wheel bolt torque DODGE TRUCK 1993 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 128 of 1502

FRONT

SUSPENSION

AND

AXLE

2 - 75

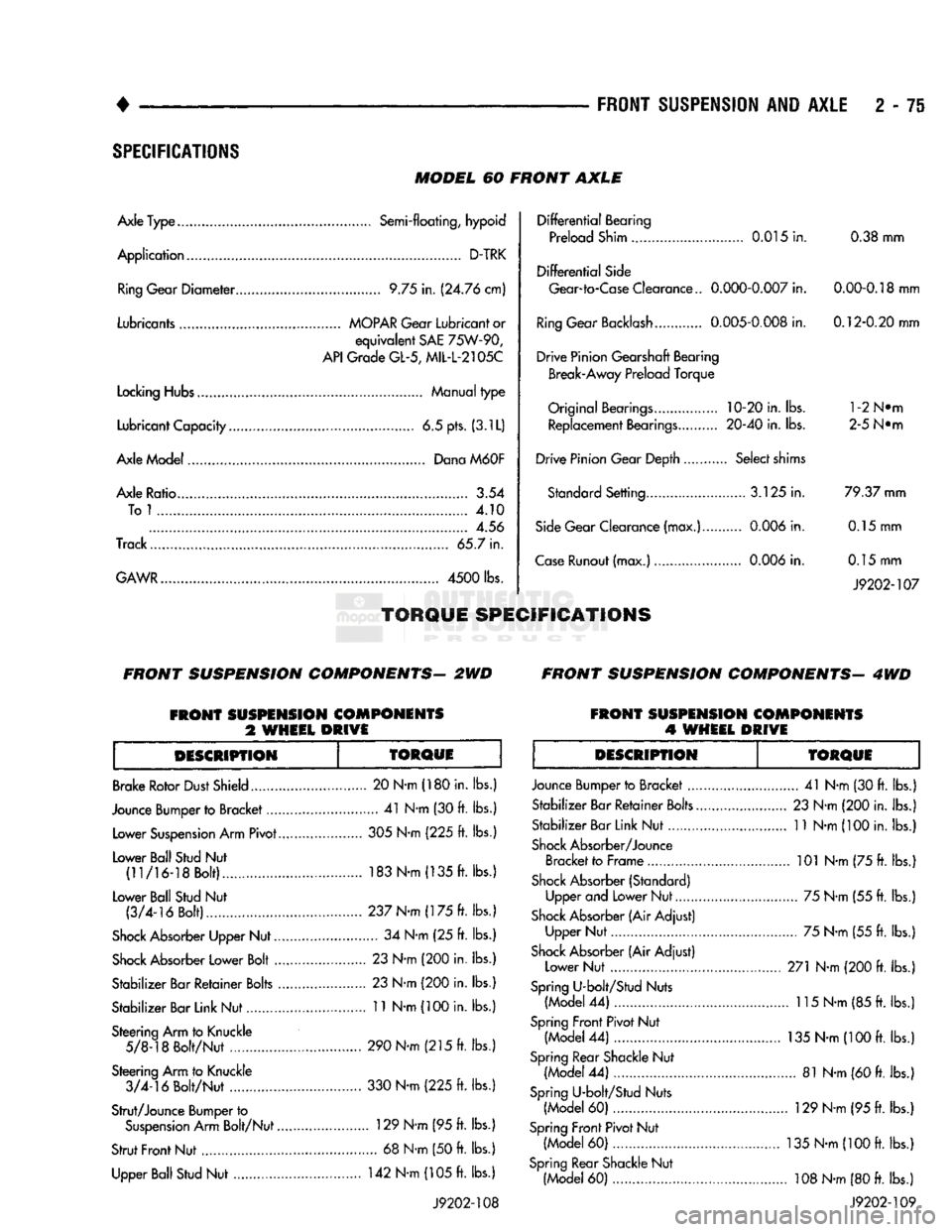

SPECIFICATIONS

MODEL

60

FRONT

AXLE

Axle Type........

Semi-floating,

hypoid

Application

D-TRK Ring Gear

Diameter

9.75

in.

(24.76 cm)

Lubricants

MOPAR

Gear

Lubricant

or

equivalent

SAE

75W-90,

API

Grade

GL-5,

MIL-L-2105C

Locking

Hubs Manual

type

Lubricant Capacity

6.5

pts. (3.1L)

Axle Model Dana

M60F

Axle Ratio.........

3.54

Tol

4.10

4.56

Track... 65.7

in.

GAWR....................

4500

lbs.

TORQUE

SPECIFICATIONS

Differential

Bearing

Preload Shim 0.015

in.

0.38

mm

Differential

Side Gear-to-Case Clearance..

0.000-0.007

in.

0.00-0.18

mm

Ring

Gear Backlash 0.005-0,008

in.

0.12-0.20 mm

Drive Pinion Gearshaft Bearing Break-Away Preload Torque

Original

Bearings....

10-20

in. lbs. l-2N®m Replacement Bearings. 20-40

in.

lbs. 2-5 N®m

Drive Pinion Gear Depth Select shims Standard Setting.... 3.125

in.

79.37 mm

Side

Gear Clearance (max.) 0.006

in.

0.15

mm

Case

Runout (max.) 0.006

in.

0.15

mm

J9202-107

FRONT

SUSPENSION

COMPONENTS-

2WD

FRONT

SUSPENSION

COMPONENTS-

4WD

FRONT

SUSPENSION

COMPONENTS

%

WHEEL

DRIVE

FRONT

SUSPENSION

COMPONENTS

4

WHEEL

DRIVE

DESCRIPTION

TOROUE

Brake Rotor

Dust

Shield

Jounce Bumper to Bracket.... Lower

Suspension

Arm Pivot.

Lower Ball Stud

Nut

(11/16-18 Bolt)...............

Lower Ball Stud

Nut

(3/4-16 Bolt).....

Shock

Absorber Upper Nut..

Shock

Absorber Lower Bolt

..

Stabilizer Bar Retainer

Bolts

.

Stabilizer Bar Link Nut

Steering Arm to Knuckle 5/8-18 Bolt/Nut

.............

Steering Arm to Knuckle 3/4-16 Bolt/Nut . 20 N-m (180 in.

lbs.

....

41

N-m

(30

ft. lbs.

305

N-m (225

ft. lbs.

183

N-m (135

ft. lbs.

237 N-m (175

ft. lbs.

....

34

N-m

(25 ft.

lbs. .

23

N-m

(200

in. lbs.

.

23

N-m

(200

in. lbs.

. 11 N-m

(100

in. lbs.

Strut/Jounce Bumper to

Suspension

Arm Bolt/Nut.

Strut

Front

Nut Upper Ball Stud

Nut

290 N-m (215

ft. lbs.

330 N-m (225

ft.

lbs.

.. 129 N-m (95

ft.

lbs.

....

68

N-m

(50

ft.

lbs.

142

N-m

(105

ft.

lbs.

J9202-108

DESCRIPTION

TORQUE

Jounce Bumper to Bracket

....

Stabilizer Bar Retainer

Bolts..

Stabilizer Bar Link Nut

Shock

Absorber/Jounce Bracket to Frame

Shock

Absorber (Standard) Upper and Lower Nut

Shock

Absorber (Air Adjust) Upper Nut

Shock

Absorber (Air Adjust) Lower Nut

Spring

U-bolt/Stud Nuts (Model

44) ...

Spring

Front Pivot Nut (Model

44)

Spring

Rear Shackle

Nut

(Model

44)

Spring

U-bolt/Stud Nuts (Model

60)

Spring

Front

Pivot Nut (Model

60)

Spring

Rear Shackle Nut (Model

60)

...

41

N-m (30

ft.

lbs.)

23

N-m (200 in.

lbs.)

11

N-m

(100

in.

lbs.)

.. 101 N-m (75

ft.

lbs.)

.... 75 N-m (55

ft.

lbs.)

.... 75 N-m (55

ft.

lbs.)

271 N-m

(200

ft.

lbs.)

.. 115 N-m (85

ft.

lbs.)

135

N-m (100

ft.

lbs.)

.... 81 N-m

(60

ft.

lbs.)

..

129

N-m

(95

ft.

lbs.)

135

N-m (100

ft.

lbs.)

,.

108

N-m

(80

ft.

lbs.)

J9202-109

Page 129 of 1502

2

- 76

FRONT

SUSPENSION

AND

AXLE

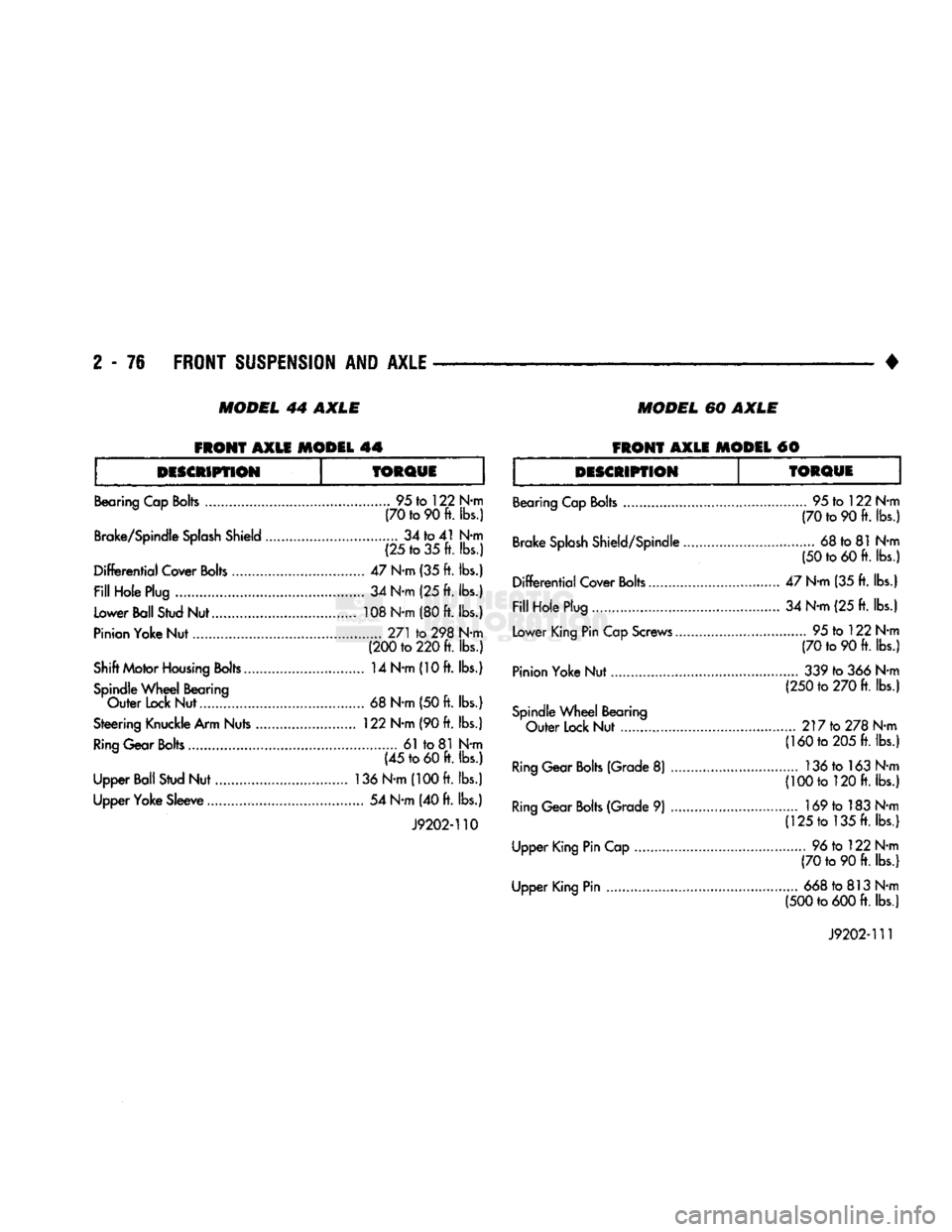

MODEL

44 AXLE

MODEL

60 AXLE

FRONT

AXLE MODEL 44

FRONT

AXLE MODEL #0

DESCRIPTION

TORQUE

Bearing Cap

Bolts

95 to 122 N-m (70 to 90 ft. lbs.)

Brake/Spindle

Splash

Shield 34 to 41 N-m

(25 to 35 ft. lbs.)

Differential

Cover

Bolts

47 N-m (35 ft. lbs.)

Fill

Hole Plug 34 N-m (25 ft. lbs.)

Lower Ball Stud Nut 108 N-m (80 ft. lbs.)

Pinion Yoke Nut 271 to 298 N-m (200 to 220 ft. lbs.)

Shift Motor

Housing

Bolts 14 N-m (10 ft. lbs.) Spindle

Wheel

Bearing

Outer

Lock Nut...... 68 N-m (50 ft. lbs.)

Steering Knuckle Arm Nuts 122 N-m (90 ft. lbs.)

Ring

Gear

Bolts

61 to 81 N-m (45 to 60 ft. lbs.)

Upper Ball Stud Nut 136 N-m (100 ft. lbs.)

Upper Yoke Sleeve 54 N-m (40 ft. lbs.)

J9202-110

DESCRIPTION

TORQUE

Bearing Cap Bolts

Brake

Splash

Shield/Spindle.

Differential

Cover Bolts

Fill

Hole Plug

Lower King Pin Cap Screws...

Pinion Yoke Nut.

Spindle

Wheel

Bearing

Outer

Lock Nut

Ring

Gear

Bolts

(Grade 8)

Ring

Gear

Bolts

(Grade 9)

Upper King Pin Cap

Upper King Pin 95 to 122 N-m

(70 to 90 ft. lbs.)

68 to 81 N-m

(50 to 60 ft. lbs.)

47 N-m (35 ft. lbs.) 34 N-m (25 ft. lbs.) 95 to 122 N-m

(70 to 90 ft. lbs.) 339 to 366 N-m

(250 to 270 ft. lbs.)

.... 217 to 278 N-m (160 to 205 ft. lbs.)

136tol63N-m

(100 to 120 ft. lbs.)

..... 169 to 183 N-m (125 to 135 ft. lbs.)

96 to 122 N-m

(70 to 90 ft. lbs.)

668 to 813 N-m

(500 to 600 ft. lbs.)

J9202-111

Page 137 of 1502

3

- 8

REAR SUSPENSION

AND

AXLE

• level. Where axle bearing damage is slight, the noise

is usually not noticeable at speeds above 30 mph.

LOW SPEED KNOCK

Low speed knock is generally caused by a worn

U-joint or by worn side-gear thrust washers. A worn

pinion gear shaft bore will also cause low speed knock.

VIBRATION

Vibration at the rear of the vehicle is usually

caused by a:

• Damaged drive shaft

• Missing drive shaft balance weight

• Worn, out-of-balance wheel and tires

• Loose wheel lug nuts

• Worn U-joint • Loose spring U-bolts

• Loose/broken rear springs or shackles

• Damaged axle shaft bearings

• Loose pinion gear nut

• Excessive pinion yoke run out

• Bent axle shaft Check for loose or damaged front-end components

or engine/transmission mounts. These components

can contribute to what appears to be a rear-end vi

bration. Do not overlook engine accessories, brackets and drive belts. All driveline components should be examined be

fore starting any repair. Refer to Group 22, Wheels and Tires for additional

information.

DRIVELINE SNAP

A snap or clunk noise when the vehicle is shifted

into gear (or the clutch engaged), can be caused by: • High engine idle speed

• Loose engine/transmission/transfer case mounts

9

Worn U-joints

• Loose spring shackles or U-bolts

• Loose pinion gear nut and yoke

• Excessive ring gear backlash

• Excessive differential side gear-to-case clearance A worn bushing in the transmission extension

housing can also cause noise. The source of a snap or a clunk noise can be deter

mined with the assistance of a helper. Raise the ve

hicle on a hoist with the wheels free to rotate. Instruct the helper to shift the transmission into gear. Listen for the noise, a mechanics stethoscope is

helpful in isolating the source of a noise.

LIMITED

SLIP DIFFERENTIAL

Under normal traction conditions, engine torque is

divided evenly. With low-traction surfaces, engine

torque is transferred to the wheel with the most tire

traction. When diagnosing a limited-slip differential

problem condition, the wheel with the least traction can continue spinning. The most common problem is a chatter noise when

turning corners. Check for incorrect or contaminated lubricant. Replace the gear lubricant if necessary.

• With Sure-Grip differentials add a container of

MOPAR® Hypoid Gear Additive This will correct the condition in most instances. If

the chatter persists, clutch damage could have oc curred. After changing the lubricant, drive the vehicle and

make 10 to 12 slow, figure-eight turns. This maneu

ver will pump lubricant through the clutches.

Page 140 of 1502

•

REAR

SUSPENSION

AND

AXLE

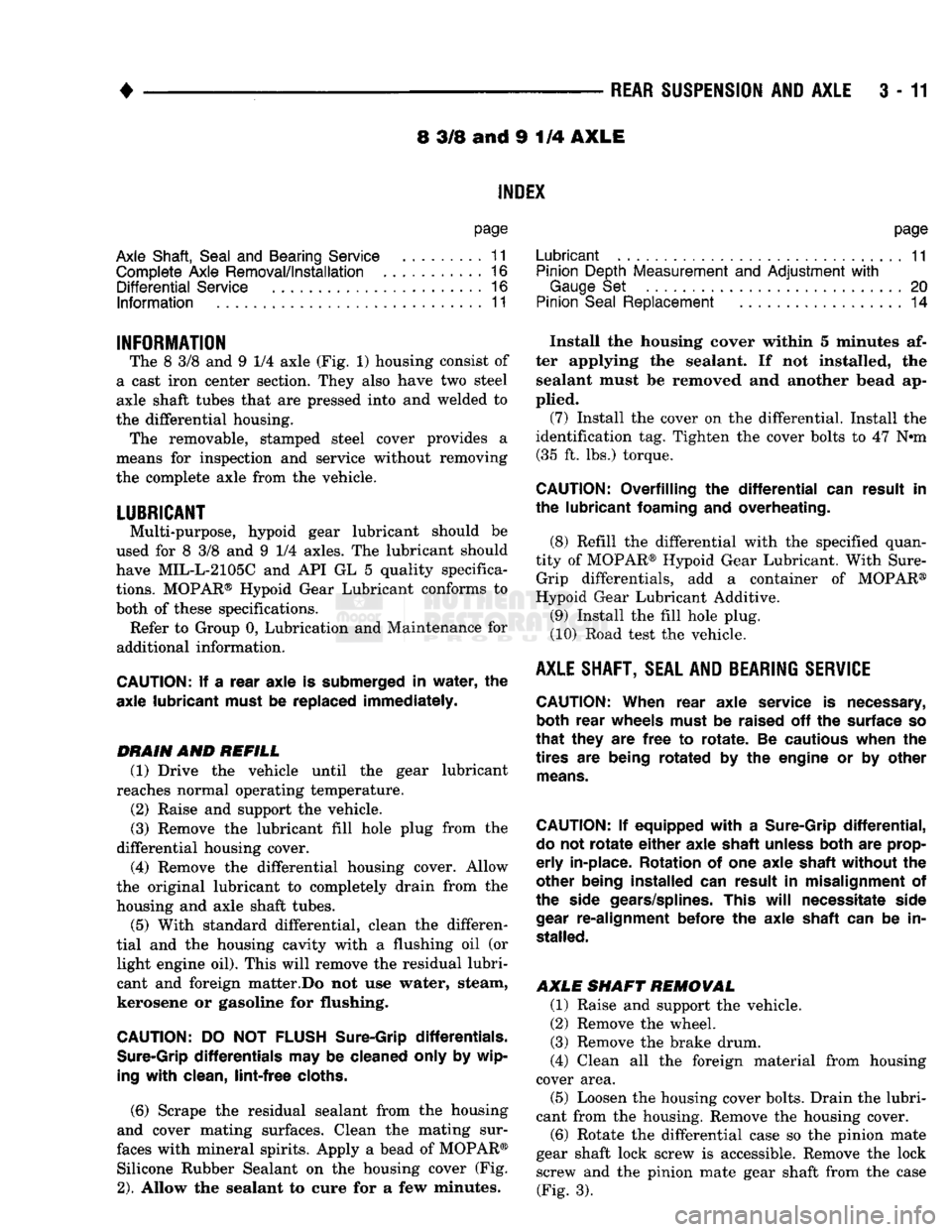

3 - 11 8 3/8 and 9 1/4

AXLE

INDEX

page

Axle Shaft, Seal

and

Bearing Service

......... 11

Complete Axle Removal/Installation

16

Differential

Service

16

Information

11

INFORMATION

The 8 3/8 and 9 1/4 axle (Fig. 1) housing consist of

a cast iron center section. They also have two steel

axle shaft tubes that are pressed into and welded to

the differential housing. The removable, stamped steel cover provides a

means for inspection and service without removing

the complete axle from the vehicle.

LUBRICANT

Multi-purpose, hypoid gear lubricant should be

used for 8 3/8 and 9 1/4 axles. The lubricant should

have MIL-L-2105C and API GL 5 quality specifica

tions.

MOPAR® Hypoid Gear Lubricant conforms to

both of these specifications.

Refer to Group 0, Lubrication and Maintenance for

additional information.

CAUTION:

If a

rear axle

is

submerged

in

water,

the

axle lubricant must

be

replaced immediately.

DRAIN

AND

REFILL

(1) Drive the vehicle until the gear lubricant

reaches normal operating temperature.

(2) Raise and support the vehicle.

(3) Remove the lubricant fill hole plug from the

differential housing cover.

(4) Remove the differential housing cover. Allow

the original lubricant to completely drain from the

housing and axle shaft tubes. (5) With standard differential, clean the differen

tial and the housing cavity with a flushing oil (or light engine oil). This will remove the residual lubri

cant and foreign matter.Do not use water, steam,

kerosene or gasoline for flushing.

CAUTION:

DO NOT

FLUSH

Sure-Grip differentials.

Sure-Grip

differentials

may be

cleaned only

by

wip

ing

with

clean,

lint-free

cloths.

(6)

Scrape the residual sealant from the housing

and cover mating surfaces. Clean the mating sur

faces with mineral spirits. Apply a bead of MOPAR® Silicone Rubber Sealant on the housing cover (Fig.

2).

Allow the sealant to cure for a few minutes.

page

Lubricant

11

Pinion Depth Measurement

and

Adjustment

with

Gauge

Set 20

Pinion

Seal

Replacement

14

Install the housing cover within 5 minutes af

ter applying the sealant. If not installed, the sealant must be removed and another bead ap

plied. (7) Install the cover on the differential. Install the

identification tag. Tighten the cover bolts to 47 N#m (35 ft. lbs.) torque.

CAUTION:

Overfilling

the

differential

can

result

in

the lubricant foaming

and

overheating.

(8) Refill the differential with the specified quan

tity of MOPAR® Hypoid Gear Lubricant. With Sure- Grip differentials, add a container of MOPAR®

Hypoid Gear Lubricant Additive.

(9) Install the fill hole plug.

(10) Road test the vehicle.

AXLE

SHAFT, SEAL AND BEARING

SERVICE

CAUTION:

When rear axle service

is

necessary, both rear wheels must

be

raised

off the

surface

so

that

they

are

free

to

rotate.

Be

cautious when

the

tires

are

being rotated

by the

engine

or by

other

means.

CAUTION:

If

equipped

with

a

Sure-Grip

differential,

do

not

rotate

either

axle shaft unless both

are

prop

erly

in-place. Rotation

of one

axle shaft without

the

other being installed

can

result

in

misalignment

of

the side gears/splines. This

will

necessitate side

gear

re-alignment before

the

axle shaft

can be in

stalled.

AXLE SHAFT REMOVAL

(1) Raise and support the vehicle.

(2) Remove the wheel.

(3) Remove the brake drum.

(4) Clean all the foreign material from housing

cover area.

(5) Loosen the housing cover bolts. Drain the lubri

cant from the housing. Remove the housing cover.

(6)

Rotate the differential case so the pinion mate

gear shaft lock screw is accessible. Remove the lock screw and the pinion mate gear shaft from the case (Fig. 3).

Page 143 of 1502

3

- 14

REAR SUSPENSION

AND

AXLE

3

- 18

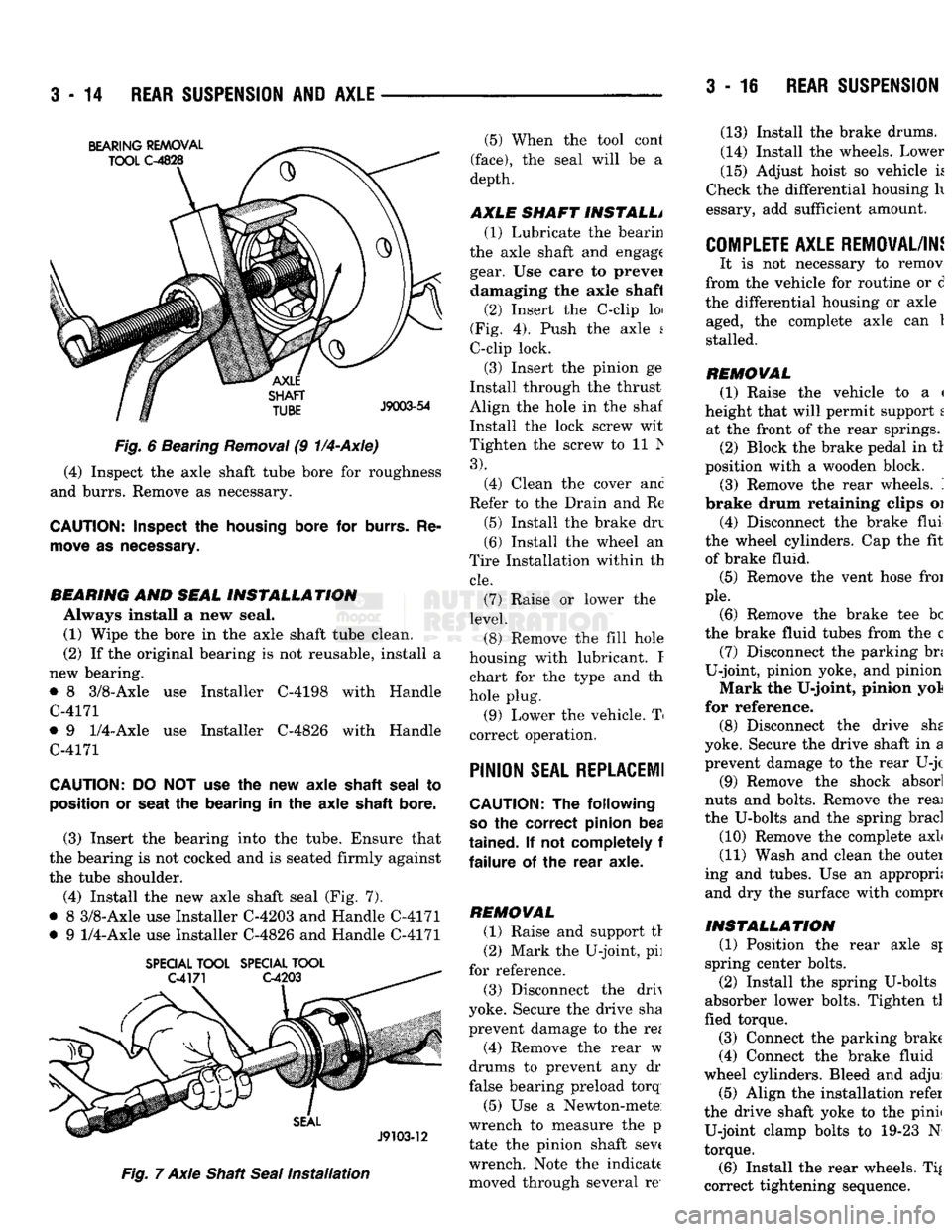

REAR SUSPENSION Fig.

6 Bearing

Removal

(9

1/4-Axle)

(4) Inspect the axle shaft tube bore for roughness

and burrs. Remove as necessary.

CAUTION:

Inspect

the

housing

bore for

burrs.

Re

move

as

necessary.

BEARING

AND

SEAL

INSTALLATION

Always install a new seal. (1) Wipe the bore in the axle shaft tube clean.

(2) If the original bearing is not reusable, install a

new bearing.

• 8 3/8-Axle use Installer C-4198 with Handle

C-4171

• 9

1/4-Axle

use Installer C-4826 with Handle

C-4171

CAUTION:

DO NOT use the new axle

shaft

seal

to

position

or

seat

the bearing in the axle

shaft

bore.

(3) Insert the bearing into the tube. Ensure that

the bearing is not cocked and is seated firmly against

the tube shoulder.

(4) Install the new axle shaft seal (Fig. 7).

• 8 3/8-Axle use Installer C-4203 and Handle C-4171

• 9

1/4-Axle

use Installer C-4826 and Handle C-4171

SPECIAL

TOOL

SPECIAL

TOOL

Fig.

7 Axle Shaft

Seal

Installation

(5) When the tool cont

(face),

the seal will be a

depth.

AXLE SHAFT INSTALL* (1) Lubricate the bearin

the axle shaft and engage gear. Use care to prevei damaging the axle shaft

(2) Insert the C-clip loi

(Fig. 4). Push the axle s

C-clip lock.

(3) Insert the pinion ge

Install through the thrust

Align the hole in the shaf

Install the lock screw wit

Tighten the screw to 11 Is

3).

(4) Clean the cover anc

Refer to the Drain and Re

(5) Install the brake drv

(6) Install the wheel an

Tire Installation within th

cle.

(7) Raise or lower the

level.

(8) Remove the fill hole

housing with lubricant. I chart for the type and th

hole plug.

(9) Lower the vehicle. T

correct operation.

PINION

SEAL REPLACE!!

CAUTION:

The following

so

the correct pinion bea

tained.

If not completely f

failure

of the rear axle.

REMOVAL (1) Raise and support tr

(2) Mark the U-joint, pi]

for reference.

(3) Disconnect the drh

yoke. Secure the drive sha

prevent damage to the re*

(4) Remove the rear w

drums to prevent any dr

false bearing preload torq

(5) Use a Newton-mete

wrench to measure the p

tate the pinion shaft sev( wrench. Note the indicate moved through several re' (13) Install the brake drums.

(14) Install the wheels. Lower

(15) Adjust hoist so vehicle k

Check the differential housing h

essary, add sufficient amount.

COMPLETE AXLE REMOVAL/IN!

It is not necessary to remov

from the vehicle for routine or d

the differential housing or axle aged, the complete axle can 1

stalled.

REMOVAL (1) Raise the vehicle to a <

height that will permit support t at the front of the rear springs. (2) Block the brake pedal in tl

position with a wooden block. (3) Remove the rear wheels. '.

brake drum retaining clips oi

(4) Disconnect the brake flui

the wheel cylinders. Cap the fit of brake fluid.

(5) Remove the vent hose froi

pie.

(6) Remove the brake tee be

the brake fluid tubes from the c (7) Disconnect the parking bn

U-joint, pinion yoke, and pinion

Mark the U-joint, pinion yol

for reference. (8) Disconnect the drive she

yoke. Secure the drive shaft in a prevent damage to the rear U-jc

(9) Remove the shock absorl

nuts and bolts. Remove the reai

the U-bolts and the spring brad

(10) Remove the complete axL

(11) Wash and clean the outei

ing and tubes. Use an appropri; and dry the surface with comprc

INSTALLATION

(1) Position the rear axle sj

spring center bolts.

(2) Install the spring U-bolts

absorber lower bolts. Tighten tl

fled torque.

(3) Connect the parking brake

(4) Connect the brake fluid

wheel cylinders. Bleed and adjui (5) Align the installation refer

the drive shaft yoke to the pinii U-joint clamp bolts to 19-23 N

torque.

(6) Install the rear wheels. Ti|

correct tightening sequence.

Page 159 of 1502

3

- 32

REAR

SUSPENSION

AND

AXLE

•

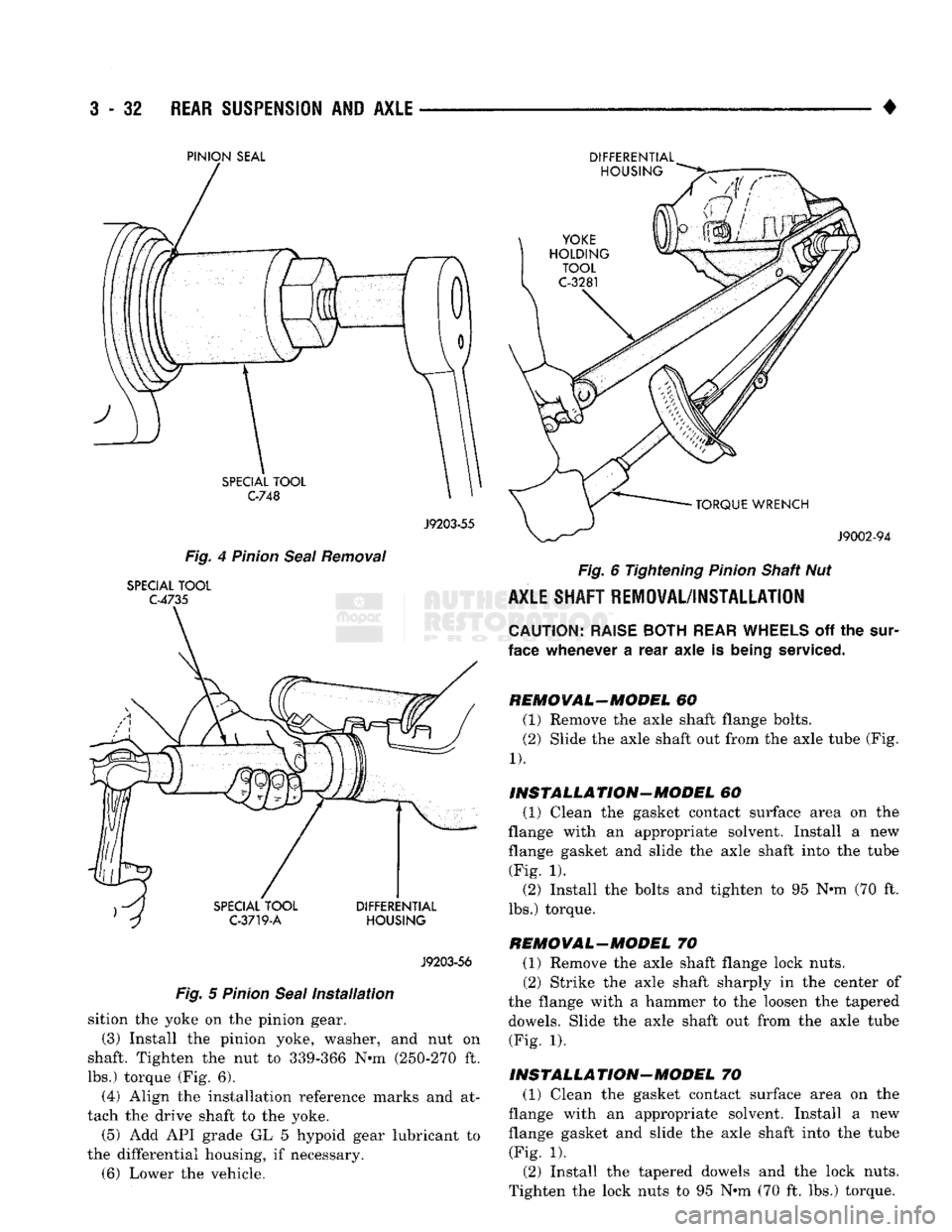

PINION SEAL

J9203-55

Fig.

4

Pinion

Seal

Removal

SPECIAL

TOOL

C-4735

J9203-56

Fig.

5

Pinion

Seal

Installation

sition the yoke on the pinion gear.

(3) Install the pinion yoke, washer, and nut on

shaft. Tighten the nut to 339-366 N-m (250-270 ft.

lbs.) torque (Fig. 6).

(4) Align the installation reference marks and at

tach the drive shaft to the yoke.

(5) Add API grade GL 5 hypoid gear lubricant to

the differential housing, if necessary. (6) Lower the vehicle.

DIFFERENTIAL

Fig.

6 Tightening

Pinion

Shaft Nut

AXLE

SHAFT

REiOWAL/INSTALLATlON

CAUTION:

RAISE

BOTH

REAR

WHEELS

off the

sur

face whenever a rear axle is being

serviced.

REMOVAL-MODEL 60 (1) Remove the axle shaft flange bolts.

(2) Slide the axle shaft out from the axle tube (Fig.

1).

INSTALLATION-MODEL 60 (1) Clean the gasket contact surface area on the

flange with an appropriate solvent. Install a new flange gasket and slide the axle shaft into the tube (Fig. 1). (2) Install the bolts and tighten to 95 N»m (70 ft.

lbs.) torque.

REMOVAL-MODEL 70 (1) Remove the axle shaft flange lock nuts. (2) Strike the axle shaft sharply in the center of

the flange with a hammer to the loosen the tapered dowels. Slide the axle shaft out from the axle tube (Fig. 1).

INSTALLATION-MODEL 70 (1) Clean the gasket contact surface area on the

flange with an appropriate solvent. Install a new

flange gasket and slide the axle shaft into the tube

(Fig. 1). (2) Install the tapered dowels and the lock nuts.

Tighten the lock nuts to 95 N*m (70 ft. lbs.) torque.

Page 160 of 1502

•

REAR

SUSPENSION

AND

AXLE

3 - 33

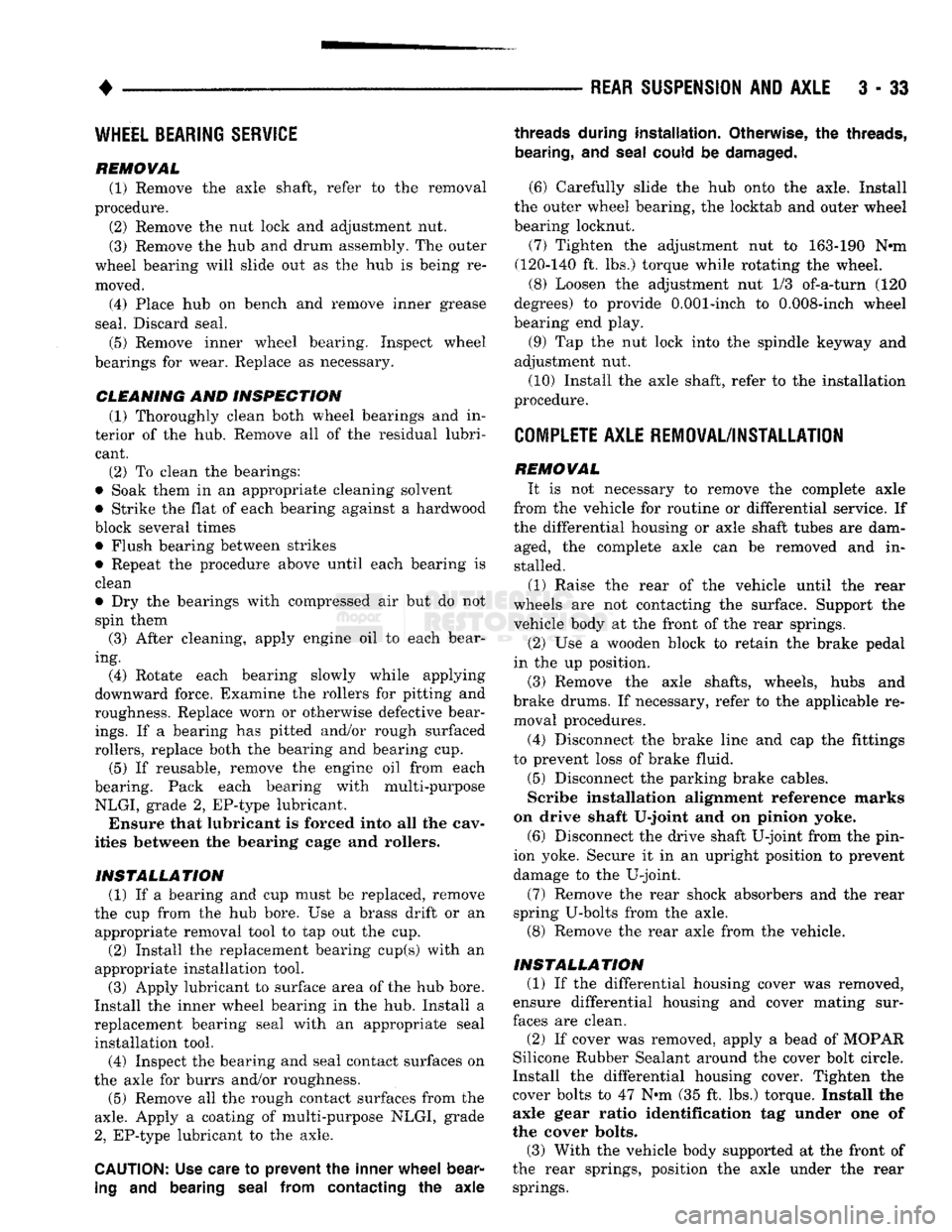

WHEEL BEARING SERVICE

REMOVAL (1) Remove the axle shaft, refer to the removal

procedure. (2) Remove the nut lock and adjustment nut.

(3) Remove the hub and drum assembly. The outer

wheel bearing will slide out as the hub is being re

moved. (4) Place hub on bench and remove inner grease

seal. Discard seal. (5) Remove inner wheel bearing. Inspect wheel

bearings for wear. Replace as necessary.

CLEANING AND INSPECTION (1) Thoroughly clean both wheel bearings and in

terior of the hub. Remove all of the residual lubri cant. (2) To clean the bearings:

• Soak them in an appropriate cleaning solvent

• Strike the flat of each bearing against a hardwood

block several times • Flush bearing between strikes

• Repeat the procedure above until each bearing is clean

• Dry the bearings with compressed air but do not

spin them (3) After cleaning, apply engine oil to each bear

ing. (4) Rotate each bearing slowly while applying

downward force. Examine the rollers for pitting and

roughness. Replace worn or otherwise defective bear

ings.

If a bearing has pitted and/or rough surfaced

rollers, replace both the bearing and bearing cup. (5) If reusable, remove the engine oil from each

bearing. Pack each bearing with multi-purpose

NLGI, grade 2, EP-type lubricant. Ensure that lubricant is forced into all the cav

ities between the bearing cage and rollers.

INSTALLATION (1) If a bearing and cup must be replaced, remove

the cup from the hub bore. Use a brass drift or an appropriate removal tool to tap out the cup. (2) Install the replacement bearing cup(s) with an

appropriate installation tool.

(3) Apply lubricant to surface area of the hub bore.

Install the inner wheel bearing in the hub. Install a

replacement bearing seal with an appropriate seal installation tool. (4) Inspect the bearing and seal contact surfaces on

the axle for burrs and/or roughness.

(5) Remove all the rough contact surfaces from the

axle.

Apply a coating of multi-purpose NLGI, grade

2,

EP-type lubricant to the axle.

CAUTION:

Use care to prevent the inner

wheel

bear

ing

and bearing

seal

from contacting the axle

threads

during installation. Otherwise, the

threads,

bearing,

and

seal

could

be

damaged.

(6) Carefully slide the hub onto the axle. Install

the outer wheel bearing, the locktab and outer wheel

bearing locknut.

(7) Tighten the adjustment nut to 163-190 Nnn

(120-140 ft. lbs.) torque while rotating the wheel. (8) Loosen the adjustment nut 1/3 of-a-turn (120

degrees) to provide 0.001-inch to 0.008-inch wheel

bearing end play.

(9) Tap the nut lock into the spindle keyway and

adjustment nut.

(10) Install the axle shaft, refer to the installation

procedure.

COMPLETE AXLE REMOVAL/INSTALLATION

REMOVAL It is not necessary to remove the complete axle

from the vehicle for routine or differential service. If

the differential housing or axle shaft tubes are dam aged, the complete axle can be removed and in

stalled.

(1) Raise the rear of the vehicle until the rear

wheels are not contacting the surface. Support the

vehicle body at the front of the rear springs.

(2) Use a wooden block to retain the brake pedal

in the up position.

(3) Remove the axle shafts, wheels, hubs and

brake drums. If necessary, refer to the applicable re moval procedures.

(4) Disconnect the brake line and cap the fittings

to prevent loss of brake fluid. (5) Disconnect the parking brake cables.

Scribe installation alignment reference marks

on drive shaft U-joint and on pinion yoke. (6) Disconnect the drive shaft U-joint from the pin

ion yoke. Secure it in an upright position to prevent

damage to the U-joint.

(7) Remove the rear shock absorbers and the rear

spring U-bolts from the axle. (8) Remove the rear axle from the vehicle.

INSTALLATION (1) If the differential housing cover was removed,

ensure differential housing and cover mating sur

faces are clean.

(2) If cover was removed, apply a bead of MOPAR

Silicone Rubber Sealant around the cover bolt circle.

Install the differential housing cover. Tighten the

cover bolts to 47 N»m (35 ft. lbs.) torque. Install the axle gear ratio identification tag under one of

the cover bolts.

(3) With the vehicle body supported at the front of

the rear springs, position the axle under the rear springs.

Page 161 of 1502

3

- 34

REAR SUSPENSION

AND

AXLE

• (4) Install the spring U-bolts and tighten the nuts

with the specified torque.

(5) Install the shock absorbers.

(6) Connect the parking brake cables.

(7) Connect the brake lines. Install the hubs and

brake drums. Adjust the wheel bearings (refer to Wheel Bearing Adjustment).

(8) Remove the block from the brake pedal. Bleed

and adjust the brakes.

(9) Connect the drive shaft to the pinion yoke with

the reference marks aligned. Tighten the U-joint clamp bolts to 21 N-m (16 ft. lbs./186 in. lbs.) torque.

(10) Install the rear wheels and tighten the lug

nuts with the specified torque (refer to Group 22,

Wheels And Tires). (11) Raise the rear of the vehicle, remove the sup

ports,

level the vehicle and position the supports. (12) Remove the fill hole plug from the differential

housing cover. Fill the differential housing to the correct level with MOPAR Hypoid Gear Lubricant, or

an equivalent product. Add 4 ounces of MOPAR Hypoid Gear Lubri

cant Additive for Trac-Lok equipped axles. (13) Install the fill hole plug. Remove the supports

and lower the vehicle. (14) Road test the vehicle to evaluate the results of

the repair.

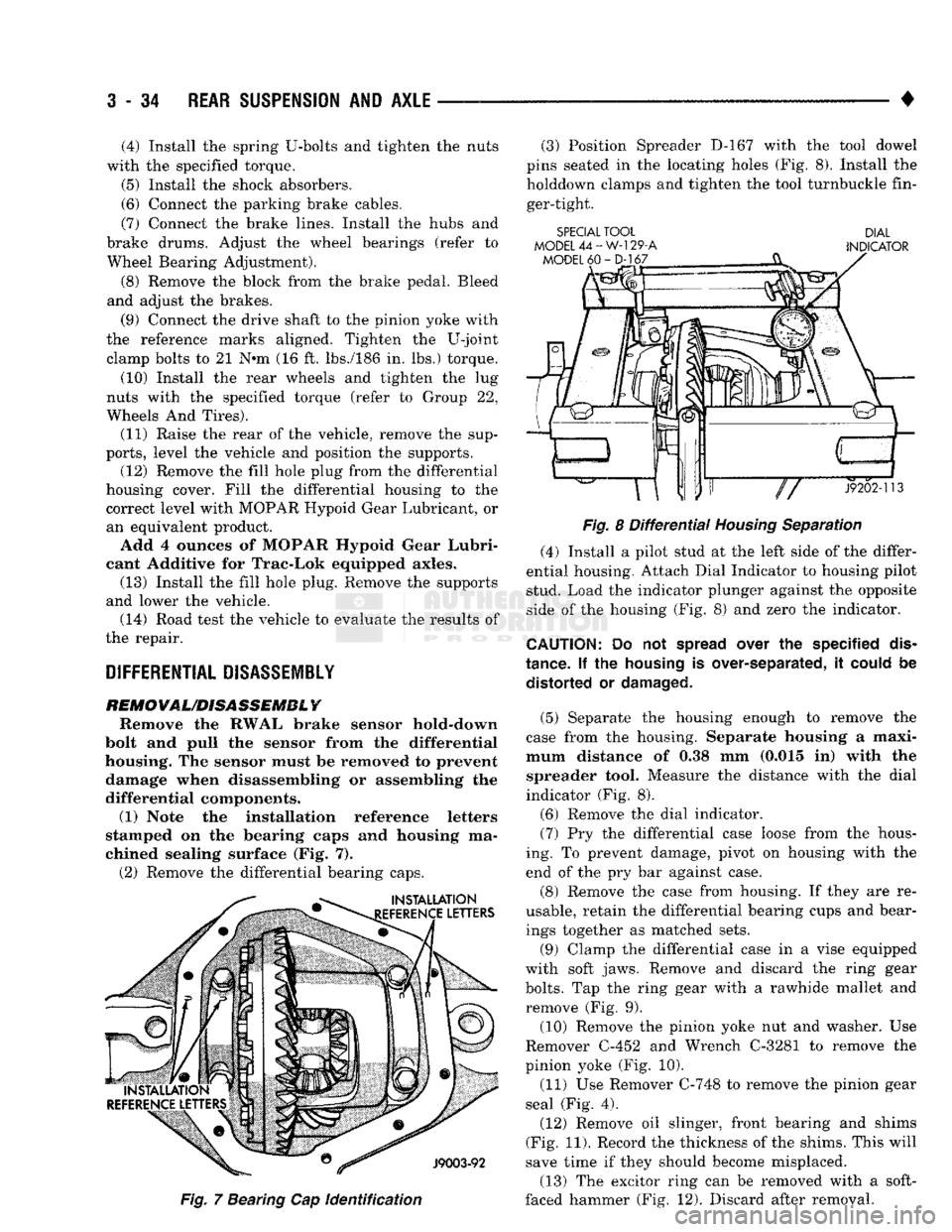

DIFFERENTIAL

DISASSEMBLY

RE MO VA

L/DISA

SSEMBL Y

Remove the RWAL brake sensor

hold-down

bolt and pull the sensor from the differential

housing. The sensor must be removed to prevent damage when disassembling or assembling the differential components.

(1) Note the installation reference letters

stamped on the bearing caps and housing ma

chined sealing surface (Fig. 7). (2) Remove the differential bearing caps.

Fig.

7 Bearing Cap

identification

(3) Position Spreader D-167 with the tool dowel

pins seated in the locating holes (Fig. 8). Install the holddown clamps and tighten the tool turnbuckle fin

ger-tight.

SPECIAL TOOL DIAL

MODEL

44-W-129-A

INDICATOR

Fig.

8

Differential

Housing

Separation

(4) Install a pilot stud at the left side of the differ

ential housing. Attach Dial Indicator to housing pilot

stud. Load the indicator plunger against the opposite

side of the housing (Fig. 8) and zero the indicator.

CAUTION:

Do not

spread

over the specified

dis

tance. If the

housing

is over-separated, it

could

be distorted or

damaged.

(5) Separate the housing enough to remove the

case from the housing. Separate housing a maxi

mum distance of 0.38 mm (0.015 in) with the spreader tool. Measure the distance with the dial

indicator (Fig. 8).

(6) Remove the dial indicator. (7) Pry the differential case loose from the hous

ing. To prevent damage, pivot on housing with the

end of the pry bar against case.

(8) Remove the case from housing. If they are re

usable, retain the differential bearing cups and bear ings together as matched sets.

(9) Clamp the differential case in a vise equipped

with soft jaws. Remove and discard the ring gear

bolts.

Tap the ring gear with a rawhide mallet and

remove (Fig. 9).

(10) Remove the pinion yoke nut and washer. Use

Remover C-452 and Wrench C-3281 to remove the

pinion yoke (Fig. 10).

(11) Use Remover C-748 to remove the pinion gear

seal (Fig. 4).

(12) Remove oil slinger, front bearing and shims

(Fig. 11). Record the thickness of the shims. This will

save time if they should become misplaced.

(13) The excitor ring can be removed with a soft-

faced hammer (Fig. 12). Discard after removal.

Page 213 of 1502

5

- 26

BRAKES

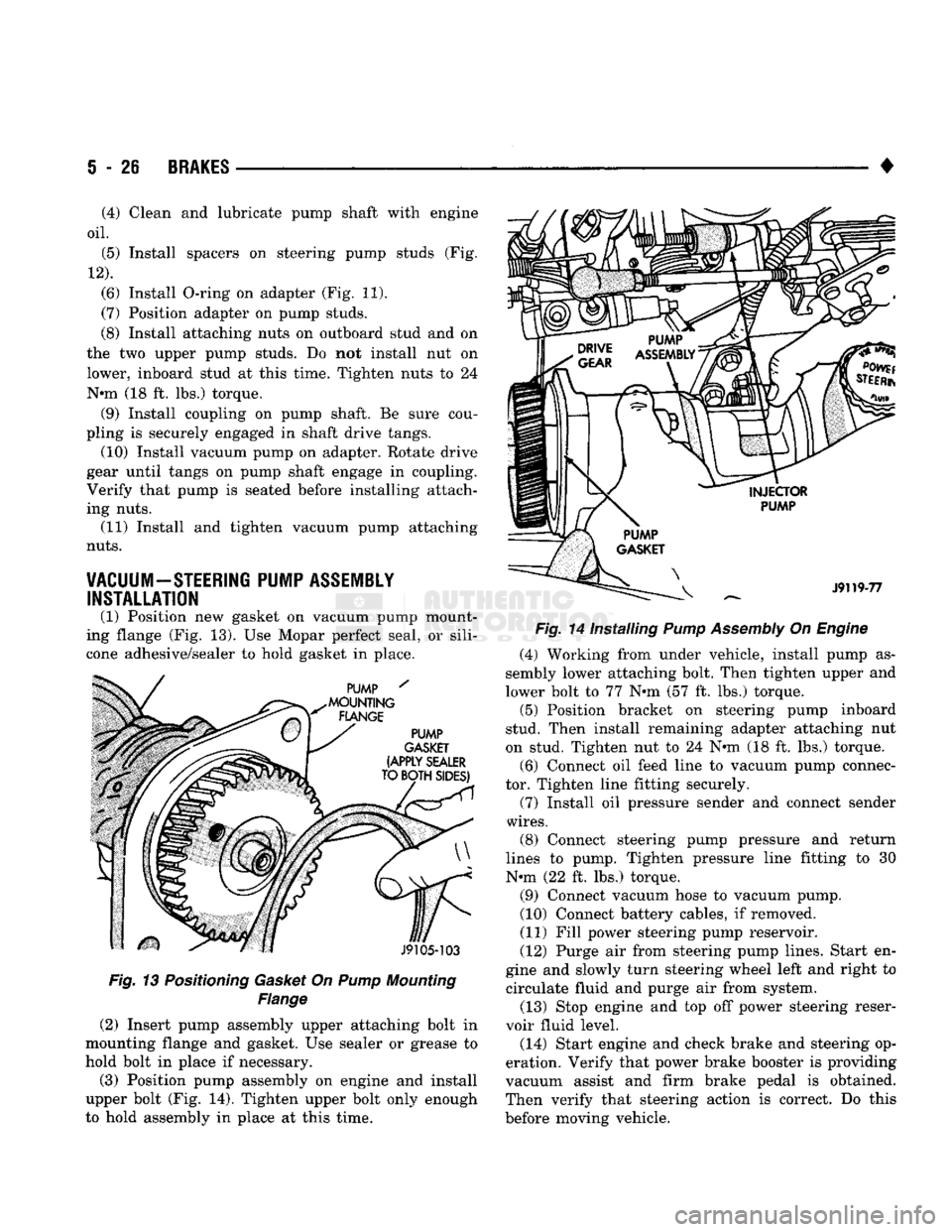

Fig. 13 Positioning Gasket On Pump Mounting

Flange

(2) Insert pump assembly upper attaching bolt in

mounting flange and gasket. Use sealer or grease to

hold bolt in place if necessary.

(3) Position pump assembly on engine and install

upper bolt (Fig. 14). Tighten upper bolt only enough

to hold assembly in place at this time. •

Fig. 14 Installing Pump Assembly On Engine (4) Working from under vehicle, install pump as

sembly lower attaching bolt. Then tighten upper and

lower bolt to 77 N»m (57 ft. lbs.) torque. (5) Position bracket on steering pump inboard

stud. Then install remaining adapter attaching nut

on stud. Tighten nut to 24 N«m (18 ft. lbs.) torque.

(6) Connect oil feed line to vacuum pump connec

tor. Tighten line fitting securely.

(7) Install oil pressure sender and connect sender

wires.

(8) Connect steering pump pressure and return

lines to pump. Tighten pressure line fitting to 30

N-m (22 ft. lbs.) torque.

(9) Connect vacuum hose to vacuum pump.

(10) Connect battery cables, if removed.

(11) Fill power steering pump reservoir.

(12) Purge air from steering pump lines. Start en

gine and slowly turn steering wheel left and right to circulate fluid and purge air from system.

(13) Stop engine and top off power steering reser

voir fluid level.

(14) Start engine and check brake and steering op

eration. Verify that power brake booster is providing

vacuum assist and firm brake pedal is obtained.

Then verify that steering action is correct. Do this

before moving vehicle.

(4) Clean and lubricate pump shaft with engine

oil.

(5) Install spacers on steering pump studs (Fig.

12).

(6) Install O-ring on adapter (Fig. 11).

(7) Position adapter on pump studs.

(8) Install attaching nuts on outboard stud and on

the two upper pump studs. Do not install nut on

lower, inboard stud at this time. Tighten nuts to 24

N-m (18 ft. lbs.) torque. (9) Install coupling on pump shaft. Be sure cou

pling is securely engaged in shaft drive tangs. (10) Install vacuum pump on adapter. Rotate drive

gear until tangs on pump shaft engage in coupling.

Verify that pump is seated before installing attach

ing nuts. (11) Install and tighten vacuum pump attaching

nuts.

VACUUM-STEERING PUMP ASSEMBLY INSTALLATION

(1) Position new gasket on vacuum pump mount

ing flange (Fig. 13). Use Mopar perfect seal, or sili

cone adhesive/sealer to hold gasket in place.

Page 216 of 1502

•

BRAKES

5 - 29 presses the outboard shoe lining against the opposite

side of the rotor to complete braking action.

The application or release of fluid pressure causes

only a very slight movement of the caliper and pis

ton. At brake release, the piston and caliper return

to the non-applied position.

The brakeshoes do not retract an appreciable dis

tance from the rotor. The minimal running clearance

between the lining and rotor provides improved re sponse and reduced pedal travel. It also helps in pre

venting dirt and foreign material from lodging

between the shoe and rotor surfaces.

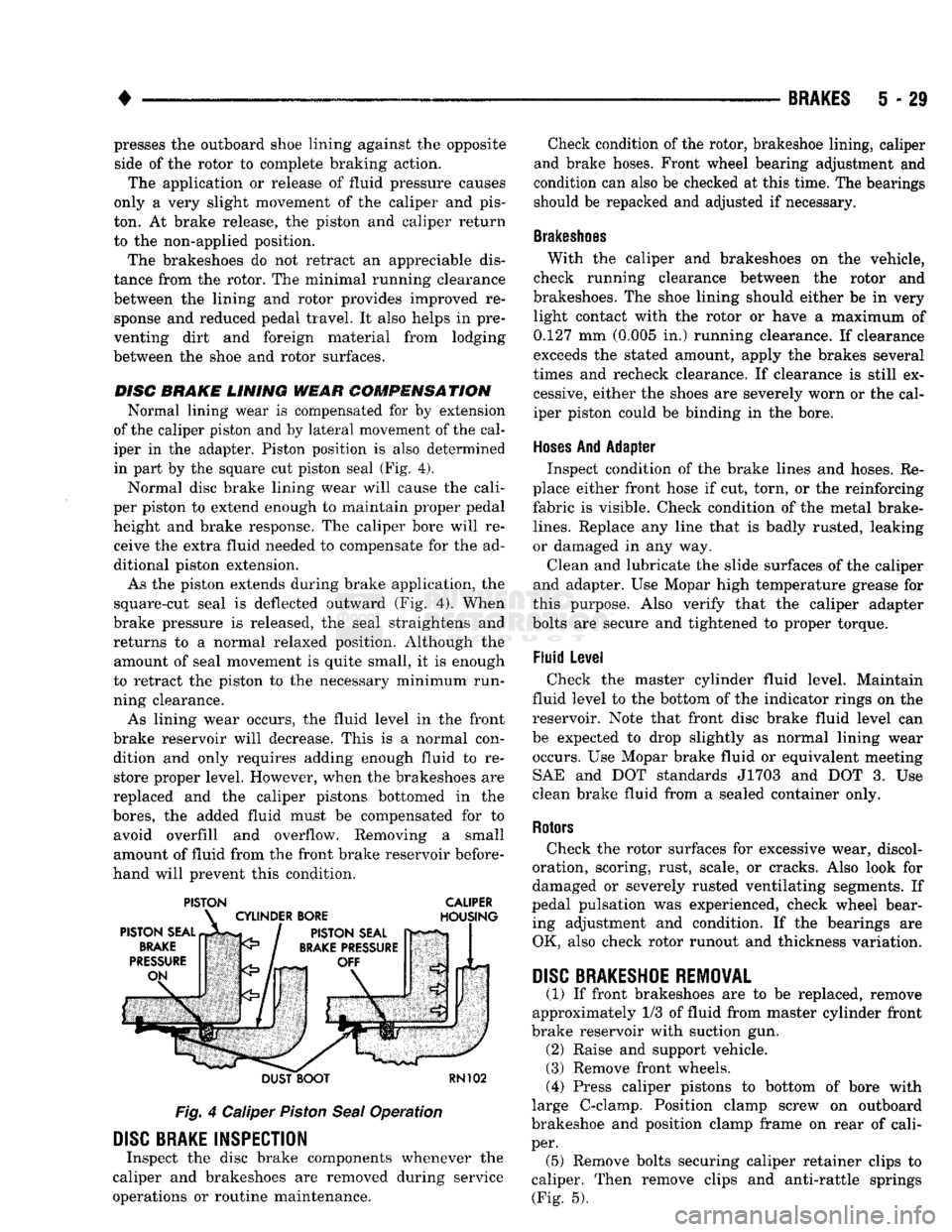

DISC

BRAKE

LINING WEAR COMPENSATION

Normal lining wear is compensated for by extension

of the caliper piston and by lateral movement of the cal

iper in the adapter. Piston position is also determined

in part by the square cut piston seal (Fig. 4).

Normal disc brake lining wear will cause the cali

per piston to extend enough to maintain proper pedal height and brake response. The caliper bore will receive the extra fluid needed to compensate for the ad

ditional piston extension.

As the piston extends during brake application, the

square-cut seal is deflected outward (Fig. 4). When

brake pressure is released, the seal straightens and

returns to a normal relaxed position. Although the amount of seal movement is quite small, it is enough

to retract the piston to the necessary minimum run

ning clearance.

As lining wear occurs, the fluid level in the front

brake reservoir will decrease. This is a normal con dition and only requires adding enough fluid to restore proper level. However, when the brakeshoes are

replaced and the caliper pistons bottomed in the

bores,

the added fluid must be compensated for to avoid overfill and overflow. Removing a small

amount of fluid from the front brake reservoir before

hand will prevent this condition.

PISTON CALIPER

DUST BOOT

RN102

Fig.

4 Caliper

Piston

Seal

Operation

DISC

BRAKE INSPECTION

Inspect the disc brake components whenever the

caliper and brakeshoes are removed during service

operations or routine maintenance. Check condition of the rotor, brakeshoe lining, caliper

and brake hoses. Front wheel bearing adjustment and

condition can also be checked at this time. The bearings

should be repacked and adjusted if necessary.

Brakeshoes

With the caliper and brakeshoes on the vehicle,

check running clearance between the rotor and

brakeshoes. The shoe lining should either be in very light contact with the rotor or have a maximum of

0.127 mm (0.005 in.) running clearance. If clearance

exceeds the stated amount, apply the brakes several

times and recheck clearance. If clearance is still ex cessive, either the shoes are severely worn or the cal

iper piston could be binding in the bore.

Hoses

And Adapter Inspect condition of the brake lines and hoses. Re

place either front hose if cut, torn, or the reinforcing

fabric is visible. Check condition of the metal brake-

lines.

Replace any line that is badly rusted, leaking

or damaged in any way.

Clean and lubricate the slide surfaces of the caliper

and adapter. Use Mopar high temperature grease for

this purpose. Also verify that the caliper adapter

bolts are secure and tightened to proper torque.

Fluid Level Check the master cylinder fluid level. Maintain

fluid level to the bottom of the indicator rings on the

reservoir. Note that front disc brake fluid level can

be expected to drop slightly as normal lining wear occurs. Use Mopar brake fluid or equivalent meeting SAE and DOT standards J1703 and DOT 3. Use

clean brake fluid from a sealed container only.

Rotors

Check the rotor surfaces for excessive wear, discol

oration, scoring, rust, scale, or cracks. Also look for

damaged or severely rusted ventilating segments. If

pedal pulsation was experienced, check wheel bear ing adjustment and condition. If the bearings are OK, also check rotor runout and thickness variation.

DISC

BRAKESHOE

REMOVAL

(1) If front brakeshoes are to be replaced, remove

approximately 1/3 of fluid from master cylinder front

brake reservoir with suction gun. (2) Raise and support vehicle.

(3) Remove front wheels.

(4) Press caliper pistons to bottom of bore with

large C-clamp. Position clamp screw on outboard

brakeshoe and position clamp frame on rear of cali

per. (5) Remove bolts securing caliper retainer clips to

caliper. Then remove clips and anti-rattle springs (Fig. 5).