Heat FIAT MAREA 2000 1.G User Guide

[x] Cancel search | Manufacturer: FIAT, Model Year: 2000, Model line: MAREA, Model: FIAT MAREA 2000 1.GPages: 330

Page 84 of 330

Marea- Marea Weekend 9

2000 range ©

Engine

Fuel feed system

10.

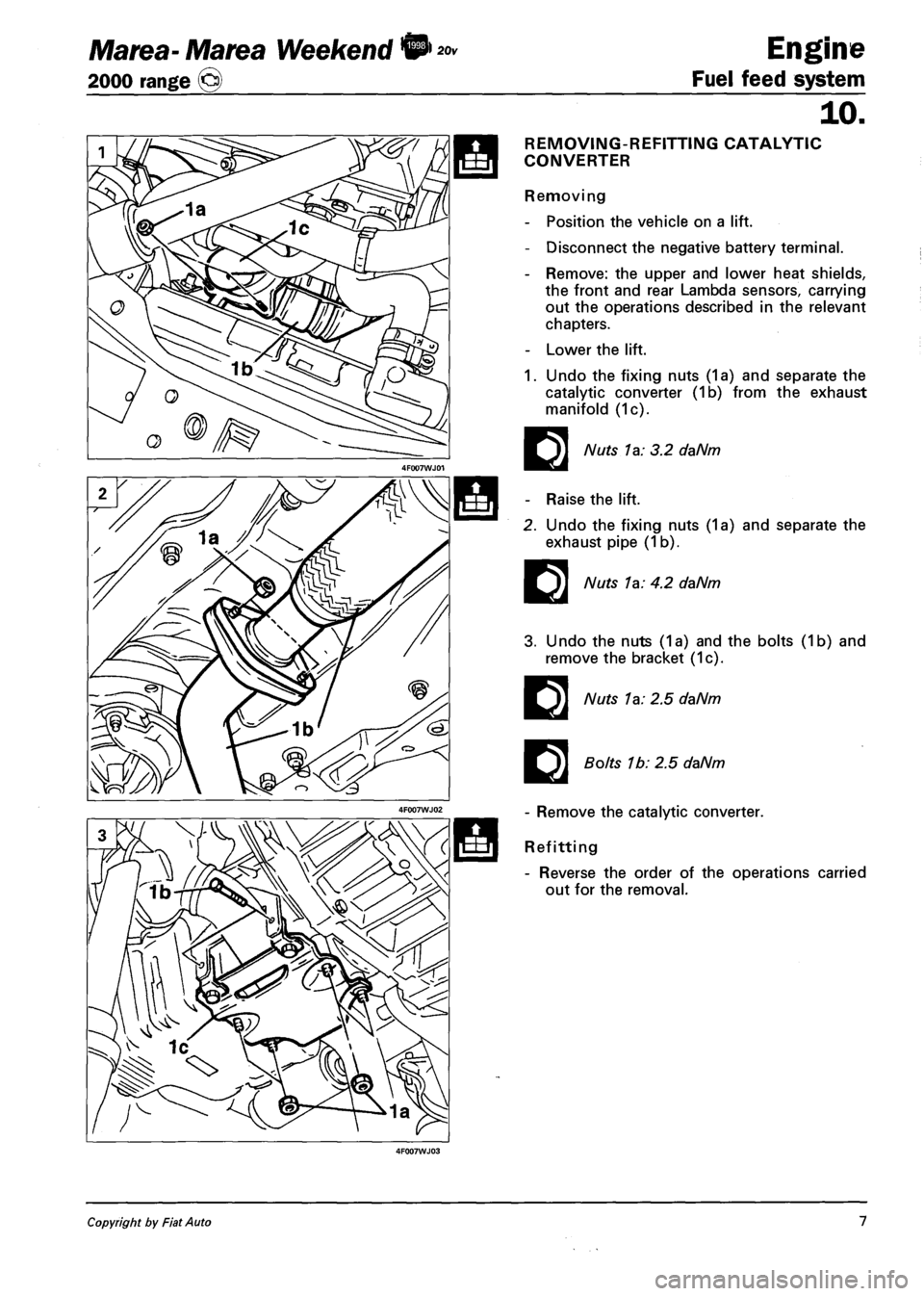

REMOVING-REFITTING CATALYTIC

CONVERTER

Removing

- Position the vehicle on a lift.

- Disconnect the negative battery terminal.

- Remove: the upper and lower heat shields,

the front and rear Lambda sensors, carrying

out the operations described in the relevant

chapters.

- Lower the lift.

1. Undo the fixing nuts (1a) and separate the

catalytic converter (1b) from the exhaust

manifold (1c).

E

Nuts la: 3.2 daNm

- Raise the lift.

2. Undo the fixing nuts (1a) and separate the

exhaust pipe (1 b).

EI

Nuts 1a: 4.2 daNm

3. Undo the nuts (1a) and the bolts (1b) and

remove the bracket (1c).

E

E

Nuts 1a: 2.5 daNm

Bolts 1b: 2.5 daNm

- Remove the catalytic converter.

Refitting

- Reverse the order of the operations carried

out for the removal.

Copyright by Fiat Auto 7

Page 86 of 330

Marea- Marea Weekend 9 \) JTD

2000 range O

Engine

Index

FUEL SYSTEM

- Introduction

- System management strategies

- Fuel system functional diagram

- Diagram showing information ente

ring/leaving the control unit and

sensors/actuators

INJECTION SYSTEM WIRING DIA

GRAM

- Injection electronic control unit

- Rpm sensor

- Timing sensor

- Air flow meter

- Injectors

- Engine coolant temperature sensor

- Fuel temperature sensor

- Fuel pressure sensor

- Heater plugs control unit

- Accelerator pedal potentiometer

- Brake pedal switch

- Clutch pedal switch

- Excess pressure sensor

- Atmospheric pressure sensor

page

1

1

1

2

8

10

12

13

13

14

15

15

15

16

16

17

17

17

17

THROTTLE CASING

- Removing-refitting

E.G.R. VALVE

- Removing-refitting

E.G.R. VALVE SELF-ADJUSTMENT

MOTOR

- Removing-refitting

E.G.R. VALVE HEAT EXCHANGER

- Removing-refitting

SOLENOID VALVE ON VACUUM

RESERVOIR FOR THROTTLE CA

SING PNEUMATIC VALVE

- Removing-refitting

VACUUM RESERVOIR

- Removing-refitting

10.

page

30

31

32

32

34

34

FUEL SUPPLY CIRCUIT 18

- Immersed (auxiliary) pump and fuel

gauge assembly 19

- Fuel filter 19

- Pressure pump 20

- Fuel pressure regulator 20

- Multifunction valve 21

- Supply manifold (rail) 21

- Inertia safety switch 22

AIR SUPPLY CIRCUIT 23

- Throttle case 24

- Turbocharger 25

SUPERCHARGING PRESSURE

CONTROL SOLENOID VALVE

- Removing-refitting 35

FUEL FILTER

- Removing-refitting 35

PRESSURE REGULATOR

- Removing-refitting 36

EMISSION CONTROL DEVICES 27

- Oxidizing catalytic converter 27

- Exhaust gas recirculation circuit

(EGR) 27

- Recirculation circuit for crankcase

vapours (blow-by) 29

Copyright by Fiat Auto VI 01 Cancels anil replaces

Page 88 of 330

Engine

Fuel feed system

Marea- Marea Weekend © ™

2000 range ©

10.

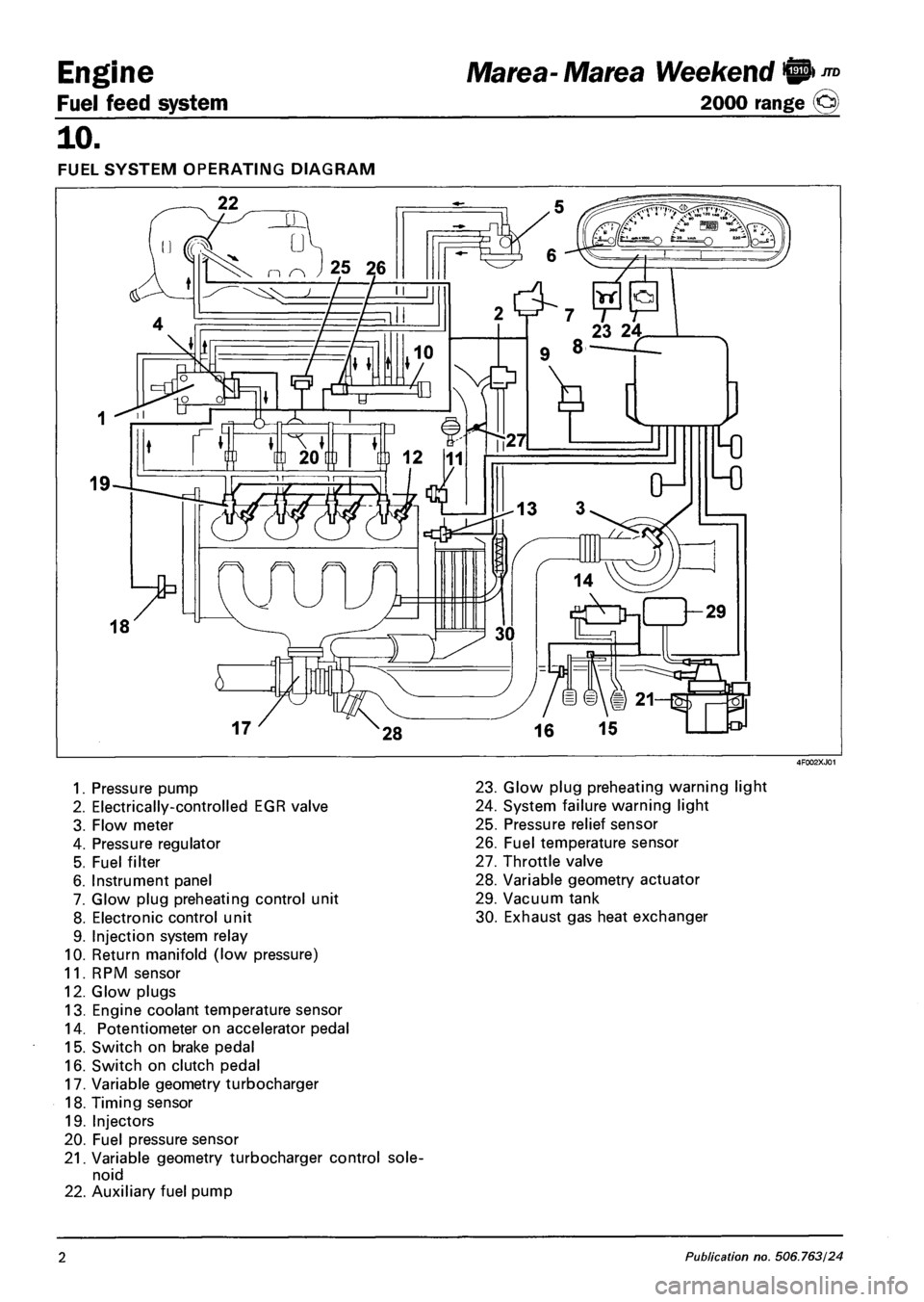

FUEL SYSTEM OPERATING DIAGRAM

1. Pressure pump

2. Electrically-controlled EGR valve

3. Flow meter

4. Pressure regulator

5. Fuel filter

6. Instrument panel

7. Glow plug preheating control unit

8. Electronic control unit

9. Injection system relay

10. Return manifold (low pressure)

11. RPM sensor

12. Glow plugs

13. Engine coolant temperature sensor

14. Potentiometer on accelerator pedal

15. Switch on brake pedal

16. Switch on clutch pedal

17. Variable geometry turbocharger

18. Timing sensor

19. Injectors

20. Fuel pressure sensor

21. Variable geometry turbocharger control sole

noid

22. Auxiliary fuel pump

23. Glow plug preheating warning light

24. System failure warning light

25. Pressure relief sensor

26. Fuel temperature sensor

27. Throttle valve

28. Variable geometry actuator

29. Vacuum tank

30. Exhaust gas heat exchanger

2 Publication no. 506.763/24

Page 90 of 330

Fuel feed system

Engine Marea- Marea Weekend 9 ™

2000 range (Q)

10.

Control of idle speed

On the basis of signals from the rpm sensor and engine coolant temperature sensor, the injection control

unit controls the pressure governor and alters the injector control times to maintain idle speed stable at all

times.

Under certain conditions, the idle speed control unit also considers battery voltage.

Control of maximum speed limitation

According to rpm level, the injection control unit limits maximum speed by means of two types of inter

vention:

- as maximum speed approaches, it reduces the amount of fuel injected to reduce line pressure;

- when maximum speed is exceeded, it inhibits operation of the auxiliary pump and injectors.

Control of maximum torque limitation

On the basis of rpm level, the injection control unit computes limit torque and maximum permitted fume

index parameters on the basis of predefined, stored maps.

It then corrects the above parameters using engine coolant temperature and car speed data. The resulting

values are then used to modulate the amount of fuel to be injected by adjusting the pressure regulator and

injectors.

Control of fuel temperature

The injection control uint is kept constantly informed of fuel temperature by a sensor on the return mani

fold.

If fuel temperature exceeds a set value (about 110 °C), the control unit reduces line pressure by adjusting

the pressure governor, leaving injection times unaltered.

Control of coolant temperature

The injection control unit is constantly informed of coolant temperature by a sensor on the thermostat.

If engine coolant temperature or air conditioning fluid pressure exceeds certain levels, the control unit

performs the following actions:

- It reduces the amount of fuel injected by adjusting the pressure governor and injectors (power reduc

tion);

- it controls the engine radiator cooling fan.

Control of glow plugs

The injection control unit controls operation of the glow plug preheating control unit to bring the tem

perature in the combution chambers up to levels that promote fuel self-ignition and thus make start-up

easier.

The control unit controls the operation of the glow plug control unit for a certain time both before (pre

heating) and after (postheating) engine start-up and also controls activation of the warning light on the

control panel.

Preheating, postheating and glow plug warning light activation times vary according to engine coolant

temperature.

4 Publication no. 506.763/24

Page 93 of 330

Marea- Marea Weekend 9 ™

2000 range ©

Engine

Fuel feed system

10.

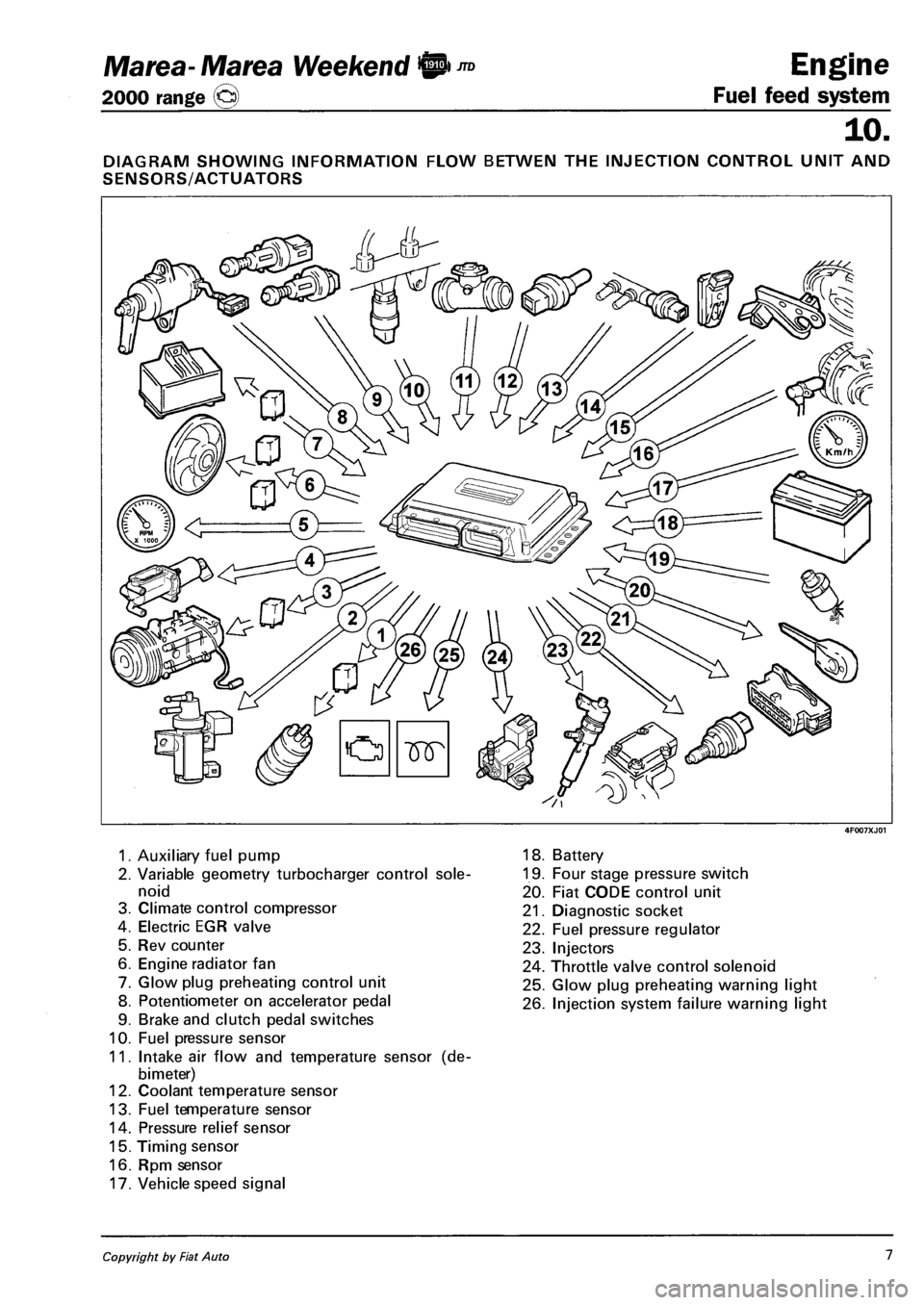

DIAGRAM SHOWING INFORMATION FLOW BETWEN THE INJECTION CONTROL UNIT AND

SENSORS/ACTUATORS

1. Auxiliary fuel pump

2. Variable geometry turbocharger control sole

noid

3. Climate control compressor

4. Electric EGR valve

5. Rev counter

6. Engine radiator fan

7. Glow plug preheating control unit

8. Potentiometer on accelerator pedal

9. Brake and clutch pedal switches

10. Fuel pressure sensor

11. Intake air flow and temperature sensor (de-

bimeter)

12. Coolant temperature sensor

13. Fuel temperature sensor

14. Pressure relief sensor

15. Timing sensor

16. Rpm sensor

17. Vehicle speed signal

18. Battery

19. Four stage pressure switch

20. Fiat CODE control unit

21. Diagnostic socket

22. Fuel pressure regulator

23. Injectors

24. Throttle valve control solenoid

25. Glow plug preheating warning light

26. Injection system failure warning light

Copyright by Fiat Auto 1

Page 95 of 330

Marea- Marea Weekend 9 ™

2000 range ©) Fuel feed system

Engine

10.

Compents of injection system wiring diagram

1. Vehicle speepd

2. Rev counter

3. Engine radiator fan low speed relay

4. Radiator fan high speed activation relay

5. Potentiometer on accelerator pedal

6. Timing sensor

7. Fuel pressure sensor

8. EGR system modulator solenoid

9. Fuel pressure regulator

10. Glow plug preheating warning light on control panel

11. Injection system failure warning light

12. Air conditioning system relay

13. Coolant temperature sensor

14. Rpm sensor

15. Fuel temperature sensor

16. Diagnostic socket

17. Fiat CODE control unit

18. Four stage pressure switch

19. Injection electronic control unit

20. Pressure relief sensor

21. 7.5A fuse protecting electronic injection system ( + 15 power supply from ignition switch)

22. 7.5A fuse protecting electronic injection system ( + 30 power supply from ignition switch)

23. Main injection system relay

24. 30A fuse protecting injection system

25. Auxiliary fuel pump relay

26. Glow plug preheating control unit

27. Intake air flow and temperature sensor (debimeter)

28. Brake pedal switch

29. Clutch pedal switch

30. Ignition switch

31. Battery

32. Inertia switch

33. Auxiliary fuel pump (submerged in tank)

34. 60A fuse protecting glow plug control unit

35. Cylinder no. 1 glow plug

36. Cylinder no. 2 glow plug

37. Cylinder no. 3 glow plug

38. Cylinder no. 4 glow plug

39. Cylinder no. 1 injector

40. Cylinder no. 2 injector

41. Cylinder no. 3 injector

42. Cylinder no. 4 injector

43. Throttle valve control solenoid

44. Variable geometry turbocharger control solenoid

45. Diesel filter heater relay

Copyright by Fiat Auto 9

Page 97 of 330

Ma tea- Ma tea Weekend !@ ™

2000 range ©

Engine

Fuel feed system

10.

37 Not connected

38 Not connected

39 Not connected

40 Not connected

41 Not connected

42 Not connected

43 Not connected

44 Not connected

45 Not connected

46 Not connected

47 Engine rpm signal output

48 Diagnostic line k

49 Vehicle speed signal input

50 Not connected

51 Activation signal from 4-stage pressure switch

52 Activation signal from 3-stage pressure switch

53 Not connected

54 Not connected

55 Not connected

56 Not connected

57 Not connected

58 Key ON signal

59 Brake switch

60 Air conditioner activation request

61 Clutch switch

62 Glow plug diagnosis

63 Not connected

64 Not connected

65 Not connected

66 Not connected

67 Not connected

68 Not connected

69 Not connected

70 Not connected

71 Not connected

72 Not connected

73 Not connected

74 Not connected

75 Not connected

76 Accelerator pedal 1 earth

77 Accelerator pedal 1 signal

78 Accelerator pedal 1 power supply

79 Accelerator pedal 2 earth

80 Accelerator pedal 2 signal

81 Accelerator pedal 2 power supply

82 Diesel temperature sensor (pin 1)

83 Diesel temperature sensor (pin 2)

84 Coolant temperature sensor (pin 1)

85 Coolant temperature sensor (pin 2)

86 Air flow meter (pin 1)

87 Not connected

88 Air flow meter (pin 3)

89 Air flow meter (pin 5)

90 Fuel pressure sensor (pin 3)

91 Fuel pressure sensor (pin 2)

92 Fuel pressure sensor (pin 1)

93 Turbo pressure sensor (pin 1)

94 Turbo pressure sensor (pin 3)

95 Turbo pressure sensor (pin 2)

96 Not connected

97 Air flow meter (pin 4)

98 Not connected

99 RPM sensor (pin 1)

100 RPM sensor (pin 2)

101 RPM sensor (pin 3)

102 RPM sensor (pin 1)

103 Timing sensor (pin 2)

104 Timing sensor (pin 3)

105 Not connected

106 Not connected

107 Not connected

108 Fuel pressure regulator

109 Fuel pressure regulator

110 Not connected

111 Heater relay control Fuel filter

112 Not connected

113 Not connected

114 Cylinder 4 injector control

115 Not connected

116 Not connected

117 Cylinder 1 and 2 injector power supply

118 Cylinder 3 and 4 injector power supply

119 Cylinder 1 injector control

120 Cylinder 2 injector control

121 Cylinder 3 injector control

Copyright by Fiat Auto 11

Page 99 of 330

Marea- Marea Weekend 9"°

2000 range ©

Engine

Fuel feed system

10.

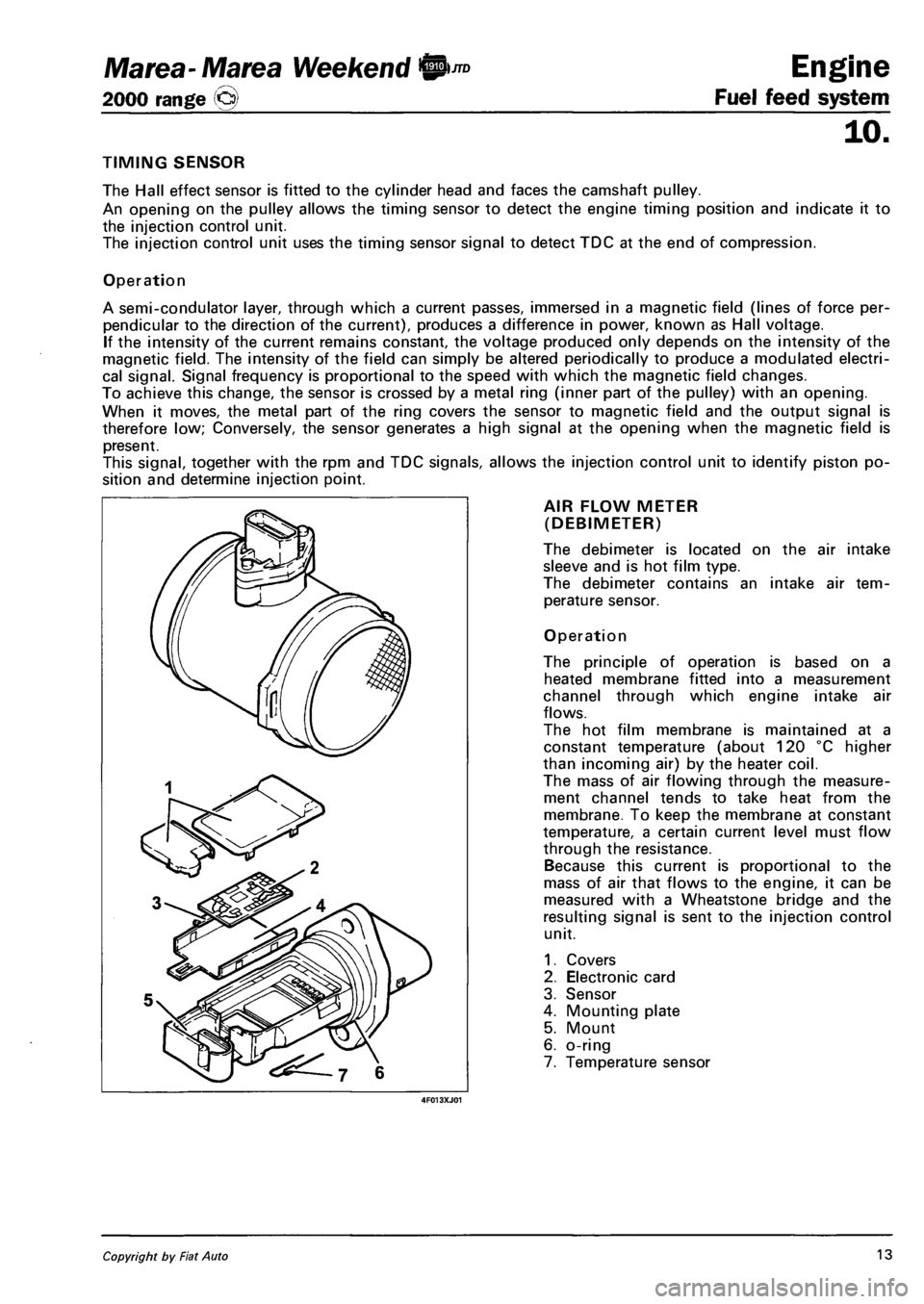

TIMING SENSOR

The Hall effect sensor is fitted to the cylinder head and faces the camshaft pulley.

An opening on the pulley allows the timing sensor to detect the engine timing position and indicate it to

the injection control unit.

The injection control unit uses the timing sensor signal to detect TDC at the end of compression.

Operation

A semi-condulator layer, through which a current passes, immersed in a magnetic field (lines of force per

pendicular to the direction of the current), produces a difference in power, known as Hall voltage.

If the intensity of the current remains constant, the voltage produced only depends on the intensity of the

magnetic field. The intensity of the field can simply be altered periodically to produce a modulated electri

cal signal. Signal frequency is proportional to the speed with which the magnetic field changes.

To achieve this change, the sensor is crossed by a metal ring (inner part of the pulley) with an opening.

When it moves, the metal part of the ring covers the sensor to magnetic field and the output signal is

therefore low; Conversely, the sensor generates a high signal at the opening when the magnetic field is

present.

This signal, together with the rpm and TDC signals, allows the injection control unit to identify piston po

sition and determine injection point.

AIR FLOW METER

(DEBIMETER)

The debimeter is located on the air intake

sleeve and is hot film type.

The debimeter contains an intake air tem

perature sensor.

Operation

The principle of operation is based on a

heated membrane fitted into a measurement

channel through which engine intake air

flows.

The hot film membrane is maintained at a

constant temperature (about 120 °C higher

than incoming air) by the heater coil.

The mass of air flowing through the measure

ment channel tends to take heat from the

membrane. To keep the membrane at constant

temperature, a certain current level must flow

through the resistance.

Because this current is proportional to the

mass of air that flows to the engine, it can be

measured with a Wheatstone bridge and the

resulting signal is sent to the injection control

unit.

1. Covers

2. Electronic card

3. Sensor

4. Mounting plate

5. Mount

6. o-ring

7. Temperature sensor

Copyright by Fiat Auto 13

Page 102 of 330

![FIAT MAREA 2000 1.G User Guide Engine

Fuel feed system

JTD Marea-Marea Weekend ©

2000 range ©

10.

iH

ft

B I 0 ] I D

[ 0 0 1 1

D

0 1 <fi=2 1 1 15J

GLOW PLUG PREHEATING CONTROL

UNIT

The glow plugs are controlled by mea FIAT MAREA 2000 1.G User Guide Engine

Fuel feed system

JTD Marea-Marea Weekend ©

2000 range ©

10.

iH

ft

B I 0 ] I D

[ 0 0 1 1

D

0 1 <fi=2 1 1 15J

GLOW PLUG PREHEATING CONTROL

UNIT

The glow plugs are controlled by mea](/img/10/4653/w960_4653-101.png)

Engine

Fuel feed system

JTD Marea-Marea Weekend ©

2000 range ©

10.

iH

ft

B I 0 ] I D

[ 0 0 1 1

D

0 1

UNIT

The glow plugs are controlled by means of a

preheating control unit under the direct con

trol of the injection control unit.

The preheating control unit contains a smart

relay that sends a return response (feedback)

to the injection control unit, which is thus in

formed of faults in the preheating control unit

or glow plug short-circuits to earth.

The figure shows the connectors on the base

of the preheating control unit and the pin-out

1. Earth

2. Injection control unit (pin 22)

3. Power supply from main injection relay

4. Not connected

5. Injection control unit (pin 62)

8. Positive from battery (+30)

G. Glow plugs (only four outputs are used)

ACCELERATOR

PEDAL POTENTIOMETER

Accelerator pedal position is converted to an

electrical voltage signal and send to the injec

tion control unit by a potentiometer connected

to the accelerator pedal.

Accelerator pedal position is processed to

gether with rpm information to provide injec

tion times and pressure.

The sensor consists of a case (1) secured to

the pedal by a flange, which contains an axi-

ally-positioned shaft (2) connected to two

potentiometers (3): main and safety potenti

ometers.

A coil spring on the shaft ensures the correct

resistance to pressure while a second spring

ensures return upon release.

16 Publication no. 506.763/24

Page 104 of 330

Engine

Fuel feed system

JTD Marea- Marea Weekend 0

2000 range ©

10.

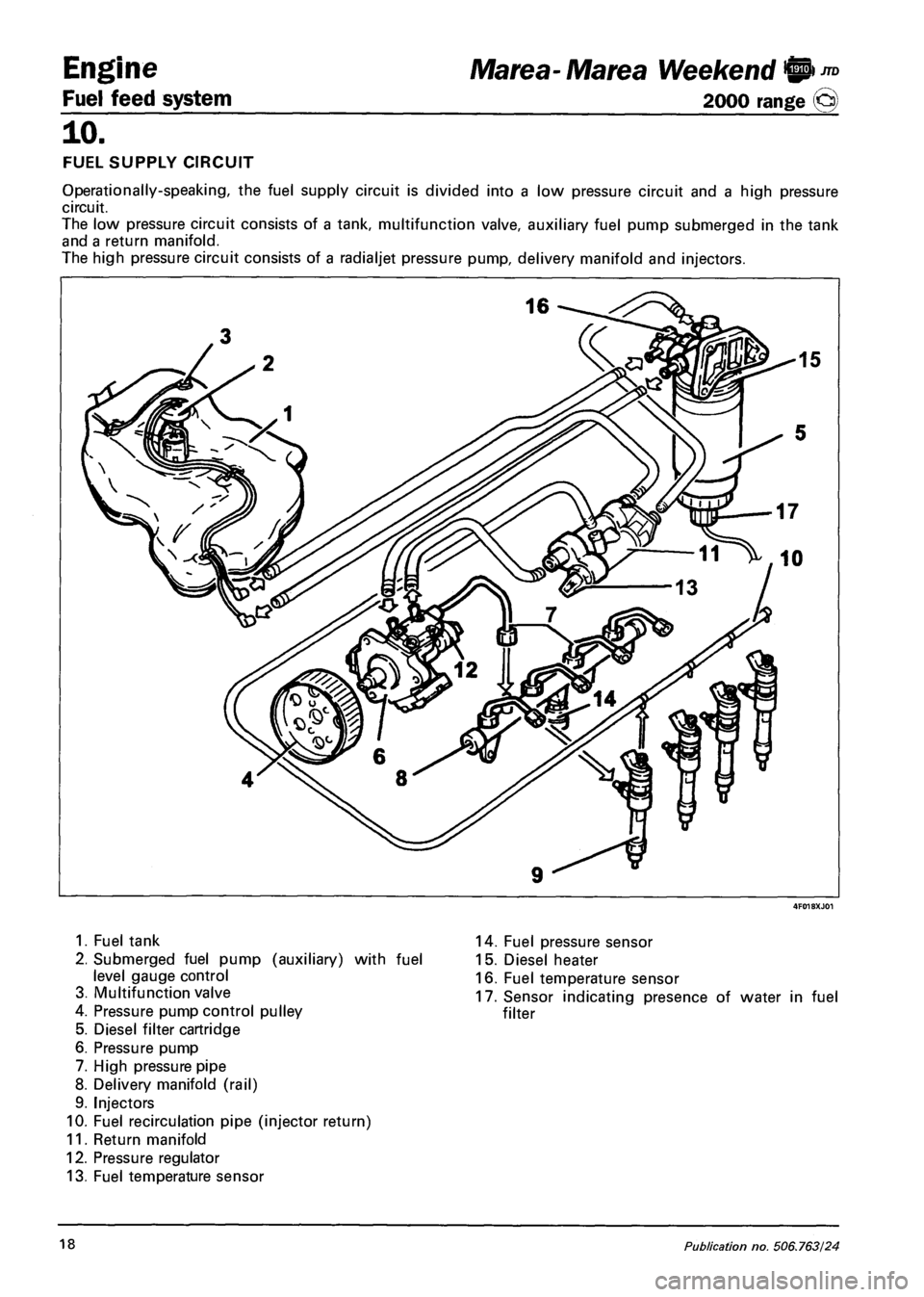

FUEL SUPPLY CIRCUIT

Operationally-speaking, the fuel supply circuit is divided into a low pressure circuit and a high pressure

circuit.

The low pressure circuit consists of a tank, multifunction valve, auxiliary fuel pump submerged in the tank

and a return manifold.

The high pressure circuit consists of a radialjet pressure pump, delivery manifold and injectors.

1. Fuel tank

2. Submerged fuel pump (auxiliary) with fuel

level gauge control

3. Multifunction valve

4. Pressure pump control pulley

5. Diesel filter cartridge

6. Pressure pump

7. High pressure pipe

8. Delivery manifold (rail)

9. Injectors

10. Fuel recirculation pipe (injector return)

11. Return manifold

12. Pressure regulator

13. Fuel temperature sensor

14. Fuel pressure sensor

15. Diesel heater

16. Fuel temperature sensor

17. Sensor indicating presence of water in fuel

filter

18 Publication no. 506.763/24