ECU FORD CAPRI 1974 Service Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1974, Model line: CAPRI, Model: FORD CAPRI 1974Pages: 205, PDF Size: 43.75 MB

Page 152 of 205

-

)

Chapter 9 Braking system

,,-

")_'J ,

: ~~ 11111JIII/IIIJ II /I /III Ii hIIllllIlIlIllllIlll 11111#111111 III! -------

8

9

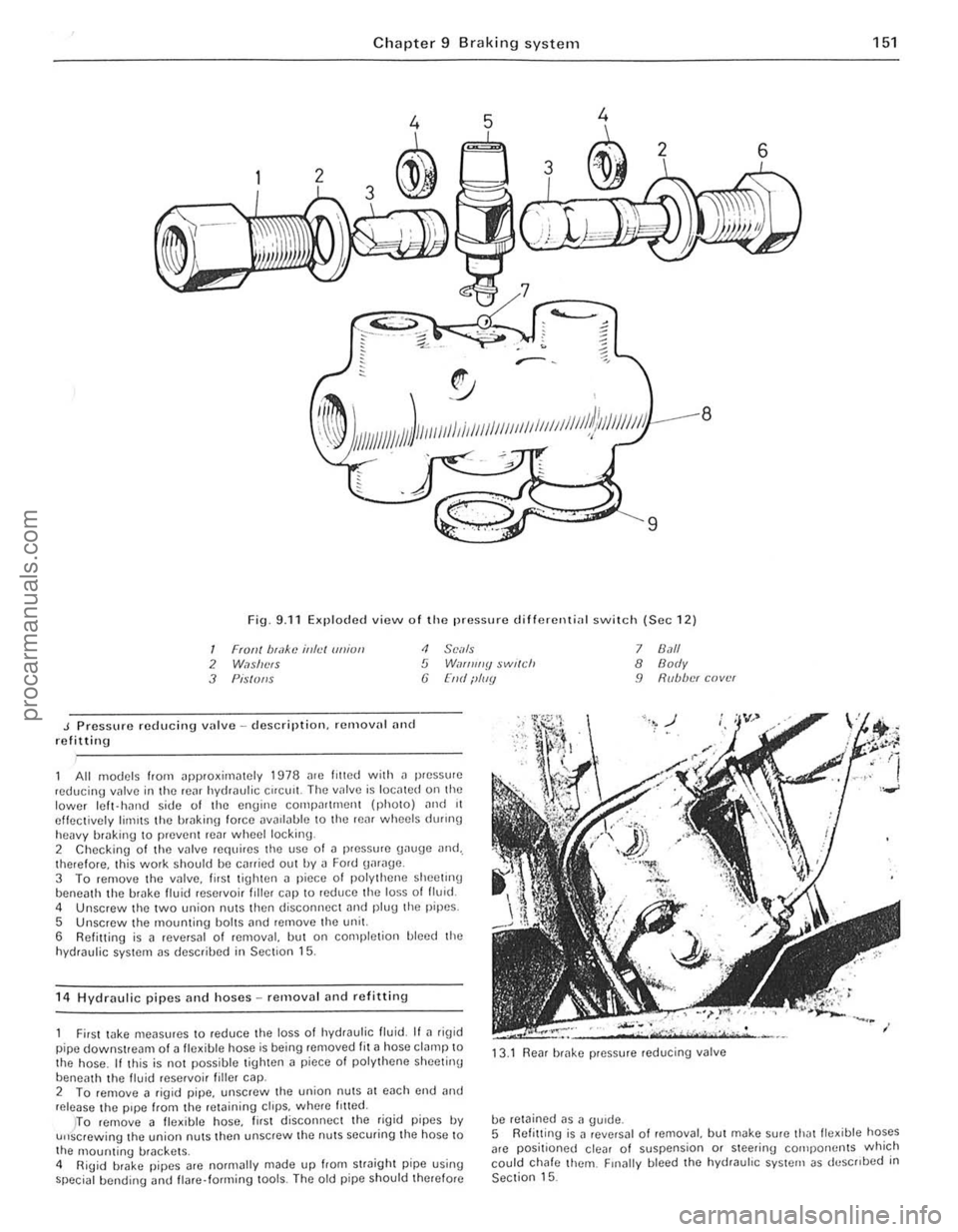

Fig. 9.11 Exploded view o f Iho pressure d ifferenti

J Pressure reducing vulve -description. remalln' nnd refitting

<1 SCi/Is 5 W,If/ll//y $wl(ch (j [lid ilIIIY

All models from ~pproxirniltely 1978 me lilted with il pressure ,educing valve in the rC~f hydraulic Cifelli!. The IInlve is IOCillCd on the lower Icft- hJrHJ side of the engine compn((mcnt (phOIO) ,mel 11 effectively limIts the hrakin\1 force DV

5 Unscrew the mounting bolts ,md remove the unit.

6 Refitting is a reversal of removal, but on completion bleed the

hydraulic system as descrihed in Section 15.

1 4

Hydraulic pipes and hoses -removal and refittin g

7 8.1/1 8 Body 9 R(lb/w( cover

First wke meilsures to reduce the loss 01 hydraulic fluid. If ~ rig id

pipe downstream of a fle~ible hose is being removed fit ~ hose clamp to

the hose . If this is not possible tighten a piece 01 polythene sheetinu

beneath th e livid reservoi r filler cap. 13

.1

Rear brake pressure reducing valve

2 To femove a figid pipe, unscrew the union nutS;]1 each cnd and release the pipe from the retaining ctrps. wh(Jre /riled.

be retained as a gUide.

151

)TO remove 11 fle~ible hose, lirst disconnec t the rigid pipes IN u"screwing the union nuts then unscrew the nuts securing the hose to

the 1l10unting brackets .

4 RiUid brake pipes arc normally made up from straight pipe using special bending <.rnd flare· forming lools. The old pipe should therefore 5

Refitt ing

is J revNsal o f removal, but make sure thJtlle~ible hoses

arc positioned clear of suspension or steering cOlilpo rwnts which

could chafe them. Finally bleed the hydrauhc system as deSCribed in Section 15.

••

procarmanuals.com

Page 156 of 205

) Chapter 9 Braking syste m 155

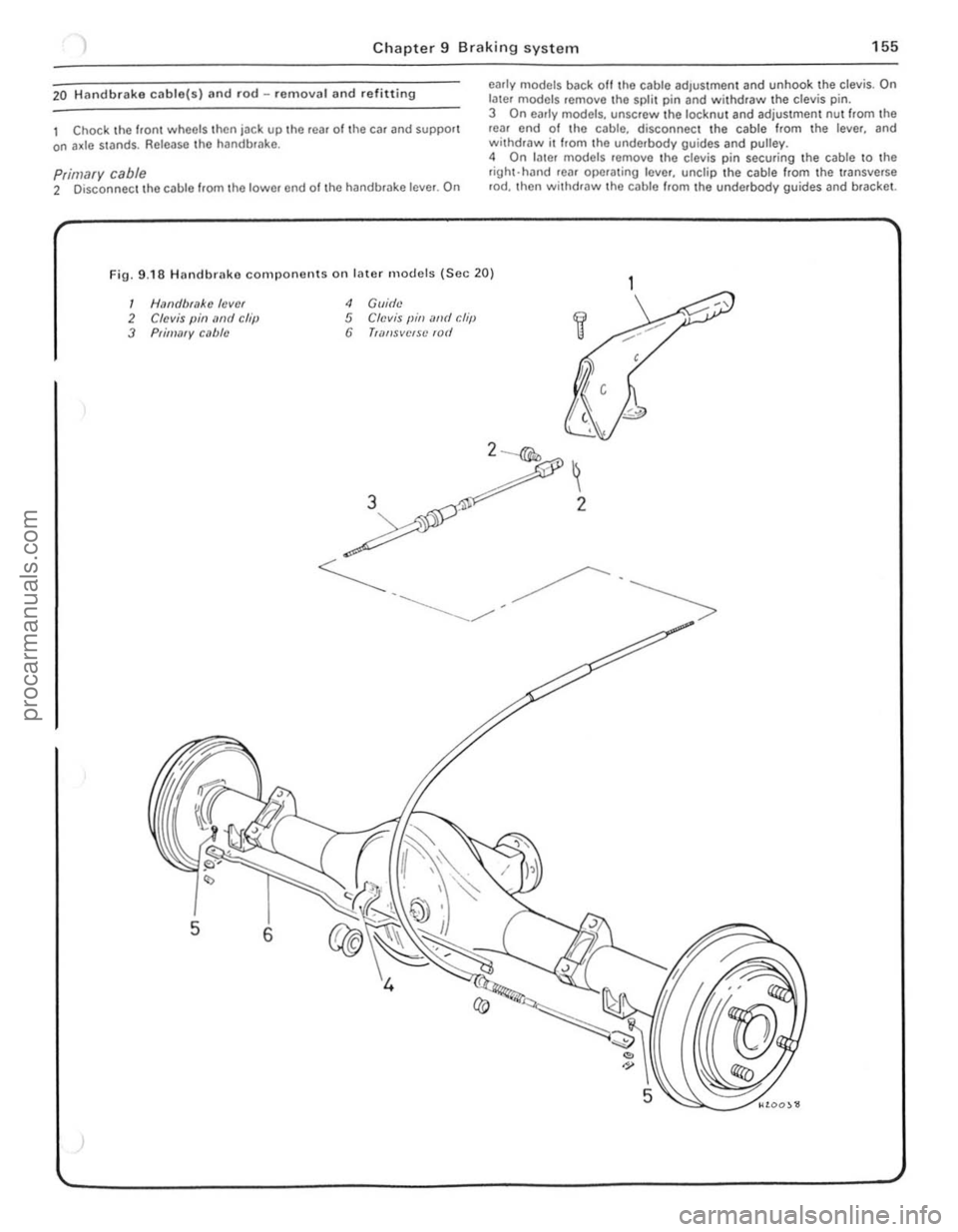

20 Hllndbrake ctlble(s) and rod -removal and refitting

I Chock the hon wheels Ihen jack up Ihe rea, ollhe car and support on a~le stands. Release tho handbfilke .

p,imary cable 2 Disconnect \heCllble flom Ihe lower end of Ihe handbrilke lever. On

c1'IIIy mOdels back 011 the cable ad,ustment and unhook the clevis . On latcr models remove the split pin and withdraw the clevis pin. 3 On early models, unscrew the locknut and adjustme nt nut hom the rOlll end 01 Ihe cable. disconnect the cable Irom Ihe lever, and withdraw it Irom the underbody guides and pulley.

4 On l

•

I HaN/brake lever 2 Clevis pin lIml chi) 3 Prif!!lIfY clIble

4 Gllidc 5 Clevis {lin illld r:hiJ 6 TWf/sveISC lOti

3

, , ,

, '. , /

·f

! I i ,

I:

!

1 1

i 1·

!

j j

procarmanuals.com

Page 157 of 205

,

156 Chapter 9 Brakin g syste m

Secondary cc1ble (early models) 5 Loosen 1I1c lock.nut ~nd unscrew the adju stment ferrule from the right-hand rear clevis.

6 Remove the split pin and clevis pin securing the secanda.v caulo \0 the left-hand Icar operating le ve l. 7 htrac the clip, remove the clovis pin. and withdraw the pullcy wheel from the lever on the Ical a~le. 8 Remove Ihe cable from the lever.

Transverse rod (later models) 9 Disconne ct the cable from the righi-hand rear opCfating Icvcr by

removing the split pin and clovis pin. to Uncl.p the cable hom the 'Hlnsvcrse rod . 11 Remove Iho spli, pin and clevis pin securing the fod 10 the Icft·h~nd le;!1 operating lever . 12 Slide the transverse rod Irom the guide on the rOM axle . 13 Check thO {luide bush lor wear and dama ge and renew It il necessary by prising il oul and pressing a new bush irllo POSilioll.

All models 14 Refining is a r e versa' of removal. but lubr icllto the lin kage as )scflhed in Section 2, and atljl' stthe cable as (fescri bed in Section 18.

21 VilCUUrll sorvo unit -dosCrilHion

A vacuum servo unit is linod Into the lir,lk e hydrallirc cil cu il. 111 series with I he 111,1S ler cylinde f. to provide assiswnco to the dllver whlln Ihe brake pedal is depressed . Thi s reduces the eHolI le{luired try the driller to oper,lIe the brakes, under all brak ing condi tions .

This unit operates by vacuum, obtained from Ihe indu ction mnni rold and comprises basicall y iI booster diilphragnl and check lIallle . The servo unit and hydraulic master cylinder are connected

t o gether so that th e serllO unit piston rod acts as the master cylrnder pUShrod. The driller's b rilking ellon is trilnsmitted through allot her PIi ShlOd 10 the serllO unit piston and ils built-in COmrol system . The scrllo unll pislon docs not fit tightly inro the cylinder. but has a strong ,lltl flhril!Jlllto ke el) liS edges in COllst ilnt COntaCI with I he cylinder Willi_

23 rilult diagnosis -hrilking system

~ylllptom

-'ceSSllle ped,,1 u;tllel

nrakcs pull 10 ono Side

Or;tke ludder

E~cessive eHor l to stop car

so ensuring an i1inigh t seal between the two parts, The fo rward

chamber is held undelllaCUUm condi tions cleilted in the inle t manifold of the engine and during periods when the brake pedill is not in use, the controls open a passtlge 10 the rear ch ambe ., so placing it under lIacuum conditions as well. When the b.ake pedal is dep.essed. the lIacuum pass.Jge to the rear chamber is CUI oH and the chamber expos ed to atmospheric pressure. The consequent rush 01 ail pushes

the servo piston lorward in tile lIacuum chamber and operates the main push rod to the m.Jster cylindcl. The controls are designed so that assistance is given under all condllions. When the brakes are 1'101 requ ired, vacuum in the rear chamuer i s .e -es tabl ished when the br.Jke ped.J1 is released . All air Irom the atmosphe.e entering tho rear ch.Jmbe. is passed through II sma ll air trlter. Und er normal opcr.Jting cond itions tho IIflC(IUm serllO unit is lIery relraule and does not require ollerhaul e~cepl at IIcry high mile,1geS. In this case it is far bcner 1 0 o bta in a serllice e~hange uni l. r,1the, than rcp;ti . the o,igi'lo11 unit . Although inlernal components we,e once .Jv'lIlaule 10 ' ovcrhauling purposes this service has no w been

d,scont,nue(t .

22 Vacuulll servo unit _ remOlla l MId re filtillg

I RemOIlO the master cylinder as desc.ihed In Section 10. 2 D,scolllwc l thc vacuum hose from the non·return lIalve on the serllo \lI1it. 3 Work i,,!) insido thc cal. remOlle th e lower l;t cia panel below the stccring column. 4 E~tractlhc clip and l)ul1 outlho clellis pin attaching Ihe push.od to the l ootu .ake ped;t!. 5 Unsc.ew the nuts securing thc mount ing b.ack.et to the bulkhead.

then withdraw thc serllo unit and bracket from the engine COlllp,lJtlnen t, 6 UnSClew th e nuts ar1(1 serlar,lle the braket 110m the SCIIIO uni, . 7 netrning IS;t rell e.sal 0 1 remOllal w ith leference .Jlso 10 Section 1 0 when retrumg Ihe master cylrnder.

Renson(s)

RC.Jr blake self adju sting mechanism faulty All i n hydrilulic system

WOIll or cont,llllina led /rnin{Js Seized Caliper or wheel cy linde r

E~cessille run-out or distortion of discs o. drums

Worn Of cont aminated linings Brake backplate or caliper l oose WOIll suspensio n bailloints

SerllO unit faulty

Worn or conwmin.Jted linings

I

J

procarmanuals.com

Page 162 of 205

Chapter 10 Suspension and steering 161

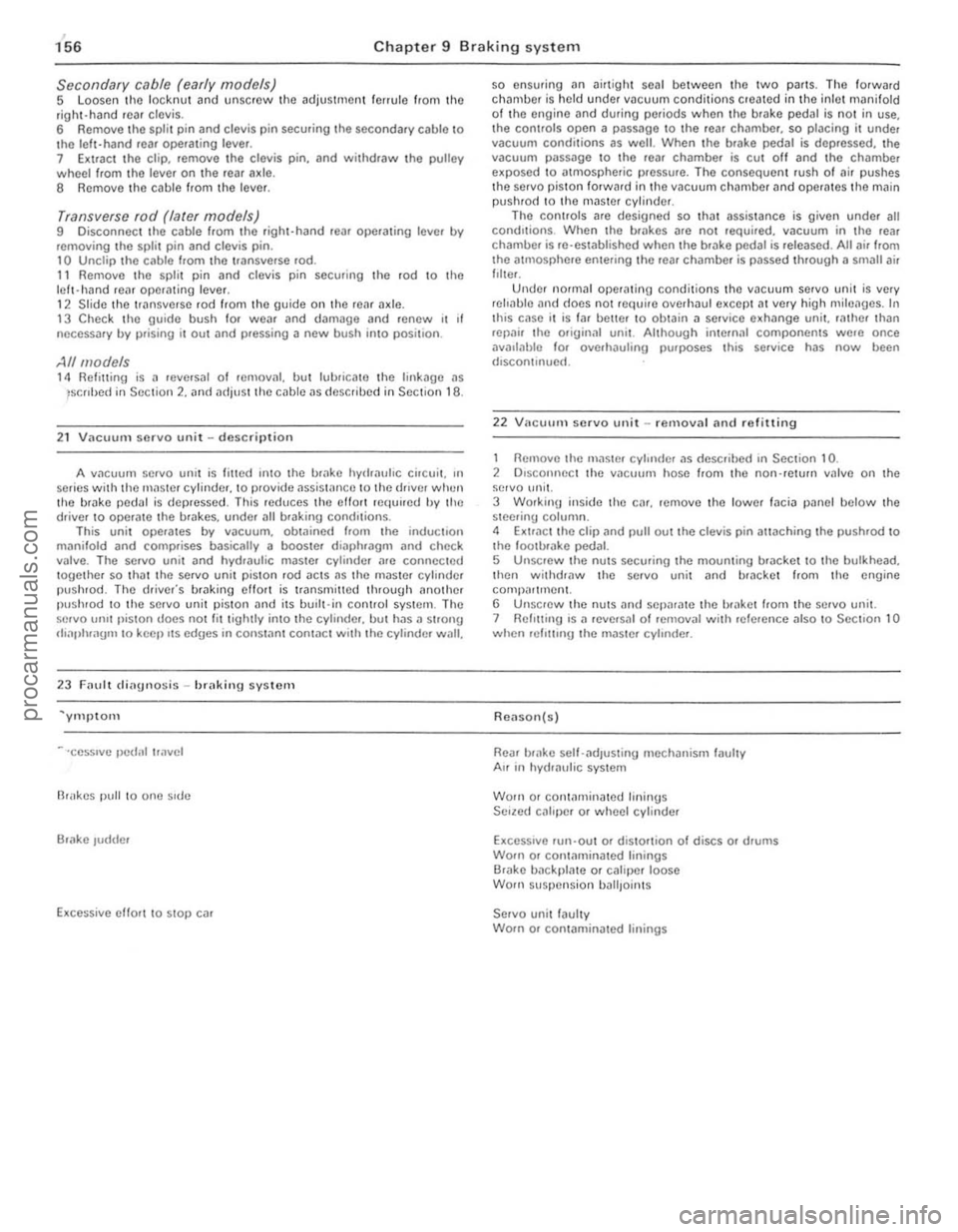

fig. 10.11 Drivebelt [ldjustlllent pulley holts on 3.0 litre models -arrowed (Sec 2)

2 Routine maintenance

At the "*',vals spec ,f,ed III the Routine MainhHlance $()(;t,on in the front of til() manunl c,lIIy out the 101l0wlIl\j p,o(;cdures.

Check lyres for illflalioll, wear and conditioll 1 Check [lnd If necessary adjust the tyre pressures .

2 Check [III t yres for WC[lr and condition with referenc e to Section 21

Check power steering pump drive belt tensiof) 3 Check thm the deflection of the drivebelt m,dway ulon!) its lonyest nlll between upper pulleys is approxirn

(photo).

Clwck puwer steering fluid levef (lnd hydraulic huses II pOSStble the level should be checked w,th the Buid [It nOll1lal

uper,\!mg tClIll)Cr[lture . 6 On c;lrly modcls unscrcw the wing nut nnd relnove Ihe rese,voir cover ilild uaskel. The flu,d should be up 10 Ihe MAX level mark on the

reservo". 7 On later models, wrn tht! hiler C

Fig. 10. 5 Topping·up the power steering reservoir on early models (Sec 2)

8 Whele nec.ess.1'y ~dd Ihe ~pccilled lIU1d to bring Ihe level up to the

correct ,nilrk. 9 ChC(;k the hydr[luhc hoses for comJit,on and security.

Check steerinfj ,-md suspension components 10 n,ll$O tilt) front ilno reM 01 the Cill or position over an inspeclion pn. 11 Check the SleetinlJ wck and t'e 'rods for d[lm3ge und weM. Also check the wek HJbber bellows and track rod end rubber bOOIS for spfilS

ilnd leilk[lge. 12 Chec k the front ,md reilr suspension components lor d"m.Jge [lnd wear. In particuf;lr check the front suspension tr.Jck control Mm ilrod stahiliwr r"bber mounling bushes. Usc a lever to check that there is no excessive we[lr III the Iron I slispenSlon lower IJ[ll lJoints which Me

"'\()\JIill wnh the track conlrol ilflllS . 13 Check the operat,on of the I,ont ;IIHt rear shock absorbers This is

be st ilchievcd with thO} Cilr on the \lfOlind by depressing euch corner of the ca' 1111\I1. On 'ele[lsil\ljthe C()"H~r helllU checked Ihe body should ,,~c thell s"llie IIlIl11ed,mely on ,t~ way down. II there nrc sever.J1 ()sclll;ot'ons the sho(;k absorber IS weilk nnd should be renewed.

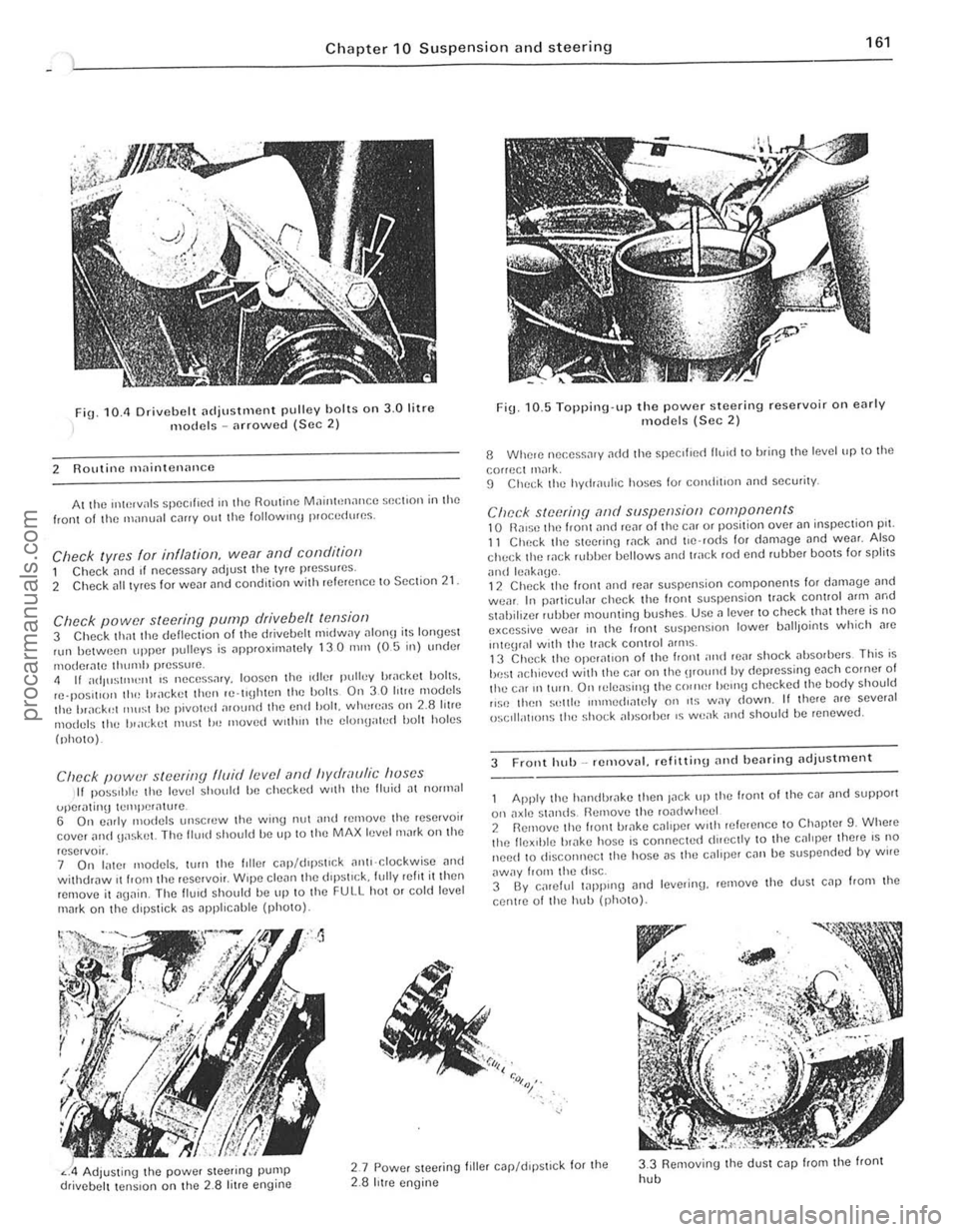

3 Front hub _ removal. refitliny and bearing adjustillent

Apply the h[llldhr[lke then Jilek tip the front 01 the cm ilnd support

on axlt! standS Remove til(! rOildwhecl 2 Rernove the front ul;lke CJllper With ,elerence 10 Ch.Jpter 9. Whele the flex,ble br[lke host! is connecte(t dueclly to the cililper ther e IS no need 10 disconnect the hose i1S thO} caliper can be suspcnded by wire

aWily from the diSC. 3 By calelul 1

" :<>,:,~,.

Adjusting the power Sleering pump drivebelt tension on the 2.8 litre engine

2.7 Powcr steeling filler c.Jp/d,pstlck for the 2.8 hIre engine

3.3 Removing the dUSI cap from the front

hob

i

i ,

~ !

procarmanuals.com

Page 163 of 205

162 Chapte r 10 S uspension and steering

)

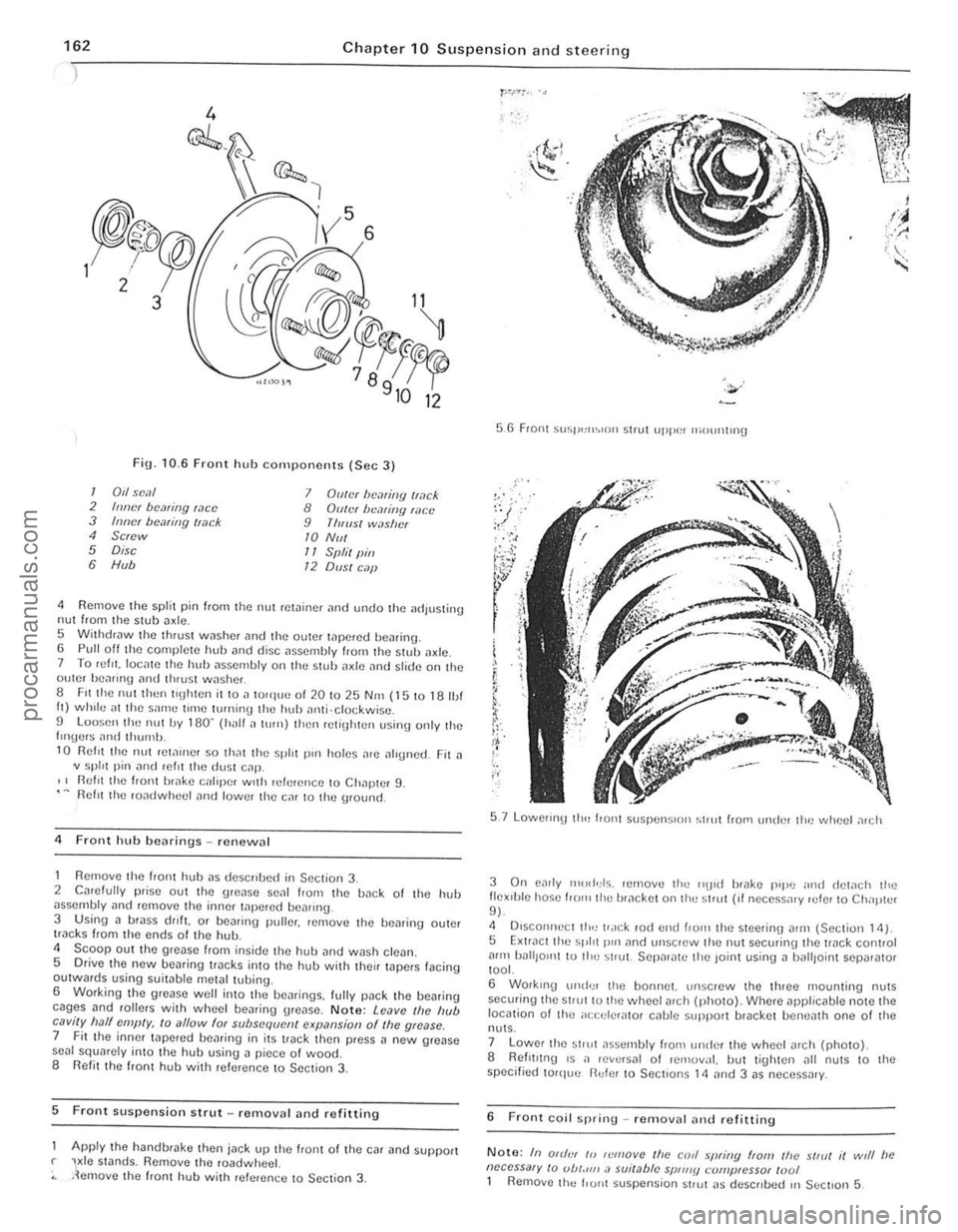

Fin· 10.6 Front

@",.,i

, 5

Y 6

hub cOnll)oncnts (Sec 3)

12

1 0,1 seal 7 Diller be,?li/!{J Iwck 2 IIIlIcr bcaring wee 8 GUiN Iwmitlfl filct' 3 Inner bemiJlg /I,?ck 9 ThlllS! wilslwf 4 Screw 10 NIII 5 Disc 11 Sf"il (lin 6 H", 12 01151 C.1jJ

4 Remove the split pin frorn the nul rC\;linCf and undo the adluS\ing nul from the stub a xle. 5 Wilhd,nw the thr ust washer and the outer tapered he,..ing. 6 Pull off the complete hub ;111(1 disc ilsscrnbly ffOIl11hc s tuh tlXlc. 7 To refit locale the huh tlSscmb ly on the stub il~lc <'Ind slide on the outer hc"rinu nnd II1

1 0 Rei" the nut ret;)u)Cr SO th~t the spill pUl holes ~re ~lIg"ed. Fit a

v split pin

2 Cmelully prise out the gre.lse senl Irom the b~ck 01 the hub

Scoop out the grease 110m inside the huh imd wash clea". S Drive the new bearing tr

glease well into th e beiu ings. lully p

Front Suspension strut _ renl0v

Apply the handbrake then jack up the Iro"t of thc car ilnd SuppOrt r ViC S\Jnds, Remove the roadwheel.

.lel1love th e front hub with referen ce to Sec lion 3,

56 Front SllSI',,"~'nll Slrut uppe, moullt"l{j

5.7 Lowellnl) 110" f'o"l SUSrlt''' S'OIl ~lr"tlro"'ll"der the wheel a,ch

I !:'~

!; ... ~

-;;

3 On e~rly n,,,dds. Icmove the "\lI d brake p'pu ""d dew ch Ihe flex'hle hose 1,0 '" the br.1ckct on thu strut (, f neccssilry ruler to Ch"p ll'r 9 ).

4 OlsconneClilHlu.u:k rod l'nd from the steer;ou n'm (Sect ion 14) 5 Extrncllhl' spirt p,,'

tool.

6 Workrng Ul1d'; r Ihe bonnet. un screw the three mounting nuts sec(Jl iog the 51'Ul 10 the wheel arCh (photo). Where applicable note the location 0 1 Ihe ilce ele r" tor cnble Slipporl bracket be ne3th one of the

nulS .

7 Lower the stru t ~ssembly from undl'r the wheel arch (photo).

8 Refll,!n\) '5 i' reve rsal 01 removal. hut ti\)htcn all nuts 10 Ihe

specified torq(,e fl"fe r 10 Section s 14 and 3 as necessary.

6 F ront coil sp ring - removal and refitting

Note: In Off"" /0 ,(:mo ve Ihe corl .~"{!finy ffOIl! the strut it writ be neccssa,y /0 ub/."" .1 sui/able sP"".

Page 164 of 205

Chapter 10 S uspension and steering 163

~~--,,$iJO

~~\~

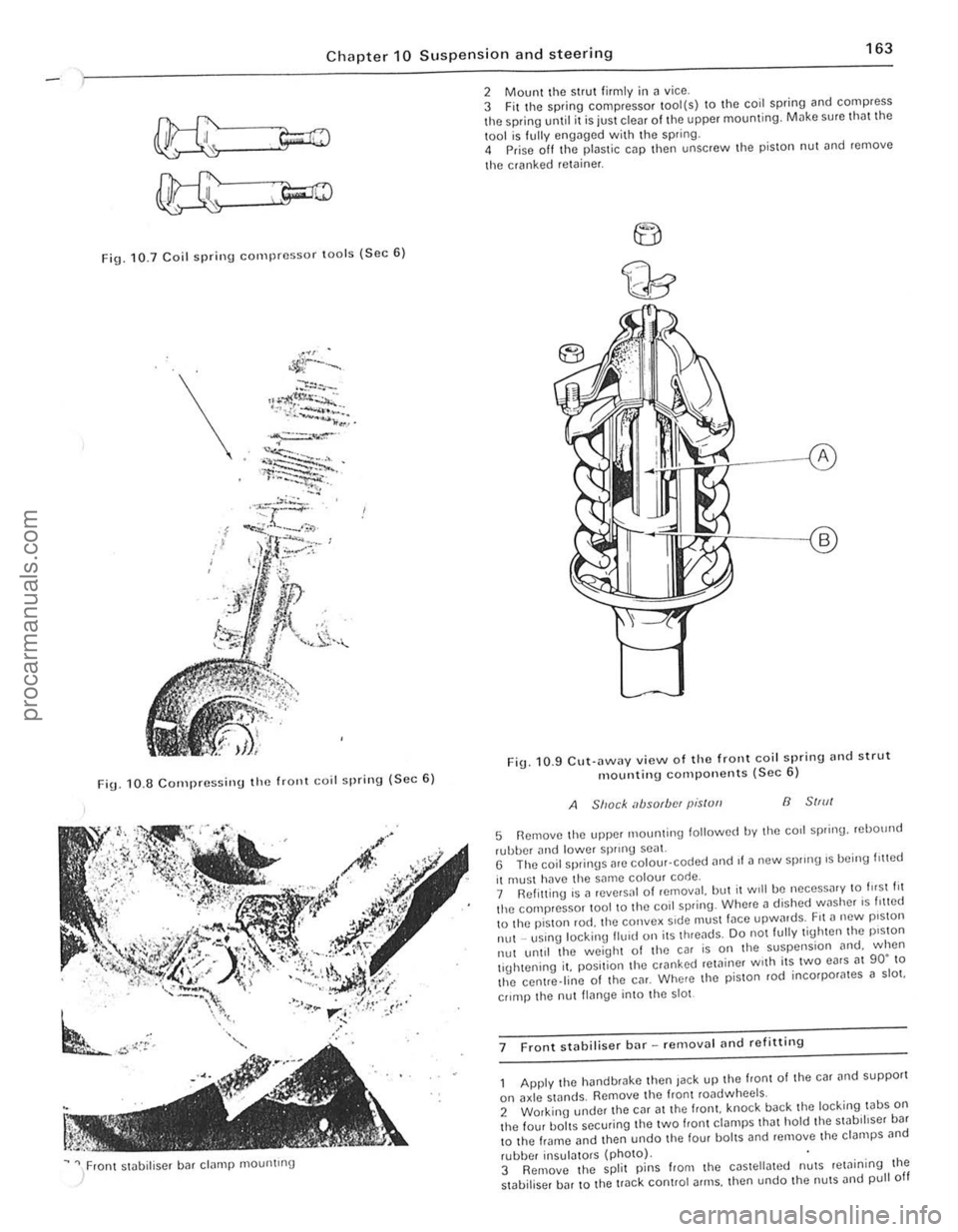

Fig. 10.7 Coil spri n g compressor lOo ls (Sec 6 )

\.

FiU. 1 0 .8 C o rn pressi nu the frOllt Goil spring ( S ec 6)

~ " / ron t stobiliser bar clamp mountrng

2 Mount the strut firmly i n ~ vice .

3 Fit t he spring compressor tool(s) to the coil spring and compress the spring until it is juSt clear of the upper mounting. Milke sure tho t the

1001 is f ully engilged with the spring.

4 Prise off Ihe plastic cap then unscrew Ihe pis ton nut ~nd remove

t he cranked

retoiner .

F ig . 10 .9 CU\·

ilWilY view o f th e front coil spring nnd strut mountin g compo nents (Sec 6)

A Shack absorbfN pis/ull B 51,,11

5 Remove Ihe upper 1110unling lollowed by Ihe corl spring. rebOllnd

rubber and lowe r sprrnU seal. G The coil springs are colour· coded ,1nd II a new sprong 's being I,!led

il muSI hilve the same colour code.

7 Ref itting is a reve,sal 01 removal. but il Will be neceSS

lhe centre.line of Ihe CM. Where the p iSlon rod incorpor

II~nge into the 5101

7 F ront stabiliser bar -removal

he hand brake then Jack up the front of the car and supporl

on axle stands. Remove Ihe fronl roadwheels.

2 Working under Ihe CM at the Irani. knock back the loc king tabS on the four baits securing tile two f,ont ct~mps Iha t hold the swb,hser ba r

t o the frame and then undo t he four bol tS and remove lhe clampS

,

I " I , ,

j

!

procarmanuals.com

Page 165 of 205

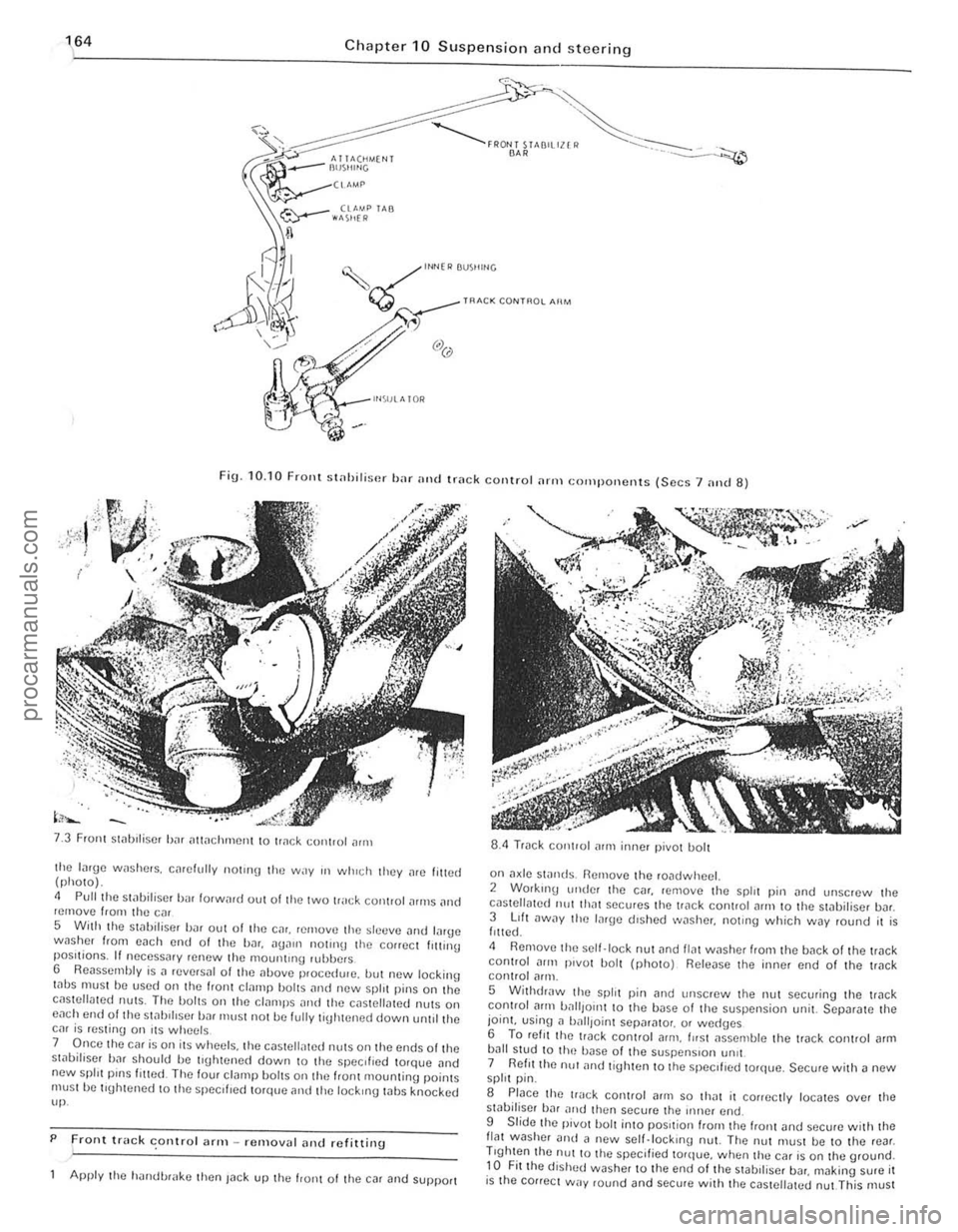

Chapter 10 Suspension and steering

~ l"Nfl> BUS"'''G

~ TRACK CONT~O~ AIIM

Fig. 10. 10 FrOllt st

Front Slilblliser bJr iltlilchmCIll to tr

5 With the stilbiliscr bilr out of tire Cilr. rernovtl the sltltlve Jlld lilrge wnsher from each end 01 the bar.

7 Once the car is on its wheels. the c(lsteli,lted nUlS on Ihe ends olthe st,)bifiser bar should be tl\[htened down to the specIfIed torqlJe .. nd new spill pinS filled The four cl(lmp bOilS on the IranI mountinu poinlS must he tluhtened 10 the specliled torque and tile lockIng whs knocked up.

P

Front truck conlro l ;lrm -removal alld refitting .

Apply the h'lIldl.>r

on a~le swnds. Remove the roadwheel. 2 Working ullde! the C(lr. remove the spirt pin (lnd unscrew Ihe cilslellmed 11111 Ih"t secures the trilck coniroi

5 WithdrJw the split pin [lnd Ullscrew the nut securing the trilck control Jflll battlOIl1 10 the base 01 the suspension unit. SCpar[lte the joint. using n ball,oinl Sepnr[llo,. or wed(Jcs 6 To ret, I thc lI"ck conlrol arm . fllsl JsscOlble the track conlrol [lrm bJIl stud to Ih(~ bilse of the suspenSIon !m't 7 Reflllhe nu! ilnd tighten to the speCIfIed torque. Secure with a new spirt pin.

S Place the track control (lrill so IhJt il conectly locates over the sliIbiliser hJr nltd then secure the iIlller end.

9 Slide Ihe pivot bolt into pOSItion "0111 the "onl and sccure w ith Ihe flat washer Dud il new scll.lock,no nut. The nut must be to the rear . Trghten the nUl to Ihe specified torque. when thu car is on the ground. to Fit the dished washer to the end of the stabll iscr bDr. making sure it is the cOllect way round and secure wit h the cas tellated nut This must

-------------------------.. procarmanuals.com

Page 168 of 205

) Chapter 10 Susp e nsion an d steerin g 167

• ____ I,,, .. r,,,.,

.. , ..

"""""

/

..... . '''M'

""'''''' . ..... >'< '.' AU ... , ..... • Ut ~" ... '''toI •• " .. (', @

........ ' ........ -~~ ' • • ~Mr

.,,·,"'·'·,v"""" ".$"'" ''''.''''.",,~. ~

."', ~

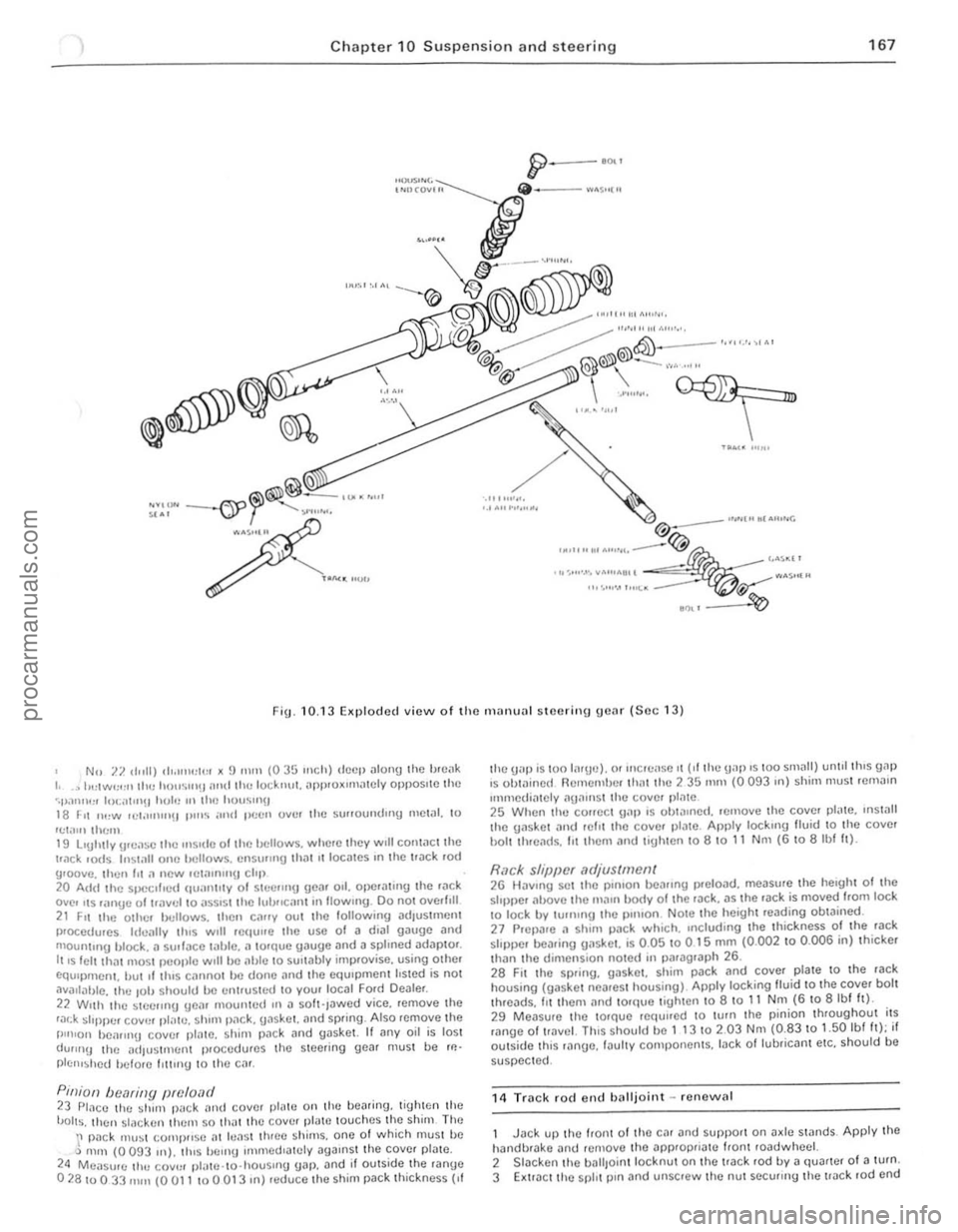

F ig. 10. 13 Ellplodcd view o f the IlHII HHl I steering gear (Soc 13)

No 7.7. d"lI) ''''''''':1\:1 )( !) nit" (035 Inch) deep

22 Wllh the ~Ieelmg Ueilr mountud III iI so h·Jawcd yice. remoye the r,:u:k ~I'ppur coy", pl!!Ie. shim p,1ck. {lilskor. mid sprIng . Also "Jmoye the I"n'on bOilflll\J coyer plalC. sh im pac k and gaskot. It i1ny oil is lost dUIIIl!) thc adJustfllenl procedures thO steering gea r must be rl!'

plc'''~hcd hclore IllIIng to Iho cm.

P,niOIl bec1ring preload 23 PlilCC the shun p,l c k alld covcr pl1lle 011 Ihe bearinU. lighten the 'JOlts. then s lacken Ihcm 50 .hal Ihe covel platc louches the shim The \' pilck Illll~t (;omj}lIs e ill hlil st three sh ims. one 01 which musl bc Q m,n (0 093 In). tlus bern!) ullllledlalely agaIns t the COYcr plate. 24 Measure Ihl! COV'" pl,lle .to·housllIg gilp. and if outside I he ranUe 02810033 fllill (0 all 10 a 013 In) reduce 'he shim pack th ic kness {If

Ihe UilP is '00 li1rud. or Illcrei lse II ("the gap IS 100 slllilll) unlll Ihls gill) IS Ob'ilillcd Remembe r Ihat lhc 2 35 111m (0 093 III) shim Illustrcmillll

Immcdiately "UilIllSt Ihe cover pl;)'e 25 When the COIICCt \1.11) IS ohl!!lIlcd. rernoye Ihc coy!;'. pl"le. IlIs!.111 thc gasket ilild r efit ,ho coyer ,)IJ tc. Am)ly locklllg lIuid 10 Ihe coyer hOi' th.eilds. lit Ihem ;)"d lighlen,o a 10 11 N m (6 \0 albf It).

Rack sl/iJpcr .1djus(mell( 26 HilYlllg set thO pOlllon bearing preloJd. measure 'he heIght 01 the stopper il!J.OYC the IIIillll body 0 1 the rJck. as ,he rilck is moyed Irom lock \0 lock by turnIng 'he pillion NOIe thc height reilding obtained. 27 Pr CPilre ;l shim pack w hiCh. Including the thickness 01 the 'ilck sloppe r beJring {JilslIet. is 0.05 to 0 15 mill (0.002 10 0 .006 in) thicker than ,he dimcnSlo n lIoted In piuagrilph 26. 2a FII Ihe spring. gas ke t. shim pilck and coyel plate to 'h e ra ck housing (gaske l ncareSt housing) Apply locking lIuid 10 the coyer bolt thrcads. III them illld 10rque tigh.e n to 8 10 11 Nm (6 to 8 Ibl h). 29 Measur e thc ,orque rC(tullcd \0 lurn Ihe p inion throughout i,s mnge of I!.lY cl. ThiS should bc 1 t 3 10 2.03 Nm (0.83 to 1.50 Ibl It); if oulside th,s ,ange. Iilul,y componcnts. lack ollubriCilnt etc. should be

suspected.

1 4

Track rocl end balljo int -renew al

Jack up thc loon. Of thO Cil r and SUf)pOrt on Jx le stands Apply the halldbrilke ;)nd re!llove Ihe applopriil'C Iiont roadwhcel. 2 Slacken Ihe baliJo in l locknut 011 the track rod by iI quarter 01 a turn. 3 Extra ct the spl, t p,n Jnd unscrew thc nul securrng the !Jilc k .od ond

, .. • • ..

::

procarmanuals.com

Page 172 of 205

Chapter 10 Suspension and steering 171

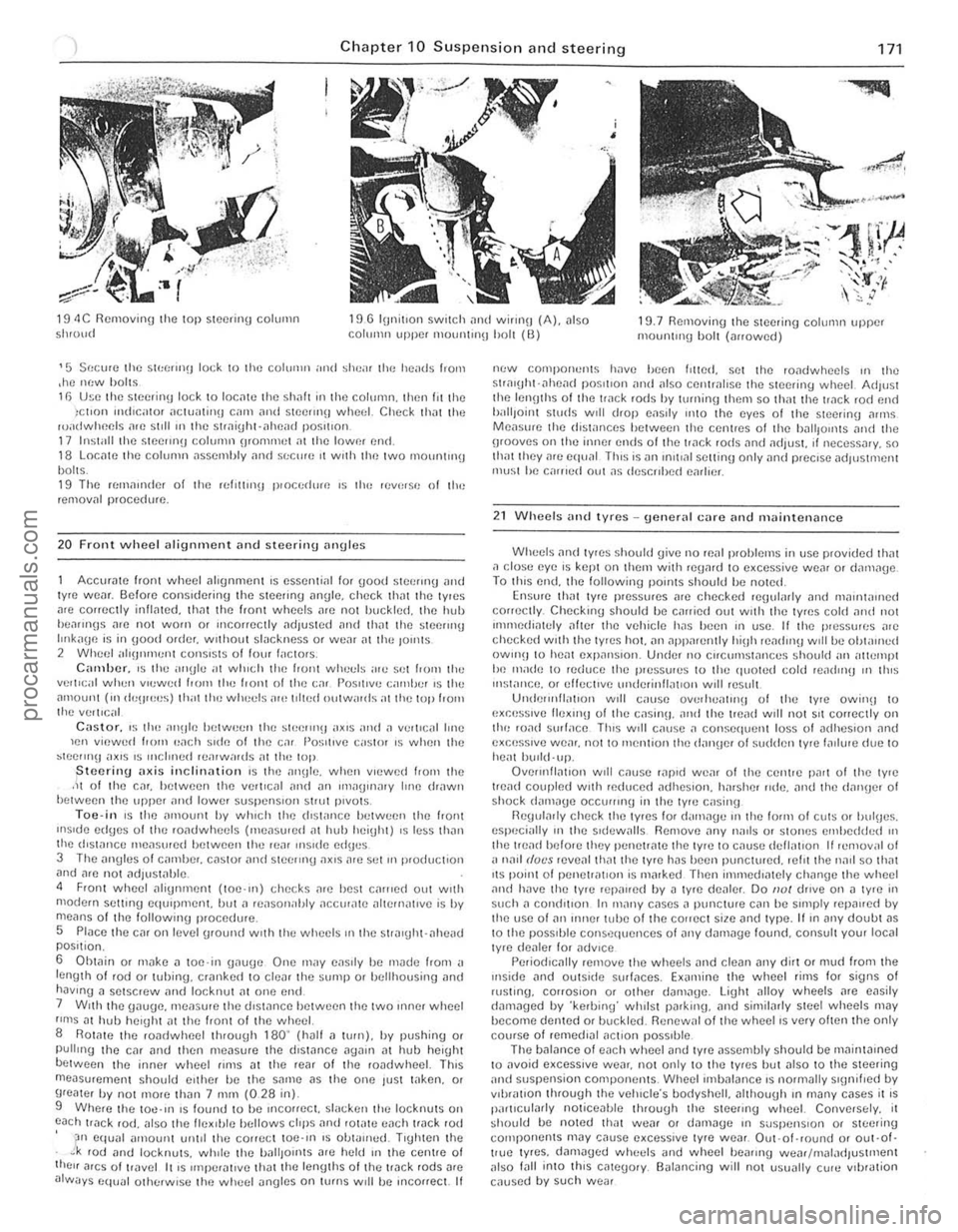

19 4C Removinu the top steering column Shroud 19 G lunitlon SWitch ,1nd wirlllU (A). also COllll'lII upper mOlUllnl!J holt (0) 19.7 Removing the steering column uppcr mounlul(J holt (arrowed)

'5 Secure Ihe SIt:(;(1I1(1 lock 10 Ihe colulIlIl ,lIal ~heil' the h eads I,om ,he m:w holt~ 11) U~e the stecrin\J lock to locate the shaft in Ihe column. then III Ihe )ct,on mdlGltor OICIlJalinn GUll alld Stecrmn wheel. CtlCC~ that Ihe ruadwheels afC st,lIln the 5trai\jht·ahead P05,110l1. 17 Install the Stce!Ul(J column orommet Oil the lowm en(t. 18 LOCille the column assembly ami sr:c",e It wrth the Iwo mOllrlllng bolts. 19 The ((,milliuler of the rellllUI\J proccrl",e ,~ th" reverSI! of lhe removill procedure,

20 F ront wheel alignment and steering ilngles

Accurate front whcel alignment IS essential lor good stoer"'g and lyre WOiJr. Scion) cons,dering the steering angle. check Ihat Ihe tyres

are correctly inflated. tllnt the front wheel s arc nOI IJlJckled. the hub hea"nns arc not worn o r mcorrectly adjusted und thilt the sleflr"'g IlIlkaUfl is in IJood order. wllhout slackness or we,ll at thu Jo,nls

2 WIH;f; 1 "I'!JIununt co"s'st~ 01 loUl I"ctors, C;"lliJcr_ IS the ""Ule "t wilich the front whet:ls ,lie sci from Ihe

verllcal when v'ewud 100'" the IrOnt 01 the c"r 1'0sIt,ve camber 's Ihe .. mount (111 de\J'ee~) th"t til() whucls ,ue toited outwards at the lOp 100'"

thu vert,c;,1

Castor. ,~tho i"'~Jlu between the SIl,erlIlU ,,~,s OIrld.1 v..,'I,e.11 lone len viewud IrOIll p,lch ~,dfl 01 the C,lI 1'0~;llIve castor 's when the ~tcermu ",x,s 'S ",cloned rUiHw,,,ds ill the top jStcerinu ilxis inclin,,{ion 's lhe illl\Jle. when VIewed frOI11 the .It 01 the Cilr. bel ween the verltcal and "n 1Il'''U>I1.1ry hne drawn betwCl)n the upper ilnd lower suspensIon strut p,vots, Toe-i n IS the ilmoUl,t by wh,ch tlte dl5li"'Ce helween the frOrlt

IIlsuJu ed\Je~ 01 the rOildwhecls ('He,lsu1ed m huh heiuht) ,s less thiln lhe d'sWrlCI) ",e

6

Oht"in or m"ke

ne:w components have heen I'lted. set the ro"dwheels ,n the stral\jht·ilheil(f p05otrOn and also cent",lrse the steering wheel. AdJ"st the len\Jths of the track rods hy lllll1ing tltem so th,,! the track rod end IJ,litJoinl studs w,11 drop eils,ly onlO the eyes of the steer inu ilrlllS Measllfe the dislilllces between the centres of the hilllfOllllS illld the grooves on Ihe inner ends of the track rods and ildjust. ,r neceSSilry. so Ihiltthey me equ,ll Thl~ is all lII,t,,,1 sellinlJ only and prec,se ildillstmellt mu~t he carried oul as descrrhed earheL

21 Wheels and lyres -uonNal care and milintenl1nce

Wheels ilild tyre~ shOuld give no reill problems in usc provided thm ,1 close eye IS kept on Ihe", with re\janlto excessive weilr or dilmilge To llns end. the following pOllltS should he noted Ensure thm lyre pressures ",e checked re\Jularly ami ma,ntallled correctly. Checklllg should be c,Hried out woth the tyres cold alld nOI IIlHlledialely alter the vehicle hilS heen "I usc. II the pressures are checked w'th the tyres hOI. iln ap(l,Hently hi\jh readmlJ w,1l be ohw'lled OWlnH to heilt expJnsron. Under n<) Cllcumst

eSpecii\lIy 111 the s,dewalls Remove any na,ls or stones ell\bedded 111 the tread hefore they penetr"te lhe tyre 10 cnuse dcfliltlon If remov,,1 {)i

dilll1i1ged by ·kerbing· wh,lst par king. and simililrly stee l wheels may hecome denIed or buckled, Renewnl of the wheel rs very ohenthe only course of rellled'ill ilct,on poss,ble, The balance 01 each wheel Jnd tyre ilssembly should be mainta,ned to ilvoid excess,ve weilr, not only 10 the tyres but illso to the s teering and suspension components. Wheel imbillilnce 's normilily S'\ln, f,ed by v,i)rilllOn through the veillcle·s bodyshell. illthouUh III many c~ses it IS piullcularly nOliceahle Ihrouoh the steenng whuel. Conversely. it ~hould bc noted thilt weilr o r dilnlaUc 111 suspellS IOll or steer ing components may '.:ause e~ceSSlve tyre wear. Out·of·round or out-of· t!Ue lyres, damaged wheels and wheel !leafing weilf/ nlilladJustntent also lilll into th

,.

:.

procarmanuals.com

Page 178 of 205

) Chapter 11 Bodywork and fittin g 17 7

~!t~InS its oriOin,11 sh~flC. There is lillie point in trying to restore the original s hllpe complClC ly, as the me1011 on the darnllged arca will have stretched on impact ilnd cannOl be reshaped fully !O its original contou r, II is belter to bring the level of the dellt up to 11 poin t which is aboul ~ in (3 111111) below the level 01 the surrounding bodywork . In cases whe.e the dent is very shallow anywi'lY. i, is nOI worth trying \0 pull 1 ou t 111 all, II the ull{lersidc 01 the dent is accessible. il can be hammercd oul gently from behind, using a malleI with a wooden or plastic head. WhilSt doing Ihis. hold a suitable block of wood l'flllly a{),111151 the outside 01 the panel 10 absorb the impact from the hammer blowS and thuS Il,event 11 Imge area of the bodywo.k hom being 'belled,ouf, Should tho dem be in a section of tho bodywo.k which has iI double skin or SOI1IIl other filclOr mokil1g It inaccesslhle from behind, a

dllferent technique is cillied lor, Drill severill sm;1U holes through the

mewl II1slde the i1reil (Jilrtlcul,ldy in tho deeper section, Then screw long sel1·tap~ing screws into the holes IllSt suffIcien tly for Ihem to gilln iI good purchase In the mewl. Now the Ilen t C"n he 1)lJlled out by pulllllg on the protruding headS of the screws wllh iI pnll of pliers. The no.t stilgo of the rep,lir is the .emOllill of the PilUlt from the 113Ued meil, and hom nn Inch or so of tho SurroundlilU 'SOUfl(r

Jdywork , Tills is accomplished most oilslly by usil1U a wire brush or ab'~sllle pild on " ,)owe< dflll, ~,lthou9h It Clln he done Just i1S e ively hy hnmf usmg shoots 01 1I1)'i151110 P.l,)C •. To COlll,llete the p

thorelore decide whether to renew the whole polllel (II this IS possihle) or to .ep[lir the affoctod illoa. New body Po1nols arc not ,1S expensive as mos t flCOple think and it is often (Iuicker and mo.e satislacto • .,. to fit" new t)anelthan to auempt to rellair larue n.e,1S 01 corrosion.

RenlOlifl all f,llln\Js hom the .. lIeeted a.o" cxcoptthose which Will

act ~s ,1 uu,(ie t o the oliUllwl shape 01 the (i,lIlla\je(i bodywork (ell hn,1(1lnll1l) ~h.~lIs etc). ThOll, USlnu tin snIps or ~ h"cks

d epreSSion fo r Ih c frllcr pas\(!

'll/lle hrush the aHected Me[l to 'CIilOlle tiro powdery rust from the ,ICO 01 the lelllilllllll!l lIlet,,1 P;lInl thc "flected arc" wllh lUst

IIII"I)ltll1l) p""'t. If the hilck 01 the ,usle.1 me,1 's accesSlhle treolt tillS

" delo.o frlhflU cml t

me sh. or altlflll1l1um t",Joe. AlulIll"'um 0' pl;1strc mesh IS Il.oh"bl.,. lile hest m

Aluminium wpe should be us ed lor slll ;rll 0' vCly narrow holes. Pull a picce oil tho .011 ond tri'" It to tho apIl

ove . the hole, rt C[ln be overlapped II tho thickness of one piece is

i nsufficient. Burnish down the 00ges of tho tapO With the handle 01 "

screwdrillC ' or srmllOf, to ensure that the ",po.s securely auached to the

metal undomeath .

Bodywork rCIJ<1irs -filling a"d re-sprayi"g BefOte uSlIlg thiS Seetion, soe the Sections on denl. doep scratc h.

rust holes "nd gash repai.s . M~ny types of hodyfllfer Me ~val'ahlo, but Uonerally spe~k.ng those nrOpnelOry kits which conlain 0 till of f illor paste and a tube of resin h~fdener Me best for this type of rcp,llf A wide, !ieKilJle pl

hardener carefully (follow the m"kCI's instructions on the pack) othe.wrse thO folic. Will !>tt too rill)luly or tOO Slowly . Using the

"pplicator apply the filler paste to Ihe prcpared area: draw the

applicalOr across the surfaco 01 tho IllIer to achieve the correct contour and to lovel the fillef surface. As soon /1S it contour that approxim"tes 10 thO corrOCt one is achielled, SlOp wo.kinU the pas le - il you carryon too long the pasto will becomc sticky and begin to 'pick up' on tho

app lic"tol. Continue to add thin layels of Iiller paste at twenty· minute intervals until the level of the filler is just pfoud of the surrounding bodywork Once the IllIer has hardened, excess can be removed using a met;!1 plane or IiIe. F.om then on. progressively finer grades of abrasive paper should be used. starling with a 40 grade p.oduction paper and l.nishing With 400 o."de wet·and·dry paper . Always wrap the abrasille p"pcr IIrOUlld a flat rubber, cork. or wooden block -otherwise the surfaco 01 the frller Will nOI be completely flat. DUling the smoothing of the fIller SUI face the wel·and·dry paper shoufd be periodically rinsod in walCr. ThiS will ensure thaI alle.y smooth linish is imparted 10 the frller (It th O flllni SHIIJO. At t!\l S st1lge the 'dont ' shoul(! be surrounded by a ring of bme

mowl, whIch in IUfn Should he encirclod !.Iy the finely 'feathered' edge

0 1 th e good paintwork . Rinse tho repair nrea wilh clean water, until all 01 the dust I>roduced by the rubblllu·down operation has gone. Sp."y the whole .ep.1ir a.oa with" light coat of primer -this will show UI> any ,mpcrfOChons in lhe su.face of the fll1e •. Repai. theso Iml)CdectlOIlS with frosh 1,110' paste or bodySlOpper, and onco mOte

smoOth the sUfl

he call1od out in a w".m, dry, wind loss and dus t free atmosphero. This condition can be created mtllicially II you have access to a large indoor working "reil. but rl you nre lorced to work in the open. you Will have to pick your day lIe.y ca.efully . II you a.e working indoors. dousin\J the

floor in the work mea with water will holp 10 SOllie the dust which would otherwise be in the iltmosphe.e . If the ,epai. mea is con fined to one bod.,. pilllOl, mask off tho SUffoundlflg panels; lhis Will hell) 10 minllllise tho effocts 01 a slight mis,match in lH,lint colou.s Bodywo.k hUUlUS (eU ch.omo strips. door handles Otc) Will "'SO noed to be

"';1sked ot! Use uenume fII

S ilray on t he t op CO"1. "\Jain bUlldmu ull the tluckness by usul9

sOllof1lllhlfl'"ye .s 01 p<111l!. S Ia .t spraying in theCllnlre 01 the .epair mOil and theil, USH\g a clfcular mOllon, work outwards untrlthe whole ropmr

"rea ond al>out 2 inches 01 tho surrounding origmal pallltwork IS COvered Remolle allm"sklng mnteflaf 1010 15 minutes alter spr

Plastic compOllc"ts Wllh the use 01 mo.o and more pl"stic l>ody components by the

vehrcle manufac turers (eg bumpers, spolle.s. and in some cases major

body panels). reCllilcation 01 damago to such items .hilS .t.>e<:0me a

mOller o f eHhor emruSling relhl'r wOtk to a specialist m thiS field, o. renewing complete components Rep"ir by the DIY owner is nOlleillly feaSible owing to Ihe cost of the equipmen t and materials reQui.ed for effecting such repairs. The baSIC technique inllolves making a grOOllo

atong th o hno of the crack in the plastic using a rotary hurr in a pow~r drill. The damnged pal! is then welded hack togeth er by uSing a hot "" gun to heat up nnd luse a pl

polyca.bonate. ABS, poIYllropylene) .

procarmanuals.com