clock FIAT FULLBACK 2017 Owner handbook (in English)

[x] Cancel search | Manufacturer: FIAT, Model Year: 2017, Model line: FULLBACK, Model: FIAT FULLBACK 2017Pages: 312, PDF Size: 12.31 MB

Page 60 of 312

Heater/Manual air

conditioning

The heater/air conditioning can only be

used while the engine is running.

2)

22)

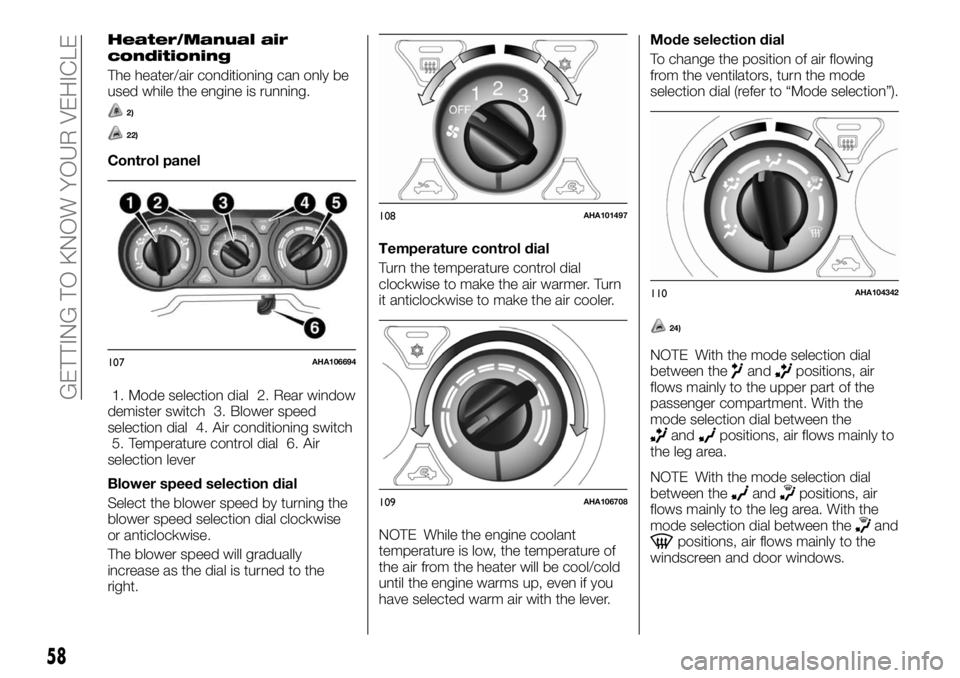

Control panel

1. Mode selection dial 2. Rear window

demister switch 3. Blower speed

selection dial 4. Air conditioning switch

5. Temperature control dial 6. Air

selection lever

Blower speed selection dial

Select the blower speed by turning the

blower speed selection dial clockwise

or anticlockwise.

The blower speed will gradually

increase as the dial is turned to the

right.Temperature control dial

Turn the temperature control dial

clockwise to make the air warmer. Turn

it anticlockwise to make the air cooler.

NOTE While the engine coolant

temperature is low, the temperature of

the air from the heater will be cool/cold

until the engine warms up, even if you

have selected warm air with the lever.Mode selection dial

To change the position of air flowing

from the ventilators, turn the mode

selection dial (refer to “Mode selection”).

24)

NOTE With the mode selection dial

between theandpositions, air

flows mainly to the upper part of the

passenger compartment. With the

mode selection dial between the

andpositions, air flows mainly to

the leg area.

NOTE With the mode selection dial

between the

andpositions, air

flows mainly to the leg area. With the

mode selection dial between the

andpositions, air flows mainly to the

windscreen and door windows.

107AHA106694

108AHA101497

109AHA106708

110AHA104342

58

GETTING TO KNOW YOUR VEHICLE

Page 82 of 312

Something is wrong with the cigarette

lighter if it does not pop back out within

approximately 30 seconds of being

pushed in. Pull it out and have the

problem corrected at Fiat Dealership.

When the cigarette lighter socket is

used as a power source for an electric

appliance, be sure that the electric

appliance operates at 12 V and has an

electric capacity of 120 W or less. In

addition, long use of the electric

appliance without running the engine

may run down the battery.

ACCESSORY SOCKET

(where provided)

The accessory socket can be used

while the ignition switch or the

operation mode is in ON or ACC. To

use a plug-in type accessory, open the

lid, and insert the plug in the accessory

socket.

36) 37)

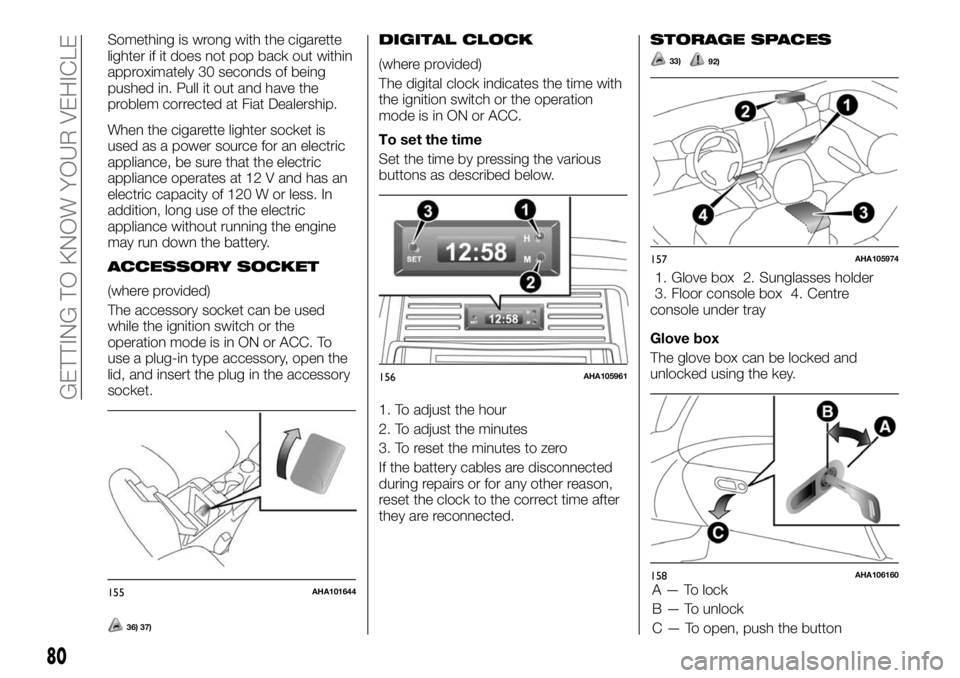

DIGITAL CLOCK

(where provided)

The digital clock indicates the time with

the ignition switch or the operation

mode is in ON or ACC.

To set the time

Set the time by pressing the various

buttons as described below.

1. To adjust the hour

2. To adjust the minutes

3. To reset the minutes to zero

If the battery cables are disconnected

during repairs or for any other reason,

reset the clock to the correct time after

they are reconnected.

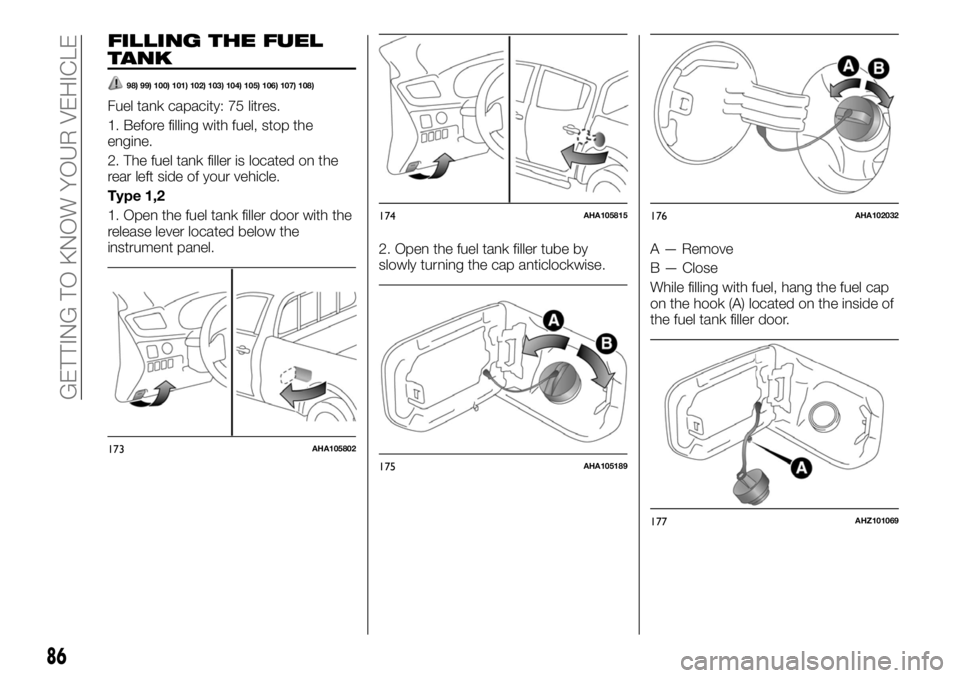

STORAGE SPACES

33)92)

1. Glove box 2. Sunglasses holder

3. Floor console box 4. Centre

console under tray

Glove box

The glove box can be locked and

unlocked using the key.

155AHA101644

156AHA105961

157AHA105974

158AHA106160

80

GETTING TO KNOW YOUR VEHICLE

A — To lock

B — To unlock

C — To open, push the button

Page 88 of 312

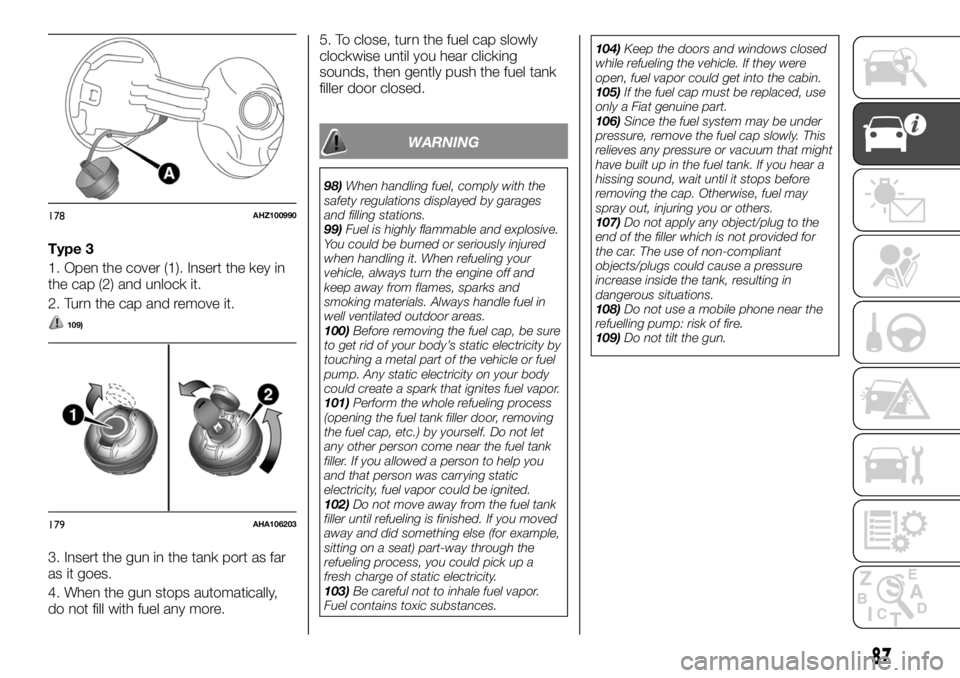

FILLING THE FUEL

TANK

98) 99) 100) 101) 102) 103) 104) 105) 106) 107) 108)

Fuel tank capacity: 75 litres.

1. Before filling with fuel, stop the

engine.

2. The fuel tank filler is located on the

rear left side of your vehicle.

Type 1,2

1. Open the fuel tank filler door with the

release lever located below the

instrument panel.

2. Open the fuel tank filler tube by

slowly turning the cap anticlockwise.A — Remove

B — Close

While filling with fuel, hang the fuel cap

on the hook (A) located on the inside of

the fuel tank filler door.

173AHA105802

174AHA105815

175AHA105189

176AHA102032

177AHZ101069

86

GETTING TO KNOW YOUR VEHICLE

Page 89 of 312

Type 3

1. Open the cover (1). Insert the key in

the cap (2) and unlock it.

2. Turn the cap and remove it.

109)

3. Insert the gun in the tank port as far

as it goes.

4. When the gun stops automatically,

do not fill with fuel any more.5. To close, turn the fuel cap slowly

clockwise until you hear clicking

sounds, then gently push the fuel tank

filler door closed.

WARNING

98)When handling fuel, comply with the

safety regulations displayed by garages

and filling stations.

99)Fuel is highly flammable and explosive.

You could be burned or seriously injured

when handling it. When refueling your

vehicle, always turn the engine off and

keep away from flames, sparks and

smoking materials. Always handle fuel in

well ventilated outdoor areas.

100)Before removing the fuel cap, be sure

to get rid of your body’s static electricity by

touching a metal part of the vehicle or fuel

pump. Any static electricity on your body

could create a spark that ignites fuel vapor.

101)Perform the whole refueling process

(opening the fuel tank filler door, removing

the fuel cap, etc.) by yourself. Do not let

any other person come near the fuel tank

filler. If you allowed a person to help you

and that person was carrying static

electricity, fuel vapor could be ignited.

102)Do not move away from the fuel tank

filler until refueling is finished. If you moved

away and did something else (for example,

sitting on a seat) part-way through the

refueling process, you could pick up a

fresh charge of static electricity.

103)Be careful not to inhale fuel vapor.

Fuel contains toxic substances.104)Keep the doors and windows closed

while refueling the vehicle. If they were

open, fuel vapor could get into the cabin.

105)If the fuel cap must be replaced, use

only a Fiat genuine part.

106)Since the fuel system may be under

pressure, remove the fuel cap slowly. This

relieves any pressure or vacuum that might

have built up in the fuel tank. If you hear a

hissing sound, wait until it stops before

removing the cap. Otherwise, fuel may

spray out, injuring you or others.

107)Do not apply any object/plug to the

end of the filler which is not provided for

the car. The use of non-compliant

objects/plugs could cause a pressure

increase inside the tank, resulting in

dangerous situations.

108)Do not use a mobile phone near the

refuelling pump: risk of fire.

109)Do not tilt the gun.

178AHZ100990

179AHA106203

87

Page 219 of 312

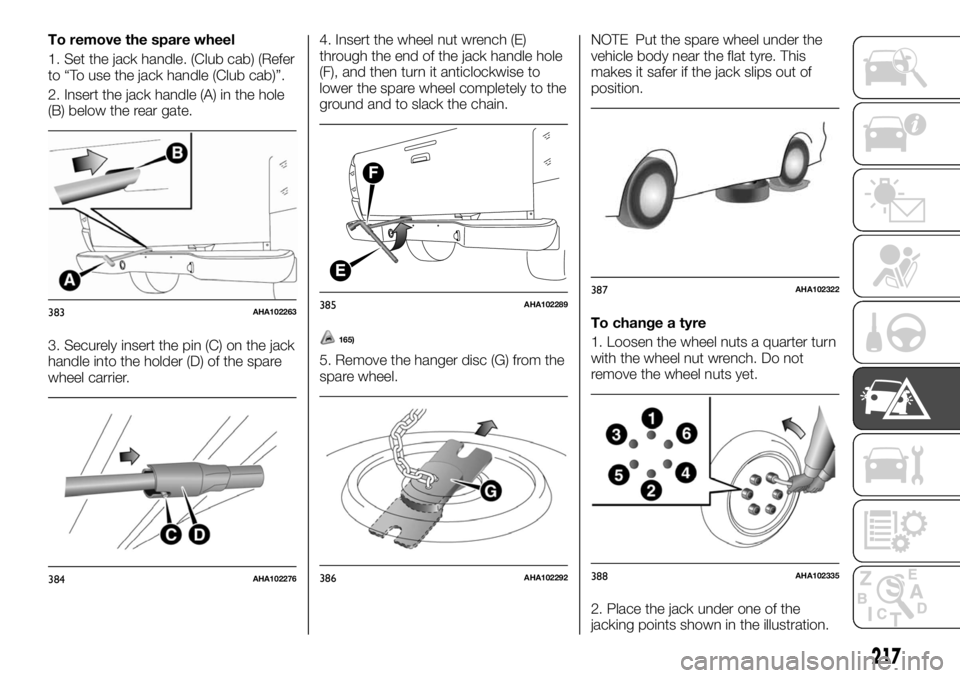

To remove the spare wheel

1. Set the jack handle. (Club cab) (Refer

to “To use the jack handle (Club cab)”.

2. Insert the jack handle (A) in the hole

(B) below the rear gate.

3. Securely insert the pin (C) on the jack

handle into the holder (D) of the spare

wheel carrier.4. Insert the wheel nut wrench (E)

through the end of the jack handle hole

(F), and then turn it anticlockwise to

lower the spare wheel completely to the

ground and to slack the chain.

165)

5. Remove the hanger disc (G) from the

spare wheel.NOTE Put the spare wheel under the

vehicle body near the flat tyre. This

makes it safer if the jack slips out of

position.

To change a tyre

1. Loosen the wheel nuts a quarter turn

with the wheel nut wrench. Do not

remove the wheel nuts yet.

2. Place the jack under one of the

jacking points shown in the illustration.

383AHA102263

384AHA102276

385AHA102289

386AHA102292

387AHA102322

388AHA102335

217

Page 220 of 312

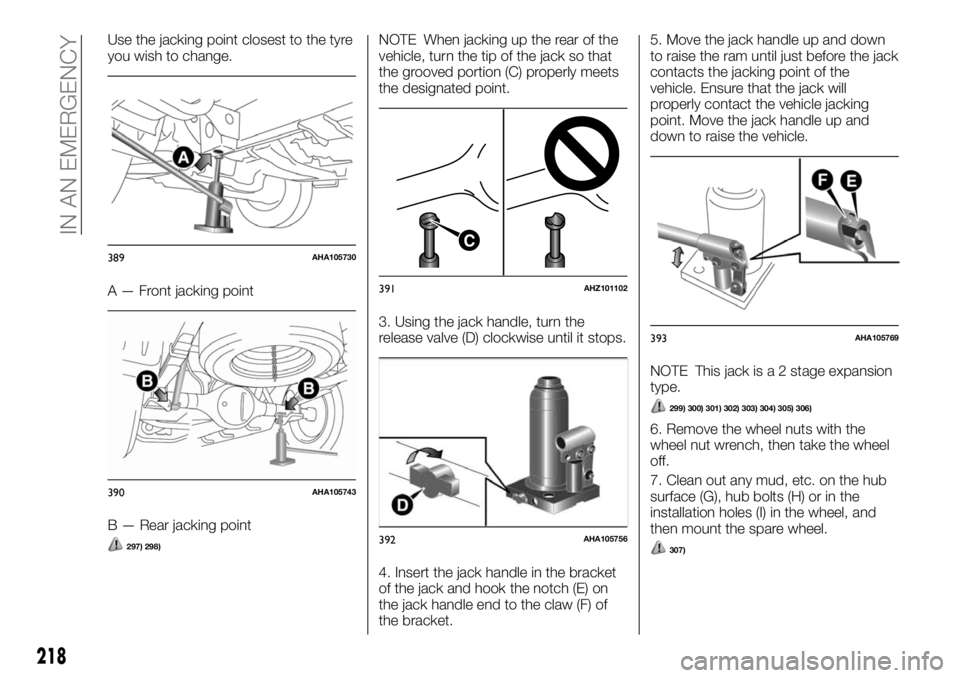

Use the jacking point closest to the tyre

you wish to change.

A — Front jacking point

B — Rear jacking point

297) 298)

NOTE When jacking up the rear of the

vehicle, turn the tip of the jack so that

the grooved portion (C) properly meets

the designated point.

3. Using the jack handle, turn the

release valve (D) clockwise until it stops.

4. Insert the jack handle in the bracket

of the jack and hook the notch (E) on

the jack handle end to the claw (F) of

the bracket.5. Move the jack handle up and down

to raise the ram until just before the jack

contacts the jacking point of the

vehicle. Ensure that the jack will

properly contact the vehicle jacking

point. Move the jack handle up and

down to raise the vehicle.

NOTE This jack is a 2 stage expansion

type.

299) 300) 301) 302) 303) 304) 305) 306)

6. Remove the wheel nuts with the

wheel nut wrench, then take the wheel

off.

7. Clean out any mud, etc. on the hub

surface (G), hub bolts (H) or in the

installation holes (I) in the wheel, and

then mount the spare wheel.

307)

389AHA105730

390AHA105743

C

391AHZ101102

392AHA105756

393AHA105769

218

IN AN EMERGENCY

Page 221 of 312

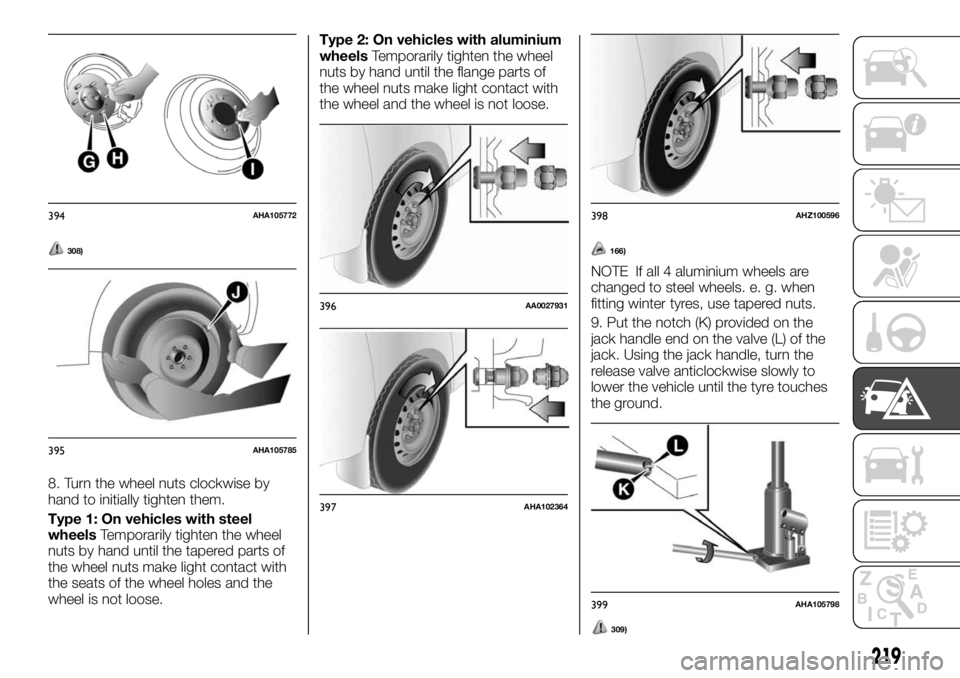

308)

8. Turn the wheel nuts clockwise by

hand to initially tighten them.

Type 1: On vehicles with steel

wheelsTemporarily tighten the wheel

nuts by hand until the tapered parts of

the wheel nuts make light contact with

the seats of the wheel holes and the

wheel is not loose.Type 2: On vehicles with aluminium

wheelsTemporarily tighten the wheel

nuts by hand until the flange parts of

the wheel nuts make light contact with

the wheel and the wheel is not loose.

166)

NOTE If all 4 aluminium wheels are

changed to steel wheels. e. g. when

fitting winter tyres, use tapered nuts.

9. Put the notch (K) provided on the

jack handle end on the valve (L) of the

jack. Using the jack handle, turn the

release valve anticlockwise slowly to

lower the vehicle until the tyre touches

the ground.

394AHA105772

395AHA105785

396AA0027931

397AHA102364

398AHZ100596

399AHA105798

219

309)

Page 222 of 312

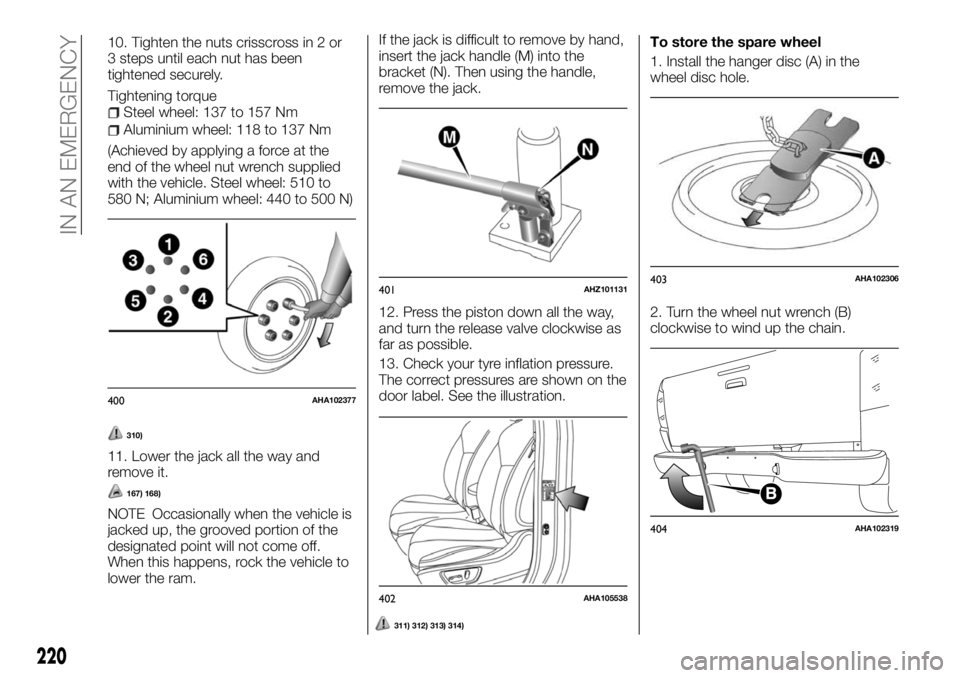

10. Tighten the nuts crisscross in 2 or

3 steps until each nut has been

tightened securely.

Tightening torque

Steel wheel: 137 to 157 Nm

Aluminium wheel: 118 to 137 Nm

(Achieved by applying a force at the

end of the wheel nut wrench supplied

with the vehicle. Steel wheel: 510 to

580 N; Aluminium wheel: 440 to 500 N)

310)

11. Lower the jack all the way and

remove it.

167) 168)

NOTE Occasionally when the vehicle is

jacked up, the grooved portion of the

designated point will not come off.

When this happens, rock the vehicle to

lower the ram.If the jack is difficult to remove by hand,

insert the jack handle (M) into the

bracket (N). Then using the handle,

remove the jack.

12. Press the piston down all the way,

and turn the release valve clockwise as

far as possible.

13. Check your tyre inflation pressure.

The correct pressures are shown on the

door label. See the illustration.

311) 312) 313) 314)

To store the spare wheel

1. Install the hanger disc (A) in the

wheel disc hole.

2. Turn the wheel nut wrench (B)

clockwise to wind up the chain.

400AHA102377

401AHZ101131

402AHA105538

403AHA102306

404AHA102319

220

IN AN EMERGENCY

Page 224 of 312

306)Do not turn the raised wheel. The

tyres still on the ground could turn and

make your vehicle fall off the jack.

307)Handle the wheel carefully when

changing the tyre, to avoid scratching the

wheel surface.

308)Mount the spare wheel with the valve

stem (J) facing outboard. If you cannot see

the valve stem (J), you have installed the

wheel backwards. Operating the vehicle

with the spare wheel installed backwards

can cause vehicle damage and result in an

accident.

309)Be sure to open the release valve

slowly. If it is opened quickly, the vehicle will

drop abruptly and the jack may come out

of position, causing a serious accident.

310)Never use your foot or a pipe

extension for extra force in the wheel nut

wrench. If you do so, you will tighten the

nut too much.

311)The tyre pressure should be

periodically checked and maintained at the

specified pressure while the tyre is stowed.

312)After changing the tyre and driving the

vehicle about 1,000 km, retighten the

wheel nuts to make sure that they have not

come loose.

313)If the steering wheel vibrates when

driving after changing the tyre, we

recommend you to have the tyres checked

for balance.

314)Do not mix one type of tyre with

another or use a different size from the one

listed. This would cause early wear and

poor handling.315)The spare wheel should always be

securely in position. If a flat tyre is

changed, put the flat tyre in the spare

wheel mounting position with the wheel

outer surface upward, and use the wheel

nut wrench to secure it firmly.

316)Never tamper with the inflation valve.

Never introduce tools of any kind between

rim and tyre. Check tyre and spare wheel

pressure regularly, referring to the values

shown in the "Technical specifications"

section.

317)The moving components of the jack

(screw and joints) can also cause injuries:

do not touch them. If you come into

contact with lubricating grease, clean

yourself thoroughly.

IMPORTANT

163)Avoid using different size tyres from

the one listed and the combined use of

different types of tyres, as this can affect

driving safety.

164)Even if a wheel has the same rim size

and offset as the specified type of wheel,

its shape may prevent it from being fitted

correctly. Consult an authorised Fiat

Dealership before using wheels that you

have.

165)When installing or removing the spare

wheel, please observe the followings. If you

do not follow them, it could result in break

the spare wheel carrier. Do not use the

power tool. Use the wheel nut wrench

stowed on the vehicle. Do not apply a force

of 400 N or more at the end of the wheel

nut wrench.166)Never apply oil to either the wheel

bolts or the nuts or they will tighten too

much.

167)If the release valve is loosened too

much (2 or more turns) in the anticlockwise

direction, the jack’s oil will leak and the jack

cannot be used.

168)Close the release valve slowly when

lowering the vehicle, or the valve may be

damaged.

222

IN AN EMERGENCY

Page 239 of 312

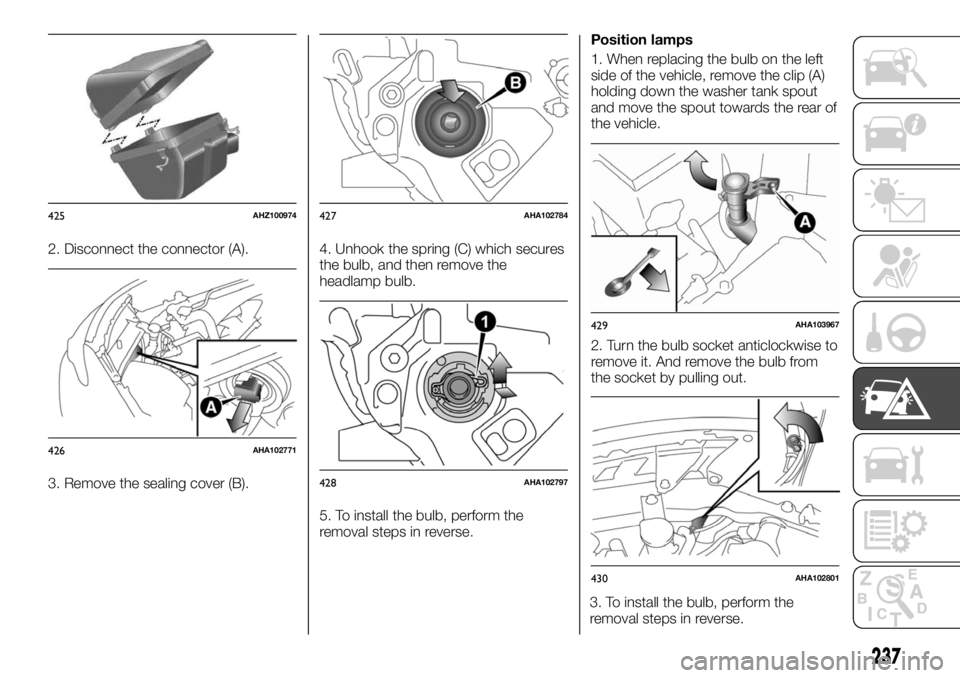

2. Disconnect the connector (A).

3. Remove the sealing cover (B).4. Unhook the spring (C) which secures

the bulb, and then remove the

headlamp bulb.

5. To install the bulb, perform the

removal steps in reverse.Position lamps

1. When replacing the bulb on the left

side of the vehicle, remove the clip (A)

holding down the washer tank spout

and move the spout towards the rear of

the vehicle.

2. Turn the bulb socket anticlockwise to

remove it. And remove the bulb from

the socket by pulling out.

425AHZ100974

426AHA102771

427AHA102784

428AHA102797

429AHA103967

430AHA102801

237

3. To install the bulb, perform the

removal steps in reverse.