relay DODGE TRUCK 1993 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 254 of 1502

CLUTCH

6 - 1

CLUTCH

CONTENTS

page

CLUTCH

DIAGNOSIS

2

CLUTCH

COMPONENTS

MECHANICAL COMPONENTS

The clutch mechanism

in

AD

models with

a gas or

diesel engine consists

of a

single, dry-type clutch disc and

a

diaphragm style clutch cover.

A

hydraulic

linkage

is

used

to

engage/disengage

the

clutch disc

and cover.

The transmission input shaft

is

supported

in the

crankshaft

by a

bearing.

A

sleeve type release bear

ing

is

used

to

operate

the

clutch cover pressure plate.

The release bearing

is

operated

by a

release fork

in

the clutch housing.

The

fork pivots

on a

ball stud

mounted inside

the

housing.

The

release fork

is

actu ated

by a

hydraulic slave cylinder mounted

in the

housing.

The

slave cylinder

is

operated

by a

clutch master cylinder mounted

on the

dash panel.

The

cyl

inder push

rod is

connected

to the

clutch pedal.

The clutch disc

has

cushion springs

in the

disc

hub.

The clutch disc facing

is

riveted

to the hub. The

fac ing

is

made from

a

non-asbestos material.

The

clutch

cover pressure plate

is a

diaphragm type with

a one-

piece spring

and

multiple release fingers.

The

pres sure plate release fingers

are

preset during

manufacture

and are not

adjustable.

A

265 mm

clutch disc

and

cover

are

used

in

models

with

a 3.9L

engine.

A 280 mm

clutch disc

and

cover are used

in

models with

a 5.2L, or

5.9L engine.

A

330 mm

clutch disc

and

cover

are

used

in

models

equipped with

the

optional

5.9L

Cummins diesel

en

gine.

Some diesel models

are

also equipped with

a

clutch pedal interlock switch.

The

switch

is in

circuit

with

the

starter relay

and is

actuated

by the

clutch

pedal

and

push

rod. The

clutch pedal must

be

fully depressed

in

order

to

start

the

engine.

HYDRAULIC LINKAGE COMPONENTS

The hydraulic linkage consists

of a

remote reser

voir, clutch master cylinder, clutch slave cylinder and interconnecting fluid lines.

The clutch master cylinder

is

connected

to the

clutch pedal

and the

slave cylinder

is

connected

to

the clutch release fork.

The

master cylinder

is

mounted

on the

drivers' side

of the

dash panel adja

cent

to the

brake master cylinder.

page

CLUTCH

SERVICE

11

CLUTCH LINKAGE FLUID

The clutch fluid reservoir, master cylinder, slave

cylinder

and

fluid lines

are

prefilled with fluid

at the

factory during assembly operations. The hydraulic system should

not

require additional

fluid under normal circumstances.

In

fact,

the

reser

voir fluid level will actually increase

as

normal clutch wear occurs.

For

this reason,

it is

impor

tant

to

avoid overfilling,

or

removing fluid from

the reservoir. If inspection

or

diagnosis indicates additional fluid

may

be

needed,

use

Mopar brake fluid,

or an

equiv

alent meeting

SAE and DOT

standards J1703

and

DOT

3. Do not use any

other type

of

fluid.

CLUTCH

COMPONENT LUBRICATION

Proper clutch component lubrication

is

important

to satisfactory operation.

The

correct lubricant

and

not overlubricating

are

equally important. Apply rec

ommended lubricant sparingly

to

avoid disc

and

pres sure plate contamination. Clutch

and

transmission components requiring

lu

brication

are:

• pilot bearing

• release lever pivot ball stud

• release lever contact surfaces

• clutch disc

hub

splines

• clutch pedal pivot shaft bore

• clutch pedal bushings

• input shaft splines

• input shaft pilot

hub

• transmission front bearing retainer slide surface Do

not

apply grease

to any

part

of the

clutch

cover,

or

disc.

RECOMMENDED LUBRICANTS

Use Mopar multi-purpose grease

for the

clutch

pedal bushings

and

pivot shaft.

Use

Mopar high tem

perature grease

(or

equivalent)

for all

other lubrica

tion requirements. Apply recommended amounts

and

do

not

over lubricate.

Page 330 of 1502

•

ELECTRICAL

8A - 9

ENGINE STARTER MOTOR TEST PROCEDURES

GENERAL INFORMATION

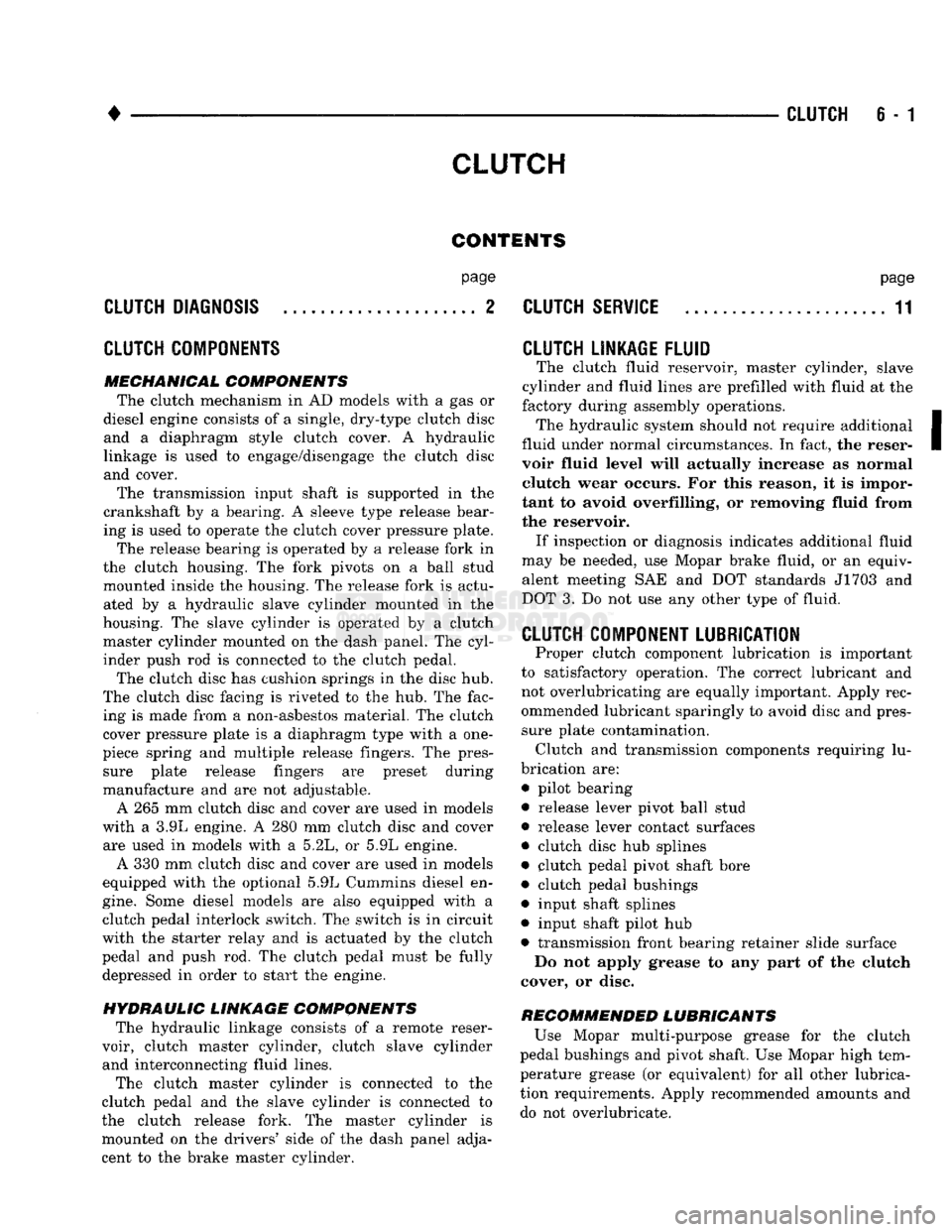

The starting system consists of an:

• ignition switch

• starter relay

• park/neutral position switch (automatic transmis sion)

• clutch switch (diesel engine-manual transmission)

• wiring harness

• battery

• starter motor with an integral solenoid. These components form 2 separate circuits. A high

amperage circuit that feeds the starter motor up to

300+ amps-gas engine; 500+ amps-diesel engine,

and a control circuit that operates on less than 20

amps (Fig. 1).

a.

BATTERY +

1

IGNITION

SWITCH 1 AUTOMATIC TRANSMISSION

•

J

NEUTRAL SAFETY SWITCH

I 4-

"JL"

MOTOR

m, ...

STA3-TERSOLENO,Dnlh

STARTER RELAY

1"

898A-14

Fig.

1 Starting

System

Components

STARTER SYSTEM DIAGNOSTIC INSPECTIONS

Before removing any unit from the starter motor

system for repair, perform the following inspections:

BATTERY

INSPECTION

To determine condition of the battery, perform the

testing procedure outlined in the Battery Section.

WIRING INSPECTION

Inspect wiring for damage. Inspect all connections

at the starter motor solenoid, park/neutral position

switch (if equipped), back-up lamp switch connector,

ignition/start switch, and battery (including all

ground connections). Clean and tighten all connec

tions as required.

SOLENOID, RELAY

AND

IGNITION/START

SWITCH

INSPECTION

Inspect the solenoid, relay and switch to determine

their condition. Also, if equipped with automatic

transmission, inspect condition of the park/neutral position switch. Testing information can be found in

the following pages.

If the following components are working properly

remove the starter motor and follow procedures in

the Testing Section. • battery wiring

switch

solenoid

relay

park/neutral position switch

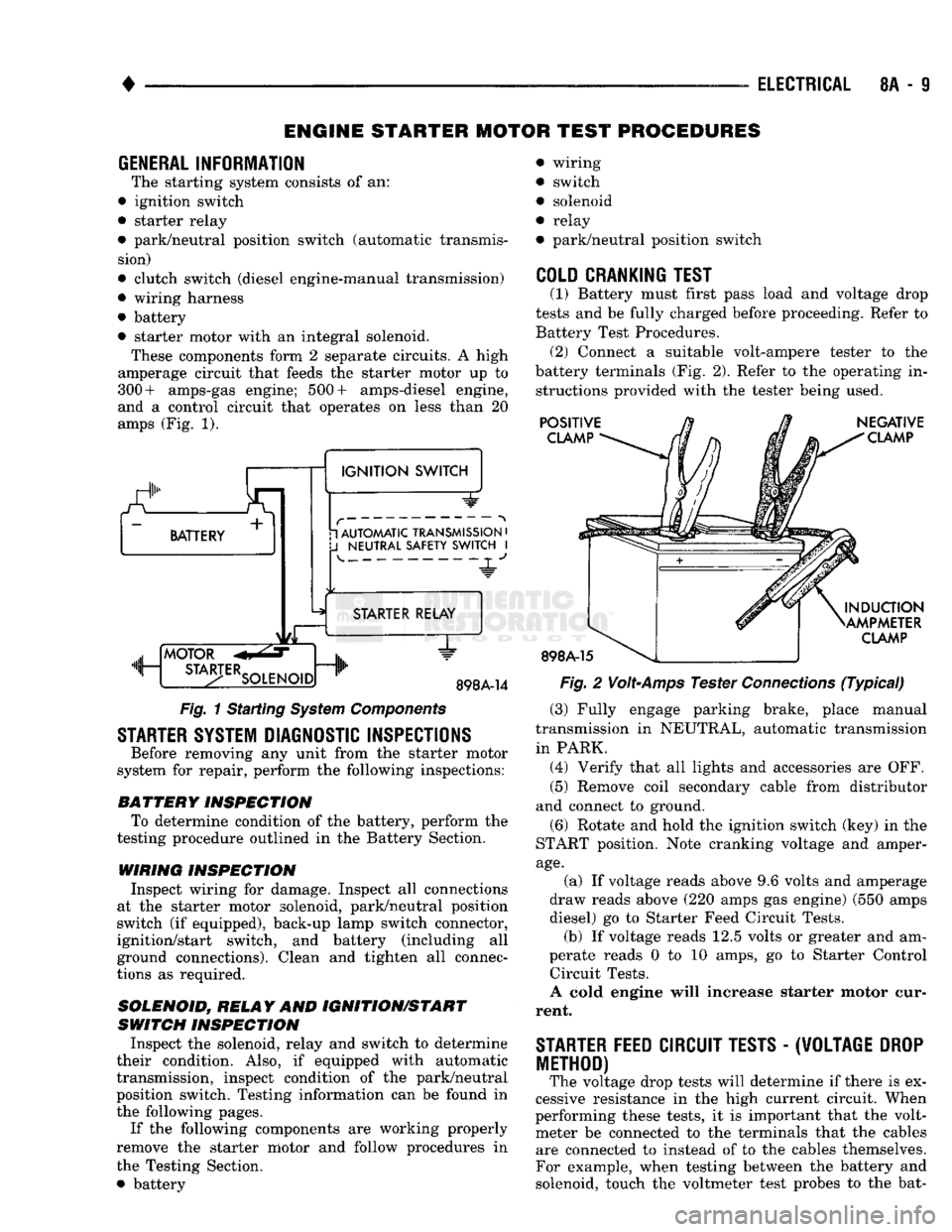

COLD CRANKING TEST

(1) Battery must first pass load and voltage drop

tests and be fully charged before proceeding. Refer to Battery Test Procedures. (2) Connect a suitable volt-ampere tester to the

battery terminals (Fig. 2). Refer to the operating in structions provided with the tester being used.

POSITIVE

CLAMP

898A-15

NEGATIVE

CLAMP

INDUCTION

AMPMETER

CLAMP

Fig.

2

Volt-Amps

Tester

Connections

(Typical)

(3) Fully engage parking brake, place manual

transmission in NEUTRAL, automatic transmission

in PARK. (4) Verify that all lights and accessories are OFF. (5) Remove coil secondary cable from distributor

and connect to ground.

(6) Rotate and hold the ignition switch (key) in the

START position. Note cranking voltage and amper

age.

(a) If voltage reads above 9.6 volts and amperage

draw reads above (220 amps gas engine) (550 amps

diesel) go to Starter Feed Circuit Tests. (b) If voltage reads 12.5 volts or greater and am-

perate reads 0 to 10 amps, go to Starter Control Circuit Tests.

A cold engine will increase starter motor cur

rent.

STARTER

FEED

CIRCUIT TESTS

-

(W0LTAGE

DROP

METHOD)

The voltage drop tests will determine if there is ex

cessive resistance in the high current circuit. When

performing these tests, it is important that the volt meter be connected to the terminals that the cables are connected to instead of to the cables themselves.

For example, when testing between the battery and

solenoid, touch the voltmeter test probes to the bat-

Page 331 of 1502

8A

- 10

ELECTRICAL

•

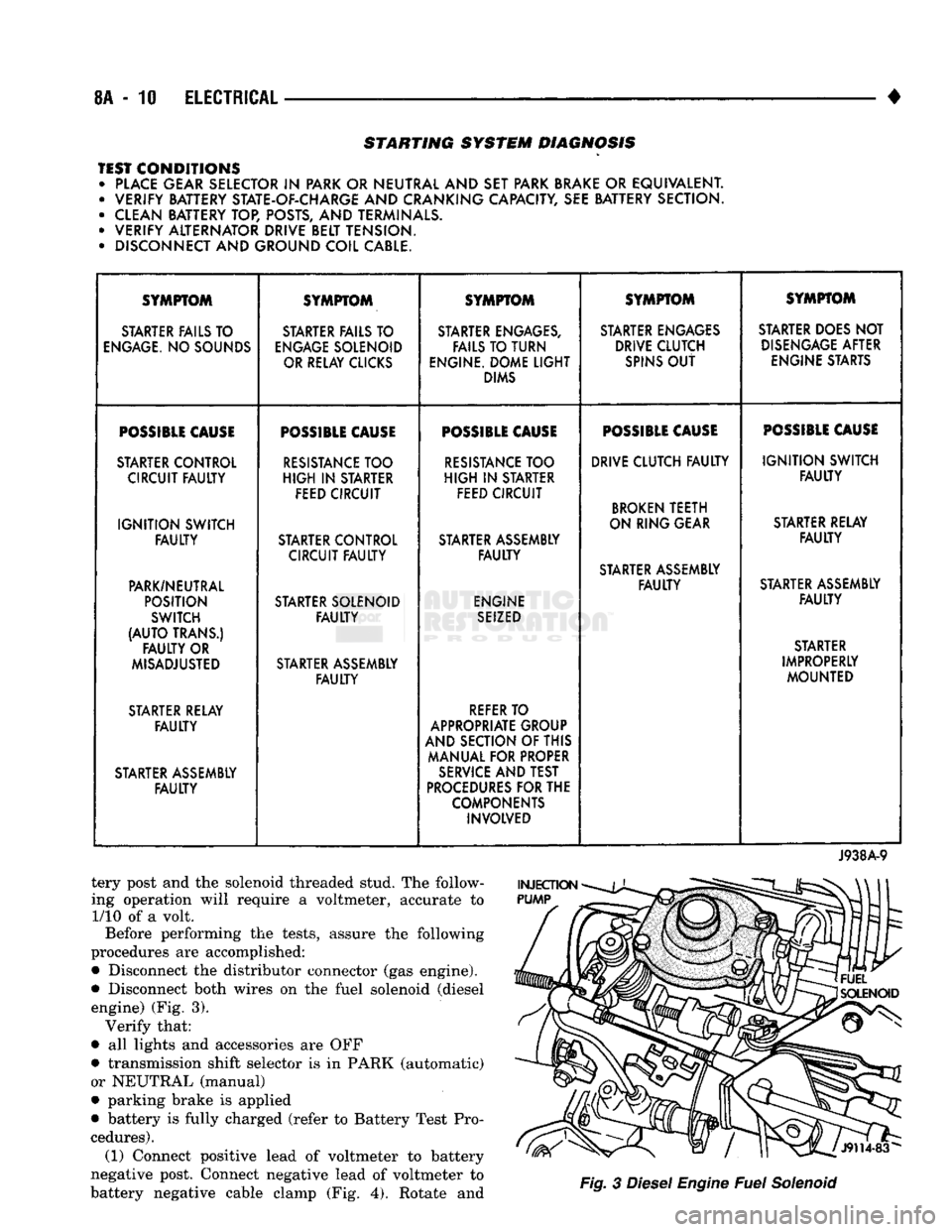

STARTING SYSTEM DIAGNOSIS

TEST CONDITIONS • PLACE GEAR SELECTOR

IN

PARK OR NEUTRAL AND SET PARK BRAKE

OR

EQUIVALENT. • VERIFY BATTERY STATE-OF-CHARGE AND CRANKING CAPACITY, SEE BATTERY SECTION.

• CLEAN BATTERY TOP, POSTS, AND TERMINALS.

• VERIFY ALTERNATOR DRIVE BELT TENSION.

• DISCONNECT AND GROUND COIL CABLE. SYMPTOM

SYMPTOM SYMPTOM SYMPTOM SYMPTOM

STARTER FAILS TO STARTER FAILS TO STARTER ENGAGES, STARTER ENGAGES STARTER DOES NOT

ENGAGE.

NO SOUNDS

ENGAGE

SOLENOID FAILS TO TURN DRIVE CLUTCH

DISENGAGE

AFTER

OR RELAY CLICKS ENGINE. DOME

LIGHT

SPINS

OUT

ENGINE STARTS

DIMS

POSSIBLE

CAUSE

POSSIBLE

CAUSE

POSSIBLE

CAUSE

POSSIBLE

CAUSE

POSSIBLE

CAUSE

STARTER CONTROL

RESISTANCE

TOO

RESISTANCE

TOO DRIVE CLUTCH

FAULTY

IGNITION

SWITCH

CIRCUIT

FAULTY

HIGH

IN

STARTER

HIGH

IN

STARTER

FAULTY

FEED CIRCUIT FEED CIRCUIT

BROKEN

TEETH

IGNITION

SWITCH ON RING GEAR

STARTER RELAY

FAULTY

STARTER CONTROL STARTER ASSEMBLY

FAULTY

CIRCUIT

FAULTY FAULTY

STARTER ASSEMBLY

PARK/NEUTRAL

FAULTY

STARTER ASSEMBLY

POSITION STARTER SOLENOID ENGINE

FAULTY

SWITCH

FAULTY

SEIZED

(AUTO

TRANS.) STARTER

FAULTY

OR STARTER

MISADJUSTED STARTER ASSEMBLY IMPROPERLY

FAULTY

MOUNTED

STARTER RELAY

REFER

TO

FAULTY

APPROPRIATE GROUP

AND SECTION OF THIS

MANUAL FOR PROPER

STARTER ASSEMBLY

SERVICE

AND TEST

FAULTY

PROCEDURES

FOR THE

COMPONENTS INVOLVED

J938A-9

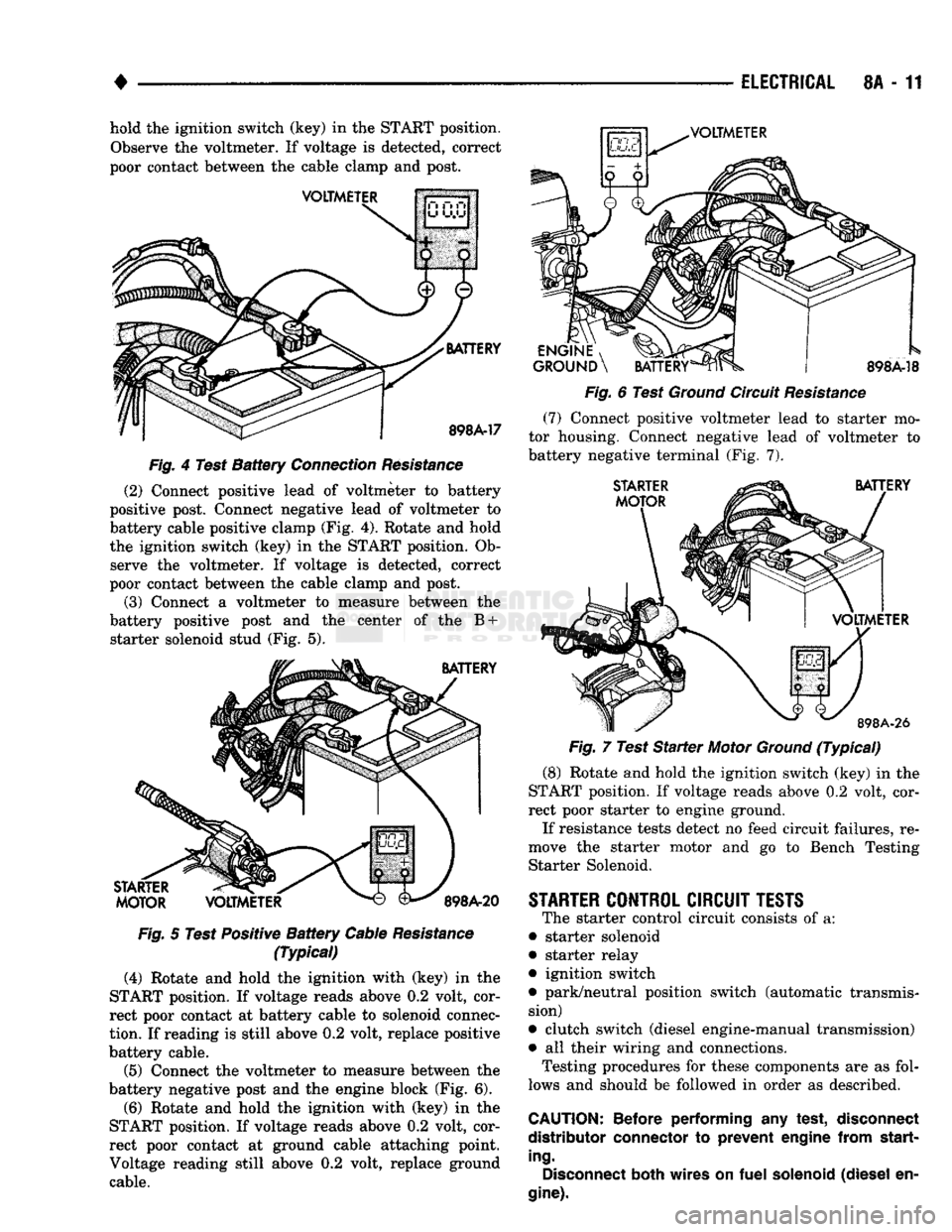

tery post and the solenoid threaded stud. The follow

ing operation will require a voltmeter, accurate to 1/10 of a volt.

Before performing the tests, assure the following

procedures are accomplished:

•

Disconnect the distributor connector (gas engine).

•

Disconnect both wires on the fuel solenoid (diesel engine) (Fig. 3). Verify that:

•

all lights and accessories are OFF

•

transmission shift selector is in PARK (automatic)

or NEUTRAL (manual)

•

parking brake is applied

•

battery is fully charged (refer to Battery Test Pro

cedures). (1) Connect positive lead of voltmeter to battery

negative post. Connect negative lead of voltmeter to

battery negative cable clamp (Fig. 4). Rotate and

Fig.

3

Diesel

Engine

Fuel

Solenoid

Page 332 of 1502

•

ELECTRICAL

8A - 11 hold the ignition switch (key) in the START position.

Observe the voltmeter. If voltage is detected, correct

poor contact between the cable clamp and post.

VOLTMETER

VOLTMETER

BATTERY

898A-17

Fig.

4 Test

Battery

Connection

Resistance

(2) Connect positive lead of voltmeter to battery

positive post. Connect negative lead of voltmeter to

battery cable positive clamp (Fig. 4). Rotate and hold

the ignition switch (key) in the START position. Ob serve the voltmeter. If voltage is detected, correct

poor contact between the cable clamp and post.

(3) Connect a voltmeter to measure between the

battery positive post and the center of the B + starter solenoid stud (Fig. 5).

BATTERY

STARTER

MOTOR

VOLTMETER

898A-20

Fig.

5 Test Positive

Battery

Cable

Resistance

(Typical)

(4) Rotate and hold the ighition with (key) in the

START position. If voltage reads above 0.2 volt, cor

rect poor contact at battery cable to solenoid connec

tion.

If reading is still above 0.2 volt, replace positive

battery cable.

(5) Connect the voltmeter to measure between the

battery negative post and the engine block (Fig. 6).

(6) Rotate and hold the ignition with (key) in the

START position. If voltage reads above 0.2 volt, cor

rect poor contact at ground cable attaching point.

Voltage reading still above 0.2 volt, replace ground cable.

ENGINE

, ^J^P

GROUND

\

BATTERY

898A-18

Fig.

6 Test

Ground

Circuit

Resistance

(7)

Connect positive voltmeter lead to starter mo

tor housing. Connect negative lead of voltmeter to

battery negative terminal (Fig. 7).

STARTER

MOTOR

BATTERY

VOLTMETER

898A-26

Fig.

7 Test

Starter

Motor

Ground

(Typical)

(8) Rotate and hold the ignition switch (key) in the

START position. If voltage reads above 0.2 volt, cor

rect poor starter to engine ground.

If resistance tests detect no feed circuit failures, re

move the starter motor and go to Bench Testing Starter Solenoid.

STARTER

CONTROL

CIRCUIT

TESTS

The starter control circuit consists of a:

• starter solenoid

• starter relay

• ignition switch

• park/neutral position switch (automatic transmis sion)

• clutch switch (diesel engine-manual transmission)

• all their wiring and connections.

Testing procedures for these components are as fol

lows and should be followed in order as described.

CAUTION:

Before

performing

any

test,

disconnect

distributor

connector

to

prevent

engine

from

start

ing.

Disconnect

both

wires

on

fuel

solenoid

(diesel

en

gine).

Page 333 of 1502

8A

- 12

ELECTRICAL

•

ENGINE

STARTER

RELAY

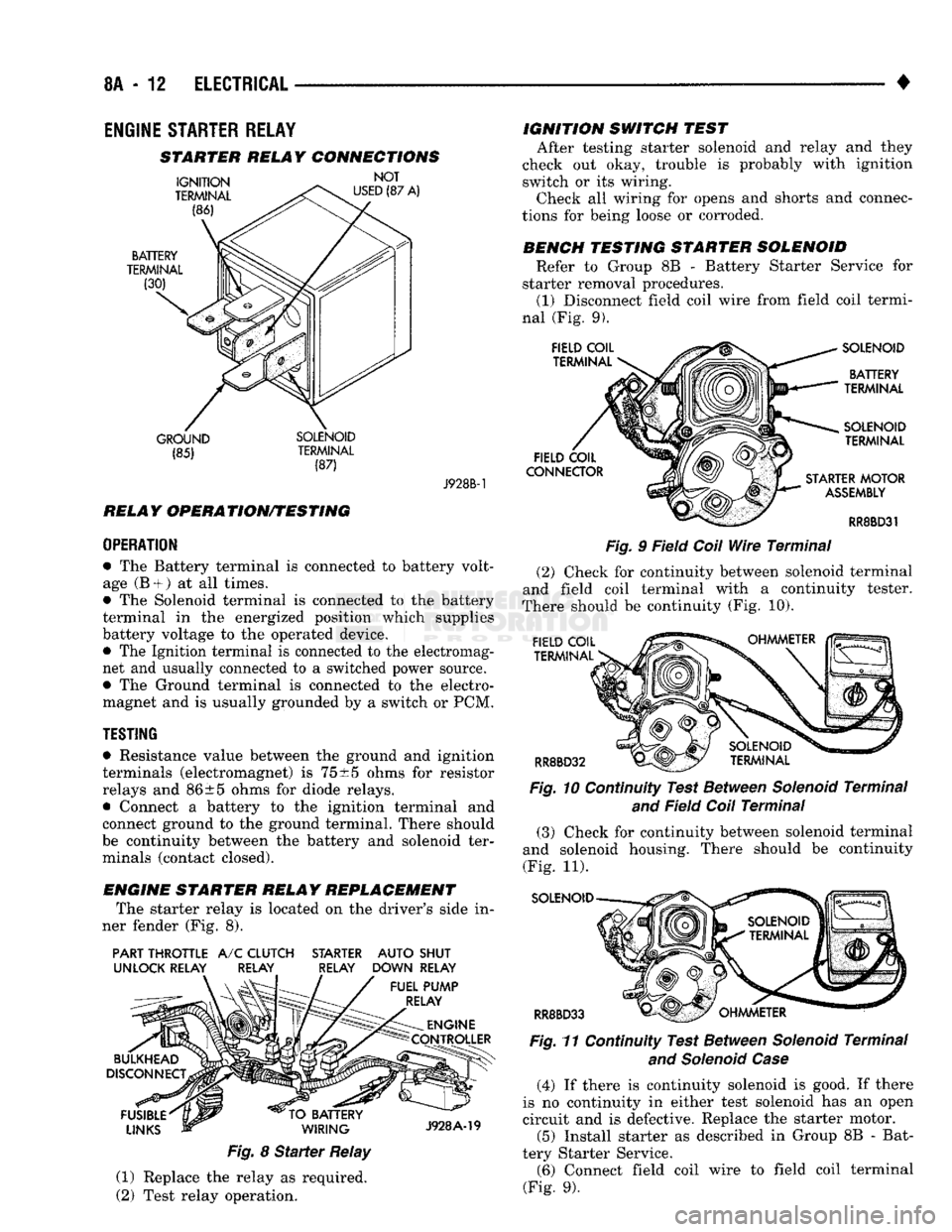

STARTER RELAY CONNECTIONS

GROUND SOLENOID (85) TERMINAL

(87) J928B-1

RELAY OPERATION/TESTING

OPERATION

• The Battery terminal is connected to battery volt

age (B +

)

at all times.

• The Solenoid terminal is connected to the battery

terminal in the energized position which supplies

battery voltage to the operated device. • The Ignition terminal is connected to the electromag

net and usually connected to a switched power source.

• The Ground terminal is connected to the electro

magnet and is usually grounded by a switch or PCM.

TESTING

• Resistance value between the ground and ignition

terminals (electromagnet) is

75

±5 ohms for resistor

relays and 86±5 ohms for diode relays.

• Connect a battery to the ignition terminal and

connect ground to the ground terminal. There should

be continuity between the battery and solenoid ter minals (contact closed).

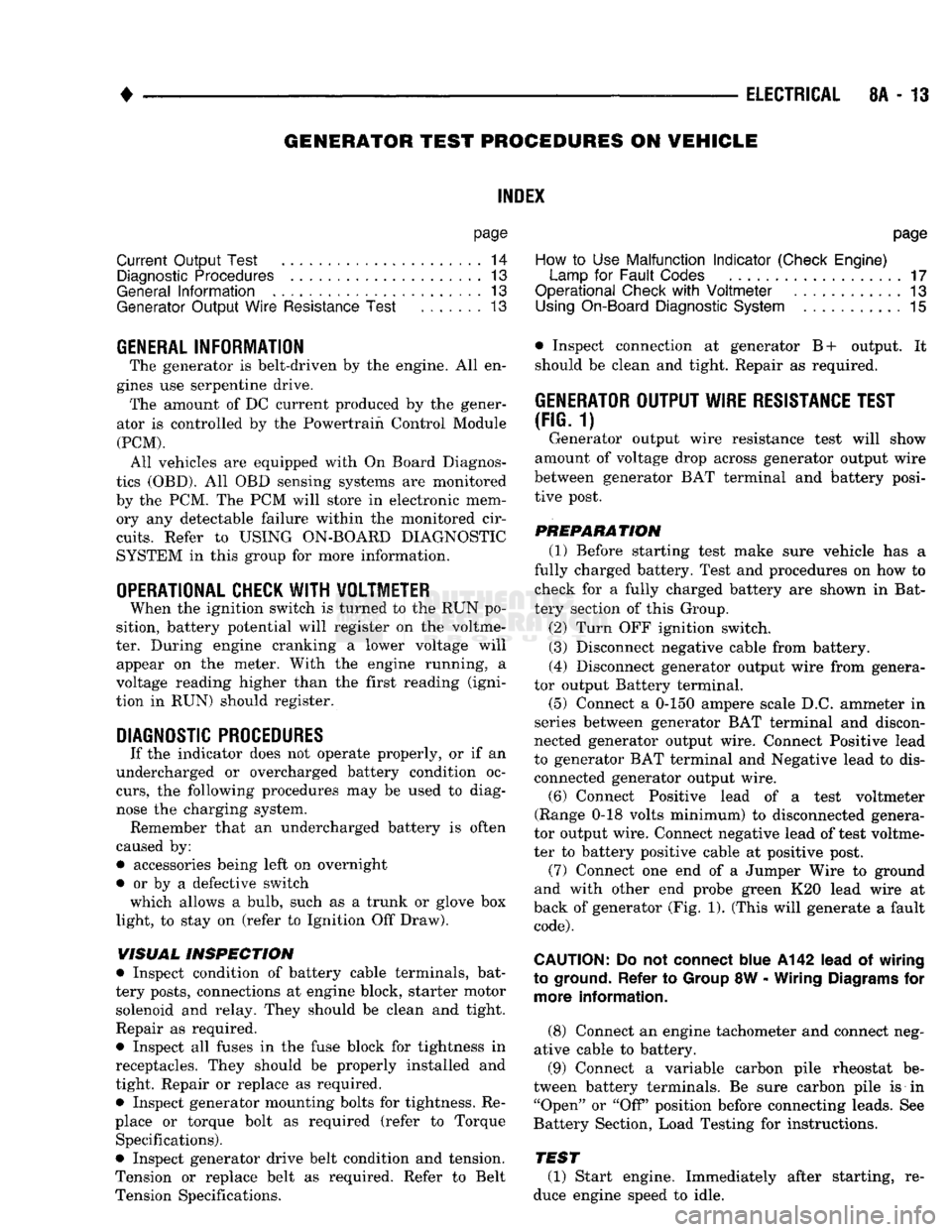

ENGINE STARTER RELAY REPLACEMENT The starter relay is located on the driver's side in

ner fender (Fig. 8).

PART THROTTLE

A/C

CLUTCH STARTER AUTO SHUT

UNLOCK RELAY RELAY RELAY DOWN RELAY

Fig.

8

Starter

Relay

(1) Replace the relay as required.

(2) Test relay operation. IGNITION SWITCH TEST

After testing starter solenoid and relay and they

check out okay, trouble is probably with ignition

switch or its wiring. Check all wiring for opens and shorts and connec

tions for being loose or corroded.

BENCH TESTING STARTER SOLENOID Refer to Group 8B - Battery Starter Service for

starter removal procedures. (1) Disconnect field coil wire from field coil termi

nal (Fig. 9).

Fig.

9 Field

Coil

Wire

Terminal

(2) Check for continuity between solenoid terminal

and field coil terminal with a continuity tester.

There should be continuity (Fig. 10).

Fig.

10 Continuity Test Between

Solenoid

Terminal

and

Field

Coil

Terminal

(3) Check for continuity between solenoid terminal

and solenoid housing. There should be continuity

(Fig. 11).

SOLENOID

RR8BD33 Fig.

11 Continuity Test Between

Solenoid

Terminal

and Solenoid Case

(4) If there is continuity solenoid is good. If there

is no continuity in either test solenoid has an open

circuit and is defective. Replace the starter motor. (5) Install starter as described in Group 8B - Bat

tery Starter Service. (6) Connect field coil wire to field coil terminal

(Fig. 9).

Page 334 of 1502

•

ELECTRICAL

8A - 13 GENERATOR TEST PROCEDURES ON

VEHICLE

INDEX

page

Current

Output

Test

......................

14

Diagnostic Procedures

13

General

Information

13

Generator

Output

Wire Resistance Test

.......

13

page

How

to

Use

Malfunction

Indicator

(Check Engine) Lamp

for

Fault

Codes

17

Operational Check

with

Voltmeter

............

13

Using

On-Board Diagnostic System

15

GENERAL

INFORMATION

The generator

is

belt-driven

by the

engine.

All en

gines

use

serpentine drive. The amount

of DC

current produced

by the

gener

ator

is

controlled

by the

Powertrain Control Module (PCM).

All vehicles

are

equipped with

On

Board Diagnos

tics (OBD).

All OBD

sensing systems

are

monitored

by

the PCM. The PCM

will store

in

electronic mem ory

any

detectable failure within

the

monitored cir

cuits.

Refer

to

USING ON-BOARD DIAGNOSTIC SYSTEM

in

this group

for

more information.

OPERATIONAL CHECK

WITH

VOLTMETER

When

the

ignition switch

is

turned

to the RUN po

sition, battery potential will register

on the

voltme

ter. During engine cranking

a

lower voltage will appear

on the

meter. With

the

engine running,

a

voltage reading higher than

the

first reading (igni

tion

in RUN)

should register.

DIAGNOSTIC PROCEDURES

If

the

indicator does

not

operate properly,

or if an

undercharged

or

overcharged battery condition

oc

curs,

the

following procedures

may be

used

to

diag

nose

the

charging system. Remember that

an

undercharged battery

is

often

caused

by:

• accessories being left

on

overnight

•

or by a

defective switch which allows

a

bulb, such

as a

trunk

or

glove

box

light,

to

stay

on

(refer

to

Ignition

Off

Draw).

WISUAL

INSPECTION

• Inspect condition

of

battery cable terminals, bat

tery posts, connections

at

engine block, starter motor solenoid

and

relay. They should

be

clean

and

tight.

Repair

as

required.

• Inspect

all

fuses

in the

fuse block

for

tightness

in

receptacles. They should

be

properly installed

and

tight. Repair

or

replace

as

required.

• Inspect generator mounting bolts

for

tightness.

Re

place

or

torque bolt

as

required (refer

to

Torque Specifications).

• Inspect generator drive belt condition

and

tension.

Tension

or

replace belt

as

required. Refer

to

Belt

Tension Specifications. • Inspect connection

at

generator

B+

output.

It

should

be

clean

and

tight. Repair

as

required.

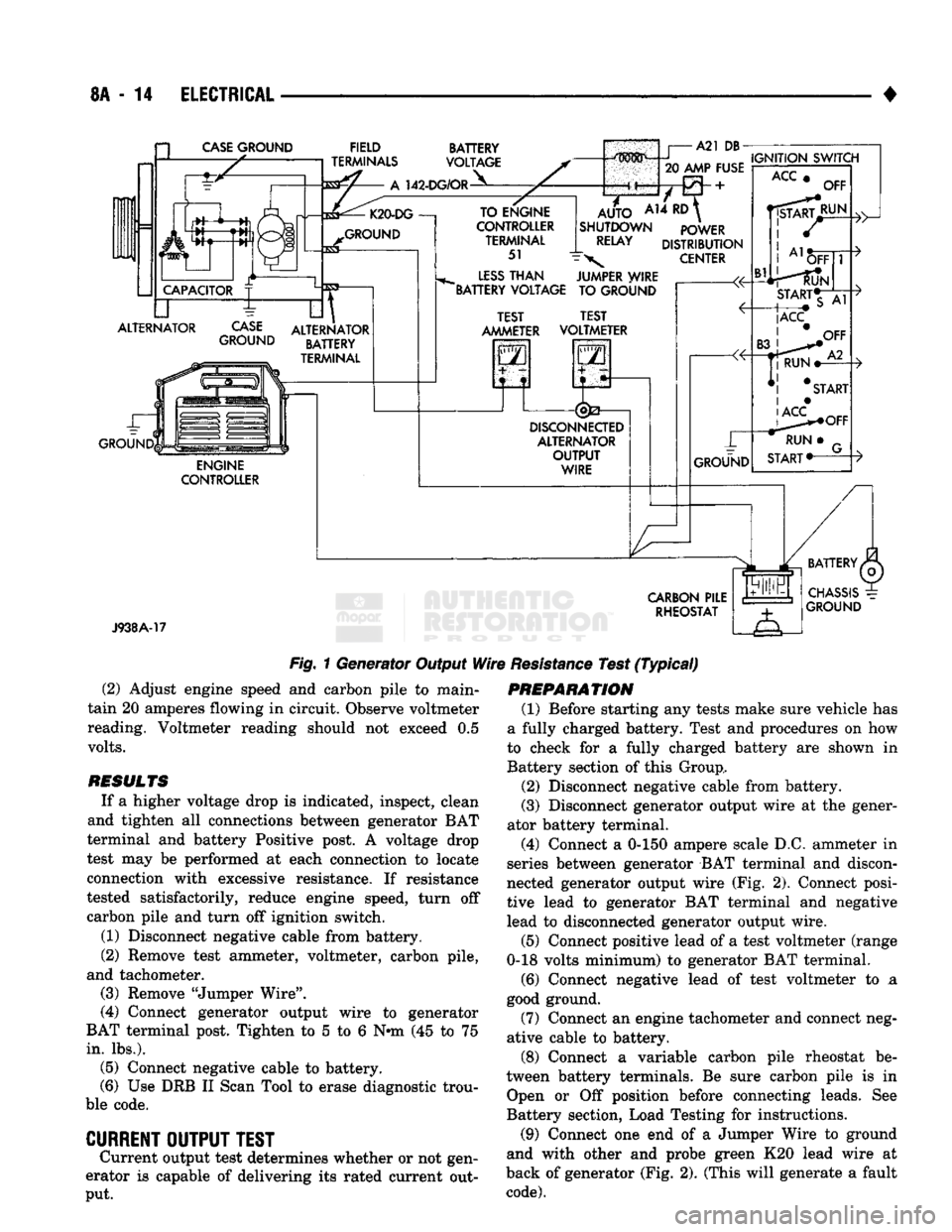

GENERATOR

OUTPUT

WIRE RESISTANCE TEST

(FIG.

1)

Generator output wire resistance test will show

amount

of

voltage drop across generator output wire

between generator

BAT

terminal

and

battery posi tive post.

PREPARATION

(1) Before starting test make sure vehicle

has a

fully charged battery. Test

and

procedures

on how to

check

for a

fully charged battery

are

shown

in

Bat

tery section

of

this Group.

(2) Turn

OFF

ignition switch.

(3)

Disconnect negative cable from battery.

(4)

Disconnect generator output wire from genera

tor output Battery terminal. (5) Connect

a 0-150

ampere scale

D.C.

ammeter

in

series between generator

BAT

terminal

and

discon

nected generator output wire. Connect Positive lead

to generator

BAT

terminal

and

Negative lead

to

dis connected generator output wire. (6) Connect Positive lead

of a

test voltmeter

(Range

0-18

volts minimum)

to

disconnected genera

tor output wire. Connect negative lead

of

test voltme

ter

to

battery positive cable

at

positive post. (7) Connect

one end of a

Jumper Wire

to

ground

and with other

end

probe green

K20

lead wire

at

back

of

generator

(Fig. 1).

(This will generate

a

fault

code).

CAUTION:

Do not

connect blue

A142

lead

of

wiring

to ground. Refer

to

Group

8W

-

Wiring Diagrams

for

more information.

(8) Connect

an

engine tachometer

and

connect neg

ative cable

to

battery.

(9) Connect

a

variable carbon pile rheostat

be

tween battery terminals.

Be

sure carbon pile

is in

"Open"

or "Off

position before connecting leads.

See

Battery Section, Load Testing

for

instructions.

TEST

(1) Start engine. Immediately after starting,

re

duce engine speed

to

idle.

Page 335 of 1502

8A

- 14

ELECTRICAL

CASE

GROUND

FIELD

TERMINALS

142-DG/OR

BATTERY

VOLTAGE

ALTERNATOR

CASE

GROUND

GROUND ALTERNATOR

BATTERY

TERMINAL

ENGINE

CONTROLLER TO ENGINE

CONTROLLER TERMINAL

51

LESS

THAN

"BATTERY VOLTAGE

m^mm i

A21 DB-

20

AMP FUSE

A14

RD

AUTO

SHUTDOWN

RELAY

IGNITION

SWITCH

POWER

DISTRIBUTION

CENTER

JUMPER WIRE TO GROUND TEST

AMMETER TEST

VOLTMETER

2

i

DISCONNEaED

ALTERNATOR

OUTPUT

WIRE

ACC

OFF

J938A-17

CARBON

PILE

RHEOSTAT

Fig.

1 Generator Output

Wire

Resistance

Test

(Typical)

(2) Adjust engine speed and carbon pile to main

tain 20 amperes flowing in circuit. Observe voltmeter

reading. Voltmeter reading should not exceed 0.5

volts.

RESULTS

If a higher voltage drop is indicated, inspect, clean

and tighten all connections between generator BAT

terminal and battery Positive post. A voltage drop

test may be performed at each connection to locate

connection with excessive resistance. If resistance

tested satisfactorily, reduce engine speed, turn off carbon pile and turn off ignition switch.

(1) Disconnect negative cable from battery.

(2) Remove test ammeter, voltmeter, carbon pile,

and tachometer. (3) Remove "Jumper Wire".

(4) Connect generator output wire to generator

BAT terminal post. Tighten to 5 to 6 Nnn (45 to 75

in.

lbs.). (5) Connect negative cable to battery.

(6) Use DRB II Scan Tool to erase diagnostic trou

ble code.

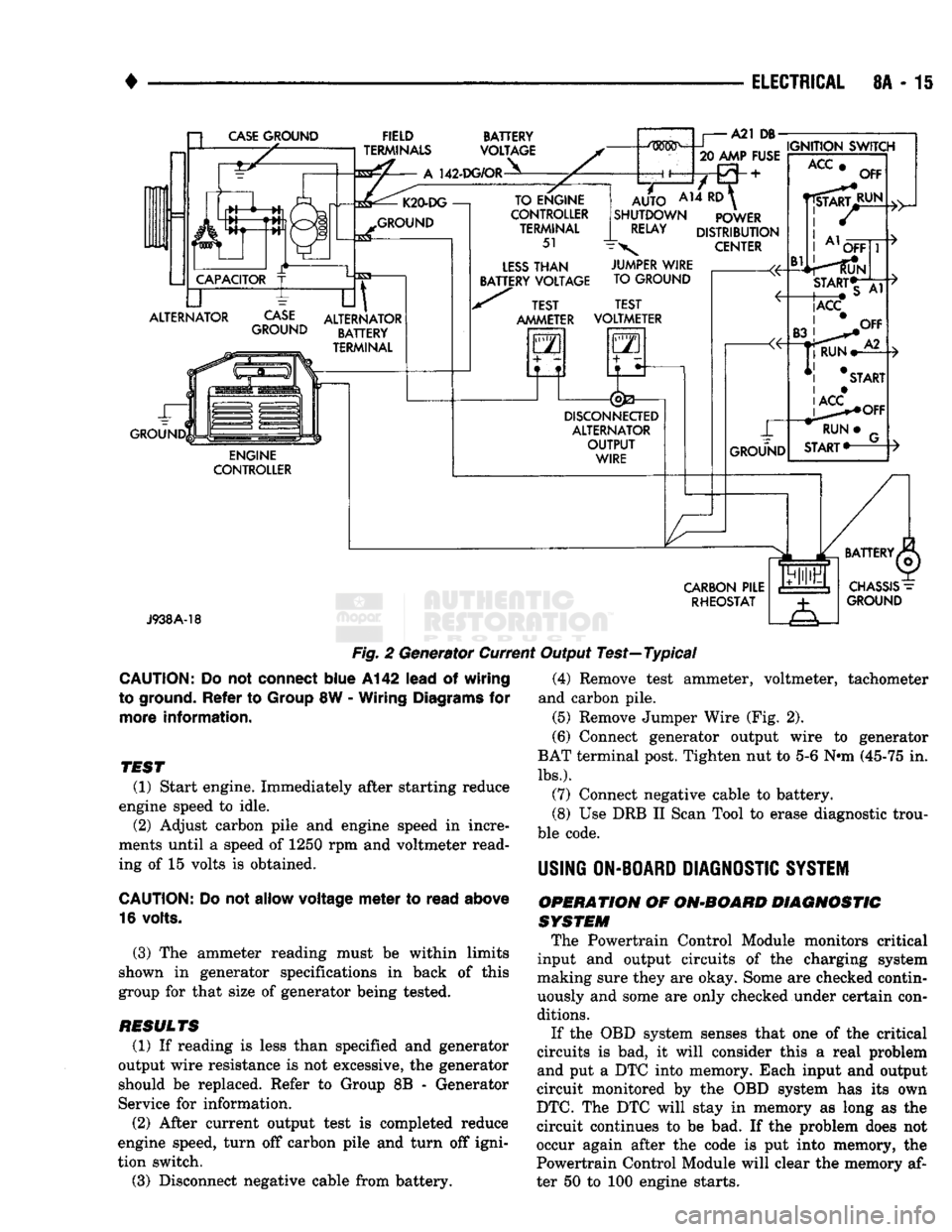

CURRENT

OUTPUT

TEST

Current output test determines whether or not gen

erator is capable of delivering its rated current out

put.

PREPARATION

(1) Before starting any tests make sure vehicle has

a fully charged battery. Test and procedures on how

to check for a fully charged battery are shown in

Battery section of this Group,

(2) Disconnect negative cable from battery.

(3) Disconnect generator output wire at the gener

ator battery terminal.

(4) Connect a 0-150 ampere scale D.C. ammeter in

series between generator BAT terminal and discon

nected generator output wire (Fig. 2). Connect posi

tive lead to generator BAT terminal and negative

lead to disconnected generator output wire.

(5) Connect positive lead of a test voltmeter (range

0-18 volts minimum) to generator BAT terminal.

(6) Connect negative lead of test voltmeter to a

good ground.

(7) Connect an engine tachometer and connect neg

ative cable to battery.

(8) Connect a variable carbon pile rheostat be

tween battery terminals. Be sure carbon pile is in Open or Off position before connecting leads. See

Battery section, Load Testing for instructions.

(9) Connect one end of a Jumper Wire to ground

and with other and probe green K20 lead wire at

back of generator (Fig. 2). (This will generate a fault

code).

Page 336 of 1502

•

ELECTRICAL

8A - 15 a

CASE

GROUND

CAPACITOR

ALTERNATOR ~L FIELD

TERMINALS

A

142-DG/OR BATTERY

VOLTAGE K20-DG

—!

GROUND

CASE

GROUND

til

ALTERNATOR BATTERY

TERMINAL ENGINE

CONTROLLER TO ENGINE

CONTROLLER TERMINAL

51

LESS

THAN

BATTERY VOLTAGE A21

DB-

.....

IGNITION SWITCH

20 AMP FUSE

AUTO

AH ^

SHUTDOWN POWER

RELAY

DISTRIBUTION

\

CENTER TEST

AMMETER JUMPER WIRE

TO GROUND

TEST

VOLTMETER

GO

5—n

DISCONNECTED

ALTERNATOR OUTPUT WIRE GROUND

ACC

Bl

OFF

RUN OFF

START*T

|ACC

CARBON

PILE RHEOSTAT

J938A-18

Fig.

2 Generator Current Output Test—Typical

CAUTION:

Do not

connect

blue

A142

lead

of

wiring

to ground.

Refer

to

Group

8W -

Wiring

Diagrams

for

more

information.

TEST

(1) Start engine. Immediately after starting reduce

engine speed to idle. (2) Adjust carbon pile and engine speed in incre

ments until a speed of 1250 rpm and voltmeter read

ing of 15 volts is obtained.

CAUTION:

Do not

allow

voltage

meter

to

read

above

16 volts.

(3) The ammeter reading must be within limits

shown in generator specifications in back of this

group for that size of generator being tested.

RESULTS

(1) If reading is less than specified and generator

output wire resistance is not excessive, the generator

should be replaced. Refer to Group 8B - Generator

Service for information.

(2) After current output test is completed reduce

engine speed, turn off carbon pile and turn off igni

tion switch.

(3) Disconnect negative cable from battery. (4) Remove test ammeter, voltmeter, tachometer

and carbon pile. (5) Remove Jumper Wire (Fig. 2).

(6) Connect generator output wire to generator

BAT terminal post. Tighten nut to 5-6 Nnn (45-75 in.

lbs.).

(7) Connect negative cable to battery.

(8) Use DRB II Scan Tool to erase diagnostic trou

ble code.

USING

ON-BOARD

DIAGNOSTIC

SYSTEM

OPERATION

OF

ON-BOARD

DIAGNOSTIC

SYSTEM

The Powertrain Control Module monitors critical

input and output circuits of the charging system

making sure they are okay. Some are checked contin

uously and some are only checked under certain con

ditions.

If the OBD system senses that one of the critical

circuits is bad, it will consider this a real problem

and put a DTC into memory. Each input and output

circuit monitored by the OBD system has its own

DTC.

The DTC will stay in memory as long as the

circuit continues to be bad. If the problem does not

occur again after the code is put into memory, the

Powertrain Control Module will clear the memory af

ter 50 to 100 engine starts.

Page 345 of 1502

8B

- 4

BATTERY/STARTER/GENERATOR SERVICE

•

STARTER SERVICE PROCEDURES

GENERAL INFORMATION

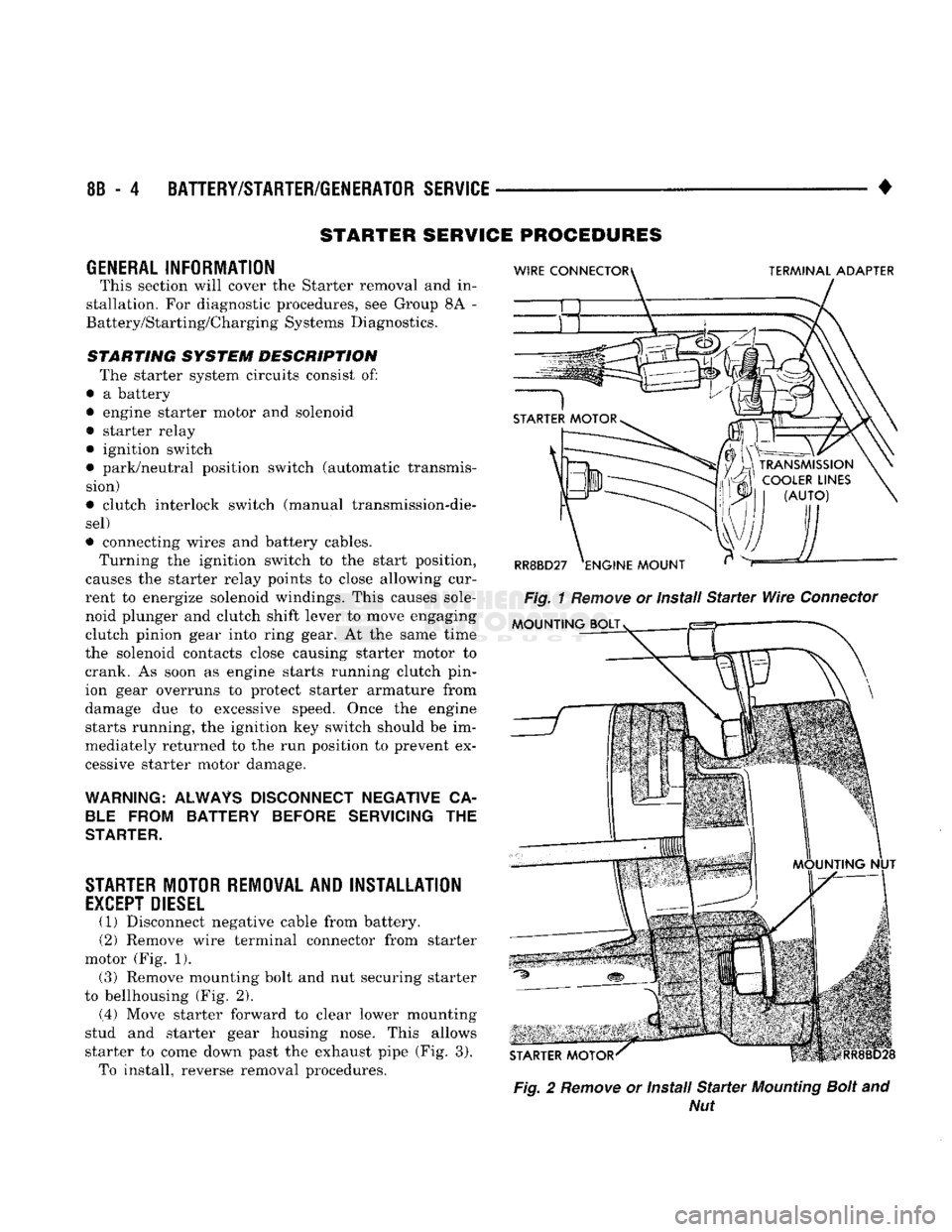

This section will cover the Starter removal and in

stallation. For diagnostic procedures, see Group 8A -

Battery/Starting/Charging Systems Diagnostics.

STARTING

SYSTEM DESCRIPTION

The starter system circuits consist of:

• a battery

• engine starter motor and solenoid

• starter relay

• ignition switch

© park/neutral position switch (automatic transmis sion)

• clutch interlock switch (manual transmission-die-

sel)

• connecting wires and battery cables. Turning the ignition switch to the start position,

causes the starter relay points to close allowing cur

rent to energize solenoid windings. This causes sole

noid plunger and clutch shift lever to move engaging

clutch pinion gear into ring gear. At the same time

the solenoid contacts close causing starter motor to

crank. As soon as engine starts running clutch pin ion gear overruns to protect starter armature from

damage due to excessive speed. Once the engine starts running, the ignition key switch should be im

mediately returned to the run position to prevent ex

cessive starter motor damage.

WARNING:

ALWAYS DISCONNECT NEGATIVE

CA

BLE FROM

BATTERY

BEFORE SERVICING

THE

STARTER.

STARTER

MOTOR REMOVAL AND INSTALLATION EXCEPT DIESEL

(1) Disconnect negative cable from battery.

(2) Remove wire terminal connector from starter

motor (Fig. 1). (3) Remove mounting bolt and nut securing starter

to bellhousing (Fig. 2).

(.4) Move starter forward to clear lower mounting

stud and starter gear housing nose. This allows

starter to come down past the exhaust pipe (Fig. 3). To install, reverse removal procedures.

Fig.

2

Remove

or Install

Starter

Mounting

Bolt

and

Nut

Page 352 of 1502

•

IGNITION

SYSTEMS

8D

- 1

CONTENTS

page page

COMPONENT IDENTIFICATION/SYSTEM DIAGNOSTICS/SERVICE PROCEDURES

7

OPERATION

1

IGNITION SWITCH

25

COMPONENT REMOVAL/INSTALLATION

..... 18

SPECIFICATIONS

28

COMPONENT

IDENTIFICATION/SYSTEM OPERATION

INDEX

page

Automatic

Shut Down (ASD) Relay

1

Camshaft Position Sensor

2

Crankshaft Position Sensor

2

Distributors

3

Engine Coolant

Temperature

Sensor

...........

4

General

Information

1

page

Ignition

Coil

3

Intake

Manifold Charge

Air

Temperature

Sensor

. . 4

Manifold Absolute Pressure (MAP) Sensor

4

Powertrain

Control

Module (PCM)

. 5

Throttle

Position Sensor

5

GENERAL

INFORMATION

Throughout this group, references

are

made

to

par

ticular vehicle models

by

alphabetical designation

or

by

the

particular vehicle nameplate.

A

chart showing a breakdown

of

alphabetical designations

is

included

in

the

Introduction group

at the

beginning

of

this

manual. 5.9L

gas

powered engines will

be

referred

to as ei

ther: LDC (Light Duty Cycle),

or

HDC (Heavy Duty Cycle). This section

of the

group, Component Identifica

tion/System Operation, will discuss ignition system operation

and

will identify ignition system compo

nents.

For diagnostic procedures

and

adjustments, refer

to

the Diagnostics/Service Procedures section

of

this

group.

For removal

and

installation

of

ignition system

components, refer

to the

Component Removal/Instal

lation section

of

this group. For other useful information, refer

to

On-Board

Di

agnostics

in the

General Diagnosis sections

of

Group

14,

Fuel System

in

this manual. For operation

of the DRB II

Diagnostic Scan Tool,

refer

to the

appropriate Powertrain Diagnostic Proce

dures service manual.

An Ignition specifications section

is

included

at the

end

of

this group.

A

general Maintenance Schedule (mileage intervals)

for

ignition related items

can be

found

in

Group

0,

Lubrication and Maintenance. This

schedule

can

also

be

found

in the

Owners Manual.

IGNITION

SYSTEMS

The ignition systems used

on all

engines

are

basi

cally identical. Similarities

and

differences between

the systems will

be

discussed.

A sequential multi-port fuel injection system

is

used

on all gas

powered engines.

The ignition system

is

controlled

by the

powertrain

control module (PCM)

on all

engines.

The

PCM

was

formerly referred

to as the

SBEC

or

engine control ler.

The ignition system consists

of:

• Spark Plugs

• Ignition Coil

• Secondary Ignition Cables

• Ignition distributor. Contains rotor

and

camshaft

position sensor • Powertrain Control Module (PCM)

• Crankshaft Position Sensor

AUTOMATIC SHUT DOWN (ASD) RELAY

The automatic shut down (ASD) relay

is

located

in

the engine compartment (Fig.

1). As one of its

func

tions,

the ASD

relay will supply battery voltage

to

the ignition coil.

The

ground circuit

for the

ASD

re

lay

is

controlled

by the

powertrain control module (PCM).

The PCM

regulates

ASD

relay operation

by

switching

the

ground circuit on-and-off.

IGNITION

SYSTEMS