ECU FORD CAPRI 1974 User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 1974, Model line: CAPRI, Model: FORD CAPRI 1974Pages: 205, PDF Size: 43.75 MB

Page 53 of 205

, ,

52 Chapter 1 Engin e

68 Connecting rods and gudgeon pins -Il~nmination a nd renovation

Refer 10 Sccuo n 18.

69 Cr,lIlkshnft -e~(lrl1in

70 Mail' and biu·end heafinUs -olwillinmion and H)!1ovation

Ilelo,r to Seo.:lIOIl 20

71 TilninU oellrs -e~i1miniltion find renOVlltio n

Re f

el to Sec t,on 21.

72 Flywhee l/ d riveplale -Okamitliltiotl lind ronovtttion

Inspf:CI lhu ffywhf)l)I 0 ' ([ttvl'pl,,": fOI (!;U";'\lC ilnd 1:I".1I:k Ih;'1 Ihe ""!I H".u docs uol have .IIlY \)Iok"n o. l);Idly wOtn teeth. :1 On ''''''''';11 I'''"''''US~IO'' mnd"b ,I IS pOSSII.Il) 10 'CHew the I"'!l \]C,II .'S Ilesl:

[xallutle Ihl} v,tlves 101 IlIls "lid !l,ooves lind the valve SIems to. e~c,'SslV') we,l' III d'~loIIIOII' 2 Ek,""l1ltJ Ihe v,oIVil hf)"d 10' SI!.!"S 01 hu",u,U of the vOllvo seillS lind ch .. !ck Ihe ht 01 Ihl) villves III Iho v,llve UUldes . 10 SCl) II Ihe villve uu,des il,e WO!ll

3 We"" valve U",dcs c;'" be r l),lIned O\It lind vlIlves w'th overs.~e Siems lilted II iI v

S To 1,1P the valves. In tt s u ction Iype gnmlonu 1001 to Ihe villvc hettd. smeil' a lu tle COil.se c;ubo.unllulll urmdmu pOIste on to I he sealing I~c e 01 Ihe vnlve ond inserllhe valve 11110 the cyJonder he"d. Rub Ihe stern of the v al ve gundlng 1001 hetween the palms 0 1 the hands. so Ihal Ihe valve,s ,otllle(l hHckwards 1I11d lo.wa.ds When II IS lelt lhOlI culling has

ceased. loft Ihe villvc. rotate It th.ough 90·, lowe. 1 and fepCill the u"n(llnu o.:.e.atlon . • e dlslllbulill9 the g"nd,ng pas!O on Ihe seal if necessilry. Conlinue Ihe process unlll a mllll gwy bOlnd IS pfoduced OIloun d the complete pe"phclY of hoth the vlllvc and t he valve seil l G RepoiJl Ihe opcrilllO" US" 'U fine o""d,nU I).Jsle. 10 ohtil'"

IInlsh. then clean lJoth Ihe valvcs and Ille v alve seals 10 ,emove IIU \llIces 01 u"ndlno pash:! 7 II 'I IS convenl,,1lI 10 liIke Ihe eyhndc. he

When Ihe cyllnde. heilds (li e removed. eilhe. in Ihe Course ovelhJul Of for inspection 01 bows 0. villve condllion when the e IS in Ihe CM . il IS nO'''1

Ihe eiliite. dilys 01 10nU stroke low .eVYlnO en!)lIles tJUllllodern enUil fuels ilnd Itrb"canlS C,1use less cOIIOOn deposils OInyway and any. b ehind lend merely 10 cause h O I .SpO IS.

75 Oil PU"',) -disnwntlino. eknmin"liOil ,,"d reOlssembly

The Oil pump mm"Itt;"S a I)ressure 0 1 ilbout 2 8 kgl/cm' (3 Ihf/in') lInd unless Ihere is ,1 sIo",IIcanl (hop In 001 P'(lSsuro willel ,)loved to he due 10 the Pllln,). rillhn. Ih;", 10 wo", heil'm!)s. 11 IS be .

t o le"ve Ihe 011 pump und'S hilhed. 2 To d'smanlle Ihe pump. fll:.1 ,emove II hOln the en!l'ne ns desc,,1 III SUClion 58 3 Remove Ihe IWO bolts seCulII1!J Ihe en d cover 10 the body 1 'emove the covel ilnd 1he .ehel v;" ve "sscmhly. Ihen Ihe Iwo P"

fOIOI assembly.

" Remove ,he IWO bolts lind ,,,ke Ihe p,ck·up w he lind SCIl' lIssembly oft Ihe pump housin!1 S Wilsh all lhe pilrlS In petlo'. usc iI hlllsh 10 cleol" Ihe Inside 01 1 pump ho usinu ilnd lhe p.cssu,.., .elle' vil've eh'!lnbel. ilnd milke 5' Ihilt ,111 p,tltlClcs 01 dill ilnd mewl n,e ,emoved Allow the pttrlS 10'~ n;IIUf,lllyor blow them d.y G Check Ihe Illslde ollho Puml) houSII'9. Ihe OilIer .;w:e ilnd Ihe 101 101 dilfllilUe and e~cesSIve weill 7 E~ll'''Ule the I111lling su.lace 01 lhe I)Ump cove. 101 we,lr It Ihe CO' IS sco,ed. o rooved. a. shows ilny s'g ns o f wea •. a new covef must I hlled 8 W,lh the ,otor assembly filted in the hOuSing. place a straighl·ed!. over Ihe end 0 1 the housing

Page 61 of 205

'.to.

60 C hapter 2 Cooling system

5 Cooling system -fillinu

Ensure 111m the cylinder hlot.k d',1111 pi,,!! IS SCfCWCU "' rumly wl(1 th .. , tlilihe coolll'U system h(')s'~s .1!tl1n POSl t'''1l and secured wIth hose clops. 2 USH1g ~ 1111~IUIC of 45% nnt,hN!IC ilnd b!/)(, wmer. 1,1) the coolll\lI system slowly. 10 nHnlnlise the fisk of "U locks Ellsure IIKIt the hC;'lC' control IS Wined \0 the 'Hor pOSItIon oll"l'W'~: ,10 IIU lock m.ly 101m Ifl the hemer 3 On fl,lIly models w i thou I 01" C'P"II~OOIi t .. llk. hll the liuhnlU ' 10 llHi

hlvel U'llcn III S!:f.rran 2 then ",ht 1110 Itll,·, ,:,,1' Where nil e~Jlan~lIl1l !OInk .s f,[h:d, t.:olllplclCly 1I1I11u; ,;)Ih;no • .11101 ,.,tn the CilP then h.llll,11 the cxp;ms",11 lank and "JI, the hlle . ,'" " (pholO) Notll 1h.11 thl) pressure (:0111 wIlh the Iln"lol" :,..;,1 "'"~, .• tW;II'S be 1111ed 10 Ihe CXI),1IlS,OIl I.,,,k

I) 01 so"'" "1\\I'''es i'" ,II, 1,1",,01 ~"".'" ", .. y I,,, I'"eti Ifl Ih" IW',h:l hose. Loo~"11 Ihe ~,c:rcw boA"", 1,11""111", ' V·.Io'IIl .",d ,cl'\lII",,, ,I wil,'u hubhle I"·,, W,,,",, 110ws 5 nUll Ih.~ ""\I,n<: al,1 I.'~I "tI,· ~'I"',~IIt~ ·~',.· •. ,I "''''ul,,!> Ih,," "lInw ,I 1U tool iHUII,,1' up til') co(,I.", ' I.·v'" '~!lh ,.'t.''''"r.,; 10 SHCl"," 7.

6 A,IIi1f{W/fl milliu re

Ap,lIl I",,,, II,,, p'''I,,''I',,'' .,,, .. ,,,,.1 1""''''''1 .. ",,(I,t'OIlS ",.1,,0:11 II", usc 0 1 ilnld"·,,,.· I',nvules. II, 11'." I, """",,10 .• 1 I" "IUlI""SI) ':''''CI~IO'' "I Ihe ,:oolu'!1 sy:. I",,, 7. Thc (:ou1l1111 ~y:.lcm I:' ""lIdlly 1I1I.~1 wllh .1 sulu'u", "I II!>'". al1lll,cc~c ;lI,d II.s 'CCOIIIll""lIl"d Ih,'1 II,,, l":u.",,t"He ,s 111,11"1.1"",,1

3 Willi 1011\1·111" tvpes olall1,I,,,cl." ""~"""'" '''''''w lhe Cl)o l:")1 "ve,y IWO VCiI'S. W,III ot hel lypCS. d'iI'lI ",,,I ",10" 110" syslcm cv,,'y Iwelv" "lO'lIhs Wh'f.hcver Ivpe.s used, 'I I11\l~1 b" "'llll' ethylclle Ulyr.oll",s" II The lollow".!) l,1ble !)IVe s;o !J'IId., 10 l""I.":I'uu ;l!)aiIl SI l

-..-.. -::-' , .

I '

If

~

Amount 0 1 ilnlilr(l(lzo 45% 40~ 30')(, 25'\', 20'¥, 15'~,

P ro tection to .J2C( 26"F) 25 C ( I3'F) 16 C ( . 3'F) IJC(·!fF) .'JC(·IG'F) IC(tI.'JF)

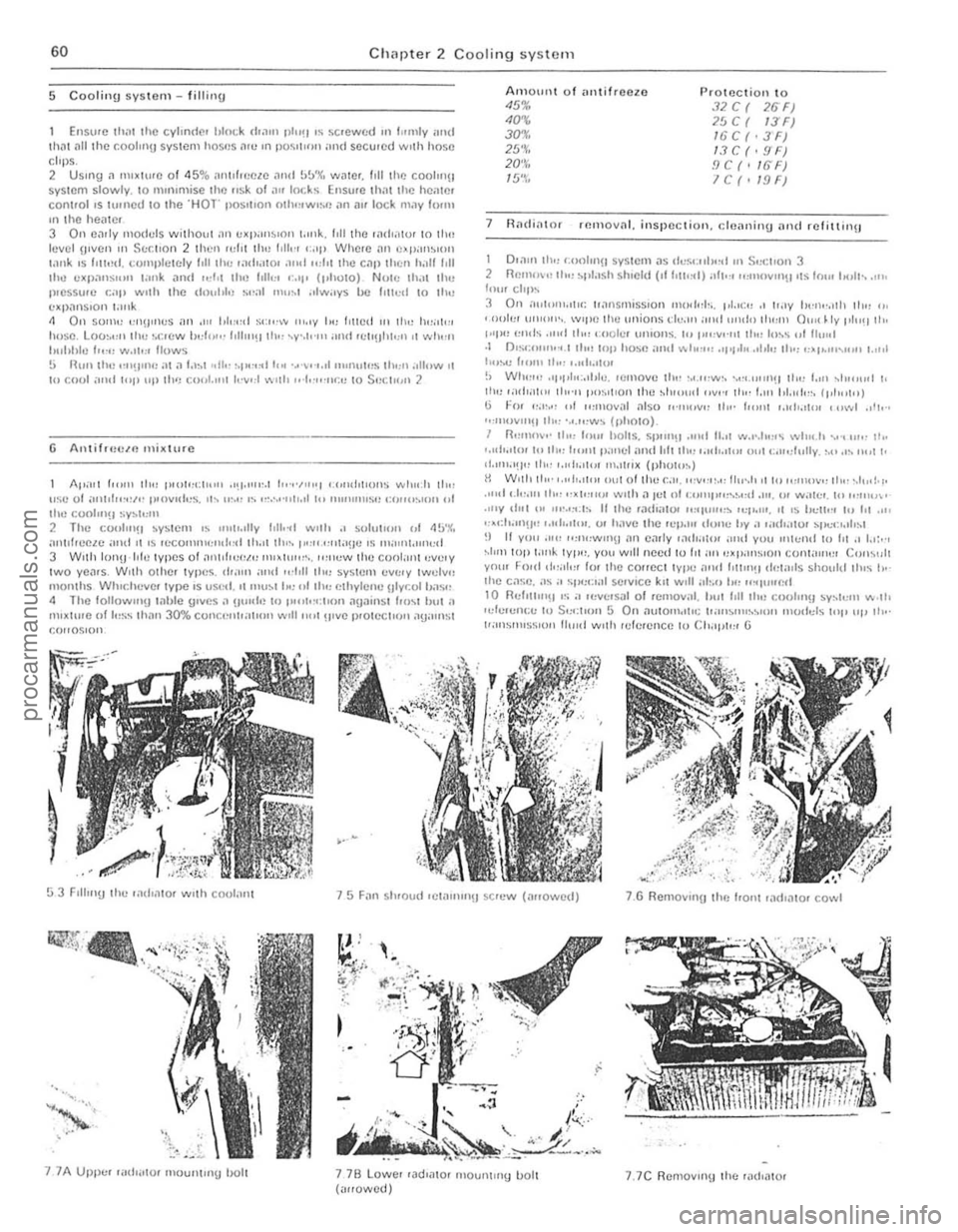

7 iladialOr rCllloval. inspection, dcaninu and relittinu

1 O,arn Ih" ,:oolll1U S ySICIII as ~h,s ... 'h,·d ,,' S",:I'OI1 3

2 flclllo\" II", :."t;I s h shlcld (,11,"" .. 1) ;011". 'I:III()VIllII.IS fOIH .. "II-. .11" 10", cft l" 3 0" ;,,,I,,!],.II,,, 1,,1nSIllISs,o n 111011,,1-.. 1'1.":,, ., I'.IV 1><·".·,,11, Ill" " . , "ole' """"",. w'l,e till! un ions de.lll ;111,1 '''}!!,' Ih,,,', Oil'! ~ Iv I'''''' II" j"IH! "",h "",I II", '."010:;' 1""0IlS. I .. 1""v""1 110" h,,~ "111,,,,1 .f O'Sf:"""'· •. 1 110.,1<)1' hosf: ,m'I .... I""" "1'1'1" .,1>1" Ih" "~I""'"'''' 1 .,,,1 h"",) I""" II .. , •• ,,10"1110 :, WI",,,, .1",,1,,:.,1>1,]. 'CIllOV!! tl". "',",w~. -."'."''''!! 110" I.", ,tl"",,1 " "w .ati""", IIo"n p"~'I,on Ihc ~h,,,,,,, '''"., II", t.III 1,1."1",, 1,,1"'1"1 l.l Fo< 1:."'" "f ",movnl ;0150 ,,''''''Vo: IIII' troll! •• ,,10,"0' • "' .... 1 .. I"" "''''')\I'''!! th" ·"."'W~ (,)hOlo). I fl"ltmv,· II", I",,, holls. SP"Il!! .• ",1 11 .• 1 w"·.h,,, .. wll".h ,-,. , "". 11 •• , ... It.,101 I" Ih" 1",," ,W(\cllIl1d Iofllll" ,.UIo.IW' Oll( .;,,,,,r,,Uv. ,."." ""t t. '1.1I11"~I" Ih.· ,."1,. ,1,,, "'.IIr,x (phUlo,,) H W'lio II,,· ,."10.,1,,, ,,"I ollhe c.". II,VI:"." tl"'.10 ,I 10 ,,,"'0",, IIII' ·.I",!." .""1 •. 1"",, til" "~I"'"'' ",,,h,1 lei 01 • . ,,,,,,,",,-~,,d .111. '" Will(:,. 10 """"" ,"'v 11", IH """".1" II Ih" 'ild':l!OI ""IUI",~ '''p.II!, ,I ,~ h..,u,', h) 1.1 .11, ..... :h,"'!!'1 ,."1,.*,,. 0 ' havc Ihc 'cp.", do"" hy.1 tiOlIr"to, ~1 ... ~:,.,Ir:.' !) II yuu .u,' "",,:w"'\] iln cady ':0<1'.'101 ;,"d YOll "!l"nd 10 t,t ., I.,:, " ~1"11 lOp 1.11I~ typ". yuu Will nccd Iu fn 111, HXI'.lI1S'OIl contill"'" COil",,, yOll' FCltd oI"ill", lor Ihe COUCCI IYPII all" h""'!1 dt,liliis should Ih,~ .,. 1he C,1~;C. :,~ :0 ~1"":t:'1 se.v,ce kll w,lI il1:.0 .,,' "~IIII!CfI 10 Refllllll!1 , .. iI t(Jv(:,s(ll 0 1 ,cl11oval .• ,,,' t,lIlh" c:l)ohliH SY~I,,'" w .l h ''''e,enl:e 1 0 S,,,;I'OIl 5 On .1ul0"'''I''; ":"'l.'"'~~l(m 1110d"ls IIII' "I' Ih ,· 1';II1"IIHSS'IJII lI",d w,th .et(l.ence lu CIo""I'" G

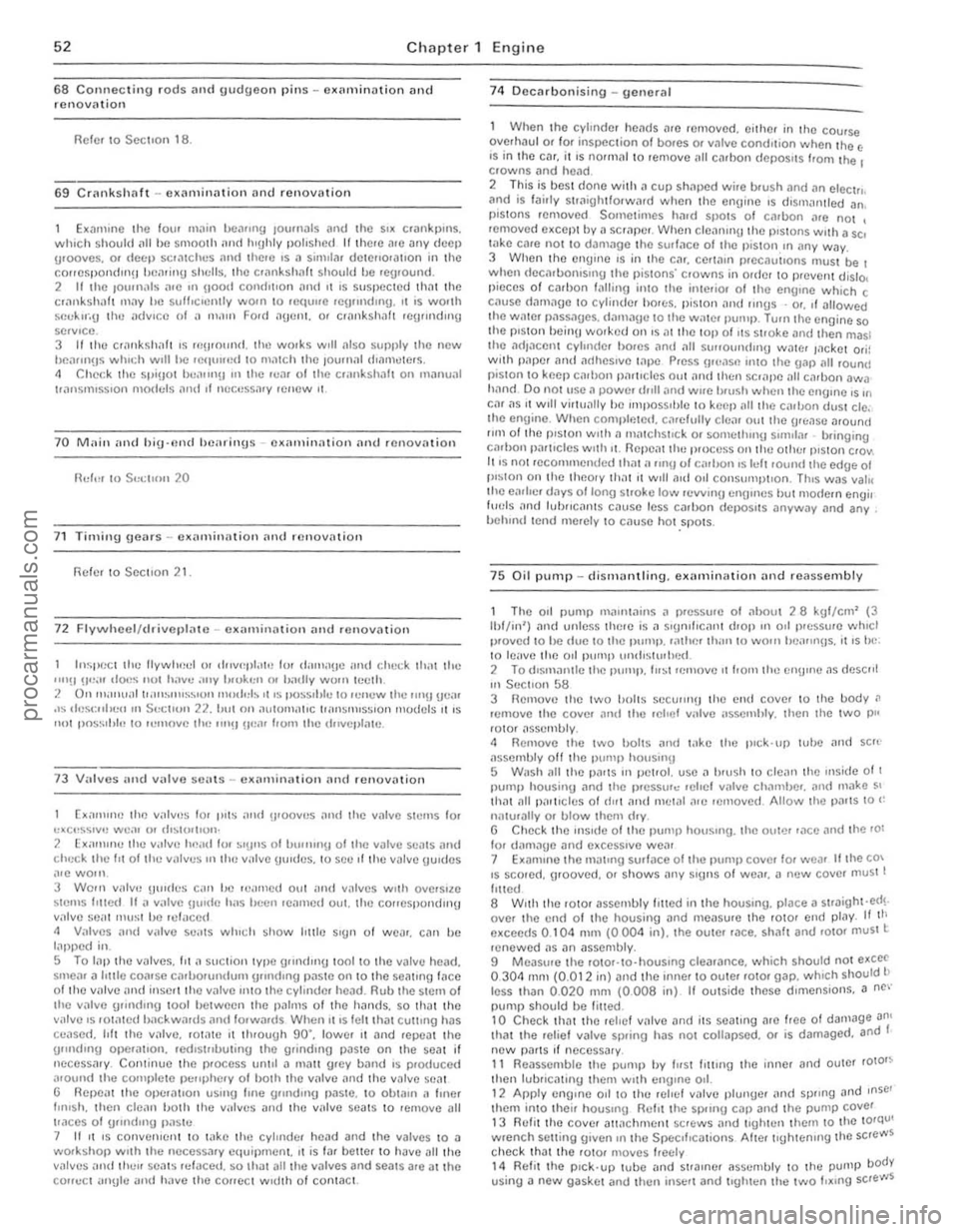

S 3 F,IhnU Ihe 'ad,;OIO' WIlh coul:",! 75 Fan s h.oud '(:Ii"""}!) sc.ew (.mowed) 7.6 RernovulU Ihe 1<0111 .adlato r cowl

"

"""

, "

7 7A Upper .mlrillOI 'n1JUIlI"'U IJ()II 7 7B Lowe •• ad'nlo, 1ll0un1111U boll ("!lowed) 7.7C ReIllOVII1\J Ihe rJ(MIO'

procarmanuals.com

Page 64 of 205

![FORD CAPRI 1974 User Guide )

)

b

Chapter 2 Cooling system 63

10 Orivcbelts -rcmoval .. nd refitting

Where ilpphcilhle. remove the power slecrinl] pump d rive b elt w Ith refe rence to Ch<lptcl 10. 2 Loosen the ill!CfI1ilt FORD CAPRI 1974 User Guide )

)

b

Chapter 2 Cooling system 63

10 Orivcbelts -rcmoval .. nd refitting

Where ilpphcilhle. remove the power slecrinl] pump d rive b elt w Ith refe rence to Ch<lptcl 10. 2 Loosen the ill!CfI1ilt](/img/11/56932/w960_56932-63.png)

)

)

b

Chapter 2 Cooling system 63

10 Orivcbelts -rcmoval .. nd refitting

Where ilpphcilhle. remove the power slecrinl] pump d rive b elt w Ith refe rence to Ch

Fm hest acce~s to th e fan. 1"~1 ,,:(l10VH th e ""hatol "s dc~c"hcd Ifl

y

SectIon 7 2 Remove the drivcbel\{s) (Section 10) 3 Wlwlc the filn hils ,1 centrill bolt unscrew Ihis ilnd wllhdrnw the fan from the extension Shilh. 4 If the Ian IS secured by

~~-~~,==========~)

I( t-ix~

(0

Fig. 2.5 Manifold spanner lor removal of the viscolls drive Inn (Sec 11)

x -2[j 0 "'''' (I 0111) Y -1201ll1ll(05ill)

e

11.5 80l1s securing filn 10 viscous cuupling 11.6 Unholting the w

Page 68 of 205

)

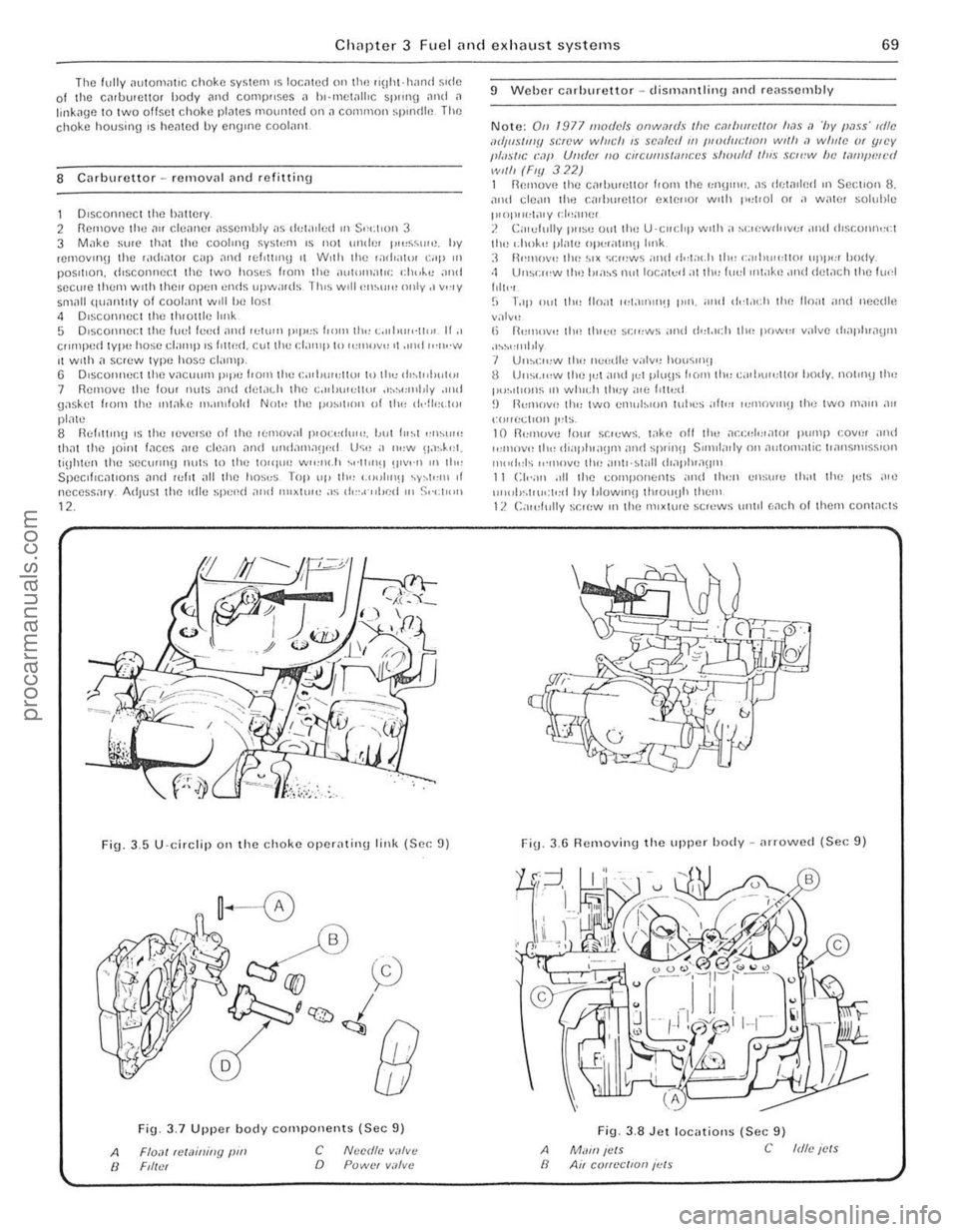

Chapter 3 Fuel and exhaust systems 67

Torque wrenc h setting s Fuel P\JlllP Inlet n'

G ene ra l SyS1c'" Iype Idl e sp ce d CO "o,

)

-

Clwpter 3 Fuel

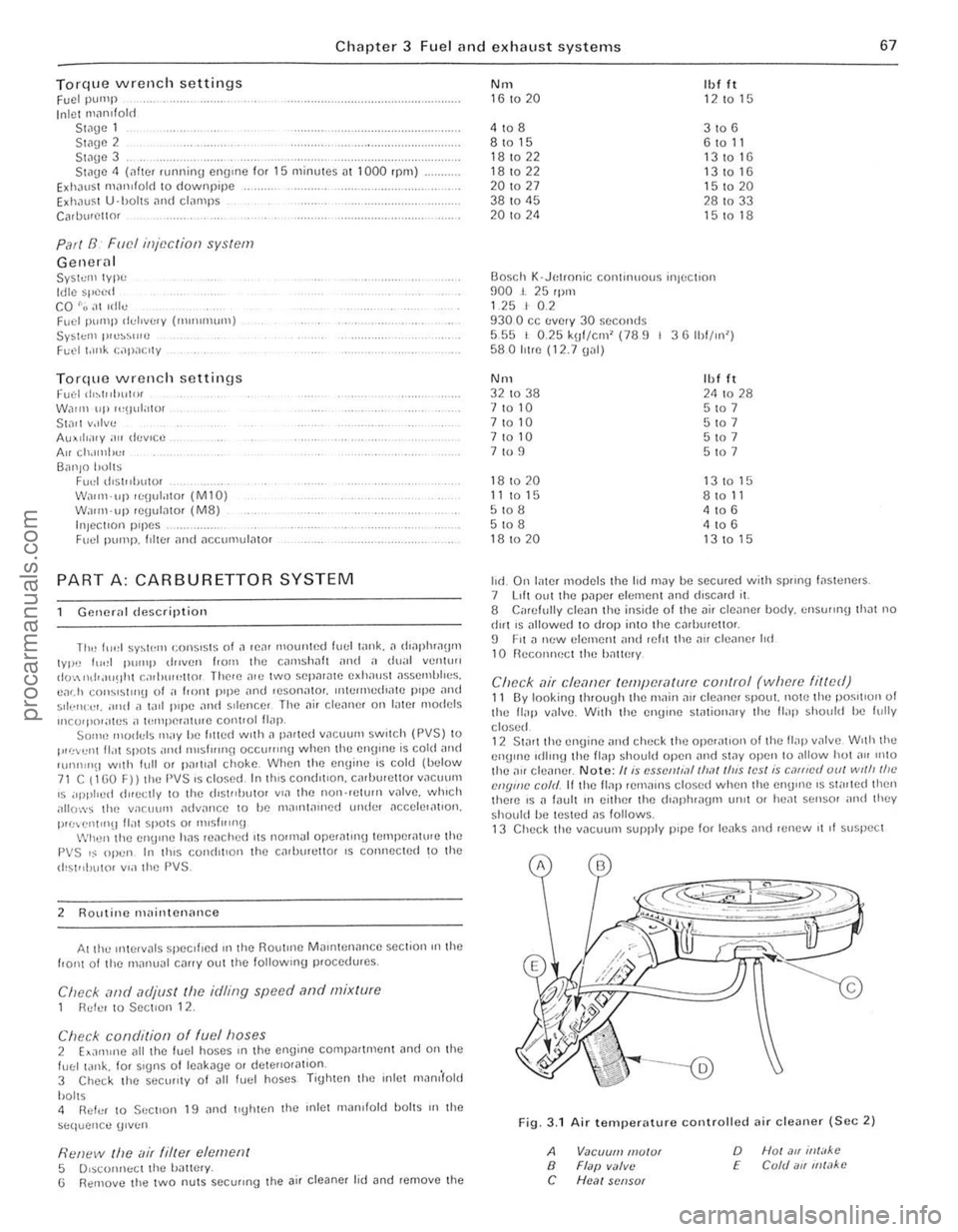

Fig. 3,5 U·circlip 011 the choke operatil\g link (Sec: 9)

A /I

Fi9 3_7 Upper body components (Sec 9)

Flo,lI telaininy pm Ftll.'t c o NlJcdto V;I/V(!

POWCI v.1lvc

9 Weber Cilrhurettor -dismilntlinu [lnd reas~ernhly

Note: On 1977 mod(!/s onw,lf(II /lIP. cmlll/id/ot 11,15 ,1 '/Jy PilIS' tdle IIdIItS/IIIY SP~'W willch IS sc,l/r:iI //I l!lodl/cllOn wl/h <1 willie (}f ljlCY 1,/,'sIIC (:,11' UlI(ler /10 CItC(ff!!s/a/lces should {/II.~ SCI('"W h e /,)t!J/JlNl'd wi/h (Fly 322) 1 R(!II1Ov(! the C.1,h"n;llor I! O"l th e ':Ol!)""' . ,1~ dr;w,lp.oI ,n Section 8. an d cl(!,lIl th.) f:ilrl""etlor extC"Of w'lh 1'.,['01 or a walt' soluhle t"OI",,:l;\,y 1'/,,;)11(:1 J. C;, rdully I"'S" 0,,1 Ihe U'CIIClrp w,th a hC,(lWII"v" •• lIul ,h~COIUlo:cl til" '.ilok" pl"w oj)l:(allnulrnk :I 1\""10\"" tire ~I X ·,,:,,'ws ;'"It ,i,-(;" .h II" , GIl1"""llor "Ill"" body. ·1 Uns';",w llr,) h'n~s nul locnl"d:ot th" ((",I ,nwk,) .'nd d el.1cll Ihe flU'l

Iolt"1 (; T"II Ollt tlo" lIo;i! ,,,t.1"lII'!J pm. ;,nd dd.1{,1r II,,) 110;11 ,Hl d needh~

v:otv" I, R"",,,v,, tlon th,c" ~c,,:ws and d"t.u:1r tlw po","", valvc d';lpl"a!)1ll .'~h,,"'tJly 7 U"hl:",W thn ncedle ~"Iv" ho,,~,nu 8 U"suo:w the It)( and Io:t pt"\Js I. o r" til" c."jJ\""l1m Imdy. not"l\) th .. , p"~.'I'o"s III wh",h 11,,;y ;0,(, f'lll:d ~) I~l"ll()v" (h" two cn ,"b,on luhes ;011'" ,,,'IIOVIII\) the two lll,lIn "" l"II rt<.:t,on t,;ts 10 1l<:!lIUVC lorn sr.'l:ws. t;JkC nil II", ,1co:"I,;r.lto , j)"Il'P co"", ,,,,d ,,,,,,,-.vOl ttl<, d',Ij,lua!l1l> ;Hld 5P(in'l SUlul,,

Fi\j. 3.6 Removing the upper h ody -nrrowed (Sec 9)

A II

Fig. 3,8 Jet locatiolls (Sec 9)

Mwn ICIS C Idlc ICIS Air COtt~'CIIOIl ;"IS

procarmanuals.com

Page 71 of 205

70 Chapter 3 Fucl and exhaust systems

liS seatmu Note ,1nd reco.d the number of lurns, so th,11 the screws can be relltted 10 their orjuin~' settings . Unscrew cilch screw fully and remove it and its SPfing . 13 Che<:k the lIoat

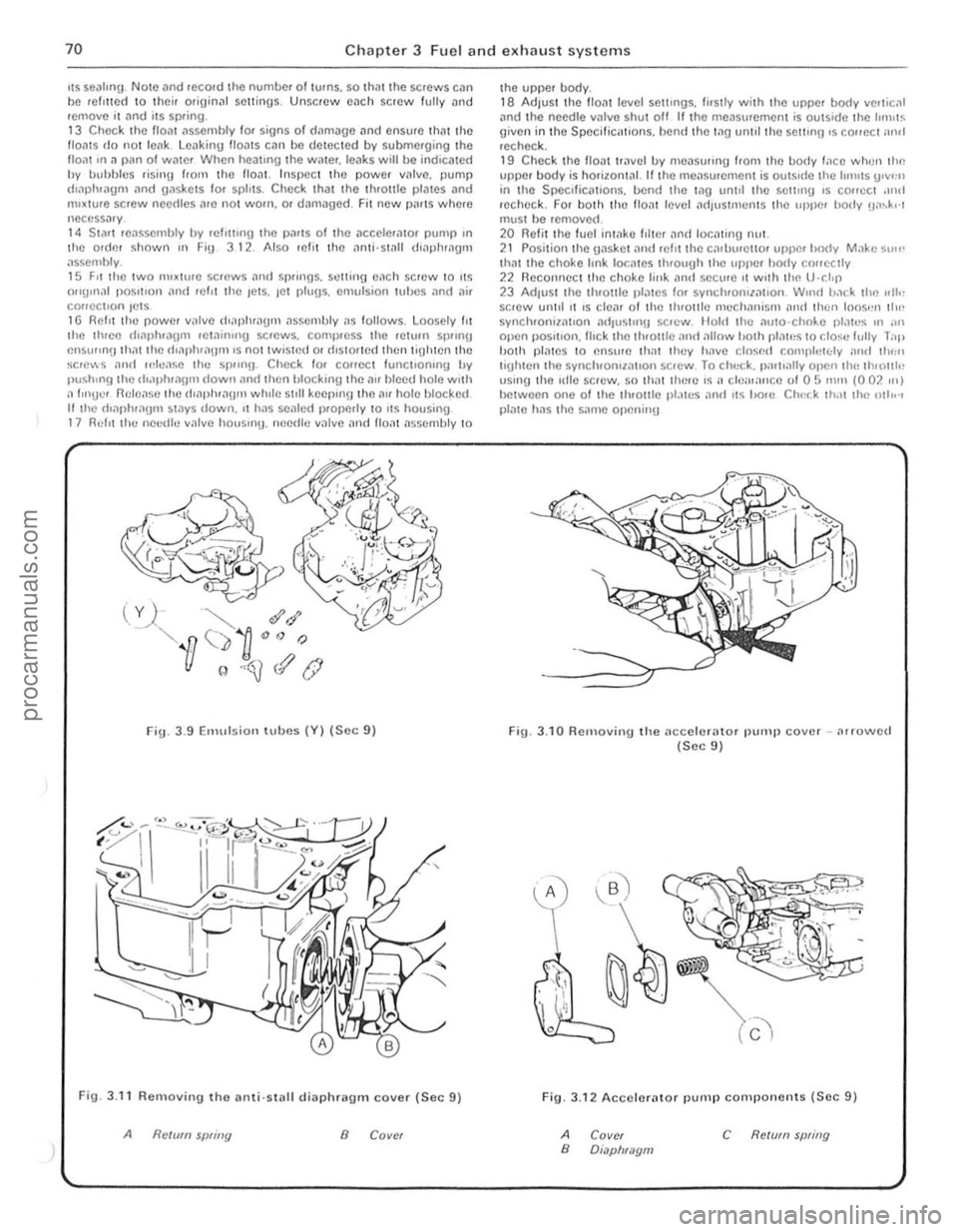

Fig. 3 .9 Emulsion t u bes (V) (Sec 9)

Fig, 3.11 Removin!J tho IIlIli'Slilll dillphragm cover (Soc 9)

Refum sWing 8 Cover

the upper body. 18 Adjuslthe flo." level settings, fi,slly w;l h the upper body verlical .md I he needle villve s hut off lithe meilsurerneot is outsIde Ihe IInlllS given in the SpecifiC

Fig. 3.10 Relllovingllie IIccelcrillor pump cover -(lrrowcd (Sec 9)

..

Fig. 3.12 Accelerator pump components (Sec 9)

A B Covcr Diapl/mom c RC/(lfll swing

procarmanuals.com

Page 72 of 205

) Chapter 3 Fuel and exhaust systems

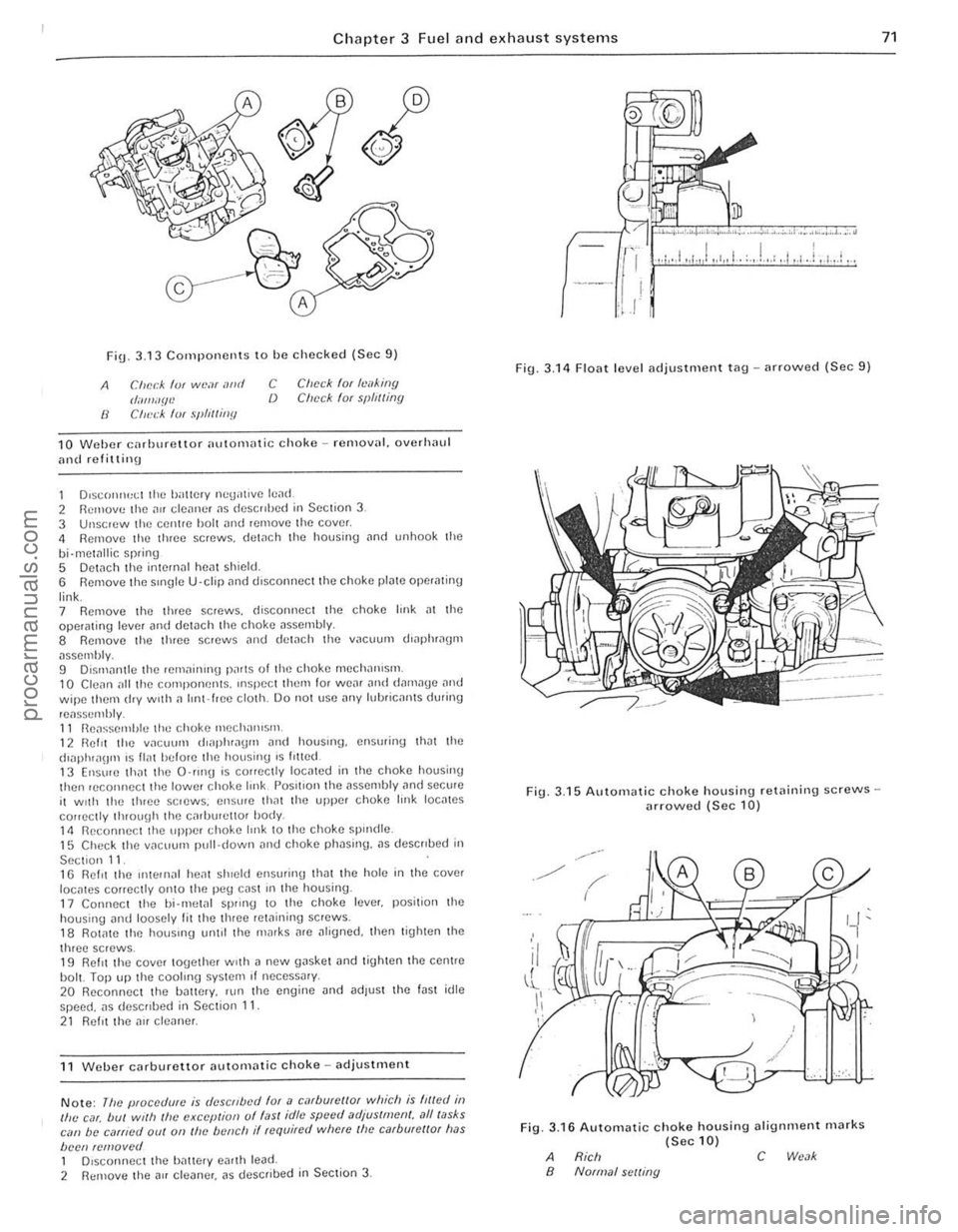

FiU _ 3.13 Components to he checked (Sec 9)

A

8

C/u':(:A fur wP.olf alJd (/illlli'f/I.l Clwck '(If .~/I"lIitJfJ

C CI)(xk for hd,ill{J {) Check (Of spfrlling

10 Weller cnrhurettor ""tom,lIie choke - rcmov,]L overhaul

and refitlinu

1 DlsconlH!~1 Ihe i)illicry nC\j

le"sselllhly. 11 Ik"ssemhle the choke meCh'1I11SI11. 12 Relit ll1e v"CUUIll til"phl1'lI)lIl alld hOUSII1,). enslllinu th"t lhe (hilphl,l()fIl IS lIolt before lile housing IS fllted. 13 Ensure thm the O-IIllg is correctly locmed in the choke housinU then reCOllnect the lower choke I",k Position the assembly and secure il WIth the thr ee sClews . ensure thnt the upper choke link loc"tes

cOlrectly tluouUh the c"rlJlJretlOf body 111 RecOllllec t the upper choke Imk to the choke Sp"l(tie. 15 Check the V"CUUIll pull· down

Note: lile pfOccc/

.l.I. .... , •• ,. ••. • .. .• . ,,~ ......... , •• , •• .;..,.: .•• ' •.•••• 1 . ;."

.,.', .,1,,/. 1,,' .. 1 . .. . , 1.,.: .. 1,.1.1,.1 .•. : ...

J

Fig. 3.1 4 F loat level adjustment t

.------

./ /' (

Fig.

/

3 .16 Automatic c hoke h ousing alignment (Sec 10)

A Rich c B Normal scl/lllg

marks

71

procarmanuals.com

Page 75 of 205

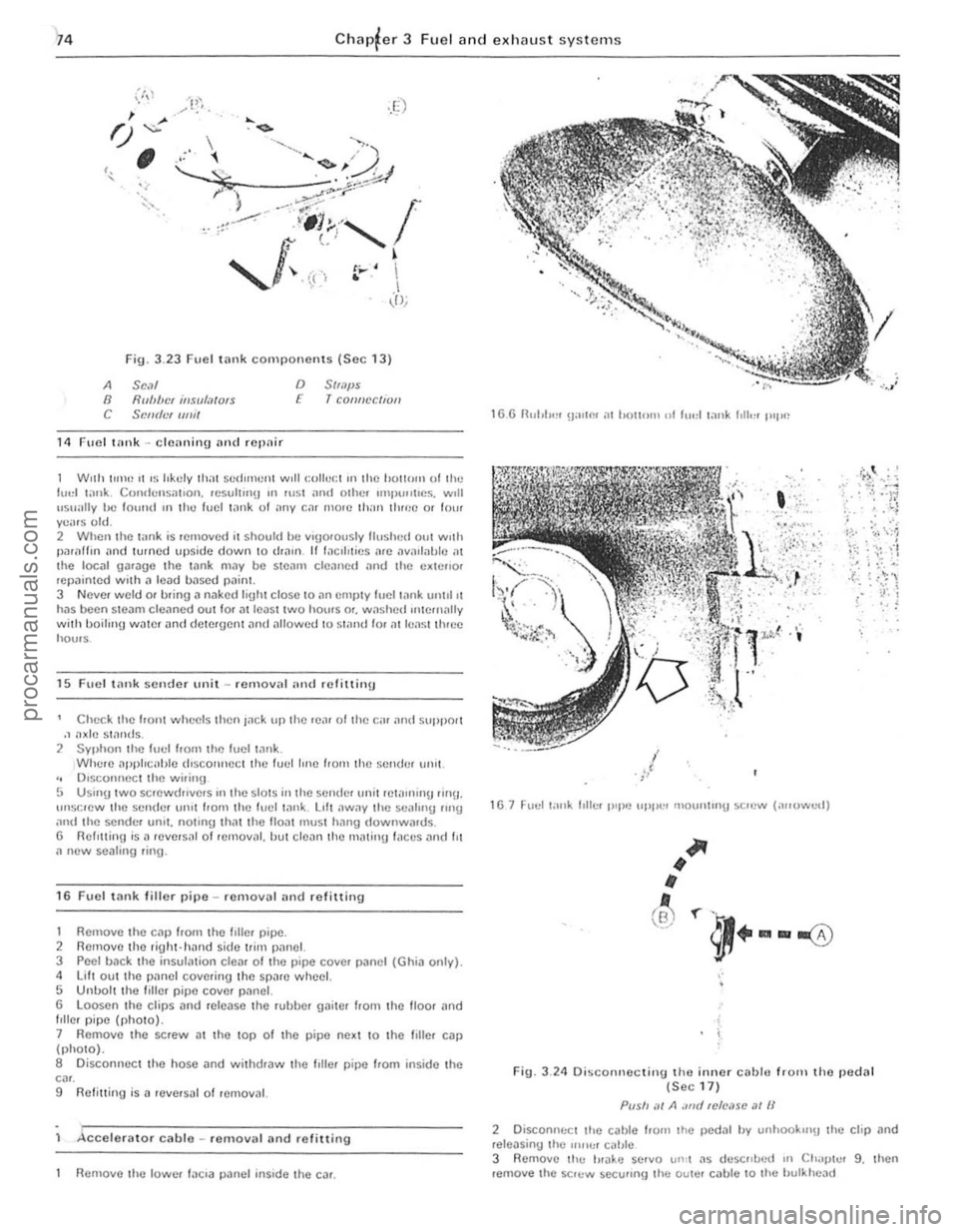

74 Chapter 3 Fuel and exhaust systems

, ;

1)'>

,

Fig. 3 .23 F el '

A

" C

Se.ll Ruhbcl ill,W/,lIQI S SI!IIIJ..'f lIoil

14 Fuel lank -cronning DrHI rcpl1ir

D SImps E , COllflcetiu"

W,lh IlI1m 11 I~ likely Ihal scd'lllcnl .... .11 COIiC(;1 1f1 the IJOIiUlIl u l the ruel wnk. Con

Check Ihe h01l1 whL'{)ls Ihen J;lc k ufllhe le;lr of Ihe 17;11 ;'Ind supporl ,1 ilxle sr,llids . 2 SYI/hon Ihe fllel hom Ih e tllcllim k. Wherc ;lpphcilhle d,scol,,'ecl Ihe fuel line hOIll the scnder unll.

" Discormoci Ihe wiring 5 USlllljlWO SC!(lw(i!lvers III Ihe 51015 inlhe sendcr unit ,e lirmlng 1111\1. unsr;'ew Ih o sender (mil loom Ihe tucllilnk Lilt ilW;lY Ihe scaling ling iln d Ihe sender unit. nO llng Ihill Ihe 110.11 must hilng downw;'IrrJs. G Re fill ing is a rever snl of .e moval . bUI clea n lile milling !;lces ;'Inel I II ;'I new sealing ring .

1 6

Fuel lank filler pipe -removal "nel refitting

I Remove the cap horn Ihe hiler pipe. 2 Re movo Ihe .ighl·twnd siele lIim p;'lllei. 3 Peel back Ih e in sul alion clear 0 1 Ih e pipe (:Over fliln cl (Ghia only). 4 Lift outlhe pimel coverinU Ihe spore wheel. 5 Unbolt Ihe IllIer pipe covor panel. 6 Lo osen th e clips and releilse Ihe rubl>C1 oail er from Ih e floor and f,llel pipo (phOIO) 7 Remove Ihe screw al Ihe lO P of Ih e pipo nexl 10 Iho filter cap (photo). 8 Disconnect the hoso and withdra w the I.ller pipe I rom in si de Ih e

car.

o Relill ing

is a rever sal 01 romov;lI,

A

cceleralor cabl o - removal and relining

Removo Ihe

lowe. lac.a panel inSide Ihe ca'.

166 Rull"'" !F"1I1';'I1 "otlom " I I"". la llk flU", l"llll

(

. ,'l

--.

. ~

1(; 7 Fuel lank flUc. Pll~ UppCI 1II0UIIIIII\I SClew (.lIwwL't I)

"

, I;'.' . :~, \;.;

: : i;. "j -' , ,' .... :r: , :'y~ it. ; '., :

Fig. 3.24 Disconnecling Ihe innor cabla from the pedal (Sec17)

Pusll M 11 ,mrl rcfc,uc ill IJ

2 Disconn(:cI Ihe cahle 1<0111 Ihe I)OOal hy unhookoug Ihe clip and rcleasing Ihe ""II:! cal,le 3 Rem oye Ihe IHal:.e servo un:1 a~ dcscfLb c(1 11 Ch;lll lcr 9. Ihen remove the SClew securrn~J Ih(: Oulcr cable to Ihe iJulkhc;'ld

-

procarmanuals.com

Page 77 of 205

76 Chap~r 3 Fuel and exhaust syste m s

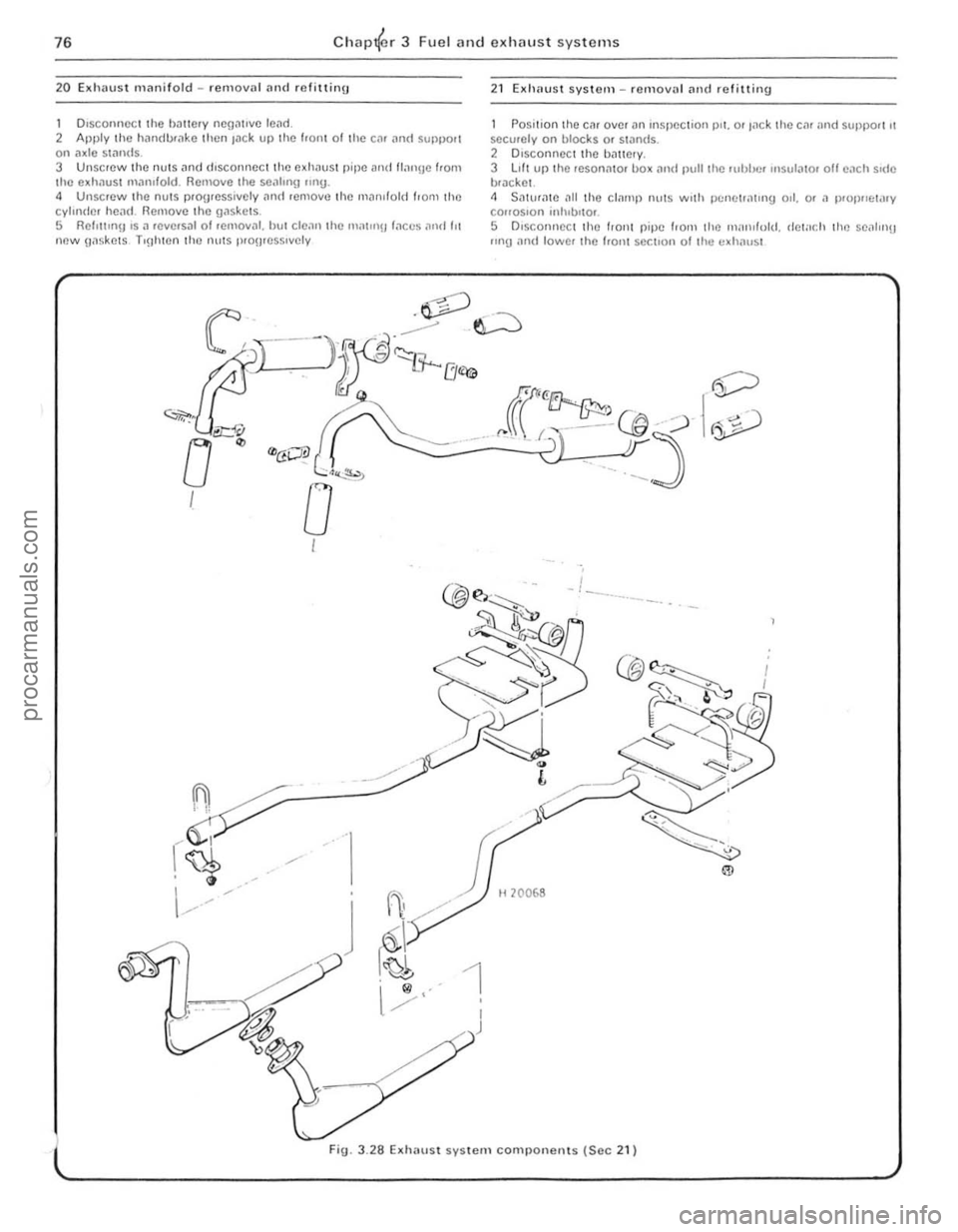

20 E~huust nlllnifold -removalllnd refitting

1 Disconnect the hallelY negillive h}ild. 2 Apply the h,lndl,)',li<.e then lilCi<. up Ihe Iront o[ Ihe Cill ilnd suppo,t on axle stands 3 Unsc,ew the nulS ilnd d,scontlect th c exh;!ust pipe alld U;lIl!) C 110m Ihe edl;!ust tIIiln"old. Rctllove the sc;!hnH tlllt!. 4 Unsc.ew the nulS p,ou,ess,vcly ;!lIff ,cmove the tIIOlrllfold from IhC

cy lrnd c. heOlct. Removc Ihe gaskels . 5 Refrllrnn IS;! Icvers;! 1 01 renIOV;!!, hUI cleOllllhe millrnlJ 1,1COS "rul Irl new n,1$kClS Tr\Jhlon Iho nuts prowossrvoly

_.-/-

-'

1

2 1 E~rH1usl s ystem -removul ilnd refitting

Posi ,ion Ihe COl' ovcr;!n in~pcction I)rl. O. 100ci<. ,hc CM Hnd suppa., II securely on blocks o. stands. 2 DrsconnC CI Iho bllttcry. 3 lrfl up the rosonmo. hox ;!nc! pull the ,ubbe, rtlsulato. off each srd e b,;!ckel. 1 50111",1IC ,111 Ihe Clmlll) nutS wrlh p<:nClfmrng all. or II jl'OPtlCI,',y

COfl05,on inillbrto • . 5 Disconn ect lhc f!Onl pipe f,om ,he milltlroid. d e tilr.h the sOOlhnu lin!] and lower the ,.onl section 01 ,he lIxhaust

F ig .

3.28 Exhaust system coml)onetllS (Sec 21 )

procarmanuals.com

Page 89 of 205

Q

Chapte r 4 Ignition system

®

0 -

-@ @

Fig. 4 .1 Diagwll1 of the hre(lkerlcs5 ignition syslem on the 2 .a litre engine (Sec 1 )

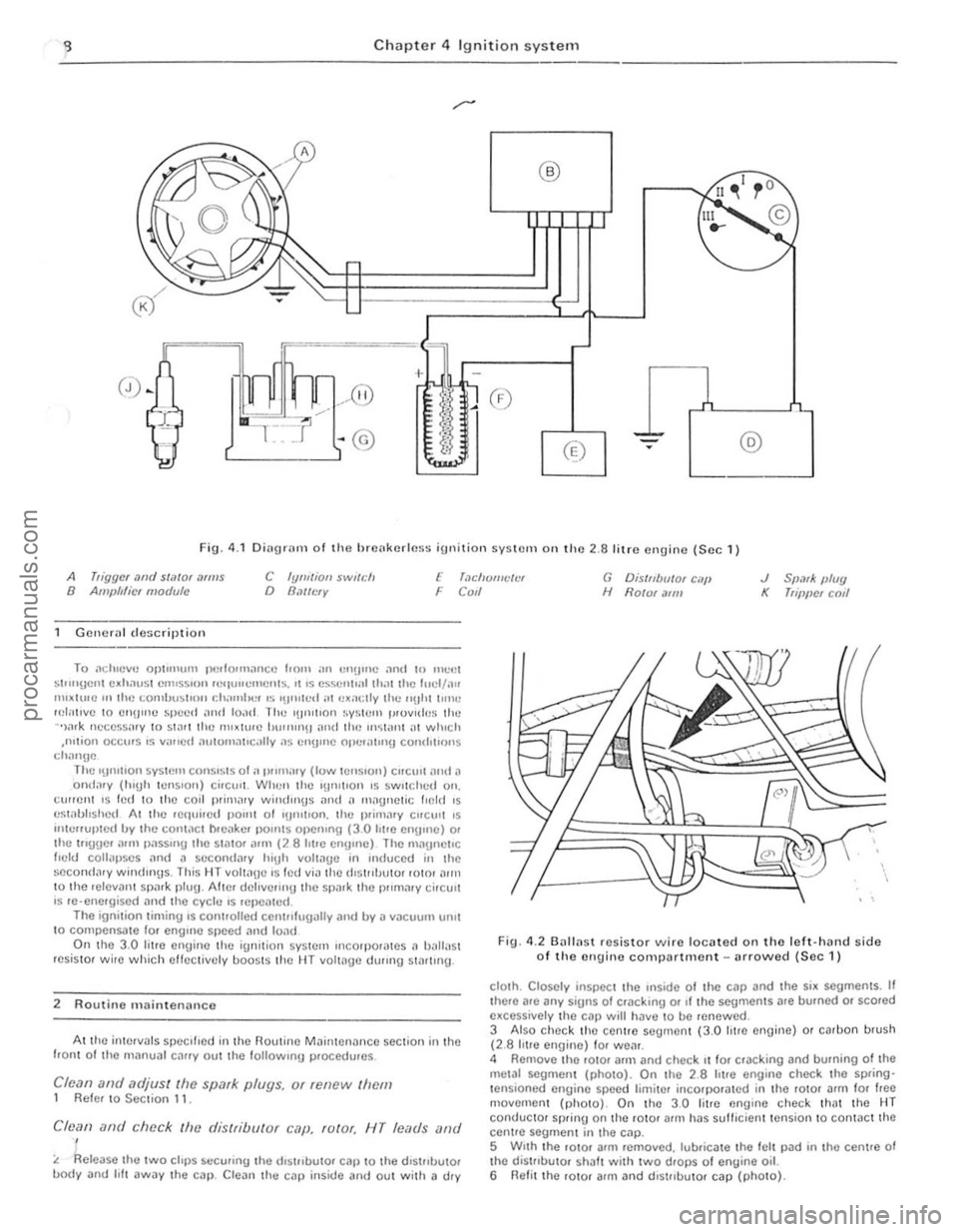

A higgcf ",,(I stiltor ,1(111$ 8 Am/Jlt/icf modufe C Iylll/ion SWJ/i:lr o BMI£'fY E 'm:lmJIIl"/l:f F COIl G D is/nUll/a , c.-,/! H Ho/or .11111 J 5p,1fK, IJ/ug K 'fi''l)CI co,1

Gcneral de:;criptio n

To ;l(; h.cvc OP\I"'U'" pCl lo.mancc hom an CIl(lUlC ;\Old In mCCI ~1""\JCUt e.h,1u~t C""5s"m r .. '

f 'eld collilpscs :Ind il 5tlCOndntV hi~h YOIIIl~~ In 'nduced i n the se~ond,1rv win(lin\!s. This HT volt:lUc IS te d via th e d'SH ,IJUtor rOIOI :Iun

1 0 the lelevllllt spnrk plu~. Alter dcllvenng the spar k the pmnnrv cirC Uli

I S re-energised lind the cvcle .s rep-Cillcd. The igni tion t iminu '5 Controlled centro lugllllV JnO UV II vacuum IHl II t o compensme lor englflC speed ,1no 10lld On Ihe 3.0 litre enginc the i~l1;lion s y Stelll II1corporales a b,1ita $1

resistor wire which effcctively UOOSIS th e HT volw~e durlllg SHul,ng.

2 Routine m aintenance

At Ihe in tervals speCIfied in tl w Rouline Ma;ntenance section in the fran I of the nl;Jnua l cJrrV out the foll owmg proc edures .

Clean and adjust Ihe spark plugs. or renew Ihem 1 Refer to Sec tion 11.

Clean ofld chec k fhe distribulor cop. rolor. NT leads illlr/

t. Re lease the twO chI'S securmg Ihe (h Slllbu101 cap 10 Ihe d'5111l1utor uodV and I, ft away t he ca l) . ereJn Ihl;l C:lP inside and oul wilh a dtv

---we F

Fig. 4 .2 (J"II(ls t resistor wire locilted on tho left·h'Hld side of the ongino compartment -urrowed (Sec 1)

clO lh . Closely inspec t the ",side of thc cap and the si. segments. It there are any siUns of Cr<1Ckulg 01 ,f the segmentS are bumcd o. scorl;ld e~cessivelv the Cal) will h ave to be renewed.

3 Also Check Ihe cenlrc segment (3.0 htr a en\]ine) or carbon brush (2.8 IIlre engine) f or wailr. 4 Remove the rOIOI arm i1nd check 1110 ' cra ck ing and burning of the melal scgmem (pholo). On the 2.8 h ire en gin e check tM Sp

d

procarmanuals.com