ESP FIAT UNO 1983 Service Owner's Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 1983, Model line: UNO, Model: FIAT UNO 1983Pages: 303, PDF Size: 10.36 MB

Page 116 of 303

affected area with rust-inhibiting paint, if the

back of the rusted area is accessible, treat

this also.

Before filling can take place, it will be

necessary to block the hole in some way. This

can be achieved by the use of aluminium or

plastic mesh, or aluminium tape.

Aluminium or plastic mesh, or glass-fibre

matting, is probably the best material to use

for a large hole. Cut a piece to the

approximate size and shape of the hole to be

filled, then position it in the hole so that its

edges are below the level of the surrounding

bodywork. It can be retained in position by

several blobs of filler paste around its

periphery.

Aluminium tape should be used for small or

very narrow holes. Pull a piece off the roll, trim

it to the approximate size and shape required,

then pull off the backing paper (if used) and

stick the tape over the hole; it can be

overlapped if the thickness of one piece is

insufficient. Burnish down the edges of the

tape with the handle of a screwdriver or

similar, to ensure that the tape is securely

attached to the metal underneath.

Bodywork repairs - filling and

respraying

Before using this Section, see the Sections

on dent, deep scratch, rust holes and gash

repairs.

Many types of bodyfiller are available, but

generally speaking, those proprietary kits

which contain a tin of filler paste and a tube of

resin hardener are best for this type of repair. A

wide, flexible plastic or nylon applicator will be

found invaluable for imparting a smooth and

well-contoured finish to the surface of the filler.

Mix up a little filler on a clean piece of card

or board - measure the hardener carefully

(follow the maker’s instructions on the pack),

otherwise the filler will set too rapidly or too

slowly. Using the applicator, apply the filler

paste to the prepared area; draw the

applicator across the surface of the filler to

achieve the correct contour and to level the

surface. As soon as a contour that

approximates to the correct one is achieved,

stop working the paste - if you carry on too

long, the paste will become sticky and begin

to “pick-up” on the applicator. Continue to

add thin layers of filler paste at 20-minute

intervals, until the level of the filler is just

proud of the surrounding bodywork.

Once the filler has hardened, the excess

can be removed using a metal plane or file.

From then on, progressively-finer grades of

abrasive paper should be used, starting with a

40-grade production paper, and finishing with

a 400-grade wet-and-dry paper. Always wrap

the abrasive paper around a flat rubber, cork,

or wooden block - otherwise the surface of

the filler will not be completely flat. During the

smoothing of the filler surface, the wet-and-

dry paper should be periodically rinsed in

water. This will ensure that a very smooth

finish is imparted to the filler at the final stage.At this stage, the “dent” should be

surrounded by a ring of bare metal, which in

turn should be encircled by the finely

“feathered” edge of the good paintwork.

Rinse the repair area with clean water, until all

of the dust produced by the rubbing-down

operation has gone.

Spray the whole area with a light coat of

primer - this will show up any imperfections in

the surface of the filler. Repair these

imperfections with fresh filler paste or

bodystopper, and once more smooth the

surface with abrasive paper. Repeat this

spray-and-repair procedure until you are

satisfied that the surface of the filler, and the

feathered edge of the paintwork, are perfect.

Clean the repair area with clean water, and

allow to dry fully.

The repair area is now ready for final

spraying. Paint spraying must be carried out

in a warm, dry, windless and dust-free

atmosphere. This condition can be created

artificially if you have access to a large indoor

working area, but if you are forced to work in

the open, you will have to pick your day very

carefully. If you are working indoors, dousing

the floor in the work area with water will help

to settle the dust which would otherwise be in

the atmosphere. If the repair area is confined

to one body panel, mask off the surrounding

panels; this will help to minimise the effects of

a slight mis-match in paint colours. Bodywork

fittings (eg chrome strips, door handles etc)

will also need to be masked off. Use genuine

masking tape, and several thicknesses of

newspaper, for the masking operations.

Before commencing to spray, agitate the

aerosol can thoroughly, then spray a test area

(an old tin, or similar) until the technique is

mastered. Cover the repair area with a thick

coat of primer; the thickness should be built

up using several thin layers of paint, rather

than one thick one. Using 400-grade wet-and-

dry paper, rub down the surface of the primer

until it is really smooth. While doing this, the

work area should be thoroughly doused withwater, and the wet-and-dry paper periodically

rinsed in water. Allow to dry before spraying

on more paint.

Spray on the top coat, again building up the

thickness by using several thin layers of paint.

Start spraying at one edge of the repair area,

and then, using a side-to-side motion, work

until the whole repair area and about 2 inches

of the surrounding original paintwork is

covered. Remove all masking material 10 to 15

minutes after spraying on the final coat of

paint.

Allow the new paint at least two weeks to

harden, then, using a paintwork renovator, or

a very fine cutting paste, blend the edges of

the paint into the existing paintwork. Finally,

apply wax polish.

5 Major body damage-

repair

5

1Major repair to the body should be left to

your Fiat dealer or specialist body repairer.

2Special jigs and alignment gauges are

required without which steering and

suspension characteristics may be incorrect

after the repairs are completed.

6 Radiator grille-

removal and refitting

1

1Open the bonnet.

2Extract the single fixing screw from the

centre of the grille slats (photo).

3Release the retaining clips and withdraw

the grille upwards from its lower spigot holes

(photo).

4Refitting is a reversal of removal.

7 Bonnet-

removal and refitting

1

1Open the bonnet and support it on its stay.

2Pencil around the hinges on the underside

Bodywork 12•3

12

If bodystopper is used, it can

be mixed with cellulose

thinners to form a really thin

paste which is ideal for

filling small holes

6.3 Grille clip6.2 Grille screw

Page 150 of 303

75If the pump is unworn, refit the rear cover

plate and tighten the screws fully.

76Apply air pressure from a tyre pump to the

oil pump oil ducts to clear any sludge or other

material and then prime the pump by pouring

clean engine oil into its intake duct at the

same time turning the oil pump inner gear with

the fingers.

77Lever out the oil seal and drive a new one

squarely into the oil pump casing (photos).

Lubricate the oil seal lips.

78Bolt the pump into position using a new

joint gasket. Note one bolt is longer than the

others (photo).

79Bolt on the oil pick-up assembly using a

new sealing washer.

80Fit the crankshaft sprocket and tighten the

bolt to specified torque.

81Fit and tension the timing belt.

82Fit the sump pan. Screw on a new oil filter

cartridge. Wait for the specified period of time

(one hour) and then fill the engine with oil.

83Run the engine for a few minutes, then

check and top up the oil level.

Pistons/connecting rods -

removal and refitting#

84Remove the sump pan.

85Unbolt and remove the oil pump

pick-up/filter screen assembly.

86The big-end bearing shells can be

renewed without having to remove the

cylinder head if the caps are unbolted and the

piston/connecting rod pushed gently about

one inch up the bore (the crankpin being at its

lowest point). If these shells are worn,however, the main bearing shells will almost

certainly be worn as well, necessitating a

complete overhaul, including crankshaft

removal.

87To remove the piston/connecting rods,

the cylinder head must be removed.

88The big-end caps and their connecting

rods are numbered 1, 2, 3 and 4 from the

timing cover end of the engine. The numbers

are located either side of the rod/cap joint on

the engine oil dipstick tube side (photo).

89Turn the crankshaft as necessary to bring

the first connecting rod big-end crankpin to its

lowest point, then unscrew the cap bolts and

remove the cap and shell bearing.

90Push the connecting rod/piston assembly

up the bore and out of the cylinder block.

There is one reservation; if a wear ridge has

developed at the top of the bores, remove this

by careful scraping before trying to remove

the piston/rod assemblies. The ridge will

otherwise prevent removal, or break the

piston rings during the attempt.

91Remove the remaining piston/connecting

rods in a similar way. If the bearing shells are

to be used again, tape them to their

respective caps or rods.

92Removal of the piston rings and

separation of the piston from the connecting

rod is covered in the next sub-Section.

93Fit the bearing shells into the connecting

rods and caps, ensuring that the recesses into

which the shells seat are clean and dry.

94Check that the piston ring gaps are evenly

spaced at 120º intervals. Liberally oil the rings

and the cylinder bores.95Fit a piston ring clamp to compress the

rings, oiling the rings and the clamp interior

surfaces liberally.

96Insert the first piston/connecting rod into

its cylinder bore. Make sure that the assembly

is the correct one for its particular bore. The

cap and rod matching numbers must be

towards the engine oil dipstick guide tube and

the arrow on the piston crown towards the

timing belt (photo).

97Push the piston into the bore until the

piston ring clamp is against the cylinder block

and then tap the crown of the piston lightly to

push it out of the ring clamp and into the bore

(photo).

98Oil the crankshaft journal and fit the

big-end of the connecting rod to the journal.

Check that the bearing shells are still in

position, then fit the big-end cap and bolts;

check that the cap is the right way round

(photo).

Supplement: Revisions and information on later models 13•25

5B.78 Fitting the oil pump5B.77B Using a socket to fit the new oil

pump oil seal5B.77A Removing the oil pump seal

5B.98 Fitting a big-end bearing cap

5B.88 Connecting rod and cap numbers

5B.97 Fitting a piston/connecting rod5B.96 Piston directional arrow

13

Page 155 of 303

crankcase. If the shells are to be used again,

keep them with their respective bearing caps.

70The thrust washers which control

crankshaft endfloat are located in the

crankcase, and retained by the turned-over

edges of the centre main bearing shell.

71The engine is now fully stripped.

Examination and renovation

72The procedures for the following items are

essentially as described in Chapter 1, Sec-

tion 18.

Cylinder block and crankcase

Crankshaft and bearings

Flywheel

Oil seals and gaskets

Cylinder head

73Using a straight-edge, check the cylinder

head gasket surface for distortion. If it

exceeds the specified tolerance, it must be

surface ground by your dealer.74Refer to Chapter 1, Section 39, for

dismantling and renovation operations. Note

that single valve springs are fitted.

Oil pump

75Checking operations are described in

sub-Section B.

Pistons and connecting rods

76Refer to sub-Section B.

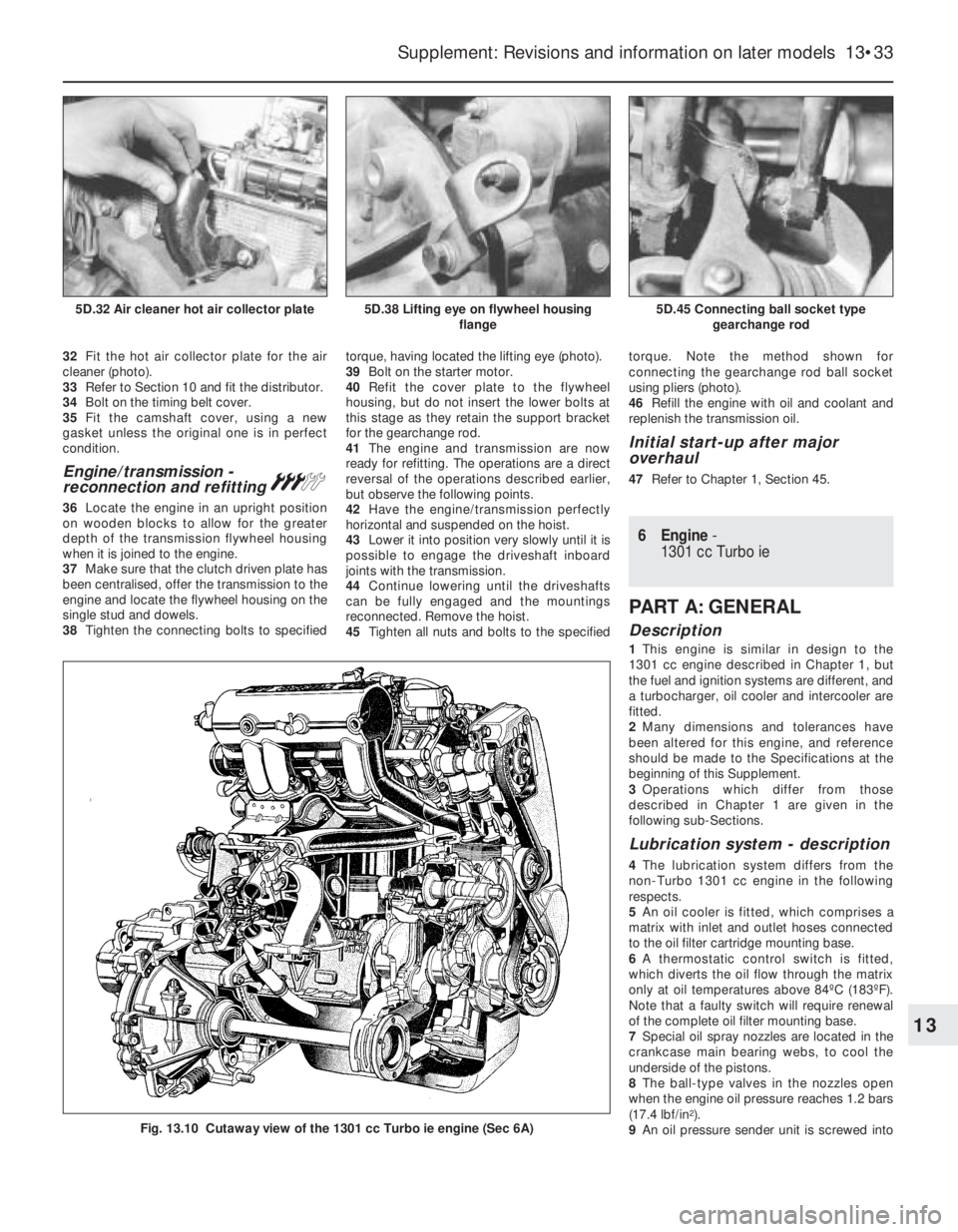

77If one or more connecting rods are

changed, it is important that its weight is

identical to that of the original. Use an

accurate balance to weigh them and remove

metal if necessary from the new rod in the

areas indicated in Fig. 13.7.

Camshaft and cam followers

78If the camshaft journals or bearings show

any sign of wear or scoring, then the

camshaft, or cylinder head, or both must be

renewed.

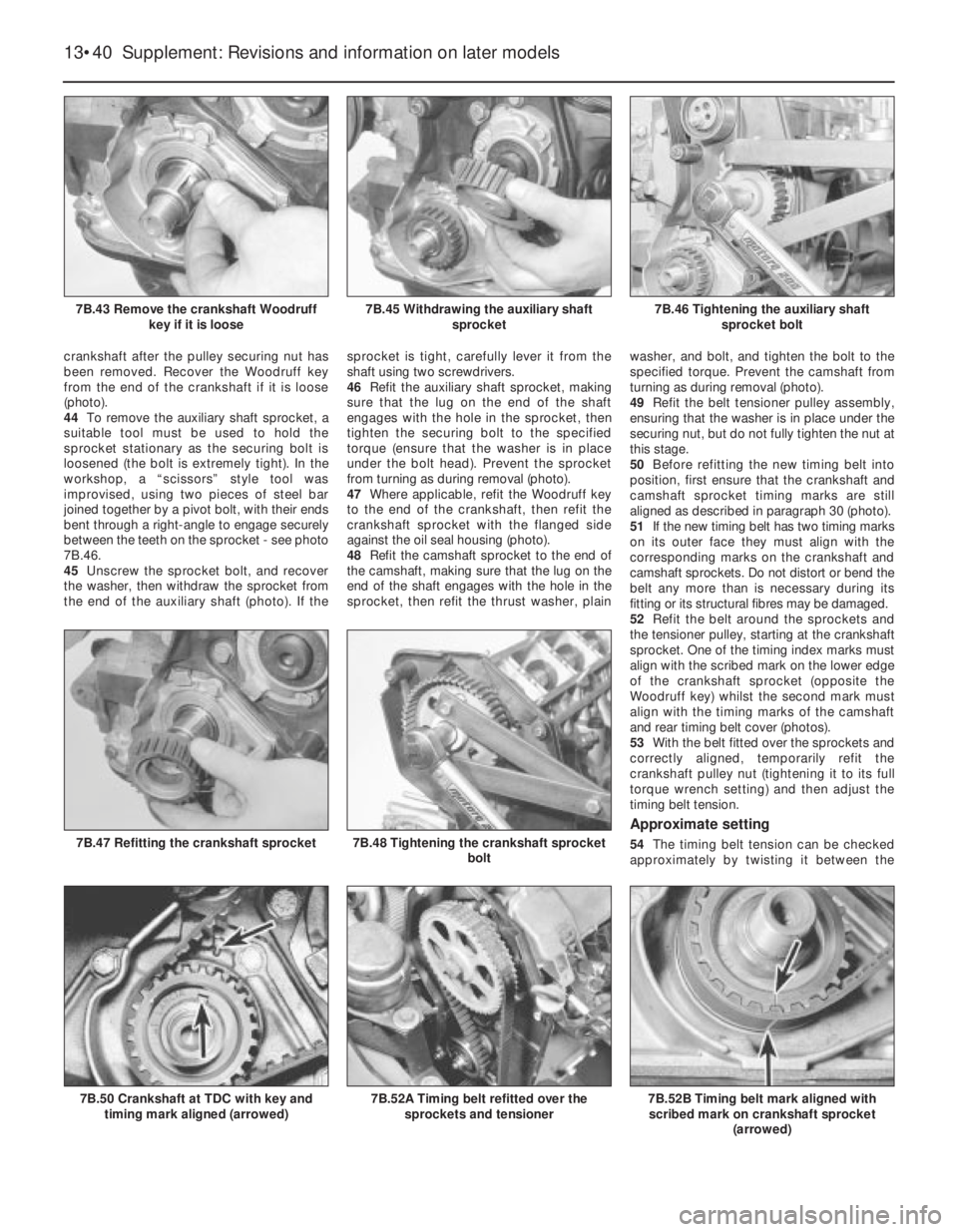

79The cam followers should be checked for

ovality using a micrometer. Unless unworn

they should be renewed.

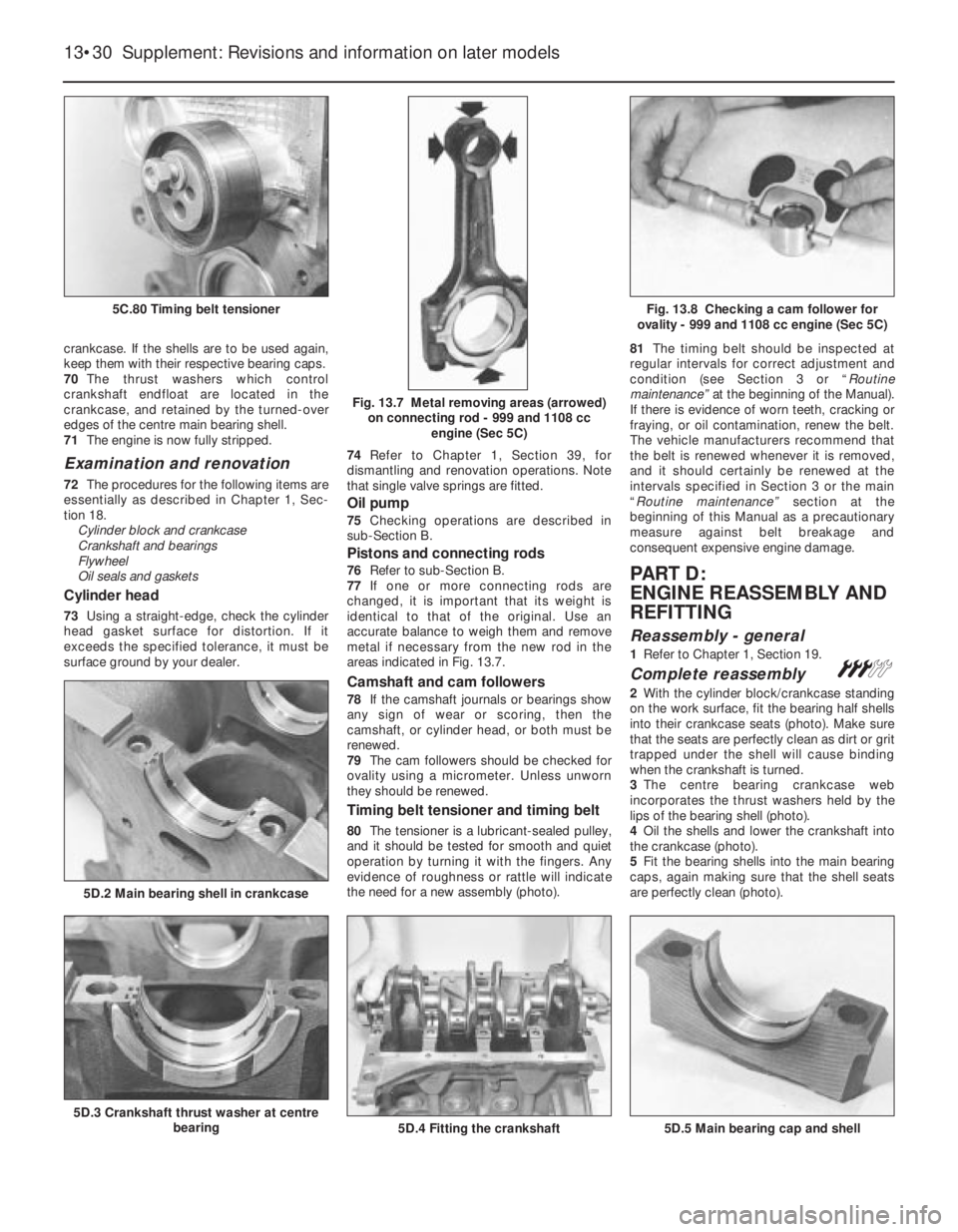

Timing belt tensioner and timing belt

80The tensioner is a lubricant-sealed pulley,

and it should be tested for smooth and quiet

operation by turning it with the fingers. Any

evidence of roughness or rattle will indicate

the need for a new assembly (photo).81The timing belt should be inspected at

regular intervals for correct adjustment and

condition (see Section 3 or “Routine

maintenance” at the beginning of the Manual).

If there is evidence of worn teeth, cracking or

fraying, or oil contamination, renew the belt.

The vehicle manufacturers recommend that

the belt is renewed whenever it is removed,

and it should certainly be renewed at the

intervals specified in Section 3 or the main

“Routine maintenance” section at the

beginning of this Manual as a precautionary

measure against belt breakage and

consequent expensive engine damage.

PART D:

ENGINE REASSEMBLY AND

REFITTING

Reassembly - general

1Refer to Chapter 1, Section 19.

Complete reassembly#

2With the cylinder block/crankcase standing

on the work surface, fit the bearing half shells

into their crankcase seats (photo). Make sure

that the seats are perfectly clean as dirt or grit

trapped under the shell will cause binding

when the crankshaft is turned.

3The centre bearing crankcase web

incorporates the thrust washers held by the

lips of the bearing shell (photo).

4Oil the shells and lower the crankshaft into

the crankcase (photo).

5Fit the bearing shells into the main bearing

caps, again making sure that the shell seats

are perfectly clean (photo).

13•30 Supplement: Revisions and information on later models

5D.5 Main bearing cap and shell5D.4 Fitting the crankshaft5D.3 Crankshaft thrust washer at centre

bearing

5D.2 Main bearing shell in crankcase

Fig. 13.8 Checking a cam follower for

ovality - 999 and 1108 cc engine (Sec 5C)

Fig. 13.7 Metal removing areas (arrowed)

on connecting rod - 999 and 1108 cc

engine (Sec 5C)

5C.80 Timing belt tensioner

Page 158 of 303

32Fit the hot air collector plate for the air

cleaner (photo).

33Refer to Section 10 and fit the distributor.

34Bolt on the timing belt cover.

35Fit the camshaft cover, using a new

gasket unless the original one is in perfect

condition.

Engine/transmission -

reconnection and refitting#

36Locate the engine in an upright position

on wooden blocks to allow for the greater

depth of the transmission flywheel housing

when it is joined to the engine.

37Make sure that the clutch driven plate has

been centralised, offer the transmission to the

engine and locate the flywheel housing on the

single stud and dowels.

38Tighten the connecting bolts to specifiedtorque, having located the lifting eye (photo).

39Bolt on the starter motor.

40Refit the cover plate to the flywheel

housing, but do not insert the lower bolts at

this stage as they retain the support bracket

for the gearchange rod.

41The engine and transmission are now

ready for refitting. The operations are a direct

reversal of the operations described earlier,

but observe the following points.

42Have the engine/transmission perfectly

horizontal and suspended on the hoist.

43Lower it into position very slowly until it is

possible to engage the driveshaft inboard

joints with the transmission.

44Continue lowering until the driveshafts

can be fully engaged and the mountings

reconnected. Remove the hoist.

45Tighten all nuts and bolts to the specifiedtorque. Note the method shown for

connecting the gearchange rod ball socket

using pliers (photo).

46Refill the engine with oil and coolant and

replenish the transmission oil.

Initial start-up after major

overhaul

47Refer to Chapter 1, Section 45.

6 Engine-

1301 cc Turbo ie

PART A: GENERAL

Description

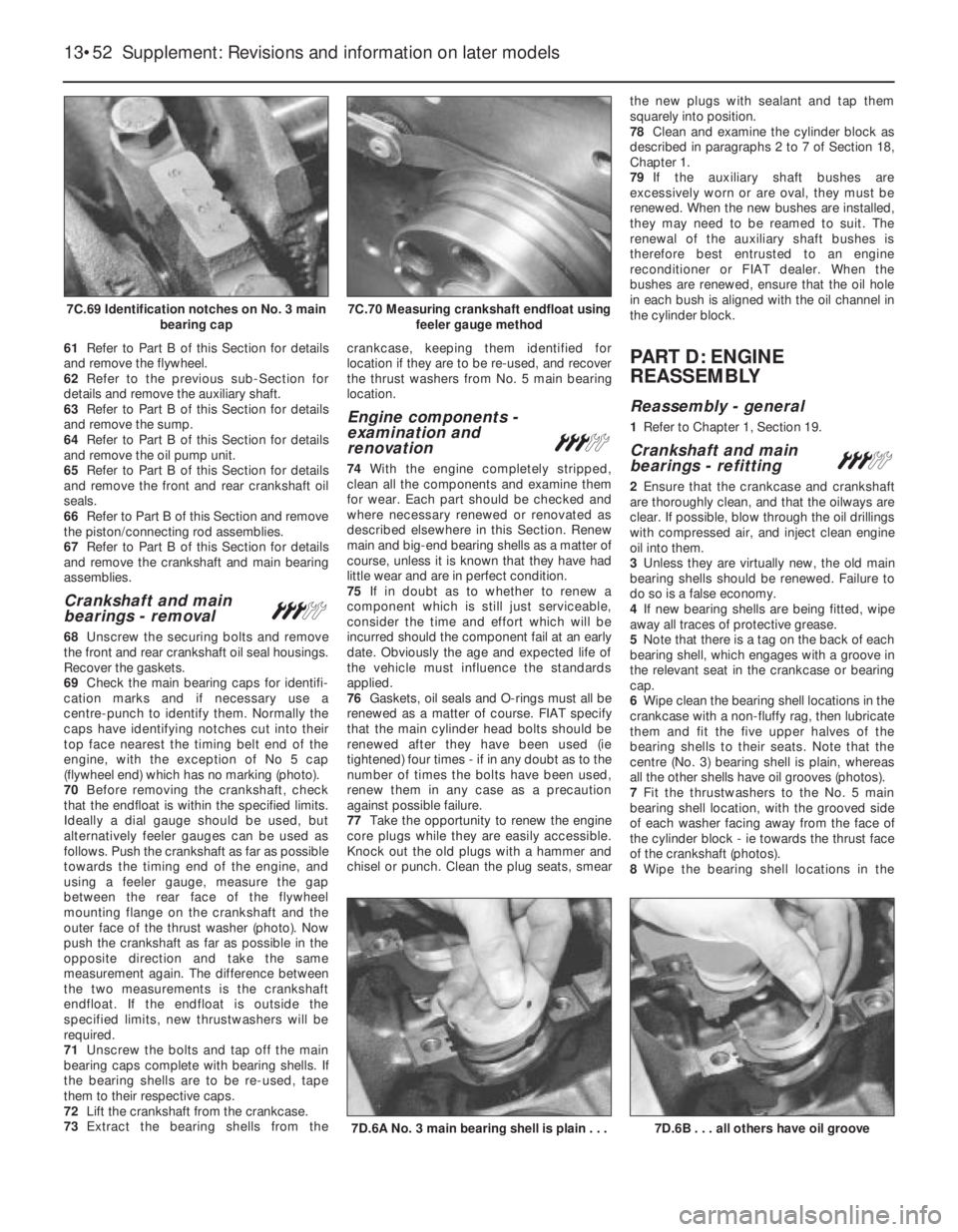

1This engine is similar in design to the

1301 cc engine described in Chapter 1, but

the fuel and ignition systems are different, and

a turbocharger, oil cooler and intercooler are

fitted.

2Many dimensions and tolerances have

been altered for this engine, and reference

should be made to the Specifications at the

beginning of this Supplement.

3Operations which differ from those

described in Chapter 1 are given in the

following sub-Sections.

Lubrication system - description

4The lubrication system differs from the

non-Turbo 1301 cc engine in the following

respects.

5An oil cooler is fitted, which comprises a

matrix with inlet and outlet hoses connected

to the oil filter cartridge mounting base.

6A thermostatic control switch is fitted,

which diverts the oil flow through the matrix

only at oil temperatures above 84ºC (183ºF).

Note that a faulty switch will require renewal

of the complete oil filter mounting base.

7Special oil spray nozzles are located in the

crankcase main bearing webs, to cool the

underside of the pistons.

8The ball-type valves in the nozzles open

when the engine oil pressure reaches 1.2 bars

(17.4 lbf/in

2).

9An oil pressure sender unit is screwed into

Supplement: Revisions and information on later models 13•33

5D.45 Connecting ball socket type

gearchange rod5D.38 Lifting eye on flywheel housing

flange5D.32 Air cleaner hot air collector plate

Fig. 13.10 Cutaway view of the 1301 cc Turbo ie engine (Sec 6A)

13

Page 163 of 303

9Turn the engine clockwise using a suitable

socket on the crankshaft pulley bolt, until the

exhaust valve of No 1 cylinder (valve No 1) is

fully closed; ie the cam lobe is pointing

directly upwards. Alternatively, the engine can

be turned by jacking up one front corner of

the vehicle and supporting it securely on an

axle stand (apply the handbrake and chock

the diagonally-opposite rear wheel before

jacking), engaging top gear and turning the

raised roadwheel in the forward direction of

travel. In both cases, it will be easier to turn

the engine if the spark plugs are removed, but

if this is done, take care not to allow dirt or

other foreign matter to enter the spark plug

holes.

10Insert a feeler gauge of the correct

thickness between the cam follower shim and

the heel of the No 1 cam lobe (photo). If

necessary, increase or reduce the thickness

of the feeler gauge until it is a firm sliding fit.

Record the thickness of the feeler gauge,

which will represent the valve clearance for

this particular valve.

11Turn the crankshaft, and repeat the

procedure for the remaining valves, recording

their respective clearances. Note that the

clearance for inlet and exhaust valves differs.

12If a clearance is incorrect, the relevant

cam follower shim must be removed, and a

thicker or thinner shim must be fitted to

achieve the correct clearance. To remove a

shim proceed as follows.

13Turn the crankshaft until the relevant cam

lobe is pointing directly upwards.

14The cam follower must now be depressed

in order to extract the shim. FIAT special tool

No 1860642000 is available for this purpose,

but alternatively a suitable tool can be

improvised (photo). The tool should locate on

the rim of the cam follower, leaving enough

room for the shim to be prised out by means

of the cut-outs provided in the cam follower

rim. Depress the cam follower by turning the

crankshaft as described previously until the

relevant cam lobe is pointing directly

downwards, then fit the tool between the

camshaft and the edge of the cam follower to

retain the cam follower in the depressed

position.

15Ensure that the tool is securely located, asthere is a risk of personal injury if the tool is

dislodged whilst the cam follower is

depressed, then turn the crankshaft until the

relevant cam lobe is pointing directly

upwards, leaving sufficient room to extract

the shim (photo). A pair of angle-nosed pliers

will greatly ease removal of the shim.

16Once the shim has been extracted,

establish its thickness. The thickness in mm

should be stamped into the face of the shim,

although it is possible for wear to obliterate

the number, in which case the use of a metric

micrometer is the only way to accurately

establish the thickness.

17Refer to the clearance recorded for the

valve concerned. If the clearance recorded

was larger than that specified, a thicker shim

must be fitted, and if the clearance recorded

was smaller than that specified, a thinner shim

must be fitted. The required thickness of shim

can be

calculated as follows.

Sample calculation - clearance too large:

Desired clearance (A) 0.40 mm

Measured clearance (B) 0.45 mm

Difference (B - A) + 0.05 mm

Original shim thickness 3.40 mm

Required shim thickness 3.40 + 0.05 =

3.45 mm

Sample calculation - clearance too small:

Desired clearance (A) 0.50 mm

Measured clearance (B) 0.35 mm

Difference (B - A) 0.15 mm

Original shim thickness 4.55 mm

Required shim thickness 4.55 - 0.15 =

4.40 mm

18Shims are available in thicknesses from

3.20 to 4.70 mm, in steps of 0.05 mm. Note

that if several shims have to be changed, they

can often be interchanged, thus avoiding the

need by buy more new shims than are

necessary.

19The shims should be fitted to the cam

followers with the stamped thickness marking

against the face of the cam follower.

20After fitting a shim, rotate the crankshaft

as described previously until the relevant cam

lobe is pointing directly downwards (resting

on the shim), then carefully remove the tool

used to retain the follower in the depressed

position.21Re-check each relevant valve clearance

after fitting the shim.

22On completion, where applicable, lower

the vehicle to the ground.

23Refit the camshaft cover, using a new

gasket.

24On the ie engine, reconnect the hoses and

refit the air cleaner unit.

25On the Turbo ie engine, reconnect the air

hose and the accelerator cable.

Timing belt tensioner

and sprockets -

removal and refitting

#

Note: The timing belt must be renewed after

removal: never refit a used drivebelt. When

fitting the new timing belt it will need to be

correctly tensioned and to achieve this the

manufacturers specify the use of special tools

1860745200 (18760745300 on Turbo model)

and 1860745100. If these tools are not readily

available, an approximate setting can be

made, but in this instance it is strongly

recommended that the car be taken to a FIAT

dealer at the earliest opportunity to have the

belt tension checked and correctly set using

the recommended tools.

26Loosen off the front right-hand side wheel

bolts, then raise and support the car at the

front end on axle stands. Remove the front

right-hand roadwheel.

27Remove the underwing shield from the

right-hand wheel arch to allow access to the

lower timing cover and alternator fixings (photo).

13•38 Supplement: Revisions and information on later models

7B.27 Underwing shield (A) showing

central compression pin (B) and retaining

clip (C). Drive pin through clip to remove

7B.15 Removing a shim from a cam

follower7B.14 Special tool for retaining cam

follower in depressed position7B.10 Measuring a valve clearance

(No 2 valve shown)

Page 165 of 303

crankshaft after the pulley securing nut has

been removed. Recover the Woodruff key

from the end of the crankshaft if it is loose

(photo).

44To remove the auxiliary shaft sprocket, a

suitable tool must be used to hold the

sprocket stationary as the securing bolt is

loosened (the bolt is extremely tight). In the

workshop, a “scissors” style tool was

improvised, using two pieces of steel bar

joined together by a pivot bolt, with their ends

bent through a right-angle to engage securely

between the teeth on the sprocket - see photo

7B.46.

45Unscrew the sprocket bolt, and recover

the washer, then withdraw the sprocket from

the end of the auxiliary shaft (photo). If thesprocket is tight, carefully lever it from the

shaft using two screwdrivers.

46Refit the auxiliary shaft sprocket, making

sure that the lug on the end of the shaft

engages with the hole in the sprocket, then

tighten the securing bolt to the specified

torque (ensure that the washer is in place

under the bolt head). Prevent the sprocket

from turning as during removal (photo).

47Where applicable, refit the Woodruff key

to the end of the crankshaft, then refit the

crankshaft sprocket with the flanged side

against the oil seal housing (photo).

48Refit the camshaft sprocket to the end of

the camshaft, making sure that the lug on the

end of the shaft engages with the hole in the

sprocket, then refit the thrust washer, plainwasher, and bolt, and tighten the bolt to the

specified torque. Prevent the camshaft from

turning as during removal (photo).

49Refit the belt tensioner pulley assembly,

ensuring that the washer is in place under the

securing nut, but do not fully tighten the nut at

this stage.

50Before refitting the new timing belt into

position, first ensure that the crankshaft and

camshaft sprocket timing marks are still

aligned as described in paragraph 30 (photo).

51If the new timing belt has two timing marks

on its outer face they must align with the

corresponding marks on the crankshaft and

camshaft sprockets. Do not distort or bend the

belt any more than is necessary during its

fitting or its structural fibres may be damaged.

52Refit the belt around the sprockets and

the tensioner pulley, starting at the crankshaft

sprocket. One of the timing index marks must

align with the scribed mark on the lower edge

of the crankshaft sprocket (opposite the

Woodruff key) whilst the second mark must

align with the timing marks of the camshaft

and rear timing belt cover (photos).

53With the belt fitted over the sprockets and

correctly aligned, temporarily refit the

crankshaft pulley nut (tightening it to its full

torque wrench setting) and then adjust the

timing belt tension.

Approximate setting

54The timing belt tension can be checked

approximately by twisting it between the

13•40 Supplement: Revisions and information on later models

7B.52B Timing belt mark aligned with

scribed mark on crankshaft sprocket

(arrowed)7B.52A Timing belt refitted over the

sprockets and tensioner7B.50 Crankshaft at TDC with key and

timing mark aligned (arrowed)

7B.48 Tightening the crankshaft sprocket

bolt7B.47 Refitting the crankshaft sprocket

7B.46 Tightening the auxiliary shaft

sprocket bolt7B.45 Withdrawing the auxiliary shaft

sprocket7B.43 Remove the crankshaft Woodruff

key if it is loose

Page 177 of 303

61Refer to Part B of this Section for details

and remove the flywheel.

62Refer to the previous sub-Section for

details and remove the auxiliary shaft.

63Refer to Part B of this Section for details

and remove the sump.

64Refer to Part B of this Section for details

and remove the oil pump unit.

65Refer to Part B of this Section for details

and remove the front and rear crankshaft oil

seals.

66Refer to Part B of this Section and remove

the piston/connecting rod assemblies.

67Refer to Part B of this Section for details

and remove the crankshaft and main bearing

assemblies.

Crankshaft and main

bearings - removal#

68Unscrew the securing bolts and remove

the front and rear crankshaft oil seal housings.

Recover the gaskets.

69Check the main bearing caps for identifi-

cation marks and if necessary use a

centre-punch to identify them. Normally the

caps have identifying notches cut into their

top face nearest the timing belt end of the

engine, with the exception of No 5 cap

(flywheel end) which has no marking (photo).

70Before removing the crankshaft, check

that the endfloat is within the specified limits.

Ideally a dial gauge should be used, but

alternatively feeler gauges can be used as

follows. Push the crankshaft as far as possible

towards the timing end of the engine, and

using a feeler gauge, measure the gap

between the rear face of the flywheel

mounting flange on the crankshaft and the

outer face of the thrust washer (photo). Now

push the crankshaft as far as possible in the

opposite direction and take the same

measurement again. The difference between

the two measurements is the crankshaft

endfloat. If the endfloat is outside the

specified limits, new thrustwashers will be

required.

71Unscrew the bolts and tap off the main

bearing caps complete with bearing shells. If

the bearing shells are to be re-used, tape

them to their respective caps.

72Lift the crankshaft from the crankcase.

73Extract the bearing shells from thecrankcase, keeping them identified for

location if they are to be re-used, and recover

the thrust washers from No. 5 main bearing

location.

Engine components -

examination and

renovation

#

74With the engine completely stripped,

clean all the components and examine them

for wear. Each part should be checked and

where necessary renewed or renovated as

described elsewhere in this Section. Renew

main and big-end bearing shells as a matter of

course, unless it is known that they have had

little wear and are in perfect condition.

75If in doubt as to whether to renew a

component which is still just serviceable,

consider the time and effort which will be

incurred should the component fail at an early

date. Obviously the age and expected life of

the vehicle must influence the standards

applied.

76Gaskets, oil seals and O-rings must all be

renewed as a matter of course. FIAT specify

that the main cylinder head bolts should be

renewed after they have been used (ie

tightened) four times - if in any doubt as to the

number of times the bolts have been used,

renew them in any case as a precaution

against possible failure.

77Take the opportunity to renew the engine

core plugs while they are easily accessible.

Knock out the old plugs with a hammer and

chisel or punch. Clean the plug seats, smearthe new plugs with sealant and tap them

squarely into position.

78Clean and examine the cylinder block as

described in paragraphs 2 to 7 of Section 18,

Chapter 1.

79If the auxiliary shaft bushes are

excessively worn or are oval, they must be

renewed. When the new bushes are installed,

they may need to be reamed to suit. The

renewal of the auxiliary shaft bushes is

therefore best entrusted to an engine

reconditioner or FIAT dealer. When the

bushes are renewed, ensure that the oil hole

in each bush is aligned with the oil channel in

the cylinder block.

PART D: ENGINE

REASSEMBLY

Reassembly - general

1Refer to Chapter 1, Section 19.

Crankshaft and main

bearings - refitting#

2Ensure that the crankcase and crankshaft

are thoroughly clean, and that the oilways are

clear. If possible, blow through the oil drillings

with compressed air, and inject clean engine

oil into them.

3Unless they are virtually new, the old main

bearing shells should be renewed. Failure to

do so is a false economy.

4If new bearing shells are being fitted, wipe

away all traces of protective grease.

5Note that there is a tag on the back of each

bearing shell, which engages with a groove in

the relevant seat in the crankcase or bearing

cap.

6Wipe clean the bearing shell locations in the

crankcase with a non-fluffy rag, then lubricate

them and fit the five upper halves of the

bearing shells to their seats. Note that the

centre (No. 3) bearing shell is plain, whereas

all the other shells have oil grooves (photos).

7Fit the thrustwashers to the No. 5 main

bearing shell location, with the grooved side

of each washer facing away from the face of

the cylinder block - ie towards the thrust face

of the crankshaft (photos).

8Wipe the bearing shell locations in the

13•52 Supplement: Revisions and information on later models

7D.6B . . . all others have oil groove7D.6A No. 3 main bearing shell is plain . . .

7C.70 Measuring crankshaft endfloat using

feeler gauge method7C.69 Identification notches on No. 3 main

bearing cap

Page 232 of 303

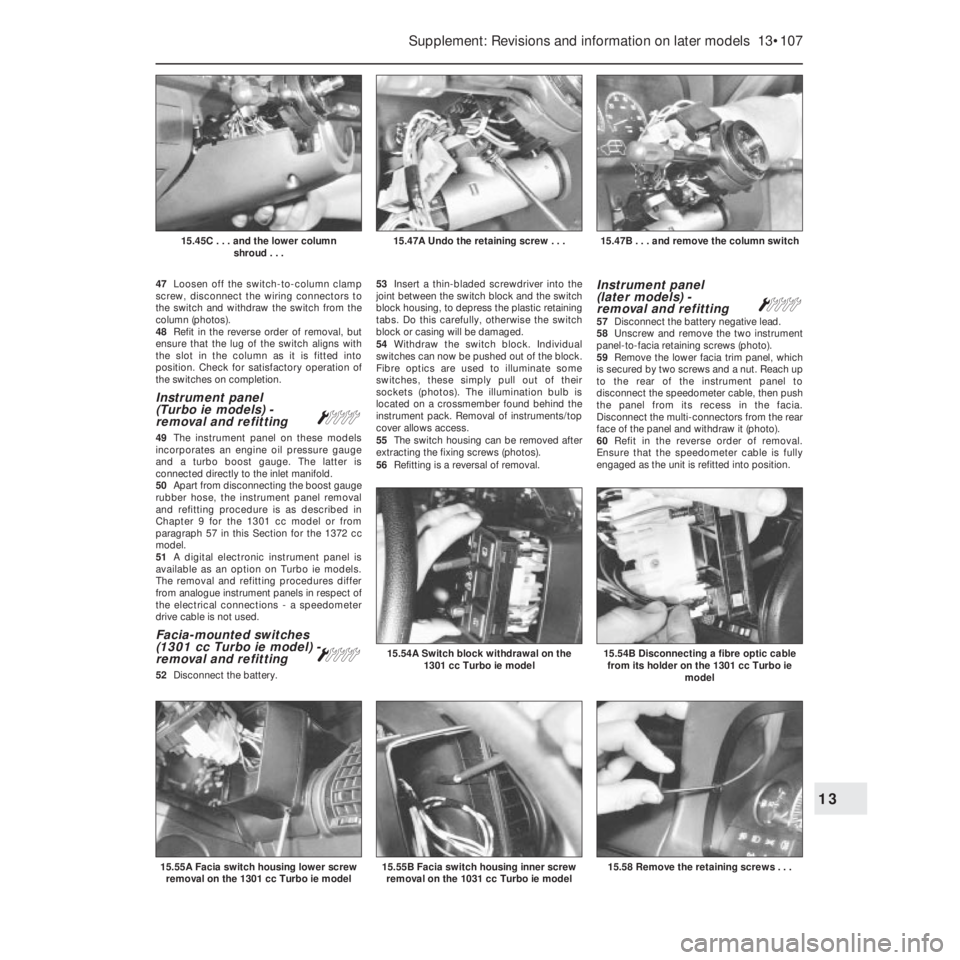

47Loosen off the switch-to-column clamp

screw, disconnect the wiring connectors to

the switch and withdraw the switch from the

column (photos).

48Refit in the reverse order of removal, but

ensure that the lug of the switch aligns with

the slot in the column as it is fitted into

position. Check for satisfactory operation of

the switches on completion.

Instrument panel

(Turbo ie models) -

removal and refitting

Á

49The instrument panel on these models

incorporates an engine oil pressure gauge

and a turbo boost gauge. The latter is

connected directly to the inlet manifold.

50Apart from disconnecting the boost gauge

rubber hose, the instrument panel removal

and refitting procedure is as described in

Chapter 9 for the 1301 cc model or from

paragraph 57 in this Section for the 1372 cc

model.

51A digital electronic instrument panel is

available as an option on Turbo ie models.

The removal and refitting procedures differ

from analogue instrument panels in respect of

the electrical connections - a speedometer

drive cable is not used.

Facia-mounted switches

(1301 cc Turbo ie model) -

removal and refitting

Á

52Disconnect the battery.53Insert a thin-bladed screwdriver into the

joint between the switch block and the switch

block housing, to depress the plastic retaining

tabs. Do this carefully, otherwise the switch

block or casing will be damaged.

54Withdraw the switch block. Individual

switches can now be pushed out of the block.

Fibre optics are used to illuminate some

switches, these simply pull out of their

sockets (photos). The illumination bulb is

located on a crossmember found behind the

instrument pack. Removal of instruments/top

cover allows access.

55The switch housing can be removed after

extracting the fixing screws (photos).

56Refitting is a reversal of removal.

Instrument panel

(later models) -

removal and refitting

Á57Disconnect the battery negative lead.

58Unscrew and remove the two instrument

panel-to-facia retaining screws (photo).

59Remove the lower facia trim panel, which

is secured by two screws and a nut. Reach up

to the rear of the instrument panel to

disconnect the speedometer cable, then push

the panel from its recess in the facia.

Disconnect the multi-connectors from the rear

face of the panel and withdraw it (photo).

60Refit in the reverse order of removal.

Ensure that the speedometer cable is fully

engaged as the unit is refitted into position.

Supplement: Revisions and information on later models 13•107

15.47B . . . and remove the column switch15.47A Undo the retaining screw . . .15.45C . . . and the lower column

shroud . . .

15.58 Remove the retaining screws . . .15.55B Facia switch housing inner screw

removal on the 1031 cc Turbo ie model

15.54B Disconnecting a fibre optic cable

from its holder on the 1301 cc Turbo ie

model15.54A Switch block withdrawal on the

1301 cc Turbo ie model

15.55A Facia switch housing lower screw

removal on the 1301 cc Turbo ie model

13

Page 233 of 303

Auxiliary control panel

(later models) -

removal and refitting

Á

61Disconnect the battery negative lead.

62Insert the flat of a screwdriver under the

trim piece at the end of the auxiliary panel as

shown and prise it free. Repeat the procedure

and remove the trim piece at the other end of

the panel (photo).

63Undo the retaining screws, withdraw the

panel from the facia. Disconnect the wiring

connectors from the panel switches to

remove the panel completely (photo).

64A switch bulb can be renewed by

untwisting the holder and removing the holder

and bulb.

65A switch unit can be removed from the

panel by unscrewing the four retaining screws.66Refitting is a reversal of the removal

procedure. Ensure that the wiring connections

are securely made and check for satisfactory

operation of the switches on completion.

Heater control panel

(later models) -

removal and refitting

Á

67Disconnect the battery negative lead.

68Pull free the heater/fresh air and blower

control knobs (photo).

69Undo the two retaining screws and

withdraw the control panel from the facia

(photos). Detach the wiring connectors from the

panel illumination lights and remove the panel.

70Refitting is a reversal of the removal

procedure. Ensure that the wiring connections

are securely made and on completion check

that the operation of the controls is satisfactory.

Trip master Á

71This electronic instrument is fitted into the

check panel of 1100SL and 1300SL models

from 1986.

72The device provides information on fuel

consumption, range, speed and elapsed time.

73With the ignition key turned to MAR,

figures are displayed in respect of the last

journey - average fuel consumption, average

speed and elapsed time (up to switching off

the ignition).

74As soon as the engine is started, the

instrument processes the current values to

include fuel consumption, range and the

actual time. 75Fuel consumption is only displayed when

the road speed exceeds 8.0 km/h (5.0 mph).

76The fuel range is only displayed after a

road speed of between 25.0 and 70.0 km/h

(15.0 to 44.0 mph) has been maintained for at

least 90 seconds or at higher speeds for

22 seconds.

77A reset button is provided, also a display

change button (from instant to average or

total values). Should the instrument reading

exceed 99 hours, 59 minutes or 1000 km

(622 miles) depressing the display change

button will display all zeros. Depress button E

to resume normal function.

78Refer to the end of the manual for a wiring

diagram of the check panel, incorporating the

trip master.

Interior roof mounted spotlamp,

switch and/or clock -

removal and refitting

Á

79Disconnect the battery negative lead.

80Prise free the lamp unit from its aperture

in the roof panel using a thin-bladed

screwdriver. The lamp bulb can be inspected

by untwisting the holder and withdrawing it

from the rear of the unit (photos). Extract the

bulb from the holder if it requires renewal.

81To remove the lamp switch from the

panel, reach through the lamp aperture and

press it free from the roof panel (photo).

Detach the wiring connectors.

82To remove the clock, reach through the

lamp aperture and undo the retaining screws

(photo). Withdraw the clock and detach the

wiring connectors.

13•108 Supplement: Revisions and information on later models

15.69B . . . and withdraw the heater control

panel15.69A . . . undo the retaining screws

(arrowed)15.68 Remove the control knobs . . .

15.63 . . . and withdraw the auxiliary

control panel

15.62 Prise free the trim covers for access

to retaining screws . . .15.59B . . . and disconnect the

speedometer cable15.59A . . . withdraw the instrument

panel . . .

Page 292 of 303

Fault FindingREF•9

REF

Introduction

The vehicle owner who does his or her own

maintenance according to the recommended

schedules should not have to use this section

of the manual very often. Modern component

reliability is such that, provided those items

subject to wear or deterioration are inspected

or renewed at the specified intervals, sudden

failure is comparatively rare. Faults do not

usually just happen as a result of sudden

failure, but develop over a period of time.

Major mechanical failures in particular are

usually preceded by characteristic symptoms

over hundreds or even thousands of miles.

Those components which do occasionally fail

without warning are often small and easily

carried in the vehicle.

With any fault finding, the first step is to

decide where to begin investigations.

Sometimes this is obvious, but on other

occasions a little detective work will be

necessary. The owner who makes half a

dozen haphazard adjustments or

replacements may be successful in curing a

fault (or its symptoms), but he will be none the

wiser if the fault recurs and he may well have

spent more time and money than was

necessary. A calm and logical approach will

be found to be more satisfactory in the long

run. Always take into account any warning

signs or abnormalities that may have been

noticed in the period preceding the fault –

power loss, high or low gauge readings,

unusual noises or smells, etc – and remember

that failure of components such as fuses or

spark plugs may only be pointers to some

underlying fault.

The pages which follow here are intended

to help in cases of failure to start or

breakdown on the road. There is also a Fault

Diagnosis Section at the end of each Chapter

which should be consulted if the preliminary

checks prove unfruitful. Whatever the fault,

certain basic principles apply. These are as

follows:Verify the fault. This is simply a matter of

being sure that you know what the symptoms

are before starting work. This is particularly

important if you are investigating a fault for

someone else who may not have described it

very accurately.

Don’t overlook the obvious. For example,

if the vehicle won’t start, is there petrol in the

tank? (Don’t take anyone else’s word on this

particular point, and don’t trust the fuel gauge

either!) If an electrical fault is indicated, look

for loose or broken wires before digging out

the test gear.

Cure the disease, not the symptom.

Substituting a flat battery with a fully charged

one will get you off the hard shoulder, but if

the underlying cause is not attended to,the

new battery will go the same way. Similarly,

changing oil-fouled spark plugs for a new set

will get you moving again, but remember that

the reason for the fouling (if it wasn’t simply an

incorrect grade of plug) will have to be

established and corrected.

Don’t take anything for granted.

Particularly, don’t forget that a ‘new’

component may itself be defective (especially

if it’s been rattling round in the boot for

months), and don’t leave components out of a

fault diagnosis sequence just because they

are new or recently fitted. When you do finally

diagnose a difficult fault, you’ll probably

realise that all the evidence was there from

the start.

Electrical faults

Electrical faults can be more puzzling than

straightforward mechanical failures, but they

are no less susceptible to logical analysis if

the basic principles of operation are

understood. Vehicle electrical wiring exists in

extremely unfavourable conditions – heat,

vibration and chemical attack and the first

things to look for are loose or corroded

connections and broken or chafed wires,especially where the wires pass through holes

in the bodywork or are subject to vibration.

All metal-bodied vehicles in current

production have one pole of the battery

‘earthed’, ie connected to the vehicle

bodywork, and in nearly all modern vehicles it

is the negative (–) terminal. The various

electrical components – motors, bulb holders,

etc – are also connected to earth, either by

means of a lead or directly by their mountings.

Electric current flows through the component

and then back to the battery via the

bodywork. If the component mounting is

loose or corroded, or if a good path back to

the battery is not available, the circuit will be

incomplete and malfunction will result. The

engine and/or gearbox are also earthed by

means of flexible metal straps to the body or

subframe; if these straps are loose or missing,

starter motor, generator and ignition trouble

may result.

Assuming the earth return to be

satisfactory, electrical faults will be due either

to component malfunction or to defects in the

current supply. Individual components are

dealt with in Chapter 9. If supply wires are

broken or cracked internally this results in an

open-circuit, and the easiest way to check for

this is to bypass the suspect wire temporarily

with a length of wire having a crocodile clip or

suitable connector at each end. Alternatively,

a 12V test lamp can be used to verify the

presence of supply voltage at various points

along the wire and the break can be thus

isolated.

If a bare portion of a live wire touches the

bodywork or other earthed metal part, the

electricity will take the low-resistance path

thus formed back to the battery: this is known

as a short-circuit. Hopefully a short-circuit will

blow a fuse, but otherwise it may cause

burning of the insulation (and possibly further

short-circuits) or even a fire. This is why it is

inadvisable to bypass persistently blowing

fuses with silver foil or wire.