sensor FIAT TEMPRA 1988 Service And Repair Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 1988, Model line: TEMPRA, Model: FIAT TEMPRA 1988Pages: 171, PDF Size: 18.05 MB

Page 7 of 171

Fluid levels (if included) are monitored by LEDs f, o and

p, indicating the levels of the fluid reservoirs.

A red LED illuminates at the position on the check panel

corresponding to a side door or a hatchback/tailgate

that is not properly closed.

SIDE AND TAIL LIGHTS

When the side and tail lights are turned on, the check

panel monitors the light bulbs, fuses and circuits.

• LED g monitors the front side lights.

• LED i monitors the tail lights.

If one of the two fuses protecting the following bulbs

blows, LEDs g, i, and m illuminate.

NUMBER PLATE LIGHTS

• LED m indicates when one or both of the number

plate light bulbs have burnt out.

REAR FOG LIGHTS

• When the fog-guard lights are turned on, LED h

monitors the light bulbs.

• When the fuse blows or a circuit malfunction occurs,

LED h illuminates, but not the panel indicator.

STOP LIGHTS

If one or both stop lights burn out, the fuse blows or a

circuit malfunction occurs, LED I or n illuminates when

braking.

• LED n monitors the left stop light.

• LED I monitors the right stop light.

If both bulbs burn out at the same time or brake pedal

switch malfunction occurs, both LEDs I and n

illuminate.

ENGINE OIL LEVEL

• LED f illuminates when the engine oil level is low (key

at MAR,engine not running).

The oil level monitoring system does not operate when

the engine is running. If the oil level warning LED

illuminates when driving, a circuit sensor malfunction

has occurred.

When starting the car on a hill or within 10 minutes of

switching off the engine the warning light may

illuminate (event will be stored in system memory). Start

the engine again on level ground to ensure the oil level

is sufficient.

COOLANT

A low coolant level is indicated by LED o (key at MAR).

The LED also illuminates when a sensor or circuit

malfunction occurs.

WINDSCREEN AND REAR SCREEN WASH LEVELS

• LED p illuminates (key at MAR) when the level in the

windscreen or rear screen wash reservoirs are low.

• The LED also indicates when a circuit or sensor

malfunction occurs.

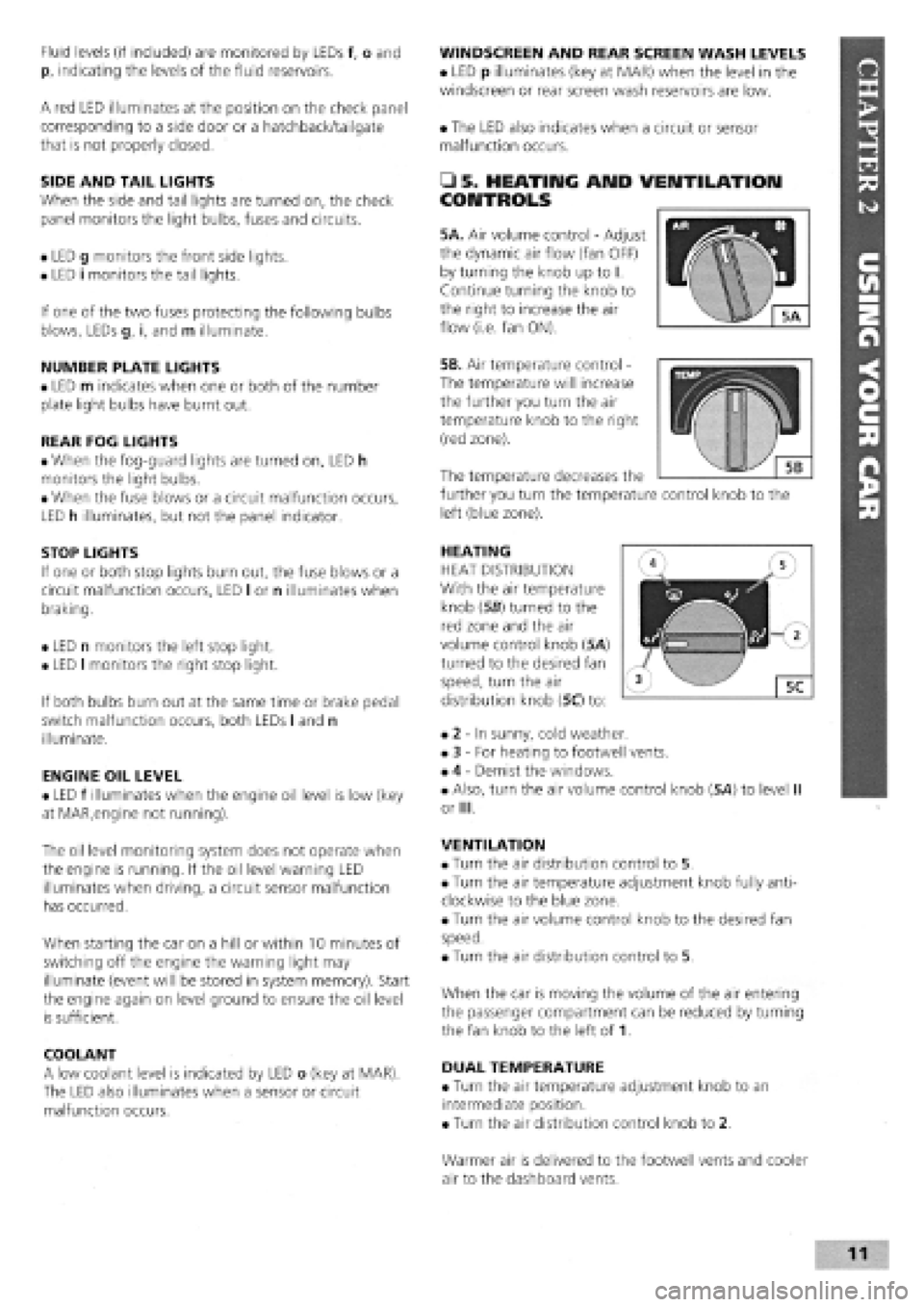

• 5. HE ATI IMG AMD VENTILATION

CONTROLS

5A. Air volume control

-

Adjust

the dynamic air flow (fan OFF)

by turning the knob up to I.

Continue turning the knob to

the right to increase the air

flow (i.e. fan ON).

5B. Air temperature control -

The temperature will increase

the further you turn the air

temperature knob to the right

(red zone).

HEATING

HEAT DISTRIBUTION

With the air temperature

knob (56) turned to the

red zone and the air

volume control knob (5A)

turned to the desired fan

speed, turn the air

distribution knob (5C) to:

• 2

-

In sunny, cold weather.

• 3

-

For heating to footwell vents.

• 4

-

Demist the windows.

• Also, turn the air volume control knob (5A) to level II

or III.

VENTILATION

• Turn the air distribution control to 5.

• Turn the air temperature adjustment knob fully anti-

clockwise to the blue zone.

• Turn the air volume control knob to the desired fan

speed.

• Turn the air distribution control to 5.

When the car is moving the volume of the air entering

the passenger compartment can be reduced by turning

the fan knob to the left of 1.

DUAL TEMPERATURE

• Turn the air temperature adjustment knob to an

intermediate position.

• Turn the air distribution control knob to 2.

The temperature decreases the

further you turn the temperature control knob to the

left (blue zone).

Warmer air is delivered to the footwell vents and cooler

air to the dashboard vents.

Page 29 of 171

Thanks

are due to the excellent, knowledgeable and helpful staff at FIAT main dealers, Ryauto of Amblecote, in the West

Midlands for supplying vehicles and for their assistance with this chapter. In particular, thanks are due to the efficient Maurice

Hough, Service Manager, the experienced Foreman, Tony Morris, and young demon mechanic, Matthew Worsfold.

Some of the suggested inspection/replacement intervals may not correspond to those shown in the original handbook. The suggested

schedule, based on FIAT'S recommendations, takes into account the age of the vehicle and the annual MoT test in the UK.

In practice, because of the split between (mainly) 12 month/9,000 mile and 18 month/13,500 mile intervals, you will need to

service your Tipo or Tempra at most, if not every, 6 month interval.

IMPORTANT NOTE: Each service should be carried out at EITHER the recommended mileage OR the recommended time

interval, whichever comes first.

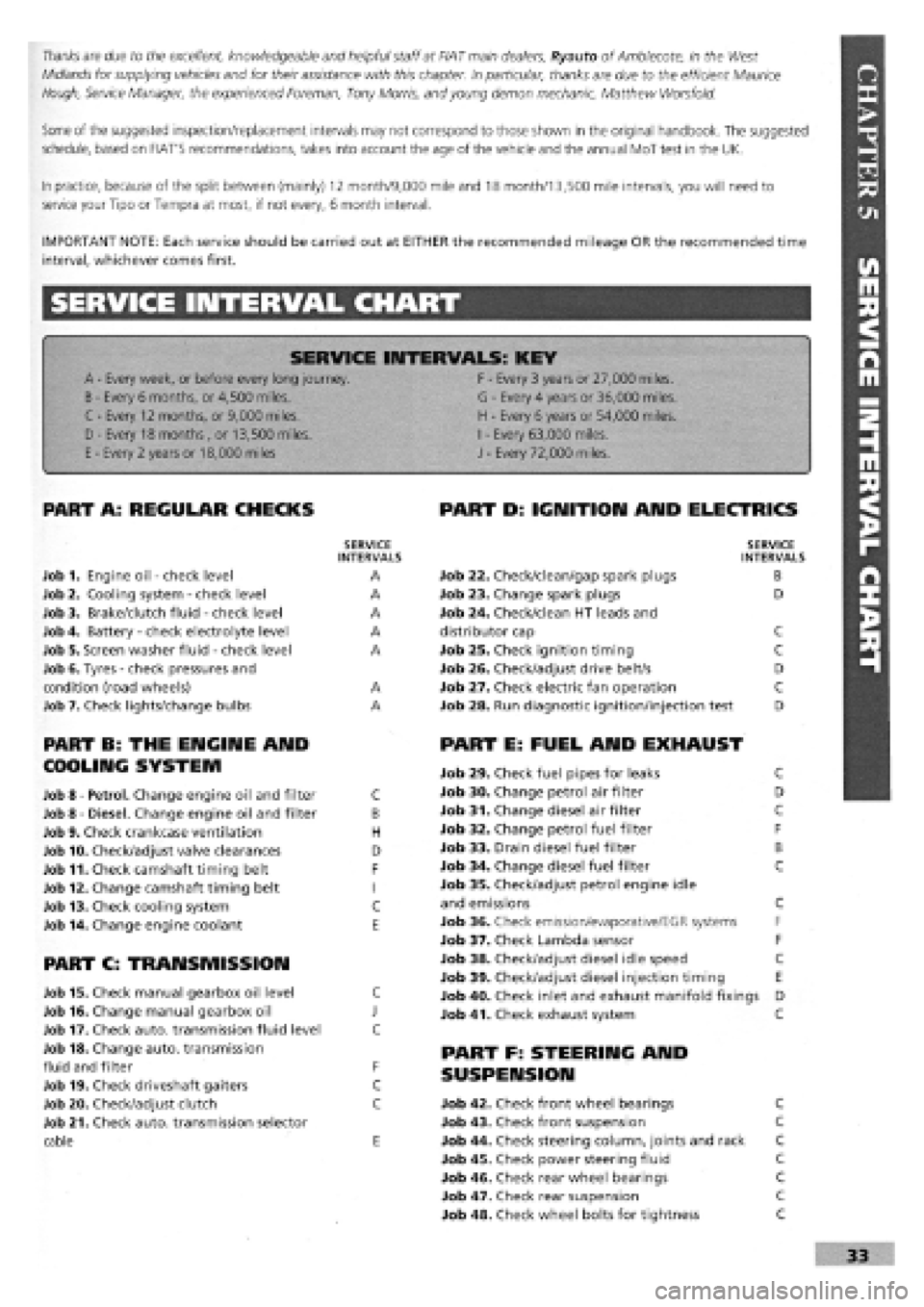

SERVICE INTERVAL CHART

SERVICE INTERVALS: KEY

A

-

Every week, or before every long journey. F

-

Every 3 years or 27,000 miles.

B

-

Every 6 months, or 4,500 miles. G

-

Every 4 years or 36,000 miles.

C - Every 12 months, or 9,000 miles. H

-

Every 6 years or 54,000 miles.

I

-

Every 63,000 miles. D - Every 18 months , or 13,500 miles.

H

-

Every 6 years or 54,000 miles.

I

-

Every 63,000 miles.

E

-

Every 2 years or 18,000 miles J

-

Every 72,000 miles.

PART A: REGULAR CHECKS

SERVICE INTERVALS

Job 1. Engine oil

-

check level A

Job 2. Cooling system

-

check level A

Job 3. Brake/clutch fluid

-

check level A

Job 4. Battery

-

check electrolyte level A

Job 5. Screen washer fluid

-

check level A

Job 6. Tyres

-

check pressures and

condition (road wheels) A

Job 7. Check lights/change bulbs A

PART B: THE ENGINE AND

COOLING SYSTEM

Job 8

-

Petrol. Change engine oil and filter C

Job 8

-

Diesel. Change engine oil and filter B

Job 9. Check crankcase ventilation H

Job 10. Check/adjust valve clearances D

Job 11. Check camshaft timing belt F

Job 12. Change camshaft timing belt I

Job 13. Check cooling system C

Job 14. Change engine coolant E

PART C: TRANSMISSION

Job 15. Check manual gearbox oil level C

Job 16. Change manual gearbox oil J

Job 17. Check auto, transmission fluid level C

Job 18. Change auto, transmission

fluid and filter F

Job 19. Check driveshaft gaiters C

Job 20. Check/adjust clutch C

Job 21. Check auto, transmission selector

cable E

PART D: IGNITION AND ELECTRICS

SERVICE INTERVALS

Job 22. Check/clean/gap spark plugs B

Job 23. Change spark plugs D

Job 24. Check/clean HT leads and

distributor cap C

Job 25. Check ignition timing C

Job 26. Check/adjust drive belt/s D

Job 27. Check electric fan operation C

Job 28. Run diagnostic ignition/injection test D

PART E: FUEL AND EXHAUST

Job 29. Check fuel pipes for leaks C

Job 30. Change petrol air filter D

Job 31. Change diesel air filter C

Job 32. Change petrol fuel filter F

Job 33. Drain diesel fuel filter B

Job 34. Change diesel fuel filter C

Job 35. Check/adjust petrol engine idle

and emissions C

Job 36. Check emission/evaporative/EGR systems F

Job 37. Check Lambda sensor F

Job 38. Check/adjust diesel idle speed C

Job 39. Check/adjust diesel injection timing E

Job 40. Check inlet and exhaust manifold fixings D

Job 41. Check exhaust system C

PART F: STEERING AND

SUSPENSION

Job 42. Check front wheel bearings C

Job 43. Check front suspension C

Job 44. Check steering column, joints and rack C

Job 45. Check power steering fluid C

Job 46. Check rear wheel bearings C

Job 47. Check rear suspension C

Job 48. Check wheel bolts for tightness C

Page 37 of 171

FACT FILE: FUSES contd. 7h. CERTAIN TIPO MODELS: Other

fuses are i) a set of three fuses (15A, 30A

and 40A) protecting the air conditioning,

when fitted, located in the engine bay,

near the horns (A). Press in the two sides

(arrowed) to remove the cover.

And ii) there is a 60A

fuse, located near the

fuse box, protecting

the fan on Diesel

vehicles.

7i. On latest vehicles,

there are two 10A

fuses (a) protecting

the electric petrol

pump and the

Lambda sensor

preheater. Remove

the screws (arrowed)

and the cover.

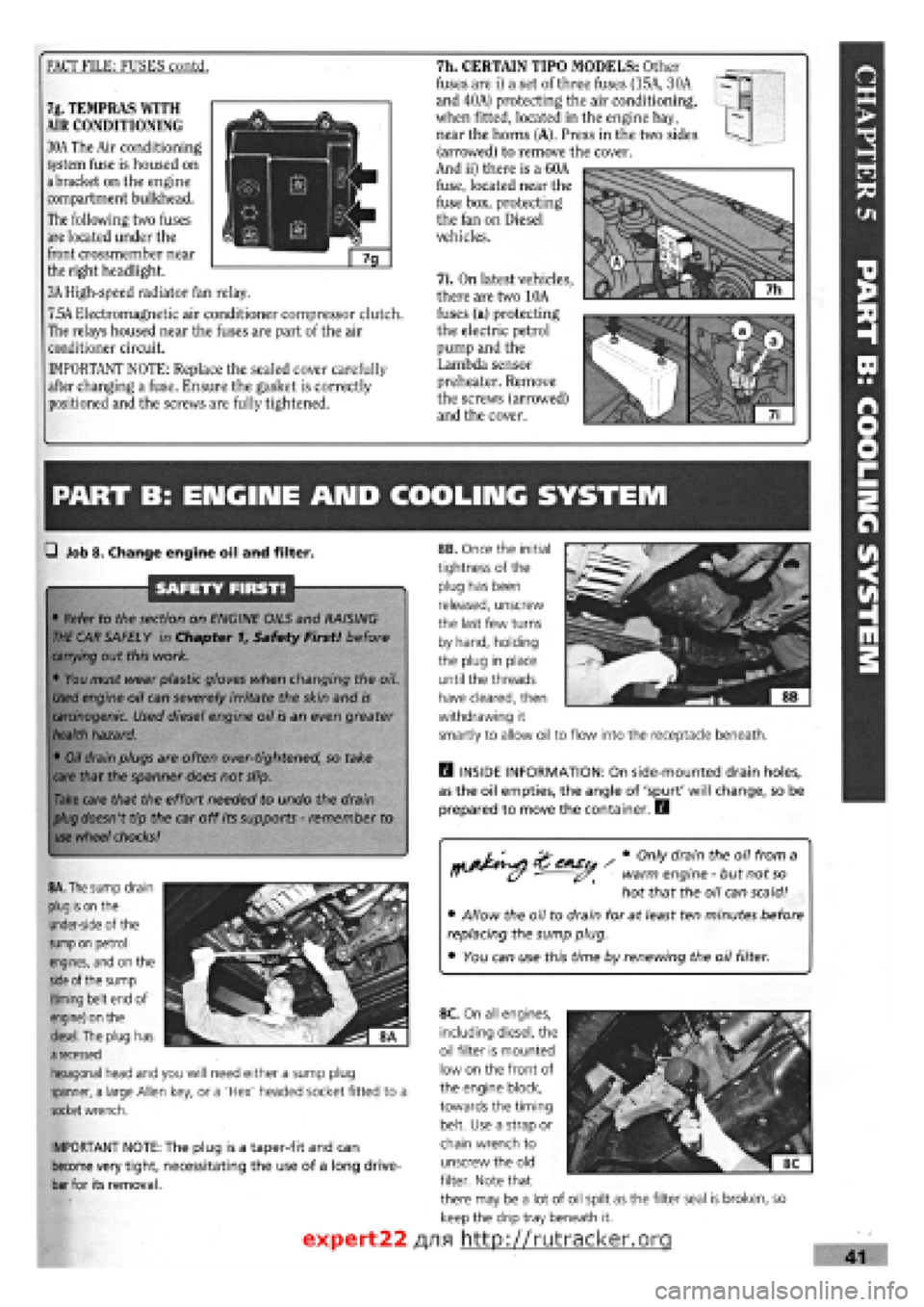

7g. TEMPRAS WITH

AIR CONDITIONING

30A The Air conditioning

system fuse is housed on

a bracket on the engine

compartment bulkhead.

The following two fuses

are located under the

front crossmember near

the right headlight.

3A High-speed radiator fan relay.

7.5A Electromagnetic air conditioner compressor clutch.

The relays housed near the fuses are part of the air

conditioner circuit.

IMPORTANT NOTE: Replace the sealed cover carefully

after changing a fuse. Ensure the gasket is correctly

positioned and the screws are fully tightened.

PART B: ENGIIME AND COOLING SYSTEM

Q Job 8. Change engine oil and filter.

SAFETY FIRST!

• Refer to the section on ENGINE OILS and RAISING

THE

CAR SAFELY in Chapter f, Safety First! before

carrying

out this work.

• You must wear plastic gloves when changing the oil.

Used

engine oil can severely irritate the skin and

is

carcinogenic.

Used diesel engine oil is an even greater

health

hazard.

•

Oil

drain plugs are often over-tightened, so take

care

that the spanner does not slip.

Take

care that the effort needed to undo the drain

plug

doesn't tip the car off its supports

-

remember to

use

wheel

chocks!

rtj&^si ' # °nly dram theu 0,7 fr°m a ff (y warm engine

-

but not

so

hot that the oil can scald!

• Allow the oil to drain for at least ten minutes before

replacing the sump plug.

• You can use this time by renewing the oil filter.

IMPORTANT NOTE: The plug is a taper-fit and can

become very tight, necessitating the use of a long drive-

bar for its removal.

H INSIDE INFORMATION: On side-mounted drain holes,

as the oil empties, the angle of 'spurt' will change, so be

prepared to move the container. E3

8A. The

sump drain

plug is on

the

under-side of the

sump on

petrol

engines, and on the

side

of the sump

(timing belt end of

engine) on the

diesel.

The plug has

a

recessed

hexagonal head and you will need either a sump plug

spanner, a large Allen key, or a 'Hex' headed socket fitted to a

socket

wrench.

8B. Once the initial

tightness of the

plug has been

released, unscrew

the last few turns

by hand, holding

the plug in place

until the threads

have cleared, then

withdrawing it

smartly to allow oil to flow into the receptacle beneath.

expert22

8C. On all engines,

including diesel, the

oil filter is mounted

low on the front of

the engine block,

towards the timing

belt. Use a strap or

chain wrench to

unscrew the old

filter. Note that

there may be a lot of oil spilt as the filter seal is broken, so

keep the drip tray beneath it.

/yifl http://rutracker.org

Page 44 of 171

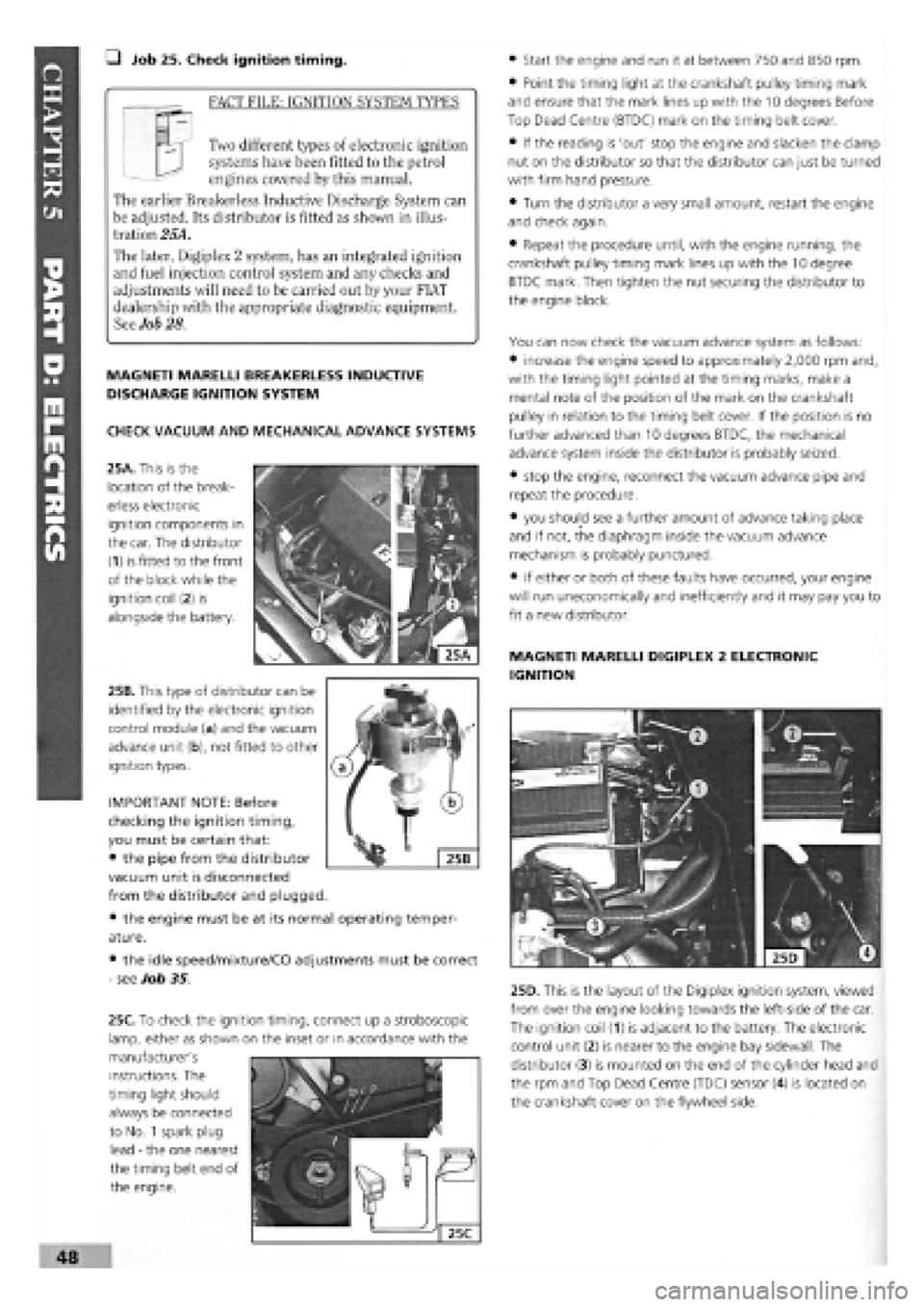

• Job 25. Check ignition timing.

_ FACT FILE: IGNITION SYSTEM TYPES

Two different types of electronic ignition

systems have been fitted to the petrol

engines covered by this manual.

The earlier Breakerless Inductive Discharge System can

be adjusted. Its distributor is fitted as shown in illus-

tration 25A.

The later, Digiplex 2 system, has an integrated ignition

and fuel injection control system and any checks and

adjustments will need to be carried out by your FIAT

dealership with the appropriate diagnostic equipment.

See Job 28.

MAGNETI MARELLI BREAKERLESS INDUCTIVE

DISCHARGE IGNITION SYSTEM

CHECK VACUUM AND MECHANICAL ADVANCE SYSTEMS

25A. This is the

location of the break-

erless electronic

ignition components in

the car. The distributor

(1) is fitted to the front

of the block while the

ignition coil

(2)

is

alongside the battery.

25B. This type of distributor can be

identified by the electronic ignition

control module (a) and the vacuum

advance unit (b), not fitted to other

ignition types.

• the engine must be at

ature.

• the idle speed/mixture/CO adjustments must be correct

-

see Job 35.

• Start the engine and run it at between 750 and 850 rpm.

• Point the timing light at the crankshaft pulley timing mark

and ensure that the mark lines up with the 10 degrees Before

Top Dead Centre (BTDC) mark on the timing belt cover.

• If the reading is 'out' stop the engine and slacken the clamp

nut on the distributor so that the distributor can just be turned

with firm hand pressure.

• Turn the distributor a very small amount, restart the engine

and check again.

• Repeat the procedure until, with the engine running, the

crankshaft pulley timing mark lines up with the 10 degree

BTDC mark. Then tighten the nut securing the distributor to

the engine block.

You can now check the vacuum advance system as follows:

• increase the engine speed to approximately 2,000 rpm and,

with the timing light pointed at the timing marks, make a

mental note of the position of the mark on the crankshaft

pulley in relation to the timing belt cover. If the position is no

further advanced than 10 degrees BTDC, the mechanical

advance system inside the distributor is probably seized.

• stop the engine, reconnect the vacuum advance pipe and

repeat the procedure.

• you should see a further amount of advance taking place

and if not, the diaphragm inside the vacuum advance

mechanism is probably punctured.

• if either or both of these faults have occurred, your engine

will run uneconomical^ and inefficiently and it may pay you to

fit a new distributor.

MAGNETI MARELLI DIGIPLEX 2 ELECTRONIC

IGNITION

25D. This is the layout of the Digiplex ignition system, viewed

from over the engine looking towards the left-side of the car.

The ignition coil (1) is adjacent to the battery. The electronic

control unit (2) is nearer to the engine bay sidewall. The

distributor (3) is mounted on the end of the cylinder head and

the rpm and Top Dead Centre (TDC) sensor (4) is located on

the crankshaft cover on the flywheel side.

IMPORTANT NOTE: Before

checking the ignition timing,

you must be certain that:

• the pipe from the distributor

vacuum unit is disconnected

from the distributor and plugged.

its normal operating temper-

instructions. The

timing light should

always be connected

to No.

1

spark plug

lead

-

the one nearest

the timing belt end of

the engine.

48

25C. To check the ignition timing, connect up a stroboscopic

lamp, either as shown on the inset or in accordance with the

manufacturer's

Page 45 of 171

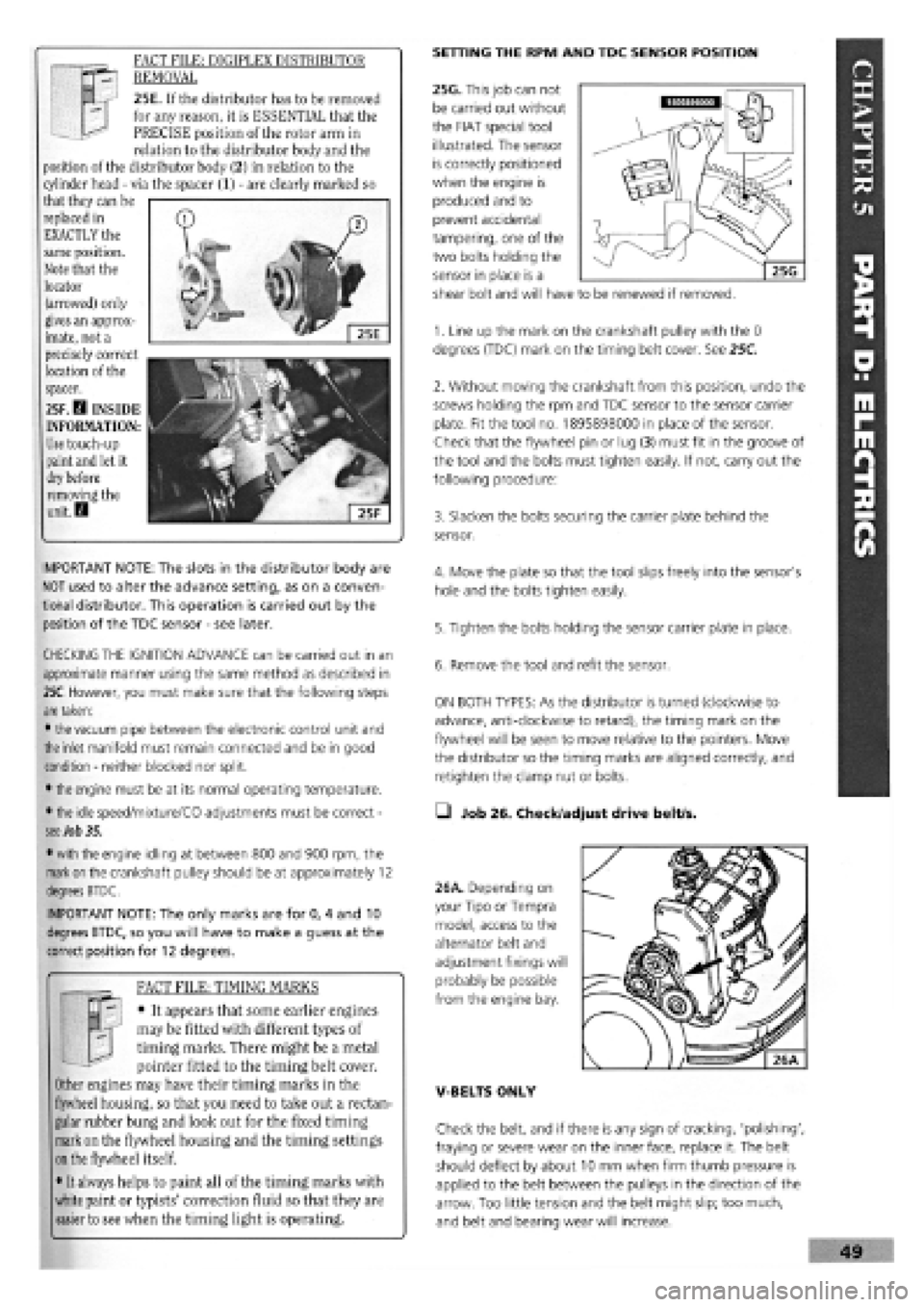

FACT FILE: DIGIPLEX DISTRIBUTOR

REMOVAL

25E. If the distributor has to be removed

for any reason, it is ESSENTIAL that the

PRECISE position of the rotor arm in

relation to the distributor body and the

position of the distributor body (2) in relation to the

cylinder head

-

via the spacer (1)

-

are clearly marked so

that they can be

replaced in

EXACTLY the

same position.

Note that the

locator

(arrowed) only

gives an approx-

imate, not a

precisely correct

location of the

spacer.

25F. D INSIDE

INFORMATION:

Use

touch-up

paint

and

let it

dry before

removing the

unit. D

SETTING THE RPM AND TDC SENSOR POSITION

25G. This job can not

be carried out without

the FIAT special tool

illustrated. The sensor

is correctly positioned

when the engine is

produced and to

prevent accidental

tampering, one of the

two bolts holding the

sensor in place is a

shear bolt and will have to be renewed if removed.

IMPORTANT NOTE: The slots in the distributor body are

NOT used to alter the advance setting, as on a conven-

tional distributor. This operation is carried out by the

position of the TDC sensor

-

see later.

CHECKING THE IGNITION ADVANCE can be carried out in an

approximate manner using the same method as described in

25C.

However, you must make sure that the following steps

are

taken:

•

the

vacuum pipe between the electronic control unit and

the

inlet manifold must remain connected and be in good

condition

-

neither blocked nor split.

•

the

engine must be at its normal operating temperature.

•

the

idle speed/mixture/CO adjustments must be correct

-

see Job 35.

•

with

the engine idling at between 800 and 900 rpm, the

mark on

the crankshaft pulley should be at approximately 12

degrees BTDC.

IMPORTANT NOTE: The only marks are for 0, 4 and 10

degrees BTDC, so you will have to make a guess at the

correct position for 12 degrees.

FACT FILE: TIMING MARKS

y-; • It appears that some earlier engines

H. j may be fitted with different types of

J timing marks. There might be a metal

pointer fitted to the timing belt cover.

Other engines may have their timing marks in the

flywheel housing, so that you need to take out a rectan-

gular rubber bung and look out for the fixed timing

mark on the flywheel housing and the timing settings

on

the flywheel itself.

• It always helps to paint all of the timing marks with

white paint or typists' correction fluid so that they are

easier to see when the timing light is operating.

1. Line up the mark on the crankshaft pulley with the 0

degrees (TDC) mark on the timing belt cover. See 25C.

2. Without moving the crankshaft from this position, undo the

screws holding the rpm and TDC sensor to the sensor carrier

plate. Fit the tool no. 1895898000 in place of the sensor.

Check that the flywheel pin or lug (3) must fit in the groove of

the tool and the bolts must tighten easily. If not, carry out the

following procedure:

3. Slacken the bolts securing the carrier plate behind the

sensor.

4. Move the plate so that the tool slips freely into the sensor's

hole and the bolts tighten easily.

5. Tighten the bolts holding the sensor carrier plate in place.

6. Remove the tool and refit the sensor.

ON BOTH TYPES: As the distributor is turned (clockwise to

advance, anti-clockwise to retard), the timing mark on the

flywheel will be seen to move relative to the pointers. Move

the distributor so the timing marks are aligned correctly, and

retighten the clamp nut or bolts.

• Job 26. Check/adjust drive belt/s.

26A. Depending on

your Tipo or Tempra

model, access to the

alternator belt and

adjustment fixings will

probably be possible

from the engine bay.

V-BELTS ONLY

Check the belt, and if there is any sign of cracking, 'polishing',

fraying or severe wear on the inner face, replace it. The belt

should deflect by about 10 mm when firm thumb pressure is

applied to the belt between the pulleys in the direction of the

arrow. Too little tension and the belt might slip; too much,

and belt and bearing wear will increase.

Page 46 of 171

26B. If adjustment is

necessary, slacken the

tensioning nut (A) and

the alternator pivot (B),

on all models. (These

are two typical

layouts.)

Use a length of wood

to pivot the alternator

away from the engine

block but take great

care not to damage the

alternator casing.

Tighten the nuts/bolts

when the tension is correct.

RIBBED BELTS ONLY

If your vehicle is fitted with a ribbed belt, pivot the alternator

as described above and tighten it when you can just twist the

belt by 1/4 turn in the middle of its longest run.

IMPORTANT NOTE:

• Belt tension should only be adjusted when the engine

is cold.

• After adjustment, run the engine for 15 to 30 seconds,

to allow the belt to bed-in, then check again.

• Experience mechanics claim that belts often go slack

when the engine heats up, producing belt squeal.

• If this happens on your vehicle, adjust the belt again

when the engine is hot. Wear industrial leather gloves

and long-sleeved overalls and take very great care not to

burn yourself on the hot engine or exhaust.

If there is an auxiliary unit, such as an air conditioning pump,

driven by a separate drive belt, examine and adjust it as

described here.

Q Job 27. Check electric fan operation.

Drive the car until it is at normal operating temperature. Park

outdoors and, with the gearbox in neutral (or 'P' in the case of

an automatic) leave the engine running. At just above normal

temperature the electric cooling fan should come on, and

then go off again when the temperature drops. Refer to your

temperature gauge, if fitted. If the fan doesn't behave, check

the thermo-switch on the radiator, along with all connections

and wires in its circuit with the fan motor. See Job 13 and

Chapter

6,

Repairs and Replacements.

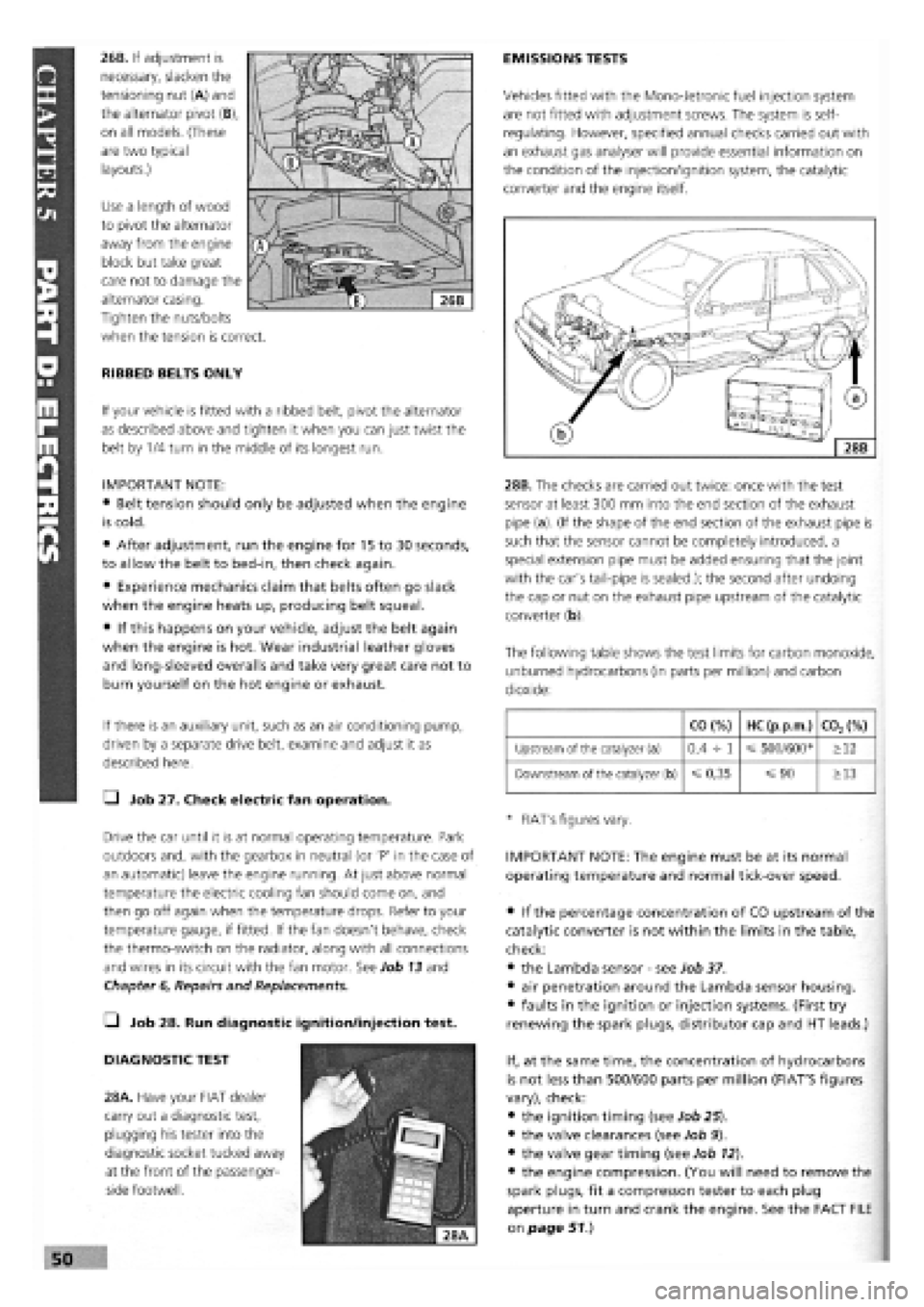

• Job 28. Run diagnostic ignition/injection test.

DIAGNOSTIC TEST

28A. Have your FIAT dealer

carry out a diagnostic test,

plugging his tester into the

diagnostic socket tucked away

at the front of the passenger-

side footwell.

EMISSIONS TESTS

Vehicles fitted with the Mono-Jetronic fuel injection system

are not fitted with adjustment screws. The system is self-

regulating. However, specified annual checks carried out with

an exhaust gas analyser will provide essential information on

the condition of the injection/ignition system, the catalytic

converter and the engine itself.

28B. The checks are carried out twice: once with the test

sensor at least 300 mm into the end section of the exhaust

pipe (a). (If the shape of the end section of the exhaust pipe is

such that the sensor cannot be completely introduced, a

special extension pipe must be added ensuring that the joint

with the car's tail-pipe is sealed.); the second after undoing

the cap or nut on the exhaust pipe upstream of the catalytic

converter (b).

The following table shows the test limits for carbon monoxide,

unburned hydrocarbons (in parts per million) and carbon

dioxide:

CO (%) HC (p.p.m.) C02(%)

Upstream of the catalyzer (a) 0,4 -h 1 500/600* >12

Downstream of the catalyzer (b)

=£

0,35 =s 90 >13

* FIAT's figures vary.

IMPORTANT NOTE: The engine must be at its normal

operating temperature and normal tick-over speed.

• if the percentage concentration of CO upstream of the

catalytic converter is not within the limits in the table,

check:

• the Lambda sensor

-

see Job 37.

• air penetration around the Lambda sensor housing.

• faults in the ignition or injection systems. (First try

renewing the spark plugs, distributor cap and HT leads.)

If, at the same time, the concentration of hydrocarbons

is not less than 500/600 parts per million (FIAT'S figures

vary), check:

• the ignition timing (see Job 25).

• the valve clearances (see Job 9).

• the valve gear timing (see Job 12).

• the engine compression. (You will need to remove the

spark plugs, fit a compresson tester to each plug

aperture in turn and crank the engine. See the FACT FILE

on page 51.)

Page 48 of 171

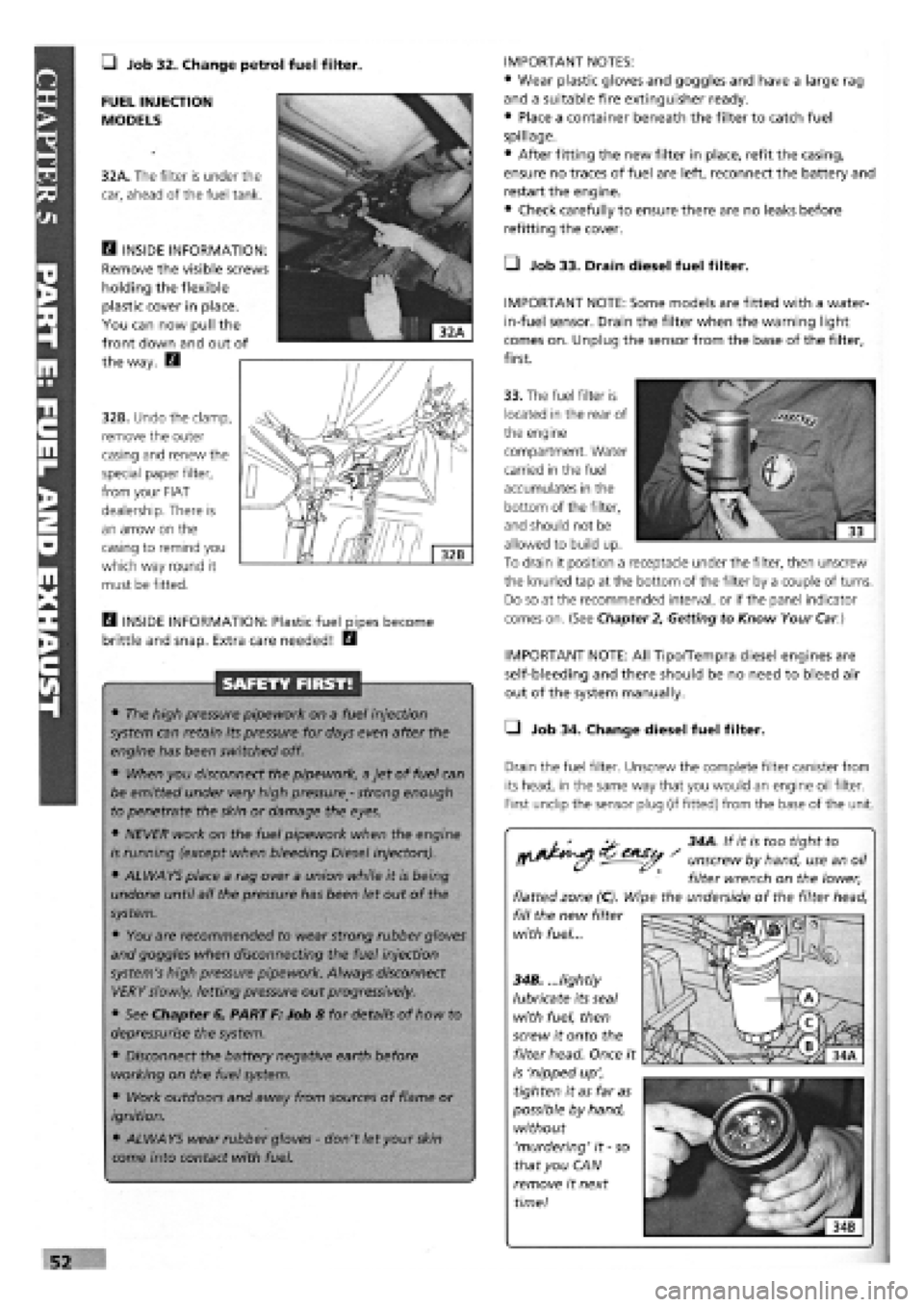

• Job 32. Change petrol fuel filter. IMPORTANT NOTES:

• Wear plastic gloves and goggles and have a large rag

and a suitable fire extinguisher ready.

• Place a container beneath the filter to catch fuel

spillage.

• After fitting the new filter in place, refit the casing,

ensure no traces of fuel are left, reconnect the battery and

restart the engine.

• Check carefully to ensure there are no leaks before

refitting the cover.

• Job 33. Drain diesel fuel filter.

IMPORTANT NOTE: Some models are fitted with a water-

in-fuel sensor. Drain the filter when the warning light

comes on. Unplug the sensor from the base of the filter,

first.

FUEL INJECTION

MODELS

32A. The filter is under the

car, ahead of the fuel tank.

E3 INSIDE INFORMATION:

Remove the visible screws

holding the flexible

plastic cover in place.

You can now pull the

front down and out of

the way. E3

32B. Undo the clamp,

remove the outer

casing and renew the

special paper filter,

from your FIAT

dealership. There is

an arrow on the

casing to remind you

which way round it

must be fitted.

33. The fuel filter is

located in the rear of

the engine

compartment. Water

carried in the fuel

accumulates in the

bottom of the filter,

and should not be

allowed to build up.

To drain it position a receptacle under the filter, then unscrew

the knurled tap at the bottom of the filter by a couple of turns.

Do so at the recommended interval, or if the panel indicator

comes on. (See Chapter

2,

Getting to Know Your

Car.)

H INSIDE INFORMATION: Plastic fuel pipes become

brittle and snap. Extra care needed! E3

SAFETY FIRST!

• The high pressure pipework on a fuel injection

system can retain its pressure for days even after the

engine has been switched off.

• When you disconnect the pipework, a jet of fuel can

be emitted under very high pressure

-

strong enough

to penetrate the skin or damage the eyes.

• NEVER work on the fuel pipework when the engine

is running (except when bleeding Diesel injectors).

• ALWAYS place a rag over a union while it is being

undone until all the pressure has been let out of the

system.

• You are recommended to wear strong rubber gloves

and goggles when disconnecting the fuel injection

system's high pressure pipework. Always disconnect

VERY slowly, letting pressure out progressively.

• See Chapter 6, PART F: Job 8 for details of how to

depressurise the system.

• Disconnect the battery negative earth before

working on the fuel system.

• Work outdoors and away from sources of flame or

ignition.

• ALWAYS wear rubber gloves

-

don't let your

skin

come into contact with fuel.

IMPORTANT NOTE: All Tipo/Tempra diesel engines are

self-bleeding and there should be no need to bleed air

out of the system manually.

• Job 34. Change diesel fuel filter.

Drain the fuel filter. Unscrew the complete filter canister from

its head, in the same way that you would an engine oil filter.

First undip the sensor plug (if fitted) from the base of the unit.

^ 34A. If it is too tight to

^^ - unscrew by hand, use an oil

filter wrench on the lower,

flatted zone (C). Wipe the underside of the filter head,

fill the new filter

with fuel...

34B. ...lightly

lubricate its seal

with fuel, then

screw it onto the

filter head. Once it

is 'nipped up',

tighten it as far as

possible by hand,

without

'murdering' it

-

so

that you CAN

remove it next

time!

Page 50 of 171

CHOKE (MANUAL) FAST IDLE ADJUSTMENT

Move the choke control lever by hand to the end of its travel

and hold it there. The main butterfly aperture (A) should now

be about 1.1 mm. If not, slacken the lock-nut (3), regulate the

adjustment screw (1), and retighten the lock-nut.

AUTOMATIC ANTI-FLOODING DEVICE ADJUSTMENT

With the choke control lever still at the end of its travel as

described in the previous paragraph, the strangler butterfly

aperture (B) should be between 3 and 3.5 mm. If not, regulate

the adjustment screw (2).

FUEL INJECTION MODELS

The idle speed and mixture settings are controlled by the

Electronic Control Unit (ECU) which is 'self-learning' and is

programmed to adjust itself to give the ideal settings under all

conditions. No manual adjustment is possible, nor provided

for. If there is a problem, see Job 29 You may need to take

your car to a FIAT dealer, with the appropriate diagnostic

equipment.

35D. At each service interval, the accelerator pivot (A).

35E. ...should be lubri-

cated with a dab of

TUTELA MRM2

grease.

The ACCELERATOR

LINKAGE must be

adjusted correctly if

the Mono-Jetronic

injection system is to operate smoothly and correctly.

• Disconnect the rod (1) from the lever (2). The pulley (3)

should now be against its closed stop.

• Check that the accelerator cable is not loose, but neither

should it be taut, and check that there is no free play in the

accelerator pedal.

• If necessary, adjust the accelerator cable by slackening the

lock-nut (B) and turning the adjuster nut (C) until the cable is

correctly tensioned. Then retighten the lock-nut.

Now reconnect the rod to the lever on the fuel injection unit

and let the engine warm up until the cooling fan has cut in at

least twice, then turn the engine off.

• With the accelerator pedal released check that the

clearance between the levers (2) and (4) is between 0.2 and

0.5 mm.

• If necessary, loosen the lockouts (5) and (6). Use a spanner

on the adjuster nut (7) to tighten or loosen the rod (1) until

the clearance is between 0.2 and 0.5 mm.

• Retighten the adjuster nuts (5) and (6).

• Finally, make sure that with the accelerator pedal

completely depressed, the butterfly in the fuel injection unit is

fully open.

• If not, the accelerator cable may be too taut or the

clearance between the levers (2) and (4) may be re-adjusted,

keeping them within the acceptable tolerances.

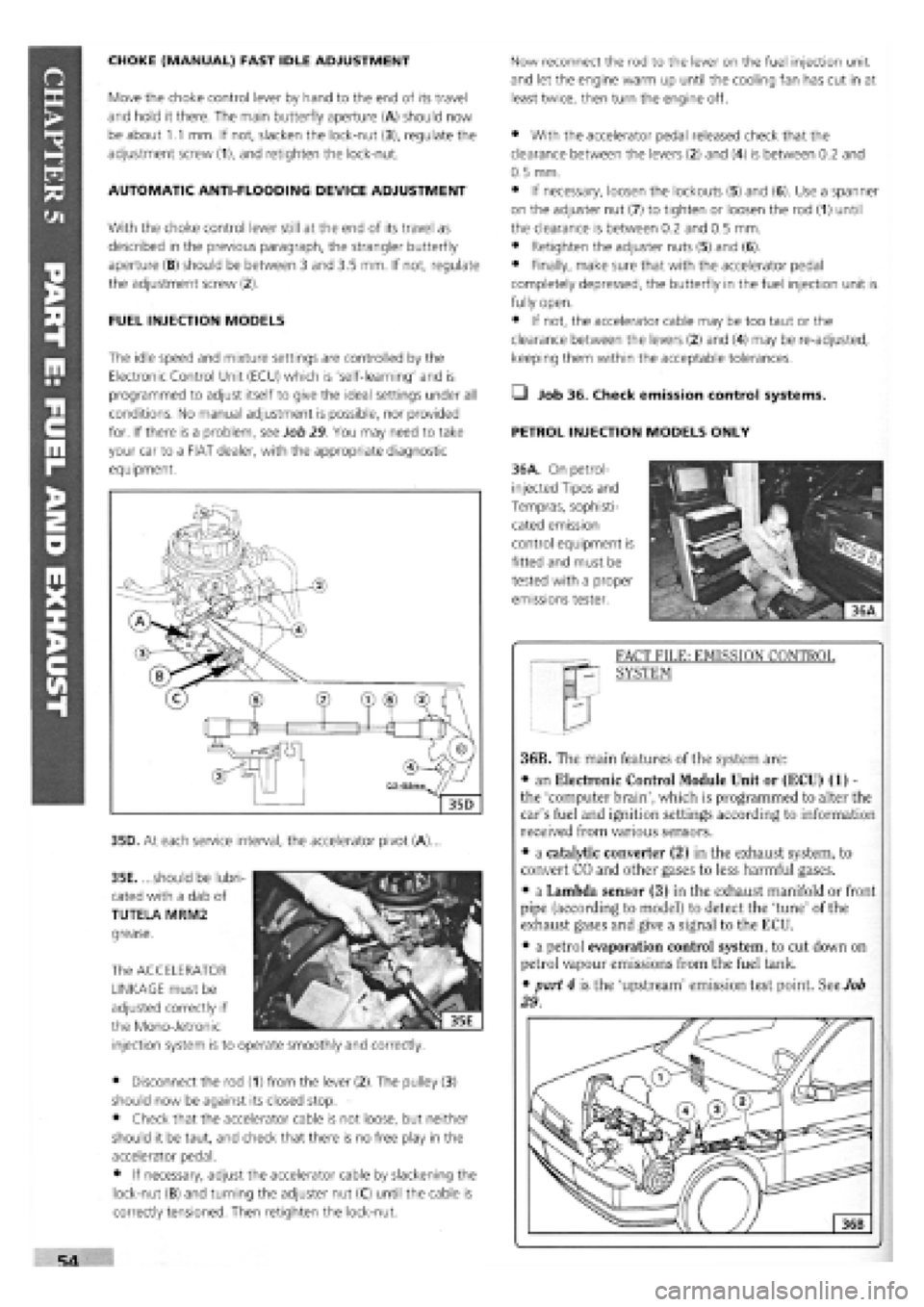

Q Job 36. Check emission control systems.

PETROL INJECTION MODELS ONLY

36A. On petrol-

injected Tipos and

Tempras, sophisti-

cated emission

control equipment is

fitted and must be

tested with a proper

emissions tester.

FACT FILE: EMISSION CONTROL

SYSTEM

36B. The main features of the system are:

• an Electronic Control Module Unit or (ECU) (1) -

the 'computer brain', which is programmed to alter the

car's fuel and ignition settings according to information

received from various sensors.

• a catalytic converter (2) in the exhaust system, to

convert CO and other gases to less harmful gases.

• a Lambda sensor (3) in the exhaust manifold or front

pipe (according to model) to detect the 'tune' of the

exhaust gases and give a signal to the ECU.

• a petrol evaporation control system, to cut down on

petrol vapour emissions from the fuel tank.

• part 4 is the 'upstream' emission test point. See Job

29.

Page 51 of 171

ELECTRONIC CONTROL MODULE: The ECU is not an item

that requires any servicing. If you think it might be faulty, ask

your FIAT dealer or fuel injection specialist to check it for you.

This must be done by someone with the correct FIAT plug-in

diagnostic equipment and data.

CATALYTIC CONVERTER: The CAT is not serviceable. If it

fails, you will be told at the MoT test. Replacement is

expensive, so we recommend you obtain a second opinion

before replacing the 'cat'.

LAMBDA SENSOR: For information concerning the sensor,

see

Job

37.

I' sensor is a simple job (see

Chapter 6, Repairs and

Replacements, PART F: FUEL AND EXHAUST), but it

can only be tested by your FIAT dealer with the correct

equipment

• If the sensor is faulty, have it renewed by your

dealer.

• Lambda sensors are very delicate and easily

damaged. It is not likely that you would be able to

return one to the supplier if you fitted it yourself.

• Lambda sensors are only fitted to cars with a

catalytic converter.

• Job 38. Check/adjust diesel idle speed.

To accurately check and adjust the diesel's idle speed you

need a diesel-specific rev-counter. If you're happy with the idle

speed, leave well alone. But if you're convinced the idle is

incorrect, it's best to take the car to a FIAT dealer. If you wish

to adjust the speed yourself, get the engine to normal

operating temperature, and check there is some free play in

the accelerator cable before proceeding.

ADJUSTMENT

-

BOSCH PUMP

D INSIDE INFORMATION: If the canister is flooded with

petrol, it is probable that one of the purge valves or

purge valve floats is faulty. Get this investigated and

rectified by a FIAT dealer. If the engine cuts out and then

restarts after a while, it could be the breather hose

valve, fitted under the fuel filler neck. This one-way

valve allows air to enter the tank as the fuel level falls,

otherwise an air lock can prevent fuel reaching the

engine. To test the valve, take off the pipe clips, remove

the valve and test it as for the canister one-way valve,

above. It should allow air to pass into the tank, but not

the other way. H

Q Job 37. Check Lambda sensor.

PETROL INJECTION MODELS ONLY

For

a

description of how the sensor works, see Job 36, FACT

FILE: EMISSION CONTROL SYSTEM. It should be checked at

the recommended interval

-

the cost of checking and

replacing the sensor is far less than that of having to replace

the catalytic converter because it has been polluted due to a

sensor fault.

38A. Adjust the idle

speed, which

should be approxi-

mately 800 rpm, by

slackening the lock-

nut of the adjuster

screw (1) then

turning the screw

inwards to increase

the speed

-

or

outwards to

decrease. Retighten the lock-nut when the speed is correct.

ADJUSTMENT

-

LUCAS/ROTODIESEL/CAV PUMP

38B. Adjust the idle speed, which should be approximately

800 rpm, by slackening the lock-nut of the adjuster screw (A)

and turning the screw to give the desired speed. Retighten the

lock-nut, then rev the engine high and allow it to return to

idle. If it goes below idle speed (i.e. it threatens to stall, or

does stall), or if it decelerates too slowly, slacken the lock-nut

of the adjuster screw (B), adjust it and check the deceleration

again. Repeat as necessary to achieve comfortable deceler-

ation without stalling, then tighten the lock-nut.

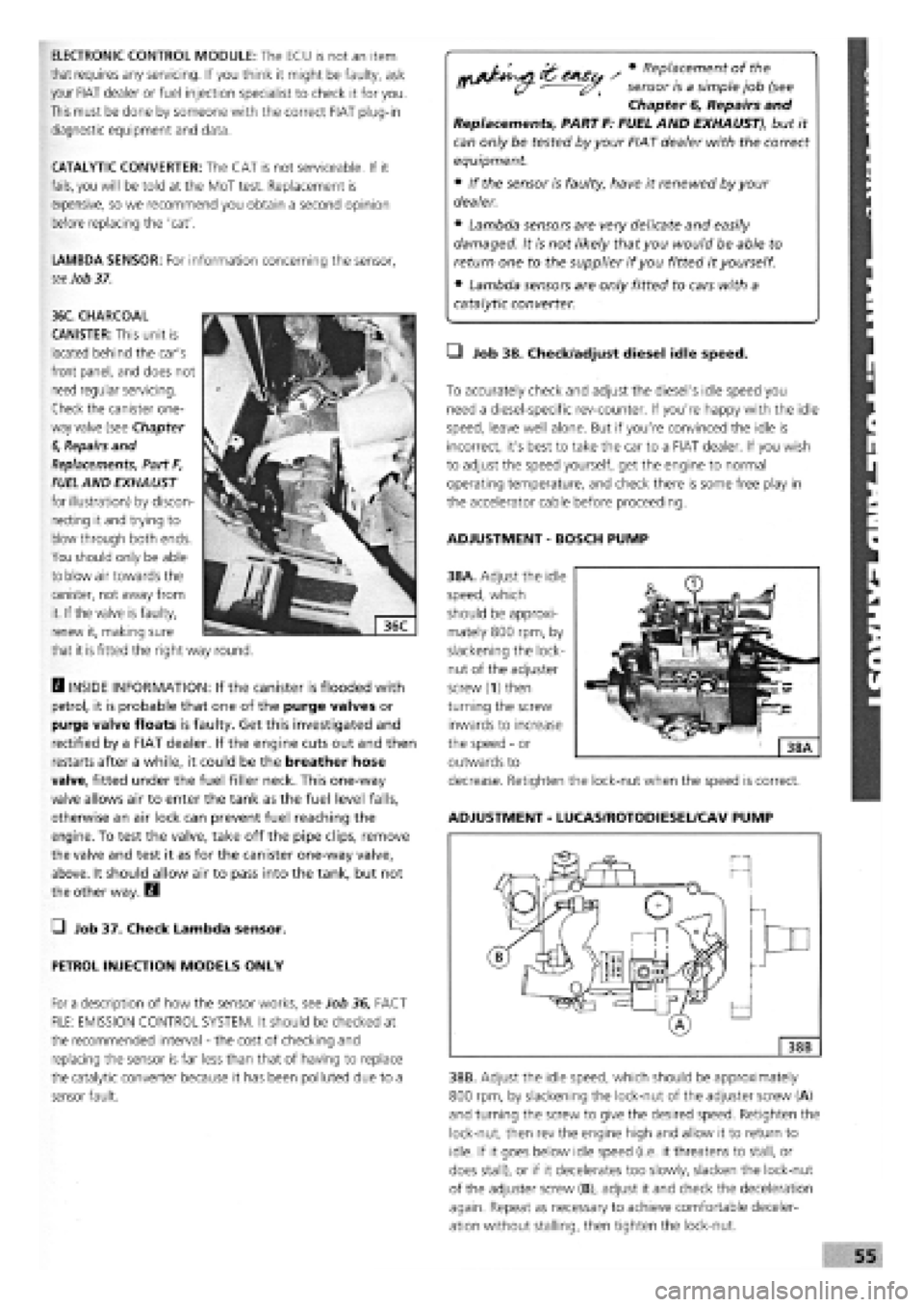

36C. CHARCOAL

CANISTER: This unit is

located behind the car's

front panel, and does not

need regular servicing.

Check the canister one-

way valve (see Chapter

6,

Repairs and

Replacements, Part F,

FUEL

AND EXHAUST

for illustration) by discon-

necting it and trying to

blow through both ends.

You should only be able

to blow air towards the

canister, not away from

it. If the valve is faulty,

renew it, making sure

that it

is

fitted the right way round.

Page 56 of 171

49H. ...and push out the nylon bush (arrowed). Reassemble

on the new pad and reattach the wire.

IMPORTANT NOTE: After fitting the pads, apply the

brakes firmly several times to adjust them.

• Job 50. Check rear brakes.

SAFETY FIRST!

Read SAFETY FIRST at the start of Job 49 before

proceeding!

GENERAL. The majority of Tipo/Tempra models are fitted with

rear drum-type rear brakes, but models with ABS anti-lock

braking have a disc-and-caliper arrangement instead.

Slacken the wheel bolts, raise the wheel, remove it and

support the car with an axle stand. Make sure that the wheels

remaining on the ground are chocked in both directions and

that the handbrake is off.

DRUM REAR BRAKES

If the drum

sticks,

try:

• screwing a pair of

bolts

into the two threaded

holes in the drum. Evenly

tightening the bolts will force the drum off the

shoes.

• tapping carefully around the drum with a hide

mallet to help loosen it.

s Vn order to fit new pads,

r> - the caliper piston must be

pushed back into the bore.

• Use an old battery hydrometer to draw about half

of the fluid from the master cylinder.

• Push the piston back into the caliper, using a G-

clamp.

• Keep an eye on the master cylinder so that it

doesn't overflow as fluid is pushed back up the pipe.

IMPORTANT NOTE: Be very sparing or grease could

migrate to the friction linings!

WEAR SENSORS I I There are certain essential checks you

should carry out for yourself, with brake

pads removed:

• Look for any obvious grooves worn into the disc.

Slight undulations are acceptable, but anything worse

and the disc should be replaced.

• Look and feel for any wear-ridge on the outer edges

of the disc. The depth will give an indication of wear.

• Check for corrosion of the disc surface. If any is

found, the brake caliper is probably faulty, and needs

checking.

• If any surface flaking is found on either side of the

disc, replace them both.

• If you are not certain whether any wear is acceptable,

ask your specialist or FIAT dealer to check.

FACT FILE: BRAKE DISC WEAR

SYMPTOMS

Before reassembling the brake, check the condition of the

brake caliper. Have an assistant VERY SLOWLY AND GENTLY

apply pressure to the brake pedal while you watch the piston

(see illustration 49B, part

8),

which should move outwards. If

it doesn't easily move, it is seized and the caliper should be

replaced. DO NOT allow the piston to project more than 10

mm or it may be forced from the caliper

-

use a G-clamp as an

'end stop'.

49F. Before

fitting the pads,

put a light smear

of brake grease

(NOT ordinary

grease) on the

pads' metal

backplates at the

points shown.

49G. If these are fitted, the contact has to be transferred from

the old backing plate to the new. Pull off the wire, push out

the brass pin...

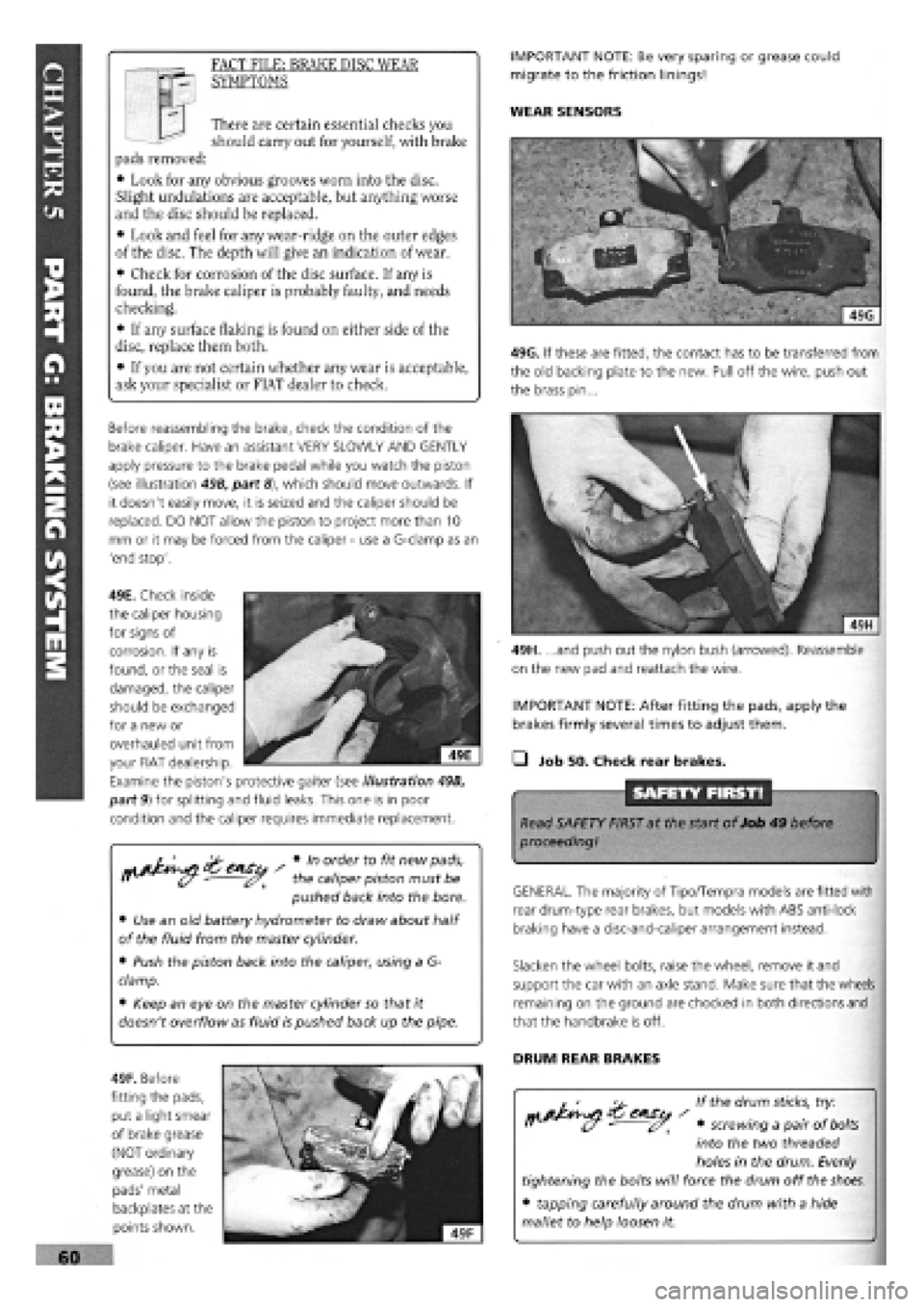

49E. Check inside

the caliper housing

for signs of

corrosion. If any is

found, or the seal is

damaged, the caliper

should be exchanged

for a new or

overhauled unit from

your FIAT dealership.

Examine the piston's protective gaiter (see illustration 49B,

part 9) for splitting and fluid leaks. This one is in poor

condition and the caliper requires immediate replacement.