bonnet FIAT TEMPRA 1988 Service And Repair Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 1988, Model line: TEMPRA, Model: FIAT TEMPRA 1988Pages: 171, PDF Size: 18.05 MB

Page 5 of 171

Please read the whole of the CHAPTER 1, SAFETY FIRST! before carrying out any work on your car.

CHAPTER 2

USING YOUR CAR

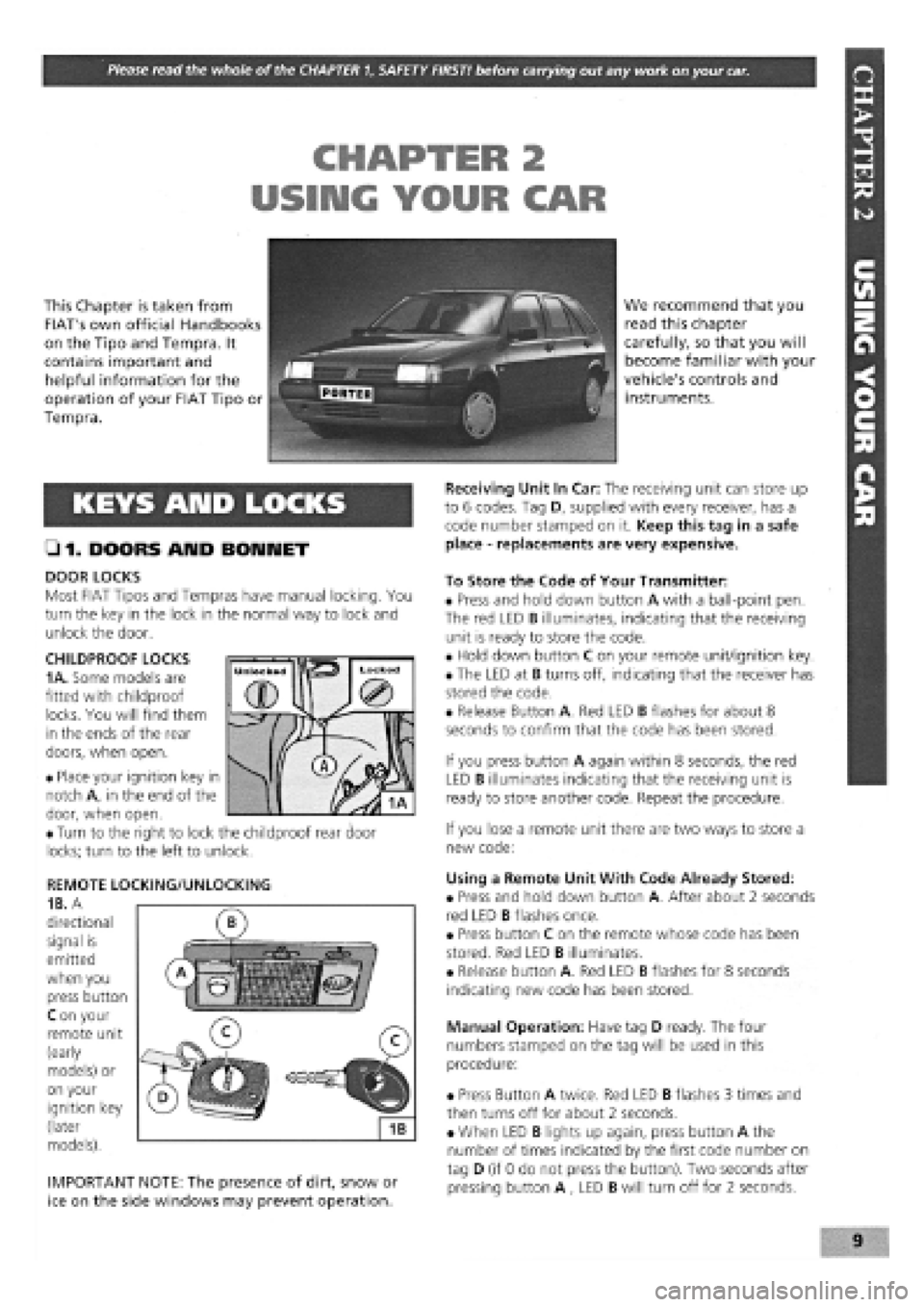

This Chapter is taken from

FIAT's own official Handbooks

on the Tipo and Tempra. It

contains important and

helpful information for the

operation of your FIAT Tipo or

Tempra.

KEYS AND LOCKS

• 1. DOORS AMD BONNET

DOOR LOCKS

Most FIAT Tipos and Tempras have manual locking. You

turn the key in the lock in the normal way to lock and

unlock the door.

CHILDPROOF LOCKS

1 A.

Some models are

fitted with childproof

locks. You will find them

in the ends of the rear

doors, when open.

• Place your ignition key in

notch A, in the end of the

door, when open.

• Turn to the right to lock the childproof rear door

locks; turn to the left to unlock.

REMOTE LOCKING/UNLOCKING

1B. A

directional

signal is

emitted

when you

press button

C on your

remote unit

(early

models) or

on your

ignition key

(later

models).

IMPORTANT NOTE: The presence of dirt, snow or

ice on the side windows may prevent operation.

We recommend that you

read this chapter

carefully, so that you will

become familiar with your

vehicle's controls and

instruments.

Receiving Unit In Car: The receiving unit can store up

to 6 codes. Tag D, supplied with every receiver, has a

code number stamped on it. Keep this tag in a safe

place

-

replacements are very expensive.

To Store the Code of Your Transmitter:

• Press and hold down button A with a ball-point pen.

The red LED B illuminates, indicating that the receiving

unit is ready to store the code.

• Hold down button C on your remote unit/ignition key.

• The LED at B turns off, indicating that the receiver has

stored the code.

• Release Button A. Red LED B flashes for about 8

seconds to confirm that the code has been stored.

If you press button A again within 8 seconds, the red

LED B illuminates indicating that the receiving unit is

ready to store another code. Repeat the procedure.

If you lose a remote unit there are two ways to store a

new code:

Using a Remote Unit With Code Already Stored:

• Press and hold down button A. After about 2 seconds

red LED B flashes once.

• Press button C on the remote whose code has been

stored. Red LED B illuminates.

• Release button A. Red LED B flashes for 8 seconds

indicating new code has been stored.

Manual Operation: Have tag D ready. The four

numbers stamped on the tag will be used in this

procedure:

• Press Button A twice. Red LED B flashes 3 times and

then turns off for about 2 seconds.

• When LED B lights up again, press button A the

number of times indicated by the first code number on

tag D (if 0 do not press the button). Two seconds after

pressing button A , LED B will turn off for 2 seconds.

Page 11 of 171

SAFETY FIRST!

If an air bag has been fitted to your vehicle:

• DO NOT apply stickers or any other objects to

the steering wheel as this may restrict the

operation of the air bag.

• NEVER travel with anything on your lap or in

front of your chest

• NEVER drive with a cigarette, pipe, pen or any

other object in your mouth.

• 12. INTERIOR LIGHTS

COURTESY LIGHT

On most models the courtesy light is positioned in the

centre of the roof.

• With the light switch in the central position the light

turns on when either of the front doors is opened.

• When the switch is in the right position the light

remains on.

• With the switch in the left position the light is

switched off.

• 13. SUNROOF OPERATION

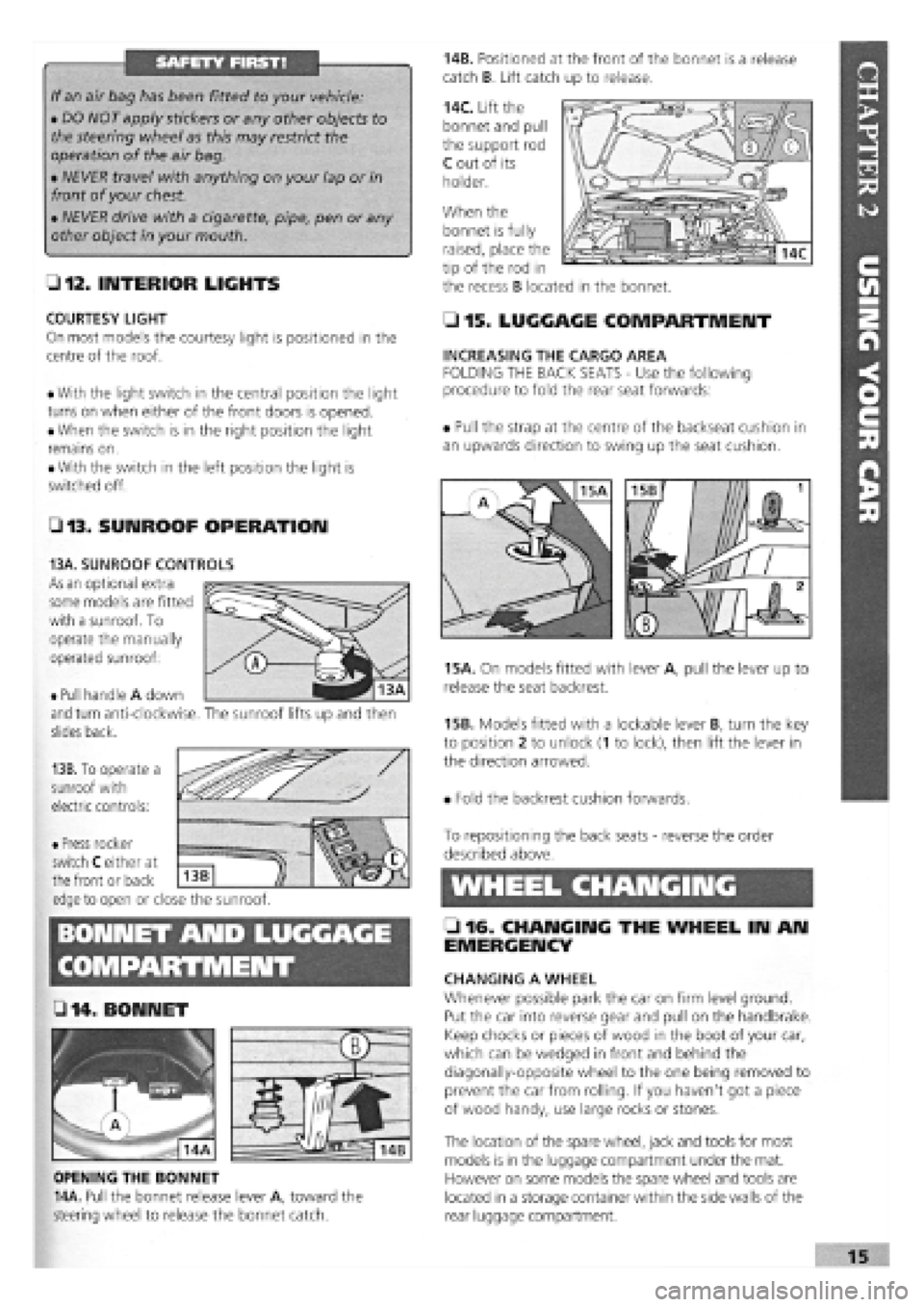

14B. Positioned at the front of the bonnet is a release

catch B. Lift catch up to release.

14C. Lift the

bonnet and pull

the support rod

C out of its

holder.

When the

• 15. LUGGAGE COMPARTMENT

INCREASING THE CARGO AREA

FOLDING THE BACK SEATS

-

Use the following

procedure to fold the rear seat forwards:

• Pull the strap at the centre of the backseat cushion in

an upwards direction to swing up the seat cushion.

15A. On models fitted with lever A, pull the lever up to

release the seat backrest.

15B. Models fitted with a lockable lever B, turn the key

to position 2 to unlock (1 to lock), then lift the lever in

the direction arrowed.

• Fold the backrest cushion forwards.

BONNET AND LUGGAGE

L 2 . fj§

• 14 .BONNET

OPENING THE BONNET

14A. Pull the bonnet release lever A, toward the

steering wheel to release the bonnet catch.

To repositioning the back seats

-

reverse the order

described above.

WHEEL CHANGING

• 16. CHANGING THE WHEEL IN AN

EMERGENCY

CHANGING A WHEEL

Whenever possible park the car on firm level ground.

Put the car into reverse gear and pull on the handbrake.

Keep chocks or pieces of wood in the boot of your car,

which can be wedged in front and behind the

diagonally-opposite wheel to the one being removed to

prevent the car from rolling. If you haven't got a piece

of wood handy, use large rocks or stones.

The location of the spare wheel, jack and tools for most

models is in the luggage compartment under the mat.

However on some models the spare wheel and tools are

located in a storage container within the side walls of the

rear luggage compartment.

bonnet is fully

raised, place the

tip of the rod in

the recess B located in the bonnet.

• Pull handle A down

and turn anti-clockwise,

slides back.

13B. To operate a

sunroof with

electric controls:

13A. SUNROOF CONTROLS

As an optional extra

some models are fitted

with a sunroof. To

operate the manually

operated sunroof:

The sunroof lifts up and then

• Press rocker

switch C either at

the front or back

edge to open or close the sunroof.

Z3

Page 54 of 171

each track rod end (TRE). Also, look out for a split gaiter.

Replace the TRE if the gaiter is split, or it will rapidly fail.

E3 INSIDE INFORMATION: Try placing your hand over the

TRE as the steering is moved. If there are any signs of

wear, replace the TRE. Q

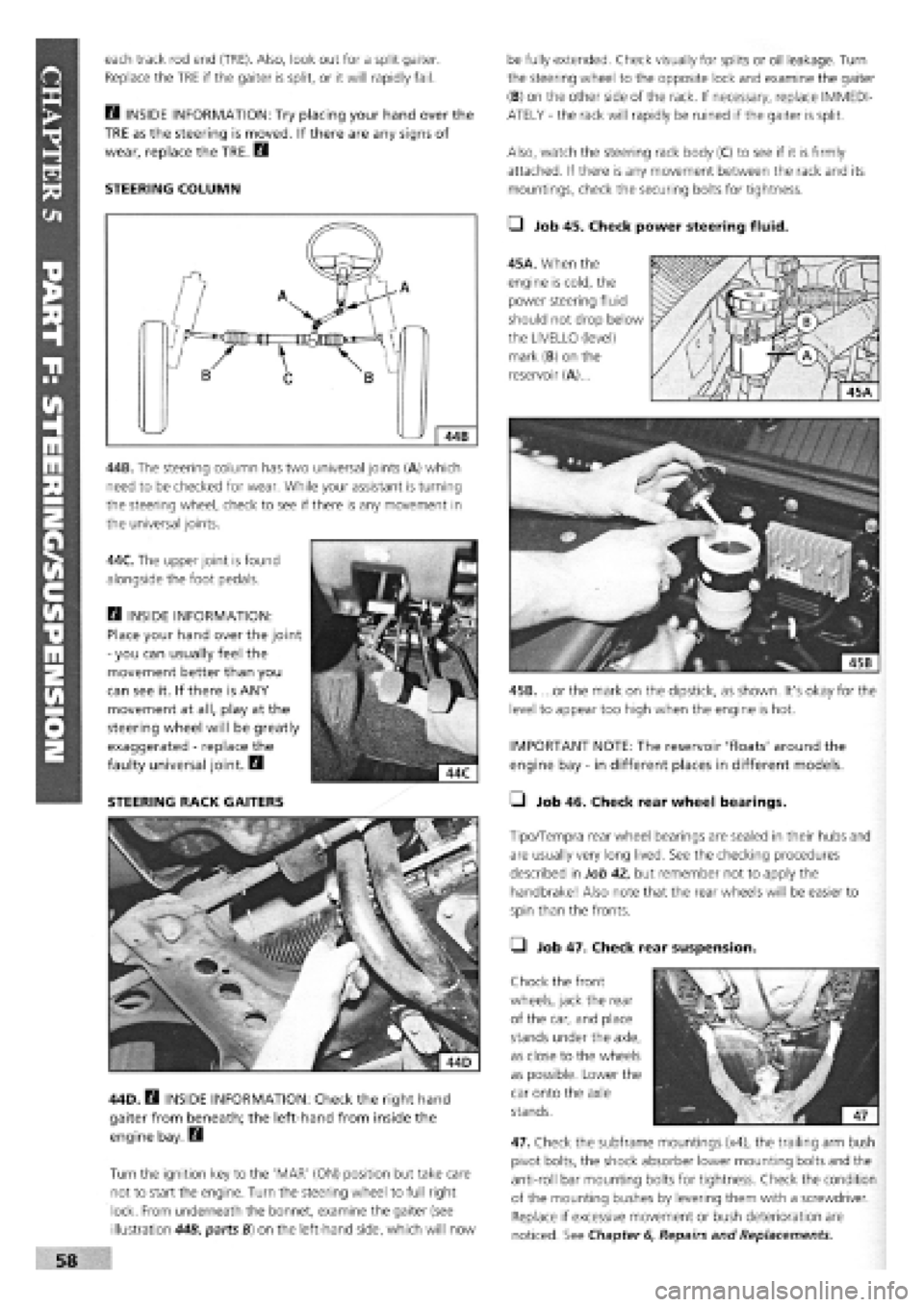

STEERING COLUMN

44B. The steering column has two universal joints (A) which

need to be checked for wear. While your assistant is turning

the steering wheel, check to see if there is any movement in

the universal joints.

44C. The upper joint is found

alongside the foot pedals.

Q INSIDE INFORMATION:

Place your hand over the joint

-

you can usually feel the

movement better than you

can see it. If there is ANY

movement at all, play at the

steering wheel will be greatly

exaggerated

-

replace the

faulty universal joint. B

STEERING RACK GAITERS

44D. B INSIDE INFORMATION: Check the right hand

gaiter from beneath; the left-hand from inside the

engine bay. Q

Turn the ignition key to the 'MAR' (ON) position but take care

not to start the engine. Turn the steering wheel to full right

lock. From underneath the bonnet, examine the gaiter (see

illustration 44B, parts B) on the left-hand side, which will now

be fully extended. Check visually for splits or oil leakage. Turn

the steering wheel to the opposite lock and examine the gaiter

(B) on the other side of the rack. If necessary, replace IMMEDI-

ATELY

-

the rack will rapidly be ruined if the gaiter is split.

Also, watch the steering rack body (C) to see if it is firmly

attached. If there is any movement between the rack and its

mountings, check the securing bolts for tightness.

• Job 45. Check power steering fluid.

45A. When the

engine is cold, the

power steering fluid

should not drop below

the LIVELLO (level)

mark (B) on the

reservoir (A)...

45B. ...or the mark on the dipstick, as shown. It's okay for the

level to appear too high when the engine is hot.

IMPORTANT NOTE: The reservoir 'floats' around the

engine bay

-

in different places in different models.

• Job 46. Check rear wheel bearings.

Tipo/Tempra rear wheel bearings are sealed in their hubs and

are usually very long lived. See the checking procedures

described in Job 42, but remember not to apply the

handbrake! Also note that the rear wheels will be easier to

spin than the fronts.

• Job 47. Check rear suspension.

Chock the front

wheels, jack the rear

of the car, and place

stands under the axle,

as close to the wheels

as possible. Lower the

car onto the axle

stands.

47. Check the subframe mountings (x4), the trailing arm bush

pivot bolts, the shock absorber lower mounting bolts and the

anti-roll bar mounting bolts for tightness. Check the condition

of the mounting bushes by levering them with a screwdriver.

Replace if excessive movement or bush deterioration are

noticed. See Chapter

6,

Repairs and Replacements.

Page 58 of 171

51. Apply the

handbrake lever by

one 'click' of the

ratchet. From inside

the car, turn the

adjusting nut (a)

until the cable is

drawn taut. Pull the

handbrake up two

more 'clicks' and check that both rear wheels are now

'locked'. Check also that both rear wheels are completely free

when the handbrake is fully OFF. When everything works

properly, lower the car to the ground, and check again that

moving the handbrake through about three notches is suffi-

cient to hold the car stationary. A proper check of handbrake

efficiency can only be carried out by a garage with a 'rolling

road' brake tester.

Q Job 52. Check brake pipes.

FLEXIBLE HOSES

Check the flexible brake pipes that connect the calipers to the

metal pipes on the body. Try bending back on themselves

those that are not contained in a protective coil, and look for

any signs of cracking, particularly at the bends. Check them all

for signs of rubbing, splitting, kinks and perishing of the

rubber. Check hoses for 'ballooning' with the brake pedal

pressed.

RIGID PIPES

Check all rigid pipes for signs of damage or corrosion and

check that all of the locating clips are sound and in place.

• Job 53. Change brake hydraulic fluid.

Change the brake fluid at the recommended interval. See

Chapter

6,

Repairs and Replacements, PART H: BRAKES,

Job 15.

H INSIDE INFORMATION: Brake fluid absorbs water from

the air. This corrodes brake components and can cause

total brake failure. With brakes applied heavily, the fluid

can heat to above 100 degrees Celsius, the water

vaporises, and the pedal goes to the floor! B

PART H: BODYWORK & INTERIOR

• Job 54. Lubricate hinges and locks.

Apply a few drops of light oil (from either an aerosol or oil

can) to the hinges of the bonnet, doors and tailgate. Dip the

door/tailgate key in graphite powder and insert the key to

lubricate the lock barrels. Grease the door and tailgate latch

mechanism (aerosol grease is handy), the bonnet release

mechanism (and the tailgate's, if applicable) and the cable

end. Don't forget the fuel tank flap hinge and the locking cap

- it's a stopper when it jams!

• Job 55. Check windscreen.

Clean the windscreen with a proprietary glass cleaner and

examine it for stone chips, cracks and scoring. While some

degree of damage is acceptable, the strict MoT Test regula-

tions limit the amount and position of such defects. Some

screen chips can be repaired and made invisible.

• Job 56. Check seat and seat belt mountings.

Your car's seat and safety belt mountings and backrest

adjustment locking mechanism will be checked as part of the

annual test, but it pays to check them beforehand. Also,

regularly check that the seat belts: a) retract easily and

smoothly, and b) 'hold' when you snatch them, or under

sharp braking.

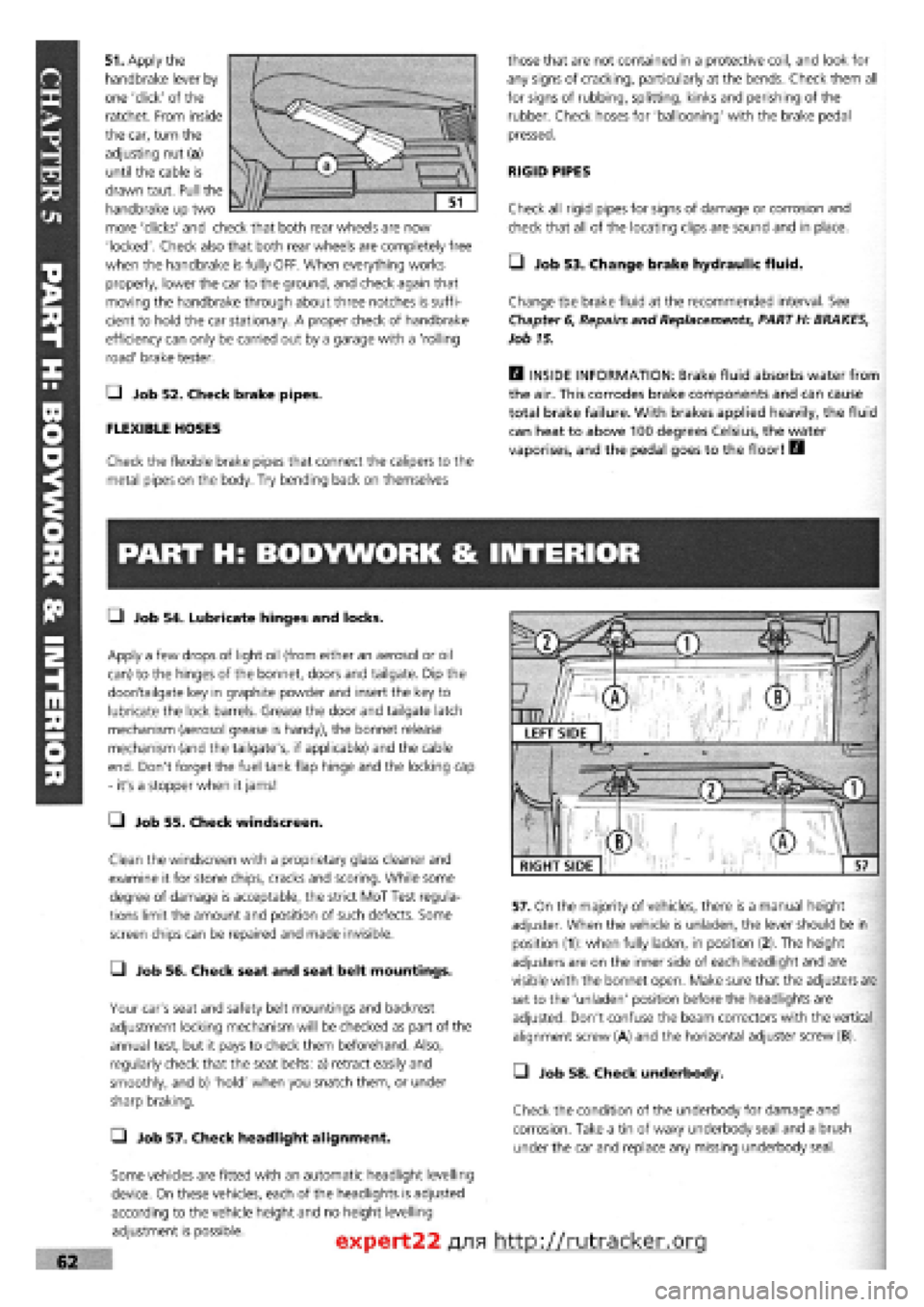

Q Job 57. Check headlight alignment.

Some vehicles are fitted with an automatic headlight levelling

device. On these vehicles, each of the headlights is adjusted

according to the vehicle height and no height levelling

adjustment is possible.

57. On the majority of vehicles, there is a manual height

adjuster. When the vehicle is unladen, the lever should be in

position (1): when fully laden, in position (2). The height

adjusters are on the inner side of each headlight and are

visible with the bonnet open. Make sure that the adjusters are

set to the 'unladen' position before the headlights are

adjusted. Don't confuse the beam correctors with the vertical

alignment screw (A) and the horizontal adjuster screw (B).

• Job 58. Check underbody.

Check the condition of the underbody for damage and

corrosion. Take a tin of waxy underbody seal and a brush

under the car and replace any missing underbody seal.

expert22 fl/ia http://rutracker.org

RIGHT SIDE

Page 76 of 171

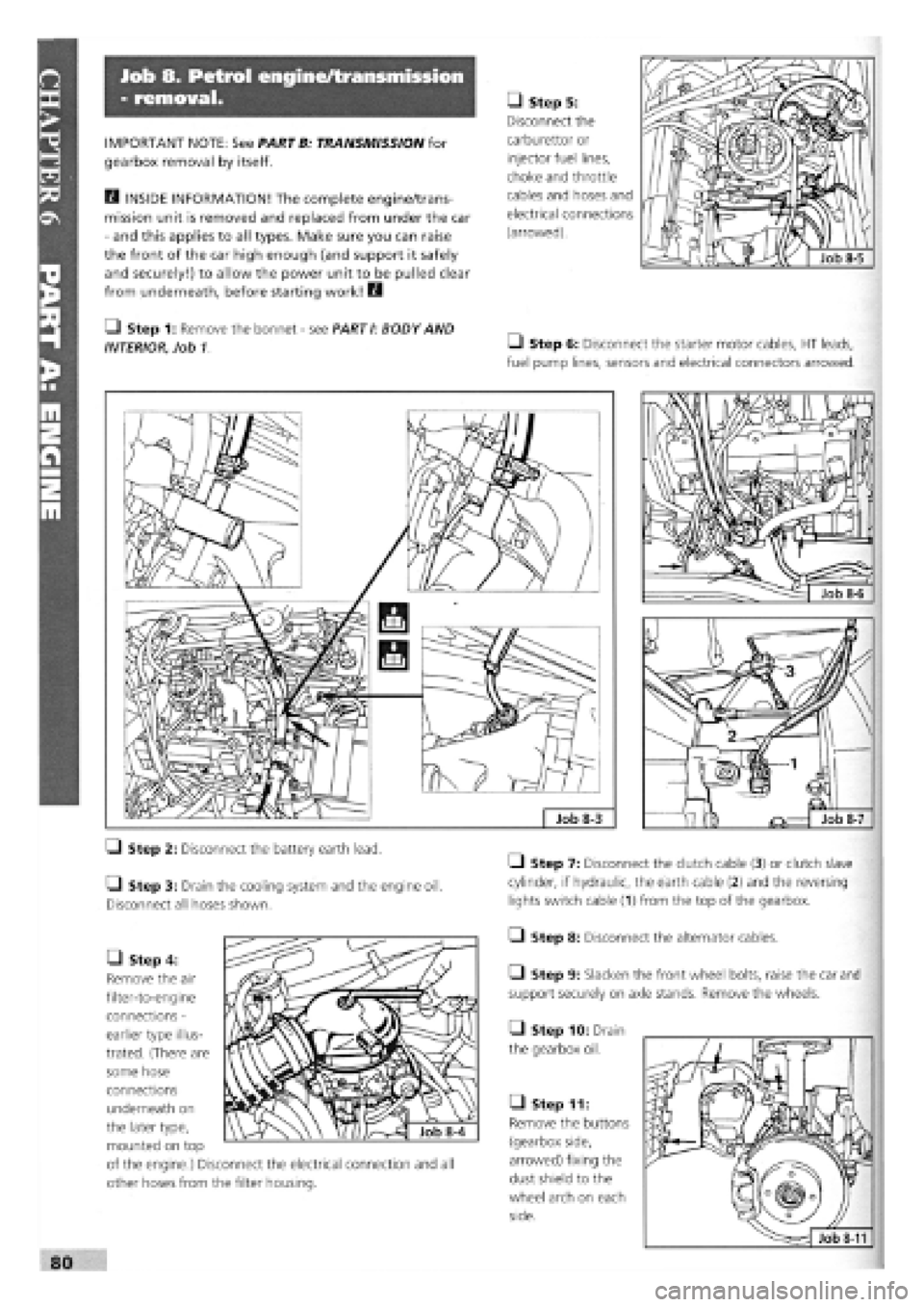

Job 8. Petrol engine/transmission

- removal.

IMPORTANT NOTE: See PARTB: TRANSMISSION for

gearbox removal by itself.

H INSIDE INFORMATION! The complete engine/trans-

mission unit is removed and replaced from under the car

- and this applies to all types. Make sure you can raise

the front of the car high enough (and support it safely

and securely!) to allow the power unit to be pulled clear

from underneath, before starting work! 13

• Step 1: Remove the bonnet

-

see PARTI: BODY AND

INTERIOR, Job 1.

• Step 5:

Disconnect the

carburettor or

injector fuel lines,

choke and throttle

cables and hoses and

electrical connections

(arrowed).

Q Step 6: Disconnect the starter motor cables, HT leads,

fuel pump lines, sensors and electrical connectors arrowed.

Job

8-7

• Step 2: Disconnect the battery earth lead.

• Step 3: Drain the cooling system and the engine oil.

Disconnect all hoses shown.

• Step 7: Disconnect the clutch cable (3) or clutch slave

cylinder, if hydraulic, the earth cable (2) and the reversing

lights switch cable

(1)

from the top of the gearbox.

• Step 8: Disconnect the alternator cables.

Q Step 9: Slacken the front wheel bolts, raise the car and

support securely on axle stands. Remove the wheels.

• Step 10: Drain

the gearbox oil.

• Step 4:

Remove the air

filter-to-engine

connections

-

earlier type illus-

trated. (There are

some hose

connections

underneath on

the later type,

mounted on top

of the engine.) Disconnect the electrical connection and all

other hoses from the filter housing.

• Step 11:

Remove the buttons

(gearbox side,

arrowed) fixing the

dust shield to the

wheel arch on each

side.

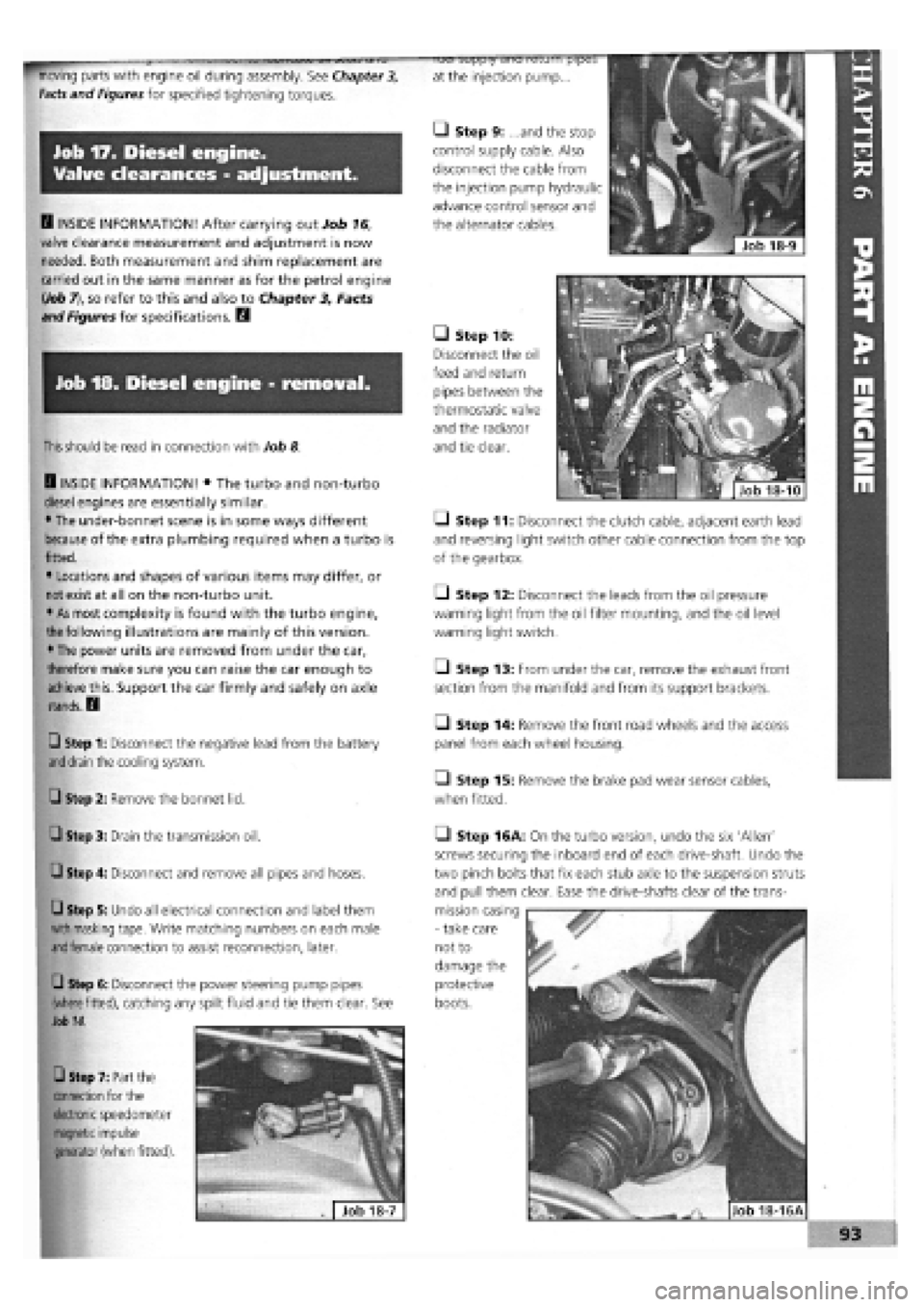

Page 89 of 171

Job 17. Diesel engine.

Valve clearances - adjustment.

D INSIDE INFORMATION! After carrying out Job 16,

valve clearance measurement and adjustment is now

needed. Both measurement and shim replacement are

carried out in the same manner as for the petrol engine

(.Job

7), so refer to this and also to Chapter 3, Facts

and Figures for specifications. B

Job 18. Diesel engine - removal.

moving parts with engine oil during assembly. See Chapter 3,

Facts

and Figures for specified tightening torques.

luei suppiy diiu leium pipe;>

at the injection pump...

• Step 9: ...and the stop

control supply cable. Also

disconnect the cable from

the injection pump hydraulic

advance control sensor and

the alternator cables.

• Step 10:

Disconnect the oil

feed and return

pipes between the

thermostatic valve

and the radiator

and tie clear.

I

This should

be read in connection with Job 8

Q INSIDE INFORMATION! • The turbo and non-turbo

diesel engines are essentially similar.

• The under-bonnet scene is in some ways different

because of the extra plumbing required when a turbo is

fitted.

• Locations and shapes of various items may differ, or

not exist at all on the non-turbo unit.

• As most complexity is found with the turbo engine,

I

the

following illustrations are mainly of this version.

• The power units are removed from under the car,

therefore make sure you can raise the car enough to

achieve this. Support the car firmly and safely on axle

stands. D

Q Step 1: Disconnect the negative lead from the battery

and drain

the cooling system. Q Step 2: Remove the bonnet lid.

• Step 3: Drain the transmission oil.

Q Step 4: Disconnect and remove all pipes and hoses.

Q Step 5: Undo all electrical connection and label them

with masking

tape. Write matching numbers on each male

and female

connection to assist reconnection, later.

Q Step 6: Disconnect the power steering pump pipes

(where fitted),

catching any spilt fluid and tie them clear. See

Job 14.

• Step 7: Part the

connection for the

electronic

speedometer

magnetic impulse

generator

(when fitted).

Q Step 11: Disconnect the clutch cable, adjacent earth lead

and reversing light switch other cable connection from the top

of the gearbox.

• Step 12: Disconnect the leads from the oil pressure

warning light from the oil filter mounting, and the oil level

warning light switch.

• Step 13: From under the car, remove the exhaust front

section from the manifold and from its support brackets.

O Step 14: Remove the front road wheels and the access

panel from each wheel housing.

• Step 15: Remove the brake pad wear sensor cables,

when fitted.

Q Step 16A: On the turbo version, undo the six 'Allen'

screws securing the inboard end of each drive-shaft. Undo the

two pinch bolts that fix each stub axle to the suspension struts

and pull them clear. Ease the drive-shafts clear of the trans-

mission casing

-

take care

not to

damage the

protective

boots.

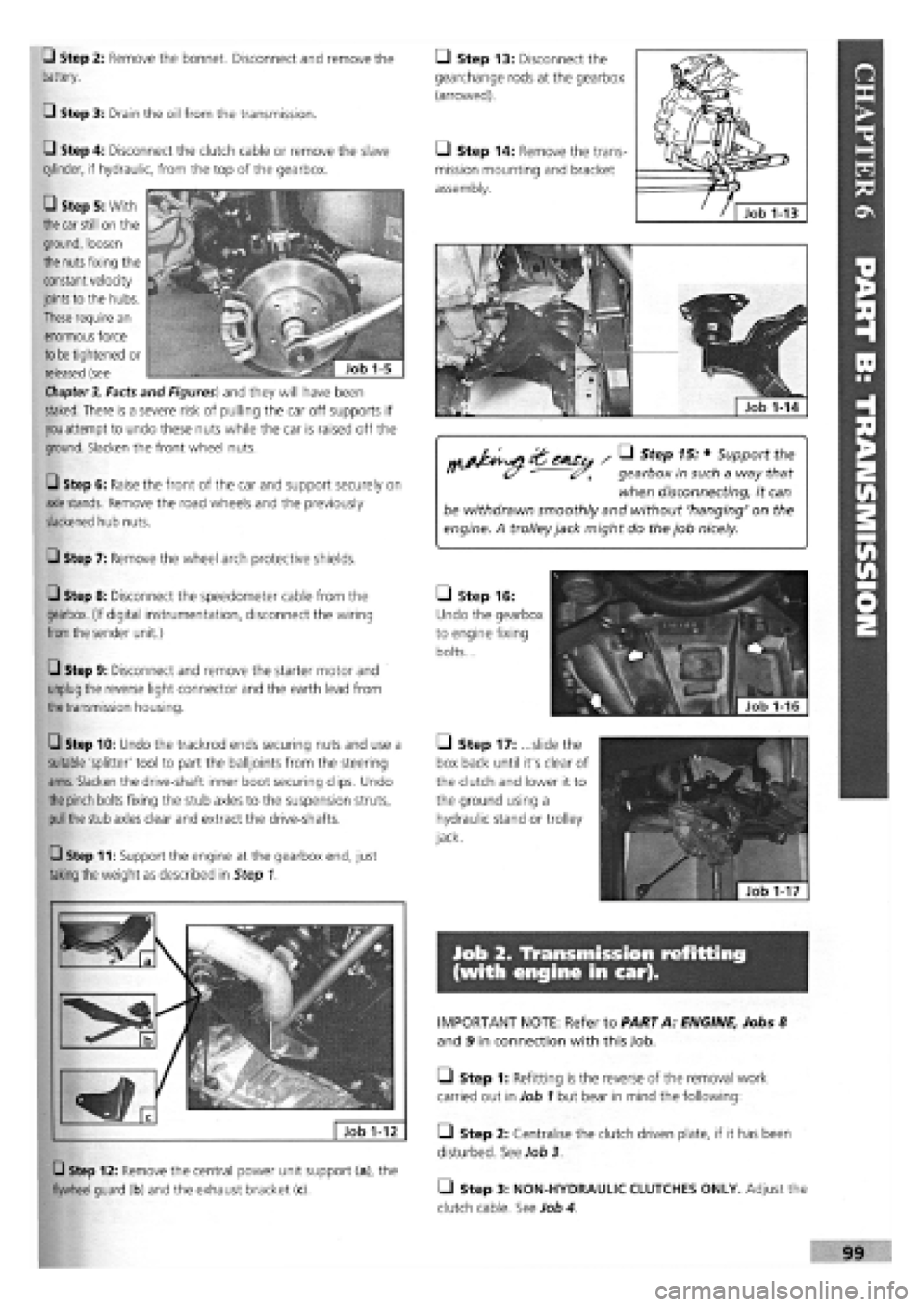

Page 95 of 171

• Step 2: Remove the bonnet. Disconnect and remove the

battery.

0 Step 3: Drain the oil from the transmission.

0 Step 4: Disconnect the clutch cable or remove the slave

cylinder, if hydraulic, from the top of the gearbox.

• Step 13: Disconnect the

gearchange rods at the gearbox

(arrowed).

O Step 14: Remove the trans-

mission mounting and bracket

assembly.

Job 2. Transmission refitting

(with engine in car).

/ a 5tep1S: • SLjpp°n the

'' £/ gearbox in such a way that

when disconnecting, it can

be withdrawn smoothly and without 'hanging' on the

engine. A trolley jack might do the job nicely.

• Step 16:

Undo the gearbox

to engine fixing

bolts...

• Step 17: ...slide the

box back until it's clear of

the clutch and lower it to

the ground using a

hydraulic stand or trolley

jack.

IMPORTANT NOTE: Refer to PART A: ENGINE, Jobs 8

and 9 in connection with this Job.

• Step 1: Refitting is the reverse of the removal work

carried out in Job 1 but bear in mind the following:

Q Step 2: Centralise the clutch driven plate, if it has been

disturbed. See Job 3.

• Step 3: NON-HYDRAULIC CLUTCHES ONLY. Adjust the

clutch cable. See Job 4

Q Step 6: Raise the front of the car and support securely on

axle stands.

Remove the road wheels and the previously

slackened hub nuts.

Q Step 7: Remove the wheel arch protective shields.

Q Step 8: Disconnect the speedometer cable from the

gearbox. (If digital instrumentation, disconnect the wiring

from

the sender unit.)

Q Step 9: Disconnect and remove the starter motor and

unplug

the reverse light connector and the earth lead from

the

transmission housing.

Q Step 10: Undo the trackrod ends securing nuts and use a

suitable 'splitter' tool to part the balljoints from the steering

arms.

Slacken the drive-shaft inner boot securing clips. Undo

the pinch

bolts fixing the stub axles to the suspension struts,

pull

the stub axles clear and extract the drive-shafts.

0 Step 11: Support the engine at the gearbox end, just

taking

the weight as described in Step 1.

Q Step 12: Remove the central power unit support (a), the

flywheel guard (b) and the exhaust bracket (c).

• Step 5: With

the

car

still

on the

ground, loosen

the nuts

fixing the

constant velocity

joints

to the hubs.

These require an

enormous force

to be

tightened or

released (see

Chapter 3,

Facts and Figures) and they will have been

staked. There is a severe risk of pulling the car off supports if

you

attempt to undo these nuts while the car is raised off the

ground. Slacken the front wheel nuts.

Job 1-14

Page 97 of 171

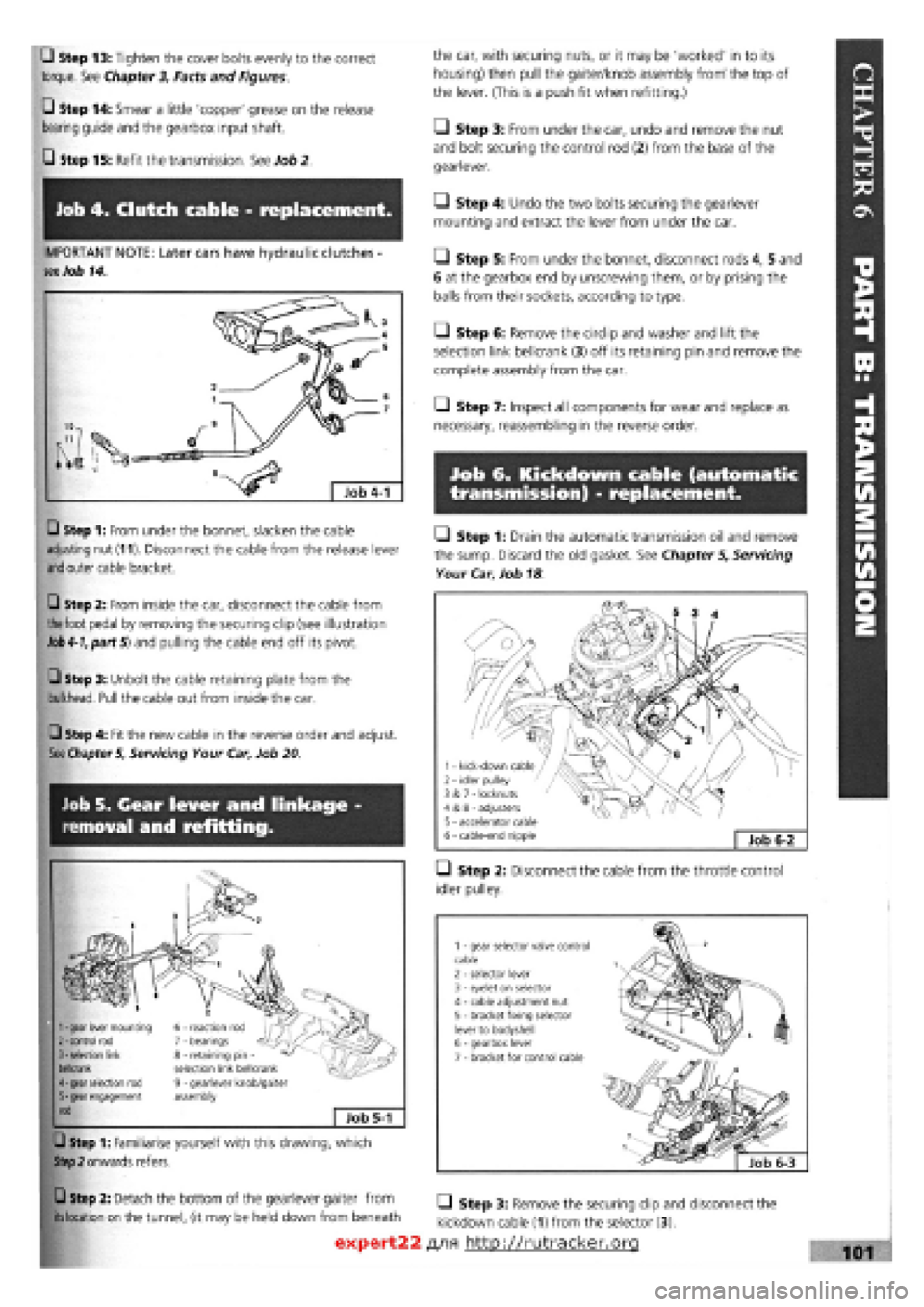

• Step 13: Tighten the cover bolts evenly to the correct

torque. See Chapter

3,

Facts and Figures.

G Step 14: Smear a little 'copper' grease on the release

bearing guide and the gearbox input shaft.

G Step 15: Refit the transmission. See Job 2.

lob 4. Clutch cable - replacement.

IMPORTANT NOTE: Later cars have hydraulic clutches

see Job 14.

• Step 1: From under the bonnet, slacken the cable

adjusting nut (11). Disconnect the cable from the release lever

and

outer cable bracket.

the car, with securing nuts, or it may be 'worked' in to its

housing) then pull the gaiter/knob assembly from the top of

the lever. (This is a push fit when refitting.)

IG Step 3: From under the car, undo and remove the nut

and bolt securing the control rod (2) from the base of the

gearlever.

• Step 4: Undo the two bolts securing the gearlever

mounting and extract the lever from under the car.

Q Step 5: From under the bonnet, disconnect rods 4, 5 and

6 at the gearbox end by unscrewing them, or by prising the

balls from their sockets, according to type.

Q Step 6: Remove the circlip and washer and lift the

selection link bellcrank (3) off its retaining pin and remove the

complete assembly from the car.

• Step 7: Inspect all components for wear and replace as

necessary, reassembling in the reverse order.

Job 6. Kickdown cable (automatic

transmission) - replacement.

Q Step 1: Drain the automatic transmission oil and remove

the sump. Discard the old gasket. See Chapter

5,

Servicing

Your Car, Job 18

G Step 2: From inside the car, disconnect the cable from

the foot

pedal by removing the securing clip (see illustration

Job 4-1,

part 5) and pulling the cable end off its pivot.

G Step 3: Unbolt the cable retaining plate from the

bulkhead. Pull the cable out from inside the car.

G Step 4: Fit the new cable in the reverse order and adjust.

See Chapter 5,

Servicing Your Car, Job 20

Job 5. Gear lever and linkage -

removal and refitting.

1

-

gear lever mounting 6 - reaction rod 2

•

control rod 3-selection link bellcrank 4

-

gear selection rod 5

-

gear engagement rod

7 - bearings 8 - retaining pin -selection link bellcrank 9 - gearlever knob/gaiter assembly

Job 5-1

^ Step 1: Familiarise yourself with this drawing, which

Step 2

onwards refers. n

J Step 2: Detach the bottom of the gearlever gaiter from

its location

on the tunnel, (it may be held down from beneath

expert22

f:

1 - kick-down cable 2 - idler pulley 3 & 7 - locknuts 4 & 8 - adjusters 5 - accelerator cable 6 - cable-end nipple Job 6-2

• Step 2: Disconnect the cable from the throttle control

idler pulley.

1 - gear selector valve control cable 2 - selector lever 3 - eyelet on selector 4 - cable adjustment nut 5 - bracket fixing selector lever to bodyshell 6 - gearbox lever 7 - bracket for control cable

Q Step 3: Remove the securing clip and disconnect the

kickdown cable (1) from the selector (3).

fl/ifl http://rutracker.org

Page 103 of 171

Job 5. Coolant pump -

replacement.

L) Step 4: Lower the switch into water until the thread is

just

covered and the terminals remain dry.

G Step 5: Heat the water slowly. The bulb should light just

below boiling point (90 to 94 degrees Celsius) and go out

when

the temperature falls below 85 to 89 degrees Celsius.

G Step 6: Refit with a new O-ring but do not over tighten.

Job 4. Thermostat - replacement.

G Step 1: Drain the cooling system.

G Step 2: Disconnect the hoses from the thermostat

housing. Illustration Type 1, part 4 (petrol), or Type 2, part

6 (diesel). Undo the bolts and remove the housing/thermostat

assembly.

G Step 3: Clean the mating surfaces, fit the new unit with a

new

gasket.

G Step 4: Reconnect the hoses and refill the cooling system

with

the correct 50/50 FL 'Paraflu' anti-freeze mixture. See

Chapter

5, Servicing Your Car.

E9 INSIDE INFORMATION! For location of the water pump,

see illustration Type 1 (petrol), or Type 2 (diesel). B

• Step 1: Raise the bonnet and drain the cooling system.

Remove the air cleaner.

• Step 2: Unplug the alternator leads, slacken the bolts and

remove the drive belt. Remove the alternator.

• Step 3: Disconnect the hoses and the metal transfer pipe

from the pump.

• Step 4: Undo the securing bolts and remove the coolant

pump.

• Step 5: Discard the old gasket and clean off the mating

surfaces.

Q Step 6: Refit in reverse order using a new gasket.

• Step 7: Adjust the drivebelt tension. See Chapter 5,

Servicing Your Car.

• Step 8: Fill the cooling system with the correct 50/50

solution of FL 'Paraflu' anti-freeze solution. See Chapter 3,

Facts and Figures.

PART D: IGNITION SYSTEMS

——

PART D: Contents

Job 1. Ignition component positions. Job 4. Distributor

-

removal and refitting (1.6 litre engine).

Job

2.

Ignition coil

-

replacement. Job 5. Electronic ignition.

Job

3.

Distributor

-

removal and refitting (1.4 litre engine).

Job 1. Ignition component

positions.

washer g - distributor spacer Job 1-2B

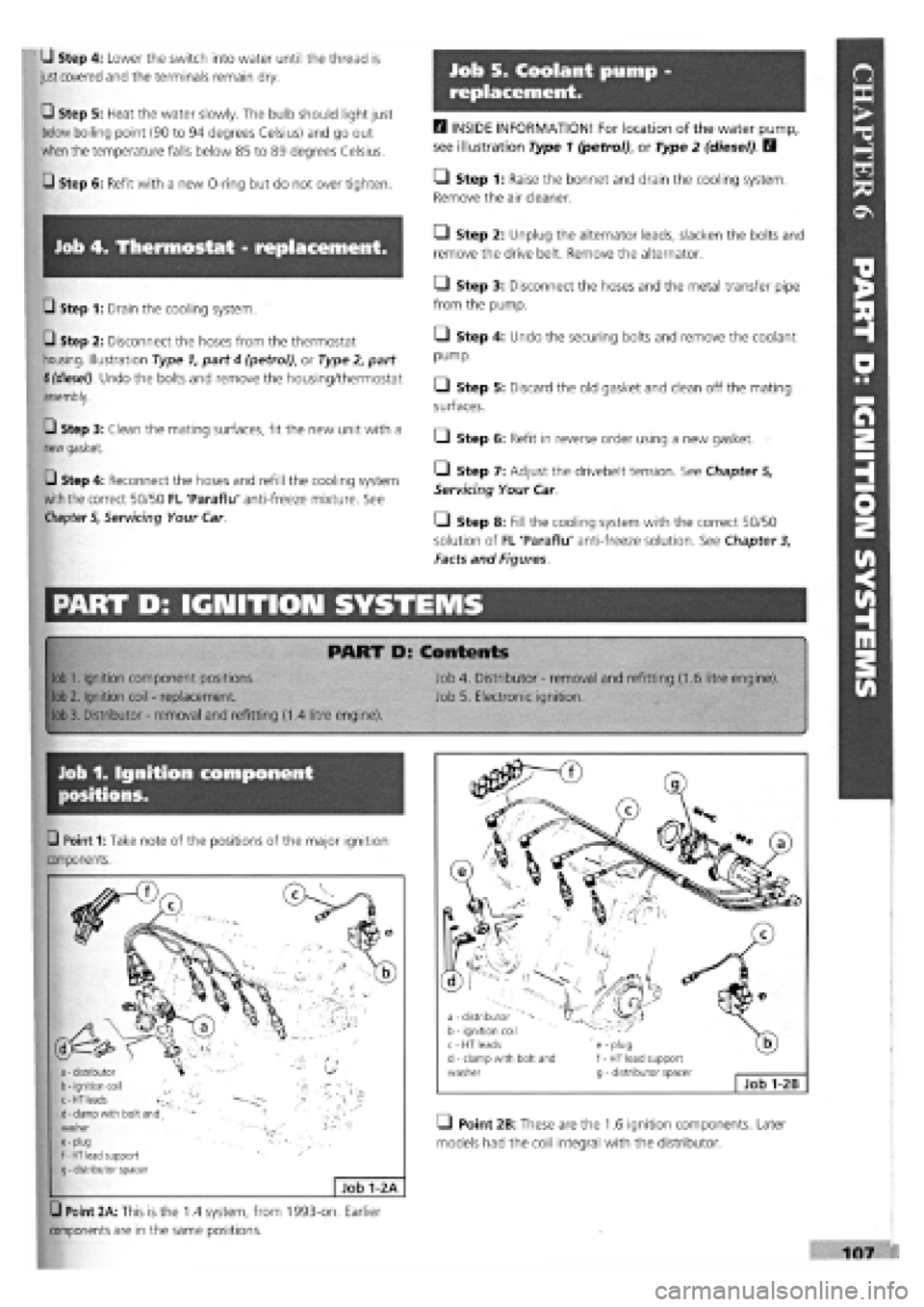

G Point 1: Take note of the positions of the major ignition

components.

Q Point 2B: These are the 1.6 ignition components. Later

models had the coil integral with the distributor.

o

a

>

H

w

w

ON

(A

H

ri

S

VI

107

G Point 2A: This is the 1.4 system, from 1993-on. Earlier

components are in the same positions.

a

-

distributor b

-

ignition coil ^ c-HT leads ^ d

-

clamp with bolt and washer e

-

plug f

-

HT lead support g

-

distributor spacer

Job 1-2 A

Page 107 of 171

Job 6. Hatchback wiper motor -

replacement.

• Step 3: Disconnect the drive cable from the back of

speedometer.

• Step 4: From under the bonnet, uncouple the two cable

halves

from the centre connector and withdraw the

speedometer section through the bulkhead.

Q Step 5: Disconnect the lower end of the cable from the

gearbox drive and remove it.

G Step 6: Follow the reverse procedure to refit the cable,

being

careful to run the cable as straight as possible, avoiding

sharp bends.

Job 5. Windscreen wiper motor -

replacement.

Q Step 1: Disconnect the battery negative (earth) terminal.

Q Step 2: Note the position of the wiper blades on the

screen. Remove the two windscreen wiper arms and then the

grille

cover.

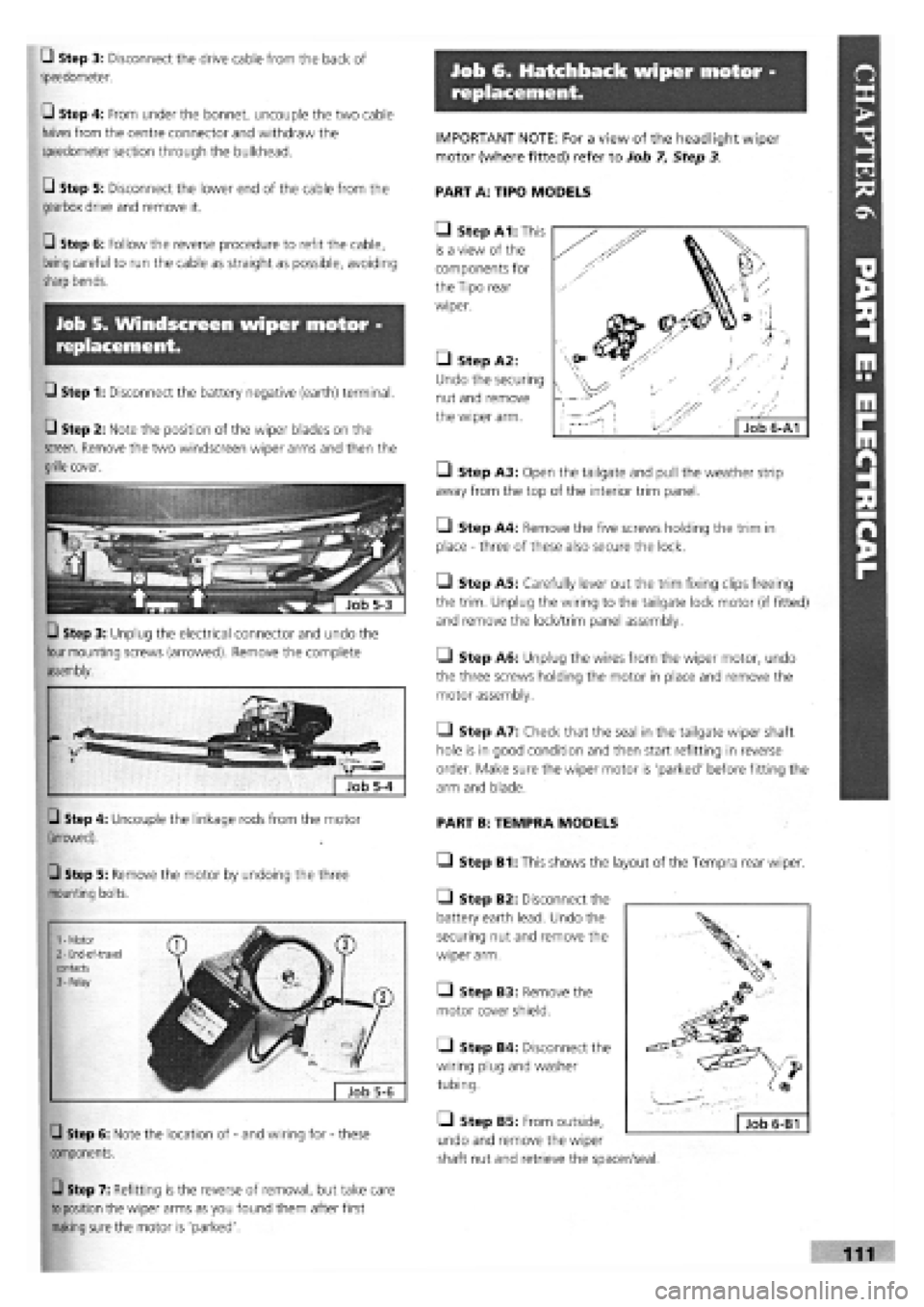

Q Step 3: Unplug the electrical connector and undo the

four mounting screws (arrowed). Remove the complete

assembly.

Q Step 4: Uncouple the linkage rods from the motor

(arrowed).

Q Step 5: Remove the motor by undoing the three

mounting bolts.

Q Step 6: Note the location of

-

and wiring for

-

these

components.

Q Step 7: Refitting is the reverse of removal, but take care

to position

the wiper arms as you found them after first

making

sure the motor is 'parked'.

IMPORTANT NOTE: For a view of the headlight wiper

motor (where fitted) refer to Job 7. Step 3.

PART A: TIPO MODELS

• Step A1: This

is a view of the

components for

the Tipo rear

wiper.

• Step A2:

Undo the securing

nut and remove

the wiper arm.

• Step A3: Open the tailgate and pull the weather strip

away from the top of the interior trim panel.

• Step A4: Remove the five screws holding the trim in

place

-

three of these also secure the lock.

Q Step A5: Carefully lever out the trim fixing clips freeing

the trim. Unplug the wiring to the tailgate lock motor (if fitted)

and remove the lock/trim panel assembly.

• Step A6: Unplug the wires from the wiper motor, undo

the three screws holding the motor in place and remove the

motor assembly.

• Step A7: Check that the seal in the tailgate wiper shaft

hole is in good condition and then start refitting in reverse

order. Make sure the wiper motor is 'parked' before fitting the

arm and blade.

PART B: TEMPRA MODELS

• Step B1: This shows the layout of the Tempra rear wiper.

Q Step B2: Disconnect the

battery earth lead. Undo the

securing nut and remove the

wiper arm.

Q Step B3: Remove the

motor cover shield.

Q Step B4: Disconnect the

wiring plug and washer

tubing.

• Step B5: From outside,

undo and remove the wiper

shaft nut and retrieve the spacer/seal.