ignition FIAT UNO 1983 Service User Guide

[x] Cancel search | Manufacturer: FIAT, Model Year: 1983, Model line: UNO, Model: FIAT UNO 1983Pages: 303, PDF Size: 10.36 MB

Page 50 of 303

Engine idles roughly

m mMixture too weak

m mAir leak in carburettor

m mAir leak at inlet manifold to cylinder head, or inlet manifold to

carburettor

m mCarburettor incorrectly adjusted

m mOther fuel system fault (see Chapter 3)

m mLow tension leads on coil loose

m mLow tension lead to distributor loose

m mDirty, incorrectly set, or pitted contact breaker points

m mTracking across inside of distributor cover

m mFaulty coil

m mIgnition leads loose

m mSpark plugs fouled or incorrectly gapped.

m mIgnition timing incorrect

m mOther ignition fault (see Chapter 4)

m mIncorrect valve clearances

m mWidely differing cylinder compressions

m mLow battery voltage (charging fault)

m mBattery leads loose on terminals

m mBattery earth strap loose on body attachment point

m mEngine earth lead loose

Pre-ignition (pinking) during acceleration

m

mIncorrect grade of fuel being used

m mIgnition timing over-advanced

m mOther ignition fault (see Chapter 4)

m mEngine overheated

m mExcessive carbon build-up

m mFuel system fault (see Chapter 3)

m mValve timing incorrect (after rebuild)

m mMixture too weak

Engine runs on after switching off

m

mIdle speed too high

m mIncorrect type of spark plug

m mOverheating

m mExcessive carbon build-up

m mOther emission control fault (see Chapter 3)

Oil being lost due to leaks

m

mLeaking oil filter gasket

m mLeaking rocker cover gasket

m mLeaking timing gear cover gasket

m mLeaking sump gasket

m mLoose sump plug

Low oil pressure (verify accuracy of sender before

dismantling engine!)

m mOil level low

m mEngine overheating

m mIncorrect grade of oil in use

m mOil filter clogged or bypass valve stuck

m mPressure relief valve stuck or defective

m mOil pick-up strainer clogged or loose

m mMain or big-end bearings worn

m mOil pump worn or mountings loose

Excessive oil consumption

m

mOverfilling

m mLeaking gaskets or drain plug washer

m mValve stem oil seals worn, damaged or missing after rebuild

m mValve stems and/or guides worn

m mPiston rings and/or bores worn

m mPiston oil return holes clogged

Oil contaminated with water

m

mExcessive cold running

m mLeaking head gasket

m mCracked block or head

Oil contaminated with fuel

m

mExcessive use of choke

m mWorn piston rings and/or bores

Unusual mechanical noises

m

mUnintentional mechanical contact (eg fan blade)

m mWorn drivebelt

m mWorn valvegear (tapping noises from top of engine) or incorrect

clearance

m mPeripheral component fault (generator, coolant pump)

m mWorn big-end bearings (regular heavy knocking, perhaps less under

load)

m mWorn main bearings (rumbling and knocking, perhaps worsening

under load)

m mSmall-end bushes or gudgeon pins worn (light metallic tapping)

m mPiston slap (most noticeable when engine cold)

m mWorn timing chain and gears (rattling from front of engine)

m mWorn crankshaft (knocking, rumbling and vibration)

1•36 All engines

Page 58 of 303

Fault finding - cooling and heating systems

2•8 Cooling and heating systems

Overheating

m mInsufficient coolant in system

m mPump ineffective due to slack drivebelt

m mRadiator blocked either internally or externally

m mKinked or collapsed hose causing coolant flow restriction

m mThermostat not working properly

m mEngine out of tune

m mIgnition timing retarded or auto advance malfunction

m mCylinder head gasket blown

m mEngine not yet run-in

m mExhaust system partially blocked

m mEngine oil level too low

m mBrakes binding

Engine running too cool

m

mFaulty, incorrect or missing thermostat

Loss of coolant

m

mLoose hose clips

m mHoses perished or leaking

m mRadiator leaking

m mFiller/pressure cap defective

m mBlown cylinder head gasket

m mCracked cylinder block or head

Heater gives insufficient output

m

mEngine overcooled (see above)

m mHeater matrix blocked

m mHeater controls maladjusted or broken

m mHeater control valve jammed or otherwise

defective

Page 65 of 303

7 Carburettor idle speed and

mixture- adjustment

4

1All carburettors have their mixture

adjustment set in production. The screw is

fitted with a tamperproof cap.

2Under normal circumstances, only the idle

speed screw need be adjusted to set the

engine idle speed to the specified level.

3Before attempting to adjust the idle speed

or mixture, it is important to have the ignition

and valve clearances correctly set and the

engine at normal operating temperature with

the air cleaner fitted.

4Where the mixture must be adjusted, prise

out the tamperproof plug and turn the mixture

screw in to weaken or out to enrich the

mixture until the engine runs smoothly without

any tendency to “hunt”.

5Ideally an exhaust gas analyser should be

used to make sure that the CO level is within

the specified range.

6Once the mixture has been correctly set,

re-adjust the idle speed screw.

8 Carburettor-

removal and refitting

2

1Remove the air cleaner.

2Disconnect the flow and return fuel hoses

from the carburettor and plug them.3Disconnect the coolant hoses from the

carburettor throttle valve plate block.

Provided the cooling system is cold and not

under pressure there should be almost no loss

of coolant. Tie the hoses up as high as

possible with a piece of wire.

4Disconnect the vacuum and vent hoses

from the carburettor.

5Disconnect the throttle and choke controls

from the carburettor.

6Unscrew the mounting flange nuts and lift

the carburettor from the intake manifold

(photo).

7Refitting is a reversal of removal. Use a new

flange gasket and make sure that the fuel

return hose is routed above the air cleaner

intake.

9 Carburettor

(Weber 32 ICEV 50/250/1)-

servicing and adjustment

4

1The carburettor top cover with float may be

removed without the need to withdraw the

carburettor from the manifold. The other

adjustments described will require removal of

the carburettor.

2Unscrew the filter plug from the top cover,

clean the filter screen and refit it.

3Extract the top cover fixing screws, lift the

cover and tilt it to unhook it from the

diaphragm capsule link rod.

4Access to the fuel inlet needle valve isobtained by carefully tapping out the float arm

pivot pin. Take care, the pivot pin pillars are

very brittle.

5Check that the needle valve body is tight

otherwise fuel can bypass the needle valve

and cause flooding.

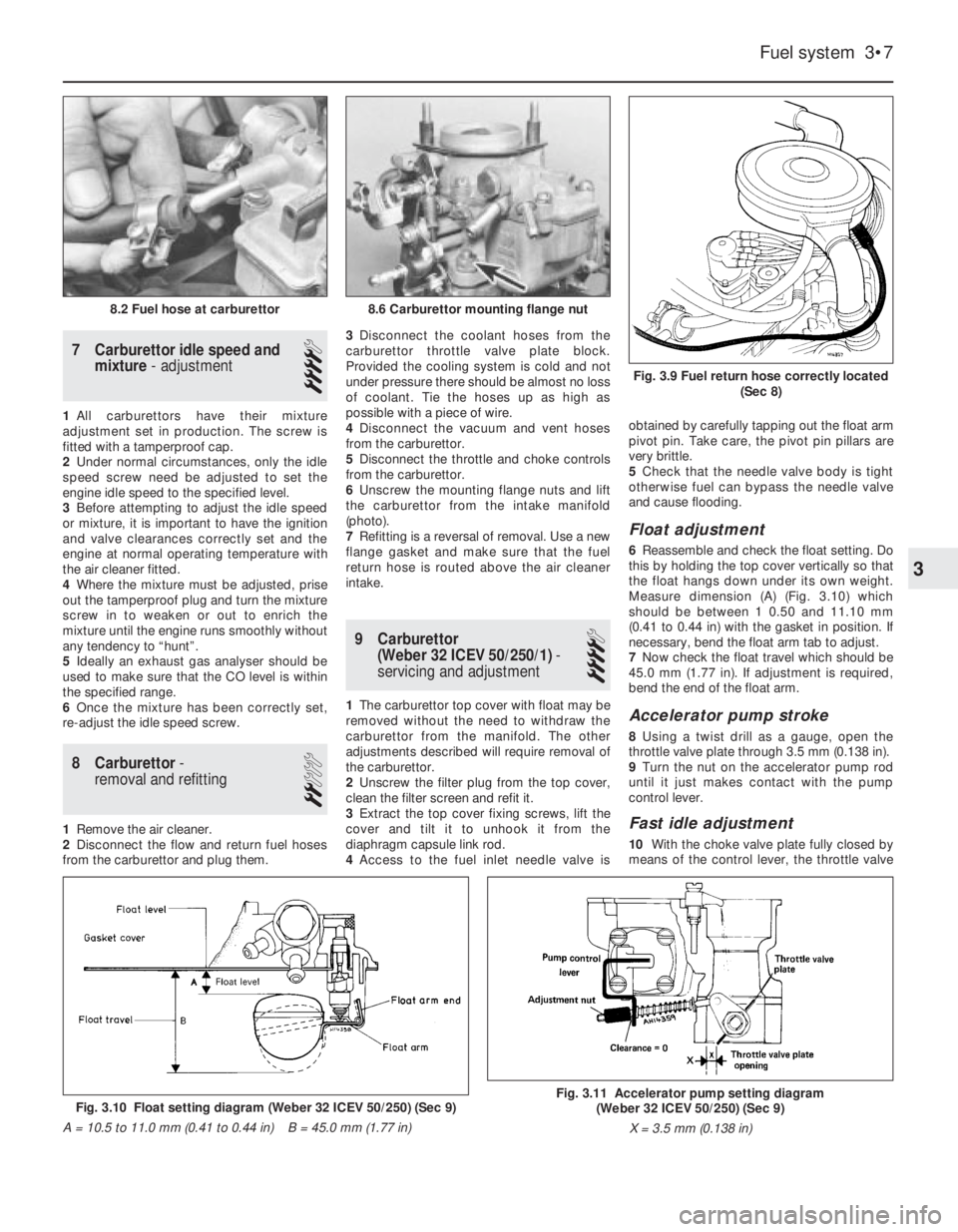

Float adjustment

6Reassemble and check the float setting. Do

this by holding the top cover vertically so that

the float hangs down under its own weight.

Measure dimension (A) (Fig. 3.10) which

should be between 1 0.50 and 11.10 mm

(0.41 to 0.44 in) with the gasket in position. If

necessary, bend the float arm tab to adjust.

7Now check the float travel which should be

45.0 mm (1.77 in). If adjustment is required,

bend the end of the float arm.

Accelerator pump stroke

8Using a twist drill as a gauge, open the

throttle valve plate through 3.5 mm (0.138 in).

9Turn the nut on the accelerator pump rod

until it just makes contact with the pump

control lever.

Fast idle adjustment

10With the choke valve plate fully closed by

means of the control lever, the throttle valve

Fuel system 3•7

Fig. 3.9 Fuel return hose correctly located

(Sec 8)

8.6 Carburettor mounting flange nut8.2 Fuel hose at carburettor

Fig. 3.10 Float setting diagram (Weber 32 ICEV 50/250) (Sec 9)

A = 10.5 to 11.0 mm (0.41 to 0.44 in) B = 45.0 mm (1.77 in)Fig. 3.11 Accelerator pump setting diagram

(Weber 32 ICEV 50/250) (Sec 9)

X = 3.5 mm (0.138 in)

3

Page 67 of 303

pump jet and give ten full strokes of the

throttle lever, pausing between each stroke to

allow fuel to finish dripping.

8The total volume of fuel collected should be

between 2.5 and 4.5 cc. Adjust the nut on the

pump control and if necessary to increase or

decrease the volume of fuel ejected.

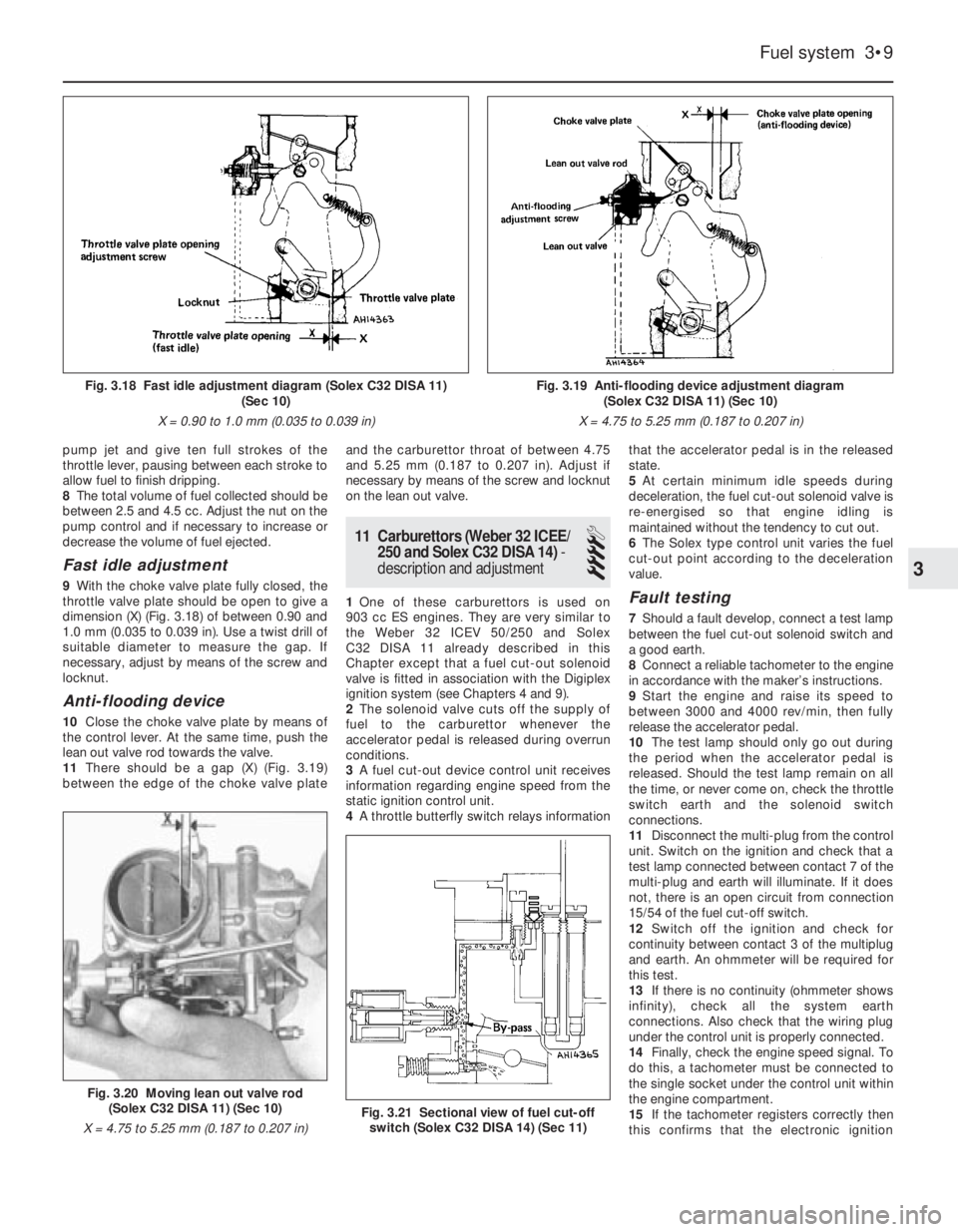

Fast idle adjustment

9With the choke valve plate fully closed, the

throttle valve plate should be open to give a

dimension (X) (Fig. 3.18) of between 0.90 and

1.0 mm (0.035 to 0.039 in). Use a twist drill of

suitable diameter to measure the gap. If

necessary, adjust by means of the screw and

locknut.

Anti-flooding device

10Close the choke valve plate by means of

the control lever. At the same time, push the

lean out valve rod towards the valve.

11There should be a gap (X) (Fig. 3.19)

between the edge of the choke valve plateand the carburettor throat of between 4.75

and 5.25 mm (0.187 to 0.207 in). Adjust if

necessary by means of the screw and locknut

on the lean out valve.

11 Carburettors (Weber 32 ICEE/

250 and Solex C32 DISA 14)-

description and adjustment

4

1One of these carburettors is used on

903 cc ES engines. They are very similar to

the Weber 32 ICEV 50/250 and Solex

C32 DISA 11 already described in this

Chapter except that a fuel cut-out solenoid

valve is fitted in association with the Digiplex

ignition system (see Chapters 4 and 9).

2The solenoid valve cuts off the supply of

fuel to the carburettor whenever the

accelerator pedal is released during overrun

conditions.

3A fuel cut-out device control unit receives

information regarding engine speed from the

static ignition control unit.

4A throttle butterfly switch relays informationthat the accelerator pedal is in the released

state.

5At certain minimum idle speeds during

deceleration, the fuel cut-out solenoid valve is

re-energised so that engine idling is

maintained without the tendency to cut out.

6The Solex type control unit varies the fuel

cut-out point according to the deceleration

value.Fault testing

7Should a fault develop, connect a test lamp

between the fuel cut-out solenoid switch and

a good earth.

8Connect a reliable tachometer to the engine

in accordance with the maker’s instructions.

9Start the engine and raise its speed to

between 3000 and 4000 rev/min, then fully

release the accelerator pedal.

10The test lamp should only go out during

the period when the accelerator pedal is

released. Should the test lamp remain on all

the time, or never come on, check the throttle

switch earth and the solenoid switch

connections.

11Disconnect the multi-plug from the control

unit. Switch on the ignition and check that a

test lamp connected between contact 7 of the

multi-plug and earth will illuminate. If it does

not, there is an open circuit from connection

15/54 of the fuel cut-off switch.

12Switch off the ignition and check for

continuity between contact 3 of the multiplug

and earth. An ohmmeter will be required for

this test.

13If there is no continuity (ohmmeter shows

infinity), check all the system earth

connections. Also check that the wiring plug

under the control unit is properly connected.

14Finally, check the engine speed signal. To

do this, a tachometer must be connected to

the single socket under the control unit within

the engine compartment.

15If the tachometer registers correctly then

this confirms that the electronic ignition

Fuel system 3•9

Fig. 3.18 Fast idle adjustment diagram (Solex C32 DISA 11)

(Sec 10)

X = 0.90 to 1.0 mm (0.035 to 0.039 in)Fig. 3.19 Anti-flooding device adjustment diagram

(Solex C32 DISA 11) (Sec 10)

X = 4.75 to 5.25 mm (0.187 to 0.207 in)

Fig. 3.21 Sectional view of fuel cut-off

switch (Solex C32 DISA 14) (Sec 11)

Fig. 3.20 Moving lean out valve rod

(Solex C32 DISA 11) (Sec 10)

X = 4.75 to 5.25 mm (0.187 to 0.207 in)

3

Page 68 of 303

control unit is functioning, if the tachometer

does not register, renew the ignition control

unit.

16If a replacement carburettor is to be fitted,

only fit the Solex assembly including the

control module, even if a Weber was originally

fitted.

12 Carburettor

(Weber 32 ICEV 51/250)-

servicing and adjustment

4

1This carburettor, fitted to 1116 cc engines,

is very similar to the unit described in Sec-

tion 9.

2The fast idle adjustment procedure is

identical, but note that dimension (A) (Fig.

3.12) should be between 0.85 and 0.90 mm

(0.033 and 0.035 in).

3The choke valve plate gap (Y) (Fig. 3.13)

should be between 5.5 and 6.5 mm (0.22 and

0.26 in) and if adjustment is required, bend

the stop on the control lever.

13 Carburettor

(Solex C32 DISA 12)-

servicing and adjustment

4

1This carburettor is an alternative to the

Weber fitted to 1116 cc engines.

2The adjustments described in Section 9

apply.

14 Carburettor

(Weber 30/32 DMTR 90/250)

- servicing and adjustment

4

1The carburettor top cover with float may be

removed without the need to withdraw the

carburettor from the manifold. The other

adjustments described in this Section will

require removal of the carburettor.

2Extract the top cover fixing screws and lift

away the top cover with float. Access to the

fuel inlet needle valve is as described in

Section 9 paragraphs 4 and 5.

Float adjustment

3Hold the cover vertically so that the floats

hang down under their own weight. Measure

the distance between the float and the surface

of the gasket on the top cover. This should be

between 6.75 and 7.25 mm (0.27 and 0.29 in).

4Bend the float arm if necessary to adjust

the setting.

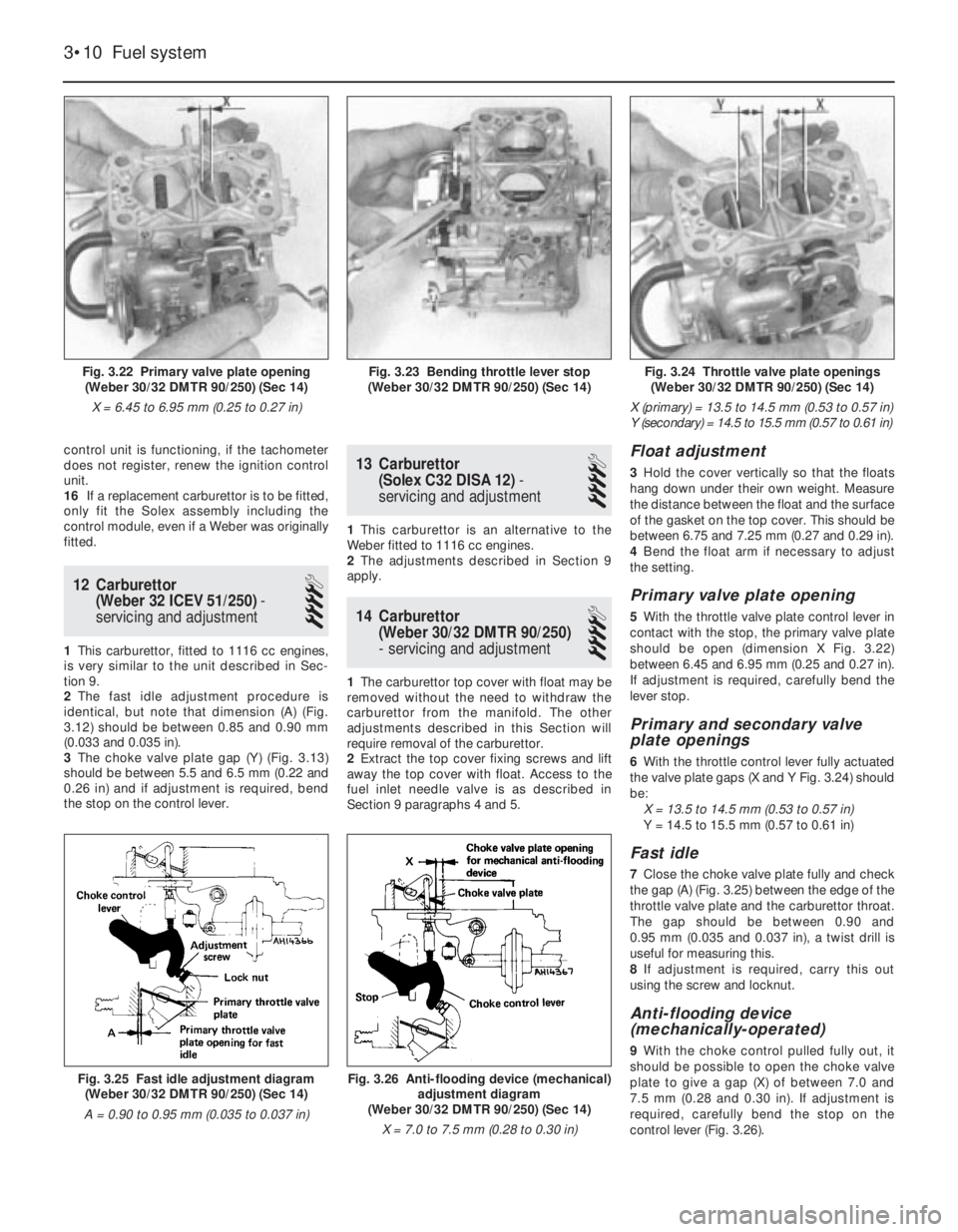

Primary valve plate opening

5With the throttle valve plate control lever in

contact with the stop, the primary valve plate

should be open (dimension X Fig. 3.22)

between 6.45 and 6.95 mm (0.25 and 0.27 in).

If adjustment is required, carefully bend the

lever stop.

Primary and secondary valve

plate openings

6With the throttle control lever fully actuated

the valve plate gaps (X and Y Fig. 3.24) should

be:

X = 13.5 to 14.5 mm (0.53 to 0.57 in)

Y = 14.5 to 15.5 mm (0.57 to 0.61 in)

Fast idle

7Close the choke valve plate fully and check

the gap (A) (Fig. 3.25) between the edge of the

throttle valve plate and the carburettor throat.

The gap should be between 0.90 and

0.95 mm (0.035 and 0.037 in), a twist drill is

useful for measuring this.

8If adjustment is required, carry this out

using the screw and locknut.

Anti-flooding device

(mechanically-operated)

9With the choke control pulled fully out, it

should be possible to open the choke valve

plate to give a gap (X) of between 7.0 and

7.5 mm (0.28 and 0.30 in). If adjustment is

required, carefully bend the stop on the

control lever (Fig. 3.26).

3•10 Fuel system

Fig. 3.26 Anti-flooding device (mechanical)

adjustment diagram

(Weber 30/32 DMTR 90/250) (Sec 14)

X = 7.0 to 7.5 mm (0.28 to 0.30 in)Fig. 3.25 Fast idle adjustment diagram

(Weber 30/32 DMTR 90/250) (Sec 14)

A = 0.90 to 0.95 mm (0.035 to 0.037 in)

Fig. 3.24 Throttle valve plate openings

(Weber 30/32 DMTR 90/250) (Sec 14)

X (primary) = 13.5 to 14.5 mm (0.53 to 0.57 in)

Y (secondary) = 14.5 to 15.5 mm (0.57 to 0.61 in)Fig. 3.23 Bending throttle lever stop

(Weber 30/32 DMTR 90/250) (Sec 14)Fig. 3.22 Primary valve plate opening

(Weber 30/32 DMTR 90/250) (Sec 14)

X = 6.45 to 6.95 mm (0.25 to 0.27 in)

Page 71 of 303

6On 1116 cc and 1301 cc models, the

exhaust system is of dual downpipe, two

silencer, two section type.

7The exhaust system is flexibly mounted

(photo).

8Do not attempt to separate the sections ofthe exhaust system, while in position in the

car. Unbolt the pipe from the manifold and,

using a screwdriver, prise off the flexible

suspension rings. Provided the car is then

raised on jacks, ramps or placed over

an inspection pit, the complete exhaust system can be withdrawn from under the car.

9If only one section is to be renewed, it is far

easier to separate once the complete system

is out of the car.

10When refitting, grease the pipe sockets

and fit the clamps loosely until the suspension

rings are connected and the downpipe bolted

up (using a new copper gasket). Check the

attitude of the sections with regard to each

other and the adjacent parts of the

underbody. Fully tighten the clamps and

downpipe flange nuts, remembering to bend

up the lockplate tabs on 1116 cc and 1301 cc

models (photo).

11On the larger engined models, it may be

necessary to raise the vehicle at the rear and

support it on axle stands so that the rear sus-

pension hangs down and is fully extended.

This will allow sufficient clearance between

the axle and the body for the exhaust system

to be withdrawn.

Fuel system 3•13

3

19.10 Exhaust pipe socket clamp19.7B Exhaust tailpipe mounting

Fault finding - fuel system

Unsatisfactory engine performance and excessive fuel consumption

are not necessarily the fault of the fuel system or carburettor. In fact they

more commonly occur as a result of ignition and timing faults. Before

acting on the following it is necessary to check the ignition system first.

Even though a fault may lie in the fuel system it will be difficult to trace

unless the ignition is correct. The faults below, therefore, assume that

this has been attended to first (where appropriate).

Smell of petrol when engine is stopped

m mLeaking fuel lines or unions

m mLeaking fuel tank

Smell of petrol when engine is idling

m

mLeaking fuel line unions between pump and carburettor

m mOverflow of fuel from float chamber due to wrong level setting,

ineffective needle valve or punctured float

Excessive fuel consumption for reasons not

covered by leaks or float chamber faults

m mWorn jets

m mOver-rich setting

m mSticking mechanism

m mDirty air cleaner element

Difficult starting when cold

m

mChoke control

m mInsufficient use of manual choke

m mWeak mixture

Difficult starting, uneven running, lack of power,

cutting out

m mOne or more jets blocked or restricted

m mFloat chamber fuel level too low or needle valve sticking

m mFuel pump not delivering sufficient fuel

m mInduction leak

Difficult starting when hot

m

mExcessive use of manual choke

m mAccelerator pedal pumped before starting

m mVapour lock (especially in hot weather or at high altitude)

m mRich mixture

Engine does not respond properly to throttle

m

mFaulty accelerator pump

m mBlocked jet(s)

m mSlack in accelerator cable

Engine idle speed drops when hot

m

mIncorrect air cleaner intake setting

m mOverheated fuel pump

Engine runs on

m

mIdle speed too high

Page 72 of 303

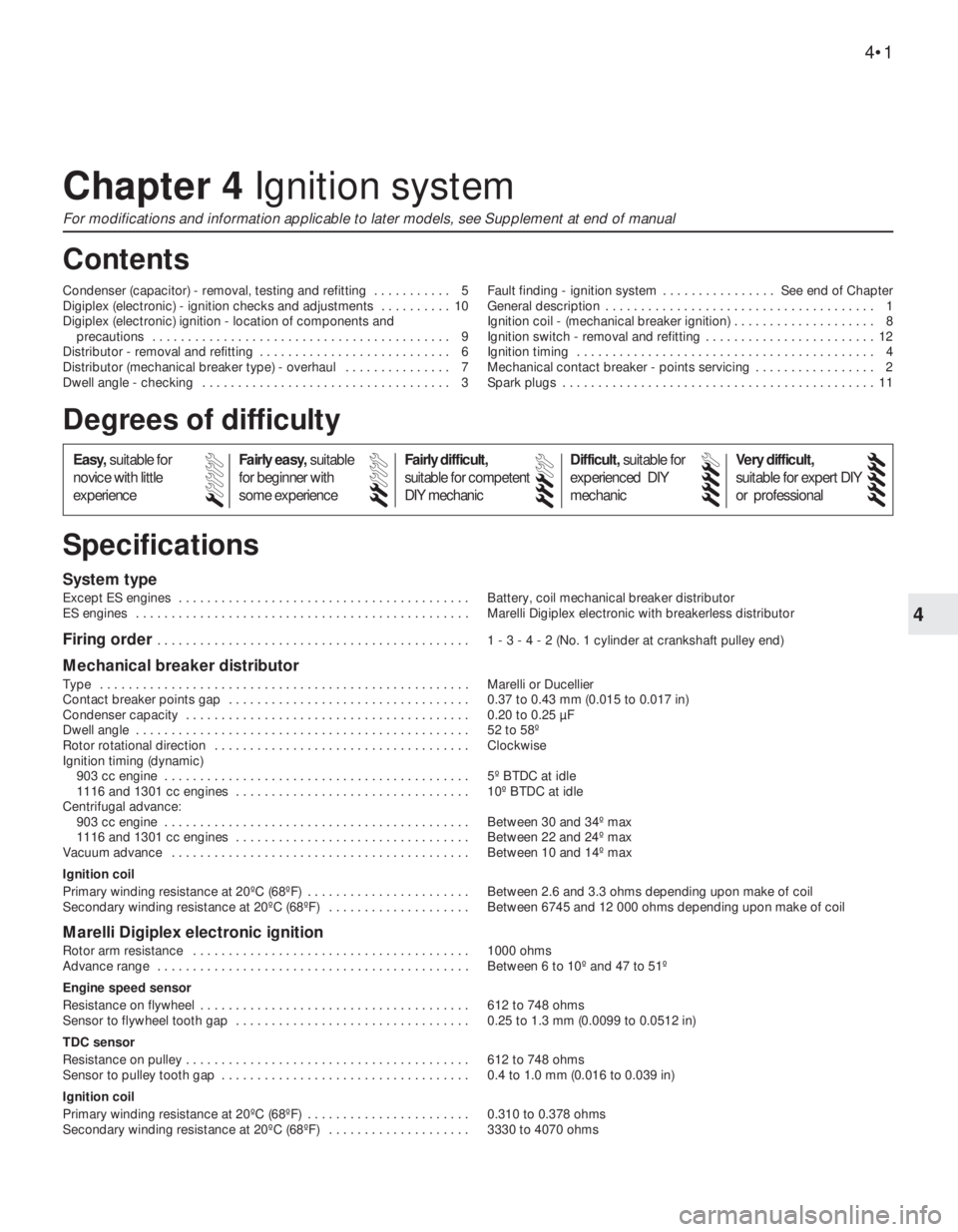

4

System type

Except ES engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Battery, coil mechanical breaker distributor

ES engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Marelli Digiplex electronic with breakerless distributor

Firing order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 3 - 4 - 2 (No. 1 cylinder at crankshaft pulley end)

Mechanical breaker distributor

Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Marelli or Ducellier

Contact breaker points gap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.37 to 0.43 mm (0.015 to 0.017 in)

Condenser capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.20 to 0.25 µF

Dwell angle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52 to 58º

Rotor rotational direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Clockwise

Ignition timing (dynamic)

903 cc engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5º BTDC at idle

1116 and 1301 cc engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10º BTDC at idle

Centrifugal advance:

903 cc engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Between 30 and 34º max

1116 and 1301 cc engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Between 22 and 24º max

Vacuum advance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Between 10 and 14º max

Ignition coil

Primary winding resistance at 20ºC (68ºF) . . . . . . . . . . . . . . . . . . . . . . . Between 2.6 and 3.3 ohms depending upon make of coil

Secondary winding resistance at 20ºC (68ºF) . . . . . . . . . . . . . . . . . . . . Between 6745 and 12 000 ohms depending upon make of coil

Marelli Digiplex electronic ignition

Rotor arm resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1000 ohms

Advance range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Between 6 to 10º and 47 to 51º

Engine speed sensor

Resistance on flywheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 612 to 748 ohms

Sensor to flywheel tooth gap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.25 to 1.3 mm (0.0099 to 0.0512 in)

TDC sensor

Resistance on pulley . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 612 to 748 ohms

Sensor to pulley tooth gap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.4 to 1.0 mm (0.016 to 0.039 in)

Ignition coil

Primary winding resistance at 20ºC (68ºF) . . . . . . . . . . . . . . . . . . . . . . . 0.310 to 0.378 ohms

Secondary winding resistance at 20ºC (68ºF) . . . . . . . . . . . . . . . . . . . . 3330 to 4070 ohms

Chapter 4 Ignition system

For modifications and information applicable to later models, see Supplement at end of manual

Condenser (capacitor) - removal, testing and refitting . . . . . . . . . . . 5

Digiplex (electronic) - ignition checks and adjustments . . . . . . . . . . 10

Digiplex (electronic) ignition - location of components and

precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Distributor - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Distributor (mechanical breaker type) - overhaul . . . . . . . . . . . . . . . 7

Dwell angle - checking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3Fault finding - ignition system . . . . . . . . . . . . . . . . See end of Chapter

General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Ignition coil - (mechanical breaker ignition) . . . . . . . . . . . . . . . . . . . . 8

Ignition switch - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . 12

Ignition timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Mechanical contact breaker - points servicing . . . . . . . . . . . . . . . . . 2

Spark plugs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4•1

Specifications Contents

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanic

Difficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert DIY

or professional

Degrees of difficulty

54321

Page 73 of 303

Spark plugs

Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion RN9YCC or RN9YC

Electrode gap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.8 mm (0.031 in)

HT leads

903 cc (45) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion LS-07

1116, 1299 and 1301 cc (55, 60 and 70) . . . . . . . . . . . . . . . . . . . . . . . . Champion LS-05

Torque wrench settingNm lbf ft

Spark plugs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 18

4•2 Ignition system

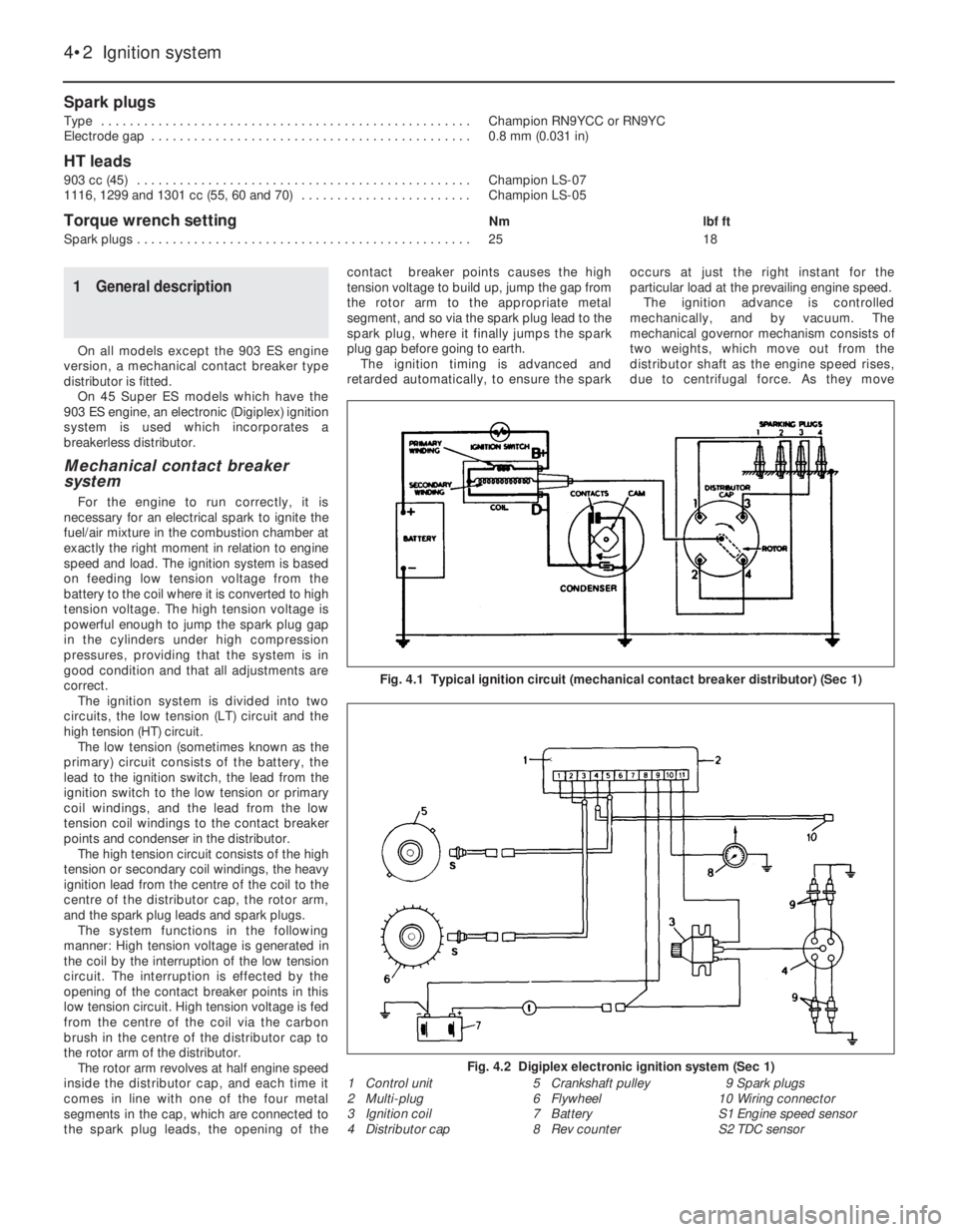

1 General description

On all models except the 903 ES engine

version, a mechanical contact breaker type

distributor is fitted.

On 45 Super ES models which have the

903 ES engine, an electronic (Digiplex) ignition

system is used which incorporates a

breakerless distributor.

Mechanical contact breaker

system

For the engine to run correctly, it is

necessary for an electrical spark to ignite the

fuel/air mixture in the combustion chamber at

exactly the right moment in relation to engine

speed and load. The ignition system is based

on feeding low tension voltage from the

battery to the coil where it is converted to high

tension voltage. The high tension voltage is

powerful enough to jump the spark plug gap

in the cylinders under high compression

pressures, providing that the system is in

good condition and that all adjustments are

correct.

The ignition system is divided into two

circuits, the low tension (LT) circuit and the

high tension (HT) circuit.

The low tension (sometimes known as the

primary) circuit consists of the battery, the

lead to the ignition switch, the lead from the

ignition switch to the low tension or primary

coil windings, and the lead from the low

tension coil windings to the contact breaker

points and condenser in the distributor.

The high tension circuit consists of the high

tension or secondary coil windings, the heavy

ignition lead from the centre of the coil to the

centre of the distributor cap, the rotor arm,

and the spark plug leads and spark plugs.

The system functions in the following

manner: High tension voltage is generated in

the coil by the interruption of the low tension

circuit. The interruption is effected by the

opening of the contact breaker points in this

low tension circuit. High tension voltage is fed

from the centre of the coil via the carbon

brush in the centre of the distributor cap to

the rotor arm of the distributor.

The rotor arm revolves at half engine speed

inside the distributor cap, and each time it

comes in line with one of the four metal

segments in the cap, which are connected to

the spark plug leads, the opening of thecontact breaker points causes the high

tension voltage to build up, jump the gap from

the rotor arm to the appropriate metal

segment, and so via the spark plug lead to the

spark plug, where it finally jumps the spark

plug gap before going to earth.

The ignition timing is advanced and

retarded automatically, to ensure the sparkoccurs at just the right instant for the

particular load at the prevailing engine speed.

The ignition advance is controlled

mechanically, and by vacuum. The

mechanical governor mechanism consists of

two weights, which move out from the

distributor shaft as the engine speed rises,

due to centrifugal force. As they move

Fig. 4.1 Typical ignition circuit (mechanical contact breaker distributor) (Sec 1)

1 Control unit

2 Multi-plug

3 Ignition coil

4 Distributor cap5 Crankshaft pulley

6 Flywheel

7 Battery

8 Rev counter9 Spark plugs

10 Wiring connector

S1 Engine speed sensor

S2 TDC sensor

Fig. 4.2 Digiplex electronic ignition system (Sec 1)

Page 74 of 303

outwards, they rotate the cam relative to the

distributor shaft, and so advance the spark.

The weights are held in position by two

springs and it is the tension of the springs

which is largely responsible for correct spark

advancement.

The vacuum advance is controlled by a

diaphragm capsule connected to the

carburettor venturi. The vacuum pressure

varies according to the throttle valve plate

opening and so adjusts the ignition advance

in accordance with the engine requirements.

Digiplex ignition system

This electronic system eliminates the

mechanical contact breaker and centrifugal

advance mechanism of conventional

distributors and uses an electronic control

unit to provide advance values according to

engine speed and load. No provision is made

for adjustment of the ignition timing.

Information relayed to the control unit is

provided by two magnetic sensors which

monitor engine speed and TDC directly from

the engine crankshaft.

A vacuum sensor in the control unit

converts intake manifold vacuum into an

electric signal.

The control unit selects the optimum

advance angle required and a closed

magnetic circuit resin coil guarantees a spark

owing to the low primary winding resistance.

Five hundred and twelve advance values

are stored in the control unit memory to suit

any combination of engine operating

conditions.

No maintenance is required to the

distributor used on this system.

Distributor drive

The mechanical breaker type distributor on

903 cc engines and the Digiplex type

distributor on 903 cc ES engines are mounted

on the cylinder head and driven from a gear

on the camshaft through a shaft which also

drives the oil pump.

The distributor on 1116 cc and 1301 cc

engines is mounted on the crankcase and is

driven from a gear on the auxiliary shaft as is

also the oil pump.

2 Mechanical contact breaker

- points servicing

3

1At the intervals specified in “Routine

Maintenance”, prise down the clips on the

distributor cap and place the cap with high

tension leads to one side.

2Pull off the rotor.

3Remove the spark shield. Mechanical wear

of the contact breaker reduces the gap.

Electrical wear builds up a “pip” of burned

metal on one of the contacts. This

|prevents the gap being measured for

re-adjustment, and also spoils the electric

circuit.

Ducellier type distributor

4To remove the contact breaker movable

arm, extract the clip and take off the washer

from the top of the pivot post.

5Extract the screw and remove the fixed

contact arm.

6Clean the points by rubbing the surfaces on

a fine abrasive such as an oil stone. The point

surface should be shaped to a gentle convex

curve. All the “pip” burned onto one contact

must be removed. It is not necessary to go on

until all traces of the crater have been

removed from the other. There is enough

metal on the contacts to allow this to be done

once. At alternate services, fit new points.

Wash debris off cleaned points and

preservatives off new ones.

7Now the distributor should be lubricated.

This lubrication is important for the correct

mechanical function of the distributor, but

excess lubrication will ruin the electrical

circuits, and give difficult starting.

8Whilst the contact breaker is off, squirt

some engine oil into the bottom part of the

distributor, onto the centrifugal advance

mechanism below the plate.

9Wet with oil the felt pad on the top of the

distributor spindle, normally covered by the

rotor arm.

10Put just a drip of oil on the pivot for the

moving contact.11Smear a little general purpose grease

onto the cam, and the heel of the moving

contact breaker.

12Refit the contact points and then set the

gap in the following way.

13Turn the crankshaft by applying a spanner

to the pulley nut or by jacking up a front

wheel, engaging top gear and turning the

roadwheel in the forward direction of

travel. Keep turning until the plastic

heel of the movable contact arm is on the

high point of a cam lobe on the distributor

shaft.

14Set the points gap by moving the fixed

contact arm until the specified feeler blades

are a sliding fit. Tighten the fixed contact arm

screw.

15Check the contact end of the rotor arm.

Remove any slightly burnt deposits using fine

abrasive paper. Severe erosion will

necessitate renewal of the rotor.

16Wipe out the distributor cap and check for

cracks or eroded contacts (photo). Renew if

evident or if the carbon brush is worn.

17Refit the spark shield, rotor and distributor

cap.

18Setting the contact breaker gap with a

feeler blade must be regarded as a means of

ensuring that the engine will start. For

optimum engine performance, the dwell angle

must be checked and adjusted as described

in Section 3.

Marelli type distributor

19Open the points with a finger nail and

inspect their condition. If they are badly

eroded or burned, then they must be

renewed. The contact points can only be

renewed complete with carrier plate as an

assembly.

20Release the low tension leads from the

terminals on the distributor body (photo).

21Extract the screws which hold the vacuum

advance capsule to the distributor body. Tilt

the capsule and release its link rod from the

contact breaker carrier plate (photo).

22Prise out the E-clip from the breaker

carrier and then withdraw the contact

assembly from the top of the distributor shaft.

Ignition system 4•3

2.21 Extracting vacuum diaphragm unit

screw2.20 Marelli distributor2.16 Interior of distributor cap showing

carbon brush

4

Page 75 of 303

Note the washers above and below the

contact assembly (photos).

23Fit the new contact assembly by reversing

the removal operations.

24Although the points gap is normally set in

production, check it using feeler blades when

the plastic heel of the movable arm is on a

high point of the shaft cam. Adjust if

necessary by inserting an Allen key (3.0 mm)

into the socket-headed adjuster screw.

25Carry out the operations described in

paragraphs 14 to 17 in this Section.

3 Dwell angle- checking

3

The dwell angle is the number of degrees

through which the distributor cam turns

between the instants of closure and opening

of the contact breaker points.

1Connect a dwell meter in accordance with

the maker’s instruction. The type of meter that

operates with the engine running is to be

preferred; any variation in contact breaker

gap, caused by wear in the distributor shaft or

bushes, or the height of the distributor cam

peaks, is evened out when using this.

2The correct dwell angle is given in the

Specifications at the beginning of this

Chapter. If the angle is too large, increase the

contact points gap. If the angle is too small,

reduce the points gap. Only very slight

adjustments should be made to the gap

before re-checking.3On Ducellier distributors, adjustment of the

dwell angle can only be carried out by

switching off the ignition, removing the

distributor cap, rotor and spark shield and

adjusting the points gap.

4Re-check once the engine is running.

Adjustment may have to be carried out

several times to obtain the correct dwell

angle.

5On Marelli distributors, adjustment of the

points gap (dwell angle) is carried out with the

engine running by inserting a 3.0 mm Allen

key in the hole provided in the distributor

body.

6Always check and adjust the dwell angle

before timing the ignition as described in

Section 4.

4 Ignition timing

3

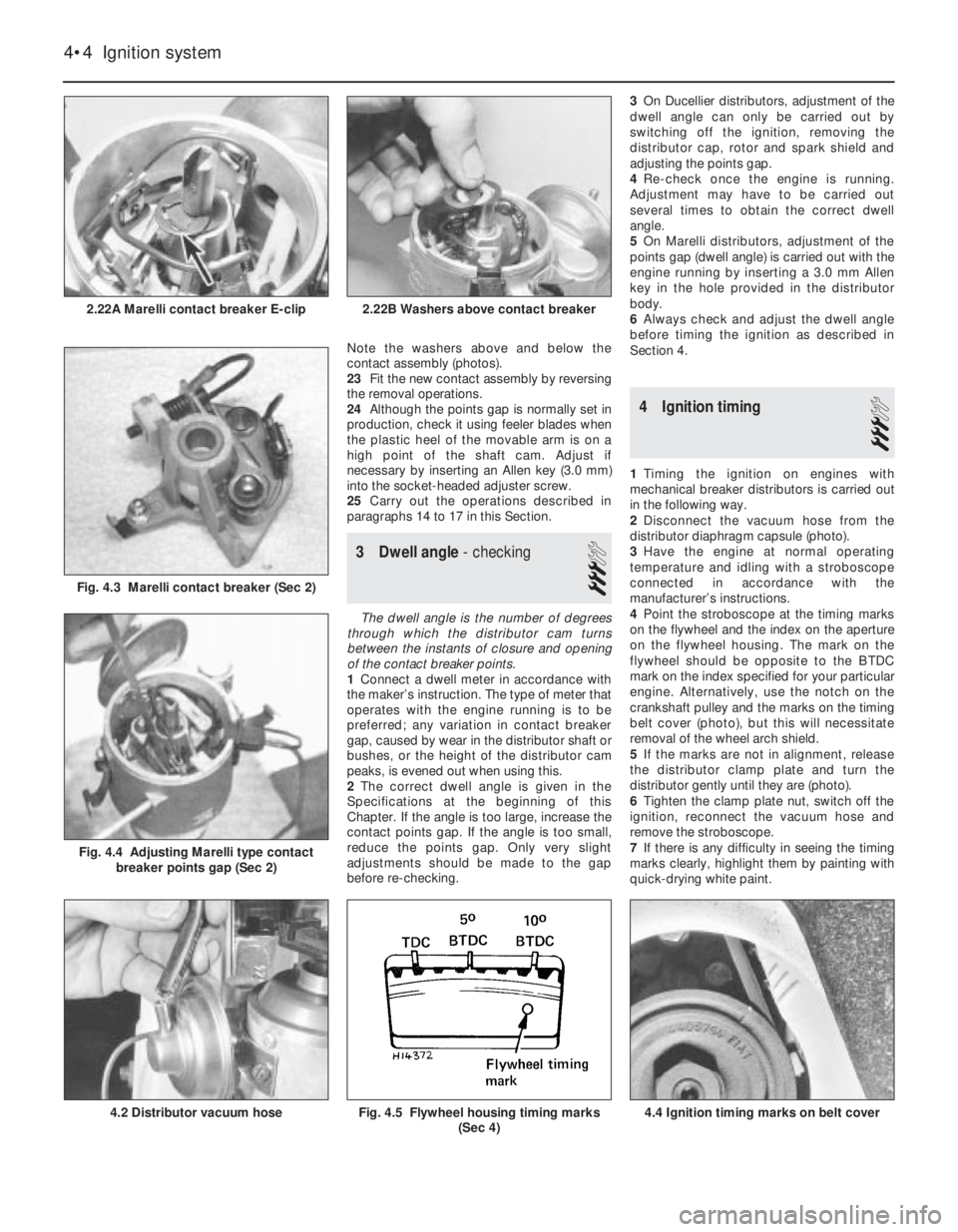

1Timing the ignition on engines with

mechanical breaker distributors is carried out

in the following way.

2Disconnect the vacuum hose from the

distributor diaphragm capsule (photo).

3Have the engine at normal operating

temperature and idling with a stroboscope

connected in accordance with the

manufacturer’s instructions.

4Point the stroboscope at the timing marks

on the flywheel and the index on the aperture

on the flywheel housing. The mark on the

flywheel should be opposite to the BTDC

mark on the index specified for your particular

engine. Alternatively, use the notch on the

crankshaft pulley and the marks on the timing

belt cover (photo), but this will necessitate

removal of the wheel arch shield.

5If the marks are not in alignment, release

the distributor clamp plate and turn the

distributor gently until they are (photo).

6Tighten the clamp plate nut, switch off the

ignition, reconnect the vacuum hose and

remove the stroboscope.

7If there is any difficulty in seeing the timing

marks clearly, highlight them by painting with

quick-drying white paint.

4•4 Ignition system

4.4 Ignition timing marks on belt coverFig. 4.5 Flywheel housing timing marks

(Sec 4)4.2 Distributor vacuum hose

Fig. 4.4 Adjusting Marelli type contact

breaker points gap (Sec 2)

Fig. 4.3 Marelli contact breaker (Sec 2)

2.22B Washers above contact breaker2.22A Marelli contact breaker E-clip