radiator cap FIAT UNO 1983 Service User Guide

[x] Cancel search | Manufacturer: FIAT, Model Year: 1983, Model line: UNO, Model: FIAT UNO 1983Pages: 303, PDF Size: 10.36 MB

Page 180 of 303

Coolant pump -

removal and refitting#

11The coolant pump is located on the

crankshaft pulley end of the engine and is

driven by the timing belt.

12The pump cannot be repaired and must

be regarded as disposable.

13Drain the cooling system.

14Remove the timing belt cover and then set

No. 1 piston to TDC. To achieve this, turn the

crankshaft pulley bolt until the camshaft

sprocket timing mark is aligned with the one

on the cylinder head.

15Release the belt tensioner and slip the

timing belt off the camshaft and coolant pump

sprockets.

16Unbolt and remove the coolant pump and

clean the mounting face of all old gasket

material.

17Apply a continuous bead of RTV silicone

sealant (instant gasket) to the mounting face

of the coolant pump and bolt it into position

(photos).

18Check that the camshaft sprocket and the

crankshaft have not been moved and fit the

timing belt to the camshaft and coolant pump

sprockets. The pump sprocket does not

require setting in any particular position

before connecting the timing belt.

19Tension the belt as described in Sec-

tion 5B of this Chapter.

20Fit the timing belt cover.

21After allowing one hour for the gasket

material to cure, refill and bleed the cooling

system.

PART B:

1301 CC TURBO IE ENGINE

Description

1The cooling system on this model has flow

and return connections to the turbocharger,

and is an essential means of cooling the

turbocharger.

2The radiator cooling fan is of two-speed

type, being controlled by a two-stage

thermostatic switch screwed into the radiator

side tank.

3According to the coolant temperature level,

the fan speed is regulated to provide the most

effective cooling.

4The remote cooling system expansion tank

is mounted in the left-hand rear corner of the

engine compartment (photo).

PART C:

1372 CC IE AND 1372 CC

TURBO IE ENGINES

Description

1The cooling system layout and components

for the 1372 cc engines is shown in

Figs. 13.29 and 13.30.

2The system on each engine operates in

essentially the same manner as that

described for the other models in Chapter 2,

but the location of components and the

coolant hose routings differ according to

model. The cooling system expansion tank

location differs according to model, being

either located on the side of the radiator ormounted separately on the side of the inner

wing panel.

3On Turbo models, the cooling system also

assists in cooling the turbocharger.

Maintenance

4The maintenance procedures are

essentially the same as those described for

the other models in Chapter 2.

Cooling system - draining,

flushing and refillingÁ

Warning: Wait until the engine is

cold before starting this

procedure. Do not allow

antifreeze to come into contact

with your skin or painted surfaces of the

vehicle. Rinse off spills immediately with

plenty of water. Never leave antifreeze

lying around in an open container or in a

puddle in the driveway or on the garage

floor. Children and pets are attracted by its

sweet smell. Antifreeze is fatal if ingested.

5Disconnect the battery negative lead.

6Working inside the vehicle, turn the heater

temperature control knob fully to the right,

which will fully open the heater coolant valve.

7With the expansion tank cap removed,

place a suitable container beneath the

radiator bottom hose.

8Loosen the clip and ease the bottom hose

away from the radiator outlet (photo). Allow

the coolant to drain into the container.

9Reposition the container under the front of

the cylinder block, and unscrew the cylinder

block drain plug (photo). Allow the coolant to

drain into the container.

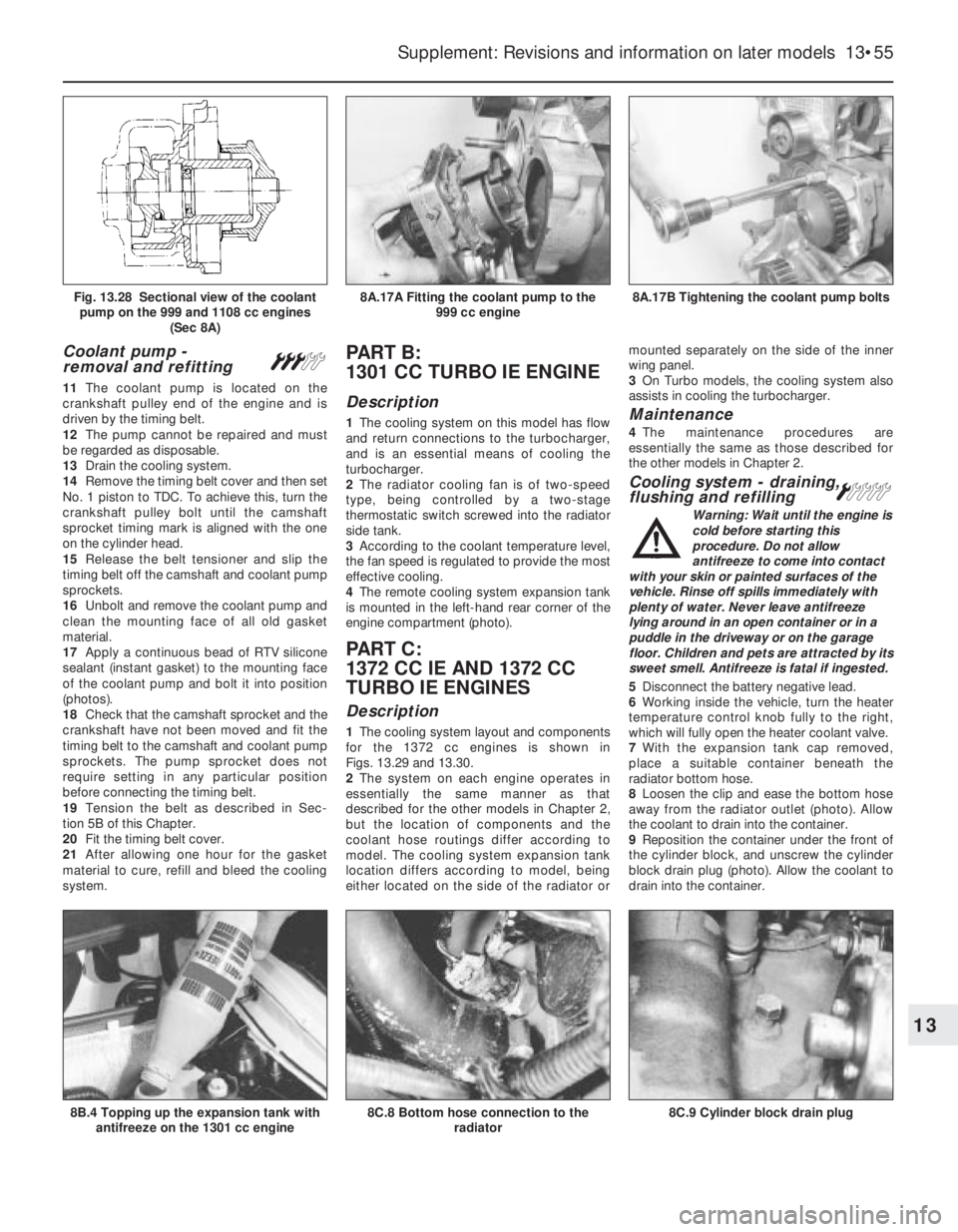

Supplement: Revisions and information on later models 13•55

8A.17B Tightening the coolant pump bolts8A.17A Fitting the coolant pump to the

999 cc engineFig. 13.28 Sectional view of the coolant

pump on the 999 and 1108 cc engines

(Sec 8A)

8C.9 Cylinder block drain plug8C.8 Bottom hose connection to the

radiator8B.4 Topping up the expansion tank with

antifreeze on the 1301 cc engine

13

Page 182 of 303

10Apply suitable sealant to the threads of

the drain plug, then refit and tighten the plug.

11Dispose of the drained coolant safely, or

keep it in a covered container if it is to be

re-used.

12If required, the system can be flushed

through as described in Section 2 of Chap-

ter 2.

13Before attempting to refill the cooling

system, make sure that all hoses have been

reconnected, that the hoses and clips are in

good condition, and that the clips are tight.

Also ensure that the cylinder block drain plug

has been refitted and tightened. Note that an

antifreeze mixture must be used all year round

to prevent corrosion of the engine

components - refer to Section 3, Chapter 2.

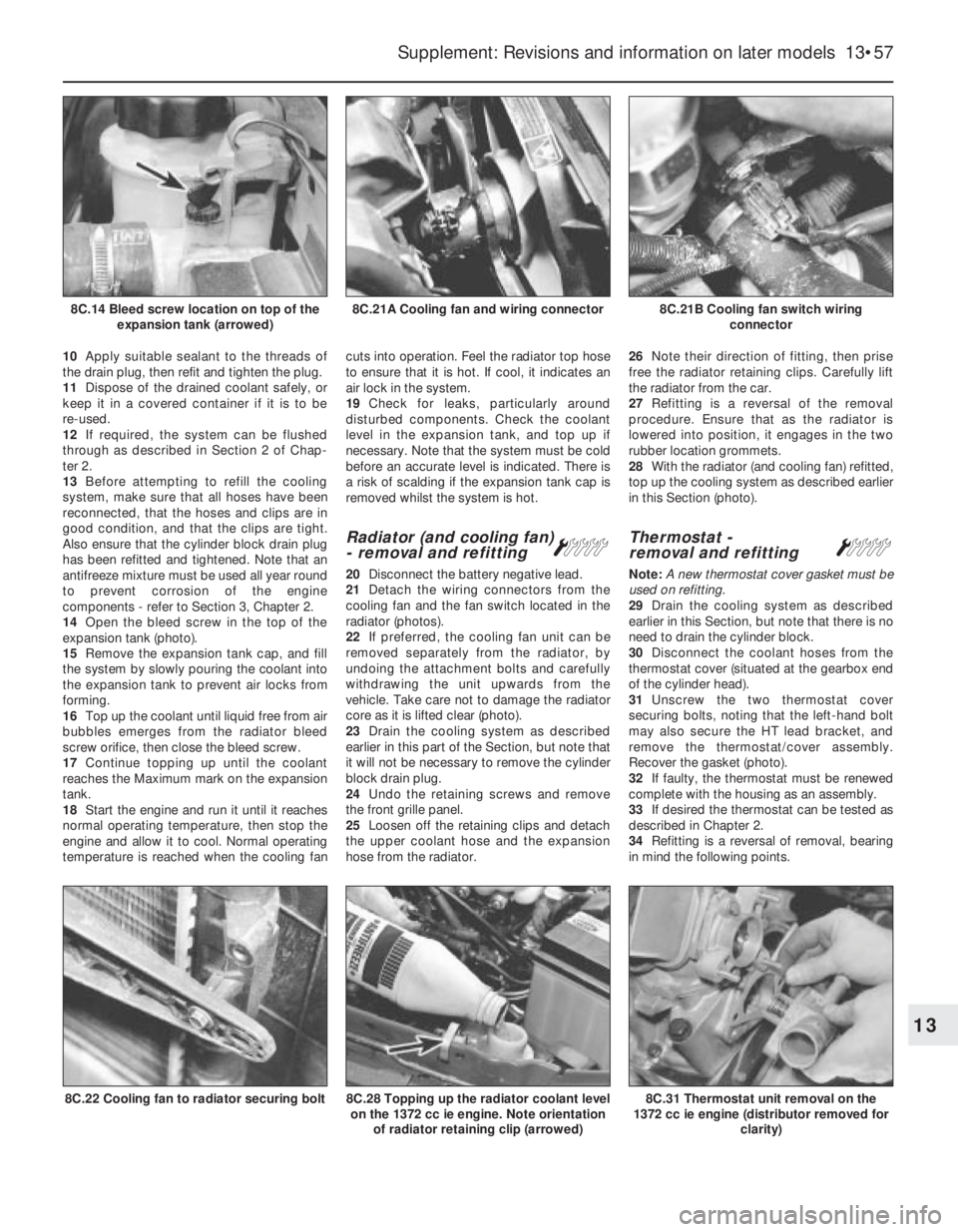

14Open the bleed screw in the top of the

expansion tank (photo).

15Remove the expansion tank cap, and fill

the system by slowly pouring the coolant into

the expansion tank to prevent air locks from

forming.

16Top up the coolant until liquid free from air

bubbles emerges from the radiator bleed

screw orifice, then close the bleed screw.

17Continue topping up until the coolant

reaches the Maximum mark on the expansion

tank.

18Start the engine and run it until it reaches

normal operating temperature, then stop the

engine and allow it to cool. Normal operating

temperature is reached when the cooling fancuts into operation. Feel the radiator top hose

to ensure that it is hot. If cool, it indicates an

air lock in the system.

19Check for leaks, particularly around

disturbed components. Check the coolant

level in the expansion tank, and top up if

necessary. Note that the system must be cold

before an accurate level is indicated. There is

a risk of scalding if the expansion tank cap is

removed whilst the system is hot.

Radiator (and cooling fan)

- removal and refitting Á

20Disconnect the battery negative lead.

21Detach the wiring connectors from the

cooling fan and the fan switch located in the

radiator (photos).

22If preferred, the cooling fan unit can be

removed separately from the radiator, by

undoing the attachment bolts and carefully

withdrawing the unit upwards from the

vehicle. Take care not to damage the radiator

core as it is lifted clear (photo).

23Drain the cooling system as described

earlier in this part of the Section, but note that

it will not be necessary to remove the cylinder

block drain plug.

24Undo the retaining screws and remove

the front grille panel.

25Loosen off the retaining clips and detach

the upper coolant hose and the expansion

hose from the radiator.26Note their direction of fitting, then prise

free the radiator retaining clips. Carefully lift

the radiator from the car.

27Refitting is a reversal of the removal

procedure. Ensure that as the radiator is

lowered into position, it engages in the two

rubber location grommets.

28With the radiator (and cooling fan) refitted,

top up the cooling system as described earlier

in this Section (photo).

Thermostat -

removal and refitting Á

Note: A new thermostat cover gasket must be

used on refitting.

29Drain the cooling system as described

earlier in this Section, but note that there is no

need to drain the cylinder block.

30Disconnect the coolant hoses from the

thermostat cover (situated at the gearbox end

of the cylinder head).

31Unscrew the two thermostat cover

securing bolts, noting that the left-hand bolt

may also secure the HT lead bracket, and

remove the thermostat/cover assembly.

Recover the gasket (photo).

32If faulty, the thermostat must be renewed

complete with the housing as an assembly.

33If desired the thermostat can be tested as

described in Chapter 2.

34Refitting is a reversal of removal, bearing

in mind the following points.

Supplement: Revisions and information on later models 13•57

8C.21B Cooling fan switch wiring

connector8C.21A Cooling fan and wiring connector8C.14 Bleed screw location on top of the

expansion tank (arrowed)

8C.31 Thermostat unit removal on the

1372 cc ie engine (distributor removed for

clarity)8C.28 Topping up the radiator coolant level

on the 1372 cc ie engine. Note orientation

of radiator retaining clip (arrowed)8C.22 Cooling fan to radiator securing bolt

13

Page 238 of 303

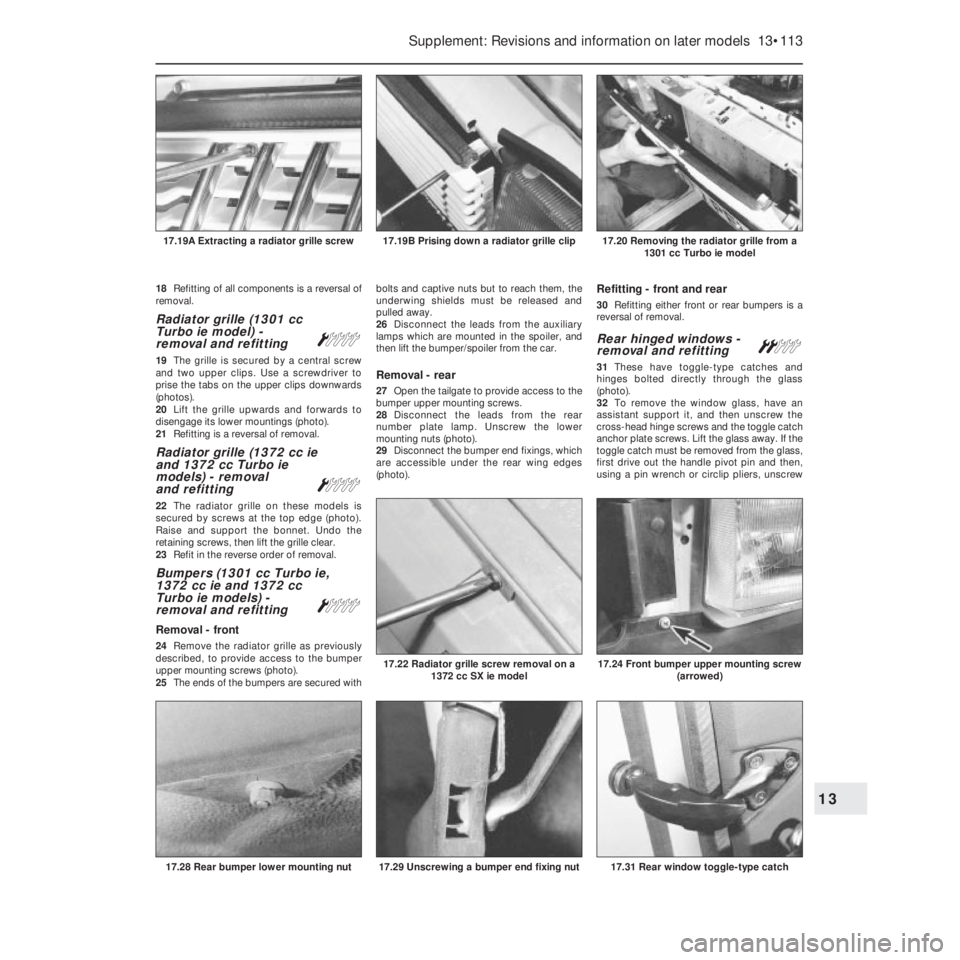

18Refitting of all components is a reversal of

removal.

Radiator grille (1301 cc

Turbo ie model) -

removal and refitting

Á

19The grille is secured by a central screw

and two upper clips. Use a screwdriver to

prise the tabs on the upper clips downwards

(photos).

20Lift the grille upwards and forwards to

disengage its lower mountings (photo).

21Refitting is a reversal of removal.

Radiator grille (1372 cc ie

and 1372 cc Turbo ie

models) - removal

and refitting

Á

22The radiator grille on these models is

secured by screws at the top edge (photo).

Raise and support the bonnet. Undo the

retaining screws, then lift the grille clear.

23Refit in the reverse order of removal.

Bumpers (1301 cc Turbo ie,

1372 cc ie and 1372 cc

Turbo ie models) -

removal and refitting

Á

Removal - front

24Remove the radiator grille as previously

described, to provide access to the bumper

upper mounting screws (photo).

25The ends of the bumpers are secured withbolts and captive nuts but to reach them, the

underwing shields must be released and

pulled away.

26Disconnect the leads from the auxiliary

lamps which are mounted in the spoiler, and

then lift the bumper/spoiler from the car.

Removal - rear

27Open the tailgate to provide access to the

bumper upper mounting screws.

28Disconnect the leads from the rear

number plate lamp. Unscrew the lower

mounting nuts (photo).

29Disconnect the bumper end fixings, which

are accessible under the rear wing edges

(photo).

Refitting - front and rear

30Refitting either front or rear bumpers is a

reversal of removal.

Rear hinged windows -

removal and refittingª

31These have toggle-type catches and

hinges bolted directly through the glass

(photo).

32To remove the window glass, have an

assistant support it, and then unscrew the

cross-head hinge screws and the toggle catch

anchor plate screws. Lift the glass away. If the

toggle catch must be removed from the glass,

first drive out the handle pivot pin and then,

using a pin wrench or circlip pliers, unscrew

Supplement: Revisions and information on later models 13•113

17.20 Removing the radiator grille from a

1301 cc Turbo ie model17.19B Prising down a radiator grille clip17.19A Extracting a radiator grille screw

17.31 Rear window toggle-type catch17.29 Unscrewing a bumper end fixing nut

17.24 Front bumper upper mounting screw

(arrowed)17.22 Radiator grille screw removal on a

1372 cc SX ie model

17.28 Rear bumper lower mounting nut

13

Page 293 of 303

Engine fails to turn when starter

operated

m mFlat battery (recharge use jump leads or

push start)

m mBattery terminals loose or corroded

m mBattery earth to body defective

m mEngine earth strap loose or broken

m mStarter motor (or solenoid) wiring loose or

broken

m mIgnition/starter switch faulty

m mMajor mechanical failure (seizure)

m mStarter or solenoid internal fault (see

Chapter 12)

Starter motor turns engine slowly

m mPartially discharged battery (recharge, use

jump leads, or push start)

m mBattery terminals loose or corroded

m mBattery earth to body defective

m mEngine earth strap loose m mStarter motor (or solenoid) wiring loose

m mStarter motor internal fault (see Chapter 9)

Starter motor spins without

turning engine

m mFlywheel gear teeth damaged or worn

m mStarter motor mounting bolts loose

Engine turns normally but fails to

start

m mDamp or dirty HT leads and distributor cap

(crank engine and check for spark)

m mNo fuel in tank (check for delivery at

carburettor) m mExcessive choke (hot engine) or insufficient

choke (cold engine)

m mFouled or incorrectly gapped spark plugs

(remove, clean and regap)

m mOther ignition system fault (see Chapter 4)

m mOther fuel system fault (see Chapter 3)

m mPoor compression (see Chapter 1)

m mMajor mechanical failure (eg camshaft drive)

Engine fires but will not run

m

mInsufficient choke (cold engine)

m mAir leaks at carburettor or inlet manifold

m mFuel starvation (see Chapter 3)

m mIgnition fault (see Chapter 4)

Engine will not start

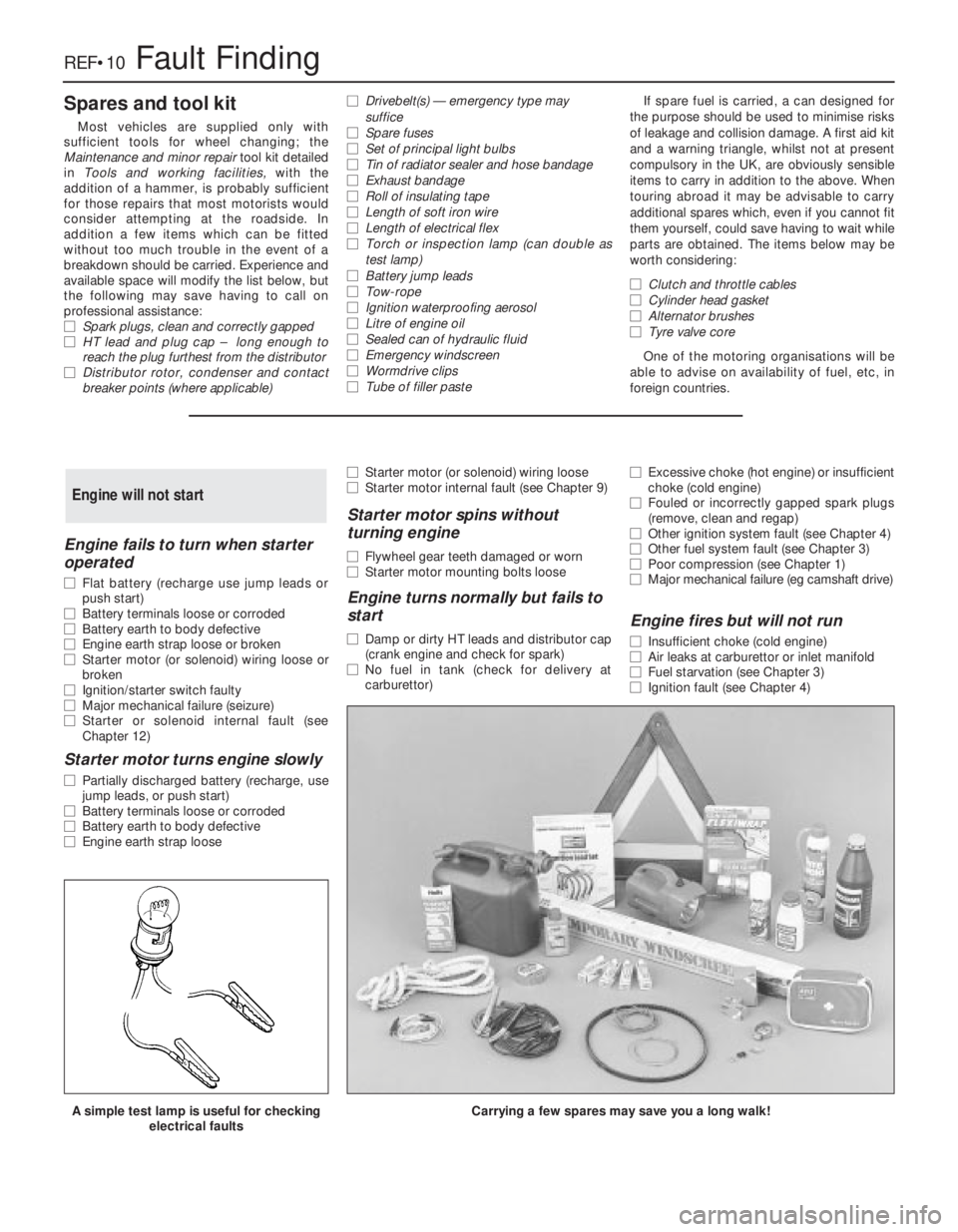

REF•10Fault Finding

Spares and tool kit

Most vehicles are supplied only with

sufficient tools for wheel changing; the

Maintenance and minor repairtool kit detailed

in Tools and working facilities,with the

addition of a hammer, is probably sufficient

for those repairs that most motorists would

consider attempting at the roadside. In

addition a few items which can be fitted

without too much trouble in the event of a

breakdown should be carried. Experience and

available space will modify the list below, but

the following may save having to call on

professional assistance:

m mSpark plugs, clean and correctly gapped

m mHT lead and plug cap – long enough to

reach the plug furthest from the distributor

m mDistributor rotor, condenser and contact

breaker points (where applicable)m mDrivebelt(s) — emergency type may

suffice

m mSpare fuses

m mSet of principal light bulbs

m mTin of radiator sealer and hose bandage

m mExhaust bandage

m mRoll of insulating tape

m mLength of soft iron wire

m mLength of electrical flex

m mTorch or inspection lamp (can double as

test lamp)

m mBattery jump leads

m mTow-rope

m mIgnition waterproofing aerosol

m mLitre of engine oil

m mSealed can of hydraulic fluid

m mEmergency windscreen

m mWormdrive clips

m mTube of filler pasteIf spare fuel is carried, a can designed for

the purpose should be used to minimise risks

of leakage and collision damage. A first aid kit

and a warning triangle, whilst not at present

compulsory in the UK, are obviously sensible

items to carry in addition to the above. When

touring abroad it may be advisable to carry

additional spares which, even if you cannot fit

them yourself, could save having to wait while

parts are obtained. The items below may be

worth considering:

m mClutch and throttle cables

m mCylinder head gasket

m mAlternator brushes

m mTyre valve core

One of the motoring organisations will be

able to advise on availability of fuel, etc, in

foreign countries.

A simple test lamp is useful for checking

electrical faultsCarrying a few spares may save you a long walk!

Page 294 of 303

Engine cuts out suddenly –

ignition fault

m mLoose or disconnected LT wires

m mWet HT leads or distributor cap (after

traversing water splash)

m mCoil failure (check for spark)

m mOther ignition fault (see Chapter 4)

Engine misfires before cutting out

– fuel fault

m mFuel tank empty

m mFuel pump defective or filter blocked

(check for delivery)

m mFuel tank filler vent blocked (suction will be

evident on releasing cap)

m mCarburettor needle valve sticking

m mCarburettor jets blocked (fuel contami-

nated)

m mOther fuel system fault (see Chapter 3)

Engine cuts out – other causes

m

mSerious overheating

m mMajor mechanical failure (eg camshaft

drive)

Ignition (no-charge) warning light

illuminated

m mSlack or broken drivebelt — retension or

renew (Chapter 9)

Ignition warning light not

illuminated

m mCoolant loss due to internal or external

leakage (see Chapter 2)

m mThermostat defective

m mLow oil level

m mBrakes binding

m mRadiator clogged externally or internally

m mElectric cooling fan not operating correctly

m mEngine waterways clogged

m mIgnition timing incorrect or automatic

advance malfunctioning

m mMixture too weak

Note: Do not add cold water to an overheated

engine or damage may result

Note: Low oil pressure in a high-mileage

engine at tickover is not necessarily a cause

for concern. Sudden pressure loss at speed is

far more significant. In any event check the

gauge or warning light sender before

condemning the engine.

Gauge reads low or warning light

illuminated with engine running

m mOil level low or incorrect grade

m mDefective gauge or sender unit m mWire to sender unit earthed

m mEngine overheating

m mOil filter clogged or bypass valve defective

m mOil pressure relief valve defective

m mOil pick-up strainer clogged

m mOil pump worn or mountings loose

m mWorn main or big-end bearings

Pre-ignition (pinking) on

acceleration

m mIncorrect grade of fuel

m mIgnition timing incorrect

m mDistributor faulty or worn

m mWorn or maladjusted carburettor

m mExcessive carbon build-up in engine

Whistling or wheezing noises

m

mLeaking vacuum hose

m mLeaking carburettor or manifold gasket

m mBlowing head gasket

Tapping or rattling

m

mIncorrect valve clearances (where appli-

cable)

m mWorn valve gear

m mWorn timing chain or belt

m mBroken piston ring (ticking noise)

Knocking or thumping

m

mUnintentional mechanical contact (eg fan

blades)

m mWorn drivebelt

m mPeripheral component fault (generator,

water pump, etc)

m mWorn big-end bearings (regular heavy

knocking, perhaps less under load)

m mWorn main bearings (rumbling and

knocking, perhaps worsening under load)

m mPiston slap (most noticeable when cold)

Engine noises

Low engine oil pressure

Engine overheatsEngine cuts out and will not restart

Fault FindingREF•11

REF

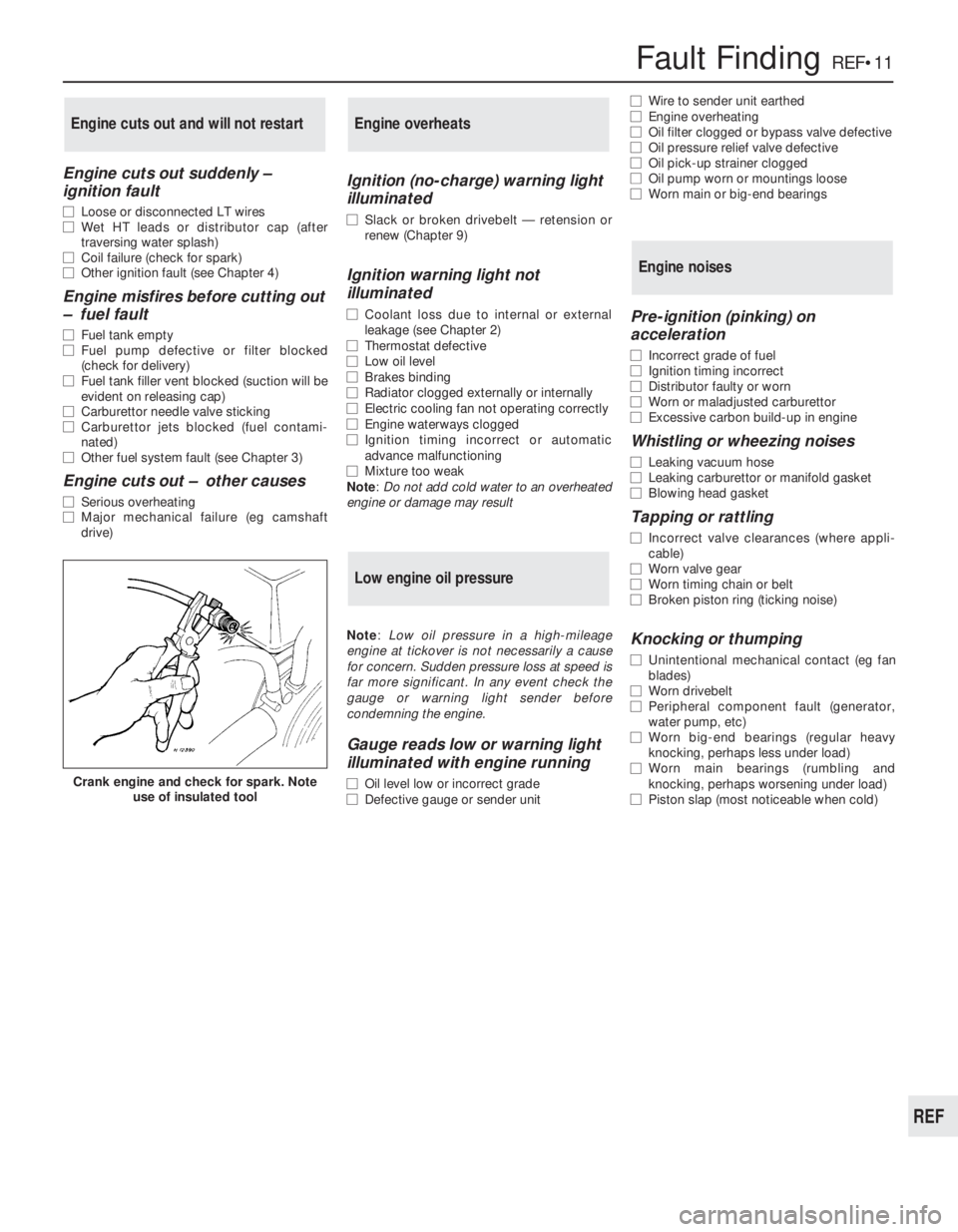

Crank engine and check for spark. Note

use of insulated tool

Page 298 of 303

Glossary of Technical TermsREF•15

REF

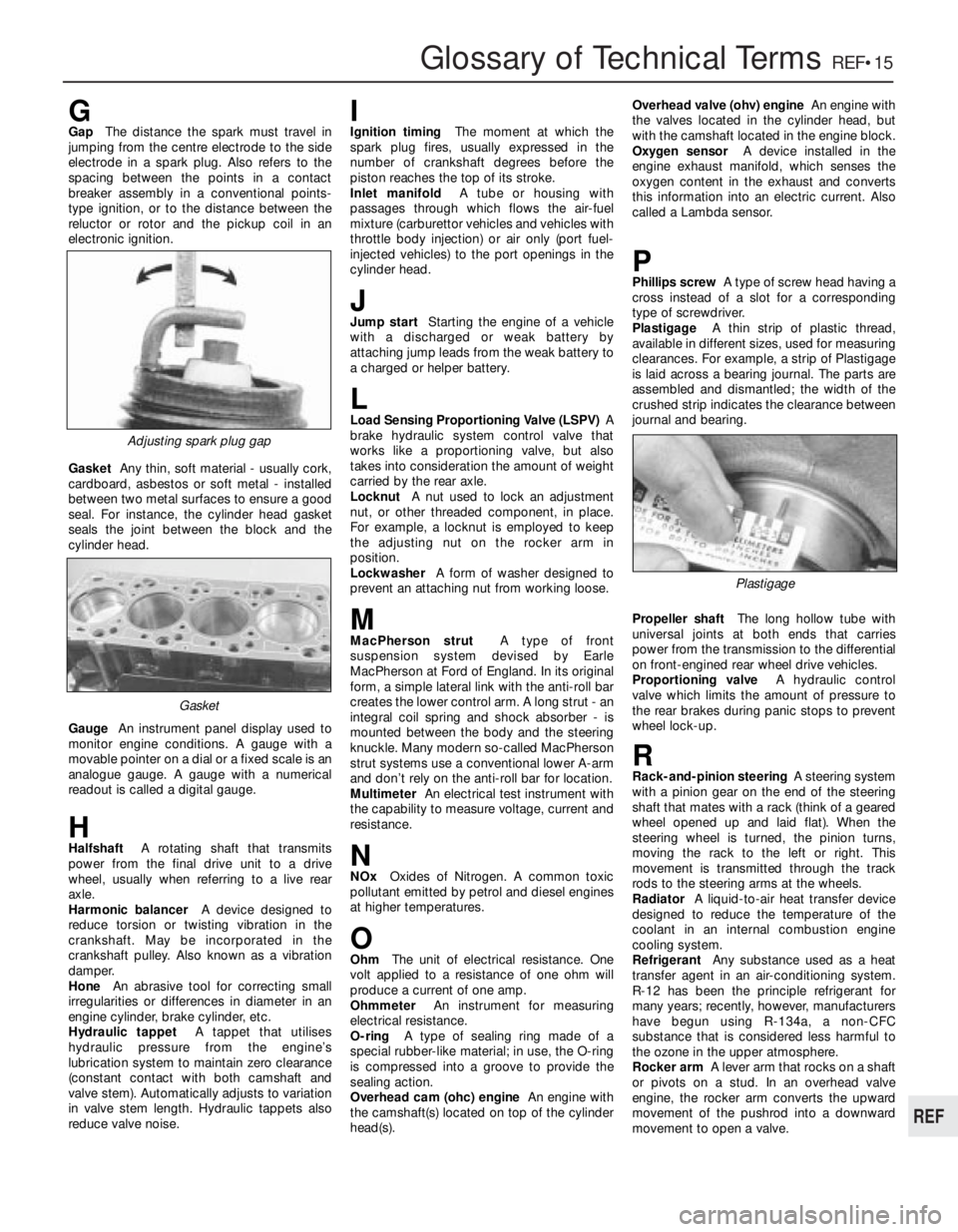

GGapThe distance the spark must travel in

jumping from the centre electrode to the side

electrode in a spark plug. Also refers to the

spacing between the points in a contact

breaker assembly in a conventional points-

type ignition, or to the distance between the

reluctor or rotor and the pickup coil in an

electronic ignition.

GasketAny thin, soft material - usually cork,

cardboard, asbestos or soft metal - installed

between two metal surfaces to ensure a good

seal. For instance, the cylinder head gasket

seals the joint between the block and the

cylinder head.

GaugeAn instrument panel display used to

monitor engine conditions. A gauge with a

movable pointer on a dial or a fixed scale is an

analogue gauge. A gauge with a numerical

readout is called a digital gauge.

HHalfshaftA rotating shaft that transmits

power from the final drive unit to a drive

wheel, usually when referring to a live rear

axle.

Harmonic balancerA device designed to

reduce torsion or twisting vibration in the

crankshaft. May be incorporated in the

crankshaft pulley. Also known as a vibration

damper.

HoneAn abrasive tool for correcting small

irregularities or differences in diameter in an

engine cylinder, brake cylinder, etc.

Hydraulic tappetA tappet that utilises

hydraulic pressure from the engine’s

lubrication system to maintain zero clearance

(constant contact with both camshaft and

valve stem). Automatically adjusts to variation

in valve stem length. Hydraulic tappets also

reduce valve noise.

IIgnition timingThe moment at which the

spark plug fires, usually expressed in the

number of crankshaft degrees before the

piston reaches the top of its stroke.

Inlet manifoldA tube or housing with

passages through which flows the air-fuel

mixture (carburettor vehicles and vehicles with

throttle body injection) or air only (port fuel-

injected vehicles) to the port openings in the

cylinder head.

JJump startStarting the engine of a vehicle

with a discharged or weak battery by

attaching jump leads from the weak battery to

a charged or helper battery.

LLoad Sensing Proportioning Valve (LSPV)A

brake hydraulic system control valve that

works like a proportioning valve, but also

takes into consideration the amount of weight

carried by the rear axle.

LocknutA nut used to lock an adjustment

nut, or other threaded component, in place.

For example, a locknut is employed to keep

the adjusting nut on the rocker arm in

position.

LockwasherA form of washer designed to

prevent an attaching nut from working loose.

MMacPherson strutA type of front

suspension system devised by Earle

MacPherson at Ford of England. In its original

form, a simple lateral link with the anti-roll bar

creates the lower control arm. A long strut - an

integral coil spring and shock absorber - is

mounted between the body and the steering

knuckle. Many modern so-called MacPherson

strut systems use a conventional lower A-arm

and don’t rely on the anti-roll bar for location.

MultimeterAn electrical test instrument with

the capability to measure voltage, current and

resistance.

NNOxOxides of Nitrogen. A common toxic

pollutant emitted by petrol and diesel engines

at higher temperatures.

OOhmThe unit of electrical resistance. One

volt applied to a resistance of one ohm will

produce a current of one amp.

OhmmeterAn instrument for measuring

electrical resistance.

O-ringA type of sealing ring made of a

special rubber-like material; in use, the O-ring

is compressed into a groove to provide the

sealing action.

Overhead cam (ohc) engineAn engine with

the camshaft(s) located on top of the cylinder

head(s).Overhead valve (ohv) engineAn engine with

the valves located in the cylinder head, but

with the camshaft located in the engine block.

Oxygen sensorA device installed in the

engine exhaust manifold, which senses the

oxygen content in the exhaust and converts

this information into an electric current. Also

called a Lambda sensor.

PPhillips screwA type of screw head having a

cross instead of a slot for a corresponding

type of screwdriver.

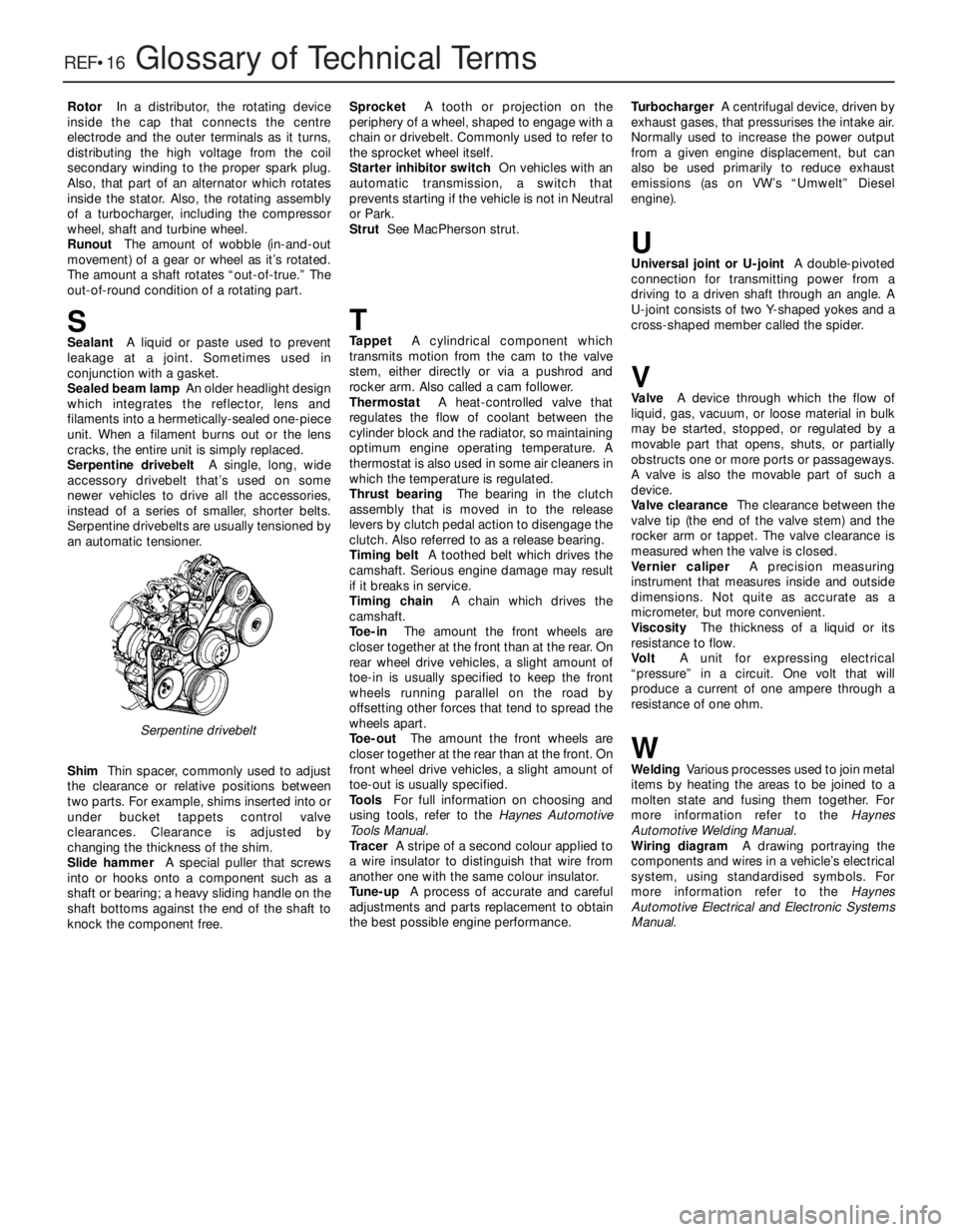

PlastigageA thin strip of plastic thread,

available in different sizes, used for measuring

clearances. For example, a strip of Plastigage

is laid across a bearing journal. The parts are

assembled and dismantled; the width of the

crushed strip indicates the clearance between

journal and bearing.

Propeller shaftThe long hollow tube with

universal joints at both ends that carries

power from the transmission to the differential

on front-engined rear wheel drive vehicles.

Proportioning valveA hydraulic control

valve which limits the amount of pressure to

the rear brakes during panic stops to prevent

wheel lock-up.

RRack-and-pinion steeringA steering system

with a pinion gear on the end of the steering

shaft that mates with a rack (think of a geared

wheel opened up and laid flat). When the

steering wheel is turned, the pinion turns,

moving the rack to the left or right. This

movement is transmitted through the track

rods to the steering arms at the wheels.

RadiatorA liquid-to-air heat transfer device

designed to reduce the temperature of the

coolant in an internal combustion engine

cooling system.

RefrigerantAny substance used as a heat

transfer agent in an air-conditioning system.

R-12 has been the principle refrigerant for

many years; recently, however, manufacturers

have begun using R-134a, a non-CFC

substance that is considered less harmful to

the ozone in the upper atmosphere.

Rocker armA lever arm that rocks on a shaft

or pivots on a stud. In an overhead valve

engine, the rocker arm converts the upward

movement of the pushrod into a downward

movement to open a valve.

Adjusting spark plug gap

Plastigage

Gasket

Page 299 of 303

REF•16Glossary of Technical Terms

RotorIn a distributor, the rotating device

inside the cap that connects the centre

electrode and the outer terminals as it turns,

distributing the high voltage from the coil

secondary winding to the proper spark plug.

Also, that part of an alternator which rotates

inside the stator. Also, the rotating assembly

of a turbocharger, including the compressor

wheel, shaft and turbine wheel.

RunoutThe amount of wobble (in-and-out

movement) of a gear or wheel as it’s rotated.

The amount a shaft rotates “out-of-true.” The

out-of-round condition of a rotating part.

SSealantA liquid or paste used to prevent

leakage at a joint. Sometimes used in

conjunction with a gasket.

Sealed beam lampAn older headlight design

which integrates the reflector, lens and

filaments into a hermetically-sealed one-piece

unit. When a filament burns out or the lens

cracks, the entire unit is simply replaced.

Serpentine drivebeltA single, long, wide

accessory drivebelt that’s used on some

newer vehicles to drive all the accessories,

instead of a series of smaller, shorter belts.

Serpentine drivebelts are usually tensioned by

an automatic tensioner.

ShimThin spacer, commonly used to adjust

the clearance or relative positions between

two parts. For example, shims inserted into or

under bucket tappets control valve

clearances. Clearance is adjusted by

changing the thickness of the shim.

Slide hammerA special puller that screws

into or hooks onto a component such as a

shaft or bearing; a heavy sliding handle on the

shaft bottoms against the end of the shaft to

knock the component free.SprocketA tooth or projection on the

periphery of a wheel, shaped to engage with a

chain or drivebelt. Commonly used to refer to

the sprocket wheel itself.

Starter inhibitor switchOn vehicles with an

automatic transmission, a switch that

prevents starting if the vehicle is not in Neutral

or Park.

StrutSee MacPherson strut.

TTappetA cylindrical component which

transmits motion from the cam to the valve

stem, either directly or via a pushrod and

rocker arm. Also called a cam follower.

ThermostatA heat-controlled valve that

regulates the flow of coolant between the

cylinder block and the radiator, so maintaining

optimum engine operating temperature. A

thermostat is also used in some air cleaners in

which the temperature is regulated.

Thrust bearingThe bearing in the clutch

assembly that is moved in to the release

levers by clutch pedal action to disengage the

clutch. Also referred to as a release bearing.

Timing beltA toothed belt which drives the

camshaft. Serious engine damage may result

if it breaks in service.

Timing chainA chain which drives the

camshaft.

Toe-inThe amount the front wheels are

closer together at the front than at the rear. On

rear wheel drive vehicles, a slight amount of

toe-in is usually specified to keep the front

wheels running parallel on the road by

offsetting other forces that tend to spread the

wheels apart.

Toe-outThe amount the front wheels are

closer together at the rear than at the front. On

front wheel drive vehicles, a slight amount of

toe-out is usually specified.

ToolsFor full information on choosing and

using tools, refer to the Haynes Automotive

Tools Manual.

TracerA stripe of a second colour applied to

a wire insulator to distinguish that wire from

another one with the same colour insulator.

Tune-upA process of accurate and careful

adjustments and parts replacement to obtain

the best possible engine performance.TurbochargerA centrifugal device, driven by

exhaust gases, that pressurises the intake air.

Normally used to increase the power output

from a given engine displacement, but can

also be used primarily to reduce exhaust

emissions (as on VW’s “Umwelt” Diesel

engine).

UUniversal joint or U-jointA double-pivoted

connection for transmitting power from a

driving to a driven shaft through an angle. A

U-joint consists of two Y-shaped yokes and a

cross-shaped member called the spider.

VValveA device through which the flow of

liquid, gas, vacuum, or loose material in bulk

may be started, stopped, or regulated by a

movable part that opens, shuts, or partially

obstructs one or more ports or passageways.

A valve is also the movable part of such a

device.

Valve clearanceThe clearance between the

valve tip (the end of the valve stem) and the

rocker arm or tappet. The valve clearance is

measured when the valve is closed.

Vernier caliperA precision measuring

instrument that measures inside and outside

dimensions. Not quite as accurate as a

micrometer, but more convenient.

ViscosityThe thickness of a liquid or its

resistance to flow.

VoltA unit for expressing electrical

“pressure” in a circuit. One volt that will

produce a current of one ampere through a

resistance of one ohm.

WWeldingVarious processes used to join metal

items by heating the areas to be joined to a

molten state and fusing them together. For

more information refer to the Haynes

Automotive Welding Manual.

Wiring diagramA drawing portraying the

components and wires in a vehicle’s electrical

system, using standardised symbols. For

more information refer to the Haynes

Automotive Electrical and Electronic Systems

Manual.

Serpentine drivebelt