ignition FIAT UNO 1983 Service Service Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 1983, Model line: UNO, Model: FIAT UNO 1983Pages: 303, PDF Size: 10.36 MB

Page 139 of 303

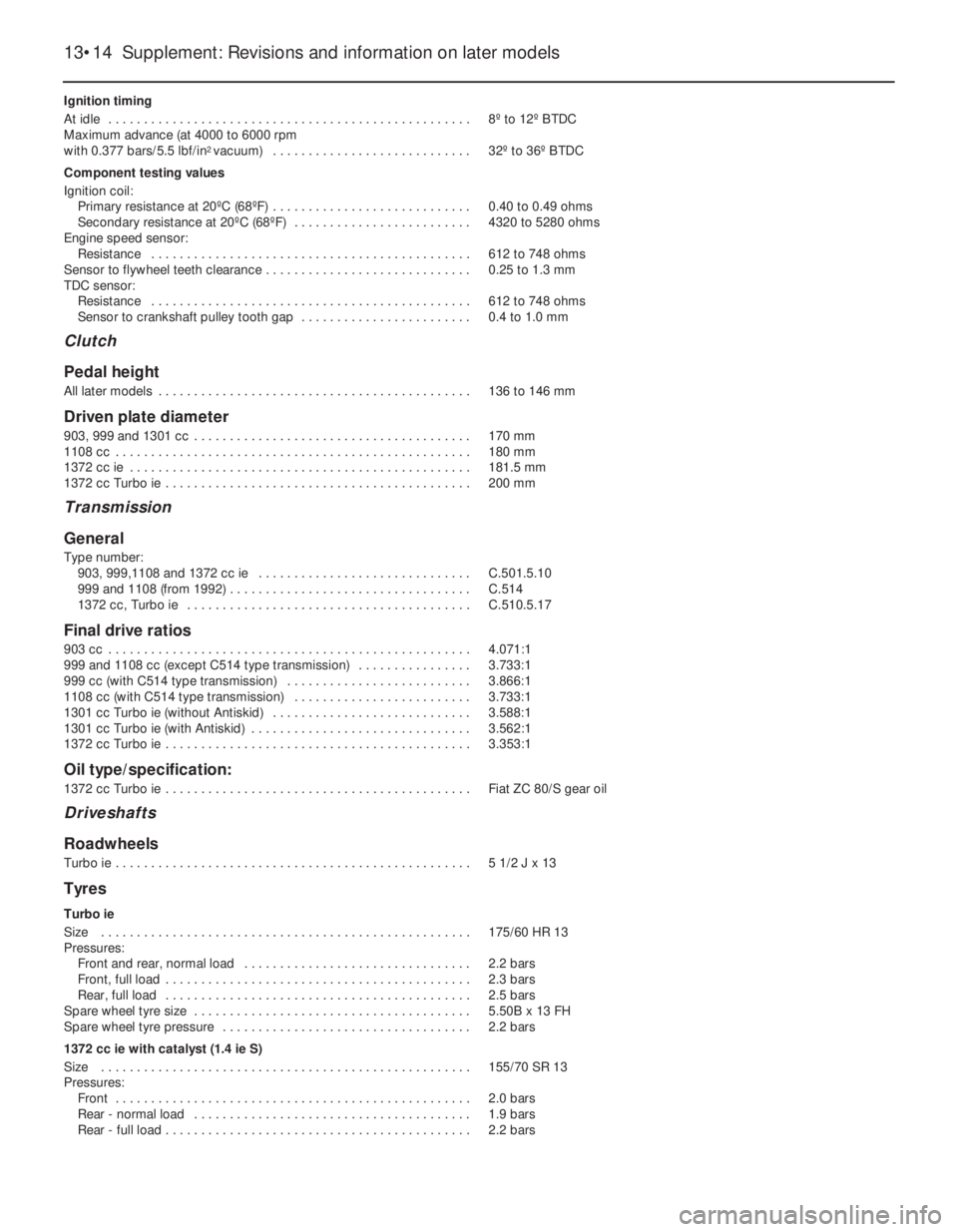

Ignition timing

At idle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8º to 12º BTDC

Maximum advance (at 4000 to 6000 rpm

with 0.377 bars/5.5 lbf/in

2 vacuum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32º to 36º BTDC

Component testing values

Ignition coil:

Primary resistance at 20ºC (68ºF) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.40 to 0.49 ohms

Secondary resistance at 20ºC (68ºF) . . . . . . . . . . . . . . . . . . . . . . . . . 4320 to 5280 ohms

Engine speed sensor:

Resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 612 to 748 ohms

Sensor to flywheel teeth clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.25 to 1.3 mm

TDC sensor:

Resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 612 to 748 ohms

Sensor to crankshaft pulley tooth gap . . . . . . . . . . . . . . . . . . . . . . . . 0.4 to 1.0 mm

Clutch

Pedal height

All later models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136 to 146 mm

Driven plate diameter

903, 999 and 1301 cc . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170 mm

1108 cc . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180 mm

1372 cc ie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181.5 mm

1372 cc Turbo ie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200 mm

Transmission

General

Type number:

903, 999,1108 and 1372 cc ie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C.501.5.10

999 and 1108 (from 1992) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C.514

1372 cc, Turbo ie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C.510.5.17

Final drive ratios

903 cc . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.071:1

999 and 1108 cc (except C514 type transmission) . . . . . . . . . . . . . . . . 3.733:1

999 cc (with C514 type transmission) . . . . . . . . . . . . . . . . . . . . . . . . . . 3.866:1

1108 cc (with C514 type transmission) . . . . . . . . . . . . . . . . . . . . . . . . . 3.733:1

1301 cc Turbo ie (without Antiskid) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.588:1

1301 cc Turbo ie (with Antiskid) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.562:1

1372 cc Turbo ie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.353:1

Oil type/specification:

1372 cc Turbo ie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fiat ZC 80/S gear oil

Driveshafts

Roadwheels

Turbo ie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 1/2 J x 13

Tyres

Turbo ie

Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175/60 HR 13

Pressures:

Front and rear, normal load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.2 bars

Front, full load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.3 bars

Rear, full load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.5 bars

Spare wheel tyre size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.50B x 13 FH

Spare wheel tyre pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.2 bars

1372 cc ie with catalyst (1.4 ie S)

Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155/70 SR 13

Pressures:

Front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.0 bars

Rear - normal load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.9 bars

Rear - full load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.2 bars

13•14 Supplement: Revisions and information on later models

Page 143 of 303

13•18 Supplement: Revisions and information on later models

Every 9000 miles (15 000 km) or

12 months (whichever comes first)

m mCheck the tyre pressures and their condition

(including the spare)

m mWhere a pad wear warning light is fitted, check its

operation

m mCheck the front brake disc pads for excessive wear

m mCheck the underbody condition (fuel and brakes

pipes, exhaust system, hoses, bushes and gaiters)

m mCheck the condition and tension of drivebelts

m mCheck the engine idle speed and CO emissions

m mCheck the EGR system (If fitted)

m mCheck fluid levels (coolant, brake fluid and

windscreen washer)

m mRenew spark plugs (1372 cc Turbo models)

m mRenew the engine oil and oil filter (non-Turbo

models)

m mCheck the HT leads and connections

m mCheck the condition of all coolant, fuel and

hydraulic hoses and connections

Every 18 000 miles (30 000 km) or

24 months (whichever comes first)

In addition to the items listed for 9000 mile (15 000 km) or 12 months

service

m mCheck the rear brake disc pads for wear (where

applicable)

m mCheck/adjust the valve clearances

m mCheck and tighten (if necessary), inlet and exhaust

manifolds

m mCheck the clutch adjustment (cable operated

models)

m mRenew the fuel filter (where applicable)

m mRenew the air cleaner element

m mRenew the spark plugs and check the HT leads

and connections (all models)

m mWhere applicable, have the ignition and injection

systems checked (special equipment needed)

m mRenew coolant

m mRenew brake fluid

Every 28 000 miles (45 000 km) or

36 months (whichever comes first)

In addition to the items listed for 9000 mile (15 000 km) or 12 months

service

m mCheck Lambda (oxygen) sensors operation (special

equipment needed)

m mCheck fuel evaporation system (where fitted)

m mCheck the transmission oil level

m mCheck the condition crankcase ventilation system

Every 37 000 miles (60 000 km) or

48 months (whichever comes first)

In addition to the items listed for 18 000 mile (30 000 km) or

24 months service

m mCheck the condition of the rear brake shoe linings

m mCheck the condition of the timing belt

Every 65 000 miles (105 000 km)

m

mRenew the timing belt

Every 74 500 miles (120 000 km)

m

mRenew the manual transmission oil

Every 250 miles (400 km), weekly or

before a long journey

m mProceed as described for the earlier models at the

start of this manual

Every 6000 miles (10 000 km) or

12 months (whichever comes first)

m mRenew the engine oil and oil filter (Turbo models

only)

3 Routine maintenance- all models from June 1991

The maintenance intervals in this manual are provided with the

assumption that you, not the dealer, will be carrying out the work.

These are the minimum maintenance intervals recommended by us, for

vehicles driven daily. If you wish to keep your vehicle in peak condition

at all times, you may wish to perform some of these procedures more

often. We encourage frequent maintenance, since it enhances the

efficiency, performance and resale value of your vehicle.

If the vehicle is driven in dusty areas, used to tow a trailer, or driven

frequently at slow speeds (idling in traffic) or on short journeys, more

frequent maintenance intervals are recommended.

When the vehicle is new, it should be serviced by an authorised

dealer to preserve the factory warranty.

Page 152 of 303

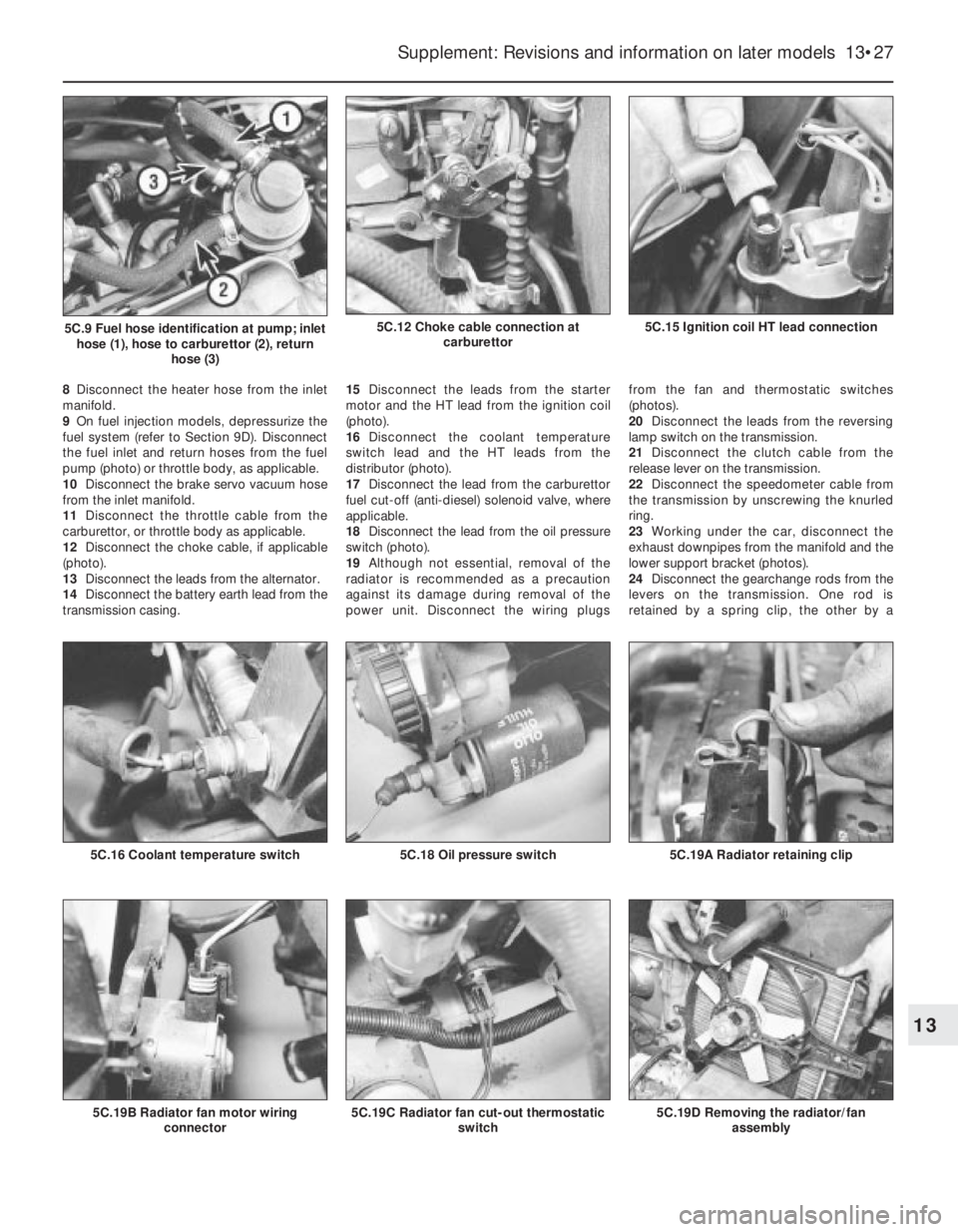

8Disconnect the heater hose from the inlet

manifold.

9On fuel injection models, depressurize the

fuel system (refer to Section 9D). Disconnect

the fuel inlet and return hoses from the fuel

pump (photo) or throttle body, as applicable.

10Disconnect the brake servo vacuum hose

from the inlet manifold.

11Disconnect the throttle cable from the

carburettor, or throttle body as applicable.

12Disconnect the choke cable, if applicable

(photo).

13Disconnect the leads from the alternator.

14Disconnect the battery earth lead from the

transmission casing.15Disconnect the leads from the starter

motor and the HT lead from the ignition coil

(photo).

16Disconnect the coolant temperature

switch lead and the HT leads from the

distributor (photo).

17Disconnect the lead from the carburettor

fuel cut-off (anti-diesel) solenoid valve, where

applicable.

18Disconnect the lead from the oil pressure

switch (photo).

19Although not essential, removal of the

radiator is recommended as a precaution

against its damage during removal of the

power unit. Disconnect the wiring plugs from the fan and thermostatic switches

(photos).

20Disconnect the leads from the reversing

lamp switch on the transmission.

21Disconnect the clutch cable from the

release lever on the transmission.

22Disconnect the speedometer cable from

the transmission by unscrewing the knurled

ring.

23Working under the car, disconnect the

exhaust downpipes from the manifold and the

lower support bracket (photos).

24Disconnect the gearchange rods from the

levers on the transmission. One rod is

retained by a spring clip, the other by a

Supplement: Revisions and information on later models 13•27

5C.15 Ignition coil HT lead connection5C.12 Choke cable connection at

carburettor5C.9 Fuel hose identification at pump; inlet

hose (1), hose to carburettor (2), return

hose (3)

5C.19D Removing the radiator/fan

assembly5C.19C Radiator fan cut-out thermostatic

switch5C.19B Radiator fan motor wiring

connector

5C.19A Radiator retaining clip5C.18 Oil pressure switch5C.16 Coolant temperature switch

13

Page 158 of 303

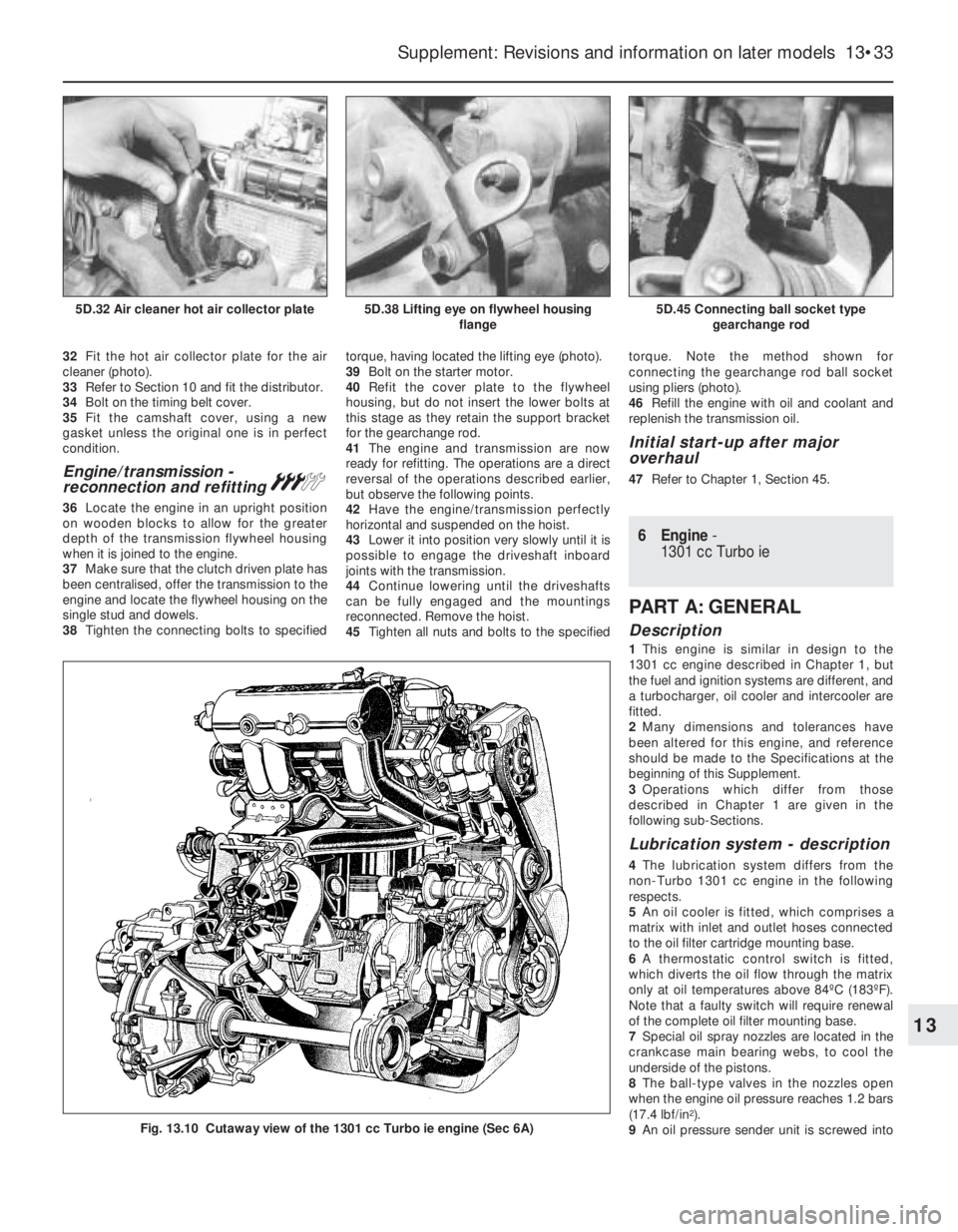

32Fit the hot air collector plate for the air

cleaner (photo).

33Refer to Section 10 and fit the distributor.

34Bolt on the timing belt cover.

35Fit the camshaft cover, using a new

gasket unless the original one is in perfect

condition.

Engine/transmission -

reconnection and refitting#

36Locate the engine in an upright position

on wooden blocks to allow for the greater

depth of the transmission flywheel housing

when it is joined to the engine.

37Make sure that the clutch driven plate has

been centralised, offer the transmission to the

engine and locate the flywheel housing on the

single stud and dowels.

38Tighten the connecting bolts to specifiedtorque, having located the lifting eye (photo).

39Bolt on the starter motor.

40Refit the cover plate to the flywheel

housing, but do not insert the lower bolts at

this stage as they retain the support bracket

for the gearchange rod.

41The engine and transmission are now

ready for refitting. The operations are a direct

reversal of the operations described earlier,

but observe the following points.

42Have the engine/transmission perfectly

horizontal and suspended on the hoist.

43Lower it into position very slowly until it is

possible to engage the driveshaft inboard

joints with the transmission.

44Continue lowering until the driveshafts

can be fully engaged and the mountings

reconnected. Remove the hoist.

45Tighten all nuts and bolts to the specifiedtorque. Note the method shown for

connecting the gearchange rod ball socket

using pliers (photo).

46Refill the engine with oil and coolant and

replenish the transmission oil.

Initial start-up after major

overhaul

47Refer to Chapter 1, Section 45.

6 Engine-

1301 cc Turbo ie

PART A: GENERAL

Description

1This engine is similar in design to the

1301 cc engine described in Chapter 1, but

the fuel and ignition systems are different, and

a turbocharger, oil cooler and intercooler are

fitted.

2Many dimensions and tolerances have

been altered for this engine, and reference

should be made to the Specifications at the

beginning of this Supplement.

3Operations which differ from those

described in Chapter 1 are given in the

following sub-Sections.

Lubrication system - description

4The lubrication system differs from the

non-Turbo 1301 cc engine in the following

respects.

5An oil cooler is fitted, which comprises a

matrix with inlet and outlet hoses connected

to the oil filter cartridge mounting base.

6A thermostatic control switch is fitted,

which diverts the oil flow through the matrix

only at oil temperatures above 84ºC (183ºF).

Note that a faulty switch will require renewal

of the complete oil filter mounting base.

7Special oil spray nozzles are located in the

crankcase main bearing webs, to cool the

underside of the pistons.

8The ball-type valves in the nozzles open

when the engine oil pressure reaches 1.2 bars

(17.4 lbf/in

2).

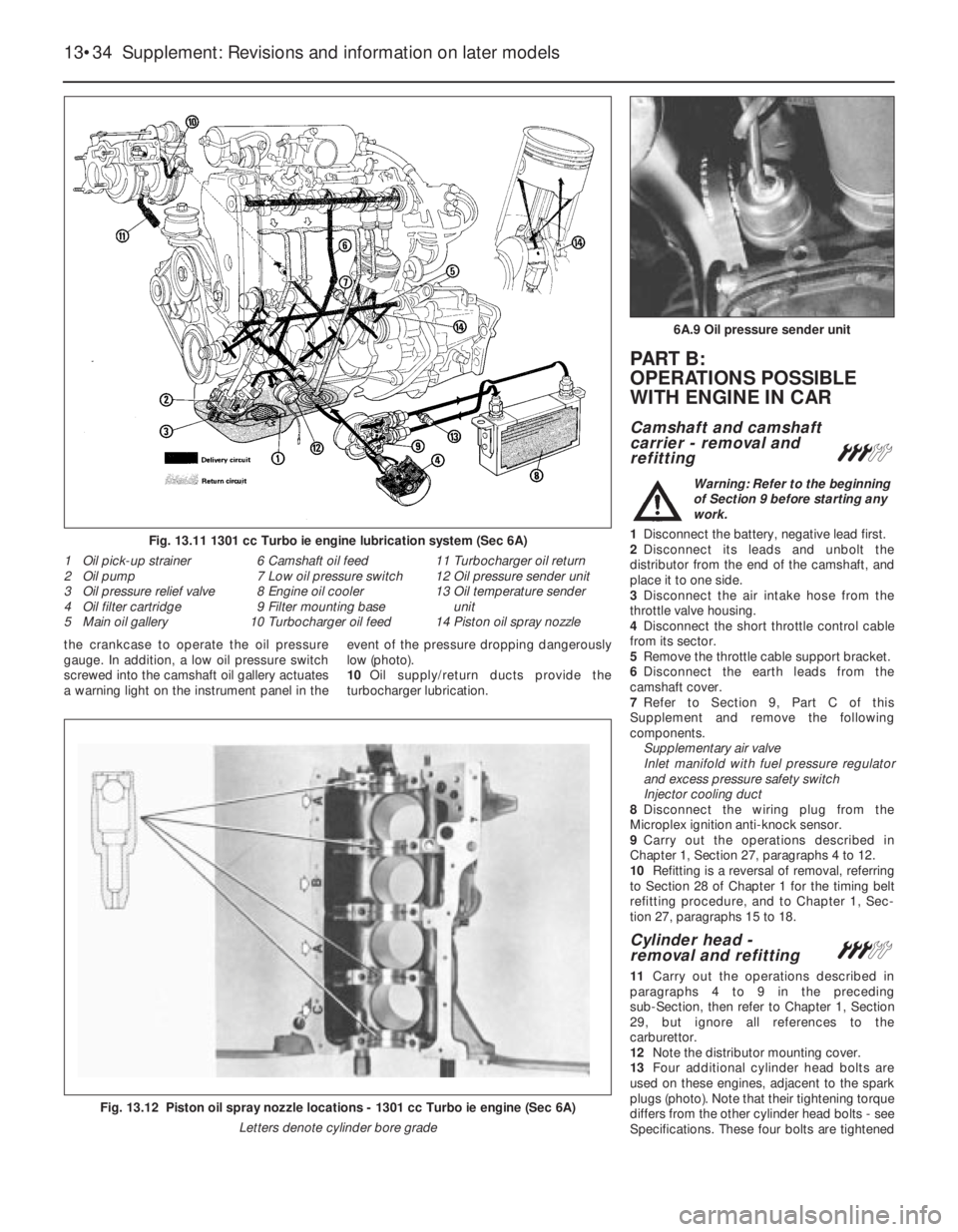

9An oil pressure sender unit is screwed into

Supplement: Revisions and information on later models 13•33

5D.45 Connecting ball socket type

gearchange rod5D.38 Lifting eye on flywheel housing

flange5D.32 Air cleaner hot air collector plate

Fig. 13.10 Cutaway view of the 1301 cc Turbo ie engine (Sec 6A)

13

Page 159 of 303

the crankcase to operate the oil pressure

gauge. In addition, a low oil pressure switch

screwed into the camshaft oil gallery actuates

a warning light on the instrument panel in theevent of the pressure dropping dangerously

low (photo).

10Oil supply/return ducts provide the

turbocharger lubrication.

PART B:

OPERATIONS POSSlBLE

WITH ENGINE IN CAR

Camshaft and camshaft

carrier - removal and

refitting

#

Warning: Refer to the beginning

of Section 9 before starting any

work.

1Disconnect the battery, negative lead first.

2Disconnect its leads and unbolt the

distributor from the end of the camshaft, and

place it to one side.

3Disconnect the air intake hose from the

throttle valve housing.

4Disconnect the short throttle control cable

from its sector.

5Remove the throttle cable support bracket.

6Disconnect the earth leads from the

camshaft cover.

7Refer to Section 9, Part C of this

Supplement and remove the following

components.

Supplementary air valve

Inlet manifold with fuel pressure regulator

and excess pressure safety switch

Injector cooling duct

8Disconnect the wiring plug from the

Microplex ignition anti-knock sensor.

9Carry out the operations described in

Chapter 1, Section 27, paragraphs 4 to 12.

10Refitting is a reversal of removal, referring

to Section 28 of Chapter 1 for the timing belt

refitting procedure, and to Chapter 1, Sec-

tion 27, paragraphs 15 to 18.

Cylinder head -

removal and refitting#

11Carry out the operations described in

paragraphs 4 to 9 in the preceding

sub-Section, then refer to Chapter 1, Section

29, but ignore all references to the

carburettor.

12Note the distributor mounting cover.

13Four additional cylinder head bolts are

used on these engines, adjacent to the spark

plugs (photo). Note that their tightening torque

differs from the other cylinder head bolts - see

Specifications. These four bolts are tightened

13•34 Supplement: Revisions and information on later models

1 Oil pick-up strainer

2 Oil pump

3 Oil pressure relief valve

4 Oil filter cartridge

5 Main oil gallery6 Camshaft oil feed

7 Low oil pressure switch

8 Engine oil cooler

9 Filter mounting base

10 Turbocharger oil feed11 Turbocharger oil return

12 Oil pressure sender unit

13 Oil temperature sender

unit

14 Piston oil spray nozzle

Fig. 13.12 Piston oil spray nozzle locations - 1301 cc Turbo ie engine (Sec 6A)

Letters denote cylinder bore grade

Fig. 13.11 1301 cc Turbo ie engine lubrication system (Sec 6A)

6A.9 Oil pressure sender unit

Page 161 of 303

Engine oil cooler -

removal and refittingÁ

23The oil cooler is mounted behind the front

bumper/spoiler (photo).

24Disconnect the oil flow and return hoses,

either from the cooler or the oil filter cartridge

mounting base. Be prepared for some

leakage of oil (photos).

25Unscrew the mounting bolts and remove

the oil cooler heat exchanger (photo).

26When refitting, make sure that the banjo

union sealing washers are in good condition.

PART C: ENGINE REMOVAL,

DISMANTLING, REASSEMBLY

AND REFITTING

Engine/transmission -

removal and separation

#

Warning: Refer to the beginning

of Section 9 before starting any

work.

1Refer to Chapter 1, Section 35, and carry

out the operations described in paragraphs 1

to 11.

2Disconnect the excessive air pressure

switch from the inlet manifold.

3Disconnect the ducts and remove the

airflow meter.

4Disconnect the leads from the spark plugs

and the distributor LT connector, and unbolt

and remove the distributor from the rear end

of the camshaft carrier.

5Disconnect the fuel return hose from the

pressure regulator. 6Disconnect the fuel inlet hose from the

injector rail.

7Disconnect the wiring plugs from the fuel

injectors.

8Disconnect the leads from the oil pressure

sender unit, the low oil pressure switch and

the coolant temperature switch.

9Remove the hose/pipe assemblies from the

intercooler.

10Disconnect the throttle control rod at the

balljoint.

11Disconnect the hoses and ducts from the

turbocharger and the mechanical bypass

valve.

12Disconnect the leads from the engine

speed and anti-knock sensors.

13Raise the front of the car and support it

securely. As the engine/transmission will

eventually be lowered to the floor, make sure

that there is sufficient clearance under the

front end for the assembly to be withdrawn. If

the car is over an inspection pit, then the car

need only be raised enough to lift the

roadwheels from the floor.

14Remove the front roadwheels.

15Disconnect the transmission earth cable.

16Working under the car, remove the engine

shields from under the wheel arches.

17Remove the engine oil cooler, and the

intercooler.

18Unscrew the fixing screws and disconnect

the driveshafts from the flanges at the

transmission final drive. The right-hand

driveshaft will not release until the upper bolt

on the suspension strut-to-hub carrier clamphas been removed, and the hub assembly

tilted downwards.

19Disconnect the exhaust downpipe from

the manifold, and then remove the front

section of the exhaust system.

20Disconnect the coolant return pipe from

the turbocharger.

21Disconnect the gearchange control rods

from the transmission selector rod. Do this by

unscrewing the self-locking nut from the bolt

which connects the clevis fork.

22Attach suitable lifting gear to the engine

lifting eyes, and take the weight of the

engine/transmission.

23Disconnect the left-front, centre-rear and

the right-hand engine/transmission mountings.

Do this by removing the bolts from the

diamond-shaped mounting plates there is no

need to disturb the flexible mounting centre

bolts.

24Lower the engine/transmission to the floor

and withdraw it from under the car.

25Carry out the operations described in

Chapter 1, Section 35, paragraphs 27 to 31.

Engine dismantling and

reassembly

26The operations are essentially as

described for the 1301 cc engine in Chapter 1,

but reference must be made to Sections 9

and 10 of this Chapter for the procedures for

removing and refitting the components of the

fuel injection, turbocharger and ignition

systems.

Engine/transmission -

reconnection and refitting

27The operations are a reversal of those

described in paragraphs 1 to 25, but

otherwise the following (photo).

a) Tighten all nuts and bolts to the specified

torque.

b) Use a new gasket at the exhaust

downpipe-to-manifold flange.

c) Check and adjust the clutch pedal travel.

d) Refill the cooling system.

e) Refill the engine and transmission with oil.

f) Reconnect the battery, negative lead

last.

13•36 Supplement: Revisions and information on later models

6C.27 Filling the engine with oil6B.25 Oil cooler mounting bolts (arrowed)

6B.24B Connections at oil filter cartridge

mounting base6B.24A Oil cooler pipe connection

(arrowed)6B.23 Oil cooler

Page 162 of 303

Initial start-up after major

overhaul

28Refer to Chapter 1, Section 45, but note

that an oil pressure gauge is fitted to indicate

oil pressure.

29Check the ignition static timing as

described in Section 10.

30Check the engine idle speed and CO level

as described in Section 9.

7 Engine-

1372 cc ie and 1372 cc

Turbo ie

PART A: GENERAL

Description

1The 1372 cc engine is similar in design to

the OHC engine fitted to the FIAT Tipo

variants. The engine is of four-cylinder, in-line,

overhead camshaft type, mounted

transversely at the front of the vehicle.

2The crankshaft runs in five main bearings.

Thrustwashers are fitted to the rear (flywheel

end) main bearing in order to control

crankshaft endfloat.

3The connecting rods are attached to the

crankshaft by horizontally split shell-type

big-end bearings. The pistons are attached to

the connecting rods by fully-floating gudgeon

pins which are secured by circlips. The

aluminium alloy pistons are fitted with three

piston rings: two compression rings and an oil

control ring.

4The camshaft is driven by a toothed belt

and operates the valves via bucket and shim

type cam followers. The camshaft is located in

a separate housing on top of the cylinder

head.

5The inlet and exhaust valves are each

closed by double valve springs, and operate

in guides pressed into the cylinder head.

6The auxiliary shaft, which is also driven by

the toothed belt, drives the oil pump.

7Lubrication is by means of a gear type

pump which draws oil through a strainer

located in the sump, and forces it through a

full-flow filter into the engine oil galleries fromwhere it is distributed to the crankshaft,

camshaft and auxiliary shaft. The big-end

bearings are supplied with oil via internal

drillings in the crankshaft. The undersides of

the pistons are cooled by oil spray nozzles

located in each main bearing location in the

crankcase.

8A crankcase ventilation system is

employed, whereby piston blow-by gases are

drawn via an oil separator into the air cleaner,

from where they are drawn into the inlet

manifold and re-burnt with fresh air/fuel

mixture.

9The 1372 cc ie engine is fitted with a Bosch

Mono-Jetronic single point fuel injection (SPi)

system. Whilst the higher performance

1372 cc Turbo ie engine is fitted with a Bosch

L3.1 (L3.2 from 1992) Jetronic multi-point

injection (MPi) system and turbocharger with

intercooler and oil cooling. The L3.2 system

models are fitted with catalytic converters.

Maintenanceª

10At the intervals specified in Section 3 or

“Routine maintenance” at the beginning of

this Manual, carry out the following tasks.

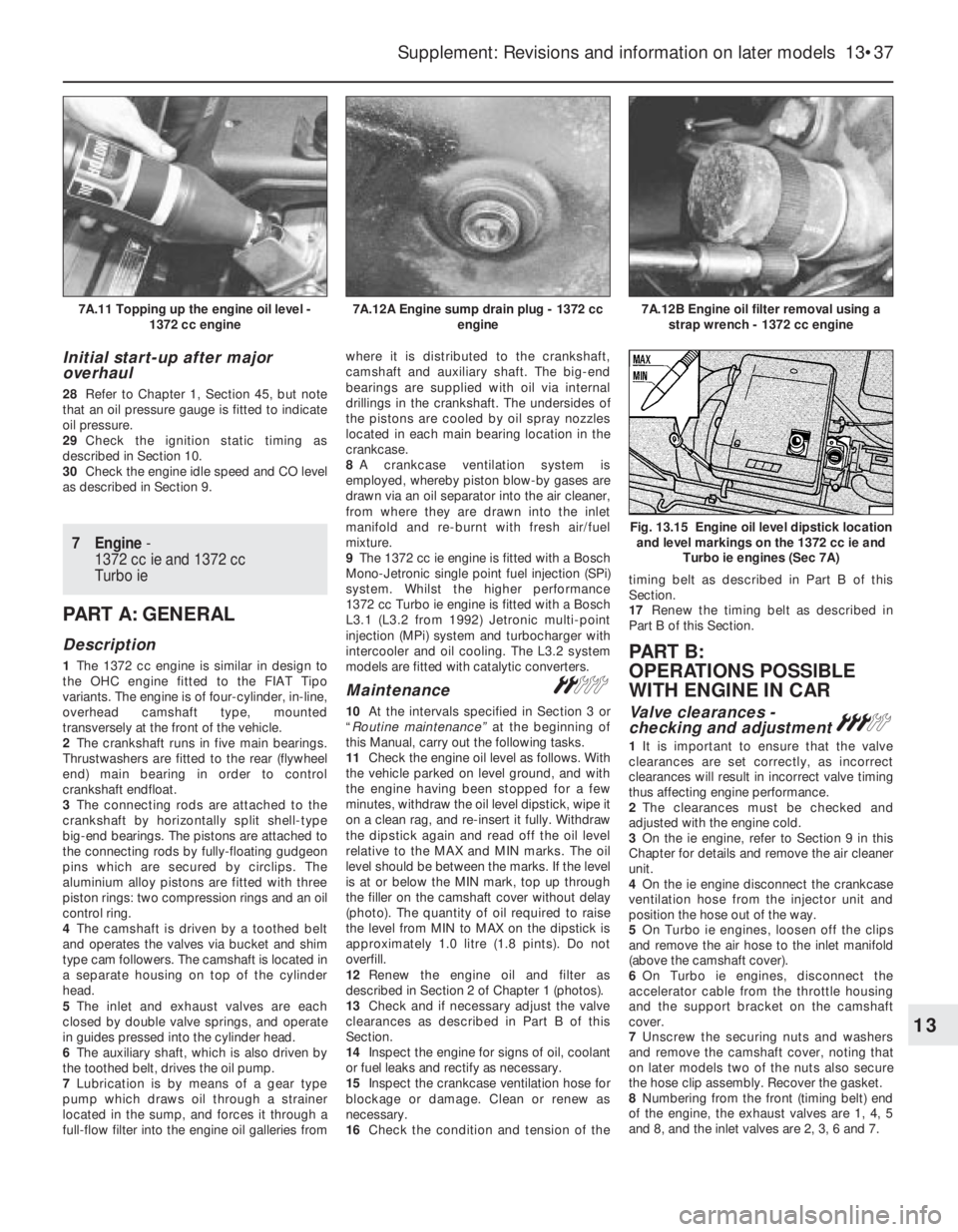

11Check the engine oil level as follows. With

the vehicle parked on level ground, and with

the engine having been stopped for a few

minutes, withdraw the oil level dipstick, wipe it

on a clean rag, and re-insert it fully. Withdraw

the dipstick again and read off the oil level

relative to the MAX and MIN marks. The oil

level should be between the marks. If the level

is at or below the MIN mark, top up through

the filler on the camshaft cover without delay

(photo). The quantity of oil required to raise

the level from MIN to MAX on the dipstick is

approximately 1.0 litre (1.8 pints). Do not

overfill.

12Renew the engine oil and filter as

described in Section 2 of Chapter 1 (photos).

13Check and if necessary adjust the valve

clearances as described in Part B of this

Section.

14Inspect the engine for signs of oil, coolant

or fuel leaks and rectify as necessary.

15Inspect the crankcase ventilation hose for

blockage or damage. Clean or renew as

necessary.

16Check the condition and tension of thetiming belt as described in Part B of this

Section.

17Renew the timing belt as described in

Part B of this Section.

PART B:

OPERATIONS POSSlBLE

WITH ENGINE IN CAR

Valve clearances -

checking and adjustment#

1It is important to ensure that the valve

clearances are set correctly, as incorrect

clearances will result in incorrect valve timing

thus affecting engine performance.

2The clearances must be checked and

adjusted with the engine cold.

3On the ie engine, refer to Section 9 in this

Chapter for details and remove the air cleaner

unit.

4On the ie engine disconnect the crankcase

ventilation hose from the injector unit and

position the hose out of the way.

5On Turbo ie engines, loosen off the clips

and remove the air hose to the inlet manifold

(above the camshaft cover).

6On Turbo ie engines, disconnect the

accelerator cable from the throttle housing

and the support bracket on the camshaft

cover.

7Unscrew the securing nuts and washers

and remove the camshaft cover, noting that

on later models two of the nuts also secure

the hose clip assembly. Recover the gasket.

8Numbering from the front (timing belt) end

of the engine, the exhaust valves are 1, 4, 5

and 8, and the inlet valves are 2, 3, 6 and 7.

Supplement: Revisions and information on later models 13•37

7A.12B Engine oil filter removal using a

strap wrench - 1372 cc engine7A.12A Engine sump drain plug - 1372 cc

engine7A.11 Topping up the engine oil level -

1372 cc engine

Fig. 13.15 Engine oil level dipstick location

and level markings on the 1372 cc ie and

Turbo ie engines (Sec 7A)

13

Page 169 of 303

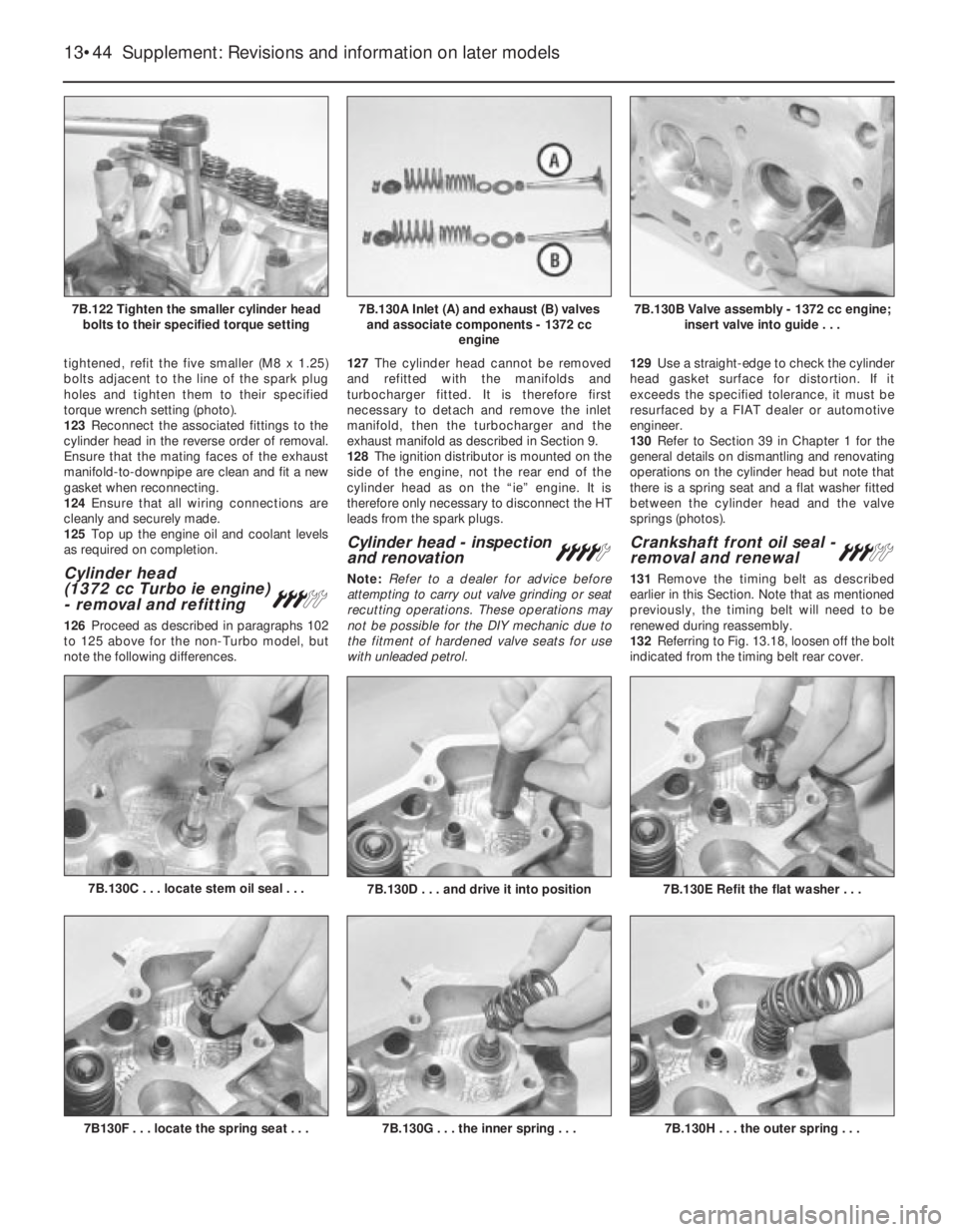

tightened, refit the five smaller (M8 x 1.25)

bolts adjacent to the line of the spark plug

holes and tighten them to their specified

torque wrench setting (photo).

123Reconnect the associated fittings to the

cylinder head in the reverse order of removal.

Ensure that the mating faces of the exhaust

manifold-to-downpipe are clean and fit a new

gasket when reconnecting.

124Ensure that all wiring connections are

cleanly and securely made.

125Top up the engine oil and coolant levels

as required on completion.

Cylinder head

(1372 cc Turbo ie engine)

- removal and refitting

#

126Proceed as described in paragraphs 102

to 125 above for the non-Turbo model, but

note the following differences.127The cylinder head cannot be removed

and refitted with the manifolds and

turbocharger fitted. It is therefore first

necessary to detach and remove the inlet

manifold, then the turbocharger and the

exhaust manifold as described in Section 9.

128The ignition distributor is mounted on the

side of the engine, not the rear end of the

cylinder head as on the “ie” engine. It is

therefore only necessary to disconnect the HT

leads from the spark plugs.

Cylinder head - inspection

and renovation¢

Note: Refer to a dealer for advice before

attempting to carry out valve grinding or seat

recutting operations. These operations may

not be possible for the DIY mechanic due to

the fitment of hardened valve seats for use

with unleaded petrol.129Use a straight-edge to check the cylinder

head gasket surface for distortion. If it

exceeds the specified tolerance, it must be

resurfaced by a FIAT dealer or automotive

engineer.

130Refer to Section 39 in Chapter 1 for the

general details on dismantling and renovating

operations on the cylinder head but note that

there is a spring seat and a flat washer fitted

between the cylinder head and the valve

springs (photos).

Crankshaft front oil seal -

removal and renewal#

131Remove the timing belt as described

earlier in this Section. Note that as mentioned

previously, the timing belt will need to be

renewed during reassembly.

132Referring to Fig. 13.18, loosen off the bolt

indicated from the timing belt rear cover.

13•44 Supplement: Revisions and information on later models

7B.130H . . . the outer spring . . .7B.130G . . . the inner spring . . .7B130F . . . locate the spring seat . . .

7B.130E Refit the flat washer . . .7B.130D . . . and drive it into position7B.130C . . . locate stem oil seal . . .

7B.130B Valve assembly - 1372 cc engine;

insert valve into guide . . .7B.130A Inlet (A) and exhaust (B) valves

and associate components - 1372 cc

engine7B.122 Tighten the smaller cylinder head

bolts to their specified torque setting

Page 174 of 303

fitting, as during removal. Note that the

compression rings are brittle, and will snap if

expanded too far.

206If new pistons are to be fitted, they must

be selected from the grades available, after

measuring the cylinder bores. Normally, the

appropriate oversize pistons are supplied by

the dealer when the block is rebored.

207Whenever new piston rings are being

installed, the glaze on the original cylinder

bores should be removed using either

abrasive paper or a glaze-removing tool in an

electric drill. If abrasive paper is used, use

strokes at 60º to the bore centre-line, to

create a cross-hatching effect.

Engine/transmission

mountings - renewalÁ

208The engine/gearbox assembly is

suspended in the engine compartment on

three mountings, two of which are attached to

the gearbox, and one to the engine.

Right-hand mounting

209Apply the handbrake, then jack up the

front of the vehicle and support it securely on

axle stands.

210Suitable lifting tackle must now be

attached to the engine in order to support it as

the engine mounting is removed. No lifting

brackets are provided, so care must be taken

when deciding on an engine lifting point. In the

workshop, a right-angled bracket was made up

by bending a suitable piece of steel plate. The

bracket was then bolted to the engine using the

rear right-hand camshaft housing securing bolt

with suitable packing washers.

211Attach the lifting tackle to the bracket on

the engine and just take the weight of the

assembly.

212Working under the vehicle, unbolt the

engine mounting bracket from the cylinder

block, and unbolt the mounting from the

body, then withdraw the bracket/mounting

assembly.

213Unscrew the nut and through-bolt,

counter holding the bolt with a second

spanner or socket, and separate the mounting

from the bracket.

214Fit the new mounting to the bracket, and

tighten the nut to the specified torque, while

counterholding the through-bolt using a

suitable spanner or socket.

215Refit the mounting bracket to the cylinder

block, and tighten the securing bolts to the

specified torque.

216Refit the mounting to the body and

tighten the securing bolts to the specified

torque.

217Disconnect the lifting tackle from the

engine, and remove the engine lifting bracket.

218Lower the vehicle to the ground.

Left-hand mountings

219Apply the handbrake, then jack up the

front of the vehicle and support it securely on

axle stands.

220Suitable lifting tackle must now be

attached to the gearbox lifting bracket inorder to support the weight of the assembly

as the mounting is removed.

221Attach the lifting tackle to the bracket on

the gearbox, and just take the weight of the

assembly.

222Working under the vehicle, unbolt the

mounting bracket from the gearbox, and

unbolt the mounting from the body, then

withdraw the bracket/mounting assembly.

223Proceed as described in paragraphs 213

and 214.

224Refit the mounting bracket to the

gearbox, and tighten the securing bolts to the

specified torque.

225Refit the mounting to the body and

tighten the mounting bolts to the specified

torque.

226Disconnect the lifting tackle from the

engine.

227Lower the vehicle to the ground.

PART C: ENGINE REMOVAL

AND DISMANTLING

Method of removal - general

1The engine (complete with transmission) is

disconnected and lowered downwards

through the engine compartment, then

withdrawn from the front underside of the car.

1372 cc engine/

transmission - removal

and separation

#

Warning: Refer to the beginning

of Section 9 before starting any

work.

2Depressurize the fuel system as described

in Section 9 of this Chapter.

3Disconnect the battery negative lead.

4Mark the position of the hinges on the

underside of the bonnet, then with the aid of

an assistant, unscrew the hinge bolts and lift

the bonnet clear of the car. Store the bonnet

in a safe area.

5Drain the engine coolant.

6Drain the engine and transmission oils.

7Disconnect and remove the air filter.

8Disconnect the coolant hoses from the

engine, including the hose to the inlet

manifold.

9Detach the ignition coil (HT) lead from the

distributor.10Compress the retaining clip and detach

the engine idle speed actuator lead from the

SPi unit (photo).

11Disconnect the brake servo vacuum pipe

from its connector on the inlet manifold.

12Disconnect the throttle cable from the SPi

unit.

13Disconnect the engine speed sensor lead.

14Release and detach the reversing light

lead from the switch on the transmission

(photo).

15Before disconnecting the hydraulic hose

from the clutch slave cylinder, remove the

filler cap from the reservoir and place a piece

of polythene sheet over the filler neck, then

refit the cap; this will help prevent excess fluid

loss. Once disconnected, plug the hose and

its cylinder connection to prevent the ingress

of dirt into the hydraulic system.

16Disconnect the wiring connector from the

alternator.

17Position a clean rag under the fuel supply

and return hose connections to the SPi unit,

then slowly unscrew the hose clips to release

the system pressure; catch fuel leakage in the

rag and dispose of it safely. Detach the hoses

and plug them to prevent ingress of dirt and

any further fuel leakage. Position the hoses

out of the way.

18Detach the wiring connector from the

engine coolant temperature sender unit

(photo).

19Release the retaining clip and detach the

wiring connector from the throttle position

switch. Also detach the associated earth

leads from the cylinder head.

Supplement: Revisions and information on later models 13•49

7C.14 Reversing light switch and lead7C.18 Engine coolant temperature sender

and wiring connector

7C.10 Engine idle speed actuator/SPi unit

lead connection (arrowed)

13

Page 176 of 303

fittings are disconnected from the engine and

transmission and positioned out of the way.

Enlist the aid of an assistant to help steady

and guide the power unit down through the

engine compartment as it is removed, If

available, position a suitable engine trolley or

crawler board under the engine/transmission

so that when lowered, the power unit can be

withdrawn from the front end of the vehicle

and moved to the area where it is to be

cleaned and dismantled.

38Carefully lower the engine and

transmission unit, ensuring that no fittings

become snagged. Detach the hoist and

withdraw the power unit from under the

vehicle.

39To separate the engine from the

transmission, unbolt and remove the starter

motor, then unscrew the retaining bolts and

withdraw the transmission from the engine. As

it is withdrawn, do not allow the weight of the

engine or transmission to be taken by the

input shaft.

40To remove the clutch unit, refer to

Chapter 5 for details.

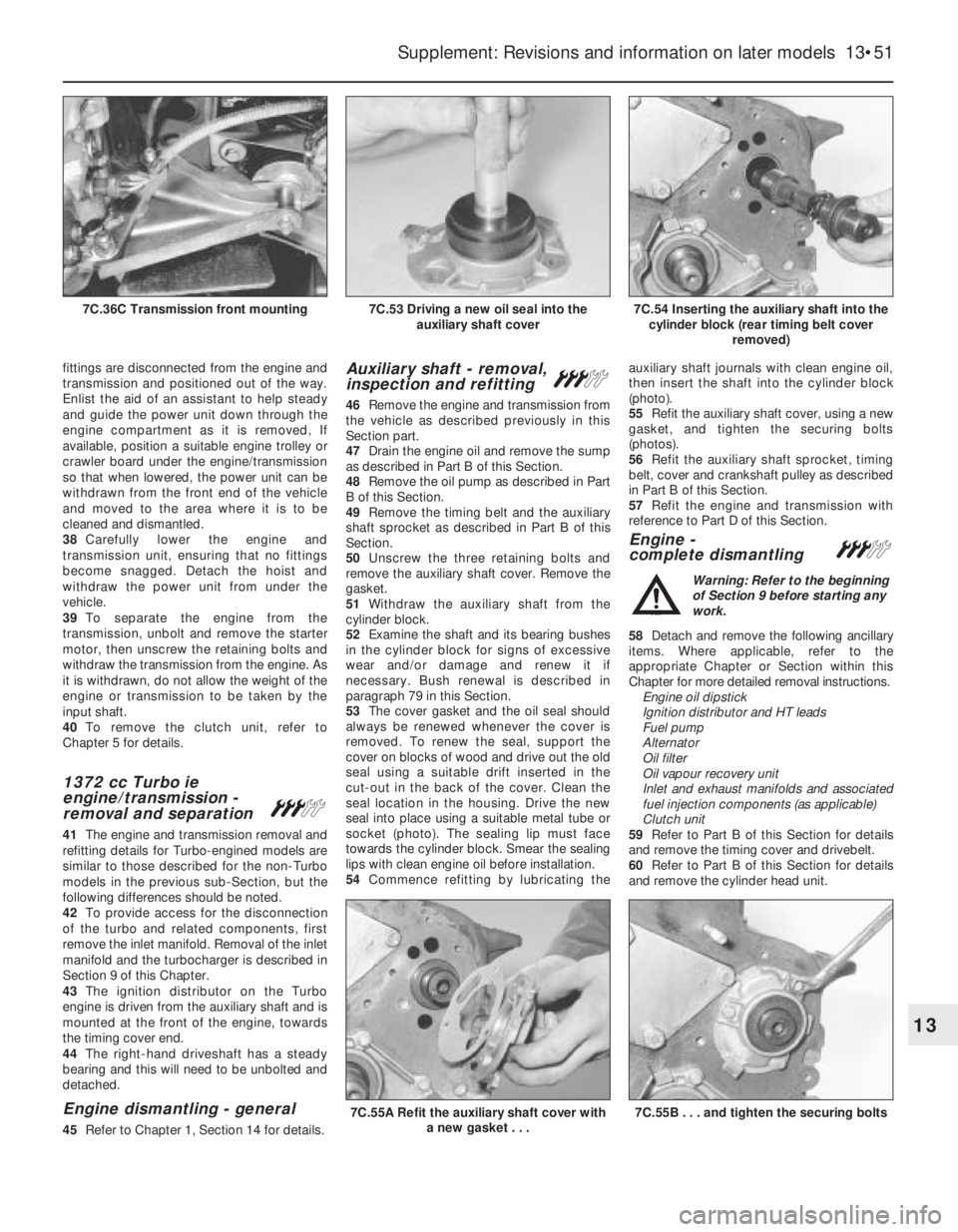

1372 cc Turbo ie

engine/transmission -

removal and separation

#

41The engine and transmission removal and

refitting details for Turbo-engined models are

similar to those described for the non-Turbo

models in the previous sub-Section, but the

following differences should be noted.

42To provide access for the disconnection

of the turbo and related components, first

remove the inlet manifold. Removal of the inlet

manifold and the turbocharger is described in

Section 9 of this Chapter.

43The ignition distributor on the Turbo

engine is driven from the auxiliary shaft and is

mounted at the front of the engine, towards

the timing cover end.

44The right-hand driveshaft has a steady

bearing and this will need to be unbolted and

detached.

Engine dismantling - general

45Refer to Chapter 1, Section 14 for details.

Auxiliary shaft - removal,

inspection and refitting #

46Remove the engine and transmission from

the vehicle as described previously in this

Section part.

47Drain the engine oil and remove the sump

as described in Part B of this Section.

48Remove the oil pump as described in Part

B of this Section.

49Remove the timing belt and the auxiliary

shaft sprocket as described in Part B of this

Section.

50Unscrew the three retaining bolts and

remove the auxiliary shaft cover. Remove the

gasket.

51Withdraw the auxiliary shaft from the

cylinder block.

52Examine the shaft and its bearing bushes

in the cylinder block for signs of excessive

wear and/or damage and renew it if

necessary. Bush renewal is described in

paragraph 79 in this Section.

53The cover gasket and the oil seal should

always be renewed whenever the cover is

removed. To renew the seal, support the

cover on blocks of wood and drive out the old

seal using a suitable drift inserted in the

cut-out in the back of the cover. Clean the

seal location in the housing. Drive the new

seal into place using a suitable metal tube or

socket (photo). The sealing lip must face

towards the cylinder block. Smear the sealing

lips with clean engine oil before installation.

54Commence refitting by lubricating theauxiliary shaft journals with clean engine oil,

then insert the shaft into the cylinder block

(photo).

55Refit the auxiliary shaft cover, using a new

gasket, and tighten the securing bolts

(photos).

56Refit the auxiliary shaft sprocket, timing

belt, cover and crankshaft pulley as described

in Part B of this Section.

57Refit the engine and transmission with

reference to Part D of this Section.

Engine -

complete dismantling#

Warning: Refer to the beginning

of Section 9 before starting any

work.

58Detach and remove the following ancillary

items. Where applicable, refer to the

appropriate Chapter or Section within this

Chapter for more detailed removal instructions.

Engine oil dipstick

Ignition distributor and HT leads

Fuel pump

Alternator

Oil filter

Oil vapour recovery unit

Inlet and exhaust manifolds and associated

fuel injection components (as applicable)

Clutch unit

59Refer to Part B of this Section for details

and remove the timing cover and drivebelt.

60Refer to Part B of this Section for details

and remove the cylinder head unit.

Supplement: Revisions and information on later models 13•51

7C.54 Inserting the auxiliary shaft into the

cylinder block (rear timing belt cover

removed)7C.53 Driving a new oil seal into the

auxiliary shaft cover7C.36C Transmission front mounting

7C.55B . . . and tighten the securing bolts7C.55A Refit the auxiliary shaft cover with

a new gasket . . .

13