

• Tighten 5/16 in. diameter bolts to 23 N-m (17 ft.

lbs.)

• Tighten 3/8 in. diameter bolts to 41 N-m (30 ft.

lbs.).

(9) Remove release lever and release bearing from

clutch housing. Apply Mopar high temperature bear

ing grease to bore of release bearing, release lever

contact surfaces and release lever pivot stud (Fig. 6).

CLUTCH

HOUSING

COAT

RELEASE

FORK

PIVOT

BALL STUD

WITH

HIGH

TEMP.

GREASE

RELEASE

FORK

(HIGH

TEMP.

GREASE)

LUBE

POINTS

(HIGH

TEMP.

GREASE)

APPLY

LIGHT

COAT

HIGH

TEMP. GREASE

TO RELEASE BEARING

BORE

LUBE

POINTS

J9106-19

Fig. 6 Clutch Release Component Lubrication

Points

(10) Apply light coat of Mopar high temperature

bearing grease to splines of transmission input shaft and to release bearing slide surface of transmission

front bearing retainer (Fig. 7). Do not overlubri- cate shaft splines. Grease contamination of disc

will result. (11) Install release lever and bearing in clutch

housing.

(12) Install clutch housing (Figs. 8 and 9). Be sure

housing is properly seated on alignment dowels be fore tightening housing bolts.

(13) Install transmission/transfer case.

(14) Check fluid level in clutch master cylinder. transmission and

CLUTCH HOUSING REMOVAL

(1) Raise vehicle and remove

transfer case if equipped. (2) Remove clutch housing bolts and remove hous

ing from engine (Figs. 8 and 9). (3) Clean housing mounting surface of engine

block with wax and grease remover.