Fig. 49 FIAT PANDA 2009 169 / 2.G Manual Online

[x] Cancel search | Manufacturer: FIAT, Model Year: 2009, Model line: PANDA, Model: FIAT PANDA 2009 169 / 2.GPages: 226, PDF Size: 5.29 MB

Page 120 of 226

119KNOW

YOUR VEHICLE

SAFETYCORRECT USE

OF THE CARWARNING LIGHTS

AND MESSAGES

IN

AN EMERGENCY

CAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

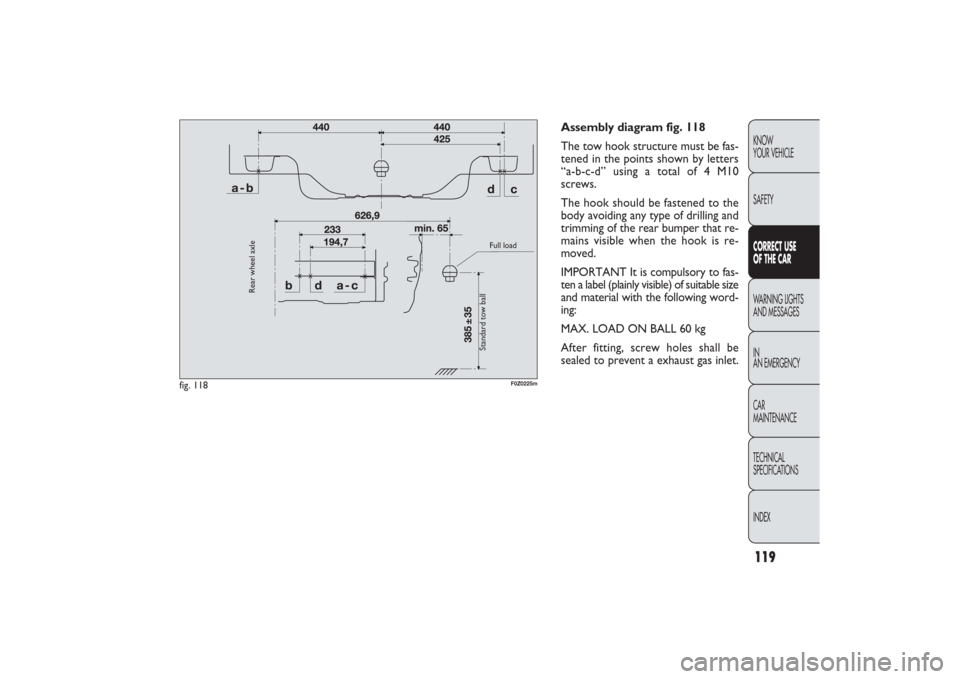

Assembly diagram fig. 118

The tow hook structure must be fas-

tened in the points shown by letters

“a-b-c-d” using a total of 4 M10

screws.

The hook should be fastened to the

body avoiding any type of drilling and

trimming of the rear bumper that re-

mains visible when the hook is re-

moved.

IMPORTANT It is compulsory to fas-

ten a label (plainly visible) of suitable size

and material with the following word-

ing:

MAX. LOAD ON BALL 60 kg

After fitting, screw holes shall be

sealed to prevent a exhaust gas inlet.

fig. 118

F0Z0225m

Rear wheel axle

Standard tow ball

Full load

111-122 PANDA EN 7-10-2009 15:01 Pagina 119

Page 121 of 226

120

KNOW YOUR

VEHICLE

SAFETYCORRECT USE

OF THE CARWARNING LIGHTS

AND MESSAGESI

IN

AN EMERGENCY

CAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

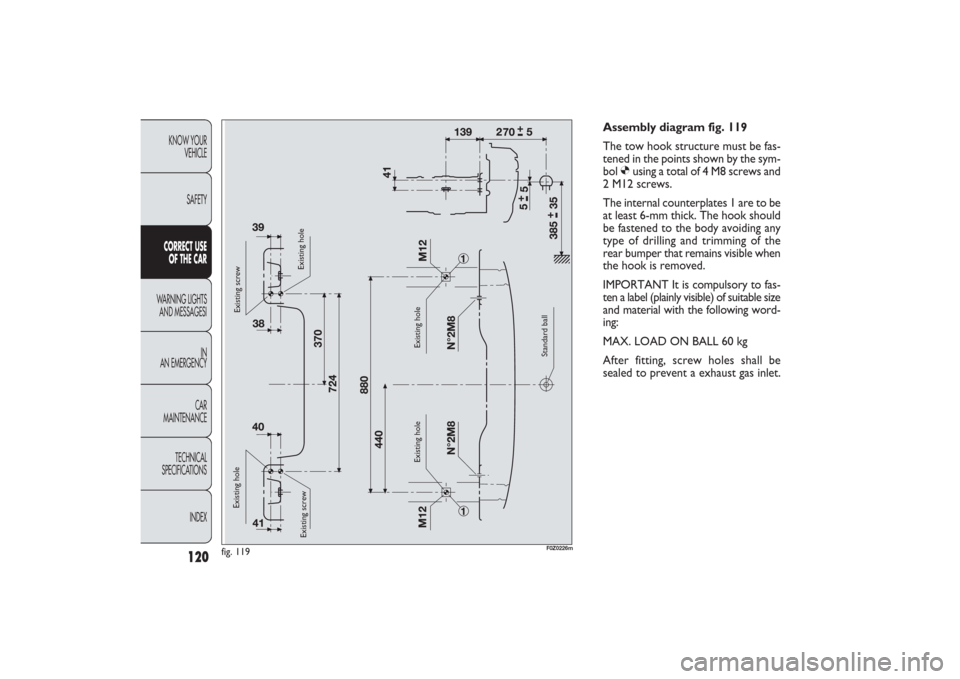

Assembly diagram fig. 119

The tow hook structure must be fas-

tened in the points shown by the sym-

bol

Ø

using a total of 4 M8 screws and

2 M12 screws.

The internal counterplates 1 are to be

at least 6-mm thick. The hook should

be fastened to the body avoiding any

type of drilling and trimming of the

rear bumper that remains visible when

the hook is removed.

IMPORTANT It is compulsory to fas-

ten a label (plainly visible) of suitable size

and material with the following word-

ing:

MAX. LOAD ON BALL 60 kg

After fitting, screw holes shall be

sealed to prevent a exhaust gas inlet.

fig. 119

F0Z0226m

Existing hole

Existing hole

Existing hole Existing hole

Standard ballExisting screw

Existing screw

111-122 PANDA EN 7-10-2009 15:01 Pagina 120

Page 136 of 226

135KNOW

YOUR VEHICLE

SAFETY

WARNING LIGHTS

AND MESSAGESIN

AN EMERGENCYCAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

IN AN EMERGENCY

STARTING THE ENGINEEMERGENCY START-UP

If the Fiat CODE system fails to deactivate engine immo-

bilising system the instrument panel warning lights

Y

and

U

stay on and the engine cannot be started.

To start the engine the emergency start-up can be per-

formed.

Read the whole procedure carefully before trying to car-

ry it out: if you make a mistake, you need to turn the ig-

nition key back to STOP and repeat the whole operation

from the beginning.

Proceed as follows:

❒

read the five-digit electronic code from the CODE card;

❒

turn the ignition key to MAR;

❒

press and hold down the accelerator pedal: the warn-

ing light

U

turns on for about 8 seconds, and then goes

off;

❒

release the accelerator pedal and count the flashes of

the warning light

U

;

❒

count the number of flashes that corresponds to the

first digit of the code on the CODE card, then press the

accelerator pedal and hold it there until the warning

light

U

comes on (for 4 seconds) and then goes off. Re-

lease the accelerator pedal;

CORRECT USE

OF THE CAR

❒

the warning light

U

will start flashing again: after it has

flashed the number of times corresponding to the

second digit on the CODE card, fully depress the ac-

celerator pedal and hold it there;

❒

do the same for the remaining digits on the CODE card;

❒

once the last digit has been entered, hold the acceler-

ator pedal pressed. The warning light

U

will light up for

four seconds and then go out. Release the accelerator

pedal;

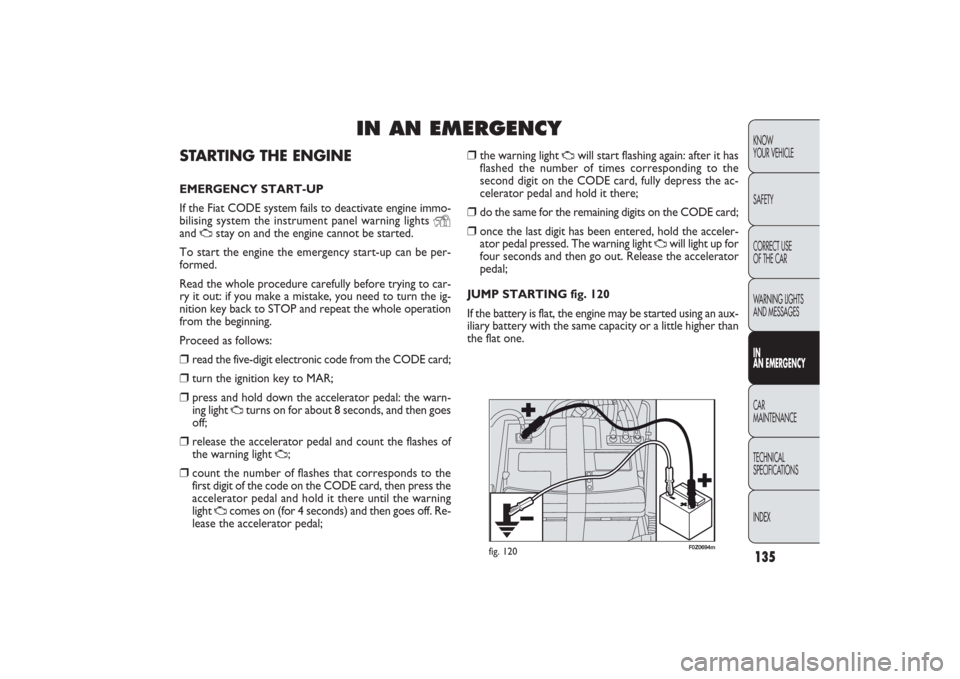

JUMP STARTING fig. 120

If the battery is flat, the engine may be started using an aux-

iliary battery with the same capacity or a little higher than

the flat one.

F0Z0694m

fig. 120

135-168 PANDA EN 7-10-2009 14:06 Pagina 135

Page 139 of 226

138KNOW

YOUR VEHICLE

SAFETY

CORRECT USE

OF THE CAR

WARNING LIGHTS

AND MESSAGES

IN

AN EMERGENCYCAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

F0Z0171m

fig. 121

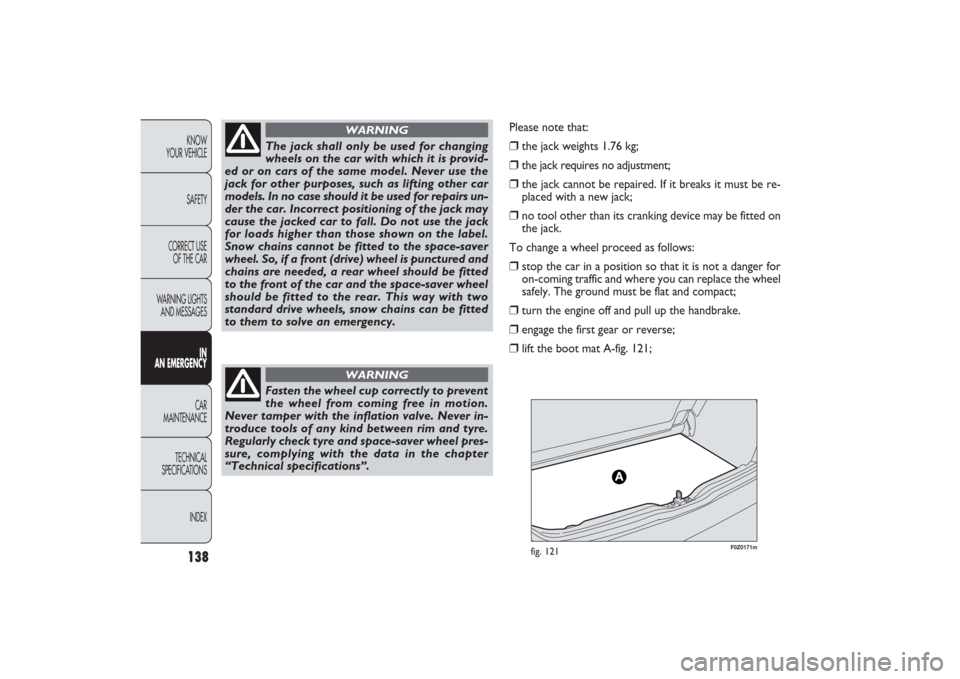

Please note that:❒

the jack weights 1.76 kg;

❒

the jack requires no adjustment;

❒

the jack cannot be repaired. If it breaks it must be re-

placed with a new jack;

❒

no tool other than its cranking device may be fitted on

the jack.

To change a wheel proceed as follows:

❒

stop the car in a position so that it is not a danger for

on-coming traffic and where you can replace the wheel

safely. The ground must be flat and compact;

❒

turn the engine off and pull up the handbrake.

❒

engage the first gear or reverse;

❒

lift the boot mat A-fig. 121;

Fasten the wheel cup correctly to prevent

the wheel from coming free in motion.

Never tamper with the inflation valve. Never in-

troduce tools of any kind between rim and tyre.

Regularly check tyre and space-saver wheel pres-

sure, complying with the data in the chapter

“Technical specifications”.

WARNING

The jack shall only be used for changing

wheels on the car with which it is provid-

ed or on cars of the same model. Never use the

jack for other purposes, such as lifting other car

models. In no case should it be used for repairs un-

der the car. Incorrect positioning of the jack may

cause the jacked car to fall. Do not use the jack

for loads higher than those shown on the label.

Snow chains cannot be fitted to the space-saver

wheel. So, if a front (drive) wheel is punctured and

chains are needed, a rear wheel should be fitted

to the front of the car and the space-saver wheel

should be fitted to the rear. This way with two

standard drive wheels, snow chains can be fitted

to them to solve an emergency.

WARNING

135-168 PANDA EN 7-10-2009 14:06 Pagina 138

Page 140 of 226

139KNOW

YOUR VEHICLE

SAFETY

CORRECT USE

OF THE CAR

WARNING LIGHTS

AND MESSAGESIN

AN EMERGENCYCAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

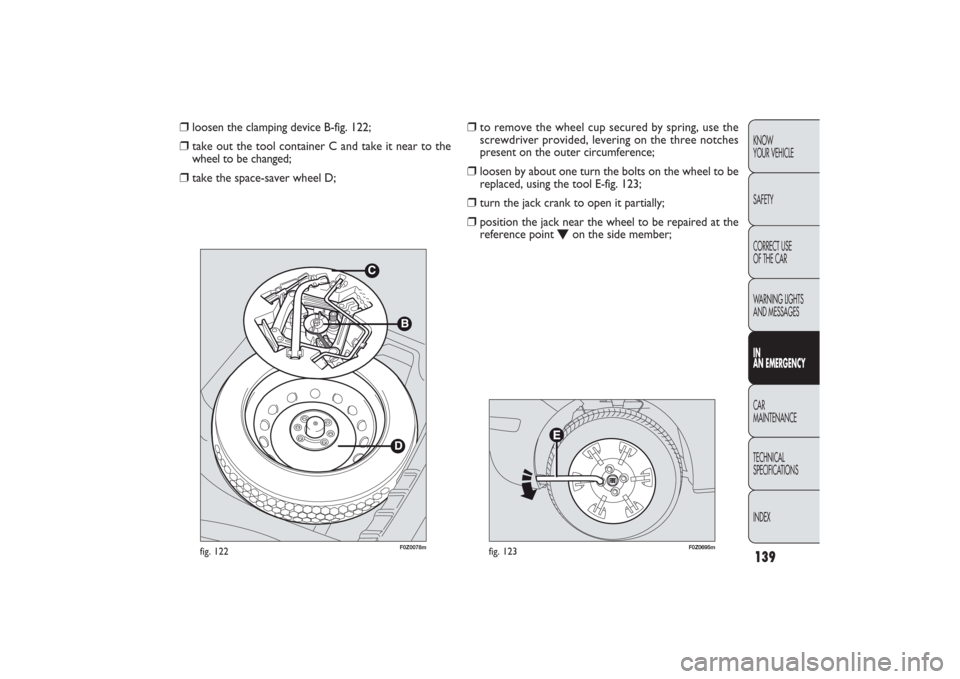

F0Z0078m

fig. 122

F0Z0695m

fig. 123

❒

to remove the wheel cup secured by spring, use the

screwdriver provided, levering on the three notches

present on the outer circumference;

❒

loosen by about one turn the bolts on the wheel to be

replaced, using the tool E-fig. 123;

❒

turn the jack crank to open it partially;

❒

position the jack near the wheel to be repaired at the

reference point

O

on the side member;

❒

loosen the clamping device B-fig. 122;

❒

take out the tool container C and take it near to the

wheel to be changed;

❒

take the space-saver wheel D;

135-168 PANDA EN 7-10-2009 14:06 Pagina 139

Page 141 of 226

140KNOW

YOUR VEHICLE

SAFETY

CORRECT USE

OF THE CAR

WARNING LIGHTS

AND MESSAGES

IN

AN EMERGENCYCAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

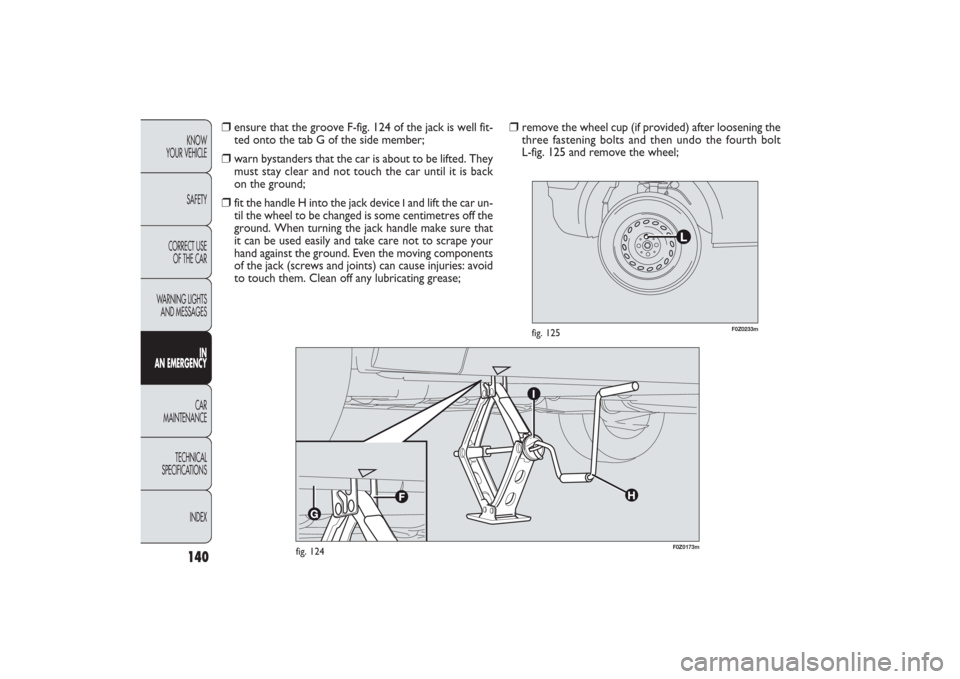

F0Z0173m

fig. 124

F0Z0233m

fig. 125

❒

remove the wheel cup (if provided) after loosening the

three fastening bolts and then undo the fourth bolt

L-fig. 125 and remove the wheel;

❒

ensure that the groove F-fig. 124 of the jack is well fit-

ted onto the tab G of the side member;

❒

warn bystanders that the car is about to be lifted. They

must stay clear and not touch the car until it is back

on the ground;

❒

fit the handle H into the jack device

Iand lift the car un-

til the wheel to be changed is some centimetres off the

ground. When turning the jack handle make sure that

it can be used easily and take care not to scrape your

hand against the ground. Even the moving components

of the jack (screws and joints) can cause injuries: avoid

to touch them. Clean off any lubricating grease;

135-168 PANDA EN 7-10-2009 14:06 Pagina 140

Page 142 of 226

141KNOW

YOUR VEHICLE

SAFETY

CORRECT USE

OF THE CAR

WARNING LIGHTS

AND MESSAGESIN

AN EMERGENCYCAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

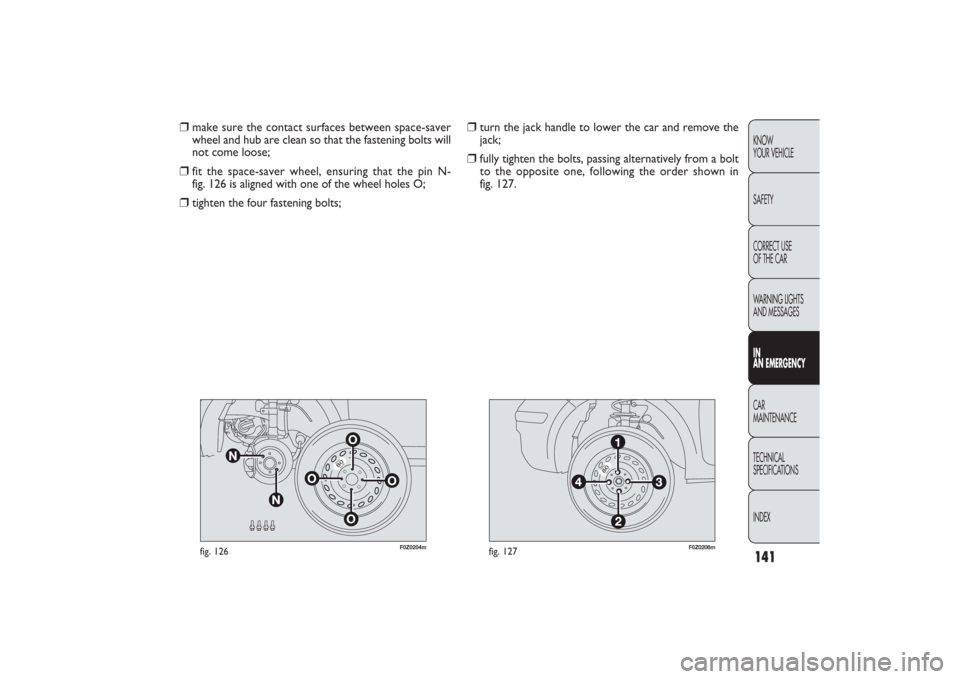

F0Z0204m

fig. 126

F0Z0206m

fig. 127

❒

turn the jack handle to lower the car and remove the

jack;

❒

fully tighten the bolts, passing alternatively from a bolt

to the opposite one, following the order shown in

fig. 127.

❒

make sure the contact surfaces between space-saver

wheel and hub are clean so that the fastening bolts will

not come loose;

❒

fit the space-saver wheel, ensuring that the pin N-

fig. 126 is aligned with one of the wheel holes O;

❒

tighten the four fastening bolts;

135-168 PANDA EN 7-10-2009 14:06 Pagina 141

Page 143 of 226

142KNOW

YOUR VEHICLE

SAFETY

CORRECT USE

OF THE CAR

WARNING LIGHTS

AND MESSAGES

IN

AN EMERGENCYCAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

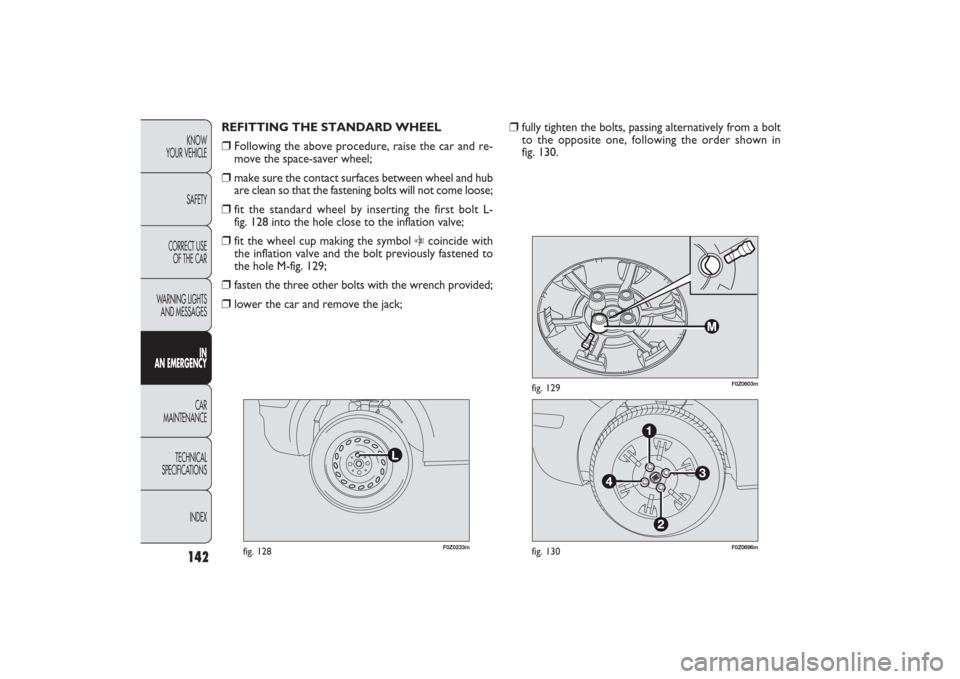

F0Z0696m

fig. 130

F0Z0603m

fig. 129

❒

fully tighten the bolts, passing alternatively from a bolt

to the opposite one, following the order shown in

fig. 130. REFITTING THE STANDARD WHEEL

❒

Following the above procedure, raise the car and re-

move the space-saver wheel;

❒

make sure the contact surfaces between wheel and hub

are clean so that the fastening bolts will not come loose;

❒

fit the standard wheel by inserting the first bolt L-

fig. 128 into the hole close to the inflation valve;

❒

fit the wheel cup making the symbol

C

coincide with

the inflation valve and the bolt previously fastened to

the hole M-fig. 129;

❒

fasten the three other bolts with the wrench provided;

❒

lower the car and remove the jack;

F0Z0233m

fig. 128

135-168 PANDA EN 7-10-2009 14:06 Pagina 142

Page 144 of 226

143KNOW

YOUR VEHICLE

SAFETY

CORRECT USE

OF THE CAR

WARNING LIGHTS

AND MESSAGESIN

AN EMERGENCYCAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

At the end of the procedure❒

stow the space-saving wheel D-fig. 122 in the space pro-

vided in the boot;

❒

fit the partially-open jack in its box C by forcing it slight-

ly to prevent it from vibrating when travelling;

❒

put the tools back into their locations;

❒

arrange the container and tools in the spare wheel and

secure the clamping device B;

❒

correctly reposition the boot stiff cover.

IMPORTANT Do not use inner tubes with tubeless tyres.

Check the inflation pressure of the tyres and the space-

saving wheel regularly.

IMPORTANT You will need to change the set of bolts if

you want to change the type of wheels fitted (alloy rims

instead of steel rims, and vice versa).The whole set of fas-

tening bolts must be replaced by another set of suitably

sized bolts and use a special space-saving wheel having dif-

ferent building characteristics.

You should keep the bolts and space-saving wheel in case

you decide to use the original type of wheel later on.

F0Z0607m

fig. 131

QUICK TYRE REPAIR KIT FIX & GO

automaticThe quick tyre repair kit Fix & Go automatic is placed in

the boot; the tool bag fig. 131 is located under the driver’s

seat and it is fastened by means of a Velcro strap.

The kit fig. 132 includes:❒

a bottle A with the sealer and fitted with:

– filling pipe B;

– a sticker C with the writing “max. 80 km/h” to be

placed in a position clearly visible by the driver (on

the dashboard) after repairing the tyre;

135-168 PANDA EN 7-10-2009 14:06 Pagina 143

Page 145 of 226

144KNOW

YOUR VEHICLE

SAFETY

CORRECT USE

OF THE CAR

WARNING LIGHTS

AND MESSAGES

IN

AN EMERGENCYCAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

F0Z0670m

fig. 133

Hand the leaflet over to the personnel

charged to manage the tyre treated using

the tyre repair kit.

WARNING

In the case of a puncture, caused by a for-

eign body, tyres that have suffered damage

up to a maximum diameter of 4 mm on the

tread or the shoulder can be repaired.

❒

instruction brochure (see fig. 133), to be used for prompt

and proper use of the quick repair kit and to be then

handed to the personnel charged with handling the treat-

ed tyre;

❒

a compressor D-fig. 132 including gauge and connec-

tions, in the container;

❒

a pair of protection gloves located in the side space of

the compressor;

❒

adapters for inflating different elements.

In the tool bag you also find the screwdriver, the tow ring

and the jack.

F0Z0607m

fig. 132

135-168 PANDA EN 7-10-2009 14:06 Pagina 144