check engine FIAT TEMPRA 1988 Service And User Guide

[x] Cancel search | Manufacturer: FIAT, Model Year: 1988, Model line: TEMPRA, Model: FIAT TEMPRA 1988Pages: 171, PDF Size: 18.05 MB

Page 29 of 171

Thanks

are due to the excellent, knowledgeable and helpful staff at FIAT main dealers, Ryauto of Amblecote, in the West

Midlands for supplying vehicles and for their assistance with this chapter. In particular, thanks are due to the efficient Maurice

Hough, Service Manager, the experienced Foreman, Tony Morris, and young demon mechanic, Matthew Worsfold.

Some of the suggested inspection/replacement intervals may not correspond to those shown in the original handbook. The suggested

schedule, based on FIAT'S recommendations, takes into account the age of the vehicle and the annual MoT test in the UK.

In practice, because of the split between (mainly) 12 month/9,000 mile and 18 month/13,500 mile intervals, you will need to

service your Tipo or Tempra at most, if not every, 6 month interval.

IMPORTANT NOTE: Each service should be carried out at EITHER the recommended mileage OR the recommended time

interval, whichever comes first.

SERVICE INTERVAL CHART

SERVICE INTERVALS: KEY

A

-

Every week, or before every long journey. F

-

Every 3 years or 27,000 miles.

B

-

Every 6 months, or 4,500 miles. G

-

Every 4 years or 36,000 miles.

C - Every 12 months, or 9,000 miles. H

-

Every 6 years or 54,000 miles.

I

-

Every 63,000 miles. D - Every 18 months , or 13,500 miles.

H

-

Every 6 years or 54,000 miles.

I

-

Every 63,000 miles.

E

-

Every 2 years or 18,000 miles J

-

Every 72,000 miles.

PART A: REGULAR CHECKS

SERVICE INTERVALS

Job 1. Engine oil

-

check level A

Job 2. Cooling system

-

check level A

Job 3. Brake/clutch fluid

-

check level A

Job 4. Battery

-

check electrolyte level A

Job 5. Screen washer fluid

-

check level A

Job 6. Tyres

-

check pressures and

condition (road wheels) A

Job 7. Check lights/change bulbs A

PART B: THE ENGINE AND

COOLING SYSTEM

Job 8

-

Petrol. Change engine oil and filter C

Job 8

-

Diesel. Change engine oil and filter B

Job 9. Check crankcase ventilation H

Job 10. Check/adjust valve clearances D

Job 11. Check camshaft timing belt F

Job 12. Change camshaft timing belt I

Job 13. Check cooling system C

Job 14. Change engine coolant E

PART C: TRANSMISSION

Job 15. Check manual gearbox oil level C

Job 16. Change manual gearbox oil J

Job 17. Check auto, transmission fluid level C

Job 18. Change auto, transmission

fluid and filter F

Job 19. Check driveshaft gaiters C

Job 20. Check/adjust clutch C

Job 21. Check auto, transmission selector

cable E

PART D: IGNITION AND ELECTRICS

SERVICE INTERVALS

Job 22. Check/clean/gap spark plugs B

Job 23. Change spark plugs D

Job 24. Check/clean HT leads and

distributor cap C

Job 25. Check ignition timing C

Job 26. Check/adjust drive belt/s D

Job 27. Check electric fan operation C

Job 28. Run diagnostic ignition/injection test D

PART E: FUEL AND EXHAUST

Job 29. Check fuel pipes for leaks C

Job 30. Change petrol air filter D

Job 31. Change diesel air filter C

Job 32. Change petrol fuel filter F

Job 33. Drain diesel fuel filter B

Job 34. Change diesel fuel filter C

Job 35. Check/adjust petrol engine idle

and emissions C

Job 36. Check emission/evaporative/EGR systems F

Job 37. Check Lambda sensor F

Job 38. Check/adjust diesel idle speed C

Job 39. Check/adjust diesel injection timing E

Job 40. Check inlet and exhaust manifold fixings D

Job 41. Check exhaust system C

PART F: STEERING AND

SUSPENSION

Job 42. Check front wheel bearings C

Job 43. Check front suspension C

Job 44. Check steering column, joints and rack C

Job 45. Check power steering fluid C

Job 46. Check rear wheel bearings C

Job 47. Check rear suspension C

Job 48. Check wheel bolts for tightness C

Page 30 of 171

PART G: BRAKING SYSTEM

Job 49. Check front brakes

Job 50. Check rear brakes

Job 51. Check/adjust handbrake

Job 52. Check brake pipes

Job 53. Change brake hydraulic fluid

SERVICE INTERVALS

C

C

C

C

E

Job 56. Check seat and seat belt mountings C

Job 57. Check headlight alignment C

Job 58. Check underbody C

Job 59. Check spare tyre B

Job 60. Change pollen filter C

Job 61. Replace airbag gas generator 10 years

PART I: ROAD TEST

PART H: BODYWORK & INTERIOR

Job 54. Lubricate hinges and locks

Job 55. Check windscreen

Job 62. Road test and specialist check. AFTER EVERY

SERVICE

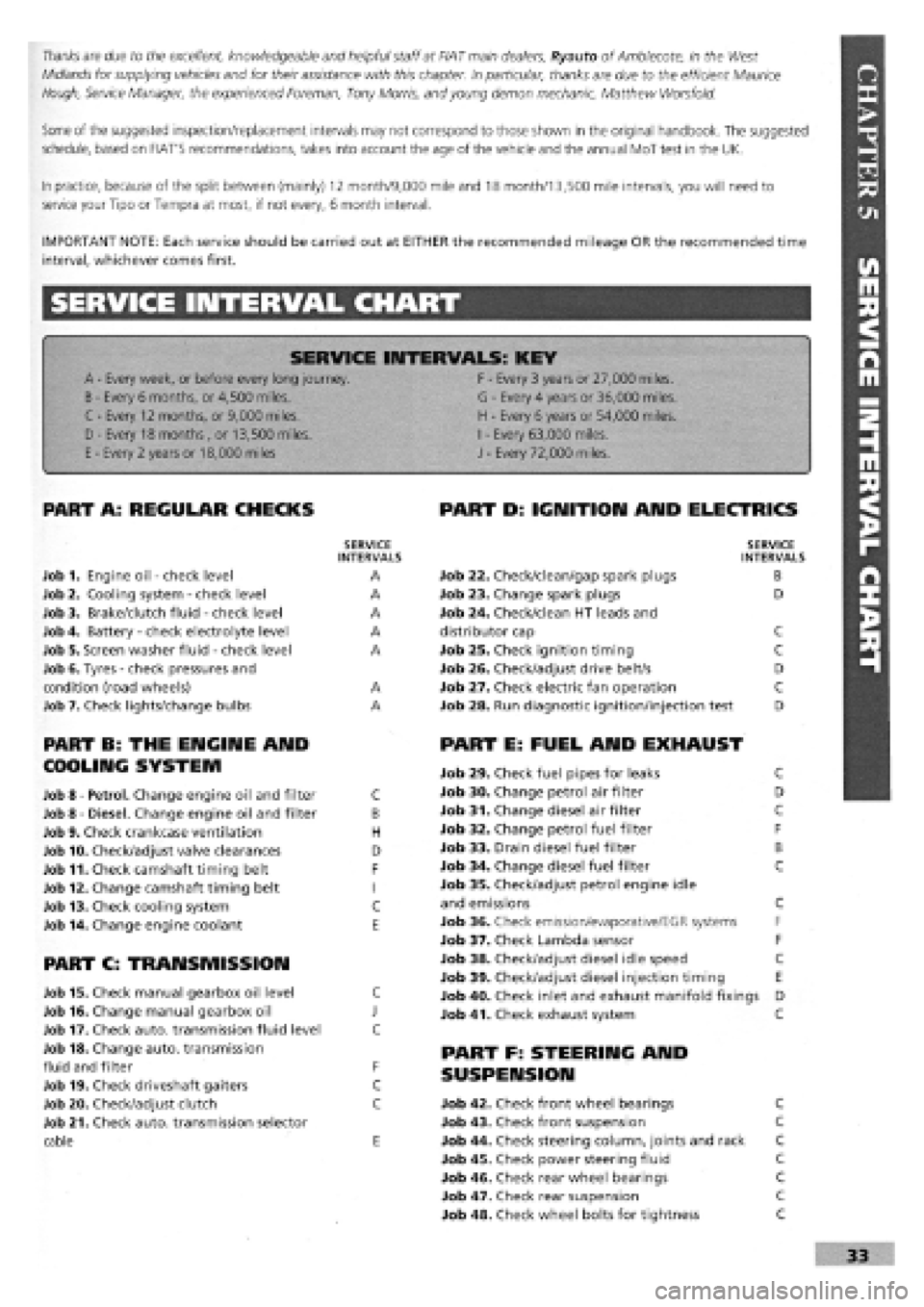

ENGINE BAY LAYOUTS

These are the engine bay layouts common to almost all Tipo/Tempras. Note that there is no carburettor fitted to fuel-injected

vehicles.

1 - PETROL ENGINES 2 - DIESEL ENGINES

1

-

oil filler cap 7

-

distributor (ignition) 12 - oil filter location

2

-

engine oil dipstick 8

-

coil (ignition) 13

-

fuel pump (mechanical)

3

-

coolant filler cap 9

-

electronic control unit (ECU), 14

-

diesel injection pump

4 - brake fluid reservoir Digiplex 2 15

-

alternator location (behind engine)

5 - battery 10

-

air filter housing

6

-

screenwash reservoir cap 11

-

fuel filter

PART A: REGULAR CHECKS

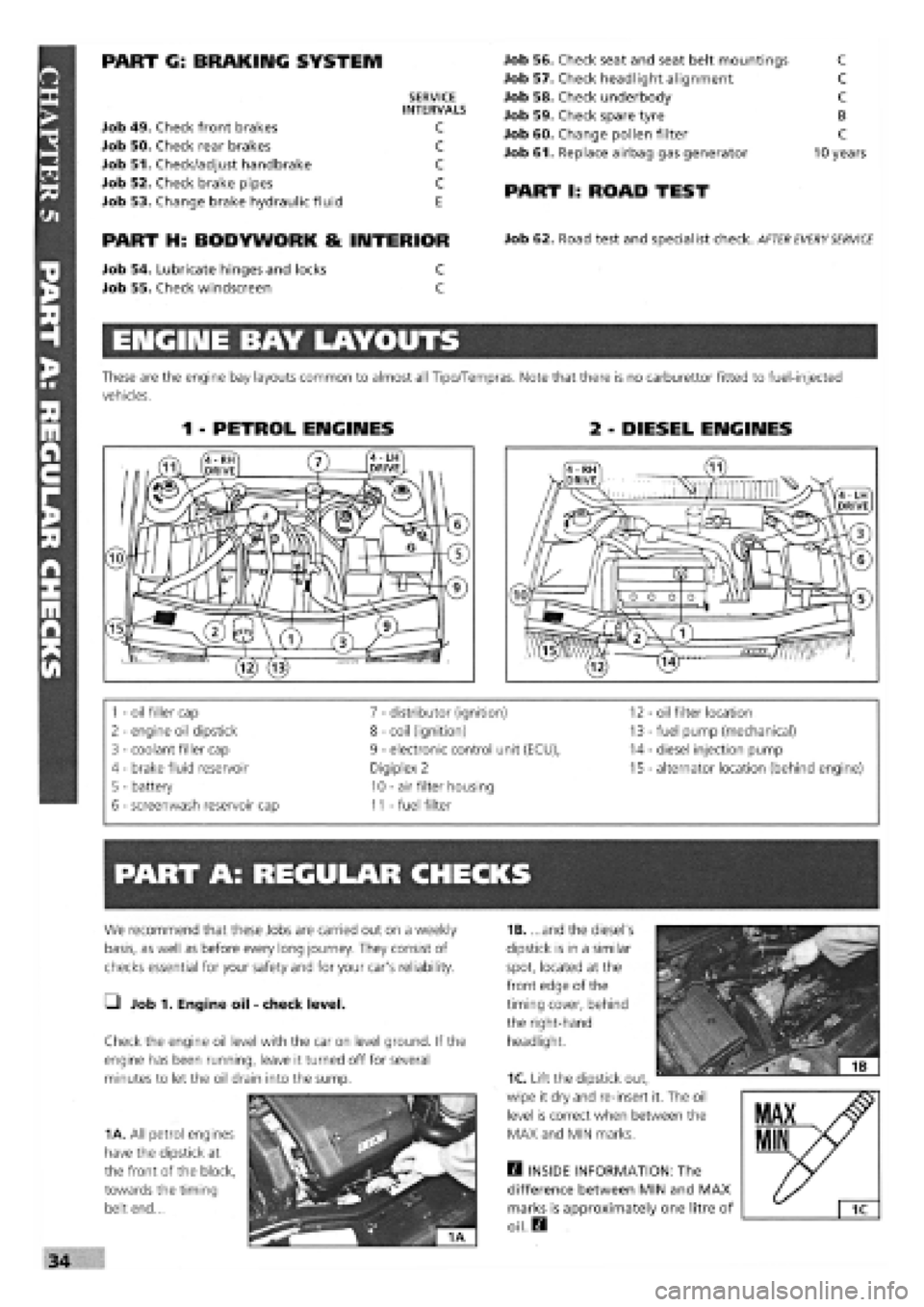

1B. ...and the diesel's

dipstick is in a similar

spot, located at the

front edge of the

timing cover, behind

the right-hand

headlight.

Q INSIDE INFORMATION: The

difference between MIN and MAX

marks is approximately one litre of

oil. Q

We recommend that these Jobs are carried out on a weekly

basis, as well as before every long journey. They consist of

checks essential for your safety and for your car's reliability.

• Job 1. Engine oil

-

check level.

Check the engine oil level with the car on level ground. If the

engine has been running, leave it turned off for several

minutes to let the oil drain into the sump.

1A. All petrol engines

have the dipstick at

the front of the block,

towards the timing

belt end...

1C. Lift the dipstick out,

wipe it dry and re-insert it. The oil

level is correct when between the

MAX and MIN marks.

Page 31 of 171

TOPPING-UP

1D. On petrol

engines the oil

filler cap is pull-

out rectangular

plug at the end

of the rocker

On diesel engines, the round cap is near the same end of the

cam cover. This cap is removed by turning a quarter-turn to

the left and lifting.

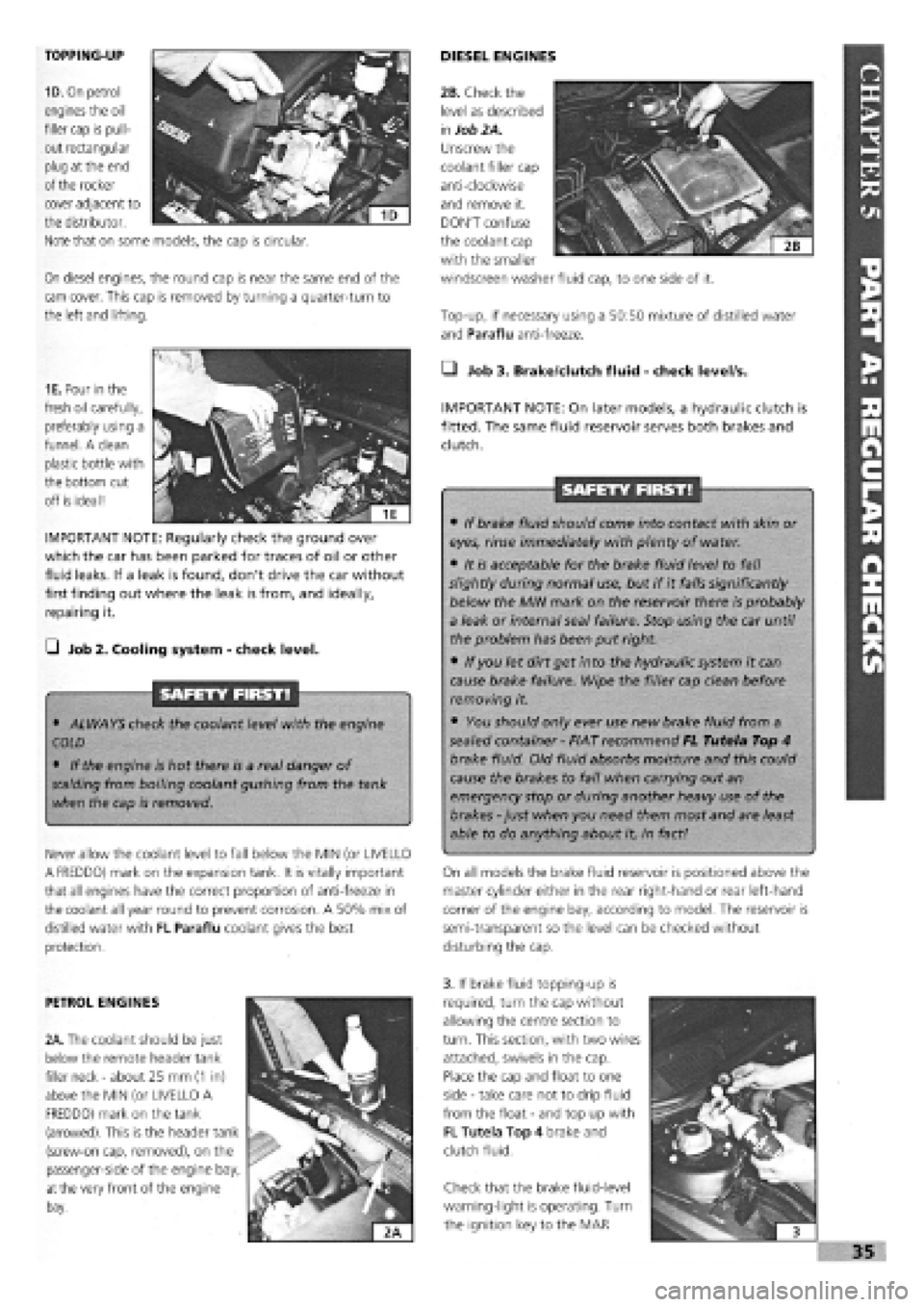

DIESEL ENGINES

Top-up, if necessary using a 50:50 mixture of distilled water

and Paraflu anti-freeze.

cover adjacent to

the distributor.

Note that on some models, the cap is circular.

1E. Pour in the

fresh oil carefully,

preferably using a

funnel. A clean

plastic bottle with

the bottom cut

off is ideal!

IMPORTANT NOTE: Regularly check the ground over

which the car has been parked for traces of oil or other

fluid leaks. If a leak is found, don't drive the car without

first finding out where the leak is from, and ideally,

repairing it.

G Job 2. Cooling system

-

check level.

SAFETY FIRST!

• ALWAYS check the coolant level with the engine

COLD

• If the engine is hot there is a real danger of

scalding

from boiling coolant gushing from the tank

when the cap is removed.

Never allow the coolant level to fall below the MIN (or UVELLO

A FREDDO) mark on the expansion tank. It is vitally important

that all engines have the correct proportion of anti-freeze in

the coolant all year round to prevent corrosion. A 50% mix of

distilled water with FL Paraflu coolant gives the best

protection.

• Job 3. Brake/dutch fluid

-

check level/s.

IMPORTANT NOTE: On later models, a hydraulic clutch is

fitted. The same fluid reservoir serves both brakes and

clutch.

SAFETY FIRST!

• If brake fluid should come into contact with skin or

eyes, rinse immediately with plenty of water.

• It is acceptable for the brake fluid level to fall

slightly during normal use, but if it falls significantly

below the MIN mark on the reservoir there is probably

a leak or internal seal failure. Stop using the car until

the problem has been put right.

• If you let dirt get into the hydraulic system it can

cause brake failure. Wipe the filler cap clean before

removing it.

• You should only ever use new brake fluid from a

sealed container

-

FIAT recommend FL Tutela Top 4

brake fluid. Old fluid absorbs moisture and this could

cause the brakes to fail when carrying out an

emergency stop or during another heavy use of the

brakes

-

just when you need them most and are least

able to do anything about it, in fact!

On all models the brake fluid reservoir is positioned above the

master cylinder either in the rear right-hand or rear left-hand

corner of the engine bay, according to model. The reservoir is

semi-transparent so the level can be checked without

disturbing the cap.

PETROL ENGINES

2A. The coolant should be just

below the remote header tank

filler neck

-

about 25 mm

(1

in)

above the MIN (or UVELLO A

FREDDO) mark on the tank

(arrowed). This is the header tank

(screw-on cap, removed), on the

passenger-side of the engine bay,

at

the very front of the engine

bay.

3. If brake fluid topping-up is

required, turn the cap without

allowing the centre section to

turn. This section, with two wires

attached, swivels in the cap.

Place the cap and float to one

side

-

take care not to drip fluid

from the float

-

and top up with

FL Tutela Top 4 brake and

clutch fluid.

Check that the brake fluid-level

warning-light is operating. Turn

the ignition key to the MAR

I

i 3

»35

2B. Check the

level as described

in

Job 2A.

Unscrew the

coolant filler cap

anti-clockwise

and remove it.

DON'T confuse

the coolant cap

with the smaller

windscreen washer fluid cap, to one side of it.

Page 32 of 171

(ignition-ON) position and press down the button between the

two terminals on the reservoir cap

-

when fitted. The warning

light on the dash should light up. When no button is fitted,

unscrew and raise the cap (ignition key ON) to check the

warning light. Check the bulb, check the fuse, or have your

FIAT dealer repair the warning system, if faulty.

• Job 4. Battery

-

check electrolyte level.

FACT FILE: DISCONNECTING THE

BATTERY

• Many vehicles depend on a constant

power supply from the battery; with

these you find yourself in trouble if you

simply disconnect the battery. You

might find the car alarm goes off, or that the engine

management system forgets all it ever 'learned', making

the car feel odd to drive until it has re-programmed

itself. You might also find that the radio refuses to

operate until its correct security code is keyed into it.

• On cars with engine management systems and/or

coded radios, you must ensure the car has a constant

electrical supply, even with the battery removed. You

will need a separate 12 volt battery; put a self-tapping

screw into the positive lead near the battery terminal

before disconnecting it, and put a positive connection

to your other battery via this screw.

• Be EXTREMELY CAREFUL to wrap insulation tape

around the connection so that no short is caused. The

negative terminal on the other battery must be

connected to the car's bodywork.

SAFETY FIRST!

• The gas given off by a battery is highly explosive.

Never smoke, use a naked flame or allow a spark in

the battery compartment.

• Never disconnect the battery (it can cause sparking)

with the battery caps removed.

• All vehicle batteries contain sulphuric acid. If the

acid comes into contact with the skin or eyes, wash

immediately with copious amounts of cold water and

seek medjcal advice.

• Do not check the battery levels within half an hour

of the battery being charged with a separate battery

charger because the addition of fresh water could

cause electrolyte to flood out.

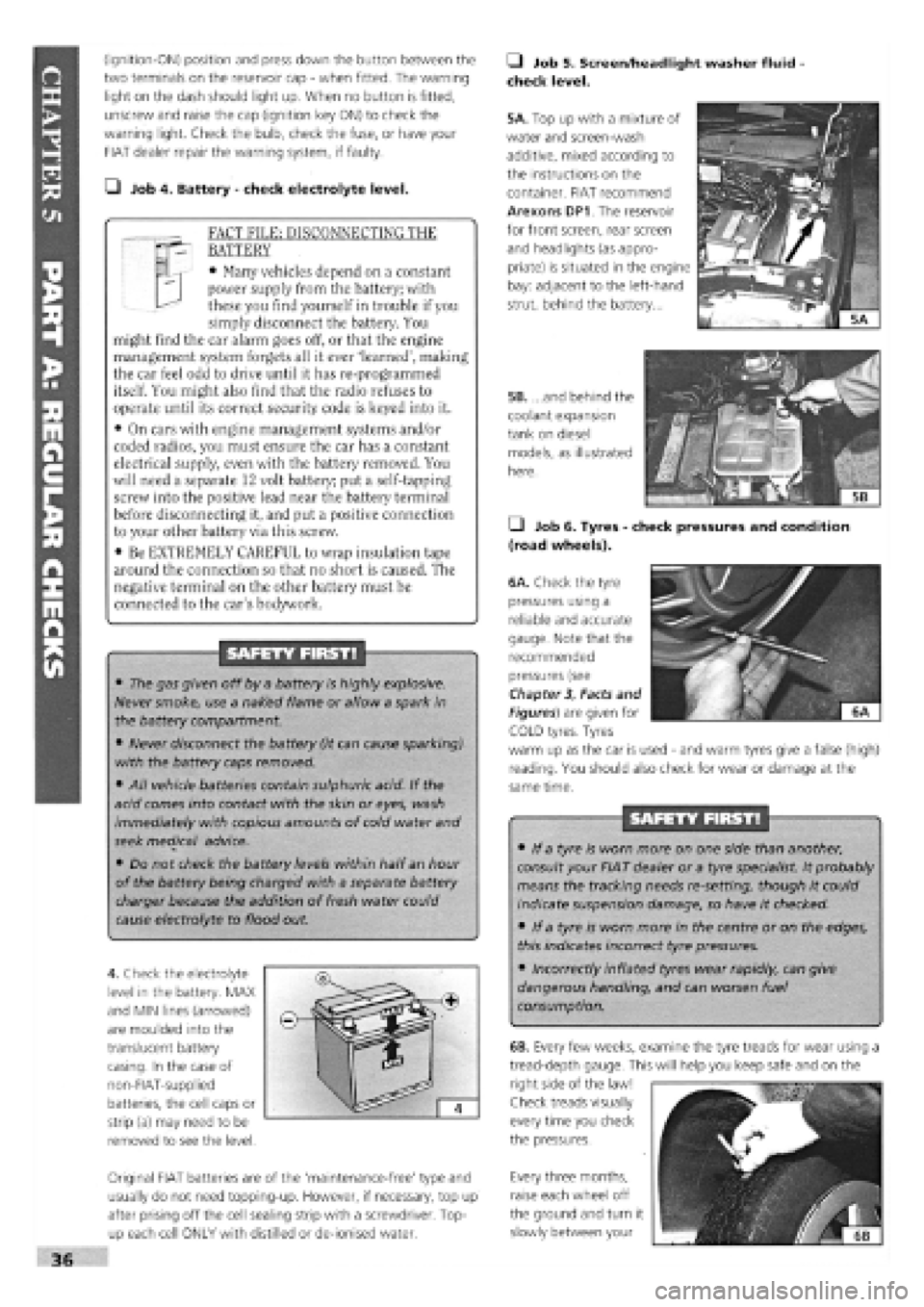

4. Check the electrolyte

level in the battery. MAX

and MIN lines (arrowed)

are moulded into the

translucent battery

casing. In the case of

non-FIAT-supplied

batteries, the cell caps or

strip (a) may need to be

removed to see the level.

Original FIAT batteries are of the 'maintenance-free' type and

usually do not need topping-up. However, if necessary, top up

after prising off the cell sealing strip with a screwdriver. Top-

up each cell ONLY with distilled or de-ionised water.

• Job 5. Screen/headlight washer fluid

check level.

5A. Top up with a mixture of

water and screen-wash

additive, mixed according to

the instructions on the

container. FIAT recommend

Arexons DP1. The reservoir

for front screen, rear screen

and headlights (as appro-

priate) is situated in the engine

bay: adjacent to the left-hand

strut, behind the battery...

5B. ...and behind the

coolant expansion

tank on diesel

models, as illustrated

here.

• Job 6. Tyres

-

check pressures and condition

(road wheels).

/

6A. Check the tyre

pressures using a

reliable and accurate

gauge. Note that the

recommended

pressures (see

Chapter

3,

Facts and

Figures) are given for ^^

iH^KKSEI ^ "'

COLD tyres. Tyres

warm up as the car is used

-

and warm tyres give a false (high)

reading. You should also check for wear or damage at the

same time.

SAFETY FIRST!

• If a tyre is worn more on one side than another,

consult your FIAT dealer or a tyre specialist. It probably

means the tracking needs re-setting, though it could

indicate suspension damage, so have it checked.

• If a tyre is worn more in the centre or on the edges,

this indicates incorrect tyre pressures.

• Incorrectly inflated tyres wear rapidly, can give

dangerous handling, and can worsen fuel

consumption.

Every three months,

raise each wheel off

the ground and turn it

slowly between your

36

6B. Every few weeks, examine the tyre treads for wear using a

tread-depth gauge. This will help you keep safe and on the

right side of the law!

Check treads visually

every time you check

the pressures.

Page 33 of 171

• Whenever a light fails to

work, check its fuse before

replacing the bulb.

• A blown bulb often causes a fuse to 'go' in

sympathy.

hands, looking and feeling for any bulges, tears or splits in the

tyre walls, especially the inner sidewalls. (See Job 59 for spare

tyre checks.)

H INSIDE INFORMATION: In time, rubber deteriorates,

increasing the risk of a blow-out. Keep your eye on the

sidewalls of older tyres. If you see any cracking, splits or

other damage scrap the tyre. If you're not sure, consult

your FIAT dealer or tyre specialist. Q

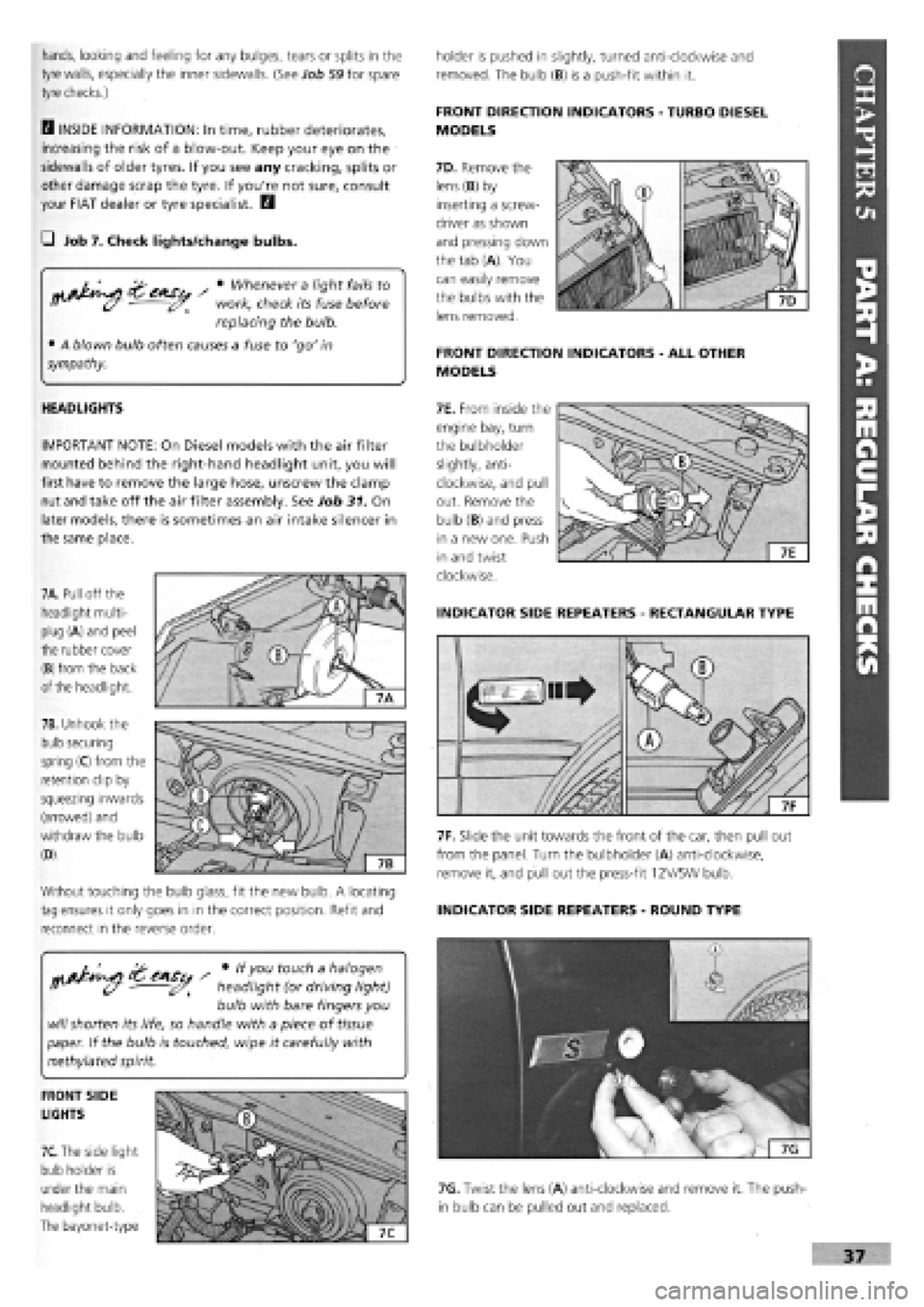

_) Job 7. Check lights/change bulbs.

7A. Pull off the

headlight multi-

plug (A) and peel

the rubber cover

(B) from the back

of the headlight.

7B. Unhook the

bulb securing

spring (C) from the

retention clip by

squeezing inwards

(arrowed) and

withdraw the bulb

(D).

Without touching the bulb glass, fit the new bulb. A locating

tag ensures it only goes in in the correct position. Refit and

reconnect in the reverse order.

HEADLIGHTS

IMPORTANT NOTE: On Diesel models with the air filter

mounted behind the right-hand headlight unit, you will

first have to remove the large hose, unscrew the clamp

nut and take off the air filter assembly. See Job 31. On

later models, there is sometimes an air intake silencer in

the same place.

7F. Slide the unit towards the front of the car, then pull out

from the panel. Turn the bulbholder (A) anti-clockwise,

remove it, and pull out the press-fit 12V/5W bulb.

INDICATOR SIDE REPEATERS

-

ROUND TYPE

holder is pushed in slightly, turned anti-clockwise and

removed. The bulb (B) is a push-fit within it.

FRONT DIRECTION INDICATORS

-

TURBO DIESEL

MODELS

7D. Remove the

lens (B) by

inserting a screw-

driver as shown

and pressing down

the tab (A). You

can easily remove

the bulbs with the

lens removed.

FRONT DIRECTION INDICATORS

-

ALL OTHER

MODELS

7E. From inside the

engine bay, turn

the bulbholder

slightly, anti-

clockwise, and pull

out. Remove the

bulb (B) and press

in a new one. Push

in and twist

clockwise.

INDICATOR SIDE REPEATERS

-

RECTANGULAR TYPE

CAS / * touc^ a halogen

• headlight (or driving light)

bulb with bare fingers you

will

shorten its life, so handle with a piece of

tissue

paper. If the bulb is touched, wipe it carefully with

methylated spirit.

FRONT SIDE

LIGHTS

7C.

The side light

bulb holder is

under the main

headlight bulb.

The bayonet-type

7G. Twist the lens (A) anti-clockwise and remove it. The push-

in bulb can be pulled out and replaced.

Page 38 of 171

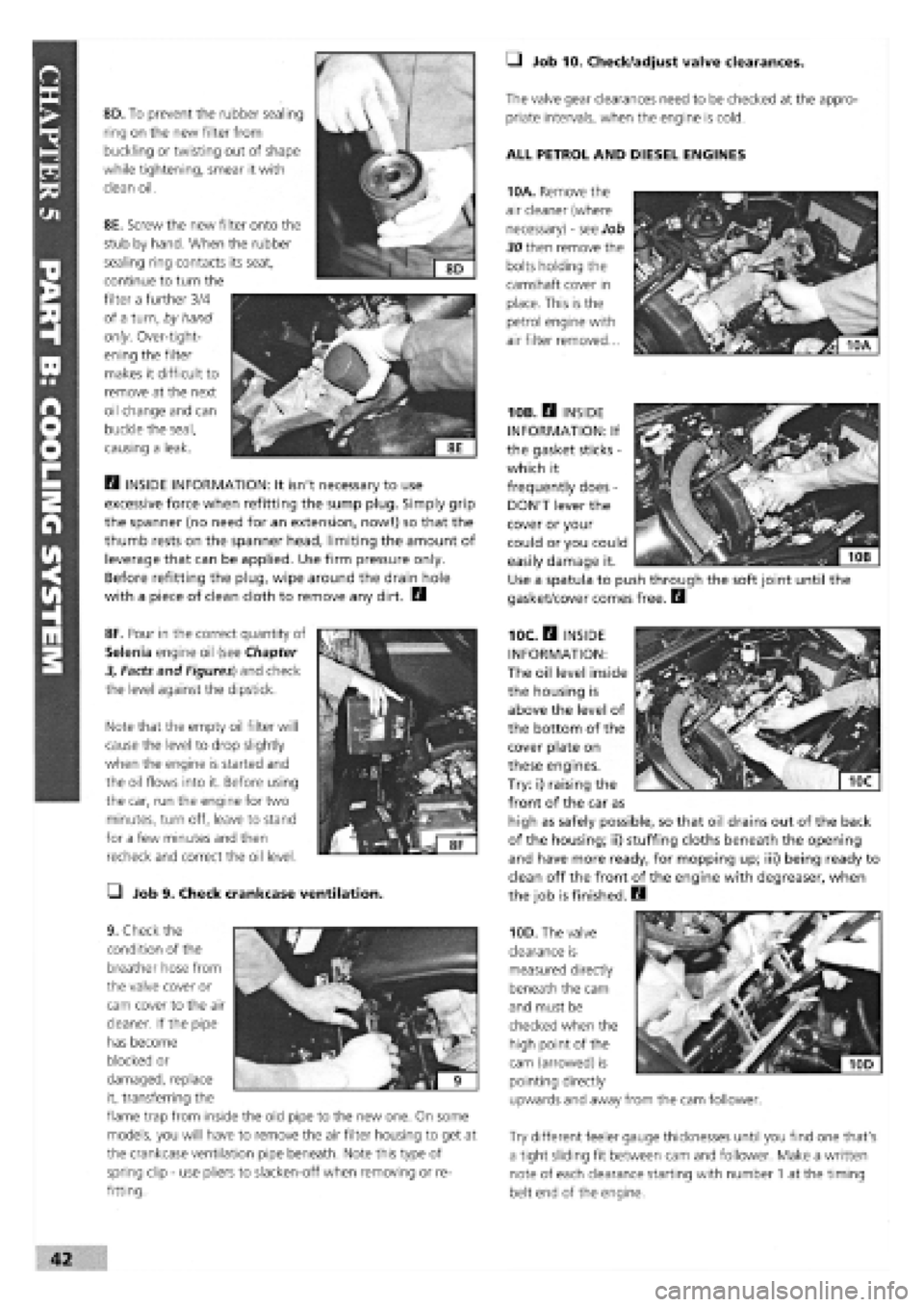

8D. To prevent the rubber sealing

ring on the new filter from

buckling or twisting out of shape

while tightening, smear it with

clean oil.

8E. Screw the new filter onto the

stub by hand. When the rubber

sealing ring contacts its seat,

continue to turn the

filter a further 3/4

of a turn, by hand

only. Over-tight-

ening the filter

makes it difficult to

remove at the next

oil change and can

buckle the seal,

causing a leak.

E3 INSIDE INFORMATION: It isn't necessary to use

excessive force when refitting the sump plug. Simply grip

the spanner (no need for an extension, now!) so that the

thumb rests on the spanner head, limiting the amount of

leverage that can be applied. Use firm pressure only.

Before refitting the plug, wipe around the drain hole

with a piece of clean cloth to remove any dirt. II

8F. Pour in the correct quantity of

Selenia engine oil (see Chapter

3, Facts and Figures) and check

the level against the dipstick.

Note that the empty oil filter will

cause the level to drop slightly

when the engine is started and

the oil flows into it. Before using

the car, run the engine for two

minutes, turn off, leave to stand

for a few minutes and then

recheck and correct the oil level.

• Job 9. Check crankcase ventilation.

10B. H INSIDE

INFORMATION: If

the gasket sticks

-

which it

frequently does -

DON'T lever the

Q Job 10. Check/adjust valve clearances.

The valve gear clearances need to be checked at the appro-

priate intervals, when the engine is cold.

ALL PETROL AND DIESEL ENGINES

10A. Remove the

air cleaner (where

necessary)

-

see Job

30 then remove the

bolts holding the

camshaft cover in

place. This is the

petrol engine with

air filter removed...

cover or your

could or you could

easily damage it.

Use a spatula to push through the soft joint until the

gasket/cover comes free. D

10C. E3 INSIDE

INFORMATION:

The oil level inside

the housing is

above the level of

the bottom of the

cover plate on

these engines.

Try: i) raising the

front of the car as

high as safely possible, so that oil drains out of the back

of the housing; ii) stuffing cloths beneath the opening

and have more ready, for mopping up; iii) being ready to

clean off the front of the engine with degreaser, when

the job is finished. D

10D. The valve

clearance is

measured directly

beneath the cam

and must be

checked when the

high point of the

cam (arrowed) is

pointing directly

upwards and away

9. Check the

condition of the

breather hose from

the valve cover or

cam cover to the air

cleaner. If the pipe

has become

blocked or

damaged, replace

it, transferring the

flame trap from inside the old pipe to the new one. On some

models, you will have to remove the air filter housing to get at

the crankcase ventilation pipe beneath. Note this type of

spring clip

-

use pliers to slacken-off when removing or re-

fitting.

Try different feeler gauge thicknesses until you find one that's

a tight sliding fit between cam and follower. Make a written

note of each clearance starting with number

1

at the timing

belt end of the engine.

from the cam follower.

Page 39 of 171

—I Job 13. Check cooling system.

SAFETY FIRST!

• The coolant level should be checked

-

and the

cooling system worked on, ONLY WHEN THE

COOLANT IS COLD. If you remove the pressure cap or

bleed screws when the engine is hot, scalding coolant

will spurt out.

• Keep anti-freeze away from children. If it is acciden-

tally swallowed or contacts skin or eyes, rinse

immediately with plenty of water and seek immediate

medical help.

Examine the cooling system hoses, looking for signs of

splitting, chafing and perishing. Squeeze the top and bottom

radiator hoses. Any hard, brittle areas or crackling sounds tell

you that the hoses are decomposing from the inside

-

replace-

ments needed!

SAFETY FIRST!

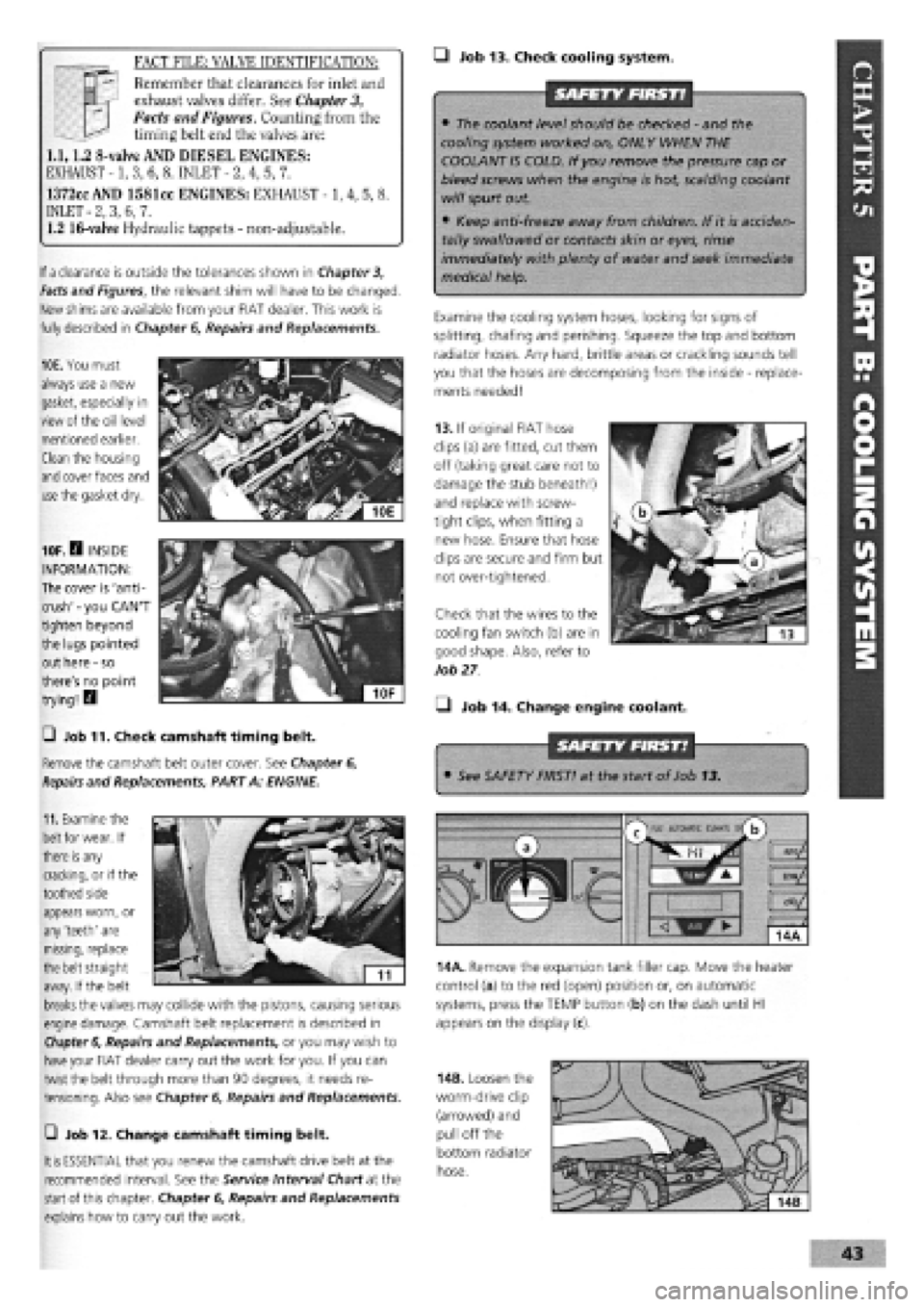

If

a

clearance is outside the tolerances shown in Chapter 3,

Facts

and Figures, the relevant shim will have to be changed.

New

shims

are available from your FIAT dealer. This work is

fully described in Chapter

6,

Repairs and Replacements.

10E. You must

always use a new

gasket, especially in

view of the oil level

mentioned earlier.

Clean the housing

and

cover faces and

use

the gasket dry.

11.

Examine the

belt

for wear. If

there

is

any

cracking, or if the

toothed side

10F.H INSIDE

INFORMATION:

The cover is 'anti-

crush'

-

you CAN'T

tighten beyond

the lugs pointed

out here

-

so

there's no point

trying! H

0 Job 11. Check camshaft timing belt.

Remove the camshaft belt outer cover. See Chapter 6,

Repairs

and Replacements, PART A: ENGINE.

FACT FILE: VALVE IDENTIFICATION:

T

—

Remember that clearances for inlet and

3™ exhaust valves differ. See

Chapter

3,

Facts and Figures. Counting from the

—^ timing belt end the valves are:

1.1,1.2 8-valve AND DIESEL ENGINES:

EXHAUST -1, 3, 6, 8. INLET

-

2, 4, 5, 7.

1372cc AND 1581cc ENGINES: EXHAUST -1, 4, 5, 8.

INLET

-

2, 3, 6, 7.

1.2 16-valve Hydraulic tappets

-

non-adjustable.

13. If original FIAT hose

clips (a) are fitted, cut them

off (taking great care not to

damage the stub beneath!)

and replace with screw-

tight clips, when fitting a

new hose. Ensure that hose

clips are secure and firm but

not over-tightened.

Check that the wires to the

cooling fan switch (b) are in

good shape. Also, refer to

Job

27

• Job 14. Change engine coolant.

• See SAFETY FIRST! at the start of Job 13.

appears worn, or

any 'teeth' are

missing, replace

the belt straight

away. If the belt

breaks

the valves may collide with the pistons, causing serious

engine damage. Camshaft belt replacement is described in

Chapter 6,

Repairs and Replacements, or you may wish to

have

your FIAT dealer carry out the work for you. If you can

twist the belt through more than 90 degrees, it needs re-

tensioning. Also see Chapter

6,

Repairs and Replacements.

m

AUtOKAlIC CtMAU s/

b

14A. Remove the expansion tank filler cap. Move the heater

control (a) to the red (open) position or, on automatic

systems, press the TEMP button (b) on the dash until HI

appears on the display (c).

—i Job 12. Change camshaft timing belt.

It is

ESSENTIAL that you renew the camshaft drive belt at the

recommended interval. See the Service Interval Chart at the

start

of this chapter. Chapter

6,

Repairs and Replacements

explains how to carry out the work.

14B. Loosen the

worm-drive clip

(arrowed) and

pull off the

bottom radiator

hose.

Page 40 of 171

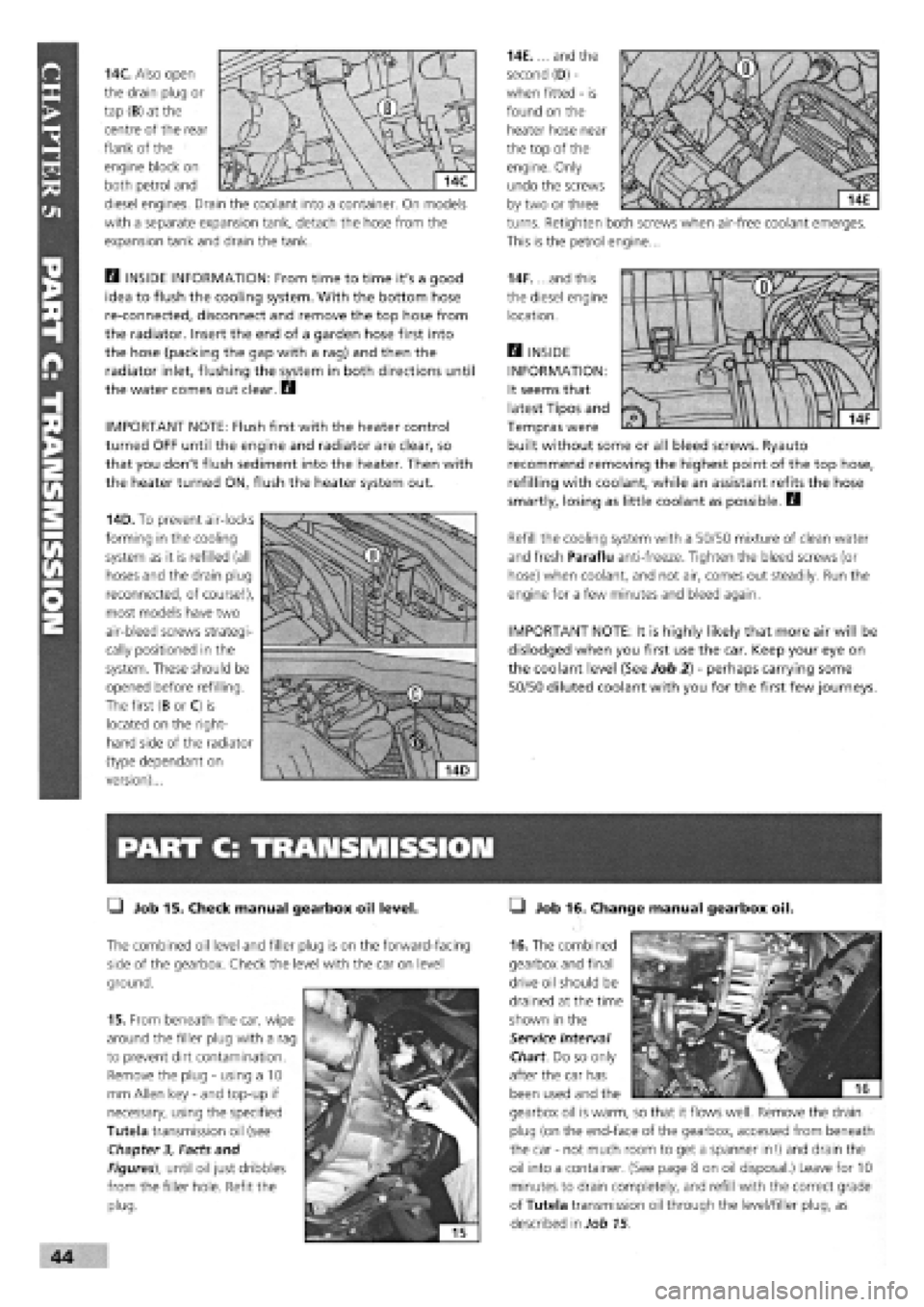

14C. Also open

the drain plug or

tap (B) at the

centre of the rear

flank of the

engine block on

both petrol and

diesel engines. Drain the coolant into a container. On models

with a separate expansion tank, detach the hose from the

expansion tank and drain the tank.

Q INSIDE INFORMATION: From time to time it's a good

idea to flush the cooling system. With the bottom hose

re-connected, disconnect and remove the top hose from

the radiator. Insert the end of a garden hose first into

the hose (packing the gap with a rag) and then the

radiator inlet, flushing the system in both directions until

the water comes out clear. Q

IMPORTANT NOTE: Flush first with the heater control

turned OFF until the engine and radiator are clear, so

that you don't flush sediment into the heater. Then with

the heater turned ON, flush the heater system out.

14D. To prevent air-locks

forming in the cooling

system as it is refilled (all

hoses and the drain plug

reconnected, of course!),

most models have two

air-bleed screws strategi-

cally positioned in the

system. These should be

opened before refilling.

The first (B or C) is

located on the right-

hand side of the radiator

(type dependant on

version)...

PART C: TRANSMISSION

• Job 15. Check manual gearbox oil level.

The combined oil level and filler plug is on the forward-facing

side of the gearbox. Check the level with the car on level

ground.

15. From beneath the car, wipe

around the filler plug with a rag

to prevent dirt contamination.

Remove the plug

-

using a 10

mm Allen key

-

and top-up if

necessary, using the specified

Tutela transmission oil (see

Chapter

3,

Facts and

Figures), until oil just dribbles

from the filler hole. Refit the

plug.

14E.... and the

second (D)

-

when fitted

-

is

found on the

heater hose near

the top of the

engine. Only

undo the screws

by two or three

turns. Retighten both screws when air-free coolant emerges.

This is the petrol engine...

14F. ...and this

the diesel engine

location.

H INSIDE

INFORMATION:

It seems that

latest Tipos and

Tempras were

built without some or all bleed screws. Ryauto

recommend removing the highest point of the top hose,

refilling with coolant, while an assistant refits the hose

smartly, losing as little coolant as possible. D

Refill the cooling system with a 50/50 mixture of clean water

and fresh Paraflu anti-freeze. Tighten the bleed screws (or

hose) when coolant, and not air, comes out steadily. Run the

engine for a few minutes and bleed again.

IMPORTANT NOTE: It is highly likely that more air will be

dislodged when you first use the car. Keep your eye on

the coolant level (See Job 2)

-

perhaps carrying some

50/50 diluted coolant with you for the first few journeys.

• Job 16. Change manual gearbox oil.

16. The combined

gearbox and final

drive oil should be

drained at the time

shown in the

Service Interval

Chart. Do so only

after the car has

been used and the

gearbox oil is warm, so that it flows well. Remove the drain

plug (on the end-face of the gearbox, accessed from beneath

the car

-

not much room to get a spanner in!) and drain the

oil into a container. (See page 8 on oil disposal.) Leave for 10

minutes to drain completely, and refill with the correct grade

of Tutela transmission oil through the level/filler plug, as

described in Job 15.

Page 41 of 171

IMPORTANT NOTE: Take care not to allow any dirt or grit

to get into the gearbox.

• Job 19. Check driveshaft gaiters.

45

B INSIDE INFORMATION: Make sure you have a 10 mm

Allen key that will fit, before you start. There's very little

room between gearbox and subframe. B

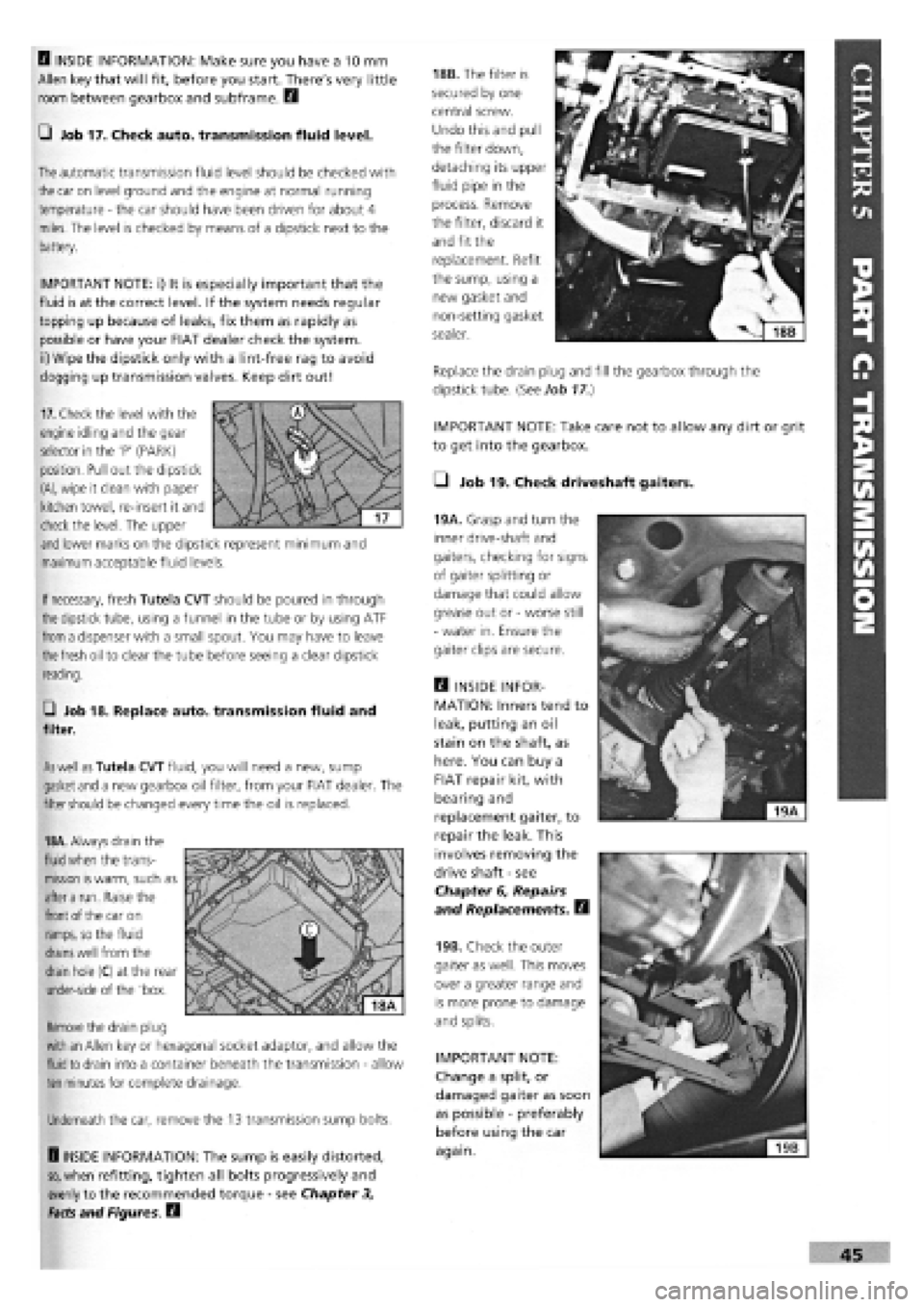

Q Job 17. Check auto, transmission fluid level.

The

automatic transmission fluid level should be checked with

the

car on level ground and the engine at normal running

temperature

-

the car should have been driven for about 4

miles. The level is checked by means of a dipstick next to the

battery.

IMPORTANT NOTE: i) It is especially important that the

fluid is at the correct level. If the system needs regular

topping up because of leaks, fix them as rapidly as

possible or have your FIAT dealer check the system,

ii) Wipe the dipstick only with a lint-free rag to avoid

clogging up transmission valves. Keep dirt out!

18B. The filter is

secured by one

central screw.

Undo this and pull

the filter down,

detaching its upper

fluid pipe in the

process. Remove

the filter, discard it

and fit the

replacement. Refit

the sump, using a

new gasket and

non-setting gasket

sealer.

Replace the drain plug and fill the gearbox through the

dipstick tube. {See Job

17.)

19A. Grasp and turn the

inner drive-shaft and

gaiters, checking for signs

of gaiter splitting or

damage that could allow

grease out or

-

worse still

-

water in. Ensure the

gaiter clips are secure.

Q INSIDE INFOR-

MATION: Inners tend to

leak, putting an oil

stain on the shaft, as

here. You can buy a

FIAT repair kit, with

bearing and

replacement gaiter, to

repair the leak. This

involves removing the

drive shaft

-

see

Chapter 6, Repairs

and Replacements. B

19B. Check the outer

gaiter as well. This moves

over a greater range and

is more prone to damage

and splits.

IMPORTANT NOTE:

Change a split, or

damaged gaiter as soon

as possible

-

preferably

before using the car

again.

If

necessary,

fresh Tutela CVT should be poured in through

the

dipstick tube, using a funnel in the tube or by using ATF

from

a dispenser with a small spout. You may have to leave

the fresh

oil to clear the tube before seeing a clear dipstick

reading.

G Job 18. Replace auto, transmission fluid and

filter.

As well as

Tutela CVT fluid, you will need a new, sump

gasket

and

a new gearbox oil filter, from your FIAT dealer. The

filter

should

be changed every time the oil is replaced.

18A.

Always drain the

fluid when

the trans-

mission

is

warm, such as

after a

run. Raise the

front

of the car on

ramps,

so the fluid

drains well

from the

drain

hole (C) at the rear

under-side of the 'box.

Remove

the drain plug

with an

Allen key or hexagonal socket adaptor, and allow the

fluid to

drain into a container beneath the transmission

-

allow

ten

minutes for complete drainage.

Underneath the car, remove the 13 transmission sump bolts.

H INSIDE INFORMATION: The sump is easily distorted,

so,

when refitting, tighten all bolts progressively and

evenly to the recommended torque

-

see Chapter 3,

Facts and Figures. B

17.

Check the level with the

engine idling and the gear

selector in the 'P' (PARK)

position. Pull out the dipstick

(A),

wipe it clean with paper

kitchen towel, re-insert it and

check the level. The upper

and

lower marks on the dipstick represent minimum and

maximum acceptable fluid levels.

Page 42 of 171

• Job 20. Check/adjust clutch. CABLE OPERATED CLUTCH

The clutch mechanism is self-adjusting, although the cable

linkage can stretch over a period of time and may need

adjustment. The adjuster is on top of the gearbox, reached

from inside the engine bay.

20C. 'Work' the clutch pedal

(X) a few times, pull back the

carpet from under the pedal,

then measure the full travel of

the pedal, which should be

between 140 and 150 mm.

/

\

/ \

/ u / Xl

1 ' ' / . V y 2

Jdi V 1 \

X. 1 —

20C

HYDRAULIC CLUTCH

20B. Check the

pipework and slave

cylinder, on the

gearbox casing,

from beneath the

20D. If not, note that after

slackening the locknut, turning

the adjusting nut inwards

along the threaded rod

(arrowed) will increase pedal

travel. Tighten the lock-nut

against the inner nut after

adjustment.

• Job 21. Check auto, transmission selector cable.

It should only be possible to start the engine when the gear

selector is in the 'P' or 'N' position. Place it in each of the

other positions and try to start the car. If it starts, the fault

must be put right! Also check that, with the ignition off and

the selector lever in 'D' (Drive), 'L' (Low), 'R' (Reverse) or 'N'

(Neutral), the timed warning buzzer should sound. If it

doesn't, the selector cable adjustment may be faulty.

See Chapter

6,

Repairs and Replacements, PART B:

TRANSMISSION AND CLUTCH, Job 8 for adjustment details.

PART D: IGNITION AND ELECTRICS

See FACT FILE: DISCONNECTING THE BATTERY on page 36

SAFETY FIRST!

• You may minimise the risk of shock when the engine is running by wearing thick rubber gloves and by NEVER

working on the system in damp weather or when standing on damp ground. Read Chapter 1, Safety First! before

carrying out any work on the ignition system.

• ELECTRONIC IGNITION SYSTEMS INVOLVE VERY HIGH VOLTAGES! All manufacturers recommend that only trained

personnel should go near the high-tension circuit (coil, distributor and HT wiring) and it is ESSENTIAL that anyone

wearing a medical pacemaker device does not go near the ignition system.

• Stroboscopic timing requires the engine to be running

-

take great care that parts of the timing light or parts of

you don't get caught up in moving components!

• Don't have loose clothing or hair.

46

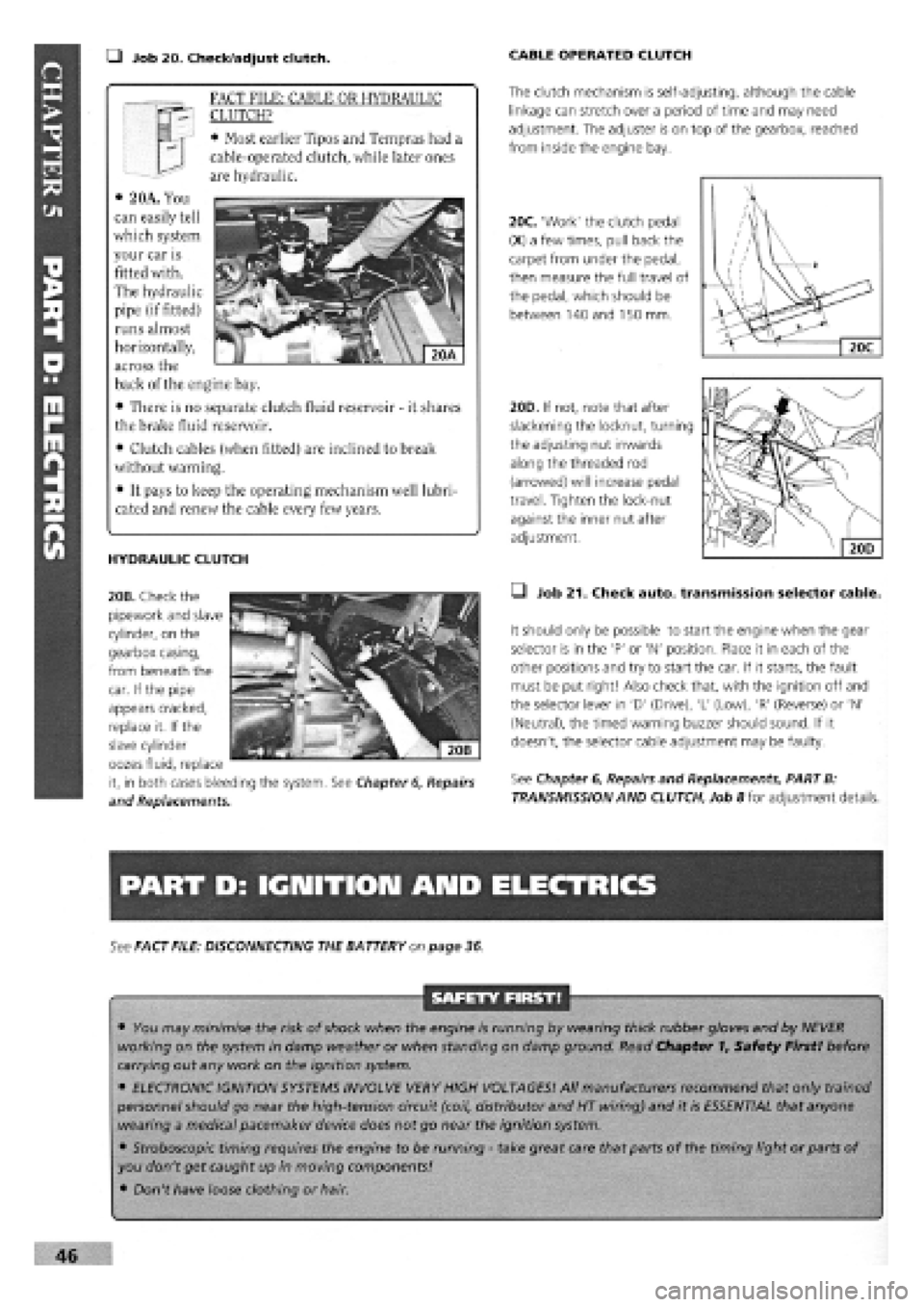

FACT FILE: CABLE OR HYDRAULIC

CLUTCH?

• Most earlier Tipos and Tempras had a

cable-operated clutch, while later ones

are hydraulic.

• 2 OA. You

can easily tell

which system

your car is

fitted with.

The hydraulic

pipe (if fitted)

runs almost

horizontally,

across the

back of the engine bay.

• There is no separate clutch fluid reservoir

-

it shares

the brake fluid reservoir.

• Clutch cables (when fitted) are inclined to break

without warning.

• It pays to keep the operating mechanism well lubri-

cated and renew the cable every few years.

car. If the pipe

appears cracked,

replace it. If the

slave cylinder

oozes fluid, replace

it, in both cases bleeding the system. See Chapter

6,

Repairs

and Replacements.