FIAT MULTIPLA 2006 1.G Owners Manual

Manufacturer: FIAT, Model Year: 2006, Model line: MULTIPLA, Model: FIAT MULTIPLA 2006 1.GPages: 266, PDF Size: 4.61 MB

Page 171 of 266

170

SAFETY

DEVICES

CORRECT USE

OF THE CAR

WARNING

LIGHTS AND

MESSAGES

CAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

IN AN

EMERGENCY

Please note:

❒the jack weight is 3.5 kg

❒the jack requires no adjustment

❒the jack cannot be repaired and in the event of a fault it must be

replaced by another original one

❒no tool other than its cranking device may be fitted on the jack.

To change a wheel proceed as follows:

❒Stop the car is a position that is not dangerous for oncoming traffic

where you can change the wheel safely. The ground should be flat and

adequately firm. At night choose a lit area;

❒Turn the engine off and pull up the handbrake;

❒Engage first gear or reverse;

❒Take out tools, jack and space-saver spare wheel;

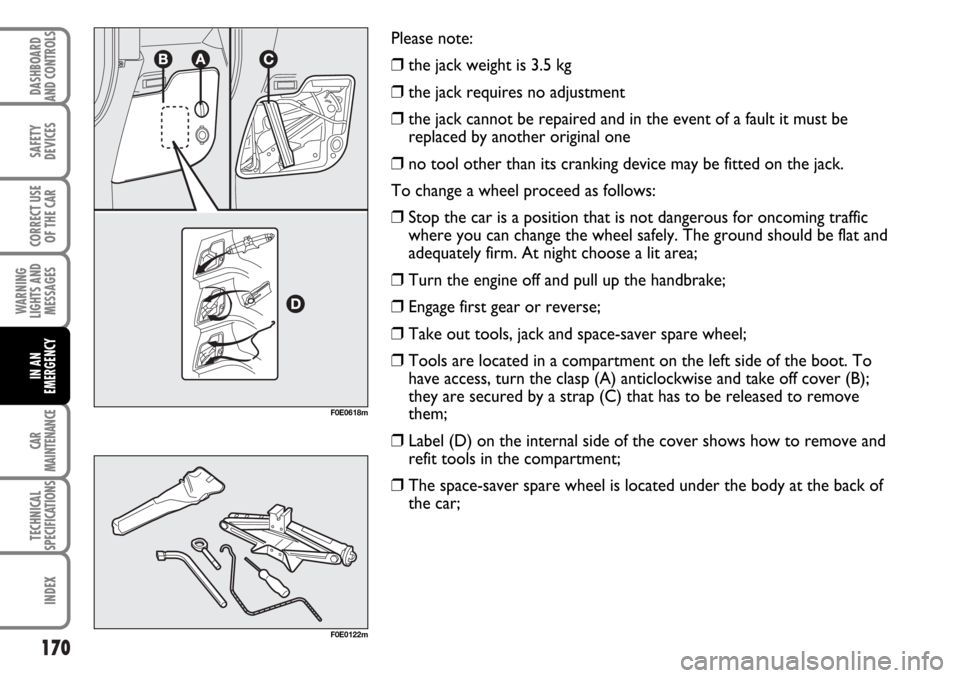

❒Tools are located in a compartment on the left side of the boot. To

have access, turn the clasp (A) anticlockwise and take off cover (B);

they are secured by a strap (C) that has to be released to remove

them;

❒Label (D) on the internal side of the cover shows how to remove and

refit tools in the compartment;

❒The space-saver spare wheel is located under the body at the back of

the car;

F0E0618m

F0E0122m

Page 172 of 266

171

SAFETY

DEVICES

CORRECT USE

OF THE CAR

WARNING

LIGHTS AND

MESSAGES

CAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

IN AN

EMERGENCY

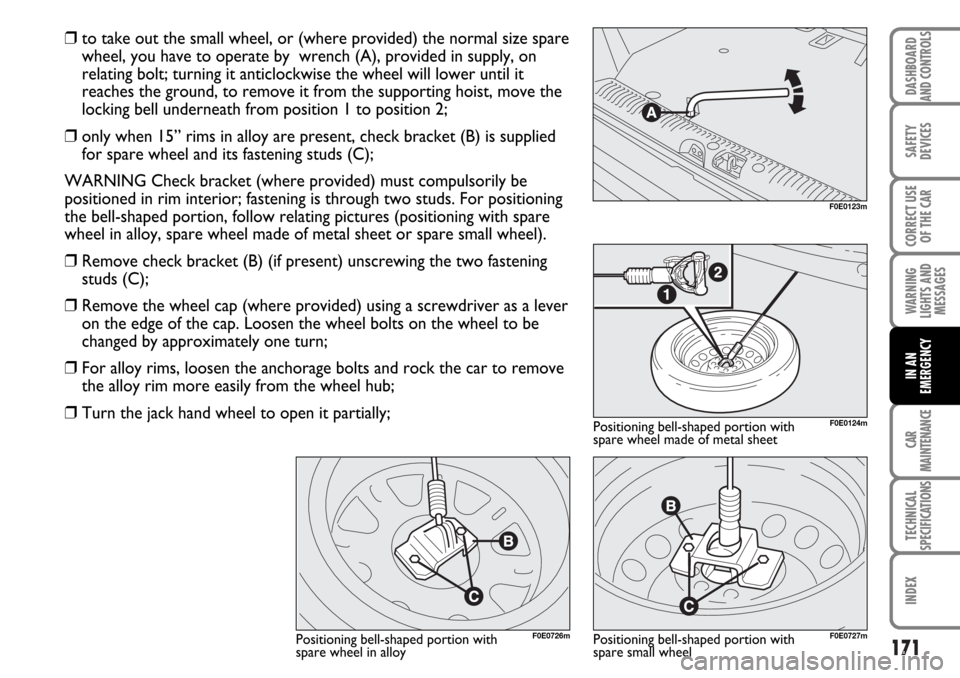

❒to take out the small wheel, or (where provided) the normal size spare

wheel, you have to operate by wrench (A), provided in supply, on

relating bolt; turning it anticlockwise the wheel will lower until it

reaches the ground, to remove it from the supporting hoist, move the

locking bell underneath from position 1 to position 2;

❒only when 15” rims in alloy are present, check bracket (B) is supplied

for spare wheel and its fastening studs (C);

WARNING Check bracket (where provided) must compulsorily be

positioned in rim interior; fastening is through two studs. For positioning

the bell-shaped portion, follow relating pictures (positioning with spare

wheel in alloy, spare wheel made of metal sheet or spare small wheel).

❒Remove check bracket (B) (if present) unscrewing the two fastening

studs (C);

❒Remove the wheel cap (where provided) using a screwdriver as a lever

on the edge of the cap. Loosen the wheel bolts on the wheel to be

changed by approximately one turn;

❒For alloy rims, loosen the anchorage bolts and rock the car to remove

the alloy rim more easily from the wheel hub;

❒Turn the jack hand wheel to open it partially;

F0E0123m

F0E0124m

F0E0727mF0E0726m

Positioning bell-shaped portion with

spare wheel made of metal sheet

Positioning bell-shaped portion with

spare small wheel Positioning bell-shaped portion with

spare wheel in alloy

Page 173 of 266

172

SAFETY

DEVICES

CORRECT USE

OF THE CAR

WARNING

LIGHTS AND

MESSAGES

CAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

IN AN

EMERGENCY

F0E0672m

F0E0127m

F0E0671m

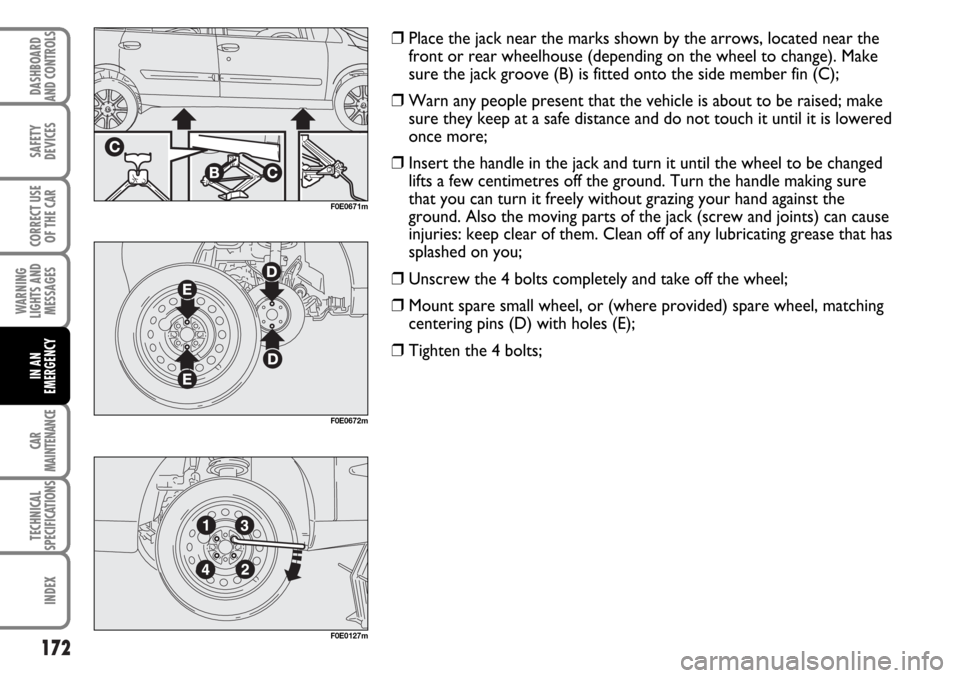

❒Place the jack near the marks shown by the arrows, located near the

front or rear wheelhouse (depending on the wheel to change). Make

sure the jack groove (B) is fitted onto the side member fin (C);

❒Warn any people present that the vehicle is about to be raised; make

sure they keep at a safe distance and do not touch it until it is lowered

once more;

❒Insert the handle in the jack and turn it until the wheel to be changed

lifts a few centimetres off the ground. Turn the handle making sure

that you can turn it freely without grazing your hand against the

ground. Also the moving parts of the jack (screw and joints) can cause

injuries: keep clear of them. Clean off of any lubricating grease that has

splashed on you;

❒Unscrew the 4 bolts completely and take off the wheel;

❒Mount spare small wheel, or (where provided) spare wheel, matching

centering pins (D) with holes (E);

❒Tighten the 4 bolts;

Page 174 of 266

173

SAFETY

DEVICES

CORRECT USE

OF THE CAR

WARNING

LIGHTS AND

MESSAGES

CAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

IN AN

EMERGENCY

WARNINGOnce the procedure has been

terminated, always check wheel correct

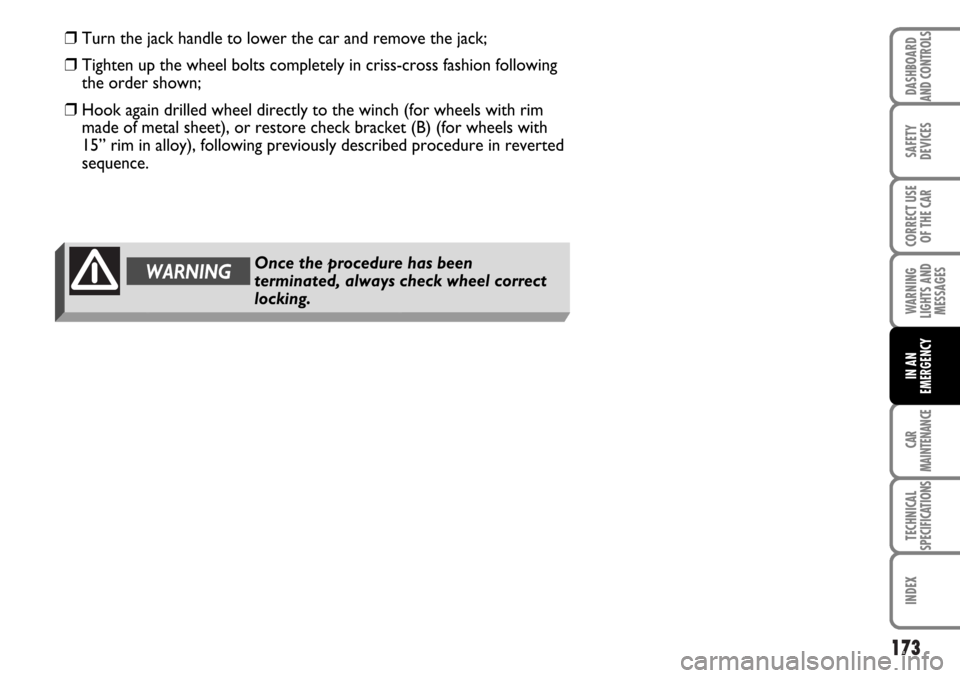

locking. ❒Turn the jack handle to lower the car and remove the jack;

❒Tighten up the wheel bolts completely in criss-cross fashion following

the order shown;

❒Hook again drilled wheel directly to the winch (for wheels with rim

made of metal sheet), or restore check bracket (B) (for wheels with

15” rim in alloy), following previously described procedure in reverted

sequence.

Page 175 of 266

174

SAFETY

DEVICES

CORRECT USE

OF THE CAR

WARNING

LIGHTS AND

MESSAGES

CAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

IN AN

EMERGENCY

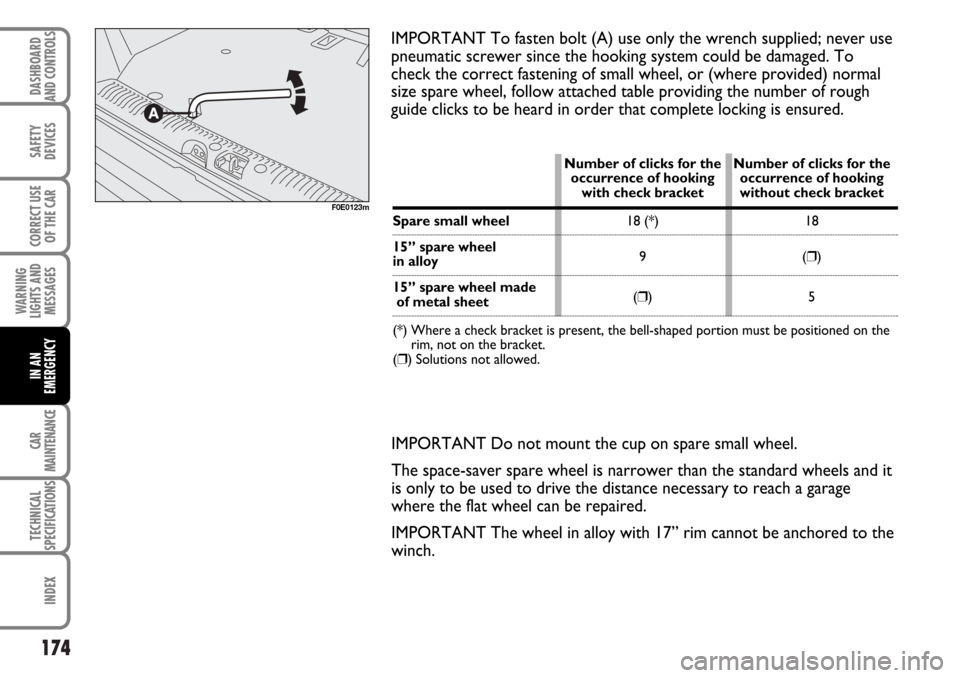

IMPORTANT To fasten bolt (A) use only the wrench supplied; never use

pneumatic screwer since the hooking system could be damaged. To

check the correct fastening of small wheel, or (where provided) normal

size spare wheel, follow attached table providing the number of rough

guide clicks to be heard in order that complete locking is ensured.

F0E0123m

IMPORTANT Do not mount the cup on spare small wheel.

The space-saver spare wheel is narrower than the standard wheels and it

is only to be used to drive the distance necessary to reach a garage

where the flat wheel can be repaired.

IMPORTANT The wheel in alloy with 17” rim cannot be anchored to the

winch.

Number of clicks for the Number of clicks for the

occurrence of hooking occurrence of hooking

with check bracket without check bracket

Spare small wheel18 (*) 18

15” spare wheel

9(❒)

in alloy

15” spare wheel made

(❒)5

of metal sheet

(*) Where a check bracket is present, the bell-shaped portion must be positioned on the

rim, not on the bracket.

(❒) Solutions not allowed.

Page 176 of 266

175

SAFETY

DEVICES

CORRECT USE

OF THE CAR

WARNING

LIGHTS AND

MESSAGES

CAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

IN AN

EMERGENCY

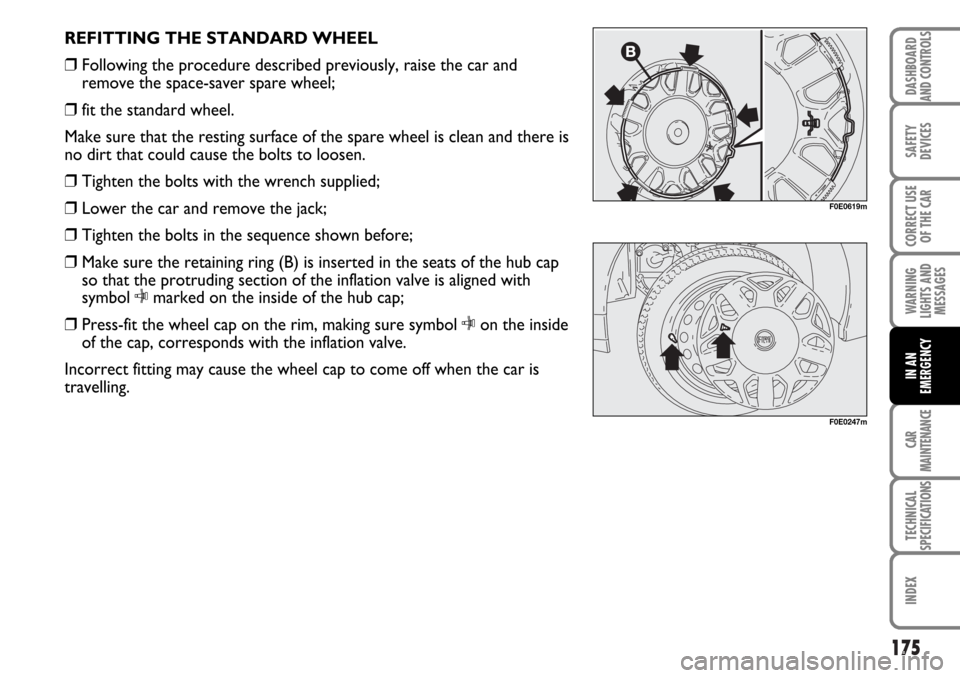

REFITTING THE STANDARD WHEEL

❒Following the procedure described previously, raise the car and

remove the space-saver spare wheel;

❒fit the standard wheel.

Make sure that the resting surface of the spare wheel is clean and there is

no dirt that could cause the bolts to loosen.

❒Tighten the bolts with the wrench supplied;

❒Lower the car and remove the jack;

❒Tighten the bolts in the sequence shown before;

❒Make sure the retaining ring (B) is inserted in the seats of the hub cap

so that the protruding section of the inflation valve is aligned with

symbol

Cmarked on the inside of the hub cap;

❒Press-fit the wheel cap on the rim, making sure symbol

Con the inside

of the cap, corresponds with the inflation valve.

Incorrect fitting may cause the wheel cap to come off when the car is

travelling.

F0E0619m

F0E0247m

Page 177 of 266

176

SAFETY

DEVICES

CORRECT USE

OF THE CAR

WARNING

LIGHTS AND

MESSAGES

CAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

IN AN

EMERGENCY

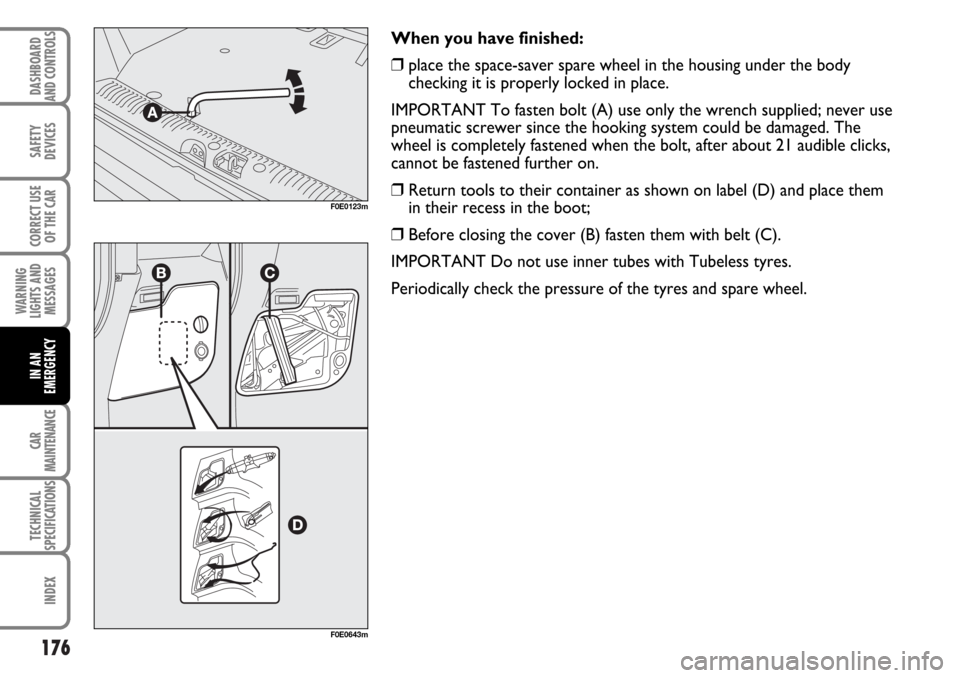

When you have finished:

❒place the space-saver spare wheel in the housing under the body

checking it is properly locked in place.

IMPORTANT To fasten bolt (A) use only the wrench supplied; never use

pneumatic screwer since the hooking system could be damaged. The

wheel is completely fastened when the bolt, after about 21 audible clicks,

cannot be fastened further on.

❒Return tools to their container as shown on label (D) and place them

in their recess in the boot;

❒Before closing the cover (B) fasten them with belt (C).

IMPORTANT Do not use inner tubes with Tubeless tyres.

Periodically check the pressure of the tyres and spare wheel.

F0E0123m

F0E0643m

Page 178 of 266

177

SAFETY

DEVICES

CORRECT USE

OF THE CAR

WARNING

LIGHTS AND

MESSAGES

CAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

IN AN

EMERGENCY

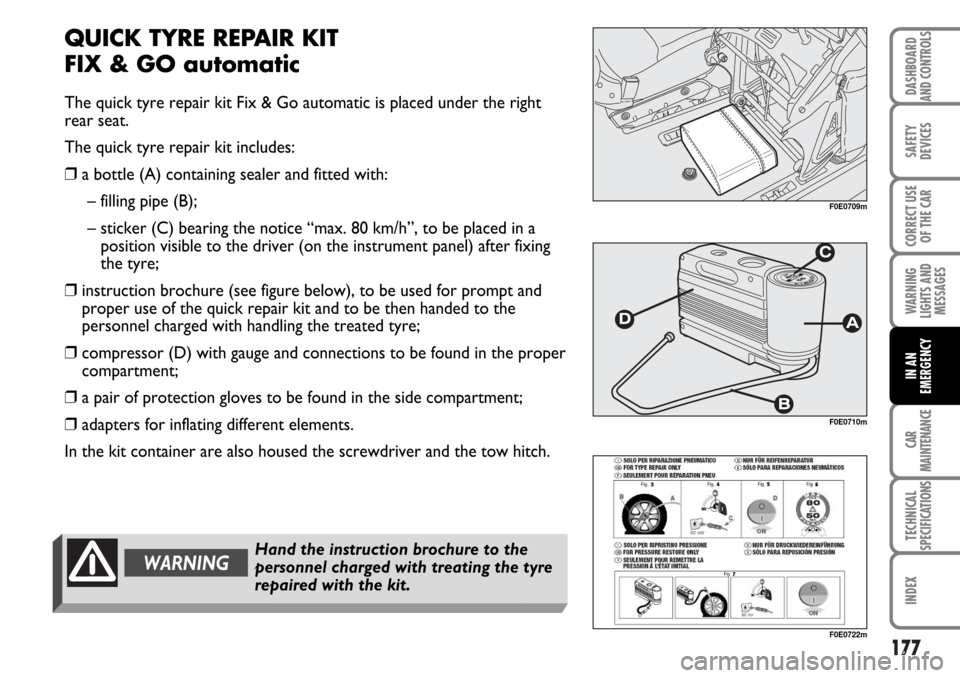

QUICK TYRE REPAIR KIT

FIX & GO automatic

The quick tyre repair kit Fix & Go automatic is placed under the right

rear seat.

The quick tyre repair kit includes:

❒a bottle (A) containing sealer and fitted with:

– filling pipe (B);

– sticker (C) bearing the notice “max. 80 km/h”, to be placed in a

position visible to the driver (on the instrument panel) after fixing

the tyre;

❒instruction brochure (see figure below), to be used for prompt and

proper use of the quick repair kit and to be then handed to the

personnel charged with handling the treated tyre;

❒compressor (D) with gauge and connections to be found in the proper

compartment;

❒a pair of protection gloves to be found in the side compartment;

❒adapters for inflating different elements.

In the kit container are also housed the screwdriver and the tow hitch.

F0E0709m

F0E0710m

F0E0722m

Hand the instruction brochure to the

personnel charged with treating the tyre

repaired with the kit.WARNING

Page 179 of 266

178

SAFETY

DEVICES

CORRECT USE

OF THE CAR

WARNING

LIGHTS AND

MESSAGES

CAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

IN AN

EMERGENCY

In the event of a puncture caused by foreign bodies, it is possible to repair tyres showing damages

on the track or shoulder up to max 4 mm diameter.

Repairs are not possible in case of damages on the wheel rim (bad groove

distortion causing air loss). Do not remove foreign bodies (screws or nails) from the

tyre.WARNING

WARNINGHoles and damages on the tyre side walls cannot be repaired. Do not use the quick

tyre repair kit if damaging is due to running with flat tyre.

Page 180 of 266

179

SAFETY

DEVICES

CORRECT USE

OF THE CAR

WARNING

LIGHTS AND

MESSAGES

CAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

IN AN

EMERGENCY

IT SHOULD BE NOTICED THAT:

The sealing fluid of the quick tyre repair kit is effective with external temperatures between -20 °C and +50 °C.

The sealing fluid has limited life.

Replace the run out cylinder. Do not throw away the cylinder and the sealing fluid. Have the

sealing fluid and the cylinder disposed of according to national and local regulations in force.

The compressor shall not be operated for more than 20 minutes. Risk of

overheating. Tyres repaired with the quick tyre repair kit shall be used temporarily

only.WARNING

WARNINGThe cylinder contains ethylene glycol. It contains latex: it can cause allergic

reactions. These substances are harmful if ingested or inhaled and irritant for the

eyes and in case of contact. In case of contact rinse immediately with water and

take off contaminated clothes. If swallowed, do not induce vomit, rinse out the

mouth, drink a lot of water and call the doctor immediately. Keep away from

children. This product must not be used by asthmatics. Do not inhale vapours

during fitting and suction operations. Call the doctor immediately in case of

allergic reactions. Keep the cylinder in the case provided for the purpose and far

from heat. The sealing fluid has limited life.