ignition FIAT UNO 1983 Service Repair Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 1983, Model line: UNO, Model: FIAT UNO 1983Pages: 303, PDF Size: 10.36 MB

Page 3 of 303

REPAIRS & OVERHAUL

Engine and Associated Systems

Engine (also see Chapter 13)Page 1•1

Cooling and heating systems (also see Chapter 13)Page2•1

Fuel system (also see Chapter 13)Page 3•1

Ignition system (also see Chapter 13)Page4•1

Transmission

Clutch (also see Chapter 13)Page5•1

Transmission (also see Chapter 13)Page6•1

Driveshafts, hubs, roadwheels and tyres (also see Chapter 13)Page7•1

Brakes

Braking system(also see Chapter 13)Page 8•1

Electrical

Electrical system(also see Chapter 13)Page 9•1

Steering and suspension

SteeringPage 10•1

Suspension (also see Chapter 13)Page 11•1

Bodywork

Bodywork (also see Chapter 13)Page 12•1

Additional information

Supplement: Revisions and information on later models Page 13•1

Wiring DiagramsPage 14•1

REFERENCE

MOT Test Checks PageREF•1

Tools and Working Facilities Page REF•5

General Repair Procedures Page REF•8

Fault FindingPage REF•9

Buying Spare Parts & Vehicle Identification Numbers PageREF•12

Glossary of Technical Terms PageREF•13

IndexPage REF•17

Contents

Page 5 of 303

Safety First!0•5

Working on your car can be dangerous.

This page shows just some of the potential

risks and hazards, with the aim of creating a

safety-conscious attitude.

General hazards

Scalding

• Don’t remove the radiator or expansion

tank cap while the engine is hot.

• Engine oil, automatic transmission fluid or

power steering fluid may also be dangerously

hot if the engine has recently been running.

Burning

• Beware of burns from the exhaust system

and from any part of the engine. Brake discs

and drums can also be extremely hot

immediately after use.

Crushing

• When working under or near

a raised vehicle,

always

supplement the

jack with axle

stands, or use

drive-on

ramps.

Never

venture

under a car which

is only supported by a jack.

• Take care if loosening or tightening high-

torque nuts when the vehicle is on stands.

Initial loosening and final tightening should

be done with the wheels on the ground.

Fire

• Fuel is highly flammable; fuel vapour is

explosive.

• Don’t let fuel spill onto a hot engine.

• Do not smoke or allow naked lights

(including pilot lights) anywhere near a

vehicle being worked on. Also beware of

creating sparks

(electrically or by use of tools).

• Fuel vapour is heavier than air, so don’t

work on the fuel system with the vehicle over

an inspection pit.

• Another cause of fire is an electrical

overload or short-circuit. Take care when

repairing or modifying the vehicle wiring.

• Keep a fire extinguisher handy, of a type

suitable for use on fuel and electrical fires.

Electric shock

• Ignition HT

voltage can be

dangerous,

especially to

people with heart

problems or a

pacemaker. Don’t

work on or near the

ignition system with

the engine running or

the ignition switched on.• Mains voltage is also dangerous. Make

sure that any mains-operated equipment is

correctly earthed. Mains power points should

be protected by a residual current device

(RCD) circuit breaker.

Fume or gas intoxication

• Exhaust fumes are

poisonous; they often

contain carbon

monoxide, which is

rapidly fatal if inhaled.

Never run the

engine in a

confined space

such as a garage

with the doors shut.

• Fuel vapour is also

poisonous, as are the vapours from some

cleaning solvents and paint thinners.

Poisonous or irritant substances

• Avoid skin contact with battery acid and

with any fuel, fluid or lubricant, especially

antifreeze, brake hydraulic fluid and Diesel

fuel. Don’t syphon them by mouth. If such a

substance is swallowed or gets into the eyes,

seek medical advice.

• Prolonged contact with used engine oil can

cause skin cancer. Wear gloves or use a

barrier cream if necessary. Change out of oil-

soaked clothes and do not keep oily rags in

your pocket.

• Air conditioning refrigerant forms a

poisonous gas if exposed to a naked flame

(including a cigarette). It can also cause skin

burns on contact.

Asbestos

• Asbestos dust can cause cancer if inhaled

or swallowed. Asbestos may be found in

gaskets and in brake and clutch linings.

When dealing with such components it is

safest to assume that they contain asbestos.

Special hazards

Hydrofluoric acid

• This extremely corrosive acid is formed

when certain types of synthetic rubber, found

in some O-rings, oil seals, fuel hoses etc, are

exposed to temperatures above 400

0C. The

rubber changes into a charred or sticky

substance containing the acid. Once formed,

the acid remains dangerous for years. If it

gets onto the skin, it may be necessary to

amputate the limb concerned.

• When dealing with a vehicle which has

suffered a fire, or with components salvaged

from such a vehicle, wear protective gloves

and discard them after use.

The battery

• Batteries contain sulphuric acid, which

attacks clothing, eyes and skin. Take care

when topping-up or carrying the battery.

• The hydrogen gas given off by the battery

is highly explosive. Never cause a spark or

allow a naked light nearby. Be careful when

connecting and disconnecting battery

chargers or jump leads.

Air bags

• Air bags can cause injury if they go off

accidentally. Take care when removing the

steering wheel and/or facia. Special storage

instructions may apply.

Diesel injection equipment

• Diesel injection pumps supply fuel at very

high pressure. Take care when working on

the fuel injectors and fuel pipes.

Warning: Never expose the hands,

face or any other part of the body

to injector spray; the fuel can

penetrate the skin with potentially fatal

results.

Remember...

DO

• Do use eye protection when using power

tools, and when working under the vehicle.

• Do wear gloves or use barrier cream to

protect your hands when necessary.

• Do get someone to check periodically

that all is well when working alone on the

vehicle.

• Do keep loose clothing and long hair well

out of the way of moving mechanical parts.

• Do remove rings, wristwatch etc, before

working on the vehicle – especially the

electrical system.

• Do ensure that any lifting or jacking

equipment has a safe working load rating

adequate for the job.

A few tips

DON’T

• Don’t attempt to lift a heavy component

which may be beyond your capability – get

assistance.

• Don’t rush to finish a job, or take

unverified short cuts.

• Don’t use ill-fitting tools which may slip

and cause injury.

• Don’t leave tools or parts lying around

where someone can trip over them. Mop

up oil and fuel spills at once.

• Don’t allow children or pets to play in or

near a vehicle being worked on.

Page 7 of 303

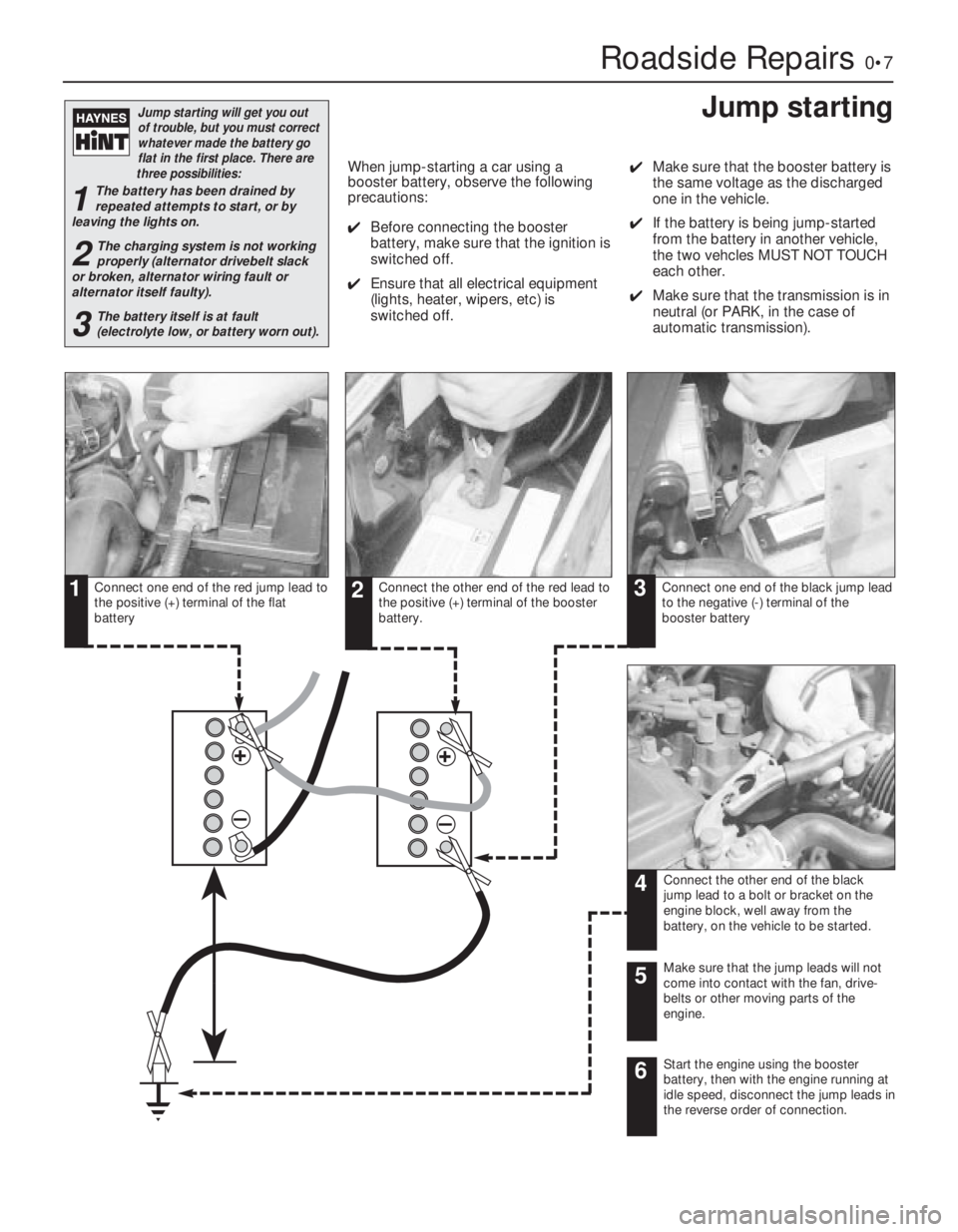

Roadside Repairs0•7

Connect one end of the red jump lead to

the positive (+) terminal of the flat

batteryConnect the other end of the red lead to

the positive (+) terminal of the booster

battery.Connect one end of the black jump lead

to the negative (-) terminal of the

booster battery

Connect the other end of the black

jump lead to a bolt or bracket on the

engine block, well away from the

battery, on the vehicle to be started.

–

+

+

–

123

4

Make sure that the jump leads will not

come into contact with the fan, drive-

belts or other moving parts of the

engine.5

Start the engine using the booster

battery, then with the engine running at

idle speed, disconnect the jump leads in

the reverse order of connection.6

Jump starting will get you out

of trouble, but you must correct

whatever made the battery go

flat in the first place. There are

three possibilities:

1The battery has been drained by

repeated attempts to start, or by

leaving the lights on.

2The charging system is not working

properly (alternator drivebelt slack

or broken, alternator wiring fault or

alternator itself faulty).

3The battery itself is at fault

(electrolyte low, or battery worn out).

Booster battery (jump) starting

When jump-starting a car using a

booster battery, observe the following

precautions:

4Before connecting the booster

battery, make sure that the ignition is

switched off.

4Ensure that all electrical equipment

(lights, heater, wipers, etc) is

switched off.4Make sure that the booster battery is

the same voltage as the discharged

one in the vehicle.

4If the battery is being jump-started

from the battery in another vehicle,

the two vehcles MUST NOT TOUCH

each other.

4Make sure that the transmission is in

neutral (or PARK, in the case of

automatic transmission).

Jump starting

Page 8 of 303

0•8Roadside Repairs

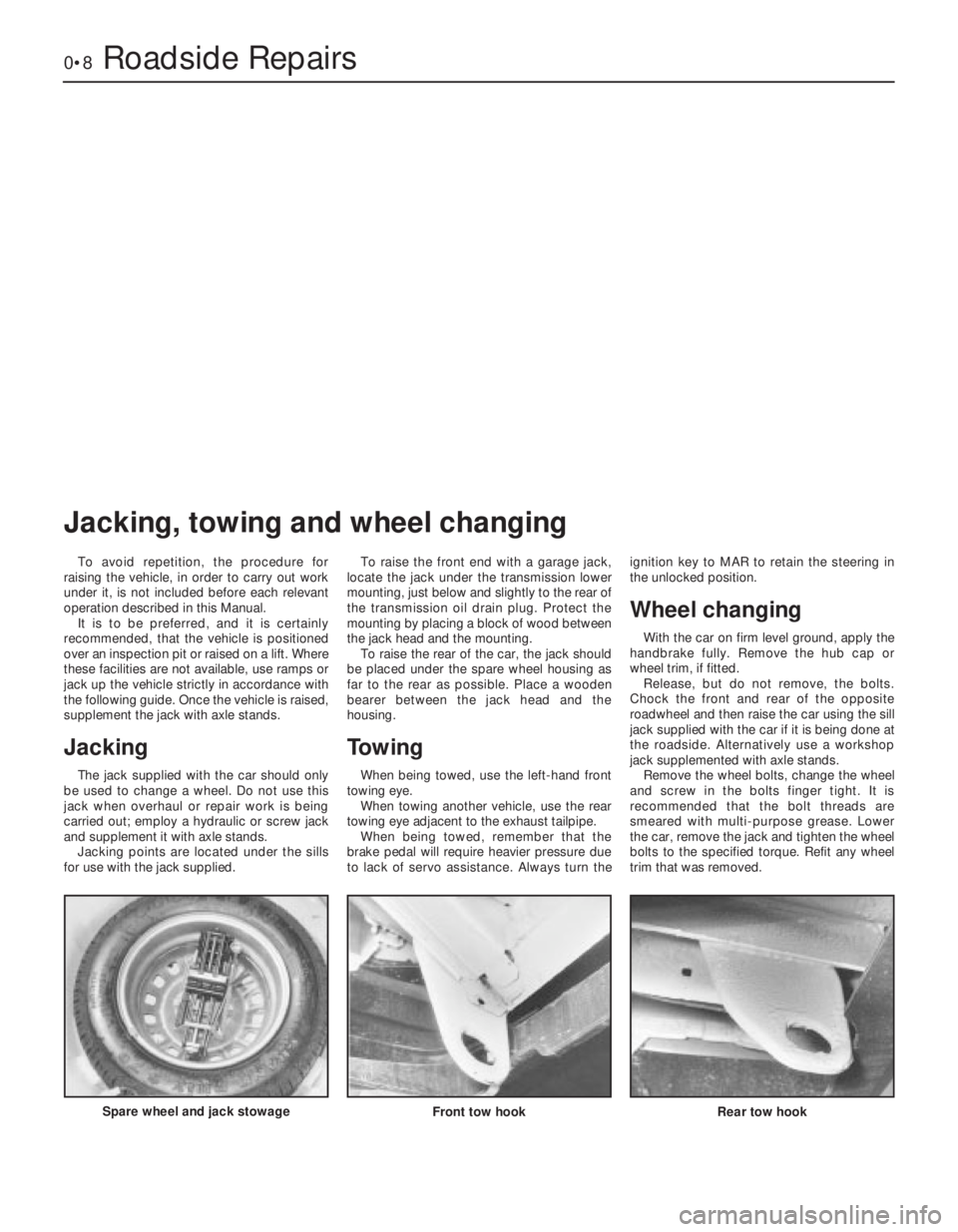

To avoid repetition, the procedure for

raising the vehicle, in order to carry out work

under it, is not included before each relevant

operation described in this Manual.

It is to be preferred, and it is certainly

recommended, that the vehicle is positioned

over an inspection pit or raised on a lift. Where

these facilities are not available, use ramps or

jack up the vehicle strictly in accordance with

the following guide. Once the vehicle is raised,

supplement the jack with axle stands.

Jacking

The jack supplied with the car should only

be used to change a wheel. Do not use this

jack when overhaul or repair work is being

carried out; employ a hydraulic or screw jack

and supplement it with axle stands.

Jacking points are located under the sills

for use with the jack supplied.To raise the front end with a garage jack,

locate the jack under the transmission lower

mounting, just below and slightly to the rear of

the transmission oil drain plug. Protect the

mounting by placing a block of wood between

the jack head and the mounting.

To raise the rear of the car, the jack should

be placed under the spare wheel housing as

far to the rear as possible. Place a wooden

bearer between the jack head and the

housing.

Towing

When being towed, use the left-hand front

towing eye.

When towing another vehicle, use the rear

towing eye adjacent to the exhaust tailpipe.

When being towed, remember that the

brake pedal will require heavier pressure due

to lack of servo assistance. Always turn theignition key to MAR to retain the steering in

the unlocked position.

Wheel changing

With the car on firm level ground, apply the

handbrake fully. Remove the hub cap or

wheel trim, if fitted.

Release, but do not remove, the bolts.

Chock the front and rear of the opposite

roadwheel and then raise the car using the sill

jack supplied with the car if it is being done at

the roadside. Alternatively use a workshop

jack supplemented with axle stands.

Remove the wheel bolts, change the wheel

and screw in the bolts finger tight. It is

recommended that the bolt threads are

smeared with multi-purpose grease. Lower

the car, remove the jack and tighten the wheel

bolts to the specified torque. Refit any wheel

trim that was removed.

Spare wheel and jack stowage

Front tow hook Rear tow hook

Jacking, towing and wheel changing

Page 10 of 303

0•10Routine maintenance

Maintenance is essential for ensuring safety and desirable for the

purpose of getting the best in terms of performance and economy

from the car. Over the years the need for periodic lubrication has been

greatly reduced if not totally eliminated. This has unfortunately tended

to lead some owners to think that because no such action is required

the items either no longer exist or will last forever. This is certainly not

the case; it is essential to carry out regular visual examinations as

comprehensively as possible in order to spot any possible defects at

an early stage before they develop into major and expensive repairs.

For information applicable to later models, see Supplement.

Every 250 miles (400 km), weekly,

or before a long journey

m mCheck engine oil level

m mCheck brake reservoir fluid level

m mCheck tyre pressures

m mCheck operation of all lights and horn

m mTop up washer fluid reservoirs, adding a screen

wash, and check operation of washers and wipers

m mCheck coolant level

m mCheck battery electrolyte level

Every 6000 miles (10 000 km)

or six months, whichever comes first

m mRenew engine oil and filter (Chapter 1, Section 2)

m mCheck drivebelt tension (Chapter 2, Section 8)

m mCheck carburettor idle speed and mixture

adjustments (Chapter 3)

m mCheck contact points and dwell angle (mechanical

breaker distributors) (Chapter 4, Section 3)

m mCheck tyre tread wear (Chapter 7, Section 7)

m mCheck disc pads for wear (Chapter 8, Section 3)

Every 36 000 miles (60 000 km)

or three years, whichever comes first

m mRenew the timing belt - 1116 and 1299/1301 cc

(Chapter 1, Section 28)

m mCheck exhaust system for corrosion (Chapter 3,

Section 19)

m mRenew contact breaker points and adjust dwell

angle (mechanical breaker distributors) (Chapter 4,

Section 3)

m mCheck and adjust ignition timing (Chapter 4,

Section 4)

m mRenew spark plugs (Chapter 4, Section 11)

m mCheck clutch adjustment (Chapter 5, Section 2)

m mCheck transmission oil level (Chapter 6, Section 2)

m mCheck driveshaft and steering rack gaiters for splits

(Chapters 7 and 10)

m mCheck rear brake shoe linings for wear (Chapter 8,

Section 4)

m mCheck handbrake travel (Chapter 8, Section 16)

m mCheck headlamp beam alignment (Chapter 9,

Section 17)

m mCheck balljoints for wear (Chapter 10, Section 2)

m mCheck front wheel alignment (Chapter 10, Section 8)

m mCheck suspension bushes for wear (Chapter 11,

Section 2)

m mCheck seat belts for fraying (Chapter 12, Section 23)

m mLubricate controls, hinges and locks

Every 24 000 miles (40 000 km)

or two years, whichever comes first

m mRenew coolant anti-freeze mixture (Chapter 2,

Section 3)

m mRenew transmission oil (Chapter 6, Section 2)

m mRenew brake hydraulic fluid (Chapter 8, Section 12)

m mCheck for underbody corrosion and clean out door

and sill drain holes (Chapter 12, Section 2)

Every 12 000 miles (20 000 km) or

12 months, whichever comes first

m mCheck and adjust valve clearances (Chapter 1,

Sections 5 and 26)

m mRenew air cleaner element (Chapter 3, Section 2)

Page 11 of 303

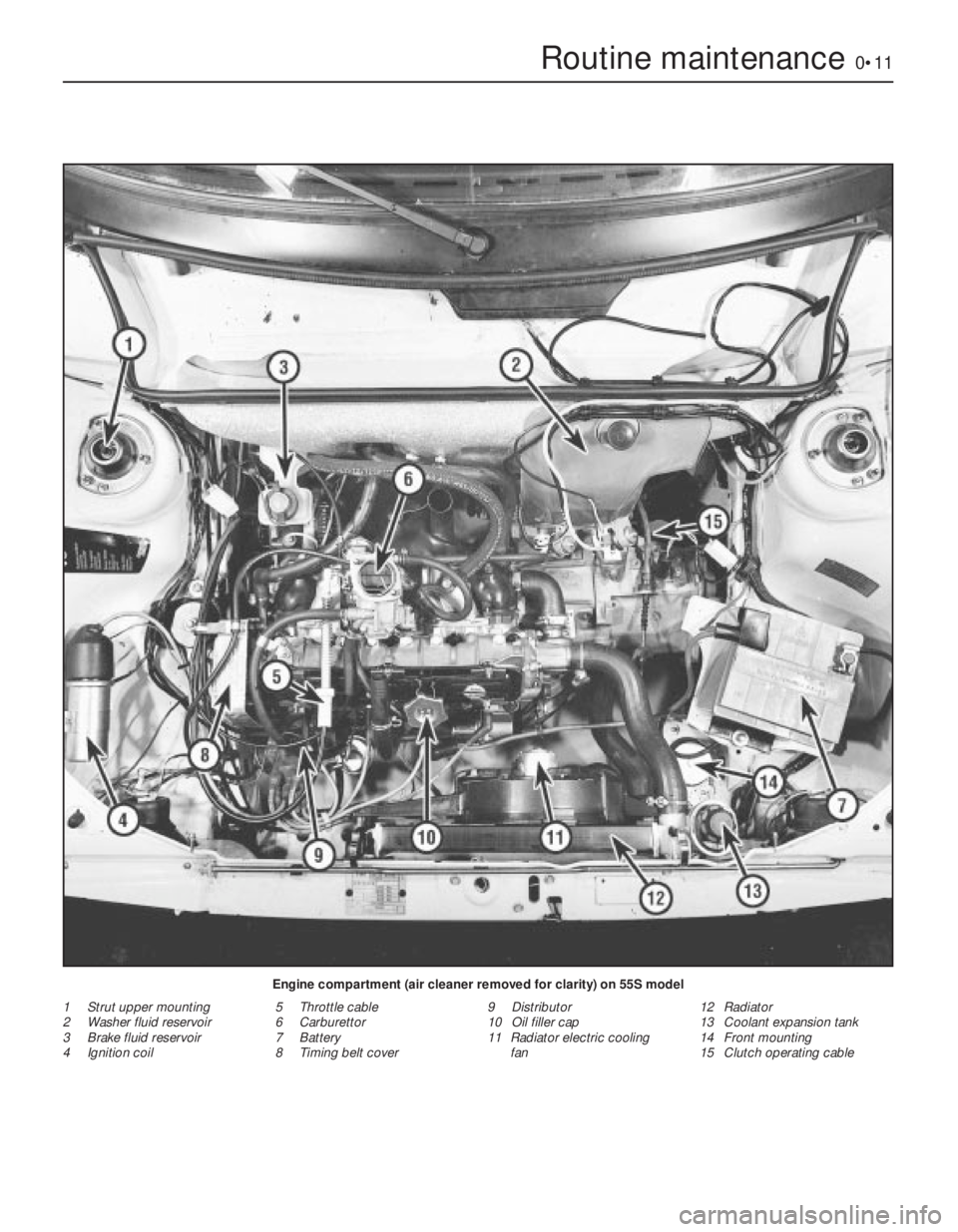

Routine maintenance0•11

Engine compartment (air cleaner removed for clarity) on 55S model

1 Strut upper mounting

2 Washer fluid reservoir

3 Brake fluid reservoir

4 Ignition coil5 Throttle cable

6 Carburettor

7 Battery

8 Timing belt cover9 Distributor

10 Oil filler cap

11 Radiator electric cooling

fan12 Radiator

13 Coolant expansion tank

14 Front mounting

15 Clutch operating cable

Page 27 of 303

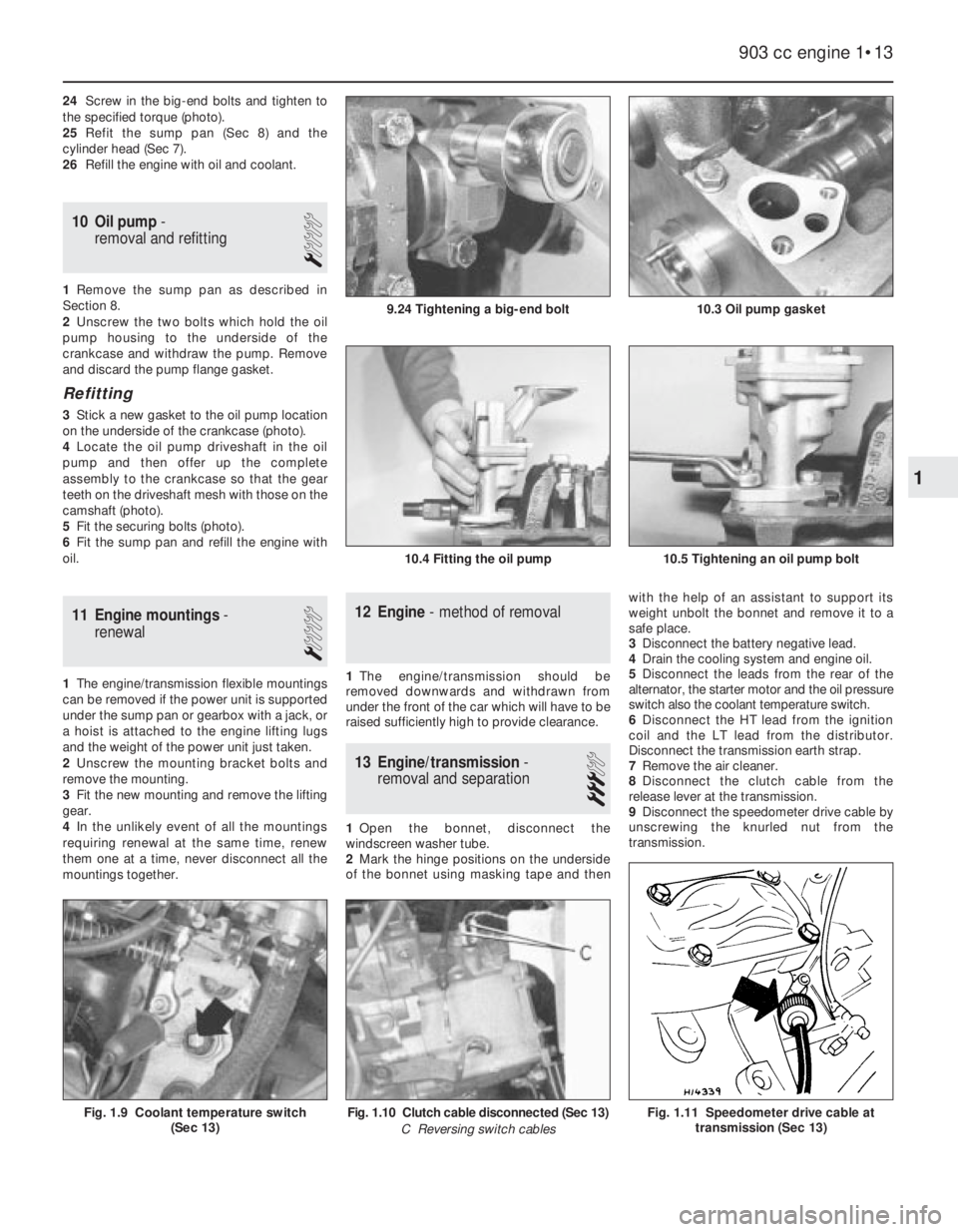

24Screw in the big-end bolts and tighten to

the specified torque (photo).

25Refit the sump pan (Sec 8) and the

cylinder head (Sec 7).

26Refill the engine with oil and coolant.

10 Oil pump-

removal and refitting

1

1Remove the sump pan as described in

Section 8.

2Unscrew the two bolts which hold the oil

pump housing to the underside of the

crankcase and withdraw the pump. Remove

and discard the pump flange gasket.

Refitting

3Stick a new gasket to the oil pump location

on the underside of the crankcase (photo).

4Locate the oil pump driveshaft in the oil

pump and then offer up the complete

assembly to the crankcase so that the gear

teeth on the driveshaft mesh with those on the

camshaft (photo).

5Fit the securing bolts (photo).

6Fit the sump pan and refill the engine with

oil.

11 Engine mountings-

renewal

1

1The engine/transmission flexible mountings

can be removed if the power unit is supported

under the sump pan or gearbox with a jack, or

a hoist is attached to the engine lifting lugs

and the weight of the power unit just taken.

2Unscrew the mounting bracket bolts and

remove the mounting.

3Fit the new mounting and remove the lifting

gear.

4In the unlikely event of all the mountings

requiring renewal at the same time, renew

them one at a time, never disconnect all the

mountings together.

12 Engine- method of removal

1The engine/transmission should be

removed downwards and withdrawn from

under the front of the car which will have to be

raised sufficiently high to provide clearance.

13 Engine/transmission-

removal and separation

3

1Open the bonnet, disconnect the

windscreen washer tube.

2Mark the hinge positions on the underside

of the bonnet using masking tape and thenwith the help of an assistant to support its

weight unbolt the bonnet and remove it to a

safe place.

3Disconnect the battery negative lead.

4Drain the cooling system and engine oil.

5Disconnect the leads from the rear of the

alternator, the starter motor and the oil pressure

switch also the coolant temperature switch.

6Disconnect the HT lead from the ignition

coil and the LT lead from the distributor.

Disconnect the transmission earth strap.

7Remove the air cleaner.

8Disconnect the clutch cable from the

release lever at the transmission.

9Disconnect the speedometer drive cable by

unscrewing the knurled nut from the

transmission.

903 cc engine 1•13

10.3 Oil pump gasket

10.4 Fitting the oil pump10.5 Tightening an oil pump bolt

9.24 Tightening a big-end bolt

Fig. 1.11 Speedometer drive cable at

transmission (Sec 13)Fig. 1.10 Clutch cable disconnected (Sec 13)

C Reversing switch cablesFig. 1.9 Coolant temperature switch

(Sec 13)

1

Page 41 of 303

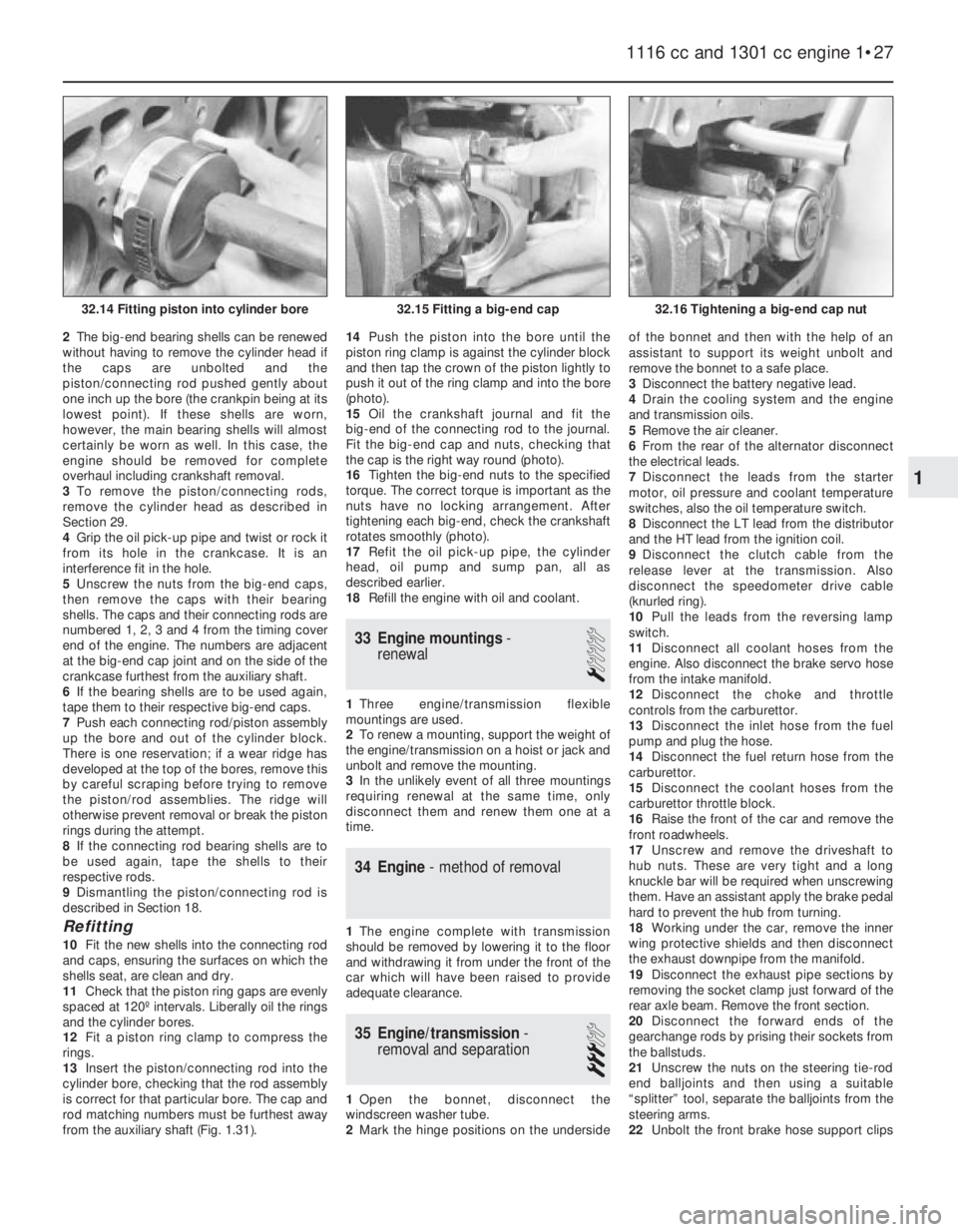

2The big-end bearing shells can be renewed

without having to remove the cylinder head if

the caps are unbolted and the

piston/connecting rod pushed gently about

one inch up the bore (the crankpin being at its

lowest point). If these shells are worn,

however, the main bearing shells will almost

certainly be worn as well. In this case, the

engine should be removed for complete

overhaul including crankshaft removal.

3To remove the piston/connecting rods,

remove the cylinder head as described in

Section 29.

4Grip the oil pick-up pipe and twist or rock it

from its hole in the crankcase. It is an

interference fit in the hole.

5Unscrew the nuts from the big-end caps,

then remove the caps with their bearing

shells. The caps and their connecting rods are

numbered 1, 2, 3 and 4 from the timing cover

end of the engine. The numbers are adjacent

at the big-end cap joint and on the side of the

crankcase furthest from the auxiliary shaft.

6If the bearing shells are to be used again,

tape them to their respective big-end caps.

7Push each connecting rod/piston assembly

up the bore and out of the cylinder block.

There is one reservation; if a wear ridge has

developed at the top of the bores, remove this

by careful scraping before trying to remove

the piston/rod assemblies. The ridge will

otherwise prevent removal or break the piston

rings during the attempt.

8If the connecting rod bearing shells are to

be used again, tape the shells to their

respective rods.

9Dismantling the piston/connecting rod is

described in Section 18.

Refitting

10Fit the new shells into the connecting rod

and caps, ensuring the surfaces on which the

shells seat, are clean and dry.

11Check that the piston ring gaps are evenly

spaced at 120º intervals. Liberally oil the rings

and the cylinder bores.

12Fit a piston ring clamp to compress the

rings.

13Insert the piston/connecting rod into the

cylinder bore, checking that the rod assembly

is correct for that particular bore. The cap and

rod matching numbers must be furthest away

from the auxiliary shaft (Fig. 1.31).14Push the piston into the bore until the

piston ring clamp is against the cylinder block

and then tap the crown of the piston lightly to

push it out of the ring clamp and into the bore

(photo).

15Oil the crankshaft journal and fit the

big-end of the connecting rod to the journal.

Fit the big-end cap and nuts, checking that

the cap is the right way round (photo).

16Tighten the big-end nuts to the specified

torque. The correct torque is important as the

nuts have no locking arrangement. After

tightening each big-end, check the crankshaft

rotates smoothly (photo).

17Refit the oil pick-up pipe, the cylinder

head, oil pump and sump pan, all as

described earlier.

18Refill the engine with oil and coolant.

33 Engine mountings-

renewal

1

1Three engine/transmission flexible

mountings are used.

2To renew a mounting, support the weight of

the engine/transmission on a hoist or jack and

unbolt and remove the mounting.

3In the unlikely event of all three mountings

requiring renewal at the same time, only

disconnect them and renew them one at a

time.

34 Engine- method of removal

1The engine complete with transmission

should be removed by lowering it to the floor

and withdrawing it from under the front of the

car which will have been raised to provide

adequate clearance.

35 Engine/transmission-

removal and separation

3

1Open the bonnet, disconnect the

windscreen washer tube.

2Mark the hinge positions on the undersideof the bonnet and then with the help of an

assistant to support its weight unbolt and

remove the bonnet to a safe place.

3Disconnect the battery negative lead.

4Drain the cooling system and the engine

and transmission oils.

5Remove the air cleaner.

6From the rear of the alternator disconnect

the electrical leads.

7Disconnect the leads from the starter

motor, oil pressure and coolant temperature

switches, also the oil temperature switch.

8Disconnect the LT lead from the distributor

and the HT lead from the ignition coil.

9Disconnect the clutch cable from the

release lever at the transmission. Also

disconnect the speedometer drive cable

(knurled ring).

10Pull the leads from the reversing lamp

switch.

11Disconnect all coolant hoses from the

engine. Also disconnect the brake servo hose

from the intake manifold.

12Disconnect the choke and throttle

controls from the carburettor.

13Disconnect the inlet hose from the fuel

pump and plug the hose.

14Disconnect the fuel return hose from the

carburettor.

15Disconnect the coolant hoses from the

carburettor throttle block.

16Raise the front of the car and remove the

front roadwheels.

17Unscrew and remove the driveshaft to

hub nuts. These are very tight and a long

knuckle bar will be required when unscrewing

them. Have an assistant apply the brake pedal

hard to prevent the hub from turning.

18Working under the car, remove the inner

wing protective shields and then disconnect

the exhaust downpipe from the manifold.

19Disconnect the exhaust pipe sections by

removing the socket clamp just forward of the

rear axle beam. Remove the front section.

20Disconnect the forward ends of the

gearchange rods by prising their sockets from

the ballstuds.

21Unscrew the nuts on the steering tie-rod

end balljoints and then using a suitable

“splitter” tool, separate the balljoints from the

steering arms.

22Unbolt the front brake hose support clips

1116 cc and 1301 cc engine 1•27

32.16 Tightening a big-end cap nut32.15 Fitting a big-end cap32.14 Fitting piston into cylinder bore

1

Page 48 of 303

to the engine. Also reconnect the brake servo

hose to the intake manifold (photos).

22Reconnect the leads to the reversing lamp

switch. Reconnect the transmission earth lead

(photos).

23Reconnect the clutch cable and adjust as

described in Chapter 5.

24Reconnect the speedometer drive cable

to the transmission and tighten the knurled

retaining ring.

25Reconnect the low tension lead to the

distributor and the high tension lead to the

ignition coil.

26Reconnnect the electrical leads to thestarter motor, the oil pressure and

temperature switches and the coolant

temperature switch.

27Connect the leads to the alternator.

28Refit the air cleaner.

29Refill the cooling system. Refill the engine

with oil.

30Reconnect the battery.

31Refit the bonnet and connect the

windscreen washer tube.

32Fit the inner wing protective shields

(photo).

45 Engine- initial start-up after

major overhaul

4

1If new bearings and rings have been fitted,

it is likely that the engine will be stiff to turn so

make sure the battery is well charged.

2Switch on the ignition and check that

appropriate warning lights come on.

3Start up the engine. If it refuses to start,

refer to the “Fault Finding” Section in the

Reference section of this Manual.

4Watch the oil pressure warning light and

alternator charging indicator light. If there is

no charge or if the oil pressure warning light

does not go out after a second or two, havinghad time to fill the new oil filter, switch off and

recheck.

5If the warning lights go out, set the engine

to run on fast idle and check the engine for

leaks.

6Check the coolant level; it will probably go

down as air locks are filled.

7Keep the engine running at a fast idle and

bring it up to normal working temperature. As

the engine warms up, there will be some odd

smells and smoke from parts getting hot and

burning off oil deposits.

8When the engine running temperature has

been reached, adjust the idling speed, as

described in Chapter 3. Check and, if

necessary, adjust the ignition timing using a

stroboscope (see Chapter 4).

9Stop the engine and wait a few minutes;

check to see if there are any coolant or oil

leaks.

10Road test the car to check that the engine

is running with the correct smoothness and

power. If it does not, refer to “Fault finding” in

the Reference section of this Manual. Do not

race the engine. If new bearings and/or

pistons and rings have been fitted, it should

be treated as a new engine and run it at

reduced speed for at east 800 km (500 miles).

11After 800 km (500 miles) change the

engine oil and filter.

1•34 1116 cc and 1301 cc engine

44.32 Inner wing protective shield44.26B Coolant temperature switch44.26A Oil pressure warning switch

44.22B Transmission earth lead

44.22A Reversing lamp switch on

transmission44.21B Brake servo hose at manifold44.21A Heater hose at manifold

Page 49 of 303

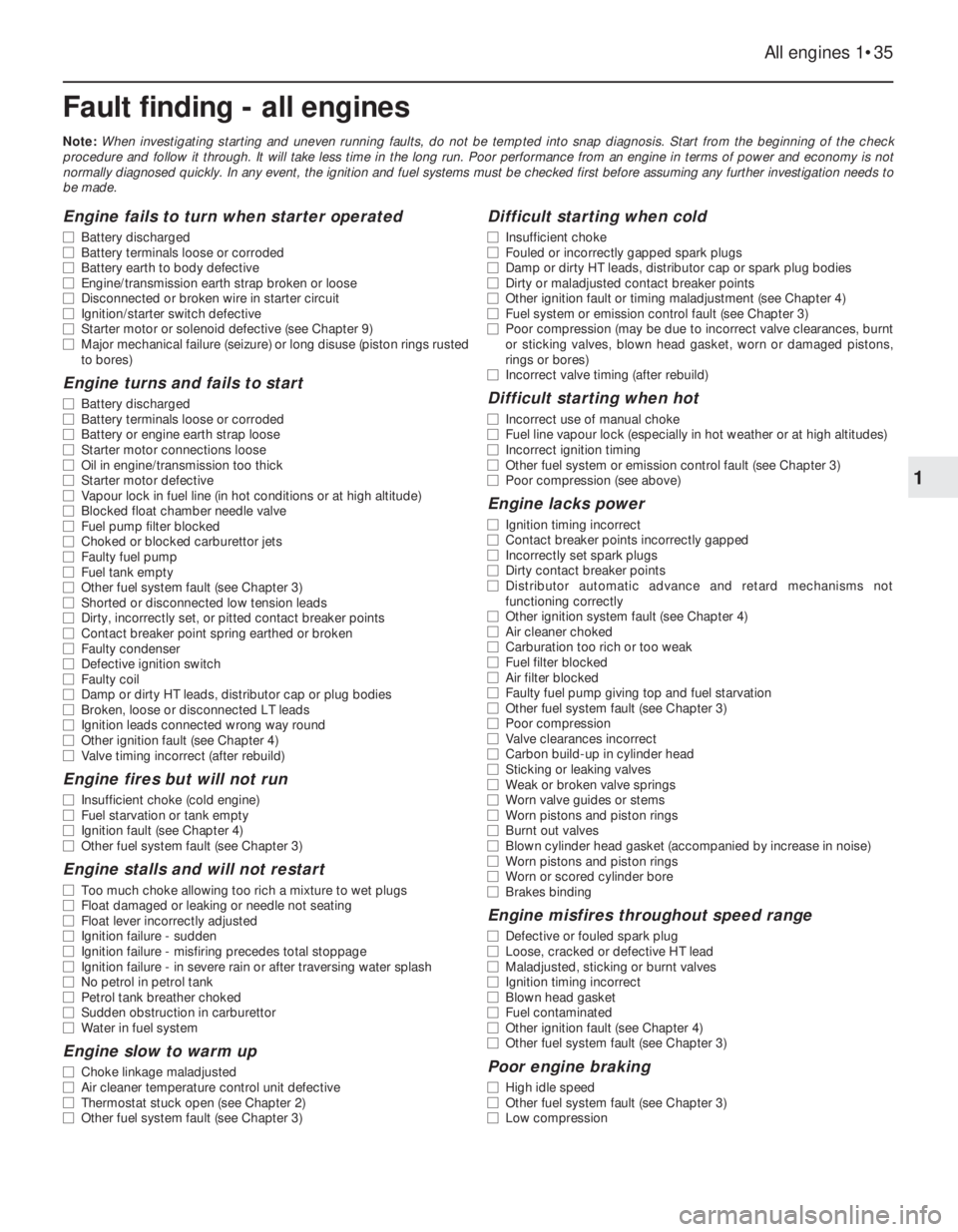

Fault finding - all engines

Note: When investigating starting and uneven running faults, do not be tempted into snap diagnosis. Start from the beginning of the check

procedure and follow it through. It will take less time in the long run. Poor performance from an engine in terms of power and economy is not

normally diagnosed quickly. In any event, the ignition and fuel systems must be checked first before assuming any further investigation needs to

be made.

All engines 1•35

1

Engine fails to turn when starter operated

m mBattery discharged

m mBattery terminals loose or corroded

m mBattery earth to body defective

m mEngine/transmission earth strap broken or loose

m mDisconnected or broken wire in starter circuit

m mIgnition/starter switch defective

m mStarter motor or solenoid defective (see Chapter 9)

m mMajor mechanical failure (seizure) or long disuse (piston rings rusted

to bores)

Engine turns and fails to start

m mBattery discharged

m mBattery terminals loose or corroded

m mBattery or engine earth strap loose

m mStarter motor connections loose

m mOil in engine/transmission too thick

m mStarter motor defective

m mVapour lock in fuel line (in hot conditions or at high altitude)

m mBlocked float chamber needle valve

m mFuel pump filter blocked

m mChoked or blocked carburettor jets

m mFaulty fuel pump

m mFuel tank empty

m mOther fuel system fault (see Chapter 3)

m mShorted or disconnected low tension leads

m mDirty, incorrectly set, or pitted contact breaker points

m mContact breaker point spring earthed or broken

m mFaulty condenser

m mDefective ignition switch

m mFaulty coil

m mDamp or dirty HT leads, distributor cap or plug bodies

m mBroken, loose or disconnected LT leads

m mIgnition leads connected wrong way round

m mOther ignition fault (see Chapter 4)

m mValve timing incorrect (after rebuild)

Engine fires but will not run

m

mInsufficient choke (cold engine)

m mFuel starvation or tank empty

m mIgnition fault (see Chapter 4)

m mOther fuel system fault (see Chapter 3)

Engine stalls and will not restart

m

mToo much choke allowing too rich a mixture to wet plugs

m mFloat damaged or leaking or needle not seating

m mFloat lever incorrectly adjusted

m mIgnition failure - sudden

m mIgnition failure - misfiring precedes total stoppage

m mIgnition failure - in severe rain or after traversing water splash

m mNo petrol in petrol tank

m mPetrol tank breather choked

m mSudden obstruction in carburettor

m mWater in fuel system

Engine slow to warm up

m

mChoke linkage maladjusted

m mAir cleaner temperature control unit defective

m mThermostat stuck open (see Chapter 2)

m mOther fuel system fault (see Chapter 3)

Difficult starting when cold

m

mInsufficient choke

m mFouled or incorrectly gapped spark plugs

m mDamp or dirty HT leads, distributor cap or spark plug bodies

m mDirty or maladjusted contact breaker points

m mOther ignition fault or timing maladjustment (see Chapter 4)

m mFuel system or emission control fault (see Chapter 3)

m mPoor compression (may be due to incorrect valve clearances, burnt

or sticking valves, blown head gasket, worn or damaged pistons,

rings or bores)

m mIncorrect valve timing (after rebuild)

Difficult starting when hot

m

mIncorrect use of manual choke

m mFuel line vapour lock (especially in hot weather or at high altitudes)

m mIncorrect ignition timing

m mOther fuel system or emission control fault (see Chapter 3)

m mPoor compression (see above)

Engine lacks power

m

mIgnition timing incorrect

m mContact breaker points incorrectly gapped

m mIncorrectly set spark plugs

m mDirty contact breaker points

m mDistributor automatic advance and retard mechanisms not

functioning correctly

m mOther ignition system fault (see Chapter 4)

m mAir cleaner choked

m mCarburation too rich or too weak

m mFuel filter blocked

m mAir filter blocked

m mFaulty fuel pump giving top and fuel starvation

m mOther fuel system fault (see Chapter 3)

m mPoor compression

m mValve clearances incorrect

m mCarbon build-up in cylinder head

m mSticking or leaking valves

m mWeak or broken valve springs

m mWorn valve guides or stems

m mWorn pistons and piston rings

m mBurnt out valves

m mBlown cylinder head gasket (accompanied by increase in noise)

m mWorn pistons and piston rings

m mWorn or scored cylinder bore

m mBrakes binding

Engine misfires throughout speed range

m

mDefective or fouled spark plug

m mLoose, cracked or defective HT lead

m mMaladjusted, sticking or burnt valves

m mIgnition timing incorrect

m mBlown head gasket

m mFuel contaminated

m mOther ignition fault (see Chapter 4)

m mOther fuel system fault (see Chapter 3)

Poor engine braking

m

mHigh idle speed

m mOther fuel system fault (see Chapter 3)

m mLow compression