wheel bolt torque DODGE TRUCK 1993 Service Service Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 817 of 1502

13

- 30 FRAME AND BUMPERS

ATTACHED COMPONENTS

SKID

PLATES

TRANSFER CASE SKID

PL

ATF

4 WD

VEHICLES

REMOVAL

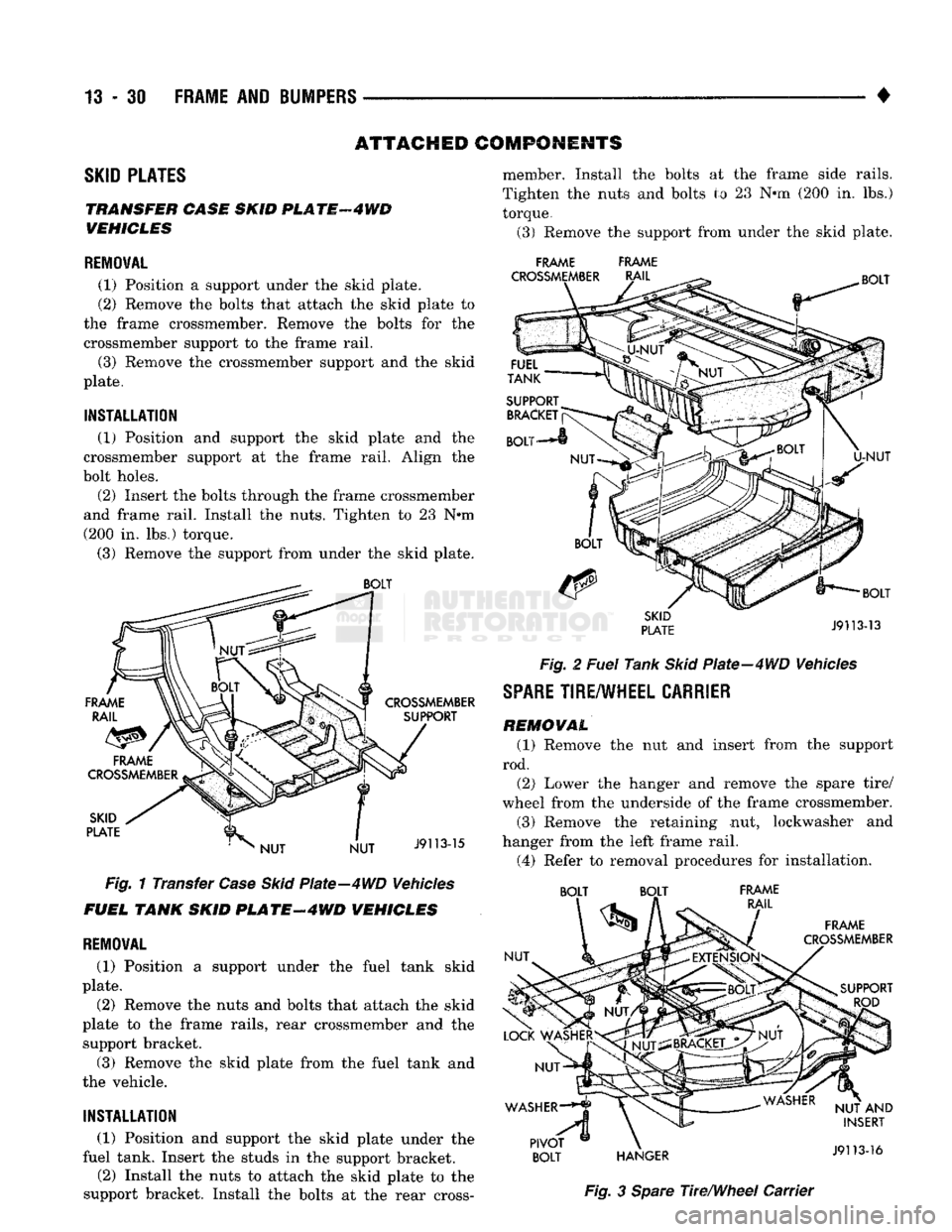

(1) Position

a

support under

the

skid plate.

(2) Remove

the

bolts that attach

the

skid plate

to

the frame crossmember. Remove

the

bolts

for the

crossmember support

to the

frame rail.

(3) Remove

the

crossmember support

and the

skid

plate.

INSTALLATION

(1) Position

and

support

the

skid plate

and the

crossmember support

at the

frame rail. Align

the

bolt holes.

(2) Insert

the

bolts through

the

frame crossmember

and frame rail. Install

the

nuts. Tighten

to 23 N*m

(200

in. lbs.)

torque.

(3) Remove

the

support from under

the

skid plate.

Fig.

1

Transfer

Case Skid

Plate—4WD Vehicles

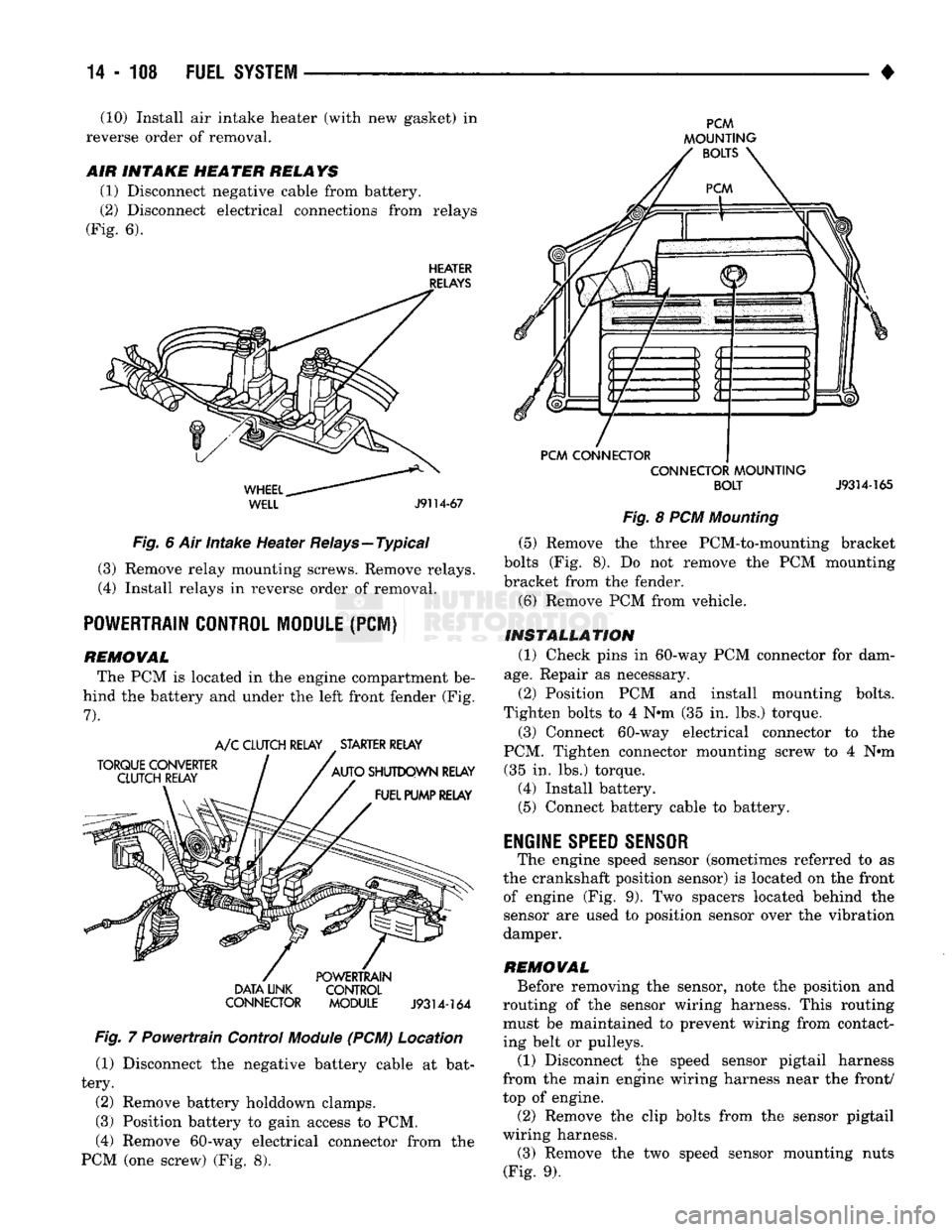

FUEL TANK SKID

PLATE-4WD

VEHICLES

REMOVAL

(1) Position

a

support under

the

fuel tank skid

plate.

(2) Remove

the

nuts

and

bolts that attach

the

skid

plate

to the

frame rails, rear crossmember

and the

support bracket.

(3) Remove

the

skid plate from

the

fuel tank

and

the vehicle.

INSTALLATION

(1) Position

and

support

the

skid plate under

the

fuel tank. Insert

the

studs

in the

support bracket.

(2) Install

the

nuts

to

attach

the

skid plate

to the

support bracket. Install

the

bolts

at the

rear cross- member. Install

the

bolts

at the

frame side rails.

Tighten

the

nuts

and

bolts

to 23 N*m (200 in. lbs.)

torque.

(3) Remove

the

support from under

the

skid plate.

FRAME FRAME

Fig.

2

Fuel

Tank

Skid

Plate-4WD Vehicles

SPARE

TIRE/WHEEL

CARRIER

REMOVAL

(1) Remove

the nut and

insert from

the

support

rod. (2) Lower

the

hanger

and

remove

the

spare tire/

wheel from

the

underside

of the

frame crossmember.

(3) Remove

the

retaining

nut,

lockwasher

and

hanger from

the

left frame rail.

(4) Refer

to

removal procedures

for

installation. BOLT BOLT FRAME

Fig.

3

Spare

The/Wheel Carrier

Page 927 of 1502

(10) Install air intake heater (with new gasket) in

reverse order of removal.

AIR

INTAKE

HE

A TER

RELA YS

(1) Disconnect negative cable from battery.

(2) Disconnect electrical connections from relays

(Fig. 6).

HEATER

RELAYS

WHEEL..

WELL

J9114-67

Fig. 6 Air intake Heater Relays—Typical (3) Remove relay mounting screws. Remove relays.

(4) Install relays in reverse order of removal.

POWERTRAIN CONTROL MODULE

(PCI)

REMOWAL The PCM is located in the engine compartment be

hind the battery and under the left front fender (Fig.

7).

TORQUE CONVERTER

CLUTCH RELAY A/C CLUTCH RELAY STARTER RELAY

AUTO SHUTDOWN RELAY FUEL PUMP RELAY DATA LINK

CONNECTOR POWERTRAIN

CONTROL

MODULE

J9314-164

Fig. 7 Powertrain Control

Module

(PCM) Location (1) Disconnect the negative battery cable at bat

tery.

(2) Remove battery holddown clamps.

(3) Position battery to gain access to PCM,

(4) Remove 60-way electrical connector from the

PCM (one screw) (Fig. 8).

PCM

MOUNTING BOLTS

PCM CONNECTOR CONNECTOR MOUNTING

BOLT

J9314-165

Fig. 8 PCM Mounting (5) Remove the three PCM-to-mounting bracket

bolts (Fig. 8). Do not remove the PCM mounting

bracket from the fender.

(6) Remove PCM from vehicle.

INSTALLATION (1) Check pins in 60-way PCM connector for dam

age.

Repair as necessary.

(2) Position PCM and install mounting bolts.

Tighten bolts to 4 N*m (35 in. lbs.) torque.

(3) Connect 60-way electrical connector to the

PCM. Tighten connector mounting screw to 4 N#m (35 in. lbs.) torque. (4) Install battery. (5) Connect battery cable to battery.

ENGINE

SPEED SENSOR

The engine speed sensor (sometimes referred to as

the crankshaft position sensor) is located on the front of engine (Fig. 9). Two spacers located behind the

sensor are used to position sensor over the vibration

damper.

REMOWAL Before removing the sensor, note the position and

routing of the sensor wiring harness. This routing must be maintained to prevent wiring from contact

ing belt or pulleys.

(1) Disconnect the speed sensor pigtail harness

from the main engine wiring harness near the front/

top of engine.

(2) Remove the clip bolts from the sensor pigtail

wiring harness. (3) Remove the two speed sensor mounting nuts

(Fig. 9).

Page 948 of 1502

•

PROPELLER SHAFTS

16 - 3

SERVICE

DIAGNOSIS/PROCEDURES

INDEX

page page

Precautions . 3 Universal

Joint

Angle Measurement ............ 4

Runout

4

Vibration

3

Unbalance

3

PRECAUTIONS

Propeller shafts are balanced by the manufacturer

to prevent vibration. Before undercoating a vehicle, the propeller shaft and the U-joints should be covered. This will prevent the undercoating from caus

ing an unbalanced condition and vibration. Use exact replacement hardware for attaching the

propeller shafts. Exact replacement will ensure safe operation. The specified torque must always be ap

plied when tightening the fasteners.

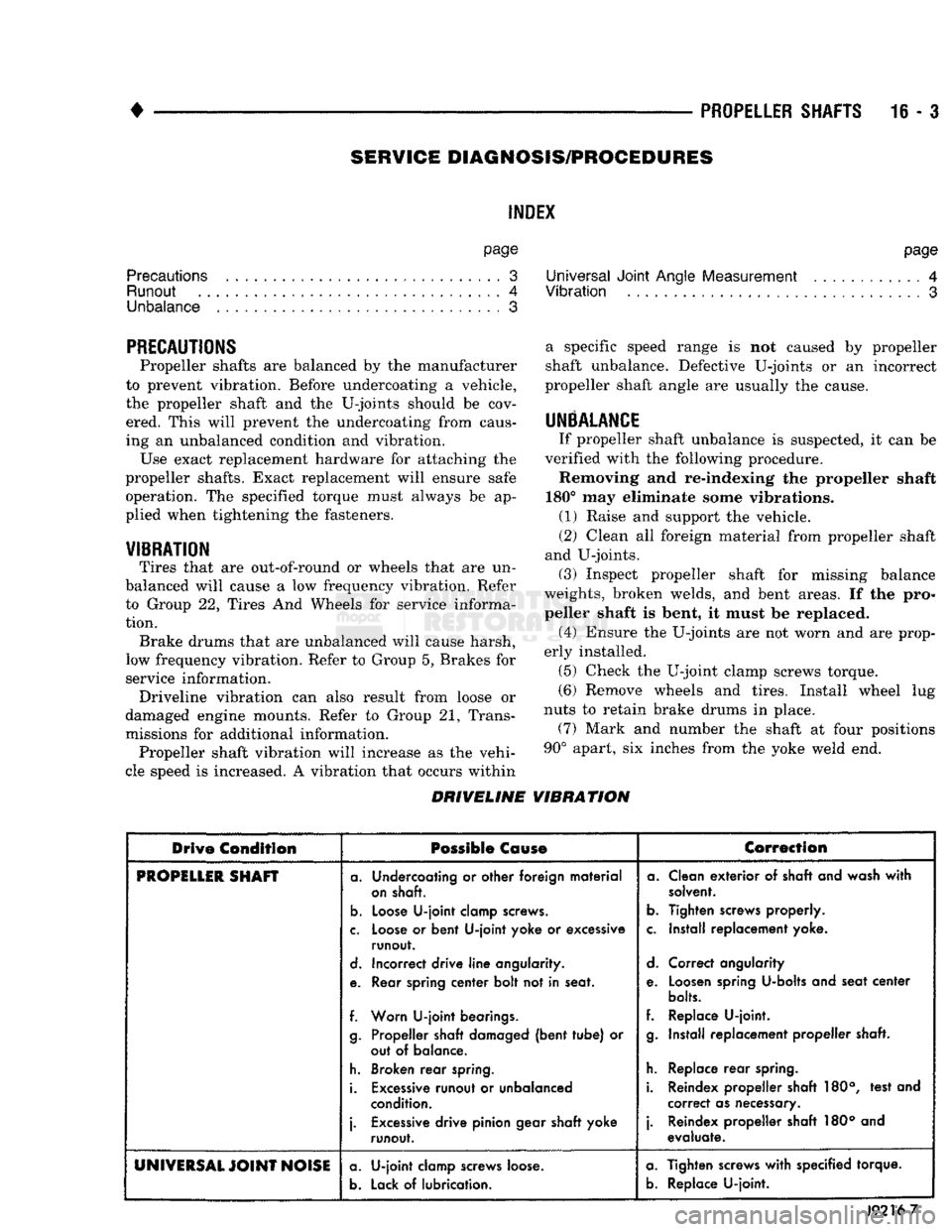

VIBRATION

Tires that are out-of-round or wheels that are un

balanced will cause a low frequency vibration. Refer to Group 22, Tires And Wheels for service informa

tion. Brake drums that are unbalanced will cause harsh,

low frequency vibration. Refer to Group 5, Brakes for

service information. Driveline vibration can also result from loose or

damaged engine mounts. Refer to Group 21, Trans

missions for additional information. Propeller shaft vibration will increase as the vehi

cle speed is increased. A vibration that occurs within a specific speed range is not caused by propeller

shaft unbalance. Defective U-joints or an incorrect

propeller shaft angle are usually the cause.

UNBALANCE

If propeller shaft unbalance is suspected, it can be

verified with the following procedure. Removing and re-indexing the propeller shaft

180° may eliminate some vibrations. (1) Raise and support the vehicle.

(2) Clean all foreign material from propeller shaft

and U-joints. (3) Inspect propeller shaft for missing balance

weights, broken welds, and bent areas. If the pro

peller shaft is bent, it must be replaced. (4) Ensure the U-joints are not worn and are prop

erly installed. (5) Check the U-joint clamp screws torque.

(6) Remove wheels and tires. Install wheel lug

nuts to retain brake drums in place. (7) Mark and number the shaft at four positions

90° apart, six inches from the yoke weld end.

DRIVELINE VIBRATION

Drive

Condition

Possible Cause

Correction

PROPiLLlR

SHAFT

a. Undercoating or other foreign material

on shaft.

b.

Loose U-joint clamp screws.

c. Loose or bent U-joint yoke or excessive runout.

d. Incorrect drive line angularity.

e. Rear spring center bolt not in seat.

f. Worn U-joint bearings. g. Propeller shaft damaged (bent tube) or out of balance.

h. Broken rear spring.

i. Excessive runout or unbalanced condition.

j.

Excessive drive pinion gear shaft yoke runout. a. Clean exterior of shaft and wash with

solvent.

b.

Tighten screws properly.

c. Install replacement yoke.

d. Correct angularity

e. Loosen spring U-bolts and seat center

bolts.

f. Replace U-joint. g. Install replacement propeller shaft.

h. Replace rear spring.

i. Reindex propeller shaft 180°, test and correct as necessary.

j.

Reindex propeller shaft 180° and evaluate.

UNIVERSAL

JOINT

NOISE a. U-joint clamp screws loose.

b.

Lack of lubrication. a. Tighten screws with specified torque.

b.

Replace U-joint.

J9216-7

Page 962 of 1502

•

STEERING STEERING

19-1

CONTENTS

page

GENERAL INFORMATION

1

POWER STEERING PUMP

11

POWER STEERING SYSTEM DIAGNOSIS

..... 2

RECIRCULATING

BALL

POWER STEERING GEAR

. 20

page

STEERING COLUMN

3i

STEERING LINKAGE

17

TORQUE SPECIFICATIONS

40

GENERAL

INFORMATION

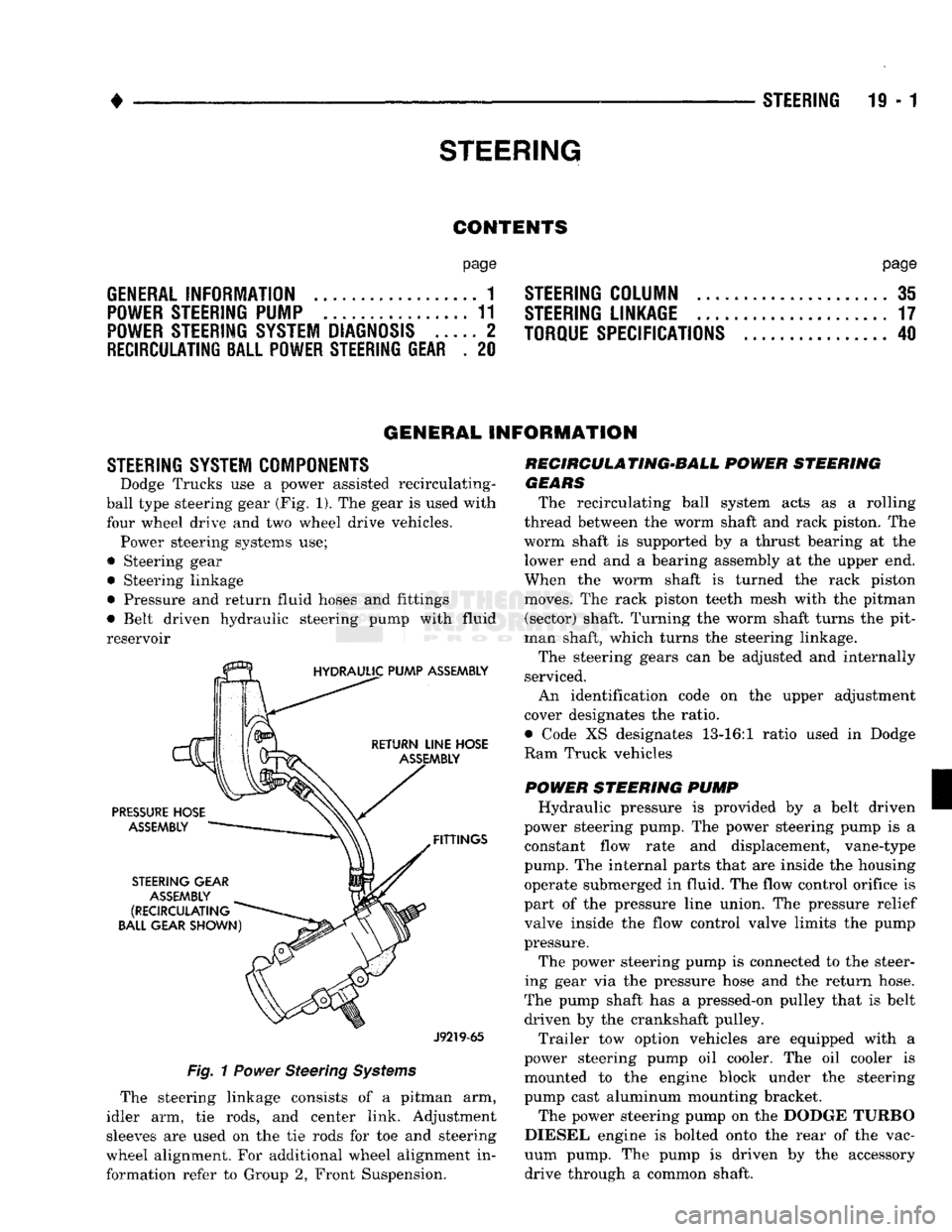

STEERING SYSTEM COMPONENTS

Dodge Trucks

use a

power

assisted recirculating-

ball

type steering gear

(Fig.

1). The

gear

is

used with

four

wheel drive

and two

wheel

drive

vehicles. Power steering systems

use;

•

Steering

gear • Steering linkage

• Pressure

and

return fluid hoses

and

fittings

• Belt driven hydraulic steering pump with

fluid

reservoir

J9219-65

Fig.

1

Power

Steering

Systems

The steering linkage consists

of a

pitman

arm,

idler

arm, tie

rods,

and

center link. Adjustment

sleeves

are

used

on the tie

rods

for toe and

steering

wheel alignment.

For

additional wheel alignment

in

formation refer

to

Group

2,

Front Suspension. RECIRCULA TING-BALL

POWER

STEERING

GEARS

The recirculating ball system acts

as a

rolling

thread between

the

worm shaft

and

rack piston.

The

worm shaft

is

supported

by a

thrust bearing

at the

lower

end

and a

bearing assembly

at

the

upper

end.

When

the

worm shaft

is

turned

the

rack piston

moves.

The

rack piston teeth mesh with

the

pitman (sector) shaft. Turning

the

worm shaft turns

the

pit

man shaft, which turns

the

steering linkage.

The steering gears

can be

adjusted

and

internally

serviced.

An identification code

on the

upper adjustment

cover designates

the

ratio.

• Code

XS

designates 13-16:1 ratio used

in

Dodge

Ram Truck vehicles

POWER

STEERING

PUMP

Hydraulic pressure

is

provided

by a

belt driven

power steering pump.

The

power steering pump

is a

constant flow rate

and

displacement, vane-type

pump.

The

internal parts that

are

inside

the

housing operate submerged

in

fluid.

The

flow control orifice

is

part

of

the

pressure line union.

The

pressure relief

valve inside

the

flow control valve limits

the

pump

pressure.

The power steering pump

is

connected

to

the

steer

ing gear

via the

pressure hose

and the

return hose.

The pump shaft

has

a

pressed-on pulley that

is

belt driven

by the

crankshaft pulley.

Trailer

tow

option vehicles

are

equipped with

a

power steering pump

oil

cooler.

The oil

cooler

is

mounted

to the

engine block under

the

steering

pump cast aluminum mounting bracket.

The power steering pump

on

the

DODGE TURBO

DIESEL engine

is

bolted onto

the

rear

of

the

vac

uum pump.

The

pump

is

driven

by the

accessory drive through

a

common shaft.

Page 965 of 1502

19

- 4

STEERING

POWER STEERING SYSTEM DIAGNOSIS

PUMP

NOISI

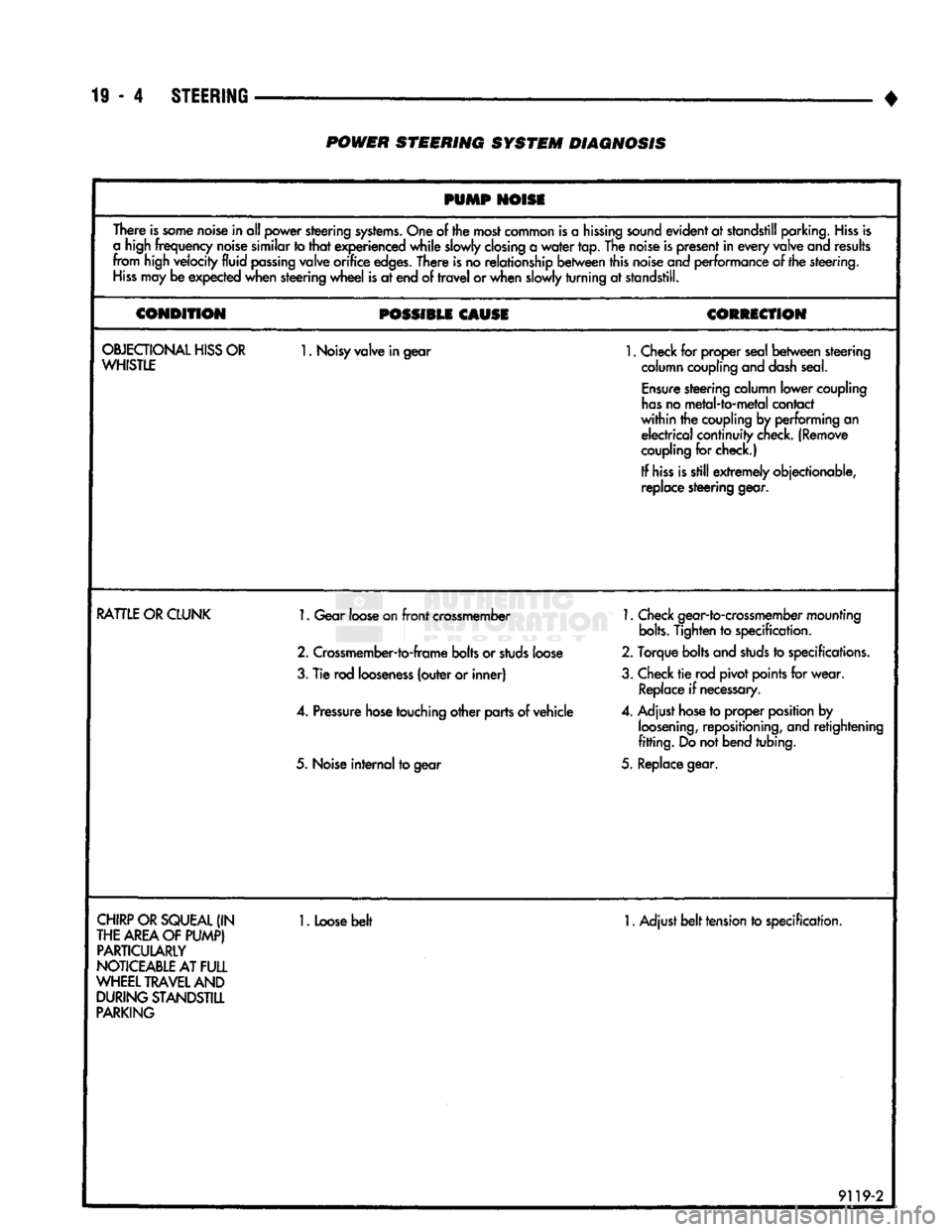

There is some noise in all power steering systems. One of the most common is a hissing sound evident at standstill parking. Hiss is

a high frequency noise similar to that experienced while slowly closing a water tap. The noise is present in every valve and results

from high velocity

fluid

passing valve orifice edges. There is no relationship between this noise and performance of the steering. Hiss may be expected when steering wheel is at end of travel or when slowly turning at standstill.

CONDITION

POSSIBU CAUSI

CORRICriON

OBJECTIONALHISSOR

WHISTLE 1.

Noisy valve in gear

1.

Check for proper seal between steering

column coupling and dash seal.

Ensure steering column lower coupling

has no metal-to-metal contact

within the coupling by performing an electrical continuity check. (Remove

coupling for check.)

If hiss is still extremely objectionable,

replace steering gear.

RATTLE

OR CLUNK

1.

Gear loose on front crossmember

2.

Crossmember-to-frame bolts or studs loose

3.

Tie rod looseness (outer or inner)

4.

Pressure hose touching other parts of vehicle

5.

Noise internal to gear

1.

Check gear-to-crossmember mounting

bolts.

Tighten to specification.

2.

Torque bolts and studs to specifications.

3.

Check tie rod pivot points for wear. Replace if necessary.

4.

Adjust hose to proper position by loosening, repositioning, and retightening

fitting. Do not bend tubing.

5.

Replace gear.

CHIRP OR SQUEAL (IN

THE AREA OF PUMP) PARTICULARLY

NOTICEABLE AT

FULL

WHEEL TRAVEL AND DURING STANDSTILL

PARKING

1.

Loose belt

1.

Adjust belt tension to specification.

9119-2

Page 976 of 1502

#

_ ,

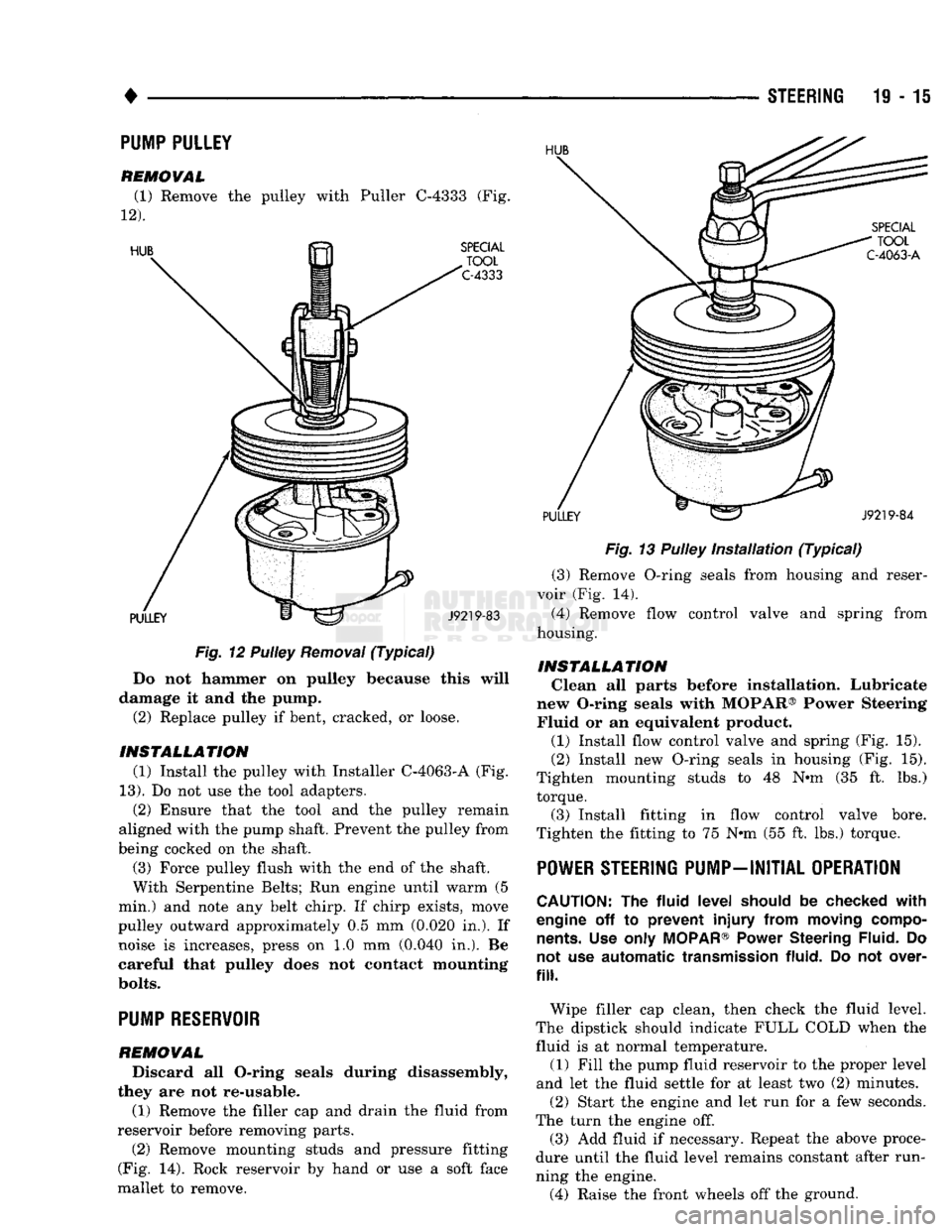

Fig.

12 Pulley

Removal

(Typical)

Do not hammer on pulley because this will

damage it and the pump. (2) Replace pulley if bent, cracked, or loose.

INSTALLATION (1) Install the pulley with Installer C-4063-A (Fig.

13).

Do not use the tool adapters. (2) Ensure that the tool and the pulley remain

aligned with the pump shaft. Prevent the pulley from

being cocked on the shaft.

(3) Force pulley flush with the end of the shaft.

With Serpentine Belts; Run engine until warm (5

min.) and note any belt chirp. If chirp exists, move

pulley outward approximately 0.5 mm (0.020 in.). If noise is increases, press on 1.0 mm (0.040 in.). Be

careful that pulley does not contact mounting

bolts.

PUMP RESERVOIR

REMOVAL

Discard all O-ring seals during disassembly,

they are not re-usable.

(1) Remove the filler cap and drain the fluid from

reservoir before removing parts. (2) Remove mounting studs and pressure fitting

(Fig. 14). Rock reservoir by hand or use a soft face

mallet to remove. STEERING 19-15

Fig.

13 Pulley

Installation

(Typical)

(3) Remove O-ring seals from housing and reser

voir (Fig. 14). (4) Remove flow control valve and spring from

housing.

INSTALLATION Clean all parts before installation. Lubricate

new O-ring seals with MOPAR® Power Steering Fluid or an equivalent product.

(1) Install flow control valve and spring (Fig. 15).

(2) Install new O-ring seals in housing (Fig. 15).

Tighten mounting studs to 48 N«m (35 ft. lbs.) torque.

(3) Install fitting in flow control valve bore.

Tighten the fitting to 75 N-m (55 ft. lbs.) torque.

POWER STEERING PUMP-INITIAL OPERATION

CAUTION:

The

fluid

level

should

be

checked

with

engine

off to

prevent

injury

from

moving

compo

nents.

Use

only

MOPAR®

Power

Steering

Fluid.

Do

not

use

automatic

transmission

fluid.

Do not

over

fill.

Wipe filler cap clean, then check the fluid level.

The dipstick should indicate FULL COLD when the fluid is at normal temperature. (1) Fill the pump fluid reservoir to the proper level

and let the fluid settle for at least two (2) minutes. (2) Start the engine and let run for a few seconds.

The turn the engine off. (3) Add fluid if necessary. Repeat the above proce

dure until the fluid level remains constant after run

ning the engine. (4) Raise the front wheels off the ground.

PUMP PULLEY

REMOVAL

(1) Remove the pulley with Puller C-4333 (Fig.

12).

Page 979 of 1502

19

- 18

STEERING

•

CAUTION:

It is

possible

to install the

center

link

re

versed

position.

This

will

result

in

incorrect

geome

try and interferences during vehicle jounce. Viewed

from the

front

of the vehicle, the

center

link

ends

should

turn

upward. Viewed

from

the side of the ve

hicle,

the

ends

should

turn

toward

the

front

of the

vehicle. The

tie-rod

ball

studs

enter

the

center

link

bores

from

the

rear.

(5) Install tie-rod ends into center link (Fig. 2).

Tighten the nuts to 54 N»m (40 ft. lbs.) torque. In stall new cotter pins.

(6) Insert tie-rod ends into steering knuckle arm

(Fig. 2). Tighten the nuts to 54 N-m (40 ft. lbs.)

torque. Install new cotter pins. (7) Remove the supports and lower the vehicle to

the surface. Adjust the wheel toe position (refer to

the Alignment Specifications chart within Group 2,

Front Suspension).

Position the clamp on the sleeve so retaining

bolt is located on the bottom side of the sleeve.

(8) After adjustment, tighten the tie-rod adjust

ment sleeve clamp bolt;

• Standard Duty— 25.4 N-m (225 in. lbs.) torque

• Heavy Duty- 34 N-m (25 ft. lbs.) torque

STEERING

LINKAGE—4WD

VEHICLES

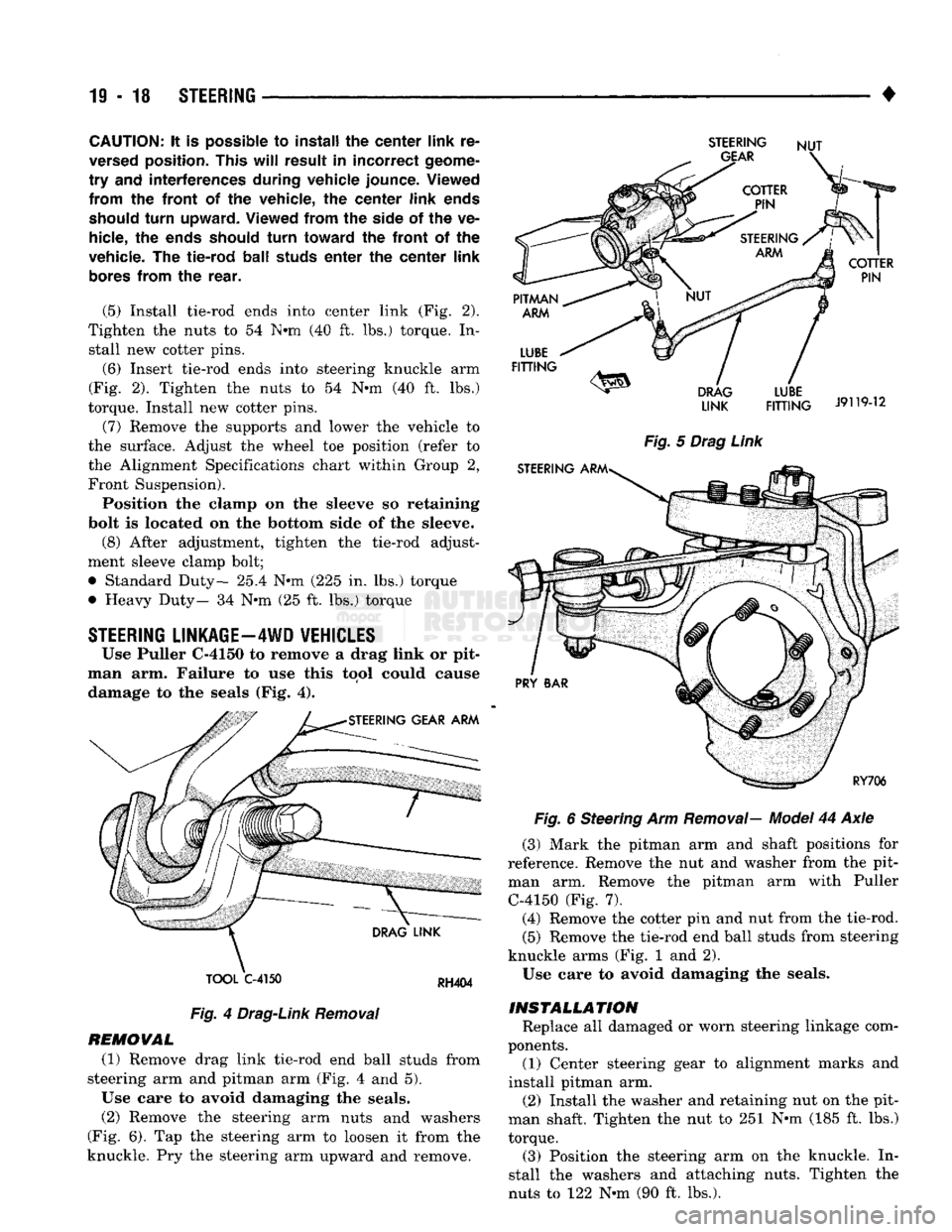

Use Puller C-4150 to remove a drag link or pit

man arm. Failure to use this tool could cause damage to the seals (Fig. 4).

TOOL

C-4150

RH404

Fig.

4

Drag-Link

Removal

REMOVAL (1) Remove drag link tie-rod end ball studs from

steering arm and pitman arm (Fig. 4 and 5).

Use care to avoid damaging the seals. (2) Remove the steering arm nuts and washers

(Fig. 6). Tap the steering arm to loosen it from the

knuckle. Pry the steering arm upward and remove.

STEERING

NUT

LINK

FITTING

J9119-12

Fig.

5

Drag

Link

Fig.

6 Steering Arm

Removal—

Model

44 Axle

(3) Mark the pitman arm and shaft positions for

reference. Remove the nut and washer from the pit

man arm. Remove the pitman arm with Puller C-4150 (Fig. 7). (4) Remove the cotter pin and nut from the tie-rod.

(5) Remove the tie-rod end ball studs from steering

knuckle arms (Fig. 1 and 2).

Use care to avoid damaging the seals.

INSTALLATION

Replace all damaged or worn steering linkage com

ponents. (1) Center steering gear to alignment marks and

install pitman arm.

(2) Install the washer and retaining nut on the pit

man shaft. Tighten the nut to 251 N-m (185 ft. lbs.)

torque. (3) Position the steering arm on the knuckle. In

stall the washers and attaching nuts. Tighten the

nuts to 122 N-m (90 ft. lbs.).

Page 980 of 1502

•

STEERING

19 - 19

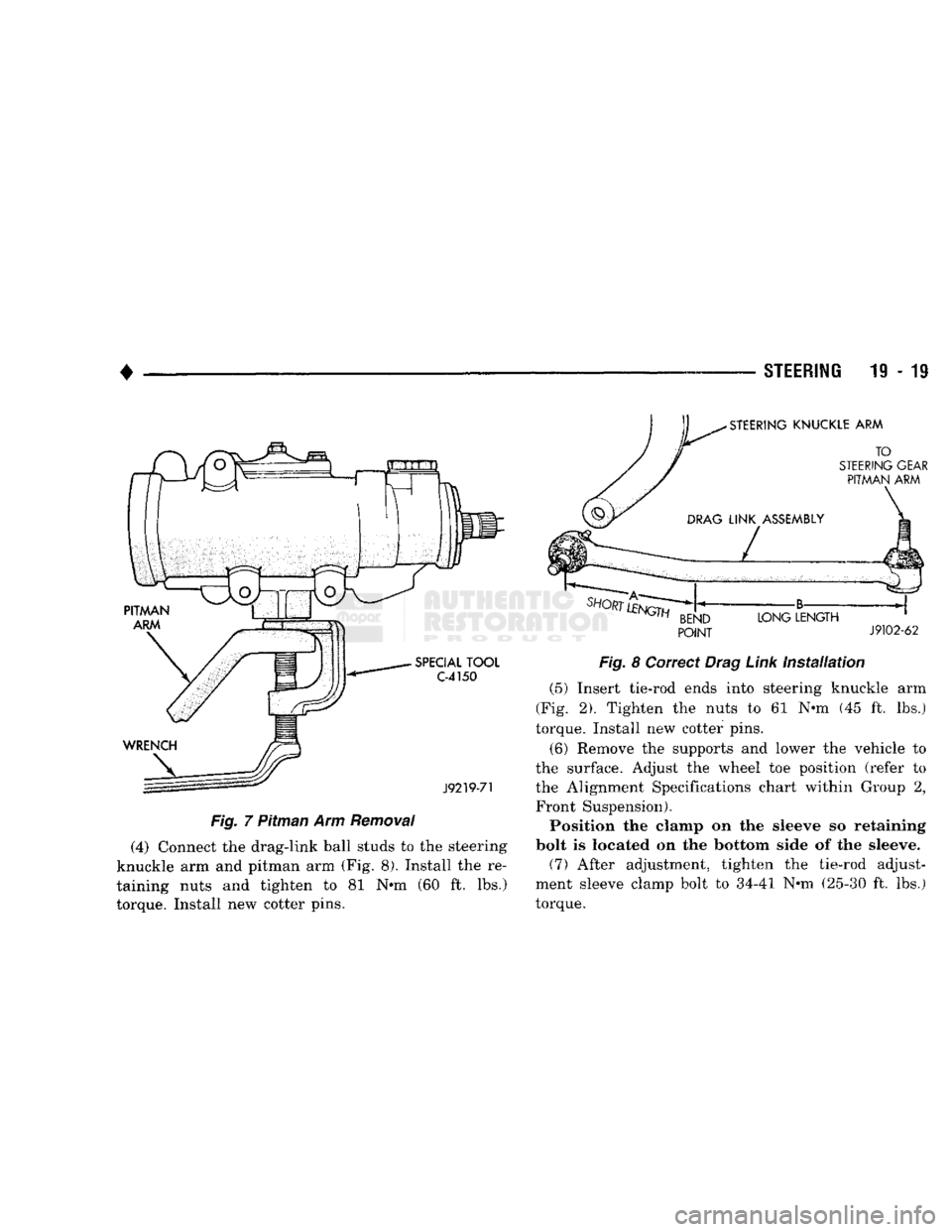

Fig.

7 Pitman Arm

Removal

(4) Connect the drag-link ball studs to the steering

knuckle arm and pitman arm (Fig. 8). Install the re

taining nuts and tighten to 81 N»m (60 ft. lbs.)

torque. Install new cotter pins.

POINT

J9102-62

Fig.

8 Correct

Drag

Link

installation

(5) Insert tie-rod ends into steering knuckle arm

(Fig. 2). Tighten the nuts to 61 N-m (45 ft. lbs.)

torque. Install new cotter pins.

(6) Remove the supports and lower the vehicle to

the surface. Adjust the wheel toe position (refer to the Alignment Specifications chart within Group 2, Front Suspension). Position the clamp on the sleeve so retaining

bolt is located on the bottom side of the sleeve. (7) After adjustment, tighten the tie-rod adjust

ment sleeve clamp bolt to 34-41 N-m (25-30 ft. lbs.)

torque.

Page 1001 of 1502

19-40

STEERING

•

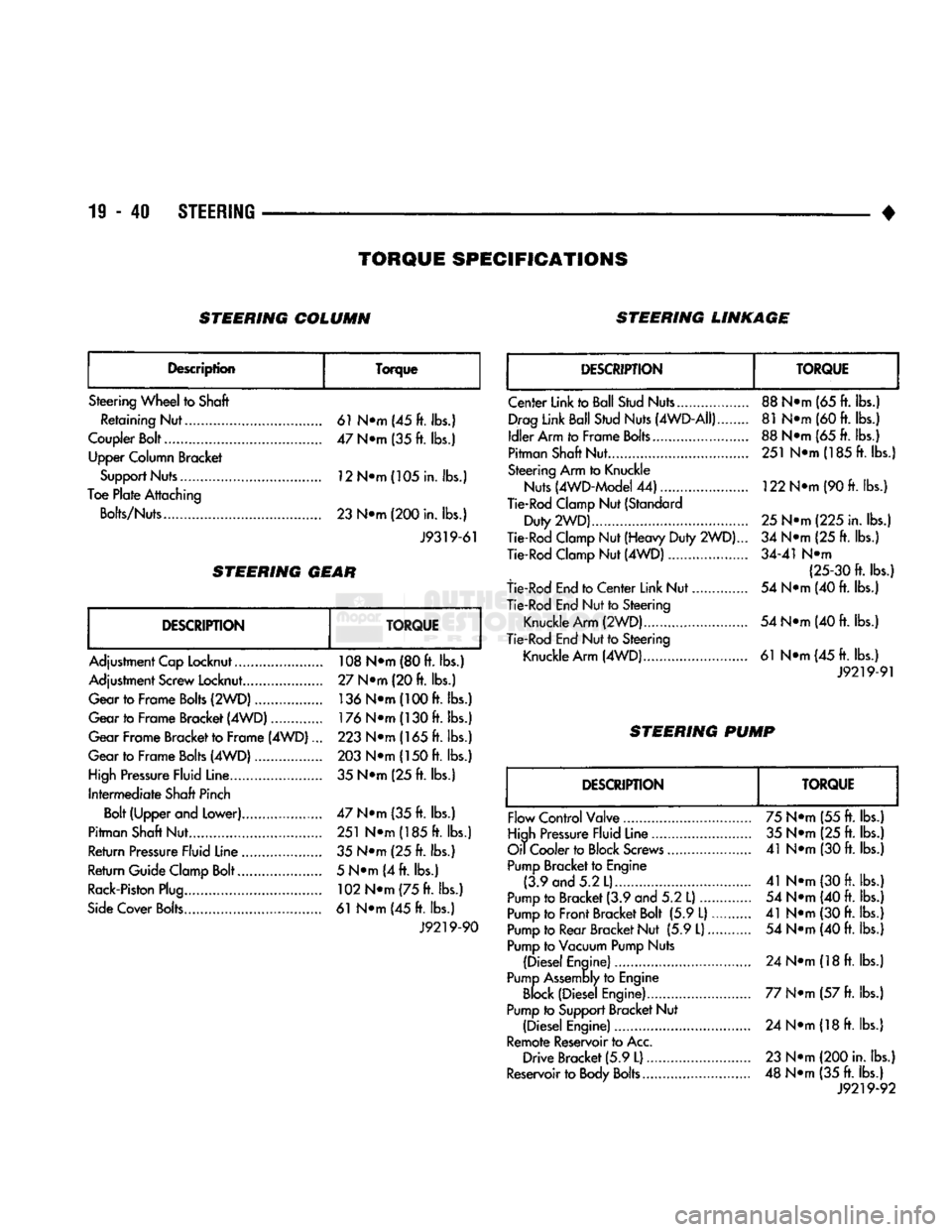

TORQUE

SPECIFICATIONS

STEERING COLUMN STEERING LINKAGE

Description Torque

Steering Wheel to Shaft Retaining Nut 61 N»m (45 ft. lbs.)

Coupler Bolt 47 N»m (35 ft. lbs.) Upper Column Bracket

Support Nuts 12N*m(105in. lbs.)

Toe Plate Attaching

Bolts/Nuts 23 N«m (200 in. lbs.)

J9319-61

STEERING

GEAR

DESCRIPTION

TORQUE

Adjustment Cap Locknut 108 N»m (80 ft. lbs.)

Adjustment Screw Locknut.... 27 N®m (20 ft. lbs.)

Gear to Frame Bolts (2WD) 136

N®m

(100 ft. lbs.)

Gear to Frame Bracket (4WD) 176

N®m

(130 ft. lbs.)

Gear Frame Bracket to Frame (4WD)... 223 N*m (165 ft. lbs.)

Gear to Frame Bolts (4WD) 203 N*m (150 ft. lbs.)

High Pressure Fluid Line. 35 N*m (25 ft. lbs.)

Intermediate Shaft Pinch Bolt (Upper and Lower) 47 N»m (35 ft. lbs.)

Pitman Shaft Nut 251 N»m (185 ft. lbs.)

Return Pressure Fluid Line 35 N*m (25 ft. lbs.)

Return Guide Clamp Bolt 5 N*m (4 ft. lbs.)

Rack-Piston Plug 102

N®m

(75 ft. lbs.)

Side Cover Bolts 61 N*m (45 ft. lbs.) J9219-90

DESCRIPTION

TORQUE

Center Link to Ball Stud Nuts..., Drag Link Ball Stud Nuts (4WD-AII)

Idler Arm to Frame Bolts...

Pitman Shaft Nut

Steering Arm to Knuckle Nuts (4WD-Model 44)

Tie-Rod Clamp Nut (Standard

Duty 2WD)....

Tie-Rod Clamp Nut (Heavy Duty

2WD).

Tie-Rod Clamp Nut (4WD)

tie-Rod End to Center Link Nut.

Tie-Rod End Nut to Steering

Knuckle

Arm

(2WD)..

Tie-Rod End Nut to Steering Knuckle Arm (4WD) 88 N®m (65 ft. lbs.)

81 N®m (60 ft. lbs.)

88 N*m (65

ft.

lbs.) 251 NTn(185ft. lbs.)

122 N*m (90

ft.

lbs.)

25

N^m (225 in. lbs.)

34 N«m (25

ft.

lbs.)

34-41 N«m (25-30 ft. lbs.)

54 N«m (40

ft.

lbs.)

54 N*m (40

ft.

lbs.)

61 N«m(45ft. lbs.)

J9219-91

STEERING PUMP

DESCRIPTION

TORQUE

Flow Control Valve

High Pressure Fluid Line

Oil Cooler to Block Screws

Pump Bracket to Engine (3.9 and 5.2 L)..

Pump to Bracket (3.9 and 5.2

L)....

Pump to Front Bracket Bolt (5.9 L).

Pump to Rear Bracket Nut (5.9

L)

Pump to Vacuum Pump Nuts

(Diesel Engine)

Pump Assembly to Engine Block (Diesel Engine)

Pump to Support Bracket Nut (Diesel Engine)

Remote Reservoir to Acc, Drive Bracket (5.9

L)

Reservoir to Body Bolts 75 N®m (55

ft.

lbs.)

35 N«*m (25 ft. lbs.)

41 N*m (30

ft.

lbs.)

41 N*m (30

ft.

lbs.) 54 N®m (40

ft.

lbs.)

41 N*m (30

ft.

lbs.) 54 N*m (40

ft.

lbs.)

24 N®m

(18

ft.

lbs.)

77 N*m (57

ft.

lbs.) 24 NTH (18

ft.

lbs.)

23 N*m (200 in. lbs.)

48 N«m (35

ft.

lbs.) J9219-92

Page 1005 of 1502

21

- 4

NV4500 MANUAL TRANSMISSION

(12) If transmission is to be disassembled for re

pair, remove drain plug and drain lubricant from transmission.

(13) move bolts/nuts attaching transmission to rear

mount.

(14) Support transmission with a transmission

jack. Secure transmission to jack with safety chains.

(15) Remove rear crossmember,

(16) Remove bolts attaching clutch slave cylinder

to clutch housing. Then move cylinder aside for

working clearance.

(17) Remove transmission harness wires from clips

on transmission shift cover. (18) Remove bolts attaching transmission to clutch

housing. (19) Slide transmission and jack rearward until

drive gear clears clutch housing. (20) Lower transmission jack and remove trans

mission from under vehicle. (21) If transmission will be overhauled, clean

transmission exterior with solvent or with steam gun.

TRANSMISSION

INSTALLATION—2-WHEEL DRIVE

(1) Apply light coat of Mopar high temperature

bearing grease to contact surfaces of following com

ponents: • drive gear splines and pilot bearing hub

• release bearing slide surface of front retainer

• pilot bearing • release bearing bore

• release fork

• release fork ball stud

• propeller shaft slip yoke (2) Fill transmission with recommended lubricant.

Correct fill level is bottom edge of fill plug hole. (3) Mount transmission on jack and position trans

mission under vehicle. (4) Raise transmission until drive gear is centered

in release bearing and clutch disc hub. (5) Move transmission forward and start drive gear

in release bearing, clutch disc and pilot bushing. (6) Work transmission forward until seated against

clutch housing. Do not allow transmission to remain

unsupported after drive gear has entered clutch disc. (7) Install and tighten transmission-to-clutch hous

ing bolts to 108 N*m (80 ft. lbs.) torque. (8) Install clutch slave cylinder. (9) Connect speed sensor and backup light switch

wires.

(10) Position transmission harness wires in clips

on shift cover. (11) Install transmission mount on transmission or

rear crossmember. (12) Install rear crossmember.

(13) Remove transmission jack and engine support

fixture. (14) Align and connect propeller shaft. (15) Fill transmission with required lubricant, if

necessary. (16) Lower vehicle.

(17) Install shift lever on transmission stub lever.

(18) Install shift boot and bezel. (19) Connect battery negative cable.

TRANSMISSION REMOVAL—4-WHEEL DRIVE

(1) Disconnect battery negative cable.

(2) Shift transmission into Neutral.

(3) Remove shift lever boot and bezel. (4) Loosen nut attaching shift lever to transmis

sion stub lever and remove shift lever from stub le

ver. (5) Raise- vehicle.

(6) Remove skid plate if equipped.

(7) If transmission will be disassembled for repair,

remove drain plug and drain lubricant from trans

mission. (8) Mark propeller shafts and yokes for assembly

reference. (9) Disconnect propeller shafts and remove propel

ler shafts. (10) Disconnect and remove exhaust system

Y-pipe. Then disconnect and lower remaining ex

haust pipes for clearance as necessary. (11) Support engine with adjustable safety stand.

(12) Disconnect speed sensor wires and disconnect

speedometer cable, if equipped. (13) Disconnect backup light switch wires.

(14) Disconnect transfer case shift linkage at

transfer case range lever. (15) Remove bolts/nuts attaching transmission to

rear support. (16) Remove crossmember bolts/nuts and remove

crossmember. (17) Support transfer case with transmission jack.

Secure transfer case to jack with safety chains. (18) Remove transfer case attaching nuts.

(19) Move transfer case rearward until input gear

clears transmission mainshaft. (20) Lower transfer case assembly and move it

from under vehicle. (21) If transmission is being removed for repair,

remove drain plug and drain lubricant from trans mission.

(22) Support transmission with transmission jack.

Secure transmission to jack with safety chains.

(23) Remove transmission harness from retaining

clips on transmission shift cover. (24) Remove bolts/nuts attaching transmission

mount to rear crossmember.

(25) Remove rear crossmember.

(26) Remove clutch slave cylinder splash shield, if

equipped.

(27) Loosen clutch slave cylinder attaching nuts

until cylinder piston rod is clear of release lever.

This reduces pressure on lever and release bearing