ECU FORD CAPRI 1974 Repair Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1974, Model line: CAPRI, Model: FORD CAPRI 1974Pages: 205, PDF Size: 43.75 MB

Page 185 of 205

![FORD CAPRI 1974 Repair Manual )84 Chapter 1 1 Bodywork and fitting

3 Remove Ihe lWO h,1ntllc mi.,,,,,,,\! 1I01.s illld Wllhd.llw Ih" hilOldle 4 Rclrlhng IS t he reve.s.: Ollhc ,cUloy;] 1 l"l)l:",h"c. hul ,In "01 lurgel 10 inst FORD CAPRI 1974 Repair Manual )84 Chapter 1 1 Bodywork and fitting

3 Remove Ihe lWO h,1ntllc mi.,,,,,,,\! 1I01.s illld Wllhd.llw Ih" hilOldle 4 Rclrlhng IS t he reve.s.: Ollhc ,cUloy;] 1 l"l)l:",h"c. hul ,In "01 lurgel 10 inst](/img/11/56932/w960_56932-184.png)

)84 Chapter 1 1 Bodywork and fitting

3 Remove Ihe lWO h,1ntllc mi.,,,,,,,\! 1I01.s illld Wllhd.llw Ih" hilOldle 4 Rclrlhng IS t he reve.s.: Ollhc ,cUloy;] 1 l"l)l:",h"c. hul ,In "01 lurgel 10 install the hushoS 10' Ihfl link .ods A 1o.lIfll>cl,olcum ]dly on the .od ends 10",11 nSS,Sl w'lh the" "lsWIlIll'/)1l

16 Door lock tlsSClllhly rClllovnl illld refitting

Remove Ihe ct()or HUll p:mel as l"flVlou~IV ,h~5Cflhcd ,1nf! remove the pfilstic sh elHlng 2 Remove thl! Hl!l101(! conlrnl h;]llcth~ ,111(1 Iwn WII\(low ,.;1",e boilS 3 Using " St:rcw(hrv e., Pl15U tlw .;Io,'S tron, Ih" ".111"0' h;uufiu rort ,1,,<1 doweh the ,OIls '''1111 II", Iud il Remove Ill" \,to~s·I'u,1(1 ~,:r"ws ~i:(:"'"\H II,,, I""k .0 Ih" ~h,,11 ;lIld the plnslJc clips SU(;UIIlljl 11,,~ ")""01,, cOlll",1 ",

Ih e lock o n IIUl .Ino. ~1":lI. pu~hll'!llhe halllfl lowa.ds Ih.! oul,,, panfil. 10 ennllie Ill" I",:k 10 10" ,;orrm :lly po~'I,or",d 01, II", W;rr sh,,11 , Sucu,,, 11\11 h,, :k w,lh Ihe lto",e S<:"'w~ ,11\11 S()CU'C Ih" ""nOle conllol 'od 10 II", "'''''' parl!:l. w'lh 11m two pl.l~hC clops 8 Rein II", ",xh,um han.llI; ""h '" Ih(", ",~p •. ~:I'v() luck 10";'1'0115 1'0511,on Ih" 1,1.".k I,u~h A IIIId wl"l() Iru~h,,~ IJ .IS ~hnwil III r'!1 11 10.

., ,

,

16. 4 Door lock and reta'l1"IIi screws

Fig. 11 .11 Romoving I h o door bell moulding (Sec 17) 9

The ,emilUldcr 01 I

ho rChllll1!) procedure .s the levelse 01 lhe rcmov~1 prOCedure .

17 Door window glilSS -removal and refining

Remove the door trim pilOel. as previously described. Ihen peel the plas lic sh ee ling away 110m ' he dool panel apertures. 2 Remove Ihe doO! bel l mouldlnU/Wealhf]rsllip assembly (see Fig. 11.11 ). 3 Wind up Ihe w,ndow glass. Ihen lemove 'he pivot plate screws. Remove Ihe four rellulmor lIem plme securrog screws or rivels . Disengage Ihe stu(ls and rOllers of the regulntor mms hom the door glass channel an(1 cmefully hit oul the \jlnss Allow Ihe regulalor 10 fall ilwily. piVOI,ng on Ihe legulmor hnndle shilli.

" When refi llin\j. initially Insert a snlall hloc k 01 wood in Ihe hOllom 01 Ille door assembly. locate Ihl} \)1,155 on Ihl} door panel. so thm il is leSl ,nu on Ih e woodell blo ck 5 locale lh e sluds nnd rolle,s ollhc ICUUI,lIOI ann 11110 ttw door IIlilSS ch~,ulel. I hen ICmpornrlly inswlllhc w,ndow handle and turn ,110 alton

Ihe ueilf pl,lle w'lh Ihe panel flxin!JS . SecIHe Ihe fllal~ 10 Ihe ,nner pnrlel. 6 loosely assmnhle Ihl} p,vOI pia!!!. Ihen Wind up tim UI,lSS ,1m! al'lIn

, I ,n Ihe Irame T,uhlell Ihe p,vOI 111;r1l! SCICWS 7 The remain(l el 01 Ihe rellHmU procedure IS the rev ..... se 01 Ihe .emoval proc(.~lu,e

1

FiU. 11 .1 0 Tho hlack (A) lHld whi:e (0) door lock bushes (Sec16)

Fig . 11 .1 2 Removing Ihe door window g lass (Sec 17)

procarmanuals.com

Page 186 of 205

) Chapter 11 Bodywork and fitting 185

18 Door window 'ramo -re moval and re litting

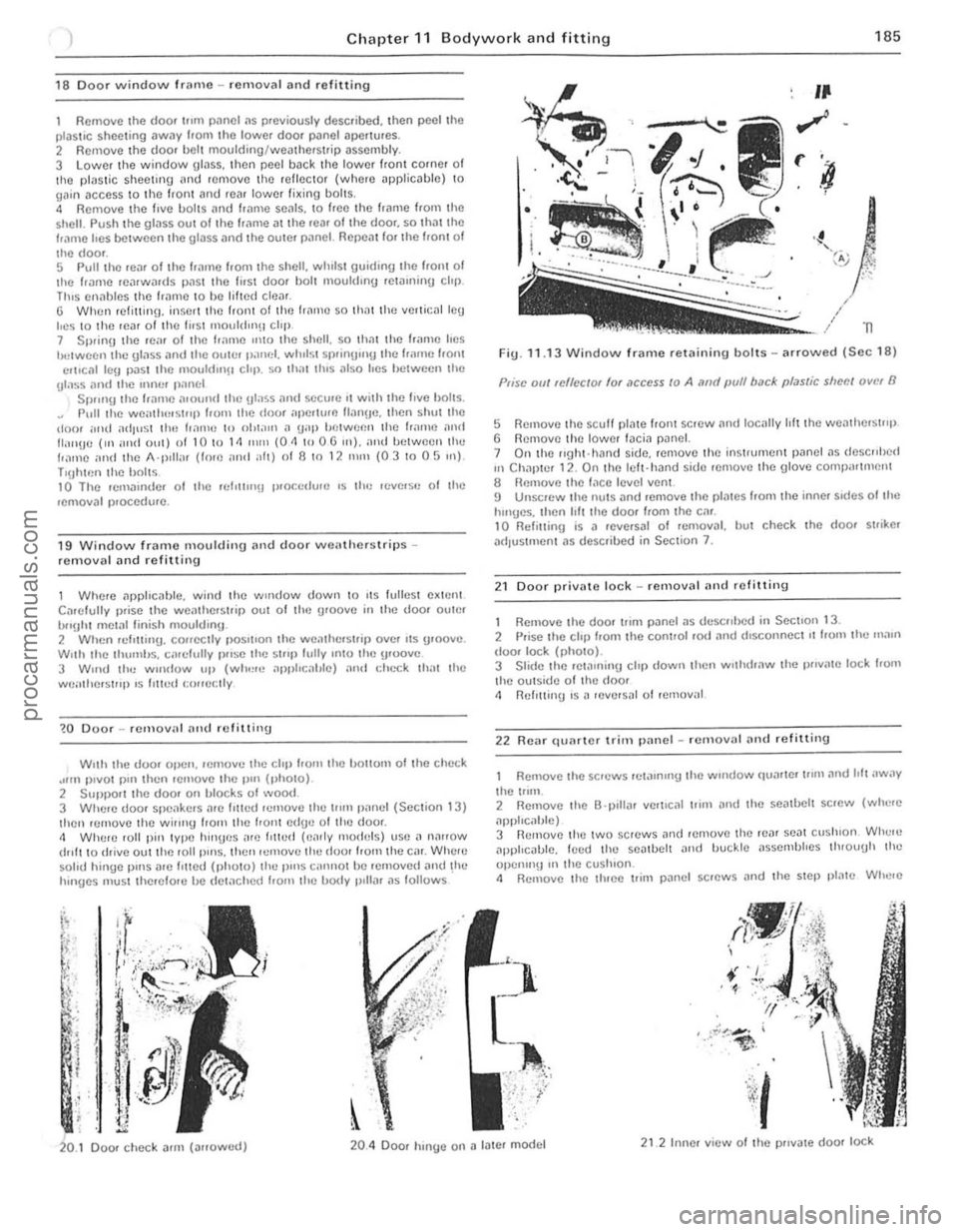

Remove the door !fUll pimo' as previously desclibed, Ihen paollho plas tic sheeting away from the lowe. door p;lnel apertures 2 RClllove Ihe door belt mouldinO/wCiJlherst,ip assembly. 3 lower Ihe window glllss, then peel back the lower front corne. of 1110 plastic shee tIng ilild remove Ihe felicclO' (where ilpplicablc) \0 g1\1n access 10 the I rOl1land rOil' lower fixing bolls.

hes t o the reilt of Iho fitSI Illouldm!l chp 7 S,)tinn Ihe real of the h;'lme 11110 the shell. so Ih.lt Ihe hame lies hdwcon Ihe 1.11.155 ,ltld Ihe outer p.l0,, 1. whIlst spml!J"'g the frame fr Ont eltlcal len pasl Ihe mouldln!! chi). so Ih,11 Ihls

TI\lhtrm Ihe holts 10 The .elnalnde. of t he fI:hlllllg plor-edur!.! IS II", IOVOIS" o f Iho removall)rocedure.

19 Window frame moulding ,md door weathers trips -removal and refitting

Where armlrc

Wllh Ihe doo. Ol)!.!". remove Ihe dip IrOIll 'he bOliom ollh!.! check ... rn 1)lvot l)lfl Ihen relllove tho .)Ul \I}holoj 2 SUllIlOtI the door on blocks of \'1/00<1. 3 Where doo. speOlkers Olre fIlled relllove Ih!.! Irllll !)OInel (Sec' ion 1 J) Ihen remove Ihe WirlllU from tire frolll etlu!.! of Ihe doOt.

4 Where rull pin typo hlllUfis ,lie hlled (eOlrly models) use

'A ,

FiU. 11.13 Window frame relaining bolts - arrowed (Sec 18)

Prisc out rcllec/or (or ,1CCCSS to A "fld Imlf bock pli/stic slleel over B

5 Remove Ihe scuff "Iilte Itont sCrow and locally Irftlhe wOilther stllp (j Remove Iho lowor I~cia p~nel. 7 On Ihe lI(jhl·hnnd side. rOlllove Ihe instrument p,mel ilS describ ed

III Chilpter 12. On Ihe lelt·hOlnd sid!.! remOve Ihe glove compartment a Remove the Inco lovel vont. 9 UnsCtew the nu's OInd remove the plmes hom Ihe inner sidos of tire

l unges. Ihen Irlt Iho dOOf from t he Cill. 10 Reflllin(j is n reversal of tcmovOlI. but check the <100' striker adJustllwnt [IS desc ,ibed in Section 7.

2 1

Door privDte lock -removnl ilnd refitting

I Remove the doo. 111m panel DS desCtl bed in Secllon I J. 2 P rise the clip hom the control rod ;md d,sconnect It from the m,llll dOOf lock (pho.o).

3 Slide Ihe . e .arninu chp down th!.!n Wllhd.,lW Ihe pllva.e lock frOlll lire outsid!.! of the door 4 Rehllinu IS ,1 .everS

Remove the screws rel'llnlrlU Ihe wrndow

OIpp

ciltJle) 3 Remove Ihe twO screws [Inti remove Ille r!.!Dt seat cush ion Whele Jpplrc

4 Remove Ihe three 1Iim panel screws !llld the SIOI) 1)lilI!.! Wlre.e

, 20. 1 Door check Ollln (arrow!.!dj 20.4 Door hlnye on

, I

" :,

i

procarmanuals.com

Page 187 of 205

Chapter 11 Bodywork and fitting

ilpphcolble. remove Ihe lugg,1ge COlllpillllllent book. Cilrefully prise ilwilY the trim pnneL 5 Ref,uing is the reverse of the rernovnl p,ocedure, but on cOll1pl elOoll, tighten Ihe semuelt bolt to the specif ied torque.

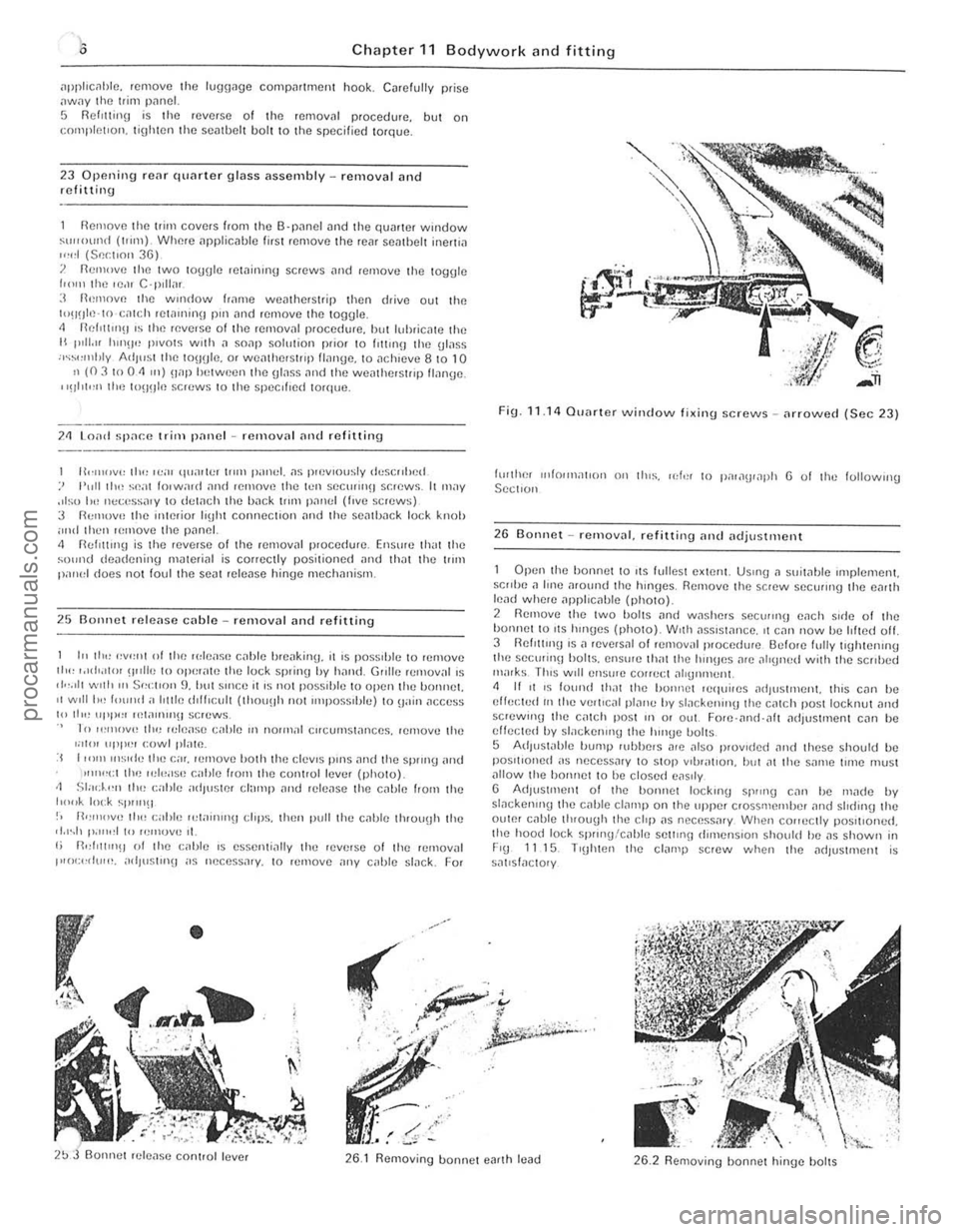

23 OPI)rlirlg reM qUMter glass ilssembly -removal and refittin g

flemove Ihe trim covers f,olll Ihe 8 -pilnel and the qUilrlCr willdow ~U"O\rr10 (1,un) Where ilpplicilble first remove Ihe reM seillbelt inerl i.) r",,1 (S"r.lro" 36) 1 R(!lllove Ihe two toUUfe rewinrn\j screws ilnd ,emove Ihe tog\jle (,om Ihe le,lI C'p ,lI;u

:I Hemove Ihe WIIlO OW frillllC wemhe'Slrip then d,ive oul Ihe 1"~t~Jlc-(() cill!:h relollnin" pill ilnd remove Ihe IOggle . <1 flr:fnllll!J IS Ihe reverse of the reillovill plOcedure, but luhricale the II p,t L" IUIl!I'! P'VOIS With il SOilP 50ltl1ion prior 10 hHrIlO Ihe Ulass :r~~""'''ty AdJusl Ihe IO!JOlc. or w Cillhe rS H'l) lIan\je. to ilcl\leve 8 to 10 n (03100 <1 In) !Flp hetween Ihe glass olnd the WeillherSlr,p flan\je.

I 'Uhl"" Ihe to!I!Jh ! screws to th e speclfred lorque.

211 Load spa,-e Irim panel -r e 'noval nnd re fitting

H",,,,,v,, Ih" ,(!ar

25 BOil net release c(lble -r e m ova l an d re fitting

I" It", <:v<:nl 01 Ih!) rdcn~e cilhle hreilking. it is posslhle 10 rerilOve Il,,, ,.Hir.llor !II ,lie to Otu""le Ihe lock spring hy hil"d. Grrllc rCrllov,,1 'S oI""tl With II, S,,,:tron 9. hul SUIC(! ii's nOI poss,hle to open Ihe bonnet. II WIlli", 1""11.1 a Iotlle d,lfl(;ull (lilou!lh nOlm,poss,bl(!) 10 WI in ilCCCSS 1011", 111'1>' " "~1aU""\I scrc ws. In """()VI~ II,,! ,,,ICilSC cabl!) II, normal CllcomS I,l n ces . rcn,ov!) Illc ,;,11" "Pl'u, cowl plain :1 I,,,,,, "'s,de IIie ca r. !(!1Il0VC bOlh Ihe cl(!vrs pins and tire sprlllg and ."""cl lire II!h,a se cahle fro", Ihe control le vcr (photo) II Sl;":~,',, 11 1I~ caht(! adJustcr elll"'p and release the cil bl!) /rO'll Ih!) h",k lock ~P""!I !-, n,,,,,,,ve It", c;,IJle "'''I,nn'!) clrps, th(!n plllllh(! cable th'oll!Jh the rI .... 1 1'"",,1 to re"'ove 11. I; n"frltrrl!1 01 Ihe cilhle IS essen li,lll y th(! 'eV(!rse of tir e r(!Ill oval PI(r<:,·rtUI". "dJIJ~t,ng ;1$ "(!cess.l!y. t o rCrilOve any cable slac k. For

•

Fig. 11 .1 4 QUMter windo w fixing screws _ .. rrowed (Sec 23)

lurllH), ,,,fonnatlon ou thiS. [(:1", II) pn,a\jlaph 6 of Ihe follow,,!U Scctron

2 6

Bonn et -removill, refitting and ildjuslnlCnt

Open 11l(! honne t 10 ,ts fulieSI eXlflnl. USrrlU n suiwble nnplemen!.

scrrhn .1 Irne around t he hrn!Jes, Remove Ihe screw seCUflllg Ihe enrlh le.ld where ,1ppircnble (photo).

2

Rcmove Ihe Iwo holts ilnd wnshers secu"no ench SIde of Ihe

bon"el 10 ItS hrnoes (phOIO)_ W'I" ass,swnce, , t C,ln IlOW he lofted off. 3 flefm"'(J IS ,) reve,s.,1 of remov,, 1 jlrocedure Before lullV "ulHenulU Ihe seCllri ll!1 holts, ensule Ih

y .

.. . . . ... .....

," . .. ~c.<

r ,:i~

;

.

' . ,., I ~.

26, 1 Removing bonnet enrth lead 26.2 Remov ing bonnel hinge boilS

procarmanuals.com

Page 202 of 205

inlet manifold - 83

main system components remova l and refilling -80 m~intenilnce, routine -79

specificiltions -67 to rque wrench settings -67 Fuel pump carburettor system cleaning - 68 re moval and refilling - 68

testing -68

fuel inject ion system removal and refining -80 Fuel system (carbureUor) accelera tor cable -74

accelerator shah and pedal - 75 air cleaner - 68

carburetlor -66, 68 to 73

description -67 e~ haust manifold - 76 lault diagnosis -85 luel pump -68 fu el wnk -73, 74 fu el lan k fille r pipe -74 fuel tank sender unit -74 inle l manifold -75 mainte nance, routine -67 specifiCiltions -66 torque wrench senings - 67 Fue l tank cleaning and repai r -74

filler pipe removal and re fi\ling .-74 remova l and refilling -73

sender uni t removal and ref il\in g -74 Fuel tank sender unit (fuel injection models) -83 Fuses

G

general -220 specifica tio ns - 199

Gearbo~ see Manual gearbO K Gudgeon pins - 37. 52

pdbrake adjus tment -153 cable(s} and rod removal and refilling 155 lever removal and refitting -154

warnin g hght switc h -225 Headlights alignment - 212 assembl y: removal and refilling ~ 211 bulbs renewal-2 13 Heater assembly: diSI11(lntting and reassembly 8ehr - 19 4 Smiths standard and heavy duty -196 assembly: removal and ret.tting -193 contlols

adjustmen t -192 removal and refilling ~ 1 93 water valve (heavy dUly heater)

removal and re fitting - 193 History o f tho nlodal-5 Horn faul t tra cing . remova l and refilling -220 Hubs, front

bearings renewal -162 removal. ret lu in g and bearing adjustment -16 1 Iraulic systam (brakes) bleed ing - 152 pipes and hoses removal and refilling -151

Index

Ignition switch and lock -224 Ignition system -87 el seq Ignition sys tem amplrlier module (2 .8 l i\(e mode ls)

r emova l and refilling - 94

condenser (3. 0 litre models) -90 COntact bre aker points (3.0 litre models) - 89

description -88

dis tributo r -

90. 92. 93 fau lt diagnosis -96

firing order -87 mainteMnce. routine -88

spare plugs - 91. 95 speci fications -87

t im ing -94

torque wrench settings -87 In strument cluster ill umina tion switch -224 removal and refitting _ 221 Instrument voltage regulator removal and refilling -226 Interior lamp and bulb

removal and refilling -217

J

Jacking -7

L

lubricants and fluids recommended - 17 lubrication chart - 17 lubrication system

M

2.8 litre engine -39 3.0 litre engi ne -53

Main and big·eOld bO(lrings e~amination and renovation -37, 52 Main bearings (3.0 litro engine) removal - 51 Maintenanco , routine bodywork and fillings d oor ch ec k straps security check - 16 locks, door chec k Straps. tuellilte r C

h andbrake linkage lubricat ion -16, 144

h ydraulic fluid levul check /lap up - 16 . 143 hydraulic flu id renewal -16. 144

line s and hoses check -16

pads ilnd shoes we." check -16 , 14 3 servo check -16 . 144 vacuum hose check -16 Clutch adjustment chock -16, 98 cooling syslem

coolan l leve l chec k/top up -16, 59 coolant renewal -16, 59 drivebelt condl tion/wnsion check -16, 59 leaks check - 59 electrical system

ballery elec tro lyt e leve l cheek /top up - 16. 200 equ ipmen t opera tio n check -16. 200 headlamps cleaning -16

253

'i

'" , '.;.l

•

procarmanuals.com