check engine FIAT TEMPRA 1988 Service And Workshop Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 1988, Model line: TEMPRA, Model: FIAT TEMPRA 1988Pages: 171, PDF Size: 18.05 MB

Page 88 of 171

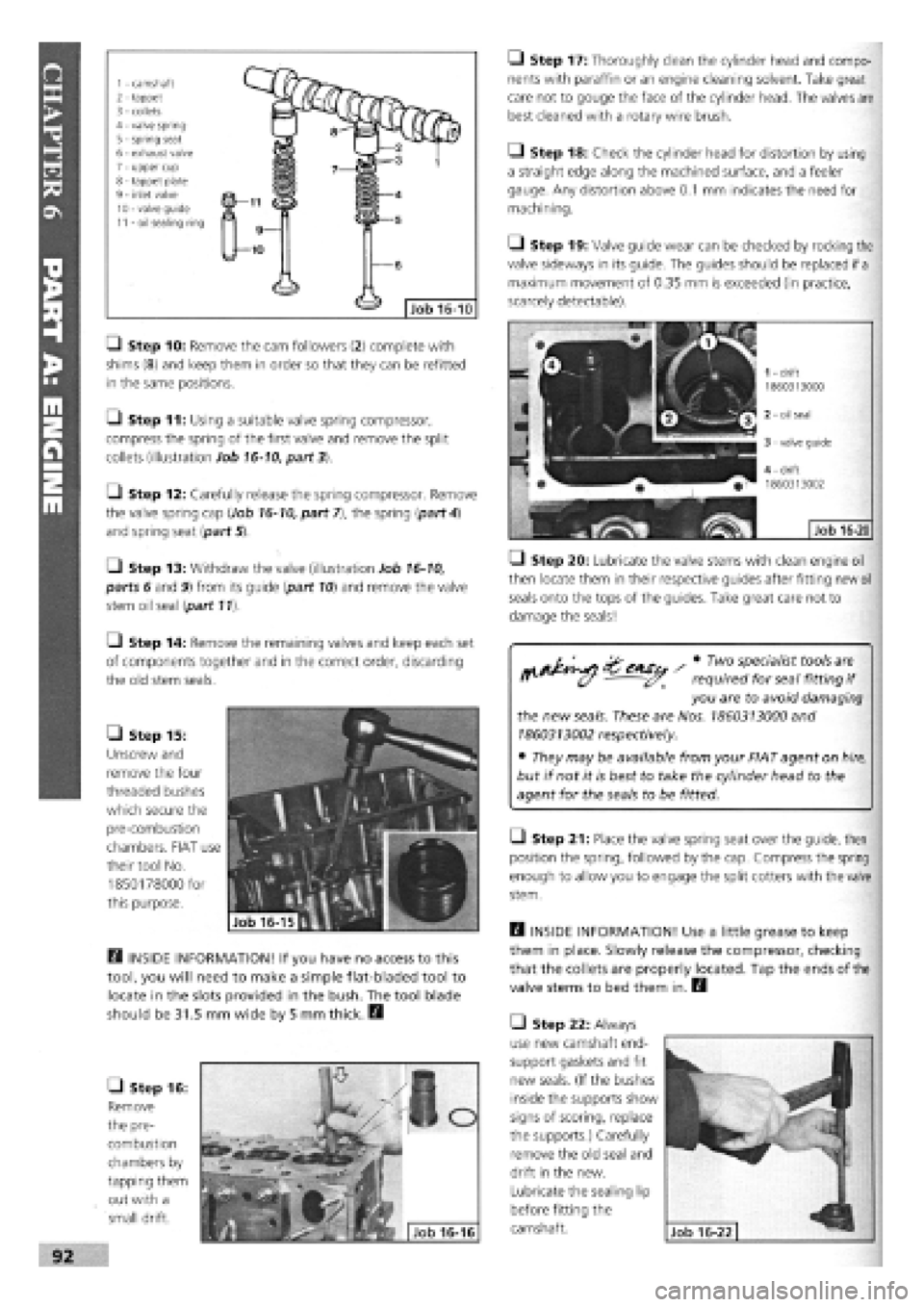

1 - camshaft 2 - tappet 3 - collets 4 - valve spring 5

-

spring seat 6 - exhaust valve 7 - upper cup 8 - tappet plate 9 - inlet valve 10 - valve guide 11 - oil sealing ring

• Step 10: Remove the cam followers (2) complete with

shims

(8)

and keep them in order so that they can be refitted

in the same positions.

O Step 11: Using a suitable valve spring compressor,

compress the spring of the first valve and remove the split

collets (illustration Job

16-10,

part 3).

[J Step 12: Carefully release the spring compressor. Remove

the valve spring cap (Job

16-10,

part 7), the spring {part

4)

and spring seat {part 5).

•

Step 13: Withdraw the valve (illustration Job

16-10,

parts 6 and 9) from its guide {part

10)

and remove the valve

stem oil seal {part 11).

Q Step 14: Remove the remaining valves and keep each set

of components together and in the correct order, discarding

the old stem seals.

• Step 15:

Unscrew and

remove the four

threaded bushes

which secure the

pre-combustion

chambers. FIAT use

their tool No.

1850178000 for

this purpose.

Q INSIDE INFORMATION! If you have no access to this

tool, you will need to make a simple flat-bladed tool to

locate in the slots provided in the bush. The tool blade

should be 31.5 mm wide by 5 mm thick. B

• Step 16:

Remove

the pre-

combustion

chambers by

tapping them

out with a

small drift.

Q Step 17: Thoroughly clean the cylinder head and compo-

nents with paraffin or an engine cleaning solvent. Take great

care not to gouge the face of the cylinder head. The valves are

best cleaned with a rotary wire brush.

• Step 18: Check the cylinder head for distortion by using

a straight edge along the machined surface, and a feeler

gauge. Any distortion above

0.1

mm indicates the need for

machining.

Q Step 19: Valve guide wear can be checked by rocking the

valve sideways in its guide. The guides should be replaced if

a

maximum movement of 0.35 mm is exceeded (in practice,

scarcely detectable).

• Step 20: Lubricate the valve stems with clean engine oil

then locate them in their respective guides after fitting new

oil

seals onto the tops of the guides. Take great care not to

damage the seals!

^ ^^iSu / * TW°

VfaliSt*?0lS

"'I

f' (y - required for seal fitting

if

you are to avoid damaging

the new

seals.

These are Nos.

1860313000

and

1860313002

respectively.

• They may be available from your FIAT agent on

hire,

but if not it is best to take the cylinder head to the

agent for the seals to be fitted.

Q Step 21: Place the valve spring seat over the guide, then

position the spring, followed by the cap. Compress the spring

enough to allow you to engage the split cotters with the valve

stem.

Q INSIDE INFORMATION! Use a little grease to keep

them in place. Slowly release the compressor, checking

that the collets are properly located. Tap the ends of the

valve stems to bed them in. B

• Step 22: Always

use new camshaft end-

support gaskets and fit

new seals. (If the bushes

inside the supports show

signs of scoring, replace

the supports.) Carefully

remove the old seal and

drift in the new.

Lubricate the sealing lip

before fitting the

camshaft.

Page 91 of 171

Q Step 2: Before starting the engine, make sure all your

electrical connections are sound and your fuel, oil and coolant

connections are correct and secure.

Q Step 3: Run the engine to working temperature and then

allow to cool. Re-check all fluid levels.

Job 20. Diesel engine.

Mountings - replacement.

See

Job

12

and Job

18,

Step 20

Job 21. Diesel engine/

transmission (removed from car)

- separation.

Q Step 1: Remove the starter motor.

• Step 2: On the turbo version, undo the flange bolts see

Job

18,

Step 16A and withdraw the drive-shaft extension, if

still

fitted.

Q Step 3: Unbolt and remove the rear engine plate and the

gearbox, being careful to support the gearbox weight as it is

withdrawn.

Job 22. Diesel engine/

transmission (removed from car)

- reconnection.

Q Step 1: Before proceeding, check the condition of the

clutch and

its release mechanism. Make sure the driven plate

is

properly centred on the flywheel

-

see PART B: TRANS-

MISSION.

Q Step 2: Now reverse the order of separation, but be

careful when

engaging the gearbox input shaft with the

clutch

driven plate that you don't 'hang' its weight on the

splines.

Also,

see

Job 11.

Job 23. Diesel engine -

dismantling.

This Job should

be read in conjunction with Job 5 The

engines are

broadly similar although the information given in

this Job takes

priority for diesel engines. It is MOST

IMPORTANT that you read the FACT FILE on page 84.

SAFETY FIRST!

•

The inside

of diesel engines are particularly filthy

places!

•

Old diesel

oil

is

carcinogenic!

•

Wear suitable

impervious gloves!

I

• Step 1: Remove the timing belt and cylinder head. See

Jobs

13

and 14.

Q Step 2: Remove the alternator, water pump and

thermostat housing distribution pipe.

• Step 3: Remove the crankshaft timing belt sprocket.

Q INSIDE INFORMATION! Note that the bolt securing

the crankshaft sprocket has a left-hand thread and must

be undone clockwise. D

• Step 4: Unbolt the timing belt tensioner and idler pulleys.

• Step 5: Remove the injection pump sprocket.

Q INSIDE INFORMATION! You will need two FIAT tools

for this operation. One (No. 1860473000) is to prevent

the sprocket from turning when undoing the nut, and

the other (extractor No. 1842128000) to pull the sprocket

from the injection pump shaft. Alternatively it may be

possible to improvise a means of preventing sprocket

rotation, and a suitable three-leg puller may be carefully

used to withdraw the sprocket. Take care not to lose the

pump shaft Woodruff key. B

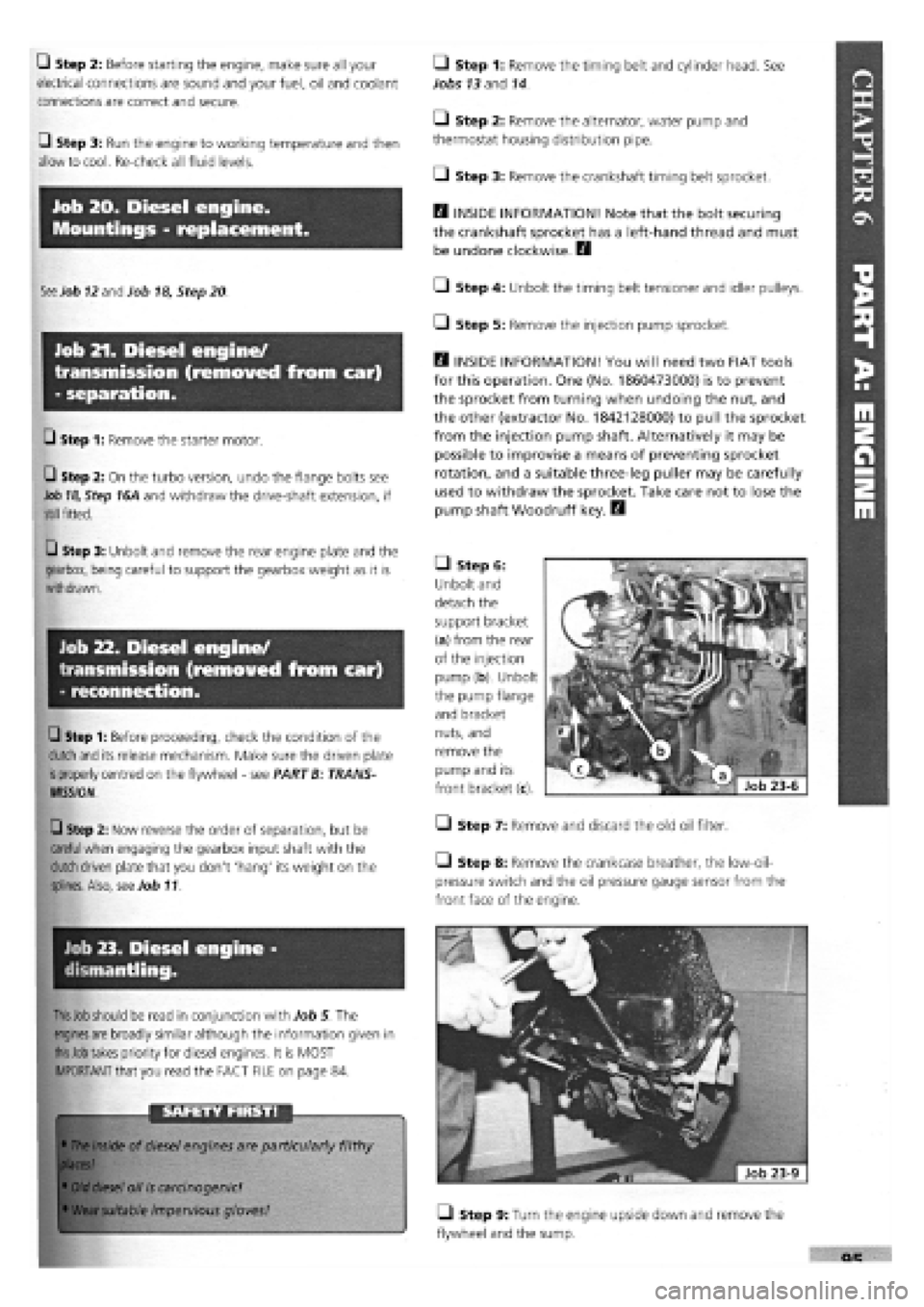

• Step 6:

Unbolt and

detach the

support bracket

(a) from the rear

of the injection

pump (b). Unbolt

the pump flange

and bracket

nuts, and

remove the

pump and its

front bracket (c).

• Step 7: Remove and discard the old oil filter.

Step 8: Remove the crankcase breather, the low-oil-

pressure switch and the oil pressure gauge sensor from the

front face of the engine.

• Step 9: Turn the engine upside down and remove the

flywheel and the sump.

Page 93 of 171

CRANKSHAFT

• Step 1: TURBO ONLY: Before fitting the crankshaft,

install the four piston sprays (a) and stake the retaining plates

(arrowed).

Q Step 2: Locate the main bearing shells so that they are

firmly seated and their tabs engage with the slots in the

journal webs.

• Step 3: Apply some grease to the smooth side of the

thrust washers and 'stick' them in position on both sides of

the rear main bearing web (at the flywheel end).

• Step 4: Oil the shells liberally with fresh engine oil and

lower the crankshaft into position.

• Step 5: Fit the remaining halves of the shells into the

bearing caps. Oil the journals and position the caps the right

way round and in the correct order.

• Step 6: Screw the bolts in finger-tight and check that the

crankshaft rotates freely and smoothly.

Q Step 7: Tighten the bolts evenly and progressively until

the specified torque setting is reached, see Chapter

3,

Facts

and Figures. Check again that the crankshaft rotates

smoothly.

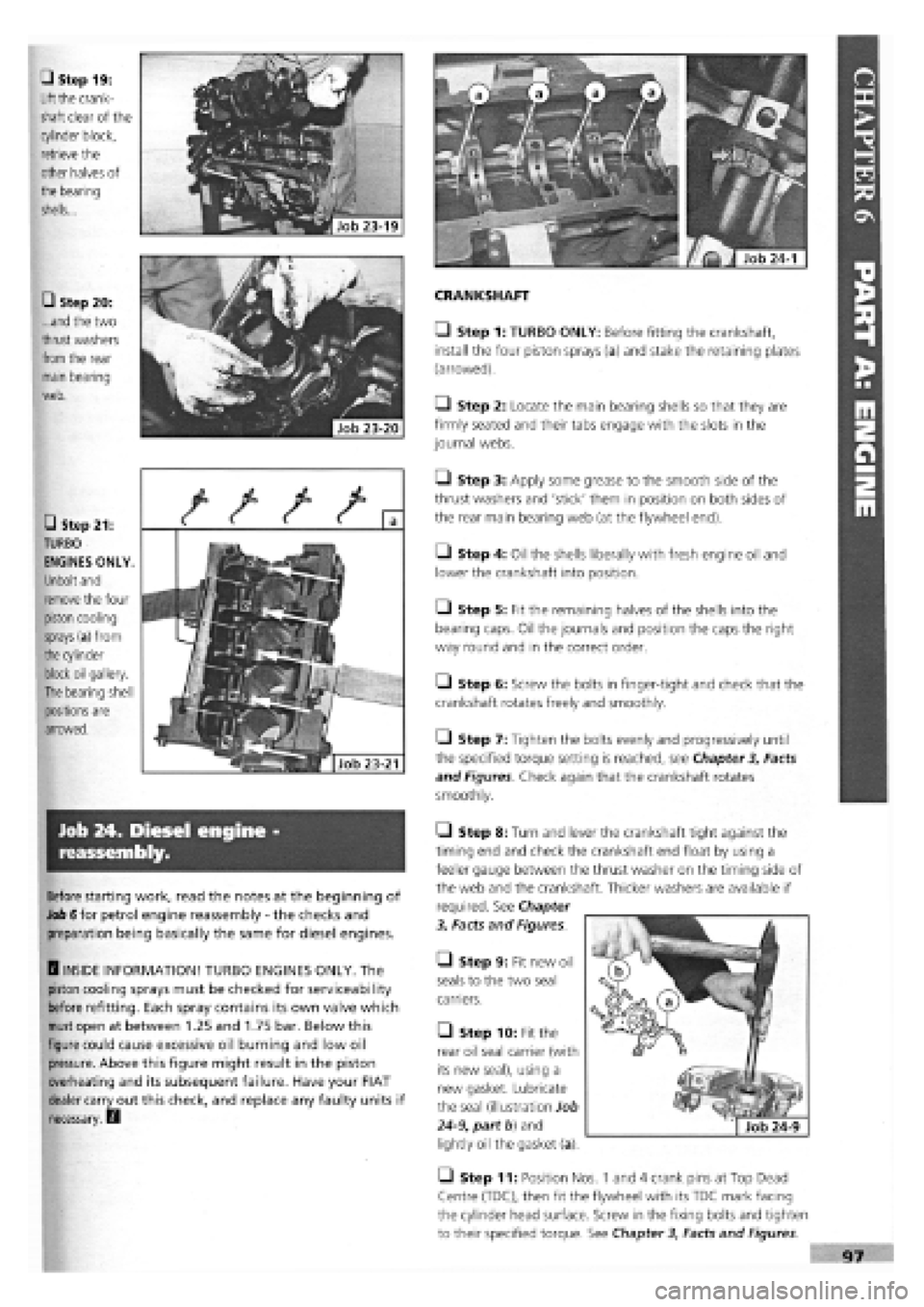

• Step 19:

Lift

the crank-

shaft clear of the

cylinder block,

retrieve the

other halves of

the

bearing

shells...

• Step 20:

...and

the two

thrust

washers

from

the rear

main bearing

web.

• Step 21:

TURBO

ENGINES ONLY.

Unbolt and

remove

the four

piston cooling

sprays

(a) from

the

cylinder

block oil gallery.

The

bearing shell

positions are

arrowed.

Job 24. Diesel engine -

reassembly.

Before starting work, read the notes at the beginning of

Job 6 for petrol engine reassembly

-

the checks and

preparation being basically the same for diesel engines.

H INSIDE INFORMATION! TURBO ENGINES ONLY. The

piston cooling sprays must be checked for serviceability

before refitting. Each spray contains its own valve which

must

open at between 1.25 and 1.75 bar. Below this

figure could cause excessive oil burning and low oil

pressure. Above this figure might result in the piston

overheating and its subsequent failure. Have your FIAT

dealer carry out this check, and replace any faulty units if

necessary. Q

• Step 9: Fit new oil

seals to the two seal

carriers.

• Step 10: Fit the

rear oil seal carrier (with

its new seal), using a

new gasket. Lubricate

the seal (illustration Job

24-9,

part b) and

lightly oil the gasket (a).

• Step 11: Position Nos. 1 and 4 crank pins at Top Dead

Centre (TDC), then fit the flywheel with its TDC mark facing

the cylinder head surface. Screw in the fixing bolts and tighten

to their specified torque. See Chapter

3,

Facts and Figures

Job 23-21

Q Step 8: Turn and lever the crankshaft tight against the

timing end and check the crankshaft end float by using a

feeler gauge between the thrust washer on the timing side of

the web and the crankshaft. Thicker washers are available if

required. See Chapter

3, Facts and Figures.

Page 94 of 171

U Step 12: Fit a new seal to the front cover/oil pump

assembly, unless a new pump is being fitted, and install with a

new gasket, lightly oiling both gasket and seal. Align the cover

with the sump support plate.

PISTON CONNECTING RODS ASSEMBLIES

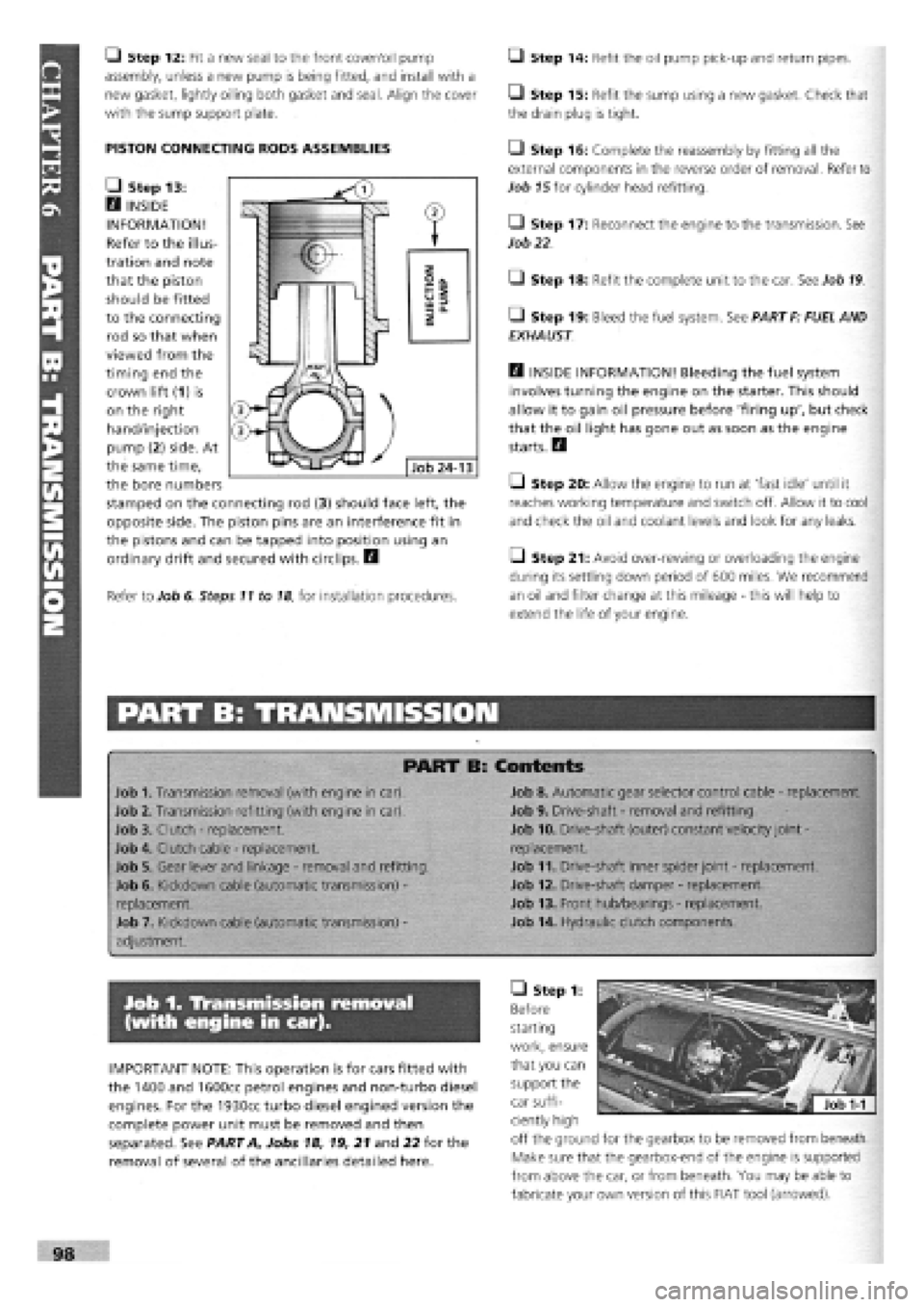

• Step 13:

H INSIDE

INFORMATION!

Refer to the illus-

tration and note

that the piston

should be fitted

to the connecting

rod so that when

viewed from the

timing end the

crown lift (1) is

on the right

hand/injection

pump (2) side. At

the same time,

the bore numbers

stamped on the connecting rod (3) should face left, the

opposite side. The piston pins are an interference fit in

the pistons and can be tapped into position using an

ordinary drift and secured with circlips. H

Refer to Job 6. Steps 11 to

18,

for installation procedures.

Q Step 14: Refit the oil pump pick-up and return pipes.

• Step 15: Refit the sump using a new gasket. Check that

the drain plug is tight.

• Step 16: Complete the reassembly by fitting all the

external components in the reverse order of removal. Refer to

Job

15

for cylinder head refitting.

• Step 17: Reconnect the engine to the transmission. See

Job

22

• Step 18: Refit the complete unit to the car. See Job

19

• Step 19: Bleed the fuel system. See PART F: FUEL AND

EXHAUST

Q INSIDE INFORMATION! Bleeding the fuel system

involves turning the engine on the starter. This should

allow it to gain oil pressure before 'firing up', but check

that the oil light has gone out as soon as the engine

starts. H

Q Step 20: Allow the engine to run at 'fast idle' until it

reaches working temperature and switch off. Allow it to cool

and check the oil and coolant levels and look for any leaks.

Q Step 21: Avoid over-rewing or overloading the engine

during its settling down period of 600 miles. We recommend

an oil and filter change at this mileage

-

this will help to

extend the life of your engine.

PART B: TRANSMISSION

PART B: Contents

Job 1. Transmission removal (with engine in car).

Job 2. Transmission refitting (with engine in car).

Job 3. Clutch

-

replacement.

Job 4. Clutch cable

-

replacement.

Job 5. Gear lever and linkage

-

removal and refitting.

Job 6. Kickdown cable (automatic transmission)

-

replacement.

Job 7. Kickdown cable (automatic transmission)

-

adjustment.

Job 8. Automatic gear selector control cable

-

replacement.

Job 9. Drive-shaft

-

removal and refitting.

Job 10. Drive-shaft (outer) constant velocity joint

-

replacement.

Job 11. Drive-shaft inner spider joint

-

replacement.

Job 12. Drive-shaft damper

-

replacement.

Job 13. Front hub/bearings

-

replacement.

Job 14. Hydraulic clutch components.

Job 1. Transmission removal

(with engine in car).

IMPORTANT NOTE: This operation is for cars fitted with

the 1400 and 1600cc petrol engines and non-turbo diesel

engines. For the 1930cc turbo diesel engined version the

complete power unit must be removed and then

separated. See PART A, Jobs 18, 19, 21 and 22 for the

removal of several of the ancillaries detailed here.

• Step 1:

Before

starting

work, ensure

that you can

support the

car suffi-

ciently high

off the ground for the gearbox to be removed from beneath.

Make sure that the gearbox-end of the engine is supported

from above the car, or from beneath. You may be able to

fabricate your own version of this FIAT tool (arrowed).

Page 96 of 171

• Step 4: Refill the gearbox with the correct grade and

quantity of FL oil. See Chapter

3,

Facts and Figures.

Section as appropriate, for the replacement of the rear

crankshaft seal. B

—1 Step 5: When the brake calipers have been refitted,

pump the brake pedal until its normal solid feel is restored.

• Step 6: Use a self-grip wrench to reconnect the gear rod

balls and sockets. Use new drive-shaft nuts, tightened to the

correct torque and staked into the shaft grooves with a

punch. See Job 9.

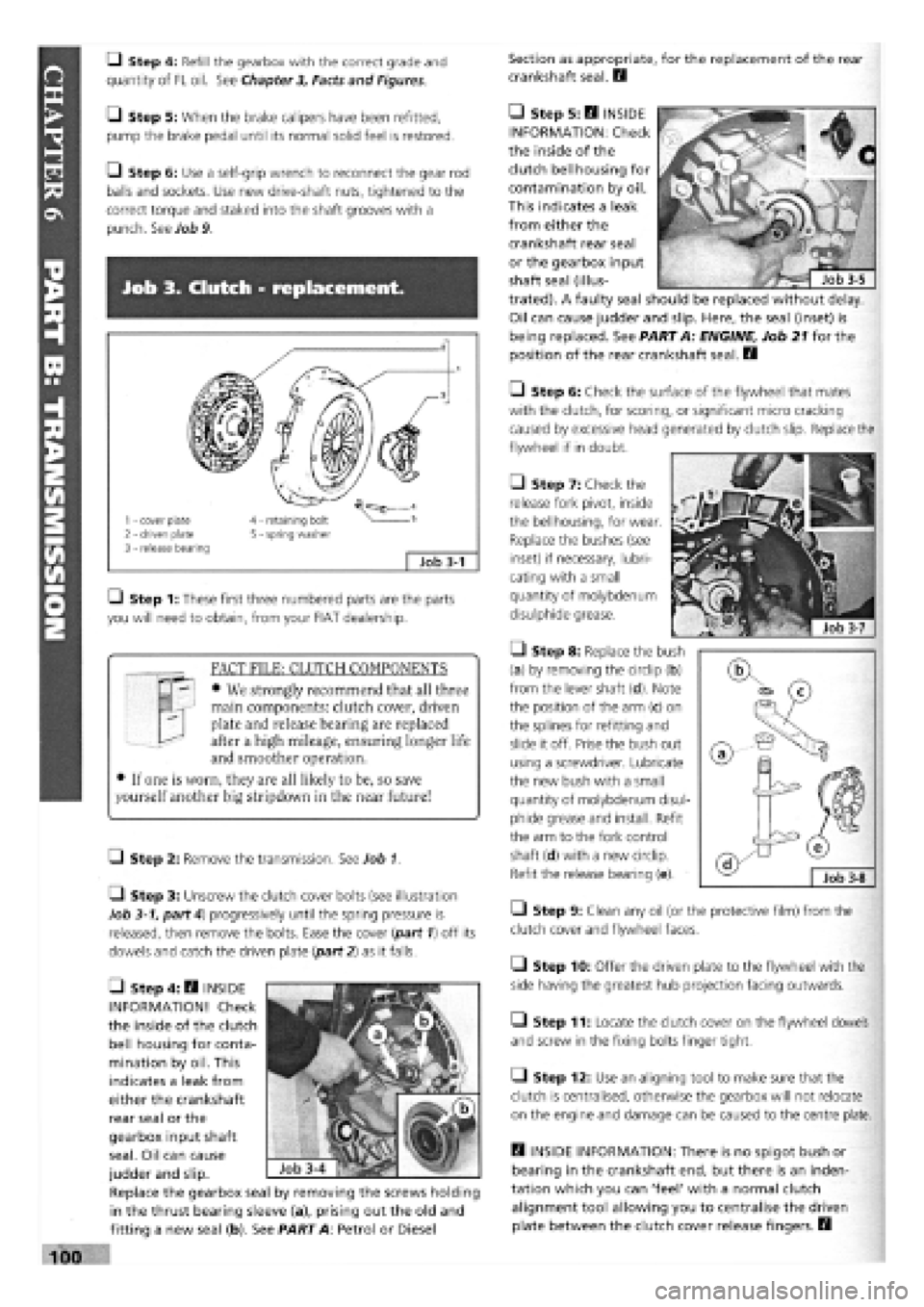

Job 3. Clutch - replacement.

1 - cover plate 2 - driven plate 3 - release bearing

4 - retaining bolt 5 - spring washer

;

Job 3-1

Q Step 1: These first three numbered parts are the parts

you will need to obtain, from your FIAT dealership.

FACT FILE: CLUTCH COMPONENTS

• We strongly recommend that all three

main components: clutch cover, driven

plate and release bearing are replaced

after a high mileage, ensuring longer life

and smoother operation.

• If one is worn, they are all likely to be, so save

yourself another big stripdown in the near future!

LI Step 2: Remove the transmission. See Job 1.

• Step 3: Unscrew the clutch cover bolts (see illustration

Job

3-1,

part 4) progressively until the spring pressure is

released, then remove the bolts. Ease the cover (part 1) off its

dowels and catch the driven plate {part 2) as it falls.

• Step 6: Check the surface of the flywheel that mates

with the clutch, for scoring, or significant micro cracking

caused by excessive head generated by clutch slip. Replace the

flywheel if in doubt.

7ZJ

• Step 7: Check the

release fork pivot, inside

the bellhousing, for wear

Replace the bushes (see

inset) if necessary, lubri-

cating with a small

quantity of molybdenum

disulphide grease.

• Step 8: Replace the bush

(a) by removing the circlip (b)

from the lever shaft (d). Note

the position of the arm (c) on

the splines for refitting and

slide it off. Prise the bush out

using a screwdriver. Lubricate

the new bush with a small

quantity of molybdenum disul-

phide grease and install. Refit

the arm to the fork control

shaft (d) with a new circlip.

Refit the release bearing (e).

• Step 9: Clean any oil (or the protective film) from the

clutch cover and flywheel faces.

• Step 10: Offer the driven plate to the flywheel with the

side having the greatest hub projection facing outwards.

• Step 11: Locate the clutch cover on the flywheel dowels

and screw in the fixing bolts finger tight.

• Step 12: Use an aligning tool to make sure that the

clutch is centralised, otherwise the gearbox will not relocate

on the engine and damage can be caused to the centre plate.

B INSIDE INFORMATION: There is no spigot bush or

bearing in the crankshaft end, but there is an inden-

tation which you can 'feel' with a normal clutch

alignment tool allowing you to centralise the driven

plate between the clutch cover release fingers. B

• Step 5: B INSIDE

INFORMATION: Check

the inside of the

clutch bellhousing for

contamination by oil.

This indicates a leak

from either the

crankshaft rear seal

or the gearbox input

shaft seal (illus-

trated). A faulty seal should be replaced without delay.

Oil can cause judder and slip. Here, the seal (inset) is

being replaced. See PART A: ENGINE, Job 21 for the

position of the rear crankshaft seal. B

• Step 4: B INSIDE

INFORMATION! Check

the inside of the clutch

bell housing for conta-

mination by oil. This

indicates a leak from

either the crankshaft

rear seal or the

gearbox input shaft

seal. Oil can cause

judder and slip.

Replace the gearbox seal by removing the screws holding

in the thrust bearing sleeve (a), prising out the old and

fitting a new seal (b). See PART A: Petrol or Diesel

Page 98 of 171

Job 8. Automatic gear selector

control cable - replacement.

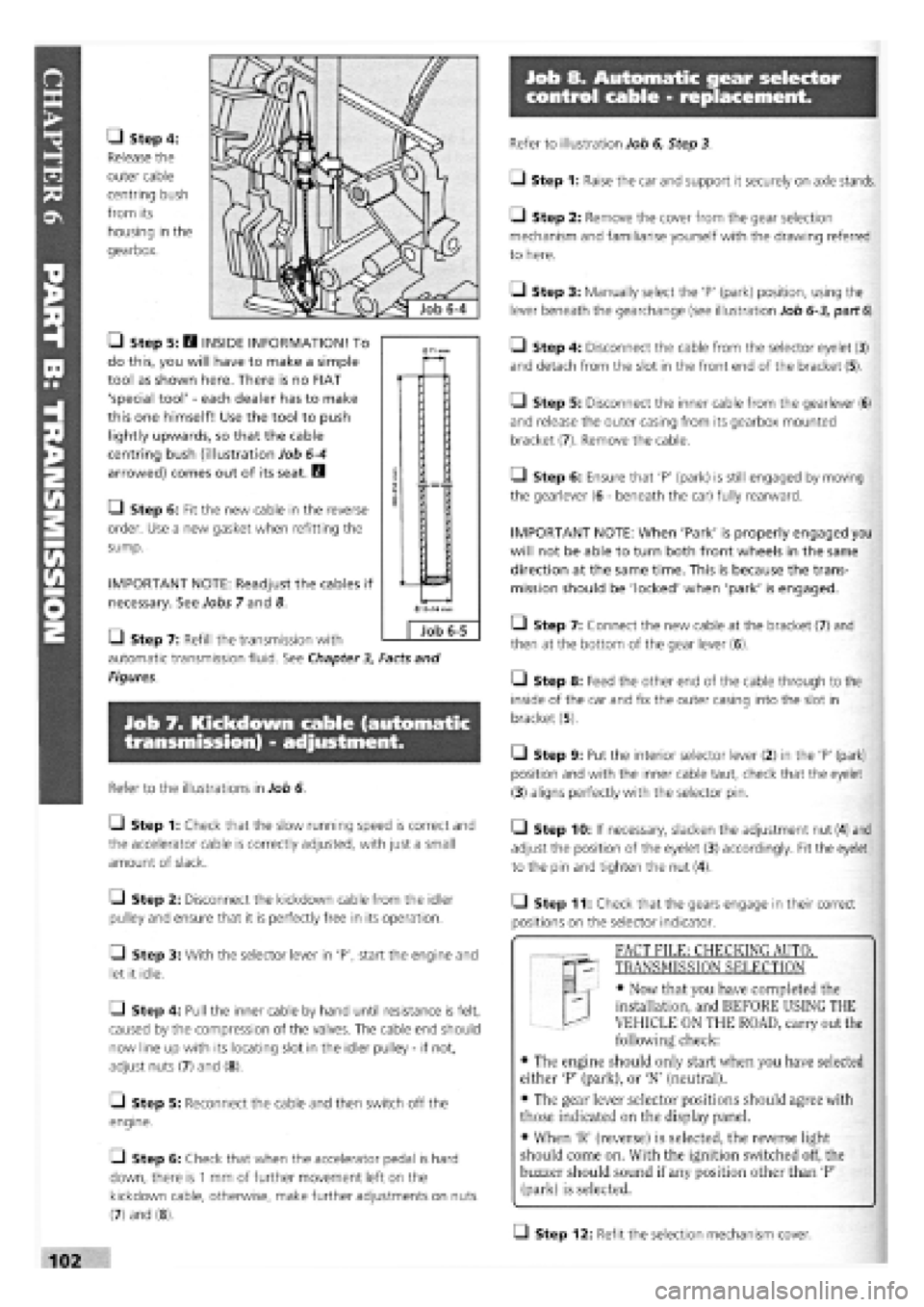

• Step 4:

Release the

outer cable

centring bush

from its

housing in the

gearbox.

• Step 5: H INSIDE INFORMATION! To

do this, you will have to make a simple

tool as shown here. There is no FIAT

'special tool'

-

each dealer has to make

this one himself! Use the tool to push

lightly upwards, so that the cable

centring bush (illustration Job

6-4

arrowed) comes out of its seat. B

• Step 6: Fit the new cable in the reverse

order. Use a new gasket when refitting the

sump.

IMPORTANT NOTE: Readjust the cables if

necessary. See Jobs 7 and 8.

Q Step 7: Refill the transmission with

automatic transmission fluid. See Chapter

3,

Facts and

Figures.

Job 7. Kickdown cable (automatic

transmission) - adjustment.

Refer to the illustrations in Job 6.

Q Step 1: Check that the slow running speed is correct and

the accelerator cable is correctly adjusted, with just a small

amount of slack.

Q Step 2: Disconnect the kickdown cable from the idler

pulley and ensure that it is perfectly free in its operation.

• Step 3: With the selector lever in 'P', start the engine and

let it idle.

Q Step 4: Pull the inner cable by hand until resistance is felt,

caused by the compression of the valves. The cable end should

now line up with its locating slot in the idler pulley

-

if not,

adjust nuts (7) and (8).

[_l Step 5: Reconnect the cable and then switch off the

engine.

• Step 6: Check that when the accelerator pedal is hard

down, there is

1

mm of further movement left on the

kickdown cable, otherwise, make further adjustments on nuts

(7) and (8).

Refer to illustration Job 6, Step 3.

• Step 1: Raise the car and support it securely on axle stands.

• Step 2: Remove the cover from the gear selection

mechanism and familiarise yourself with the drawing referred

to here.

Q Step 3: Manually select the 'P' (park) position, using the

lever beneath the gearchange (see illustration Job

6-3,

part

6).

• Step 4: Disconnect the cable from the selector eyelet (3)

and detach from the slot in the front end of the bracket (5).

Q Step 5: Disconnect the inner cable from the gearlever (6)

and release the outer casing from its gearbox mounted

bracket (7). Remove the cable.

Q Step 6: Ensure that 'P' (park) is still engaged by moving

the gearlever (6

-

beneath the car) fully rearward.

IMPORTANT NOTE: When 'Park' is properly engaged you

will not be able to turn both front wheels in the same

direction at the same time. This is because the trans-

mission should be 'locked' when 'park' is engaged.

• Step 7: Connect the new cable at the bracket (7) and

then at the bottom of the gear lever (6).

• Step 8: Feed the other end of the cable through to the

inside of the car and fix the outer casing into the slot in

bracket (5).

• Step 9: Put the interior selector lever (2) in the 'P' (park)

position and with the inner cable taut, check that the eyelet

(3) aligns perfectly with the selector pin.

• Step 10: If necessary, slacken the adjustment nut (4) and

adjust the position of the eyelet (3) accordingly. Fit the eyelet

to the pin and tighten the nut (4).

• Step 11: Check that the gears engage in their correct

positions on the selector indicator.

T "I FACT FILE: CHECKING AUTOT

qp- TRANSMISSION SELECTION

EL

-

• Now that you have completed the

installation, and BEFORE USING THE

VEHICLE ON THE ROAD, carry out the

following check:

• The engine should only start when you have selected

either 'P' (park), or 'N' (neutral).

• The gear lever selector positions should agree with

those indicated on the display panel.

• When 'R' (reverse) is selected, the reverse light

should come on. With the ignition switched off, the

buzzer should sound if any position other than 'P'

(park) is selected.

Q Step 12: Refit the selection mechanism cover.

0

Job 6-5

Page 99 of 171

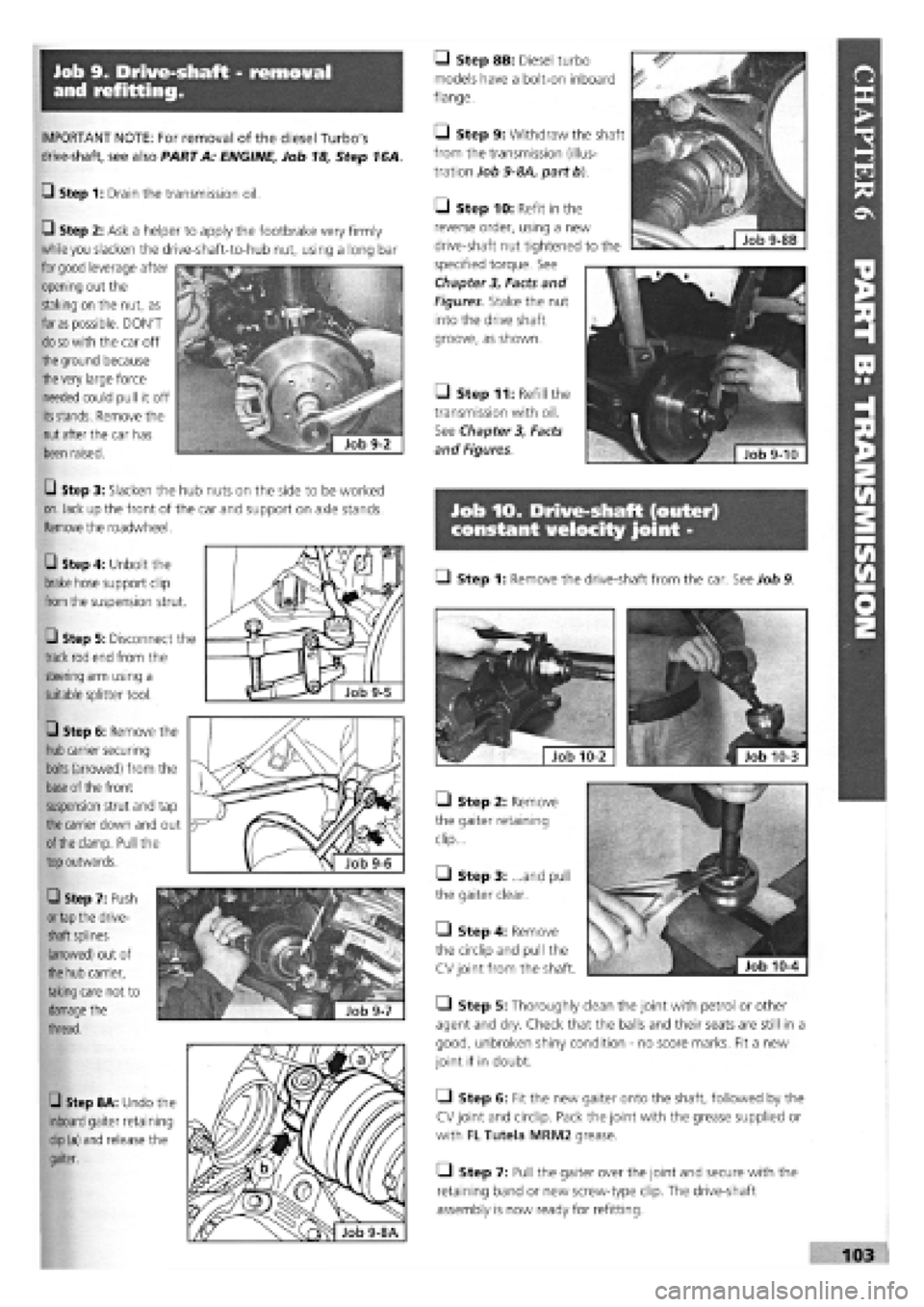

Job 9. Drive-shaft - removal

and refitting.

IMPORTANT NOTE: For removal of the diesel Turbo's

drive-shaft, see also PART A: ENGINE, Job 18, Step 16A.

G Step 1: Drain the transmission oil.

• Step 8B: Diesel turbo

models have a bolt-on inboard

flange.

• Step 9: Withdraw the shaft

from the transmission (illus-

tration Job

9-8A,

part b).

G Step 2: Ask a helper to apply the footbrake very firmly

while

you

slacken the drive-shaft-to-hub nut, using a long bar

for

good

leverage after

opening out the

staking on the nut, as

far

as

possible. DON'T

do so

with the car off

the

ground because

the

very large force

needed could pull it off

its stands.

Remove the

nut

after the car has

been raised.

Job 10. Drive-shaft (outer)

constant velocity joint -

G Step 8A: Undo the

inboard

gaiter retaining

clip

(a) and release the

gaiter.

• Step 11: Refill the

transmission with oil.

See Chapter

3,

Facts

and Figures.

G Step 3: Slacken the hub nuts on the side to be worked

on.

Jack up the front of the car and support on axle stands.

Remove the roadwheel.

G Step 6: Remove the

hub

carrier securing

bolts

(arrowed) from the

base

of the front

suspension strut and tap

the

carrier down and out

of the

clamp. Pull the

top

outwards.

G Step 7: Push

or tap

the drive-

shaft

splines

(arrowed) out of

the hub

carrier,

taking

care not to

damage

the

thread.

Q Step 1: Remove the drive-shaft from the car. See Job 9. G Step 4: Unbolt the

brake hose support clip

from

the suspension strut.

G Step 5: Disconnect the

track rod end from the

steering arm using a

suitable splitter tool.

• Step 2: Remove

the gaiter retaining

clip...

Q Step 3: ...and pull

the gaiter clear.

• Step 4: Remove

the circlip and pull the

CV joint from the shaft.

Q Step 5: Thoroughly clean the joint with petrol or other

agent and dry. Check that the balls and their seats are still in a

good, unbroken shiny condition

-

no score marks. Fit a new

joint if in doubt.

• Step 6: Fit the new gaiter onto the shaft, followed by the

CV joint and circlip. Pack the joint with the grease supplied or

with FL Tutela MRM2 grease.

Q Step 7: Pull the gaiter over the joint and secure with the

retaining band or new screw-type clip. The drive-shaft

assembly is now ready for refitting.

• Step 10: Refit in the

reverse order, using a new

drive-shaft nut tightened to the

specified torque. See

Chapter

3,

Facts and

Figures Stake the nut

into the drive shaft

groove, as shown.

Page 100 of 171

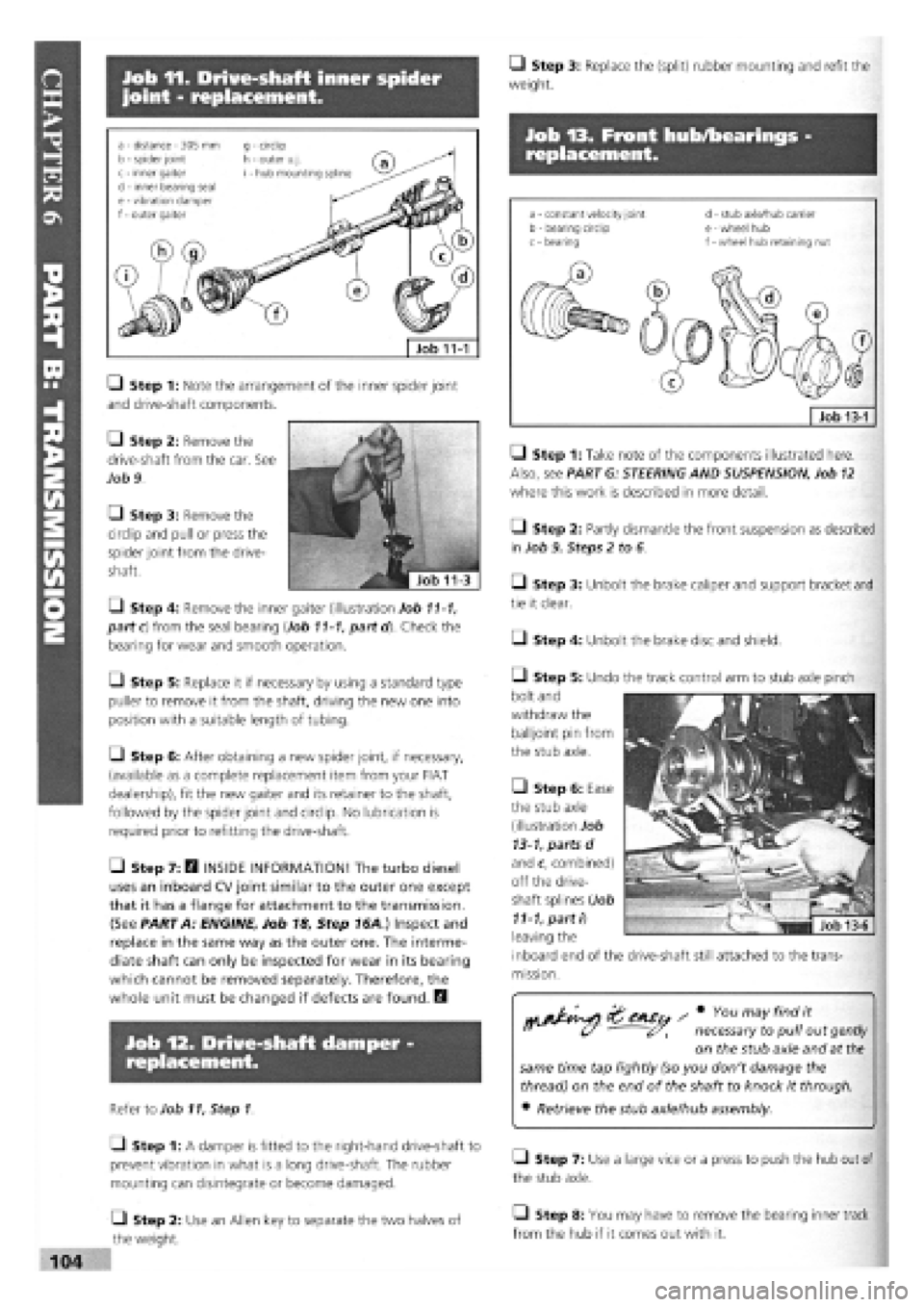

Job 11. Drive-shaft inner spider

joint - replacement.

• Step 3: Replace the (split) rubber mounting and refit the

weight.

Job 13. Front hub/bearings -

replacement.

Job 11-1

a - distance - 305 mm b - spider joint c - inner gaiter d - inner bearing seal e

-

vibration damper f

-

outer gaiter

g - circlip h - outer u.j. i - hub mounting spline

• Step 1: Note the arrangement of the inner spider joint

and drive-shaft components.

Q Step 2: Remove the

drive-shaft from the car. See

Job 9.

• Step 3: Remove the

circlip and pull or press the

spider joint from the drive-

shaft.

• Step 4: Remove the inner gaiter (illustration Job

11-1,

part c) from the seal bearing (Job

11-1,

partd). Check the

bearing for wear and smooth operation.

Q Step 5: Replace it if necessary by using a standard type

puller to remove it from the shaft, driving the new one into

position with a suitable length of tubing.

Q Step 6: After obtaining a new spider joint, if necessary,

(available as a complete replacement item from your FIAT

dealership), fit the new gaiter and its retainer to the shaft,

followed by the spider joint and circlip. No lubrication is

required prior to refitting the drive-shaft.

• Step 7: E9 INSIDE INFORMATION! The turbo diesel

uses an inboard CV joint similar to the outer one except

that it has a flange for attachment to the transmission.

(See PART A: ENGINE, Job 18, Step 16A ) Inspect and

replace in the same way as the outer one. The interme-

diate shaft can only be inspected for wear in its bearing

which cannot be removed separately. Therefore, the

whole unit must be changed if defects are found. Q

Job 12. Drive-shaft damper -

replacement.

Refer to Job

11,

Step 1

Q Step 1: A damper is fitted to the right-hand drive-shaft to

prevent vibration in what is a long drive-shaft. The rubber

mounting can disintegrate or become damaged.

Q Step 2: Use an Allen key to separate the two halves of

the weight.

s * You ™yfind *

" U ' necessary to pull out

gently

on the stub axle and at

the

same time tap lightly (so you don't damage the

thread) on the end of the shaft to knock it through.

• Retrieve the stub axle/hub assembly.

Q Step 7: Use a large vice or a press to push the hub out of

the stub axle.

• Step 8: You may have to remove the bearing inner track

from the hub if it comes out with it.

• Step 2: Partly dismantle the front suspension as described

in Job 9. Steps 2 to 6.

• Step 3: Unbolt the brake caliper and support bracket and

tie it clear.

• Step 1: Take note of the components illustrated here.

Also, see PART G: STEERING AND SUSPENSION, Job

12

where this work is described in more detail.

Q Step 4: Unbolt the brake disc and shield.

• Step 5: Undo the track control arm to stub axle pinch

bolt and

withdraw the

balljoint pin from

the stub axle.

• Step 6: Ease

the stub axle

(illustration Job

13-1,

parts d

and c, combined)

off the drive-

shaft splines (Job

11-1,

parti)

leaving the

inboard end of the

mission.

drive-shaft still attached to the trans-

Page 105 of 171

SAFETY FIRST!

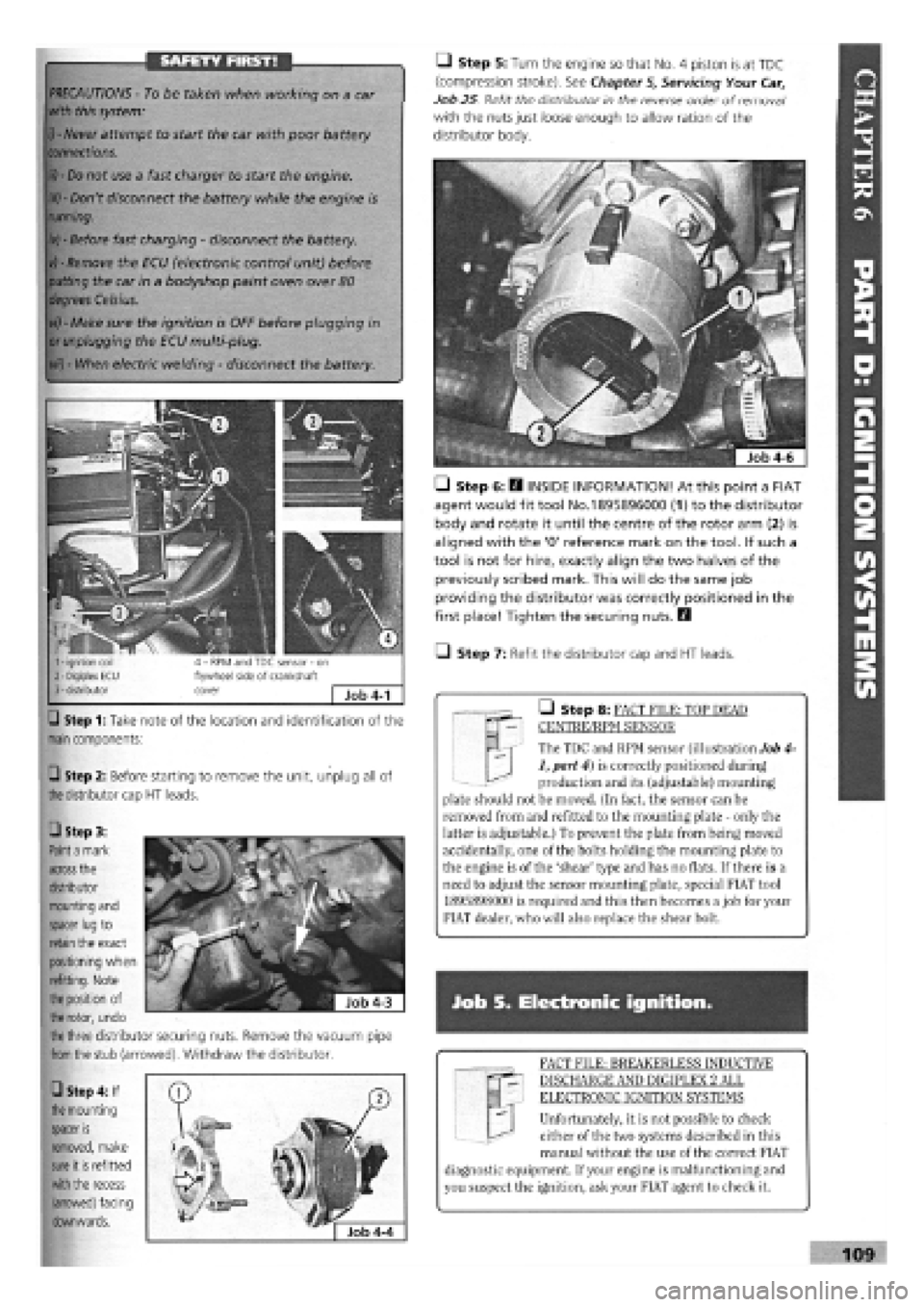

Step 1: Take note of the location and identification of the

main

components:

Q Step 2: Before starting to remove the unit, unplug all of

the

distributor cap

HT

leads.

M | The TDC and RPM sensor (illustration Job 4-

1, part 4) is correctly positioned during

production and its (adjustable) mounting

plate should not be moved. (In fact, the sensor can be

removed from and refitted to the mounting plate - only the

latter is adjustable.) To prevent the plate from being moved

accidentally, one of the bolts holding the mounting plate to

the engine is of the 'shear' type and has no flats. If there is a

need to adjust the sensor mounting plate, special FIAT tool

1895898000 is required and this then becomes a job for your

FIAT dealer, who will also replace the shear bolt.

• Step 8: FACT FILE: TOP DEAD

CENTRE/RPM SENSOR

PRECAUTIONS -

To be taken when working on a car

with this system:

i) - Never

attempt to start the car with poor battery

connections.

ii) - Do

not use a fast charger to start the engine.

iii) -

Don't disconnect the battery while the engine is

running.

iv) -

Before fast charging

-

disconnect the battery.

vj - Remove

the ECU (electronic control unit) before

putting

the car in a bodyshop paint oven over

80

degrees Celsius.

vi) -

Make sure the ignition is OFF before plugging in

or unplugging

the ECU multi-plug.

vii) -

When electric welding

-

disconnect the battery.

Q Step 5: Turn the engine so that No. 4 piston is at TDC

(compression stroke). See Chapter

5,

Servicing Your Car,

Job 25 Refit the distributor in the reverse order of removal1

with the nuts just loose enough to allow ration of the

distributor body.

• Step 6: E3 INSIDE INFORMATION! At this point a FIAT

agent would fit tool No.1895896000 (1) to the distributor

body and rotate it until the centre of the rotor arm (2) is

aligned with the '0' reference mark on the tool. If such a

tool is not for hire, exactly align the two halves of the

previously scribed mark. This will do the same job

providing the distributor was correctly positioned in the

first place! Tighten the securing nuts. Q

• Step 7: Refit the distributor cap and HT leads.

Job S. Electronic ignition.

FACT FILE: BREAKERLESS INDUCTIVE

DISCHARGE AND DIGIPLEX 2 ALL

ELECTRONIC IGNITION SYSTEMS

Unfortunately, it is not possible to check

either of the two systems described in this

manual without the use of the correct FIAT

diagnostic equipment. If your engine is malfunctioning and

you suspect the ignition, ask your FIAT agent to check it.

109

• Step 3:

Paint a

mark

across

the

distributor

mounting and

spacer lug

to

retain

the exact

positioning when

refitting. Note

the position

of

the rotor,

undo

the three

distributor securing nuts. Remove the vacuum pipe

from the

stub (arrowed). Withdraw the distributor.

• Step 4: If

the

mounting

spacer

is

removed, make

sure

it

is

refitted

with the

recess

(arrowed) facing

downwards.

Page 106 of 171

PART E: ELECTRICAL ARID INSTRUMENTS

PART E: Contents

Job 1. Alternator

-

removal and refitting. Job 10. Rear light cluster

-

replacement.

Job 2. Starter motor

-

removal and refitting. Job 11. Side repeater indicators

-

replacement.

Job 3. Instrument panel

-

removal and refitting. Job 12. Number plate light

-

replacement.

Job 4. Speedometer cable

-

replacement. Job 13. Interior/courtesy light

-

removal and refitting.

Job 5. Windscreen wiper motor

-

replacement. Job 14. Fuel gauge sender unit

-

removal and refitting.

Job 6. Hatchback wiper motor

-

replacement. Job 15. Central locking

-

replacement of components.

Job 7. Windscreen washer pump

-

replacement. Job 16. Electric windows

-

replacement of components.

Job 8. Radio aerial

-

replacement. Job 17. Diesel engines. Glow plugs

-

checking and

Job 9. Headlight cluster

-

replacement. replacement.

Job 1. Alternator - removal

and refitting.

Job 3. Instrument panel -

removal and refitting.

• Step 1: Disconnect the battery earth lead.

Q Step 2: Disconnect all the wires from the back of the

alternator

-

the main output wire is released by undoing its

securing nut. Slacken the bolt securing the inboard end of the

adjustment bar, undo and remove the bolt from the alternator

end of the bar. Slacken the drivebelt and remove it.

Q Step 3: On manual steering cars, unbolt and remove the

adjuster bracket from the cylinder block.

Q Step 4: Release the securing buttons and remove the

engine splash shield on power steering cars.

Q Step 5: Undo the nut from the long through bolt and

note the position of the washers. Support the alternator and

remove the bolt, then withdraw the alternator from the car.

Q Step 6: Refit in reverse order and make sure your

electrical connections are sound. Adjust the drivebelt tension.

See Chapter 5, Servicing Your Car

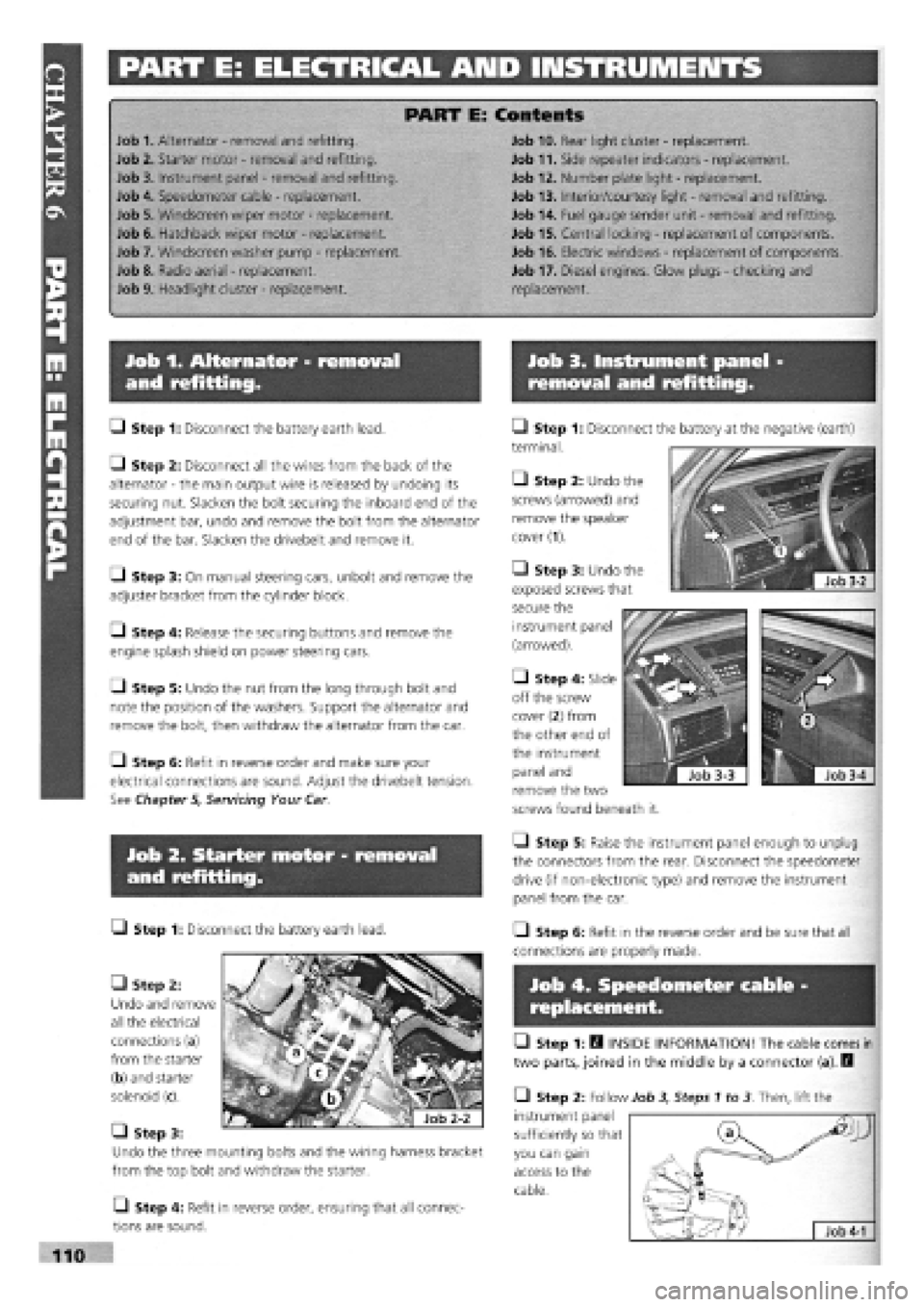

• Step 1: Disconnect

terminal.

• Step 2: Undo the

screws (arrowed) and

remove the speaker

cover (1).

Job 2. Starter motor - removal

and refitting.

• Step 1: Disconnect the battery earth lead.

• Step 2:

Undo and remove

all the electrical

connections (a)

from the starter

(b) and starter

solenoid (c).

Q Step 4: Refit in reverse order, ensuring that all connec-

tions are sound.

Q Step 5: Raise the instrument panel enough to unplug

the connectors from the rear. Disconnect the speedometer

drive (if non-electronic type) and remove the instrument

panel from the car.

Q Step 6: Refit in the reverse order and be sure that all

connections are properly made.

Job 4. Speedometer cable

replacement.

• Step 1: H INSIDE INFORMATION! The cable comes in

two parts, joined in the middle by a connector (a). Q

• Step 2: Follow Job 3, Steps 1 to 3 Then, lift the

instrument panel

sufficiently so that

you can gain

access to the

cable.

^Jj

Job

4-1

the battery at the negative (earth)

• Step 3: Undo the

exposed screws that

secure the

instrument panel

(arrowed).

• Step 4: Slide

off the screw

cover

(2)

from

the other end of

the instrument

panel and

remove the two

screws found beneath it.

• Step 3:

Undo the three mounting bolts and the wiring harness bracket

from the top bolt and withdraw the starter.