check engine FIAT TEMPRA 1988 Service And Manual PDF

[x] Cancel search | Manufacturer: FIAT, Model Year: 1988, Model line: TEMPRA, Model: FIAT TEMPRA 1988Pages: 171, PDF Size: 18.05 MB

Page 110 of 171

Job 15. Central locking -

replacement off components.

Job 14. Fuel gauge sender unit

removal and refitting.

SAFETY FIRST!

ā¢ Carry out this work out of doors, away from sources

of ignition.

ā¢ Make the open aperture on top of the fuel tank air

tight as quickly as possible.

ā¢ You should carry out this job when the fuel is at a

low level.

VEHICLES WITH ELECTRIC FUEL PUMPS

(NOT ENGINE MOUNTED)

Job 16. Electric windows -

replacement of components.

courtesy light lens and/or panel. The connectors are on

the rear of the unit.

ā¢ Step 3: The estate car has a rear courtesy light which is

removed as in Step 1 and 2

LJ Step 4: Refit in the reverse order.

PART A: ELECTRONIC CONTROL UNIT

ā¢ Step A1: You

will find the

electronic control

unit

(1)

mounted

beside the

junction unit...

PART A: ELECTRONIC CONTROL UNIT

ā¢ Step A1: Disconnect the battery at the earth terminal.

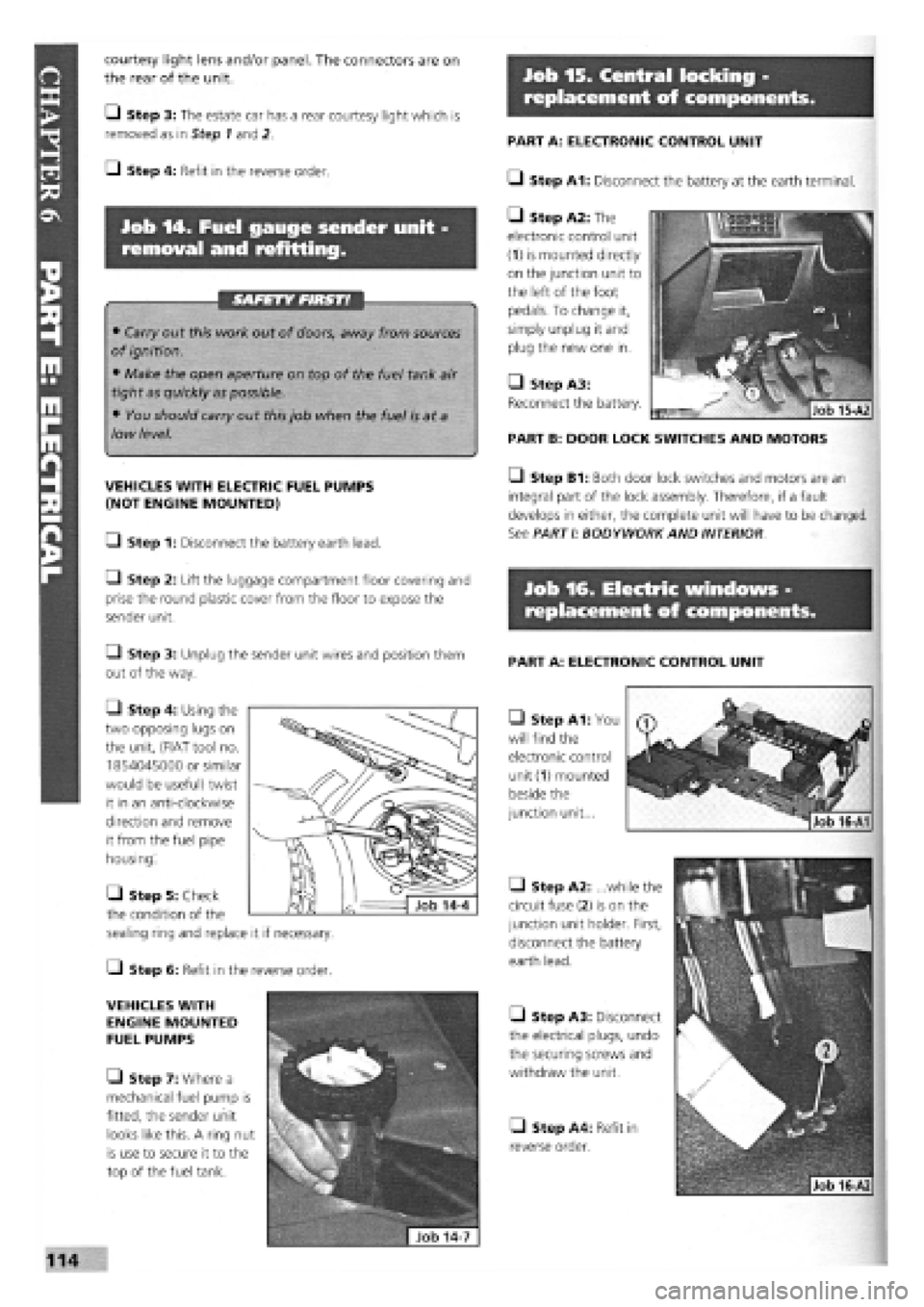

ā¢ Step A2: The

electronic control unit

(1) is mounted directly

on the junction unit to

the left of the foot

pedals. To change it,

simply unplug it and

plug the new one in.

ā¢ Step A3:

Reconnect the battery.

PART B: DOOR LOCK SWITCHES AND MOTORS

ā¢ Step B1: Both door lock switches and motors are an

integral part of the lock assembly. Therefore, if a fault

develops in either, the complete unit will have to be changed.

See PARTI: BODYWORK AND INTERIOR

ā¢ Step A2: ...while the

circuit fuse (2) is on the

junction unit holder. First,

disconnect the battery

earth lead.

ā¢ Step A3: Disconnect

the electrical plugs, undo

the securing screws and

withdraw the unit.

ā¢ Step A4: Refit in

reverse order.

Q Step 1: Disconnect the battery earth lead.

Q Step 2: Lift the luggage compartment floor covering and

prise the round plastic cover from the floor to expose the

sender unit.

Q Step 3: Unplug the sender unit wires and position them

out of the way.

ā¢ Step 4: Using the

two opposing lugs on

the unit, (FIAT tool no.

1854045000 or similar

would be useful) twist

it in an anti-clockwise

direction and remove

it from the fuel pipe

housing.

C-) Step 6: Refit in the reverse order.

VEHICLES WITH

ENGINE MOUNTED

FUEL PUMPS

ā¢ Step 7: Where a

mechanical fuel pump is

fitted, the sender unit

looks like this. A ring nut

is use to secure it to the

top of the fuel tank.

ā¢ Step 5: Check

the condition of the

sealing ring and replace it if necessary.

Job 16-A1

Page 111 of 171

Job 17. Diesel engines - Glow

plugs, checking and replacement.

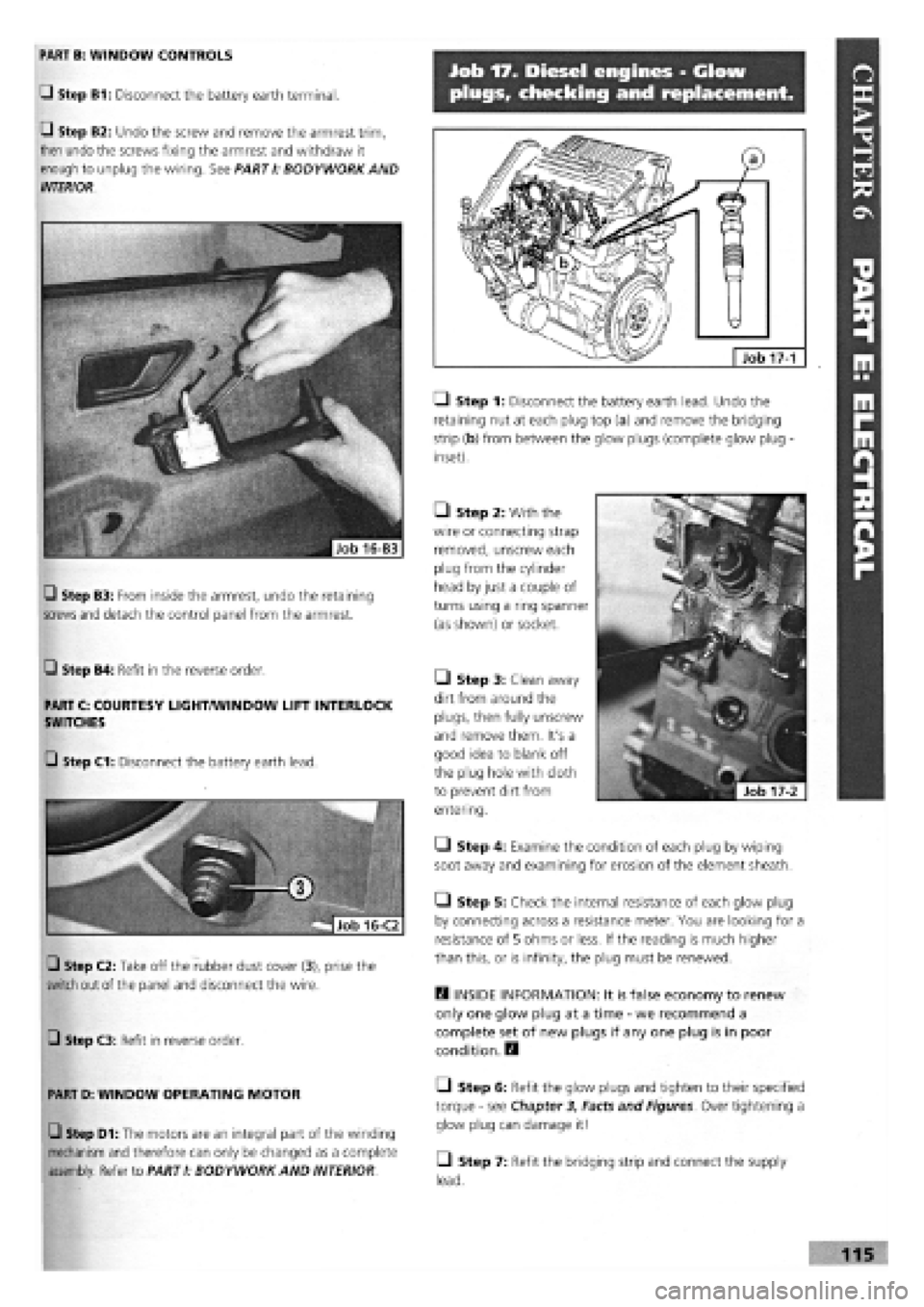

LI Step 1: Disconnect the battery earth lead. Undo the

retaining nut at each plug top (a) and remove the bridging

strip (b) from between the glow plugs (complete glow plug -

inset).

ā¢ Step 2: With the

wire or connecting strap

removed, unscrew each

plug from the cylinder

head by just a couple of

turns using a ring spanner

(as shown) or socket.

H INSIDE INFORMATION: It is false economy to renew

only one glow plug at a time

-

we recommend a

complete set of new plugs if any one plug is in poor

condition. E9

ā¢ Step 6: Refit the glow plugs and tighten to their specified

torque

-

see Chapter 3, Facts and Figures. Over tightening a

glow plug can damage it!

ā¢ Step 7: Refit the bridging strip and connect the supply

lead.

17-1

PART B: WINDOW CONTROLS

Q Step B1: Disconnect the battery earth terminal.

Q Step B2: Undo the screw and remove the armrest trim,

then undo the screws fixing the armrest and withdraw it

enough to unplug the wiring. See PARTI: BODYWORK AND

INTERIOR.

ā¢ Step 3: Clean away

dirt from around the

plugs, then fully unscrew

and remove them. It's a

good idea to blank off

the plug hole with cloth

to prevent dirt from

entering.

ā¢ Step 4: Examine the condition of each plug by wiping

soot away and examining for erosion of the element sheath.

ā¢ Step 5: Check the internal resistance of each glow plug

by connecting across a resistance meter. You are looking for a

resistance of 5 ohms or less. If the reading is much higher

than this, or is infinity, the plug must be renewed.

Q Step B4: Refit in the reverse order.

PART C: COURTESY LIGHT/WINDOW LIFT INTERLOCK

SWITCHES

Q Step C3: Refit in reverse order.

PART D: WINDOW OPERATING MOTOR

Q Step D1: The motors are an integral part of the winding

mechanism and therefore can only be changed as a complete

assembly. Refer to PART I: BODYWORK AND INTERIOR

Q Step B3: From inside the armrest, undo the retaining

screws and

detach the control panel from the armrest.

G Step C1: Disconnect the battery earth lead.

Q Step C2: Take off the rubber dust cover (3), prise the

switch out of the panel and disconnect the wire.

Page 113 of 171

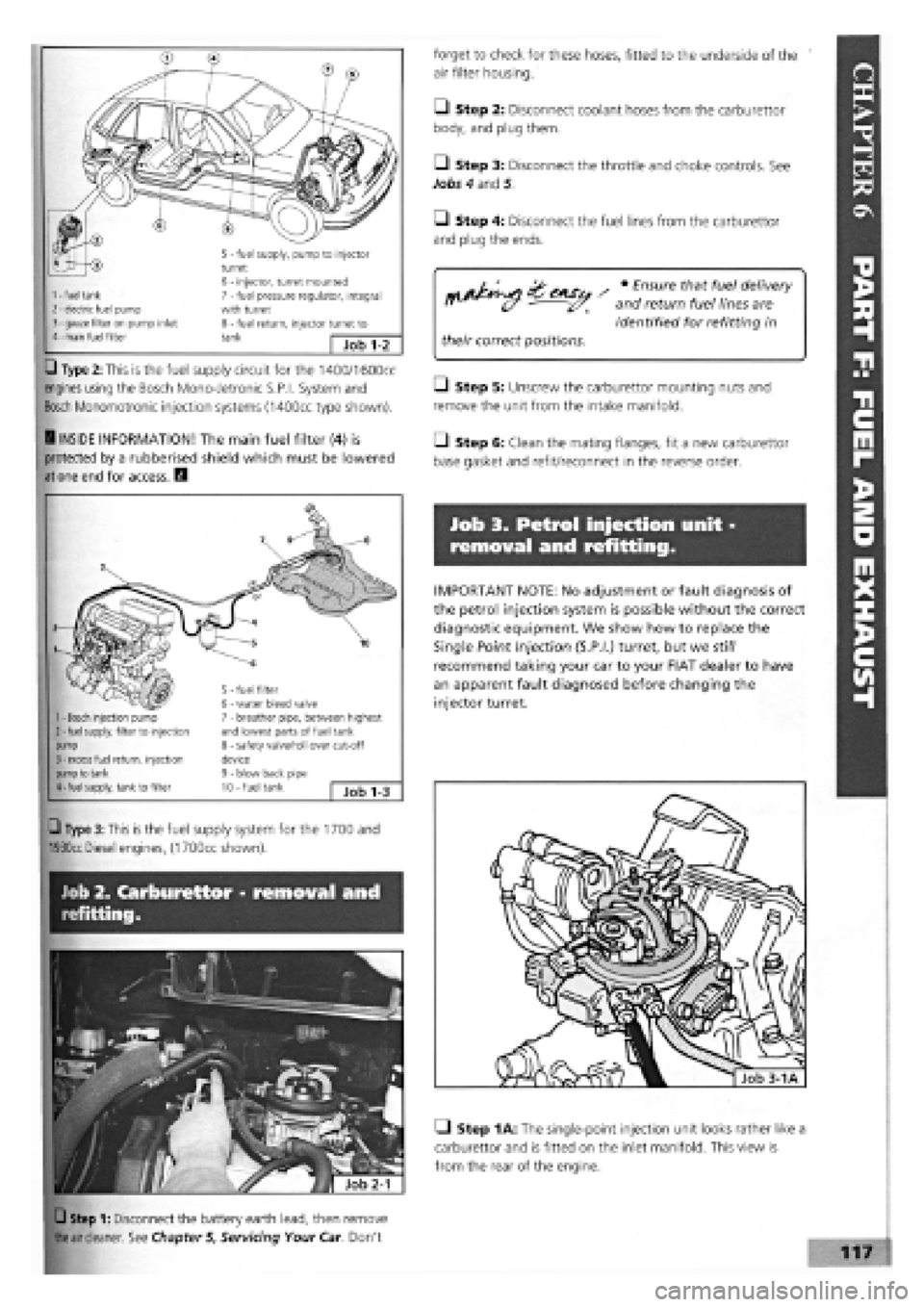

ā¢ Type 2: This is the fuel supply circuit for the 1400/1600cc

engines using the Bosch Mono-Jetronic S.P.I. System and

Bosch Monomotronic injection systems (1400cc type shown).

5 - fuel supply, pump to injector turret 6 - injector, turret mounted 7 - fuel pressure regulator, integral with turret 8 - fuel return, injector turret to tank ā Job 1-2

1

-

fuel tank 2

-

electric fuel pump 3

-

gauze filter on pump inlet 4

-

main fuel filter

H INSIDE INFORMATION! The main fuel filter (4) is

protected by a rubberised shield which must be lowered

at one end for access. H

5 - fuel filter 6 - water bleed valve 7 - breather pipe, between highest and lowest parts of fuel tank 8 - safety valve/roll over cut-off device 9 - blow back pipe 10 - fuel tank Job 1-3

1

-

Bosch injection pump 2

-

fuel supply, filter to injection pump 3

-

excess fuel return, injection pump to tank 4

-

fuel supply, tank to filter

forget to check for these hoses, fitted to the underside of the

air filter housing.

ā¢ Step 2: Disconnect coolant hoses from the carburettor

body, and plug them.

Q Step 3: Disconnect the throttle and choke controls. See

Jobs 4 and 5.

Q Step 4: Disconnect the fuel lines from the carburettor

and plug the ends.

/ ā¢ E"sure thf ā¢ delivery

" (/ and return fuel lines are

identified for refitting in

their correct positions.

ā¢ Step 5: Unscrew the carburettor mounting nuts and

remove the unit from the intake manifold.

LI Step 6: Clean the mating flanges, fit a new carburettor

base gasket and refit/reconnect in the reverse order.

Job 3. Petrol injection unit -

removal and refitting.

IMPORTANT NOTE: No adjustment or fault diagnosis of

the petrol injection system is possible without the correct

diagnostic equipment. We show how to replace the

Single Point Injection (S.P.I.) turret, but we still

recommend taking your car to your FIAT dealer to have

an apparent fault diagnosed before changing the

injector turret.

Job 2. Carburettor - removal and

refitting.

Q Type 3: This is the fuel supply system for the 1700 and

1930cc

Diesel engines, (1700cc shown).

Q Step 1: Disconnect the battery earth lead, then remove

the air cleaner.

See Chapter 5, Servicing Your Car. Don't

Q Step 1A: The single-point injection unit looks rather like a

carburettor and is fitted on the inlet manifold. This view is

from the rear of the engine.

Page 115 of 171

Job 6. Accelerator cable, petrol

injection engines - replacement

and adjustment.

Q Step 2: From inside the car,

unhook the cable nipple from the

fork (arrowed) at the top of the

pedal arm.

ā¢ Step 3: Pull out the bulkhead

grommet and release the cable.

^ ā¢ There are many different

cables, so take your old

cable as a pattern when

buying a replacement to make sure the new one is

exactly

the same.

Q Step 4: Refit in the reverse order

-

not forgetting the

grommet in the bulkhead!

Q Step 5: Check that, when the new cable is fitted:

ā¢ there

is

just the slightest amount of free-play in the cable

with the throttle closed.

ā¢ the carburettor lever is back against its stop with the throttle

fully open.

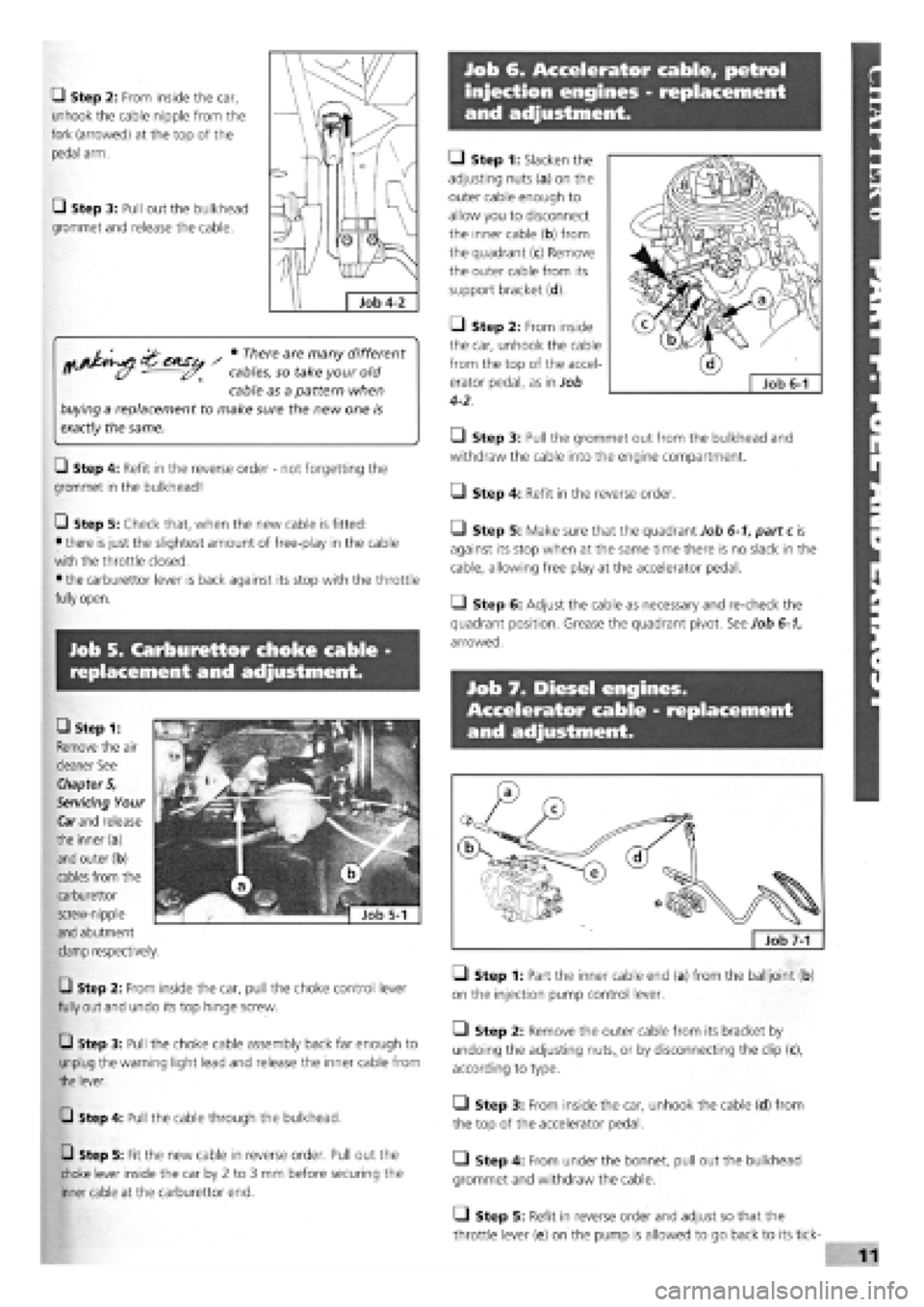

ā¢ Step 1: Slacken the

adjusting nuts (a) on the

outer cable enough to

allow you to disconnect

the inner cable (b) from

the quadrant (c) Remove

the outer cable from its

support bracket (d).

Q Step 2: From inside

the car, unhook the cable

from the top of the accel-

erator pedal, as in Job

4-2.

ā¢ Step 3: Pull the grommet out from the bulkhead and

withdraw the cable into the engine compartment.

O Step 4: Refit in the reverse order.

ā¢ Step 5: Make sure that the quadrant Job 6-1, part c is

against its stop when at the same time there is no slack in the

cable, allowing free play at the accelerator pedal.

ā¢ Step 6: Adjust the cable as necessary and re-check the

quadrant position. Grease the quadrant pivot. See Job 6-1,

arrowed.

Job 7. Diesel engines.

Accelerator cable - replacement

and adjustment.

Job 5. Carburettor choke cable -

replacement and adjustment.

Q Step 2: From inside the car, pull the choke control lever

fully out and undo its top hinge screw.

Q Step 3: Pull the choke cable assembly back far enough to

unplug the warning light lead and release the inner cable from

the lever.

Q Step 4: Pull the cable through the bulkhead.

Q Step 5: Fit the new cable in reverse order. Pull out the

choke lever inside the car by 2 to 3 mm before securing the

inner cable at the carburettor end.

Q Step 1: Part the inner cable end (a) from the balljoint (b)

on the injection pump control lever.

ā¢ Step 2: Remove the outer cable from its bracket by

undoing the adjusting

nuts,,

or by disconnecting the clip (c),

according to type.

ā¢ Step 3: From inside the car, unhook the cable (d) from

the top of the accelerator pedal.

ā¢ Step 4: From under the bonnet, pull out the bulkhead

grommet and withdraw the cable.

Q Step 5: Refit in reverse order and adjust so that the

throttle lever (e) on the pump is allowed to go back to its tick-

CD Step 1:

Remove the air

cleaner See

Chapter 5,

Servicing Your

Car

and

release

the inner(a)

and outer (b)

cables from the

carburettor

screw-nipple

and abutment

clamp respectively.

Page 116 of 171

over stop and will also reach its 'maximum speed' stop with

the pedal fully depressed.

Job 8. Mechanical fuel pump,

petrol engine (carburettored) -

replacement.

O Step 1: Disconnect the battery earth lead.

ā¢ Step 2: Find the pump on the forward facing side of the

cylinder block near the timing cover end. Disconnect the two

fuel lines from the pump and plug the ends, (labelling them

for correct refitment).

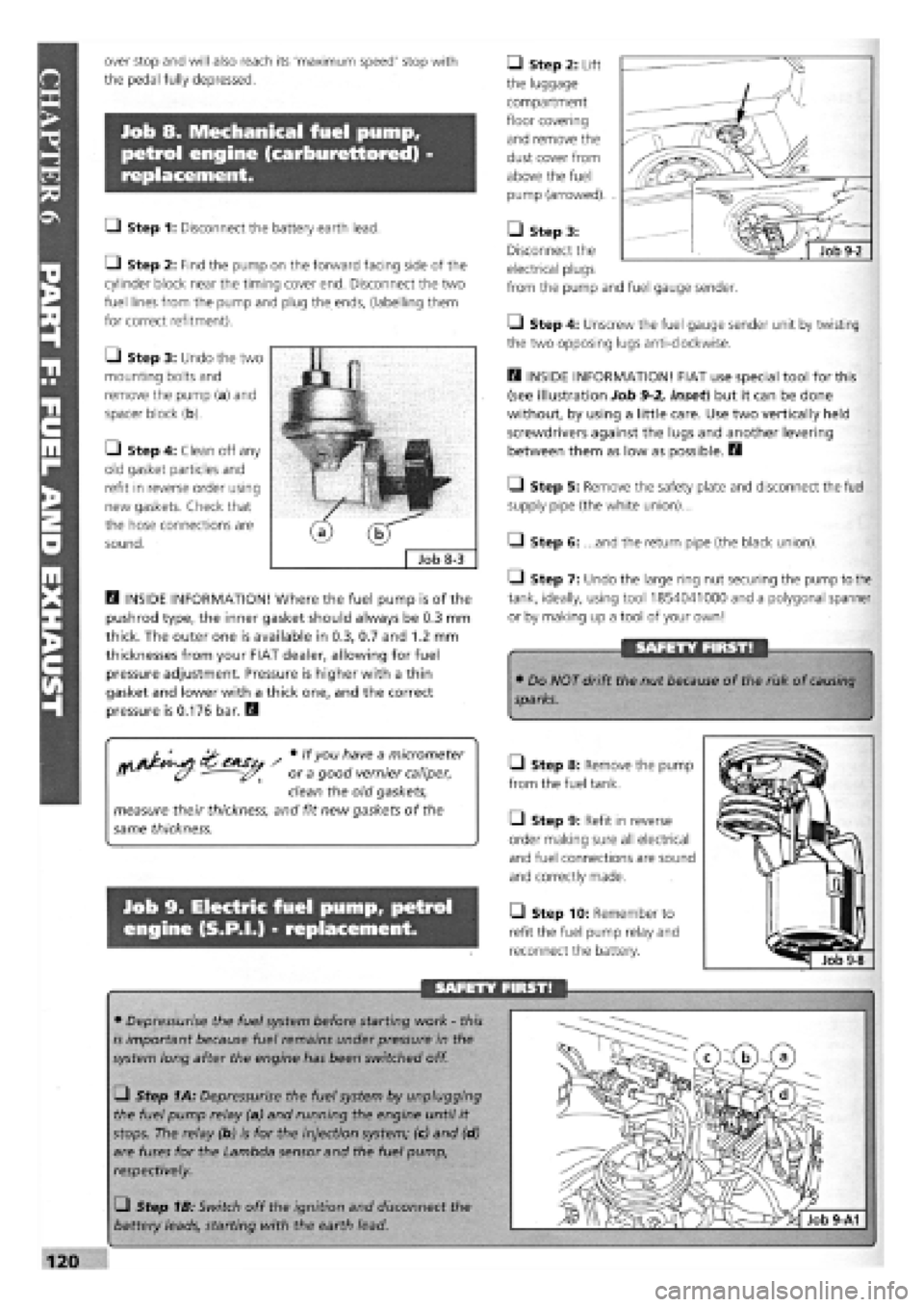

ā¢ Step 3: Undo the two

mounting bolts and

remove the pump (a) and

spacer block (b).

ā¢ Step 4: Clean off any

old gasket particles and

refit in reverse order using

new gaskets. Check that

the hose connections are

sound.

D INSIDE INFORMATION! Where the fuel pump is of the

pushrod type, the inner gasket should always be 0.3 mm

thick. The outer one is available in 0.3, 0.7 and 1.2 mm

thicknesses from your FIAT dealer, allowing for fuel

pressure adjustment. Pressure is higher with a thin

gasket and lower with a thick one, and the correct

pressure is 0.176 bar. Q

/ # lfyou h"ve a m/cromefer

ff (y - or a good vernier caliper,

clean the old gaskets,

measure their thickness, and fit new gaskets of the

same thickness.

Job 9. Electric fuel pump, petrol

engine (S.P.I.) - replacement.

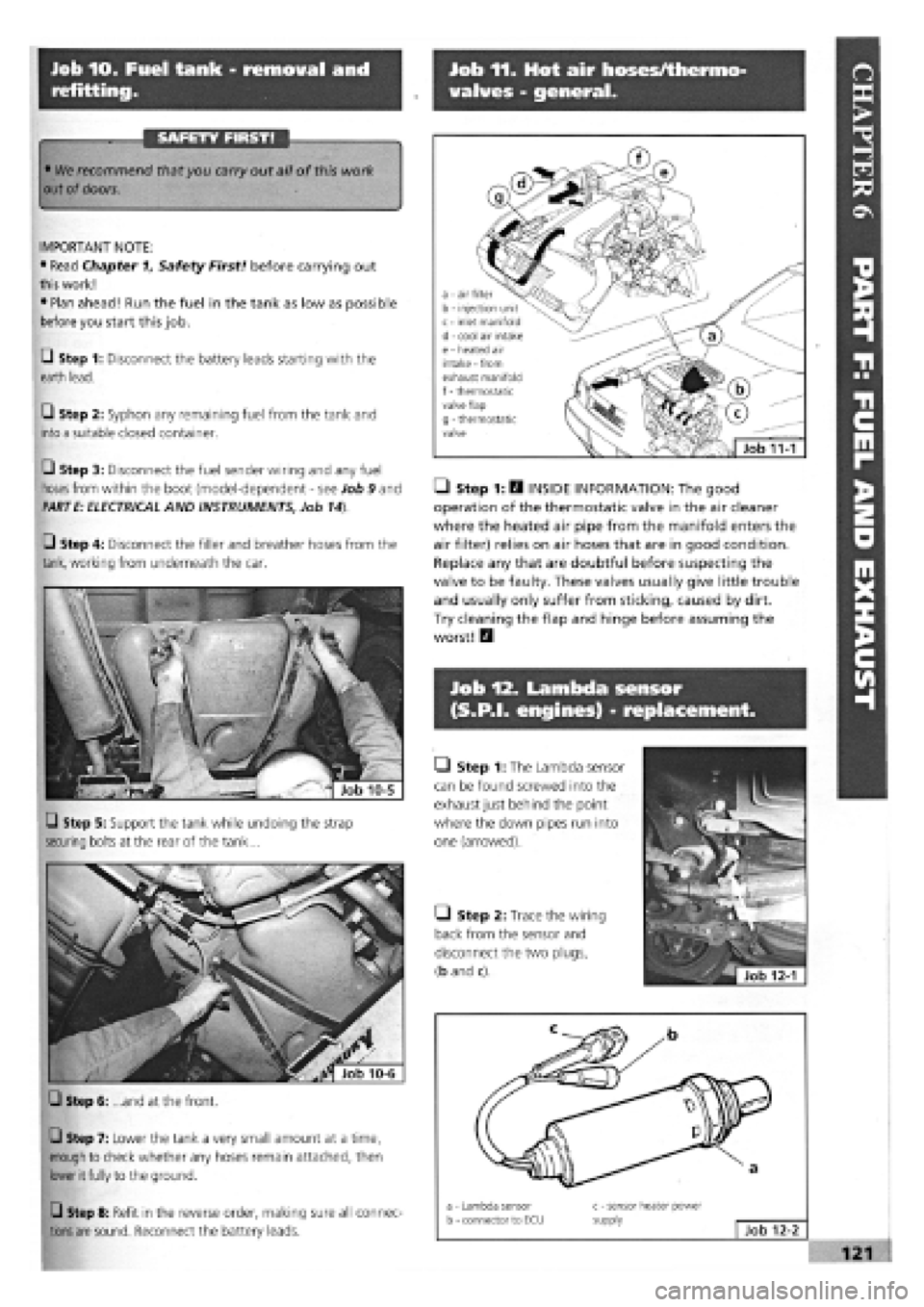

ā¢ Step 2: Lift

the luggage

compartment

floor covering

and remove the

dust cover from

above the fuel

pump (arrowed). .

ā¢ Step 3:

Disconnect the

electrical plugs

from the pump and fuel gauge sender.

ā¢ Step 4: Unscrew the fuel gauge sender unit by twisting

the two opposing lugs anti-clockwise.

D INSIDE INFORMATION! FIAT use special tool for this

(see illustration Job

9-2,

inset) but it can be done

without, by using a little care. Use two vertically held

screwdrivers against the lugs and another levering

between them as low as possible. H

Q Step 5: Remove the safety plate and disconnect the fuel

supply pipe (the white union)...

Q Step 6: ...and the return pipe (the black union).

1-1 Step 7: Undo the large ring nut securing the pump to the

tank, ideally, using tool 1854041000 and a polygonal spanner

or by making up a tool of your own!

SAFETY FIRST!

ā¢ Do NOT drift the nut because of the risk of

causing

sparks.

Q Step 8: Remove the pump

from the fuel tank.

Q Step 9: Refit in reverse

order making sure all electrical

and fuel connections are sound

and correctly made.

ā¢ Step 10: Remember to

refit the fuel pump relay and

reconnect the battery.

SAFETY FIRST!

ā¢ Depressurise the fuel system before starting work

-

this

is important because fuel remains under pressure in the

system long after the engine has been switched off.

ā¢ Step 1A: Depressurise the fuel system by unplugging

the fuel pump relay (a) and running the engine until it

stops. The relay (b) is for the injection system; (c) and (d)

are fuses for the Lambda sensor and the fuel pump,

respectively.

ā¢ Step 1B: Switch off the ignition and disconnect the

battery leads, starting with the earth lead.

Page 117 of 171

Job 10. Fuel tank - removal and

refitting.

Job 11. Hot air hoses/thermo-

valves - general.

SAFETY FIRST!

Job 12. Lambda sensor

(S.P.I, engines) - replacement.

ā¢ We recommend that you carry out all of this work

out of

doors.

I

IMPORTANT NOTE:

ā¢ Read Chapter 1, Safety First! before carrying out

this

work!

ā¢ Plan ahead! Run the fuel in the tank as low as possible

before you start this job.

Q Step 1: Disconnect the battery leads starting with the

earth lead.

ā¢ Step 2: Syphon any remaining fuel from the tank and

into a suitable closed container.

Q Step 3: Disconnect the fuel sender wiring and any fuel

hoses

from within the boot (model-dependent

-

see Job 9 and

PARTE: ELECTRICAL AND INSTRUMENTS, Job 14).

ā¢ Step 4: Disconnect the filler and breather hoses from the

tank,

working from underneath the car.

a - Lambda sensor b - connector to ECU c - sensor heater power supply Job 12-2

Q Step 5: Support the tank while undoing the strap

securing bolts at the rear of the tank...

Q Step 6: ...and at the front.

Q Step 7: Lower the tank a very small amount at a time,

enough to check whether any hoses remain attached, then

lower it fully to the ground.

Q Step 8: Refit in the reverse order, making sure all connec-

tions are

sound. Reconnect the battery leads.

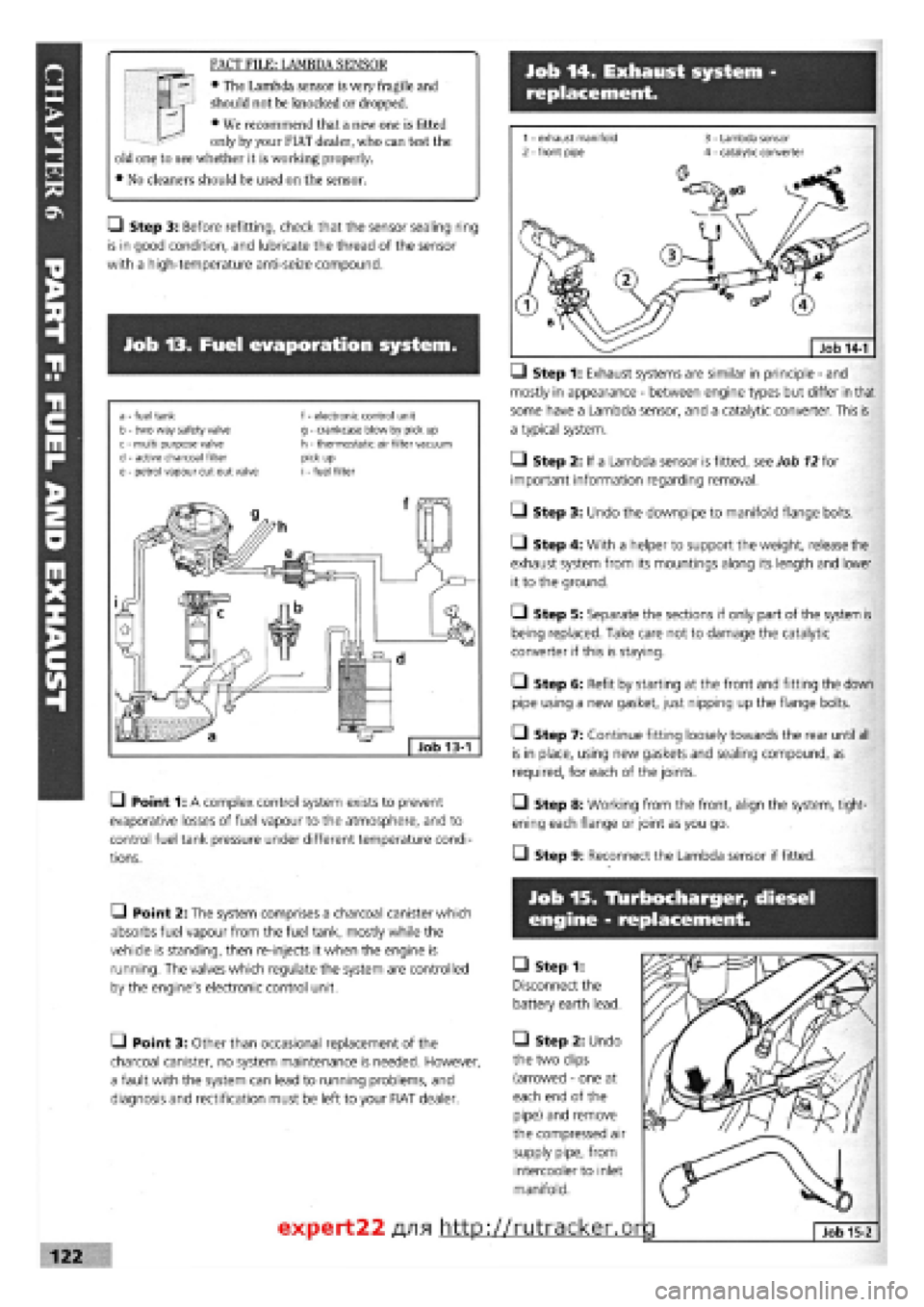

ā¢ Step 1: H INSIDE INFORMATION: The good

operation of the thermostatic valve in the air cleaner

where the heated air pipe from the manifold enters the

air filter) relies on air hoses that are in good condition.

Replace any that are doubtful before suspecting the

valve to be faulty. These valves usually give little trouble

and usually only suffer from sticking, caused by dirt.

Try cleaning the flap and hinge before assuming the

worst! Q

ā¢ Step 1: The Lambda sensor

can be found screwed into the

exhaust just behind the point

where the down pipes run into

one (arrowed).

Q Step 2: Trace the wiring

back from the sensor and

disconnect the two plugs,

(b and c).

a - air filter b - injection unit c - inlet manifold d - cool air intake e - heated air intake - from exhaust manifold f

-

thermostatic valve flap g - thermostatic valve

Job 11-1

Page 118 of 171

Job 14. Exhaust system -

replacement.

FACT FILE: LAMBDA SENSOR

ā¢ The Lambda sensor is very fragile and

should not be knocked or dropped.

ā¢ We recommend that a new one is fitted

only by your FIAT dealer, who can test the

old one to see whether it is working properly.

ā¢ No cleaners should be used on the sensor.

Q Step 3: Before refitting, check that the sensor sealing ring

is in good condition, and lubricate the thread of the sensor

with a high-temperature anti-seize compound.

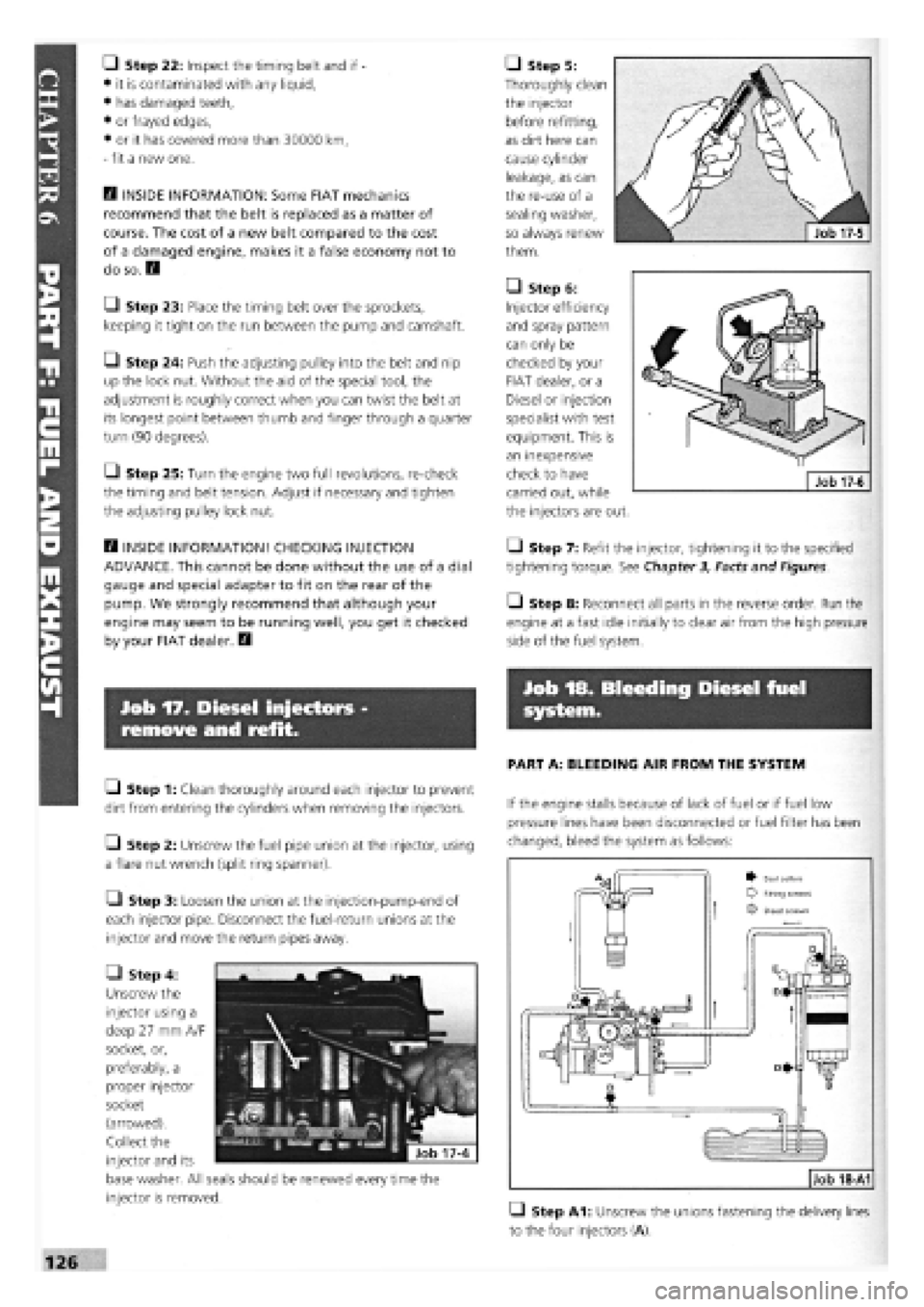

Job 13. Fuel evaporation system.

a - fuel tank b - two way safety valve c - multi purpose valve d

-

active charcoal filter e - petrol vapour cut out valve

f - electronic control unit g - crankcase blow by pick up h - thermostatic air filter vacuum pick up i - fuel filter

ā¢ Point 1: A complex control system exists to prevent

evaporative losses of fuel vapour to the atmosphere, and to

control fuel tank pressure under different temperature condi-

tions.

ā) Step 1: Exhaust systems are similar in principle

-

and

mostly in appearance

-

between engine types but differ in that

some have a Lambda sensor, and a catalytic converter. This is

a typical system.

ā¢ Step 2: If a Lambda sensor is fitted, see Job

12

for

important information regarding removal.

ā¢ Step 3: Undo the downpipe to manifold flange bolts.

ā¢ Step 4: With a helper to support the weight, release the

exhaust system from its mountings along its length and lower

it to the ground.

O Step 5: Separate the sections if only part of the system is

being replaced. Take care not to damage the catalytic

converter if this is staying.

ā¢ Step 6: Refit by starting at the front and fitting the down

pipe using a new gasket, just nipping up the flange bolts.

ā¢ Step 7: Continue fitting loosely towards the rear until all

is in place, using new gaskets and sealing compound, as

required, for each of the joints.

ā¢ Step 8: Working from the front, align the system, tight-

ening each flange or joint as you go.

ā¢ Step 9: Reconnect the Lambda sensor if fitted.

ā¢ Point 2: The system comprises a charcoal canister which

absorbs fuel vapour from the fuel tank, mostly while the

vehicle is standing, then re-injects it when the engine is

running. The valves which regulate the system are controlled

by the engine's electronic control unit.

ā¢ Point 3: Other than occasional replacement of the

charcoal canister, no system maintenance is needed. However,

a fault with the system can lead to running problems, and

diagnosis and rectification must be left to your FIAT dealer.

Job 15. Tlurbocharger, diesel

engine - replacement.

ā¢ Step 1:

Disconnect the

battery earth lead.

ā¢ Step 2: Undo

the two clips

(arrowed

-

one at

each end of the

pipe) and remove

the compressed air

supply pipe, from

intercooler to inlet

manifold.

expert22 fl/i* http://rutracker.or

Page 122 of 171

ā¢ Step 22: Inspect the timing belt and if

-

ā¢ it is contaminated with any liquid,

ā¢ has damaged teeth,

ā¢ or frayed edges,

ā¢ or it has covered more than 30000 km,

-

fit a new one.

D INSIDE INFORMATION: Some FIAT mechanics

recommend that the belt is replaced as a matter of

course. The cost of a new belt compared to the cost

of a damaged engine, makes it a false economy not to

do so.

E9

Q Step 23: Place the timing belt over the sprockets,

keeping it tight on the run between the pump and camshaft.

Q Step 24: Push the adjusting pulley into the belt and nip

up the lock nut. Without the aid of the special tool, the

adjustment is roughly correct when you can twist the belt at

its longest point between thumb and finger through a quarter

turn (90 degrees).

ā¢ Step 25: Turn the engine two full revolutions, re-check

the timing and belt tension. Adjust if necessary and tighten

the adjusting pulley lock nut.

B INSIDE INFORMATION! CHECKING INJECTION

ADVANCE. This cannot be done without the use of a dial

gauge and special adapter to fit on the rear of the

pump. We strongly recommend that although your

engine may seem to be running well, you get it checked

by your FIAT dealer. B

Job 17. Diesel injectors -

remove and refit.

Q Step 1: Clean thoroughly around each injector to prevent

dirt from entering the cylinders when removing the injectors.

Q Step 2: Unscrew the fuel pipe union at the injector, using

a flare nut wrench (split ring spanner).

ā¢ Step 3: Loosen the union at the injection-pump-end of

each injector pipe. Disconnect the fuel-return unions at the

injector and move the return pipes away.

ā¢ Step 4:

Unscrew the

injector using a

deep 27 mm A/F

socket, or,

preferably, a

proper injector

socket

(arrowed).

Collect the

injector and its

base washer. All seals should be renewed every time the

injector is removed.

ā¢ Step 5:

Thoroughly clean

the injector

before refitting,

as dirt here can

cause cylinder

leakage, as can

the re-use of a

sealing washer,

so always renew

them.

ā¢ Step 6:

Injector efficiency

and spray pattern

can only be

checked by your

FIAT dealer, or a

Diesel or injection

specialist with test

equipment. This is

an inexpensive

check to have

carried out, while

the injectors are out.

ā¢ Step 7: Refit the injector, tightening it to the specified

tightening torque. See Chapter 3, Facts and Figures.

ā¢ Step 8: Reconnect all parts in the reverse order. Run the

engine at a fast idle initially to clear air from the high pressure

side of the fuel system.

Job 18. Bleeding Diesel fuel

system.

PART A: BLEEDING AIR FROM THE SYSTEM

If the engine stalls because of lack of fuel or if fuel low

pressure lines have been disconnected or fuel filter has been

changed, bleed the system as follows:

ā¢ Step A1: Unscrew the unions fastening the delivery lines

to the four injectors (A).

Job 18-A1

^ Seal collars Fifing screws

O Bleed screws

Page 123 of 171

ā¢ Step A2: Start the engine and run until fluid emerges

from the loose injector fitting.

G Step A3: Keep the engine running and tighten the four

injector fittings.

B INSIDE INFORMATION: If the engine will not start,

check all fuel inlet pipe union points (see illustration Job

18-A1,

part D) and also the pipe fittings (Job 18-A1,

part E). Replace seal washers to eliminate the possibility

of air leaks. H

PART B: BLEEDING WATER FROM DIESEL

Bleed off water from the fuel filter as follows:

ā¢ Step B1: Unscrew the water bleed screw (Job 18-A1,

part B) under the filter.

ā¢ Step B2: Unscrew air bleed screw (Job 18-A1, part Q

above the filter.

ā¢ Step B3: Let water and fuel emerge until no more water

is present, then tighten, firstly the water bleed screw (B) under

filter, and then the air bleed screw (C) above the filter.

PART G: STEERING AND SUSPENSION

PART G: Contents

Job

1.

The systems explained.

Job

2.

Steering wheel

-

removal and refitting

Job 3. Track rod end balijoint

-

replacement.

Job

4.

Steering rack gaiter

-

replacement.

Job 5. Steering rack

-

replacement.

Job

6.

Power steering pump

-

removal and refitting

Job

7.

Lower wishbone

-

replacement.

Job 8. Bleeding the power steering.

Job 9. Front anti-roll bar

-

removal and refitting.

Job 10. Rear anti-roll bar (when fitted).

Job 11. Front shock absorber

-

replacement.

Job 12. Front wheel bearing

-

replacement.

Job 13. Rear shock absorbers and coil springs

-

replacement.

Job 14. Rear suspension and wheel bearings

-

replacement.

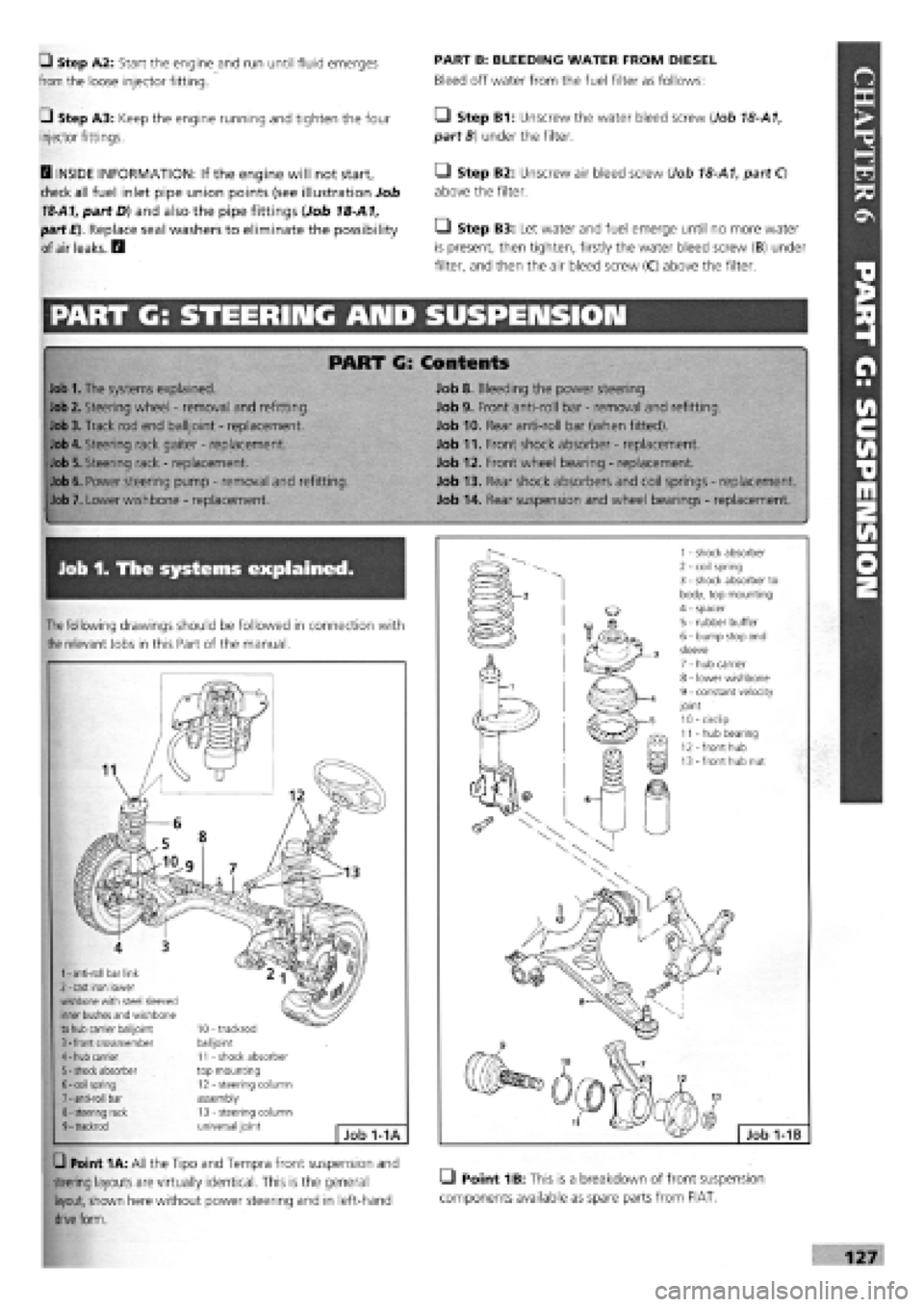

Job 1. The systems explained.

The

following drawings should be followed in connection with

the

relevant Jobs in this Part of the manual.

1

-

anti-roll bar link 2

-

cast iron lower wishbone with steel sleeved inner bushes and wishbone to hub carrier balijoint 3

-

front crossmember 4

-

hub carrier 5

-

shock absorber 6

-

coil spring 7

-

anti-roll bar 8

-

steering rack 9

-

trackrod

10 - trackrod balijoint 11 - shock absorber top mounting 12 - steering column assembly 13 - steering column universal joint Job 1-1A

G Point 1A: All the Tipo and Tempra front suspension and

steering layouts are virtually identical. This is the general LI Point 1B: This is a breakdown of front suspension

layout, shown here without power steering and in left-hand components available as spare parts from FIAT,

drive

form.

Page 127 of 171

Q Step 4: Re-assemble in the reverse order using torque

settings shown in Chapter

3,

Facts and Figures

Job 8. Bleeding the power

steering.

The power assisted steering system is self-bleeding. You

should slowly apply full lock alternately to the right and left

with the car stationary and the engine running, while an

assistant tops up the reservoir. This operation should be

carried out each time the connecting pipes are removed or

refitted.

Job 9. Front anti-roll bar -

removal and refitting.

G Step 1: Take note of the components shown here.

G Step 2: Support the car on axle stands and remove the

front wheels for access.

G Step 3: Undo the nuts at the bottom of the anti-roll links

(see illustration Job

9-1,

part 4).

G Step 4: Undo the four bolts securing the two mounting

brackets (Job

9-1,

part 8) and remove the anti-roll bar.

G Step 5: Before refitting, check the condition of the

rubber mounting blocks and bushes and replace if necessary.

Q INSIDE INFORMATION! The washers (Job

9-1,

part 6)

must be fitted with their convex side facing the rubber

bush (part 7). B

lob 10. Rear anti-roll bar (when

fitted).

ā¢ Step 3: Undo the three mounting bolts from each side

(see illustration Job

1-1D)

and wriggle the anti-roll bar from

under the car.

ā¢ Step 4: Check the anti-roll bar for obvious distortion or

corrosion and the bushes for deterioration. Replace if

necessary.

IāJ Step 5: Refit in reverse order.

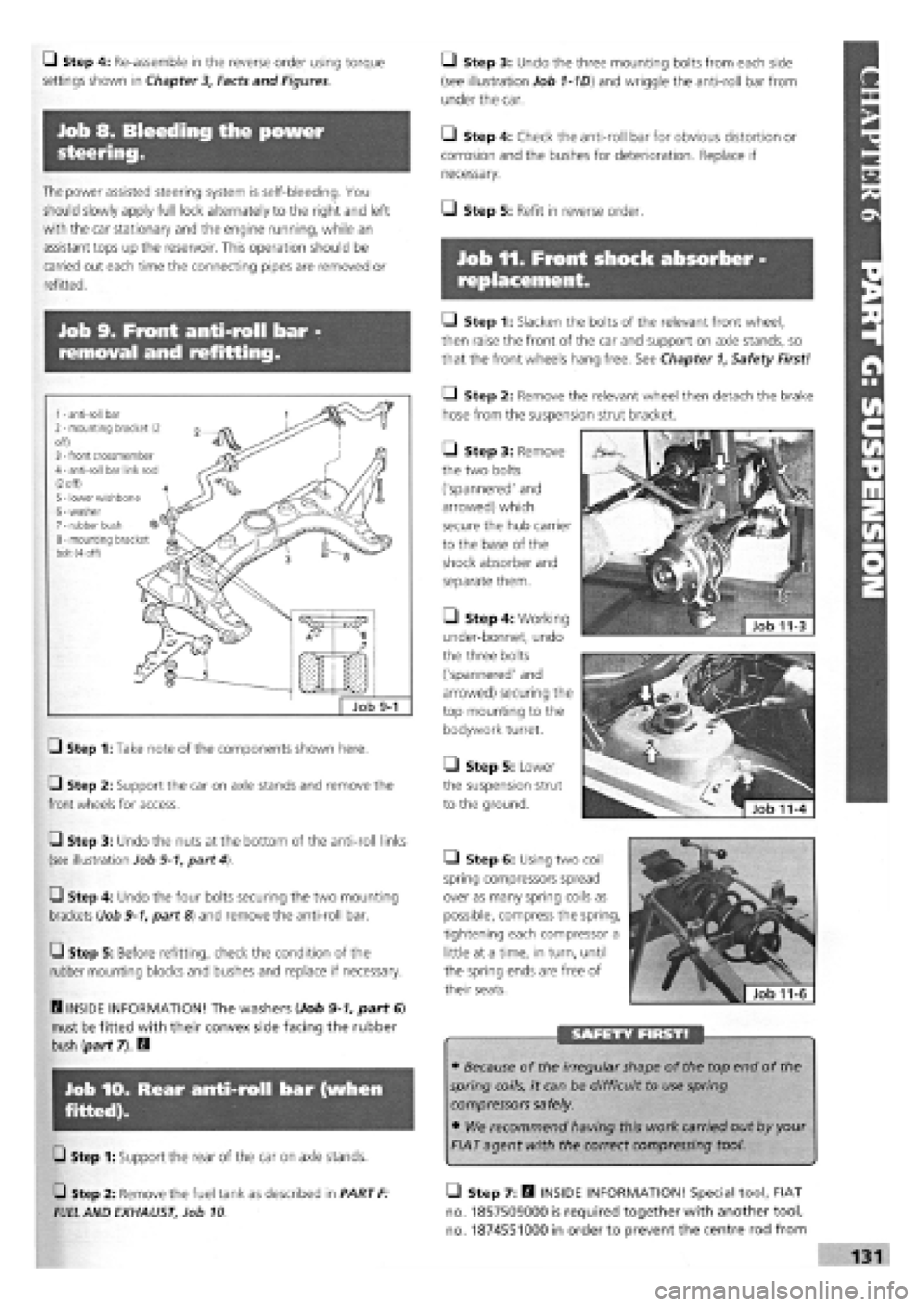

Job 11. Front shock absorber -

replacement.

Q Step 1: Slacken the bolts of the relevant front wheel,

then raise the front of the car and support on axle stands, so

that the front wheels hang free. See Chapter

1,

Safety First!

Q Step 2: Remove the relevant wheel then detach the brake

hose from the suspension strut bracket.

ā¢ Step 3: Remove

the two bolts

('spannered' and

arrowed) which

secure the hub carrier

to the base of the

shock absorber and

separate them.

ā¢ Step 4: Working

under-bonnet, undo

the three bolts

('spannered' and

arrowed) securing the

top mounting to the

bodywork turret.

ā¢ Step 5: Lower

the suspension strut

to the ground.

ā¢ Step 6: Using two coil

spring compressors spread

over as many spring coils as

possible, compress the spring,

tightening each compressor a

little at a time, in turn, until

the spring ends are free of

their seats.

ā¢ Because of the irregular shape of the top end of the

spring coils, it can be difficult to use spring

compressors safely.

ā¢ We recommend having this work carried out by your

FIAT agent with the correct compressing tool. G Step 1: Support the rear of the car on axle stands.

Job 9-1

1

-

anti-roll bar 2

-

mounting bracket (2 off) 3

-

front crossmember 4

-

anti-roll bar link rod

(2

off) 5

-

lower wishbone 6

-

washer 7

-

rubber bush 8

-

mounting bracket bolt (4 off)

G Step 2: Remove the fuel tank as described in PART

F:

FUEL

AND EXHAUST, Job 10

ā¢ Step 7: B INSIDE INFORMATION! Special tool, FIAT

no. 1857509000 is required together with another tool,

no. 1874551000 in order to prevent the centre rod from