FIAT 500L 2018 Owner handbook (in English)

Manufacturer: FIAT, Model Year: 2018, Model line: 500L, Model: FIAT 500L 2018Pages: 268, PDF Size: 4.87 MB

Page 171 of 268

when it is recharged, turn the

charger off before disconnecting it from

the battery;

reconnect the terminal to the

negative battery pole.

VERSIONS WITH

Start&Stop SYSTEM

(for versions/markets, where provided)

To recharge, proceed as follows:

disconnect connector A fig. 177

(pressing button B) from battery status

monitoring sensor C (fitted on the

negative battery terminal D);

connect the positive cable (+) of the

battery charger to the battery positive

terminal (+);

connect the negative cable (–) of the

battery charger to the pin D of the

negative battery terminal (–);

turn on the battery charger. When it

is recharged, turn the charger off before

disconnecting it from the battery;

reconnect the connector A to the

sensor C of the battery.

WARNING

162)Battery fluid is poisonous and

corrosive: avoid contact with your skin and

eyes. The battery should be charged in a

well ventilated place, away from naked

flames or possible sources of sparks:

danger of explosion and fire.163)Do not try to recharge a frozen

battery; defrost it first to prevent the risk of

explosion. If the battery was frozen, have

it inspected by specialised technicians

before recharging to check that the internal

elements are not damaged and that the

casing is not cracked, which could cause

poisonous, corrosive acid to leak.

177F0Y0153C

169

Page 172 of 268

WINDSCREEN /

REAR WINDOW

WIPERS

164)75)

REPLACING THE

WINDSCREEN WIPER

BLADES

Proceed as follows:

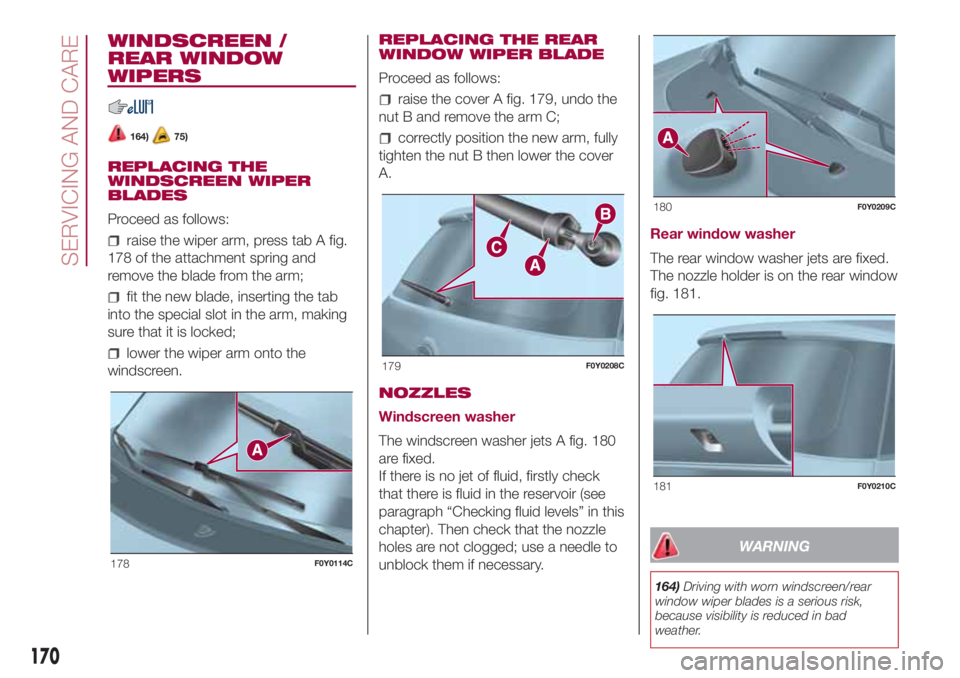

raise the wiper arm, press tab A fig.

178 of the attachment spring and

remove the blade from the arm;

fit the new blade, inserting the tab

into the special slot in the arm, making

sure that it is locked;

lower the wiper arm onto the

windscreen.REPLACING THE REAR

WINDOW WIPER BLADE

Proceed as follows:

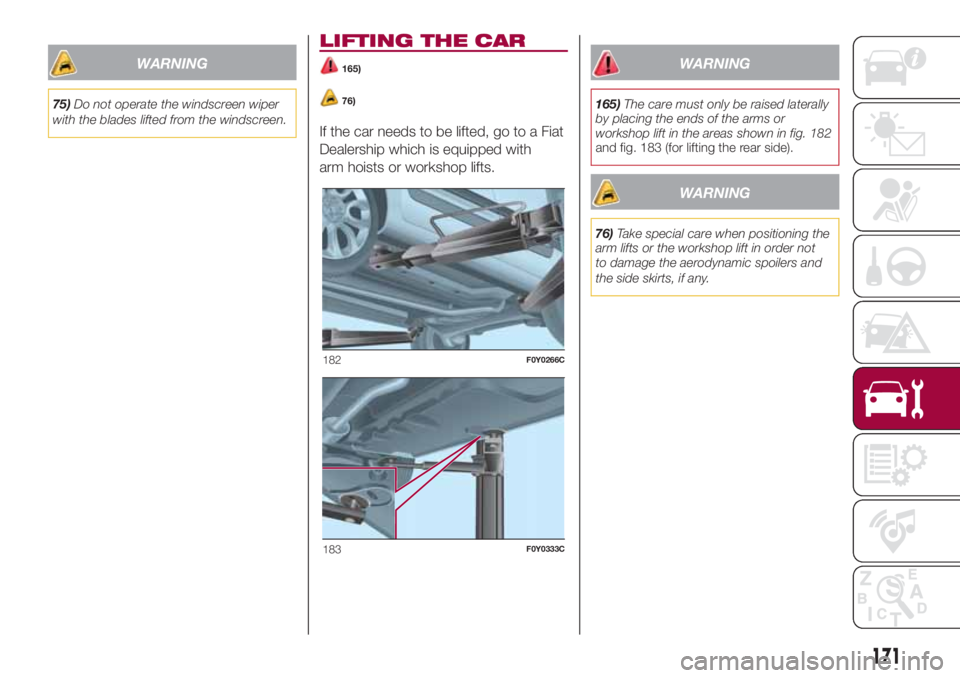

raise the cover A fig. 179, undo the

nut B and remove the arm C;

correctly position the new arm, fully

tighten the nut B then lower the cover

A.

NOZZLES

Windscreen washer

The windscreen washer jets A fig. 180

are fixed.

If there is no jet of fluid, firstly check

that there is fluid in the reservoir (see

paragraph “Checking fluid levels” in this

chapter). Then check that the nozzle

holes are not clogged; use a needle to

unblock them if necessary.Rear window washer

The rear window washer jets are fixed.

The nozzle holder is on the rear window

fig. 181.

WARNING

164)Driving with worn windscreen/rear

window wiper blades is a serious risk,

because visibility is reduced in bad

weather.

178F0Y0114C

179F0Y0208C

180F0Y0209C

181F0Y0210C

170

SERVICING AND CARE

Page 173 of 268

WARNING

75)Do not operate the windscreen wiper

with the blades lifted from the windscreen.

LIFTING THE CAR

165)

76)

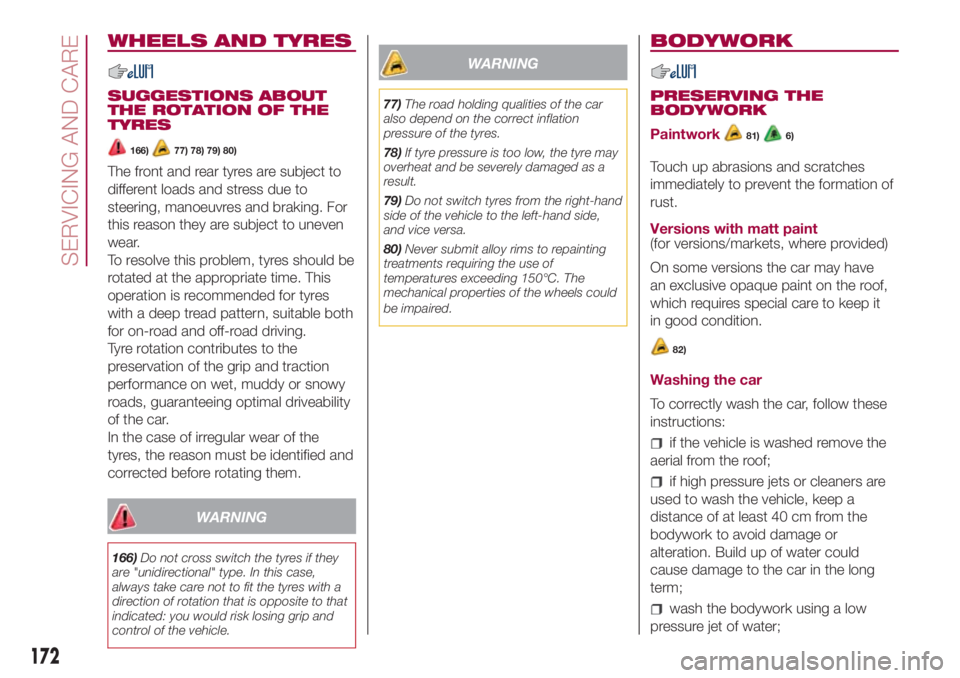

If the car needs to be lifted, go to a Fiat

Dealership which is equipped with

arm hoists or workshop lifts.

WARNING

165)The care must only be raised laterally

by placing the ends of the arms or

workshop lift in the areas shown in fig. 182

and fig. 183 (for lifting the rear side).

WARNING

76)Take special care when positioning the

arm lifts or the workshop lift in order not

to damage the aerodynamic spoilers and

the side skirts, if any.

182F0Y0266C

183F0Y0333C

171

Page 174 of 268

WHEELS AND TYRES

SUGGESTIONS ABOUT

THE ROTATION OF THE

TYRES

166)77) 78) 79) 80)

The front and rear tyres are subject to

different loads and stress due to

steering, manoeuvres and braking. For

this reason they are subject to uneven

wear.

To resolve this problem, tyres should be

rotated at the appropriate time. This

operation is recommended for tyres

with a deep tread pattern, suitable both

for on-road and off-road driving.

Tyre rotation contributes to the

preservation of the grip and traction

performance on wet, muddy or snowy

roads, guaranteeing optimal driveability

of the car.

In the case of irregular wear of the

tyres, the reason must be identified and

corrected before rotating them.

WARNING

166)Do not cross switch the tyres if they

are "unidirectional" type. In this case,

always take care not to fit the tyres with a

direction of rotation that is opposite to that

indicated: you would risk losing grip and

control of the vehicle.

WARNING

77)The road holding qualities of the car

also depend on the correct inflation

pressure of the tyres.

78)If tyre pressure is too low, the tyre may

overheat and be severely damaged as a

result.

79)Do not switch tyres from the righthand

side of the vehicle to the lefthand side,

and vice versa.

80)Never submit alloy rims to repainting

treatments requiring the use of

temperatures exceeding 150°C. The

mechanical properties of the wheels could

be impaired.

BODYWORK

PRESERVING THE

BODYWORK

Paintwork

81)6)

Touch up abrasions and scratches

immediately to prevent the formation of

rust.

Versions with matt paint

(for versions/markets, where provided)

On some versions the car may have

an exclusive opaque paint on the roof,

which requires special care to keep it

in good condition.

82)

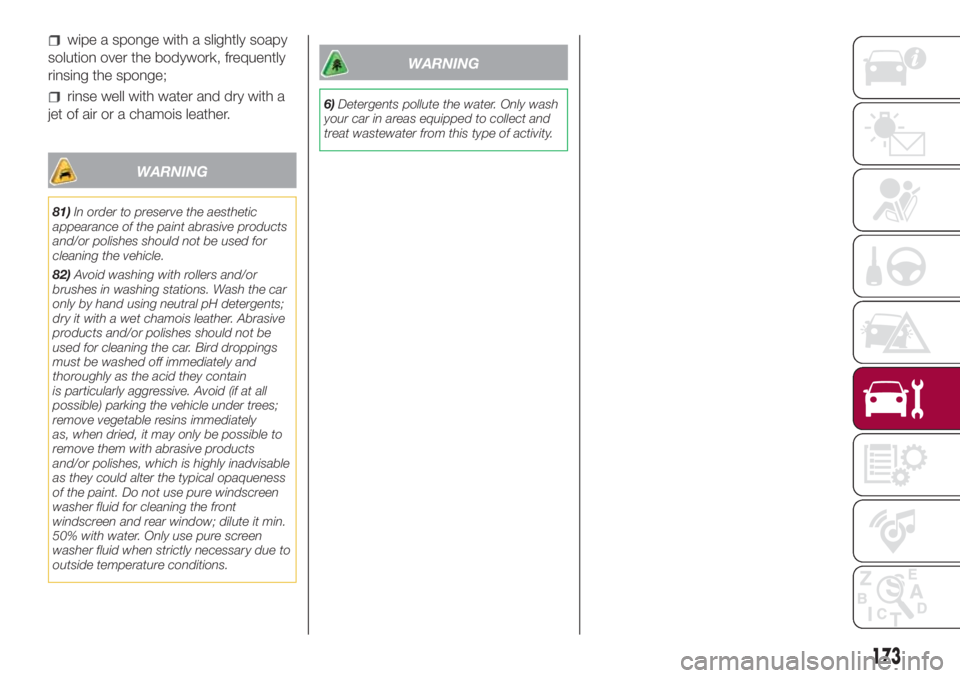

Washing the car

To correctly wash the car, follow these

instructions:

if the vehicle is washed remove the

aerial from the roof;

if high pressure jets or cleaners are

used to wash the vehicle, keep a

distance of at least 40 cm from the

bodywork to avoid damage or

alteration. Build up of water could

cause damage to the car in the long

term;

wash the bodywork using a low

pressure jet of water;

172

SERVICING AND CARE

Page 175 of 268

wipe a sponge with a slightly soapy

solution over the bodywork, frequently

rinsing the sponge;

rinse well with water and dry with a

jet of air or a chamois leather.

WARNING

81)In order to preserve the aesthetic

appearance of the paint abrasive products

and/or polishes should not be used for

cleaning the vehicle.

82)Avoid washing with rollers and/or

brushes in washing stations. Wash the car

only by hand using neutral pH detergents;

dry it with a wet chamois leather. Abrasive

products and/or polishes should not be

used for cleaning the car. Bird droppings

must be washed off immediately and

thoroughly as the acid they contain

is particularly aggressive. Avoid (if at all

possible) parking the vehicle under trees;

remove vegetable resins immediately

as, when dried, it may only be possible to

remove them with abrasive products

and/or polishes, which is highly inadvisable

as they could alter the typical opaqueness

of the paint. Do not use pure windscreen

washer fluid for cleaning the front

windscreen and rear window; dilute it min.

50% with water. Only use pure screen

washer fluid when strictly necessary due to

outside temperature conditions.

WARNING

6)Detergents pollute the water. Only wash

your car in areas equipped to collect and

treat wastewater from this type of activity.

173

Page 176 of 268

TECHNICAL DATA

Everything you may find useful for

understanding how your vehicle

is made and works is contained in this

chapter and illustrated with data, tables

and graphics. For the enthusiasts and

the technician, but also just for those

who want to know every detail of their

car.IDENTIFICATION DATA....................175

ENGINE ..........................................176

WHEELS .........................................180

DIMENSIONS ..................................188

PERFORMANCE .............................191

WEIGHTS........................................194

REFUELLING ..................................205

FLUIDS AND LUBRICANTS ............207

FUEL CONSUMPTION ....................210

CO2 EMISSIONS ...........................214

PRESCRIPTIONS FOR HANDLING

THE CAR AT THE END OF ITS

LIFE ................................................217

174

TECHNICAL DATA

Page 177 of 268

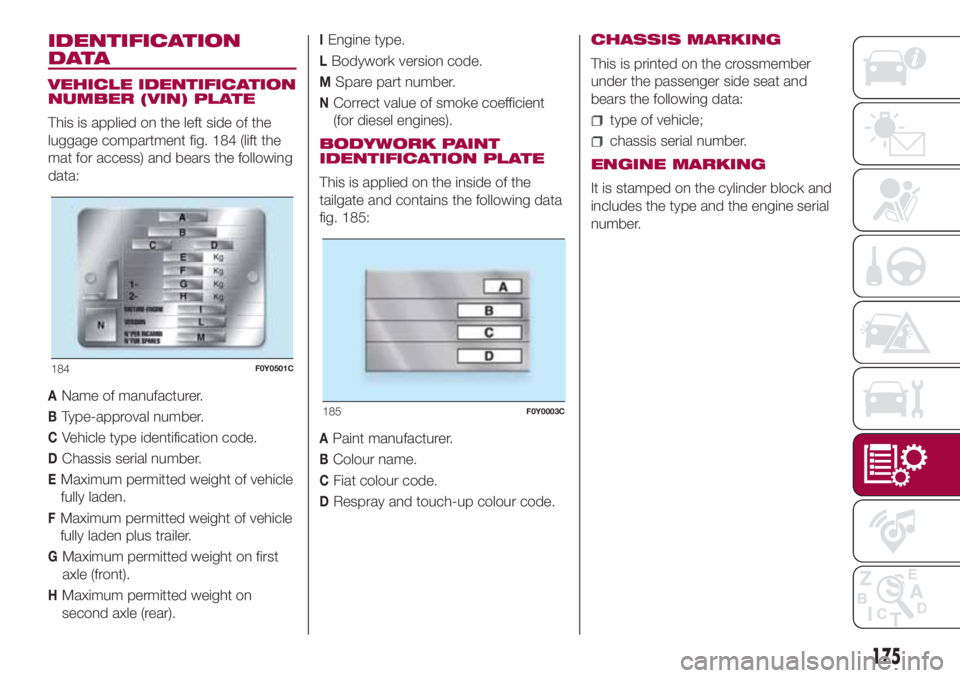

IDENTIFICATION

DATA

VEHICLE IDENTIFICATION

NUMBER (VIN) PLATE

This is applied on the left side of the

luggage compartment fig. 184 (lift the

mat for access) and bears the following

data:

AName of manufacturer.

BType-approval number.

CVehicle type identification code.

DChassis serial number.

EMaximum permitted weight of vehicle

fully laden.

FMaximum permitted weight of vehicle

fully laden plus trailer.

GMaximum permitted weight on first

axle (front).

HMaximum permitted weight on

second axle (rear).

IEngine type.

LBodywork version code.

MSpare part number.

NCorrect value of smoke coefficient

(for diesel engines).

BODYWORK PAINT

IDENTIFICATION PLATE

This is applied on the inside of the

tailgate and contains the following data

fig. 185:

APaint manufacturer.

BColour name.

CFiat colour code.

DRespray and touch-up colour code.CHASSIS MARKING

This is printed on the crossmember

under the passenger side seat and

bears the following data:

type of vehicle;

chassis serial number.

ENGINE MARKING

It is stamped on the cylinder block and

includes the type and the engine serial

number.

184F0Y0501C

185F0Y0003C

175

Page 178 of 268

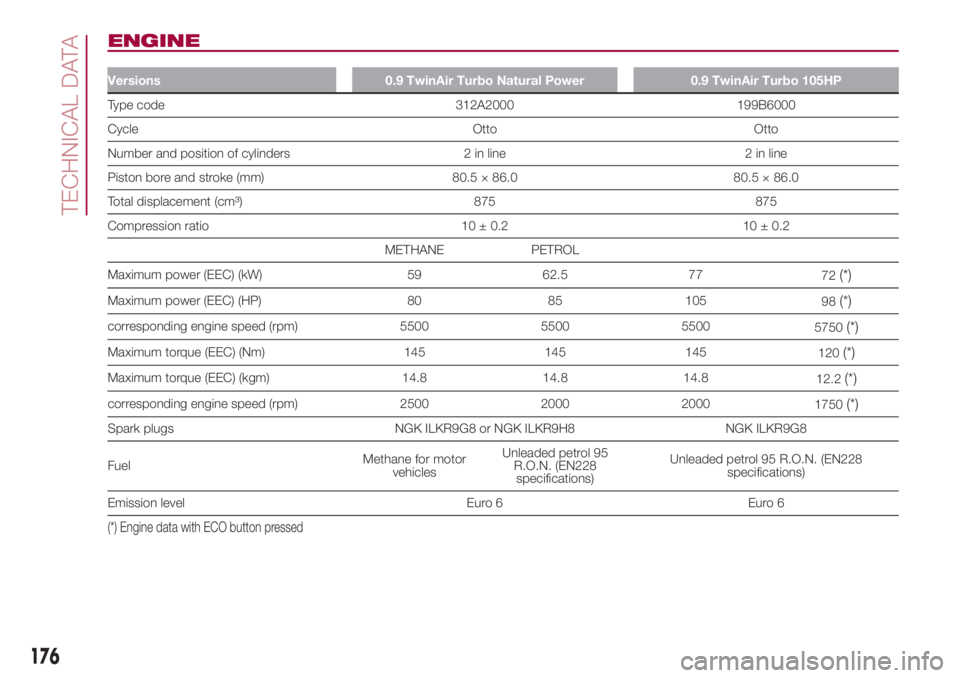

ENGINE

Versions 0.9 TwinAir Turbo Natural Power 0.9 TwinAir Turbo 105HP

Type code 312A2000 199B6000

Cycle Otto Otto

Number and position of cylinders 2 in line 2 in line

Piston bore and stroke (mm) 80.5 × 86.0 80.5 × 86.0

Total displacement (cm³) 875 875

Compression ratio 10 ± 0.2 10 ± 0.2

METHANE PETROL

Maximum power (EEC) (kW) 59 62.5 77

72

(*)

Maximum power (EEC) (HP) 80 85 105

98(*)

corresponding engine speed (rpm) 5500 5500 5500

5750(*)

Maximum torque (EEC) (Nm) 145 145 145

120(*)

Maximum torque (EEC) (kgm) 14.8 14.8 14.8

12.2(*)

corresponding engine speed (rpm) 2500 2000 2000

1750(*)

Spark plugs NGK ILKR9G8 or NGK ILKR9H8 NGK ILKR9G8

FuelMethane for motor

vehiclesUnleaded petrol 95

R.O.N. (EN228

specifications)Unleaded petrol 95 R.O.N. (EN228

specifications)

Emission level Euro 6 Euro 6

(*) Engine data with ECO button pressed

176

TECHNICAL DATA

Page 179 of 268

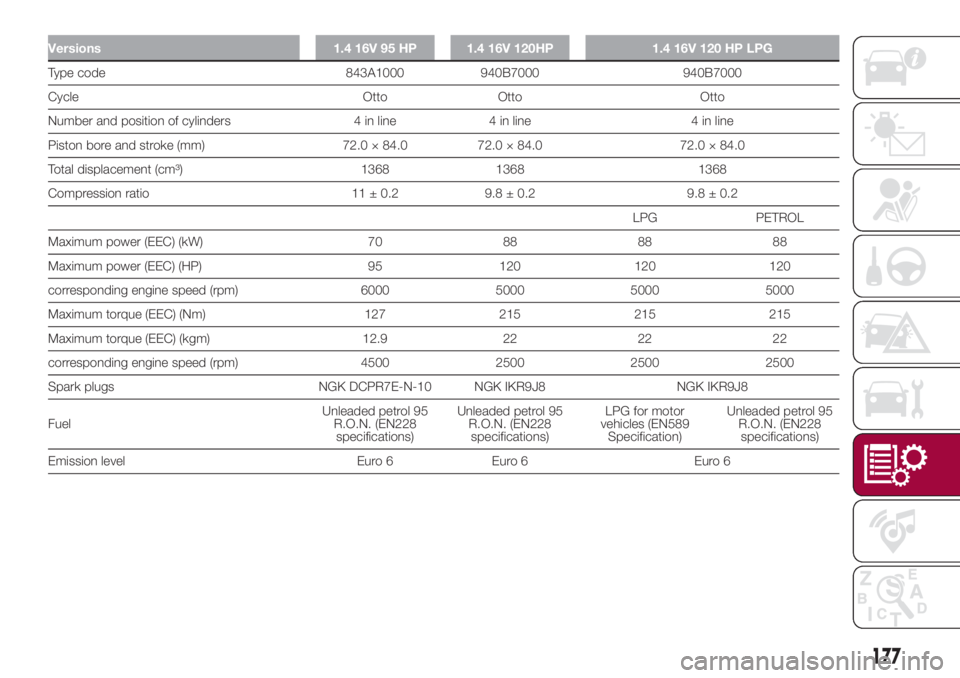

Versions 1.4 16V 95 HP 1.4 16V 120HP 1.4 16V 120 HP LPG

Type code 843A1000 940B7000 940B7000

Cycle Otto Otto Otto

Number and position of cylinders 4 in line 4 in line 4 in line

Piston bore and stroke (mm) 72.0 × 84.0 72.0 × 84.0 72.0 × 84.0

Total displacement (cm³) 1368 1368 1368

Compression ratio 11 ± 0.2 9.8 ± 0.2 9.8 ± 0.2

LPG PETROL

Maximum power (EEC) (kW) 70 88 88 88

Maximum power (EEC) (HP) 95 120 120 120

corresponding engine speed (rpm) 6000 5000 5000 5000

Maximum torque (EEC) (Nm) 127 215 215 215

Maximum torque (EEC) (kgm) 12.9 22 22 22

corresponding engine speed (rpm) 4500 2500 2500 2500

Spark plugs NGK DCPR7E-N-10 NGK IKR9J8 NGK IKR9J8

FuelUnleaded petrol 95

R.O.N. (EN228

specifications)Unleaded petrol 95

R.O.N. (EN228

specifications)LPG for motor

vehicles (EN589

Specification)Unleaded petrol 95

R.O.N. (EN228

specifications)

Emission level Euro 6 Euro 6 Euro 6

177

Page 180 of 268

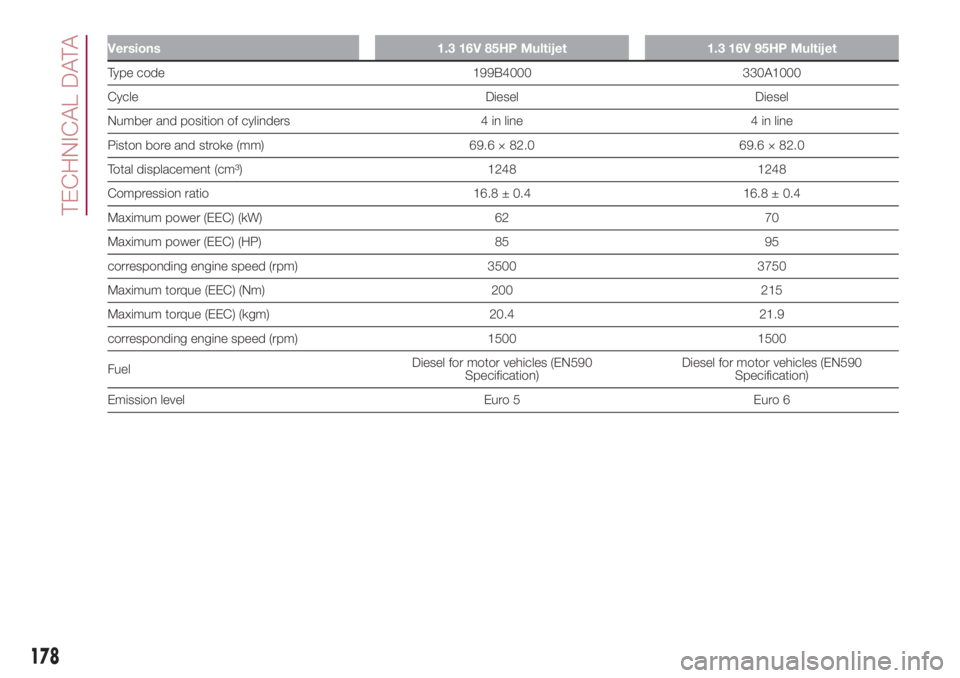

Versions 1.3 16V 85HP Multijet 1.3 16V 95HP Multijet

Type code 199B4000 330A1000

Cycle Diesel Diesel

Number and position of cylinders 4 in line 4 in line

Piston bore and stroke (mm) 69.6 × 82.0 69.6 × 82.0

Total displacement (cm³) 1248 1248

Compression ratio 16.8 ± 0.4 16.8 ± 0.4

Maximum power (EEC) (kW) 62 70

Maximum power (EEC) (HP) 85 95

corresponding engine speed (rpm) 3500 3750

Maximum torque (EEC) (Nm) 200 215

Maximum torque (EEC) (kgm) 20.4 21.9

corresponding engine speed (rpm) 1500 1500

FuelDiesel for motor vehicles (EN590

Specification)Diesel for motor vehicles (EN590

Specification)

Emission level Euro 5 Euro 6

178

TECHNICAL DATA