FORD F650 2013 12.G Owners Manual

Manufacturer: FORD, Model Year: 2013, Model line: F650, Model: FORD F650 2013 12.GPages: 378, PDF Size: 3.82 MB

Page 201 of 378

Fuse/Relay

LocationFuse Amp

RatingProtected Circuits

16 15A High beams, Indicator

17 — Not used

18 5A Dimmer switch, Interior lighting

19 15A Engine control (diesel engine only)

20 5A Starting system

21 10A DRL resistor

22 15A Air horn, Air suspension dump, Two-speed

axle, Driver-controlled locking differential

23 10A Flasher relay

24 15A Hydraulic brakes relay, Fuel heater relay

(diesel engine only), Air dryer

25 10A Blower motor relay coil

26 10A Right-hand low beam headlight

27 — Not used

28 10A Left-hand low beam headlight

29 10A Cluster, GEM

30 15A Allison electronic transmission

31 15A Mirror fold relay

Relay 1 — Interior lamps

Relay 2 — Not used

Relay 3 — Horn

Relay 4 — Not used

Relay 5 — Not used

200Fuses

2013 F-650/750(f67)

Owners Guide gf, 2nd Printing, March 2013

USA(fus)

Page 202 of 378

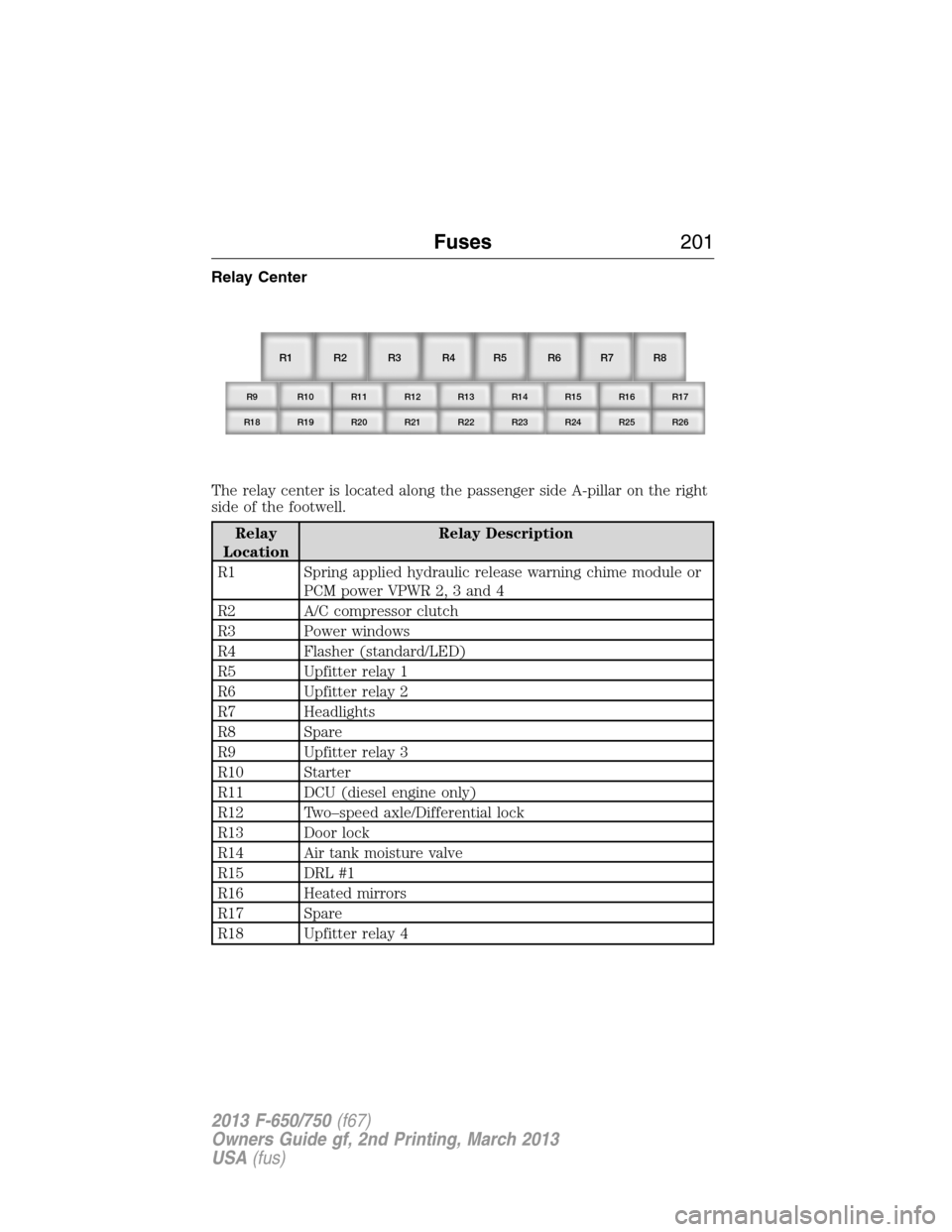

Relay Center

The relay center is located along the passenger side A-pillar on the right

side of the footwell.

Relay

LocationRelay Description

R1 Spring applied hydraulic release warning chime module or

PCM power VPWR 2, 3 and 4

R2 A/C compressor clutch

R3 Power windows

R4 Flasher (standard/LED)

R5 Upfitter relay 1

R6 Upfitter relay 2

R7 Headlights

R8 Spare

R9 Upfitter relay 3

R10 Starter

R11 DCU (diesel engine only)

R12 Two–speed axle/Differential lock

R13 Door lock

R14 Air tank moisture valve

R15 DRL #1

R16 Heated mirrors

R17 Spare

R18 Upfitter relay 4

R1

R9 R10 R11 R12 R13 R14 R15 R16 R17

R18 R19 R20 R21 R22 R23 R24 R25 R26

R2 R3 R4 R5 R6 R7 R8

Fuses201

2013 F-650/750(f67)

Owners Guide gf, 2nd Printing, March 2013

USA(fus)

Page 203 of 378

Relay

LocationRelay Description

R19 Shift interlock/EPRNDL display

R20 Selective Catalyst Reduction (SCR) system (NOx) (diesel

engine only)

R21 Run

R22 Door unlock

R23 ABS warning indicator

R24 DRL #2

R25 Park lights

R26 Spare

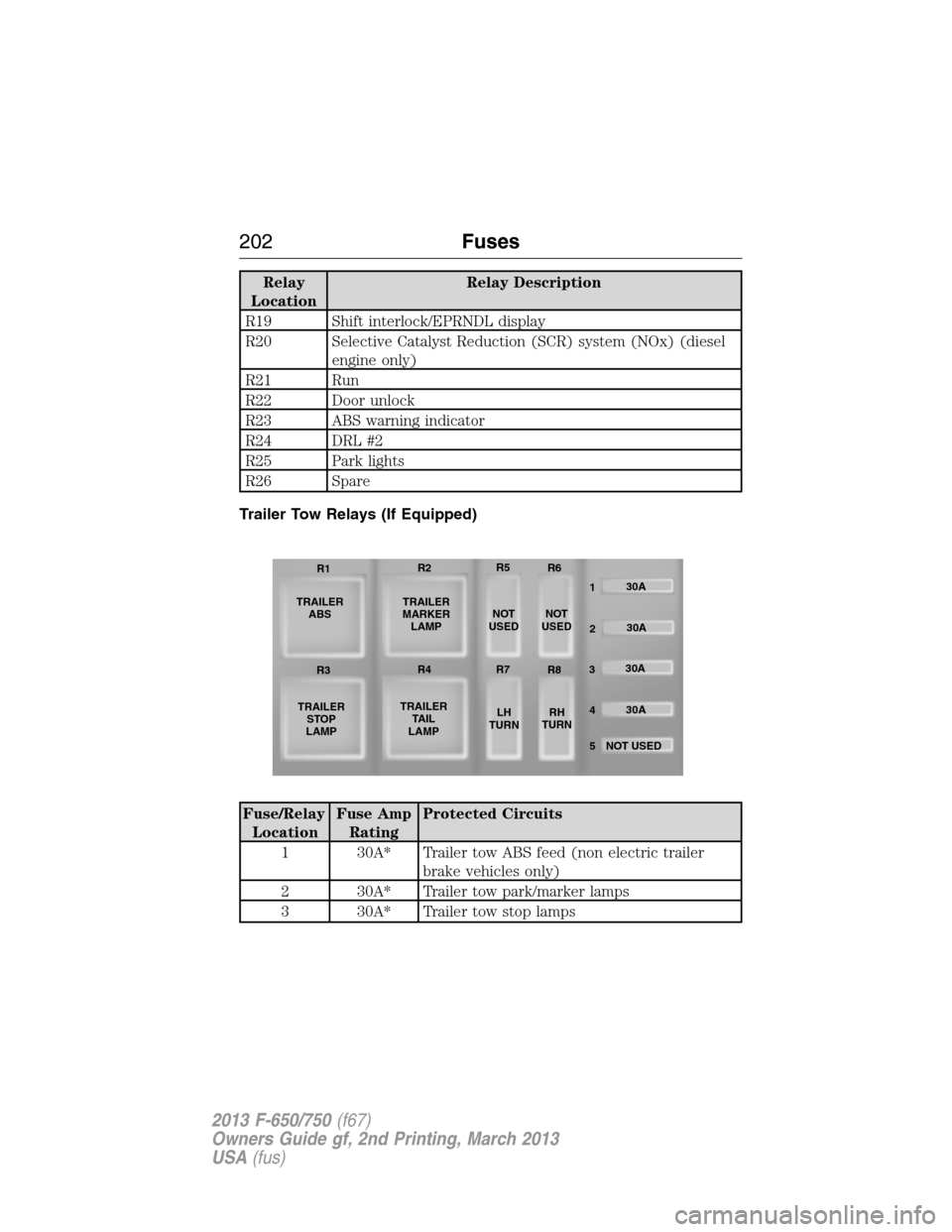

Trailer Tow Relays (If Equipped)

Fuse/Relay

LocationFuse Amp

RatingProtected Circuits

1 30A* Trailer tow ABS feed (non electric trailer

brake vehicles only)

2 30A* Trailer tow park/marker lamps

3 30A* Trailer tow stop lamps

TRAILER

ABS

TRAILER

STOP

LAMPTRAILER

MARKER

LAMP

TRAILER

TA I L

LAMPNOT

USEDNOT

USED

LH

TURNRH

TURN30A

30A

30A

30A

NOT USED

5 4 32 1 R1R2R5

R6

R3R4R7

R8

202Fuses

2013 F-650/750(f67)

Owners Guide gf, 2nd Printing, March 2013

USA(fus)

Page 204 of 378

Fuse/Relay

LocationFuse Amp

RatingProtected Circuits

4 30A* Trailer tow turn/stop lamps (combined)

Trailer tow turn lamps (separate)

5 — Not used

R1 — Trailer tow ABS relay (non electric trailer

brake vehicles only)

R2 — Trailer tow marker lamp relay

R3 — Trailer tow stop lamp relay

R4 — Trailer tow tail lamp relay

R5 — Not used

R6 — Not used

R7 — Trailer tow left turn lamp relay

R8 — Trailer tow right turn lamp relay

*Maxi fuse

Inline Fuses

Your vehicle may have several inline fuses located in, or on, the battery

cables located in the battery box (depending on application).

•All vehicles equipped with an Allison transmission have a 10 amp fuse

located in the clean power cables located in the battery box.

•All vehicles have a 30 amp fuse located in the clean power cables

located in the battery box.

•All vehicles equipped with an Eaton transmission have a 30 amp fuse

located in the clean power cables located in the battery box.

•All vehicles equipped with hydraulic brakes have a 40 amp fuse

located in the clean power cables located in the battery box. In

addition, another 30 amp fuse is located in a fuse holder just above

the power distribution center located in the vehicle’s engine

compartment.

Fuses203

2013 F-650/750(f67)

Owners Guide gf, 2nd Printing, March 2013

USA(fus)

Page 205 of 378

GENERAL INFORMATION

WARNING:Making modifications to various parts, components

and systems of the vehicle, such as brake and steering systems,

can adversely affect the quality, reliability and operation of your vehicle

and could result in property damage, personal injury or death. Such

modifications must be avoided.

WARNING:Failure to properly perform maintenance and

servicing procedures could result in vehicle damage, personal

injury or death.

WARNING:Take care when performing any maintenance,

system check or service on your vehicle. Some of the materials

may also be hazardous if used, serviced or handled improperly and

could result in property damage, personal injury or death.

Always use care when performing vehicle maintenance, repairs or system

checks. Improper or incomplete service could result in the vehicle not

working properly which may result in personal injury or damage to the

vehicle or equipment. It is the operator’s responsibility to see that the

vehicle receives proper care and maintenance. If you have any questions

about performing service, have the service done by a qualified technician.

Servicing Guidelines

When servicing your vehicle:

•always wear safety glasses for eye protection.

•always set the parking brake or chock the wheels.

•always use support stands, not a jack, when working under a raised

vehicle.

•always turn off the ignition unless a procedure requires the engine to

be running.

•always avoid contact with hot metal parts. Allow the components to

cool before working with, or around, them.

•always operate the engine in a well-ventilated area.

•do not wear loose-fitting clothing, hanging jewelry, watches or rings.

•do not smoke.

•do not work on the brakes or the clutch unless the proper

precautions are taken to avoid inhaling friction material dust.

Quality service parts are available through your dealer. If dealer parts are

not used, make sure the replacement parts are of equivalent quality.

204Maintenance

2013 F-650/750(f67)

Owners Guide gf, 2nd Printing, March 2013

USA(fus)

Page 206 of 378

WARNING:The use of inferior parts can adversely affect the

quality and reliability of your vehicle which, in turn, can result in

property damage, personal injury or death.

To avoid damage to the vehicle’s electrical components prior to electric

welding:

•disconnect both battery cables.

•attach the welder ground cable as close as possible to the part being

welded.

•it is recommended that the component be temporarily removed if

welding close to an electrical component.

Follow the checks and services in theScheduled Maintenancechapter.

Have your dealer or service center inspect your vehicle at least once a

year. Remember that regular maintenance and inspections usually

prevent serious problems from developing later.

If the owner or operator of the vehicle is a skilled technician and intends

on performing the vehicle maintenance and service, he is strongly urged

to purchase a service manual.

Electrical System

Periodically inspect electrical connectors on the outside of the cab and

on the engine and frame for corrosion and tightness. Exposed terminals,

such as the fuel sender, cranking motor, alternator and feed-through

studs, should be cleaned and re-coated with a lubricant sealing grease

such as Motorcraft® Silicone Brake Caliper Grease and Dielectic

Compound XG-3, or equivalent. This should include the ground cable

connector for batteries, engine and cab as well as the jump starting stud.

Accessory Feed Connections

Vehicle electrical systems are complex and often include powertrain

components, such as engine and transmission controls, instrument

panels, ABS, etc. While most systems operate on battery voltage

(12 volts), some systems can be as high as 90 volts or as low as five

volts. See theElectrical Circuit Diagram Manuals,available from your

vehicle’s manufacturer, to make sure that any additional body lights and

accessories are connected to circuits that are both appropriate and not

overloaded. No modification should be made to any vehicle control

system without first contacting your dealer.

Maintenance205

2013 F-650/750(f67)

Owners Guide gf, 2nd Printing, March 2013

USA(fus)

Page 207 of 378

Climate Control System

Have the air conditioning system checked each spring. The refrigerant

charge, cleanliness of the condenser-evaporator cores and belt condition

are essential to system performance.

When the air conditioning system is being used daily, remove the fresh

air filter (if equipped) once each season and check for dirt, lint, etc.

Replace the filter if necessary. Vehicles operating in unusually dusty

conditions may require more frequent filter inspection and replacement.

Front Axle

Maintaining the front axle alignment to specifications is very important

and should only be performed by a qualified technician. Regular

inspections should include:

•toe-in inspection and adjustment (if necessary), particularly with

radial tires.

•checking for proper tightness of axle mounting U-bolt nuts, attaching

or mounting bolts and nuts.

•checking the axle for damage, binding, worn parts and adequate

lubrication..

•checking the kingpins for excessive wear. This should also be done

during other scheduled maintenance (tire rotation or service, wheel

bearing service, alignment, etc.). See the workshop manual for proper

procedures.

Toe-in

It is essential that correct toe-in and tire pressure be maintained for

optimum tire wear.

Inspecting steer axle tires in the first 3000–10000 service miles

(5000–16000 service kilometers) generally shows if tires are wearing

normally.

Rapid outside shoulder wear on both tires indicates too much toe-in.

Rapid inside shoulder wear on both tires indicates too much toe-out.

In P&D-type service, left-to-right steer tire tread life differentials up to

40% can be observed depending on routes and other variables.

Follow the tire manufacturer’s recommended cold inflation pressure for

the tire size, load range (ply rating) and steer axle loading typical for

their operation (each steer axle tire equals

1�2steer axle loading).

206Maintenance

2013 F-650/750(f67)

Owners Guide gf, 2nd Printing, March 2013

USA(fus)

Page 208 of 378

Special applications may warrant a setting based on experience with the

type of tire operating loads and conditions. Radial tires are more

sensitive to toe-in setting than bias ply tires. While not insensitive to

vehicle alignment, fine tuning school bus alignment to line-haul truck

standards does not drastically improve tire tread life.

Rear Axle

Regular inspections should include:

•checking for proper tightness of axle mounting U-bolt nuts, attaching

or mounting bolts and nuts. SeeSpring U-bolt checkslater in this

chapter.

•checking the axle for damage, binding, worn parts and adequate

lubrication.

NoSpin Detroit Locker Positive Locking Differential

Vehicles equipped with this type differential have the operator’s manual

supplied with the vehicle. See that manual for maintenance inspections.

Maintenance207

2013 F-650/750(f67)

Owners Guide gf, 2nd Printing, March 2013

USA(fus)

Page 209 of 378

Brake System

Note:Persons handling brake linings should follow all precautions listed

below:

WARNING:

1. Always wear a respirator approved by the National Institute of

Occupational Studies of Health (NIOSH) or Mine Safety and Appliance

(MSA) during all brake service procedures. Wear the respirator from

removal of the wheels through assembly.

2.Neveruse compressed air or dry brushing to clean brake parts or

assemblies.

3. Clean brake parts and assemblies in open air. During assembly,

carefully place all parts on the floor to avoid getting dust in the air. Use

an industrial vacuum cleaner with a HEPA filter system to clean dust

from the brake drums, backing plates and other brake parts. After using

the vacuum, remove any remaining dust with a rag soaked in water and

wrung until nearly dry.

4.Neveruse compressed air or dry sweeping to clean the work area.

Use an industrial vacuum cleaner with a HEPA filter system and rags

soaked in water and wrung until nearly dry. Dispose of used rags with

care to avoid getting dust in the air. Use an approved respirator when

emptying vacuum cleaners and handling used rags.

5.Worker clean-up:Wash your hands before eating, drinking or

smoking. Vacuum your work clothes after use and then launder them

separately, without shaking them, to prevent fiber dust getting into the

air.

Your vehicle is equipped with non-asbestos brake linings. However,

exposure to excessive amounts of brake material (whether asbestos or

non-asbestos, fiberglass, mineral wool, aramid or carbon) may be a

serious health hazard.

208Maintenance

2013 F-650/750(f67)

Owners Guide gf, 2nd Printing, March 2013

USA(fus)

Page 210 of 378

Air Brakes

WARNING:Do not manually adjust the automatic slack adjusters

to correct excessive push rod stroke as it may result in reduced

brake effectiveness and a vehicle crash. Excessive push rod stroke

indicates that a problem exists with the automatic adjuster, with the

installation of the adjuster, or with foundation brake components that

manual adjustment does not remedy. Seek service from a qualified

facility for excessive push rod stroke.

Inspection and adjustment:Establish a regular schedule for periodic

cleaning, lubrication and adjustment inspection based on vehicle use.

Exact maintenance intervals are difficult to predetermine since vehicles

are used in a wide variety of applications and conditions. If you are

uncertain of the proper schedule for your vehicle, contact your dealer.

Regular inspections should include:

•periodic checking (every service interval) of push rod travel or brake

adjustment. This is essential for effective braking. Brake chamber

push rods on original equipment chambers now incorporate an orange

paint marker near the base of the push rod as a stroke indicator to

aid in adjustment checks. If the push rod is clean and the brakes are

out of adjustment, the orange marker can be seen protruding from

the chamber when the brakes are applied.

•checking the brake lining (every service interval). When brake lining

or blocks are worn to within 1/16th inch (1.6 millimeters) of rivets,

replace the brake linings. This inspection or adjustment should only

be performed by a qualified technician and must be in accordance

with instructions provided by the service manual.

Do not back off or disconnect the front brakes so that they are less

effective, letting the rear brakes do all the stopping of the vehicle. Do

not overlook the brakes on the trailer either. Brake condition on the

trailer is just as important as the tractor. Proper brake balance on trucks

and tractor-trailers is essential for effective braking.

Once a year, the entire brake system must be inspected:

•Rubber components for deterioration. These components should be

inspected by a qualified technician and replaced as necessary.

Replacement intervals vary according to the severity and length of

vehicle service.

•Condition of brake drums, brake chambers and slack adjusters.

•System for air leaks.

•Hose or pipes for rust, damage and deterioration.

•Operation of service and parking brakes.

Maintenance209

2013 F-650/750(f67)

Owners Guide gf, 2nd Printing, March 2013

USA(fus)