%27 FORD FESTIVA 1991 User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 1991, Model line: FESTIVA, Model: FORD FESTIVA 1991Pages: 454, PDF Size: 9.53 MB

Page 117 of 454

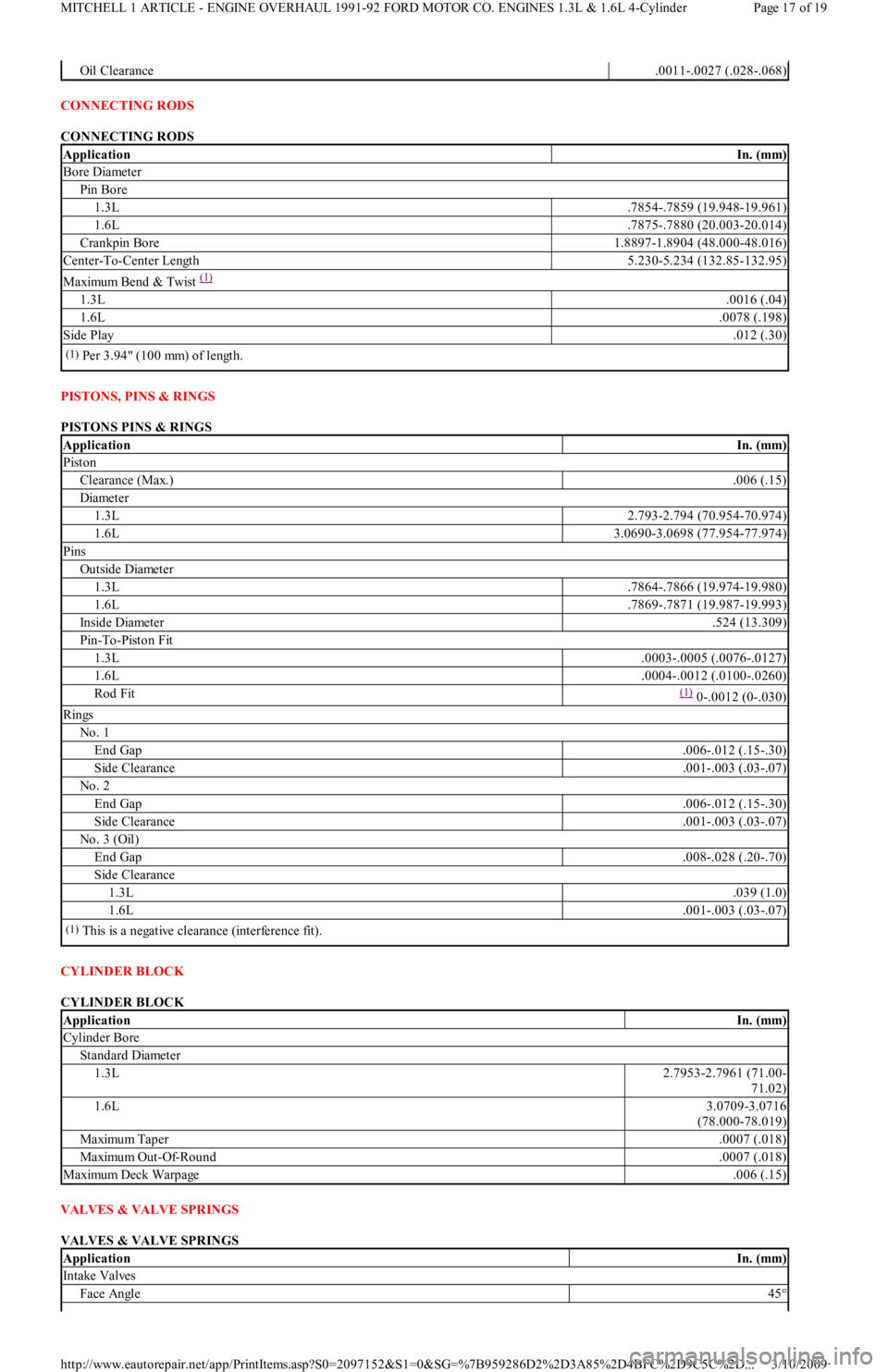

CONNECTING RODS

CONNECTING RODS

PISTONS, PINS & RINGS

PISTONS PINS & RINGS

CYLINDER BLOCK

CYLINDER BLOCK

VALVES & VALVE SPRINGS

VALVES & VALVE SPRINGS

Oil Clearance.0011-.0027 (.028-.068)

ApplicationIn. (mm)

Bore Diameter

Pin Bore

1.3L.7854-.7859 (19.948-19.961)

1.6L.7875-.7880 (20.003-20.014)

Crankpin Bore1.8897-1.8904 (48.000-48.016)

Center-To-Center Length5.230-5.234 (132.85-132.95)

Maximu m Ben d & Twist (1)

1.3L.0016 (.04)

1.6L.0078 (.198)

Side Play.012 (.30)

(1)Per 3.94" (100 mm) of length.

ApplicationIn. (mm)

Piston

Clearance (Max.).006 (.15)

Diameter

1.3L2.793-2.794 (70.954-70.974)

1.6L3.0690-3.0698 (77.954-77.974)

Pins

Outside Diameter

1.3L.7864-.7866 (19.974-19.980)

1.6L.7869-.7871 (19.987-19.993)

Inside Diameter.524 (13.309)

Pin-To-Piston Fit

1.3L.0003-.0005 (.0076-.0127)

1.6L.0004-.0012 (.0100-.0260)

Rod Fit(1) 0-.0012 (0-.030)

Rings

No. 1

End Gap.006-.012 (.15-.30)

Side Clearance.001-.003 (.03-.07)

No. 2

End Gap.006-.012 (.15-.30)

Side Clearance.001-.003 (.03-.07)

No. 3 (Oil)

End Gap.008-.028 (.20-.70)

Side Clearance

1.3L.039 (1.0)

1.6L.001-.003 (.03-.07)

(1)This is a negative clearance (interference fit).

ApplicationIn. (mm)

Cylinder Bore

Standard Diameter

1.3L2.7953-2.7961 (71.00-

71.02)

1.6L3.0709-3.0716

(78.000-78.019)

Maximu m Tap er.0007 (.018)

Maximu m Ou t -Of-Ro u n d.0007 (.018)

Maximu m Deck Warp age.006 (.15)

ApplicationIn. (mm)

In t ake Val ves

Face Angle45°

Page 17 of 19 MITCHELL 1 ARTICLE - ENGINE OVERHAUL 1991-92 FORD MOTOR CO. ENGINES 1.3L & 1.6L 4-Cylinder

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 118 of 454

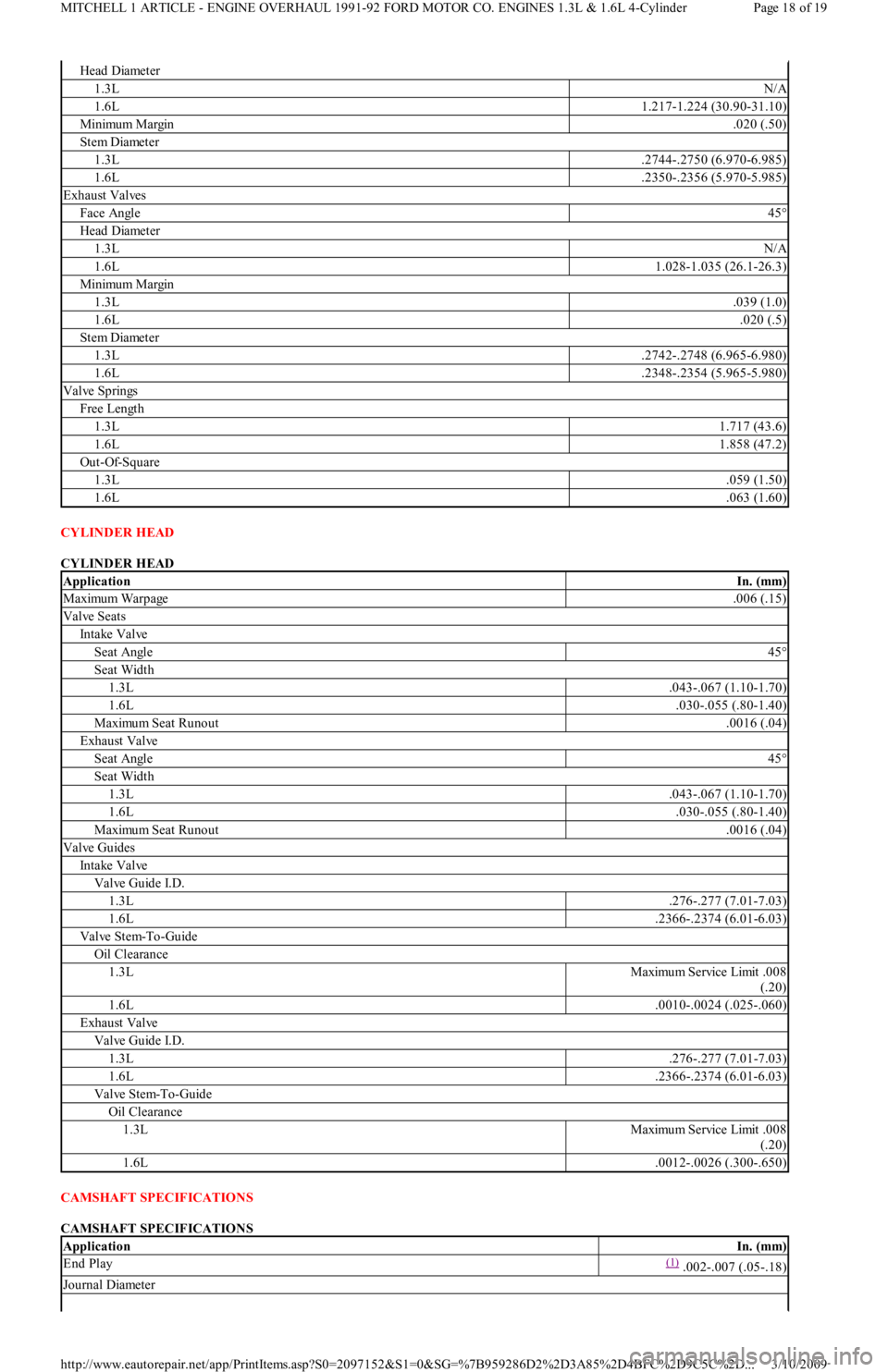

CYLINDER HEAD

CYLINDER HEAD

CAMSHAFT SPECIFICATIONS

CAMSHAFT SPECIFICATIONS

Head Diameter

1.3LN/A

1.6L1.217-1.224 (30.90-31.10)

Min imu m Margin.020 (.50)

Stem Diameter

1.3L.2744-.2750 (6.970-6.985)

1.6L.2350-.2356 (5.970-5.985)

Exhaust Valves

Face Angle45°

Head Diameter

1.3LN/A

1.6L1.028-1.035 (26.1-26.3)

Min imu m Margin

1.3L.039 (1.0)

1.6L.020 (.5)

Stem Diameter

1.3L.2742-.2748 (6.965-6.980)

1.6L.2348-.2354 (5.965-5.980)

Valve Springs

Free Length

1.3L1.717 (43.6)

1.6L1.858 (47.2)

Out-Of-Square

1.3L.059 (1.50)

1.6L.063 (1.60)

ApplicationIn. (mm)

Maximu m Warp age.006 (.15)

Valve Seats

Intake Valve

Seat Angle45°

Seat Width

1.3L.043-.067 (1.10-1.70)

1.6L.030-.055 (.80-1.40)

Maximu m Seat Ru n o u t.0016 (.04)

Exhaust Valve

Seat Angle45°

Seat Width

1.3L.043-.067 (1.10-1.70)

1.6L.030-.055 (.80-1.40)

Maximu m Seat Ru n o u t.0016 (.04)

Valve Guides

Intake Valve

Valve Guide I.D.

1.3L.276-.277 (7.01-7.03)

1.6L.2366-.2374 (6.01-6.03)

Valve Stem-To-Guide

Oil Clearance

1.3LMaximu m Service Limit .0 0 8

(.20)

1.6L.0010-.0024 (.025-.060)

Exhaust Valve

Valve Guide I.D.

1.3L.276-.277 (7.01-7.03)

1.6L.2366-.2374 (6.01-6.03)

Valve Stem-To-Guide

Oil Clearance

1.3LMaximu m Service Limit .0 0 8

(.20)

1.6L.0012-.0026 (.300-.650)

ApplicationIn. (mm)

End Play(1) .002-.007 (.05-.18)

Journal Diameter

Page 18 of 19 MITCHELL 1 ARTICLE - ENGINE OVERHAUL 1991-92 FORD MOTOR CO. ENGINES 1.3L & 1.6L 4-Cylinder

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 119 of 454

1.3L

No. 1 & 31.7102-1.7109 (43.440-

43.456)

No. 21.7091-1.7100 (43.410-

43.435)

1.6L (All Journals)1.0213-1.0222 (25.940-

25.965)

Journal Runout.002 (.05)

Lobe Height

1.3L(2) 1.4332-1.4371 (36.403-

36.503)

1.6L(3) 1.6098 (40.888)

Oil Clearance

1.3L

No. 1 & 3 Journals(4) .0014-.0033 (.035-.085)

No. 2 Journal(4) .0026-.0045 (.065-.115)

1.6L (All Journals)(4) .0014-.0033 (.035-.085)

(1)End play limit is .008" (.20 mm).

(2)Wear limit is 1.4272" (36.253 mm)

(3)Wear limit is 1.5940" (40.489)

(4)Maximum clearance is .0059" (.150 mm)

Copyr ight 2009 Mitchell Repair Information Company, LLC. All Rights Reserved.

Article GUID: A00048707

Page 19 of 19 MITCHELL 1 ARTICLE - ENGINE OVERHAUL 1991-92 FORD MOTOR CO. ENGINES 1.3L & 1.6L 4-Cylinder

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 128 of 454

Crankshaft Pulley Bolts10-13 (12-17)

Crankshaft Sprocket Bolt80-87 (108-118)

Power Steering Adjuster Nut27-38 (37-52)

Timing Belt Tensioner Adjuster Bolt14-19 (19-26)

Water Pump Pulley Bolts36-45 (49-61)

INCH Lbs. (N.m)

Camshaft Cover71-97 (8-11)

Timing Belt Cover Bolt71-97 (8-11)

Valve Cover Bolt44-79 (5-9)

Copyr ight 2009 Mitchell Repair Information Company, LLC. All Rights Reserved.

Article GUID: A00155957

Page 3 of 3 MITCHELL 1 ARTICLE - FORD 1.3L 4-Cylinder

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 144 of 454

Copyr ight 2009 Mitchell Repair Information Company, LLC. All Rights Reserved.

Article GUID: A00022701

Page 3 of 3 MITCHELL 1 ARTICLE - J - PIN VOLTAGE CHARTS 1991 ENGINE PERFORMANCE Ford/Mercury Pin Voltage Charts

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 149 of 454

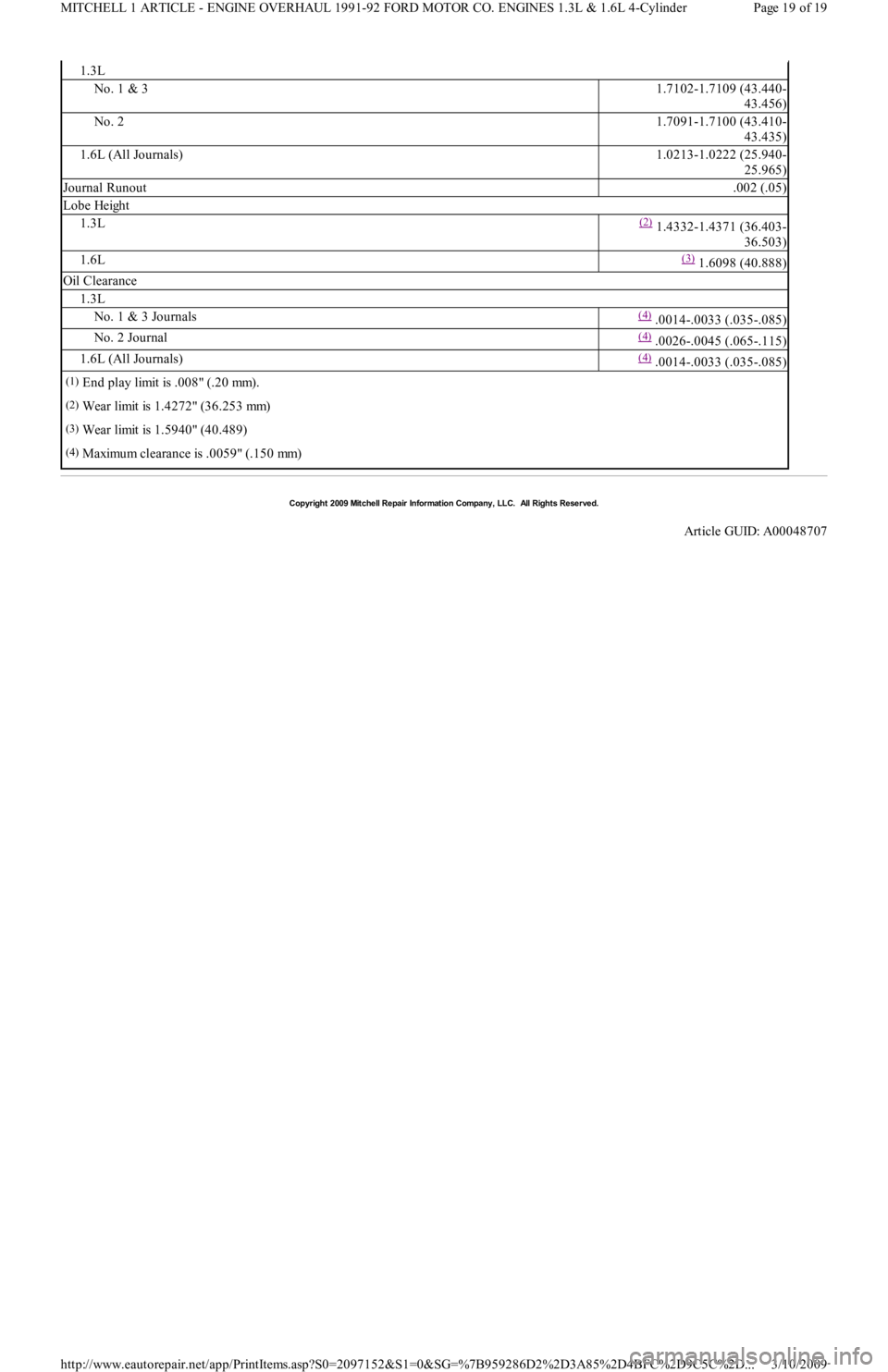

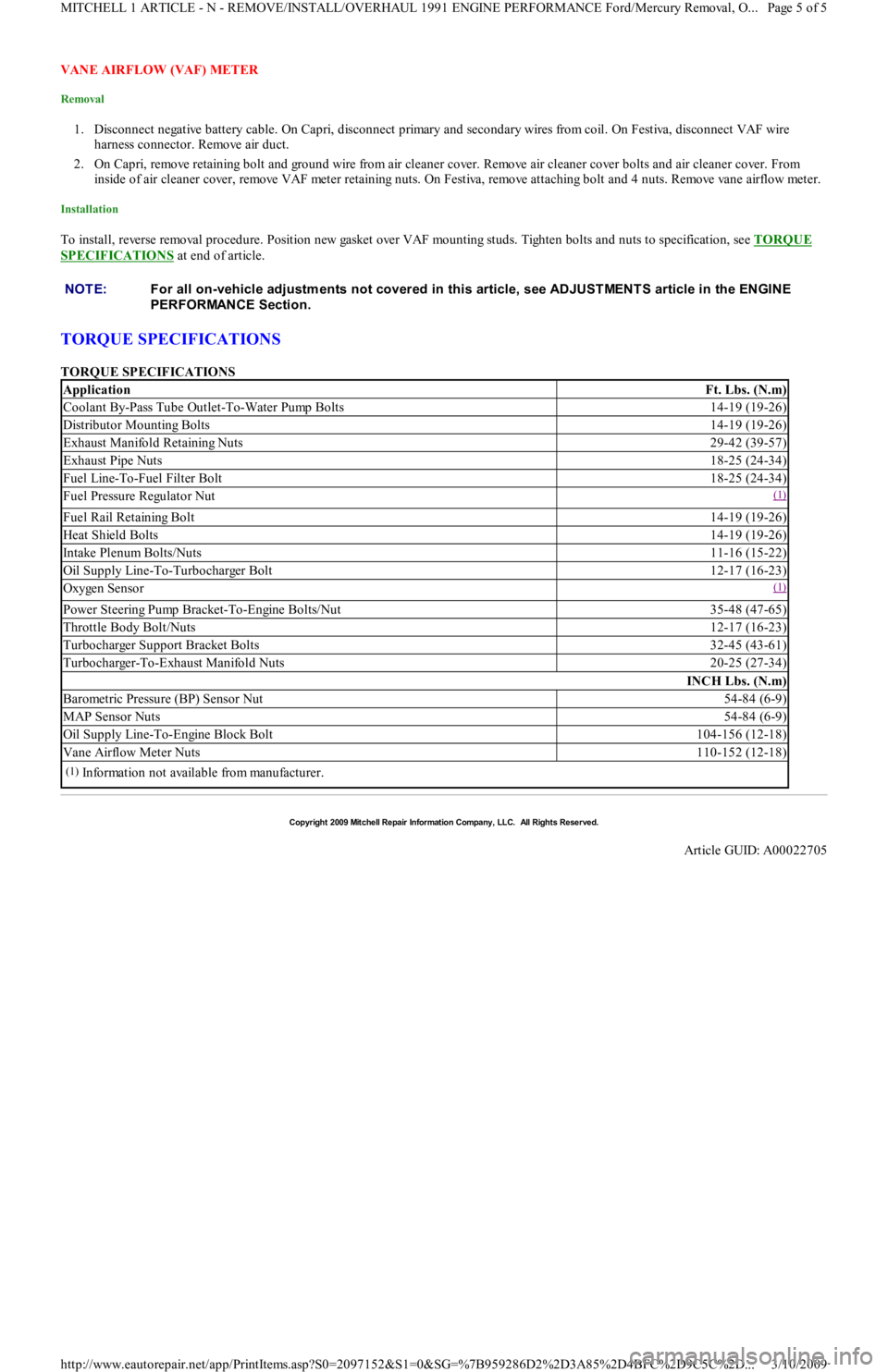

VANE AIRFLOW (VAF) METER

Removal

1. Disconnect negative battery cable. On Capri, disconnect primary and secondary wires from coil. On Festiva, disconnect VAF wire

harness connector. Remove air duct.

2. On Capri, remove retaining bolt and ground wire from air cleaner cover. Remove air cleaner cover bolts and air cleaner cover. From

inside of air cleaner cover, remove VAF meter retaining nuts. On Festiva, remove attaching bolt and 4 nuts. Remove vane airflow met er.

Installation

To install, reverse removal procedure. Position new gasket over VAF mounting studs. Tighten bolts and nuts to specification, see TORQUE

SPECIFICATIONS at end of article.

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS NOTE:For all on-vehicle adjustm ents not covered in this article, see ADJUST MENT S article in the ENGINE

PERFORMANCE Section.

ApplicationFt. Lbs. (N.m)

Coolant By-Pass Tube Outlet-To-Water Pump Bolts14-19 (19-26)

Distributor Mounting Bolts14-19 (19-26)

Exhaust Manifold Retaining Nuts29-42 (39-57)

Exhaust Pipe Nuts18-25 (24-34)

Fuel Line-To-Fuel Filter Bolt18-25 (24-34)

Fuel Pressure Regulator Nut(1)

Fuel Rail Retaining Bolt14-19 (19-26)

Heat Shield Bolts14-19 (19-26)

Intake Plenum Bolts/Nuts11-16 (15-22)

Oil Supply Line-To-Turbocharger Bolt12-17 (16-23)

Oxygen Sensor(1)

Power Steering Pump Bracket-To-Engine Bolts/Nut35-48 (47-65)

Throttle Body Bolt/Nuts12-17 (16-23)

Turbocharger Support Bracket Bolts32-45 (43-61)

Turbocharger-To-Exhaust Manifold Nuts20-25 (27-34)

INCH Lbs. (N.m)

Barometric Pressure (BP) Sensor Nut54-84 (6-9)

MAP Sensor Nuts54-84 (6-9)

Oil Supply Line-To-Engine Block Bolt104-156 (12-18)

Vane Airflow Meter Nuts110-152 (12-18)

(1)Information not available from manufacturer.

Copyr ight 2009 Mitchell Repair Information Company, LLC. All Rights Reserved.

Article GUID: A00022705

Page 5 of 5 MITCHELL 1 ARTICLE - N - REMOVE/INSTALL/OVERHAUL 1991 ENGINE PERFORMANCE Ford/Mercury Removal, O

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 150 of 454

Back To Article

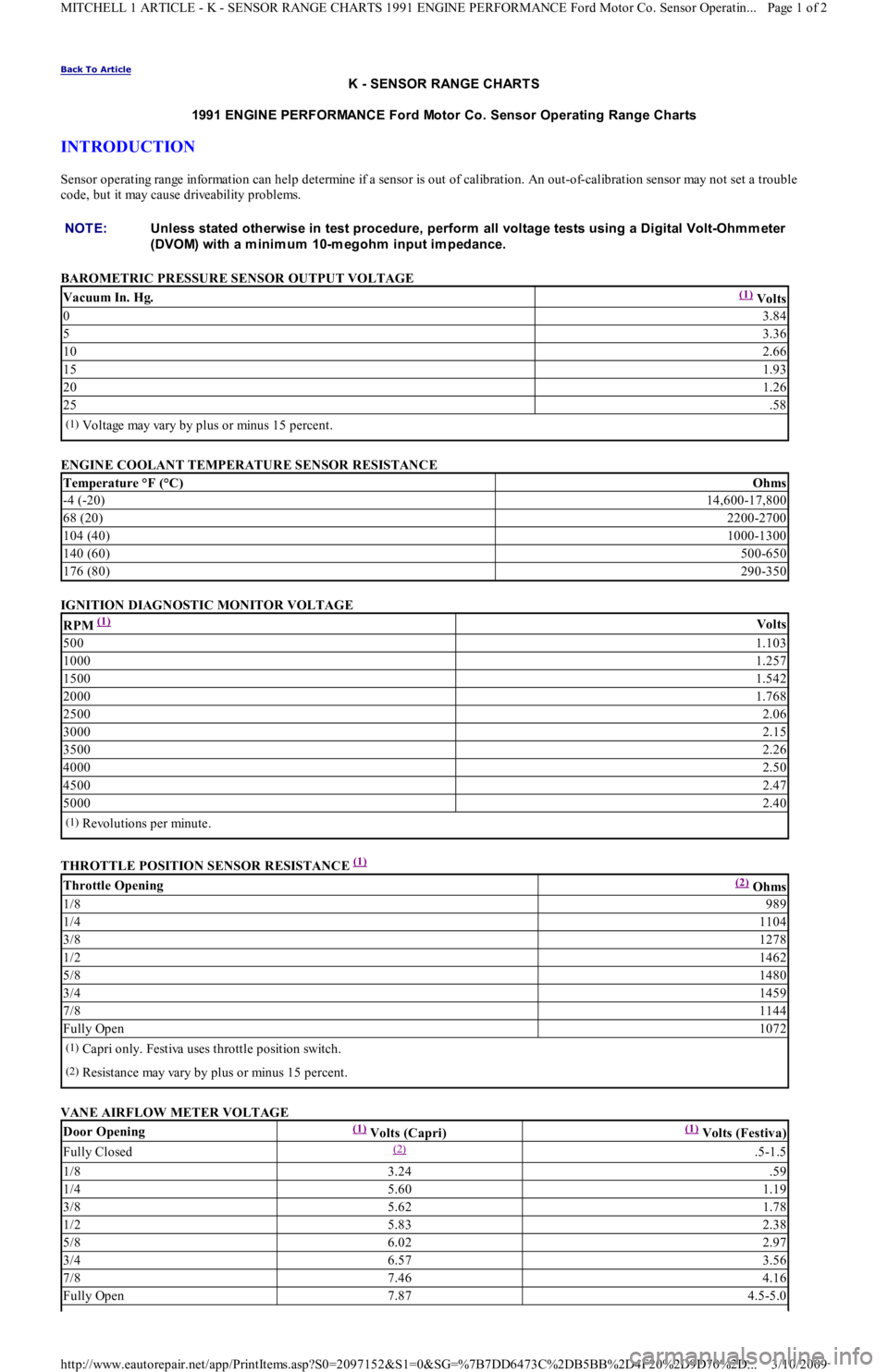

K - SENSOR RANGE CHART S

1991 ENGINE PERFORMANCE Ford Motor Co. Sensor Operating Range Charts

INTRODUCTION

Sensor operating range information can help determine if a sensor is out of calibration. An out-of-calibration sensor may not set a trouble

code, but it may cause driveability problems.

BAROMETRIC PRESSURE SENSOR OUTPUT VOLTAGE

ENGINE COOLANT TEMPERATURE SENSOR RESISTANCE

IGNITION DIAGNOSTIC MONITOR VOLTAGE

THROTTLE POSITION SENSOR RESISTANCE

(1)

VANE AIRFLOW METER VOLTAGE NOTE:Unless stated otherwise in test procedure, perform all voltage tests using a Digital Volt-Ohm m eter

(DVOM) with a m inim um 10-m egohm input im pedance.

Vacuum In. Hg.(1) Volts

03.84

53.36

102.66

151.93

201.26

25.58

(1)Voltage may vary by plus or minus 15 percent.

Temperature °F (°C)Ohms

-4 (-20)14,600-17,800

68 (20)2200-2700

104 (40)1000-1300

140 (60)500-650

176 (80)290-350

RPM (1) Volts

5001.103

10001.257

15001.542

20001.768

25002.06

30002.15

35002.26

40002.50

45002.47

50002.40

(1)Revolutions per minute.

Throttle Opening(2) Ohms

1/8989

1/41104

3/81278

1/21462

5/81480

3/41459

7/81144

Fully Open1072

(1)Capri only. Festiva uses throttle position switch.

(2)Resistance may vary by plus or minus 15 percent.

Door Opening(1) Volts (Capri)(1) Volts (Festiva)

Fully Closed(2) .5-1.5

1/83.24.59

1/45.601.19

3/85.621.78

1/25.832.38

5/86.022.97

3/46.573.56

7/87.464.16

Fully Open7.874.5-5.0

Page 1 of 2 MITCHELL 1 ARTICLE - K - SENSOR RANGE CHARTS 1991 ENGINE PERFORMANCE Ford Motor Co. Sensor Operatin

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 151 of 454

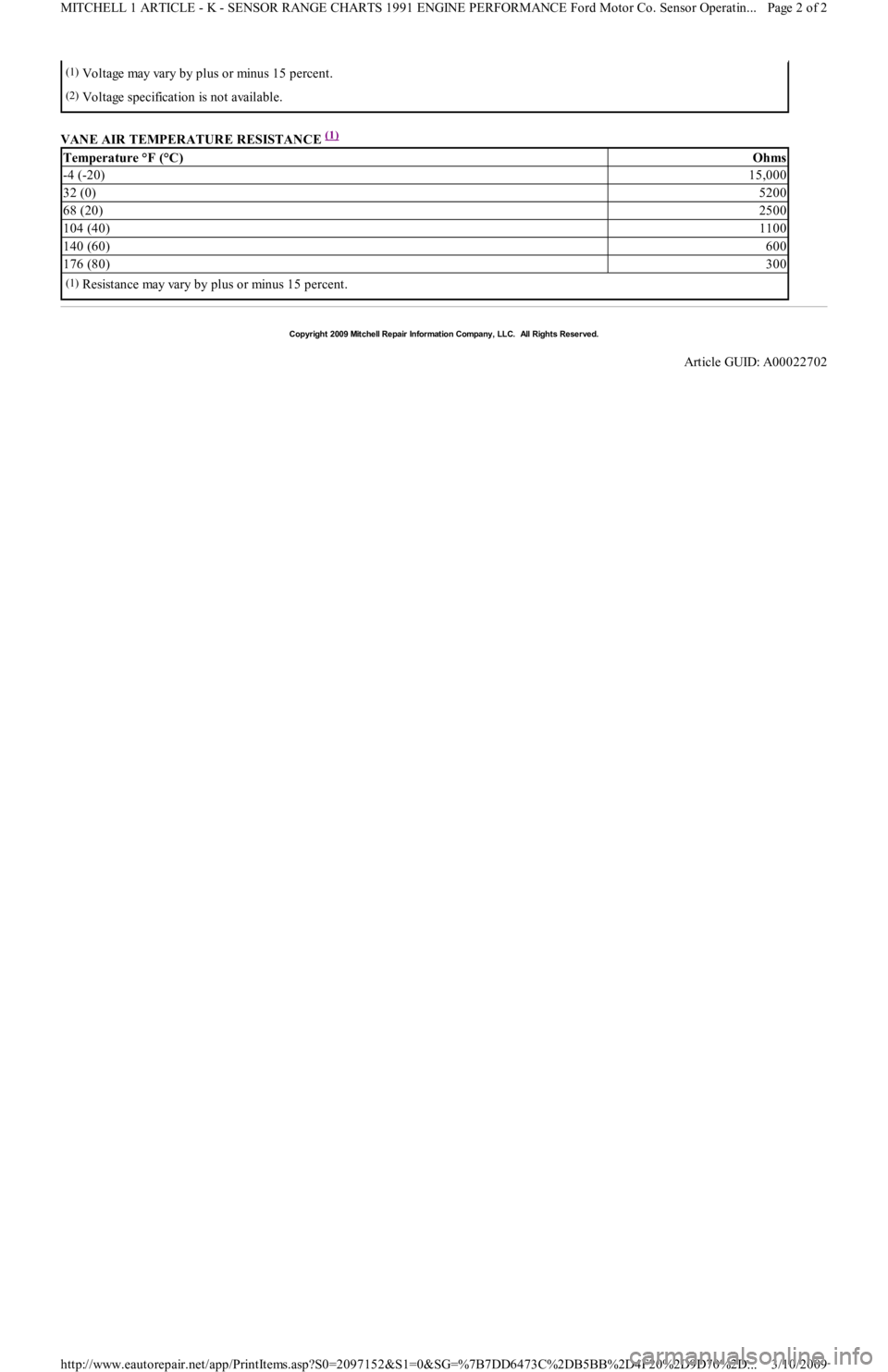

VANE AIR TEMPERATURE RESISTANCE (1)

(1)Voltage may vary by plus or minus 15 percent.

(2)Voltage specification is not available.

Temperature °F (°C)Ohms

-4 (-20)15,000

32 (0)5200

68 (20)2500

104 (40)1100

140 (60)600

176 (80)300

(1)Resistance may vary by plus or minus 15 percent.

Copyr ight 2009 Mitchell Repair Information Company, LLC. All Rights Reserved.

Article GUID: A00022702

Page 2 of 2 MITCHELL 1 ARTICLE - K - SENSOR RANGE CHARTS 1991 ENGINE PERFORMANCE Ford Motor Co. Sensor Operatin

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 152 of 454

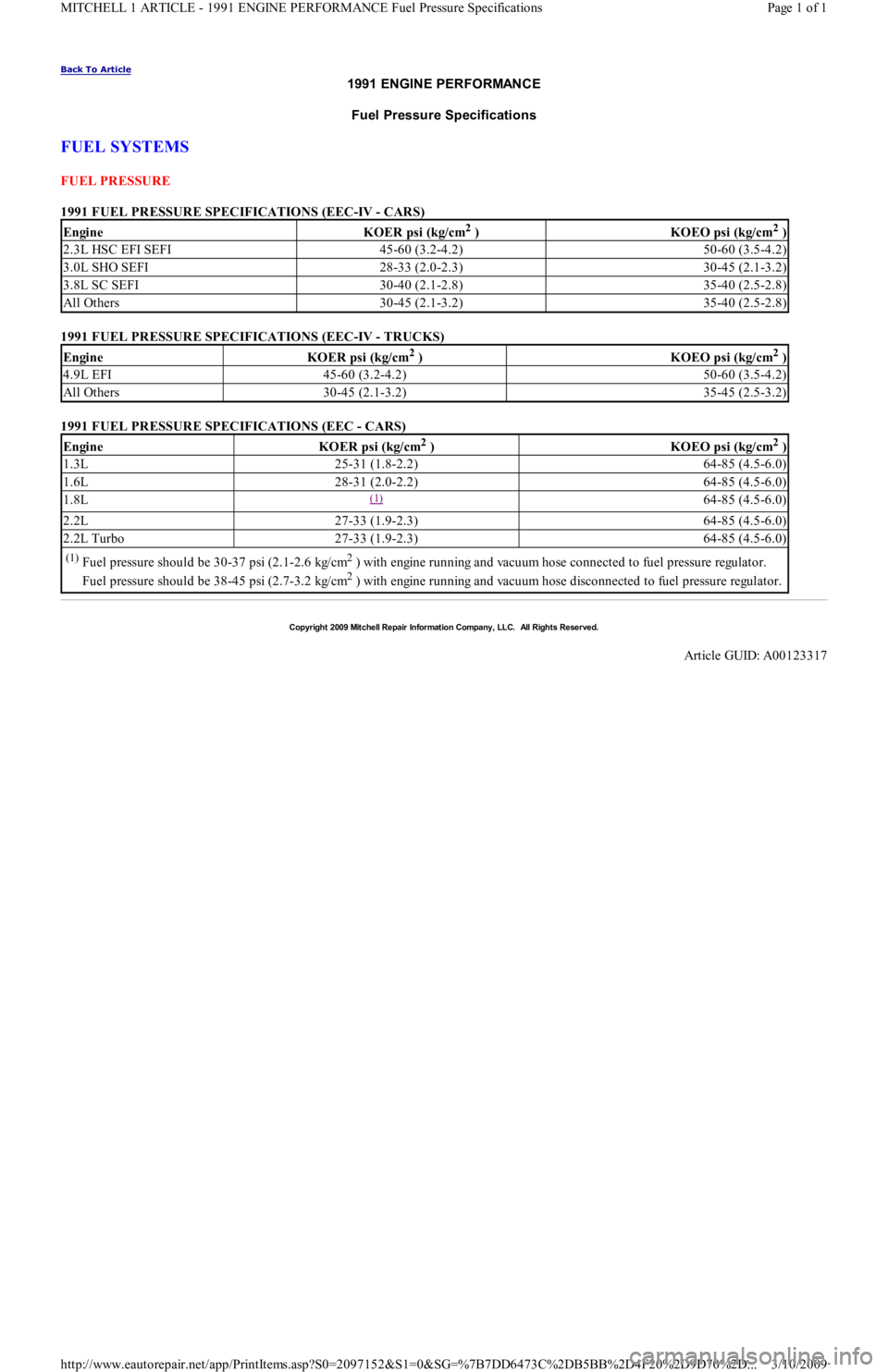

Back To Article

1991 ENGINE PERFORMANCE

Fuel Pressure Specifications

FUEL SYSTEMS

FUEL PRESSURE

1991 FUEL PRESSURE SPECIFICATIONS (EEC-IV - CARS)

1991 FUEL PRESSURE SPECIFICATIONS (EEC-IV - TRUCKS)

1991 FUEL PRESSURE SPECIFICATIONS (EEC - CARS)

EngineKOER psi (kg/cm2 )KOEO psi (kg/cm2 )

2.3L HSC EFI SEFI45-60 (3.2-4.2)50-60 (3.5-4.2)

3.0L SHO SEFI28-33 (2.0-2.3)30-45 (2.1-3.2)

3.8L SC SEFI30-40 (2.1-2.8)35-40 (2.5-2.8)

All Others30-45 (2.1-3.2)35-40 (2.5-2.8)

EngineKOER psi (kg/cm2 )KOEO psi (kg/cm2 )

4.9L EFI45-60 (3.2-4.2)50-60 (3.5-4.2)

All Others30-45 (2.1-3.2)35-45 (2.5-3.2)

EngineKOER psi (kg/cm2 )KOEO psi (kg/cm2 )

1.3L25-31 (1.8-2.2)64-85 (4.5-6.0)

1.6L28-31 (2.0-2.2)64-85 (4.5-6.0)

1.8L(1) 64-85 (4.5-6.0)

2.2L27-33 (1.9-2.3)64-85 (4.5-6.0)

2.2L Turbo27-33 (1.9-2.3)64-85 (4.5-6.0)

(1)Fuel pressure should be 30-37 psi (2.1-2.6 kg/cm2 ) with engine running and vacuum hose connected to fuel pressure regulator.

Fuel pressure should be 38-45 psi (2.7-3.2 kg/cm

2 ) with engine running and vacuum hose disconnected to fuel pressure regulator.

Copyr ight 2009 Mitchell Repair Information Company, LLC. All Rights Reserved.

Article GUID: A00123317

Page 1 of 1 MITCHELL 1 ARTICLE - 1991 ENGINE PERFORMANCE Fuel Pressure Specifications

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 162 of 454

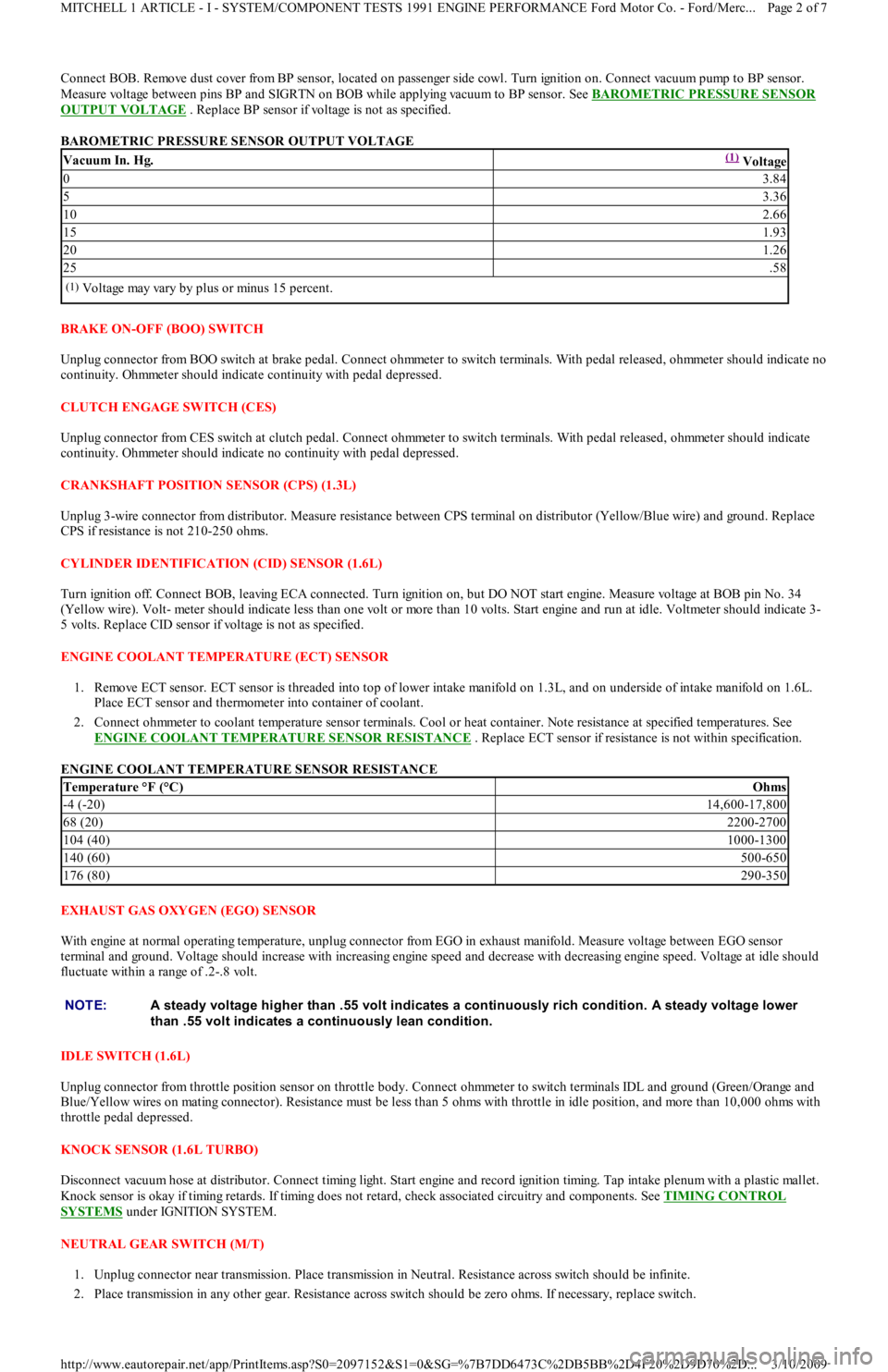

Connect BOB. Remove dust cover from BP sensor, located on passenger side cowl. Turn ignition on. Connect vacuum pump to BP sensor.

Measure voltage between pins BP and SIGRTN on BOB while applying vacuum to BP sensor. See BAROMETRIC PRESSURE SENSOR

OUTPUT VOLTAGE . Replace BP sensor if voltage is not as specified.

BAROMETRIC PRESSURE SENSOR OUTPUT VOLTAGE

BRAKE ON-OFF (BOO) SWITCH

Unplug connector from BOO switch at brake pedal. Connect ohmmeter to switch terminals. With pedal released, ohmmeter should indicate no

continuity. Ohmmeter should indicate continuity with pedal depressed.

CLUTCH ENGAGE SWITCH (CES)

Unplug connector from CES switch at clutch pedal. Connect ohmmeter to switch terminals. With pedal released, ohmmeter should indicate

continuity. Ohmmeter should indicate no continuity with pedal depressed.

CRANKSHAFT POSITION SENSOR (CPS) (1.3L)

Unplug 3-wire connector from distributor. Measure resistance between CPS terminal on distributor (Yellow/Blue wire) and ground. Replace

CPS if resistance is not 210-250 ohms.

CYLINDER IDENTIFICATION (CID) SENSOR (1.6L)

Turn ignition off. Connect BOB, leaving ECA connected. Turn ignition on, but DO NOT start engine. Measure voltage at BOB pin No. 34

(Yellow wire). Volt- meter should indicate less than one volt or more than 10 volts. Start engine and run at idle. Voltmeter should indicate 3-

5 volts. Replace CID sensor if voltage is not as specified.

ENGINE COOLANT TEMPERATURE (ECT) SENSOR

1. Remove ECT sensor. ECT sensor is threaded into top of lower intake manifold on 1.3L, and on underside of intake manifold on 1.6L.

Place ECT sensor and thermometer into container of coolant.

2. Connect ohmmeter to coolant temperature sensor terminals. Cool or heat container. Note resistance at specified temperatures. See

ENGINE COOLANT TEMPERATURE SENSOR RESISTANCE

. Replace ECT sensor if resistance is not within specification.

ENGINE COOLANT TEMPERATURE SENSOR RESISTANCE

EXHAUST GAS OXYGEN (EGO) SENSOR

With engine at normal operating temperature, unplug connector from EGO in exhaust manifold. Measure voltage between EGO sensor

terminal and ground. Voltage should increase with increasing engine speed and decrease with decreasing engine speed. Voltage at idle should

fluctuate within a range of .2-.8 volt.

IDLE SW ITCH (1.6L)

Unplug connector from throttle position sensor on throttle body. Connect ohmmeter to switch terminals IDL and ground (Green/Orange and

Blue/Yellow wires on mating connector). Resistance must be less than 5 ohms with throttle in idle position, and more than 10,000 ohms with

throttle pedal depressed.

KNOCK SENSOR (1.6L TURBO)

Disconnect vacuum hose at distributor. Connect timing light. Start engine and record ignition timing. Tap intake plenum with a plastic mallet.

Knock sensor is okay if timing retards. If timing does not retard, check associated circuitry and components. See TIMING CONTROL

SYSTEMS under IGNITION SYSTEM.

NEUTRAL GEAR SWITCH (M/T)

1. Unplug connector near transmission. Place transmission in Neutral. Resistance across switch should be infinite.

2. Place transmission in any other gear. Resistance across switch should be zero ohms. If necessary, replace switch.

Vacuum In. Hg.(1) Voltage

03.84

53.36

102.66

151.93

201.26

25.58

(1)Voltage may vary by plus or minus 15 percent.

Temperature °F (°C)Ohms

-4 (-20)14,600-17,800

68 (20)2200-2700

104 (40)1000-1300

140 (60)500-650

176 (80)290-350

NOTE:A steady voltage higher than .55 volt indicates a continuously rich condition. A steady voltage lower

than .55 volt indicates a continuously lean condition.

Page 2 of 7 MITCHELL 1 ARTICLE - I - SYSTEM/COMPONENT TESTS 1991 ENGINE PERFORMANCE Ford Motor Co. - Ford/Merc

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...