%27 FORD FESTIVA 1991 Service Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1991, Model line: FESTIVA, Model: FORD FESTIVA 1991Pages: 454, PDF Size: 9.53 MB

Page 27 of 454

Disconnect fluid lines and remove reservoir. To install, reverse removal procedure.

Removal & Installation (Festiva)

1. Disconnect negative battery cable. Remove washer reservoir filler neck attaching bolt. Remove coolant expansion reservoir. Disconnect

washer pump electrical connector. Remove left front splash shield.

2. Disconnect washer pump fluid lines and detach lines from reservoir clips. Remove reservoir attaching nuts and bolt. Detach washer

reservoir from filler neck and remove reservoir. To install, reverse removal procedure.

REAR WIPER MOTOR

Removal & Installation (Festiva)

Remove rear wiper arm and blade assembly. Remove boot from outer bushing attaching nut. Remove outer bushing attaching nut and remove

outer bushing. Remove liftgate trim panel. Disconnect wiper motor electrical connector. Remove 4 wiper motor mounting bolts and remove

motor. To install, reverse removal procedure.

REAR WIPER/WASHER SWITCH

Removal & Installation (Festiva)

Disconnect negative battery cable. Remove steering column covers. Remove screws securing instrument panel bezel to instrument panel. Pull

instrument bezel away from instrument panel. Disconnect electrical connectors from switches in bezel. Compress wiper/washer switch lock

tabs and remove switch from bezel. To install, reverse removal procedure.

REAR WASHER MOTOR & RESERVOIR

Removal & Installation (Festiva)

Open liftgate and detach reservoir cap. Remove rear quarter trim panel. Remove reservoir mounting bolts. Disconnect electrical connector

from washer pump. Disconnect fluid lines. Remove reservoir. To install, reverse removal procedure.

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS

WIRING DIAGRAMS

See appropriate chassis wiring diagram in the WIRING DIAGRAMS Section.

ApplicationINCH Lbs. (N.m)

Front Wiper Arm Retaining Nut89-124 (10-14)

Front Wiper Motor Mounting Bolts62-89 (7-10)

Rear Outer Bushing Retaining Nut27-44 (3-5)

Rear Wiper Arm Nut53-62 (6-7)

Rear Wiper Motor Mounting Bolts71-97 (8-11)

Copyr ight 2009 Mitchell Repair Information Company, LLC. All Rights Reserved.

Article GUID: A00028304

Page 5 of 5 MITCHELL 1 ARTICLE - WIPER/WASHER SYSTEM 1991 ACCESSORIES & SAFETY EQUIPMENT Ford Motor Co. Wip

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 28 of 454

Back To Article

BRAKE SYST EM

1991-92 BRAKES Disc & Drum

DESCRIPTION & OPERATION

On Capri, vehicle braking is provided by front and rear disc brakes. Front and rear brakes are a full-floating, single piston design. The rear

caliper houses a self-adjusting parking brake.

On Festiva, vehicle braking is provided by front disc brakes and rear drum brakes. Rear brakes are a standard non-servo, self-en e r giz in g d e sign .

Front brakes are a full-floating, single piston design with caliper attached to steering knuckle.

BLEEDING BRAKE SYSTEM

BLEEDING PROCEDURES

Manual Bleeding

1. Exhaust vacuum from power brake unit by depressing brake pedal several times. Fill master cylinder with clean brake fluid. Install clear

vinyl bleeder hose onto first bleeder valve to be serviced. See BRAKE LINE BLEEDING SEQUENCE table. Place other end of hose in

clean transparent container.

2. Partially fill container with clean brake fluid. Open the bleeder valve 3/4 turn. Slowly depress brake pedal through its full travel. Close

bleeder valve and release pedal. Pump pedal several times to push air toward wheel cylinders. Repeat procedure until flow of brake

fluid is clear and shows no signs of air bubbles. Proceed to next bleeder valve in sequence and repeat procedure.

BRAKE LINE BLEEDING SEQUENCE

Pressure Bleeding

1. Exhaust vacuum from power brake unit by depressing brake pedal several times. Fill master cylinder with clean brake fluid. With

pressure bleeder at least 1/2 full, connect pressure bleeder to master cylinder using appropriate adaptor.

2. Install clear vinyl bleeder hose onto first bleeder valve to be serviced. See BRAKE LINE BLEEDING SEQUENCE table. Place other

end of hose in clean transparent container. Partially fill container with clean brake fluid. Open bleeder valve 1-2 turns. Allow fluid to

run until flow of fluid is clear and shows no signs of air bubbles. Proceed to next bleeder valve in sequence and repeat procedure.

Remove pressure bleeder and fill master cylinder with clean brake fluid.

ADJUSTMENTS

BRAKE PEDAL HEIGHT (FESTIVA)

1. Block wheels to prevent vehicle from rolling. Start engine and place transmission in Neutral. Fully release parking brake. Move carpet

and insulation away from firewall and brake pedal. Measure distance horizontally between upper center of brake pedal pad and firewall.

Distance should be 8.03-8.23" (204-209 mm).

2. If pedal height is incorrect, inspect pedal assembly for missing, worn or damaged bushings or for loose attaching bolts. Ensure firewall is

not distorted and pedal is not bent. If pedal height is still not within specifications, check brake pedal, booster or master cylinder for

correct and/or correctly installed parts

BRAKE PEDAL FREE PLAY (FESTIVA)

Pump brake pedal several to bleed vacuum from power brake booster. Gently depress brake pedal by hand and measure and measure play

before resistance is felt. Free play should be .16-.28" (4-7 mm). If free play is not within specifications, adjust brake pedal push rod.

BRAKE PEDAL FLOOR CLEARANCE

Capri

1. Move carpet and insulation away from floor board and brake pedal. With engine running and using Brake Pedal Effort Gauge (021-

00001), apply 132 lbs. (59.9 kg) of force to brake pedal. Measure distance from upper surface of brake pedal pad to floor board. If

distance is less than 3.27" (83 mm), inspect pedal assembly for missing, worn or damaged bushings or for loose attaching bolts.

2. Verify that floor board is not distorted and pedal is not bent. If pedal height is still not within specifications, check brake pedal, booster

or master cylinder for correct and/or correctly installed parts. Check for air in hydraulic system.

Festiva

Move carpet and insulation away from floor board and brake pedal. Using Brake Pedal Effort Gauge (021-00001) or equivalent, apply 132

lbs. (59.9 kg) of force to brake pedal. Measure distance from upper surface of brake pedal pad to floor board. If distance is less than 2.68" (68

mm), check for air in hydraulic system, faulty automatic adjusters or excessive shoe clearance.

POWER BRAKE UNIT PUSH ROD

Capri

ApplicationSequence

CapriRR, LF, LR & RF

FestivaRR, LR, RF & LF

NOTE:Check fluid level in m aster cylinder frequently during the bleeding sequence.

Page 1 of 12 MITCHELL 1 ARTICLE - BRAKE SYSTEM 1991-92 BRAKES Disc & Drum

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 33 of 454

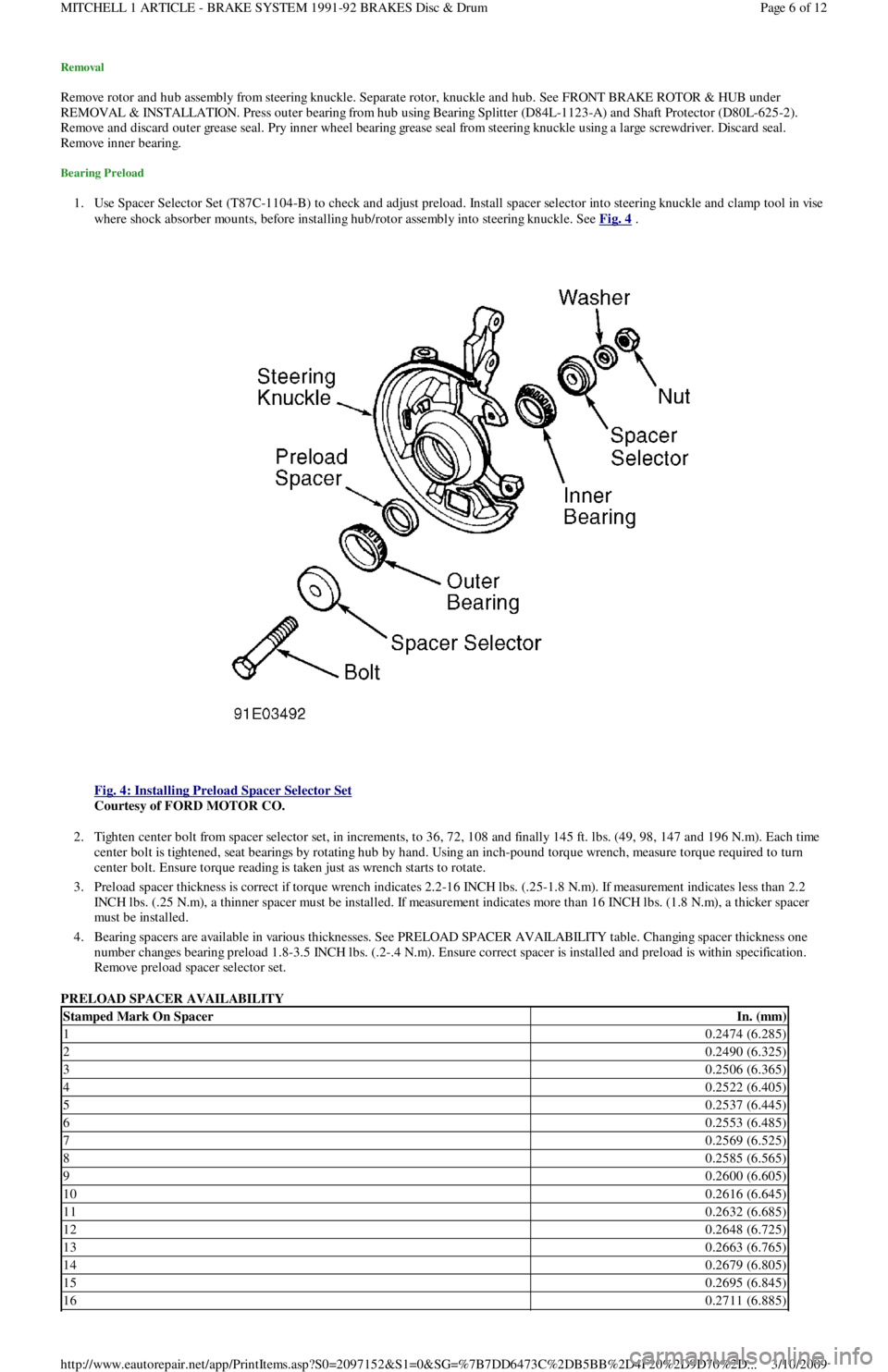

Removal

Remove rotor and hub assembly from steering knuckle. Separate rotor, knuckle and hub. See FRONT BRAKE ROTOR & HUB under

REMOVAL & INSTALLATION. Press outer bearing from hub using Bearing Splitter (D84L-1123-A) and Shaft Protector (D80L-625-2).

Remove and discard outer grease seal. Pry inner wheel bearing grease seal from steering knuckle using a large screwdriver. Discard seal.

R e mo ve in n e r b e a r in g.

Bearing Preload

1. Use Spacer Selector Set (T87C-1104-B) to check and adjust preload. Install spacer selector into steering knuckle and clamp tool in vise

where shock absorber mounts, before installing hub/rotor assembly into steering knuckle. See Fig. 4

.

Fig. 4: Installing Preload Spacer Selector Set

Courtesy of FORD MOTOR CO.

2. Tighten center bolt from spacer selector set, in increments, to 36, 72, 108 and finally 145 ft. lbs. (49, 98, 147 and 196 N.m). Each time

center bolt is tightened, seat bearings by rotating hub by hand. Using an inch-pound torque wrench, measure torque required to turn

center bolt. Ensure torque reading is taken just as wrench starts to rotate.

3. Preload spacer thickness is correct if torque wrench indicates 2.2-16 INCH lbs. (.25-1.8 N.m). If measurement indicates less than 2.2

INCH lbs. (.25 N.m), a thinner spacer must be installed. If measurement indicates more than 16 INCH lbs. (1.8 N.m), a thicker spacer

must be installed.

4. Bearing spacers are available in various thicknesses. See PRELOAD SPACER AVAILABILITY table. Changing spacer thickness one

number changes bearing preload 1.8-3.5 INCH lbs. (.2-.4 N.m). Ensure correct spacer is installed and preload is within specification.

Remove preload spacer selector set.

PRELOAD SPACER AVAILABILITY

Stamped Mark On SpacerIn. (mm)

10.2474 (6.285)

20.2490 (6.325)

30.2506 (6.365)

40.2522 (6.405)

50.2537 (6.445)

60.2553 (6.485)

70.2569 (6.525)

80.2585 (6.565)

90.2600 (6.605)

100.2616 (6.645)

110.2632 (6.685)

120.2648 (6.725)

130.2663 (6.765)

140.2679 (6.805)

150.2695 (6.845)

160.2711 (6.885)

Page 6 of 12 MITCHELL 1 ARTICLE - BRAKE SYSTEM 1991-92 BRAKES Disc & Drum

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 34 of 454

Installation

1. Lubricate bearings with appropriate wheel bearing grease. Place inner bearing into steering knuckle. Install new inner bearing gr e a se

seal, and drive seal into place using appropriate seal installer.

2. Place original outer wheel bearing preload spacer (or spacer selected during preload inspection process) into steering knuckle bore.

Place outer wheel bearing into steering knuckle bore.

3. Liberally lubricate lip of NEW outer grease seal with appropriate lubricant. Drive seal into steering knuckle bore. Install brake rotor on

hub axle hub. Tighten bolts to 33-40 ft. lbs. (45-54 N.m). Position rotor/hub assembly into steering knuckle, and press assembly into

place using adapter from spacer selector set. To complete installation, reverse removal procedure.

REAR WHEEL BEARINGS

Removal & Installation

1. Raise and support rear axle. Remove wheel. Remove wheel bearing dust cap. On Capri, remove rear brake caliper. See REAR BRAKE

CALIPER & PADS under REMOVAL & INSTALLATION. On all models, carefully unstake rear axle lock nut using a chisel. DO NOT

damage threads on axle spindle. Remove and discard axle nut.

2. On Capri, remove rotor/hub assembly. On Festiva, remove brake drum/hub assembly. On all models, DO NOT allow outer wheel

bearing to fall out of hub. Remove inner bearing grease seal. Remove inner bearing. To install rear bearings, reverse removal procedure.

Adjust rear wheel bearings. See REAR AXLE BEARINGS under ADJUSTMENTS.

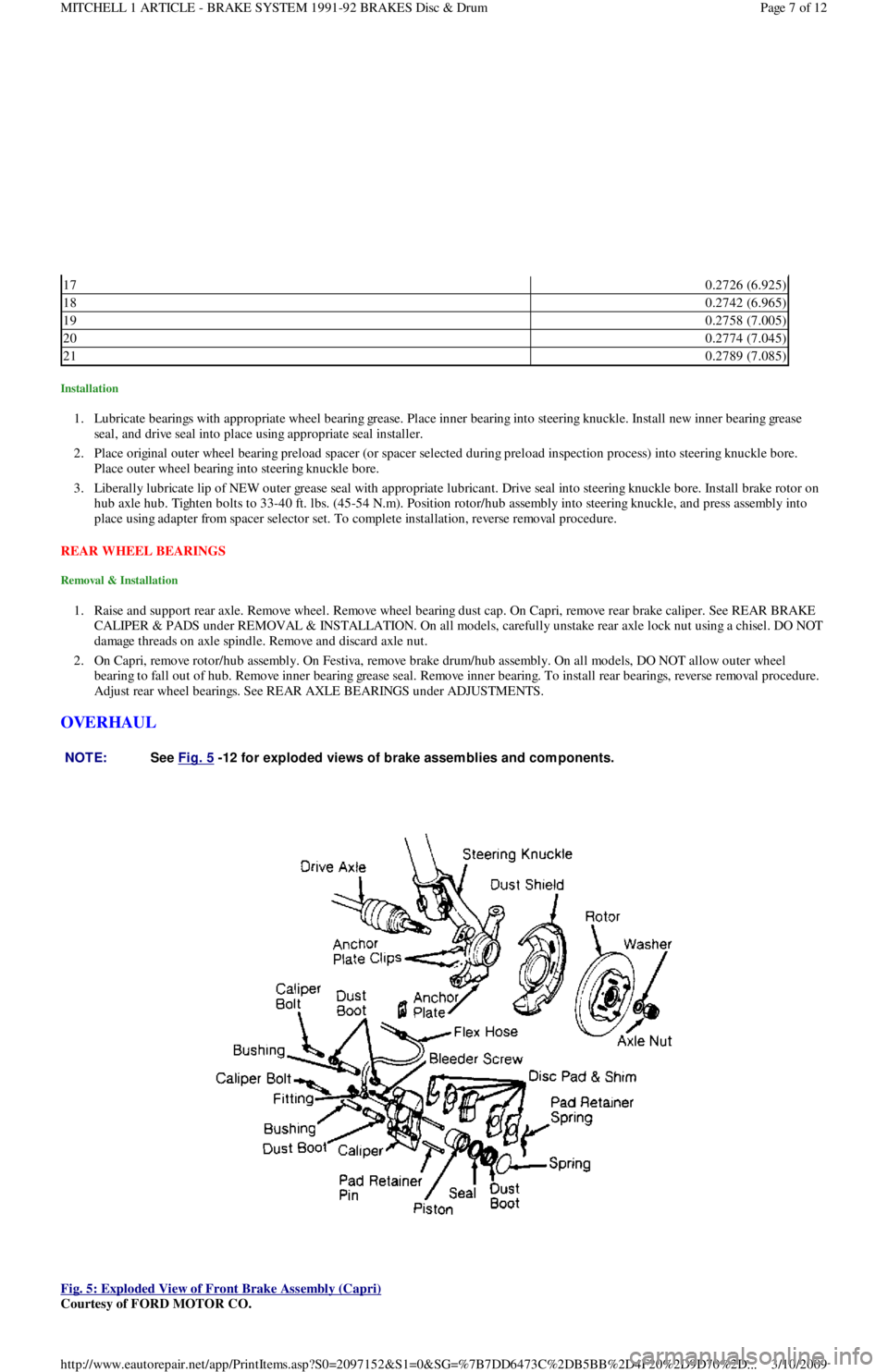

OVERHAUL

Fig. 5: Exploded View of Front Brake Assembly (Capri)

Courtesy of FORD MOTOR CO.

170.2726 (6.925)

180.2742 (6.965)

190.2758 (7.005)

200.2774 (7.045)

210.2789 (7.085)

NOTE:See Fig. 5

-12 for exploded views of brake assem blies and com ponents.

Page 7 of 12 MITCHELL 1 ARTICLE - BRAKE SYSTEM 1991-92 BRAKES Disc & Drum

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 41 of 454

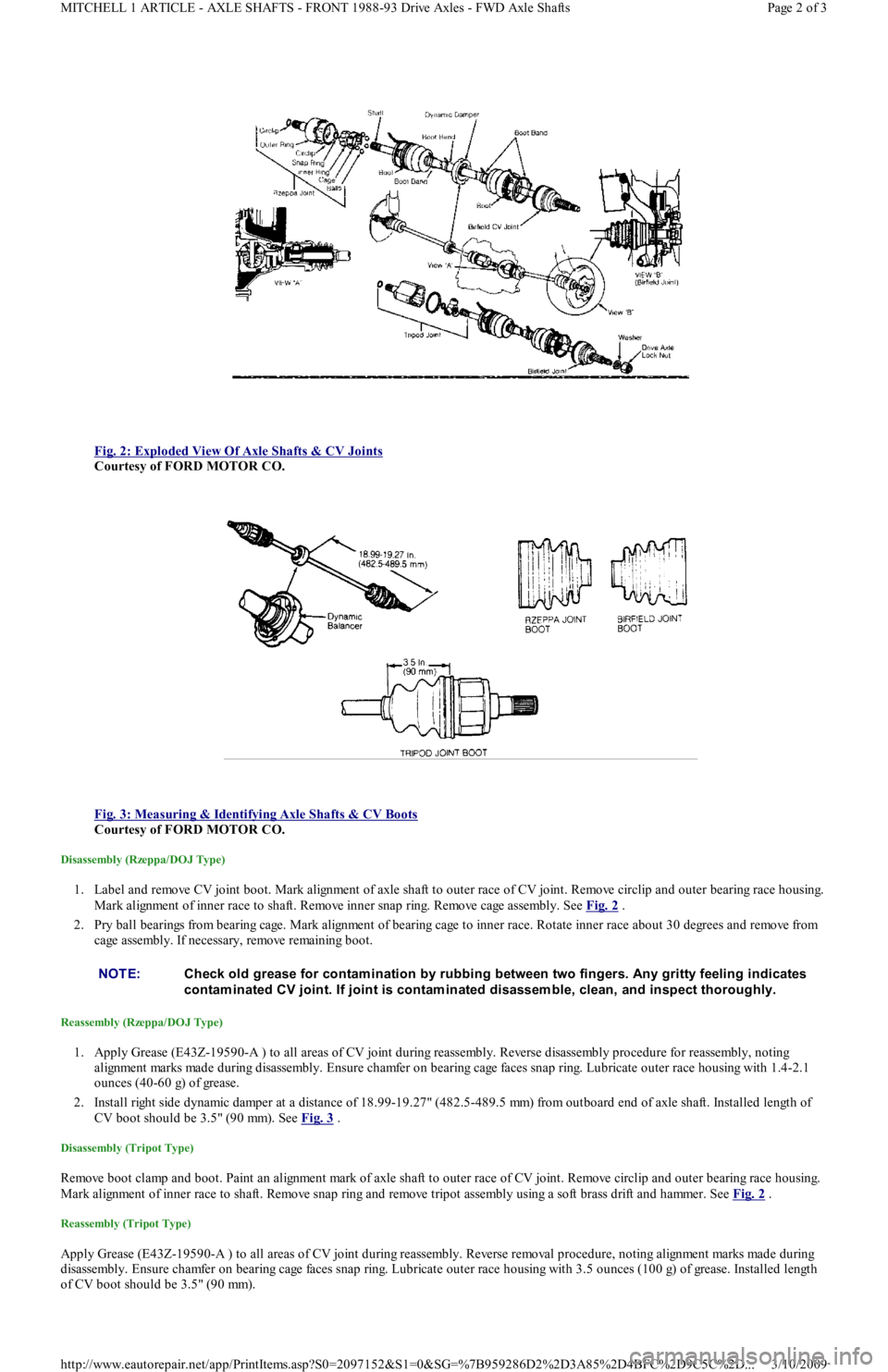

Fig. 2: Exploded View Of Axle Shafts & CV Joints

Courtesy of FORD MOTOR CO.

Fig. 3: Measuring & Identifying Axle Shafts & CV Boots

Courtesy of FORD MOTOR CO.

Disassembly (Rzeppa/DOJ Type)

1. Label and remove CV joint boot. Mark alignment of axle shaft to outer race of CV joint. Remove circlip and outer bearing race housing.

Mark alignment of inner race to shaft. Remove inner snap ring. Remove cage assembly. See Fig. 2

.

2. Pry ball bearings from bearing cage. Mark alignment of bearing cage to inner race. Rotate inner race about 30 degrees and remove from

cage assembly. If necessary, remove remaining boot.

Reassembly (Rzeppa/DOJ Type)

1. Apply Grease (E43Z-19590-A ) to all areas of CV joint during reassembly. Reverse disassembly procedure for reassembly, noting

alignment marks made during disassembly. Ensure chamfer on bearing cage faces snap ring. Lubricate outer race housing with 1.4-2.1

ounces (40-60 g) of grease.

2. Install right side dynamic damper at a distance of 18.99-19.27" (482.5-489.5 mm) from outboard end of axle shaft. Installed length of

CV boot should be 3.5" (90 mm). See Fig. 3

.

Disassembly (Tripot Type)

Remove boot clamp and boot. Paint an alignment mark of axle shaft to outer race of CV joint. Remove circlip and outer bearing race housing.

Mark alignment of inner race to shaft. Remove snap ring and remove tripot assembly using a soft brass drift and hammer. See Fig. 2

.

Reassembly (Tripot Type)

Apply Grease (E43Z-19590-A ) to all areas of CV joint during reassembly. Reverse removal procedure, noting alignment marks made during

disassembly. Ensure chamfer on bearing cage faces snap ring. Lubricate outer race housing with 3.5 ounces (100 g) of grease. Installed length

of CV boot should be 3.5" (90 mm).

NOTE:Check old grease for contam ination by rubbing between two fingers. Any gritty feeling indicates

contam inated CV joint. If joint is contam inated disassem ble, clean, and inspect thoroughly.

Page 2 of 3 MITCHELL 1 ARTICLE - AXLE SHAFTS - FRONT 1988-93 Drive Axles - FWD Axle Shafts

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 45 of 454

TROUBLE SHOOTING

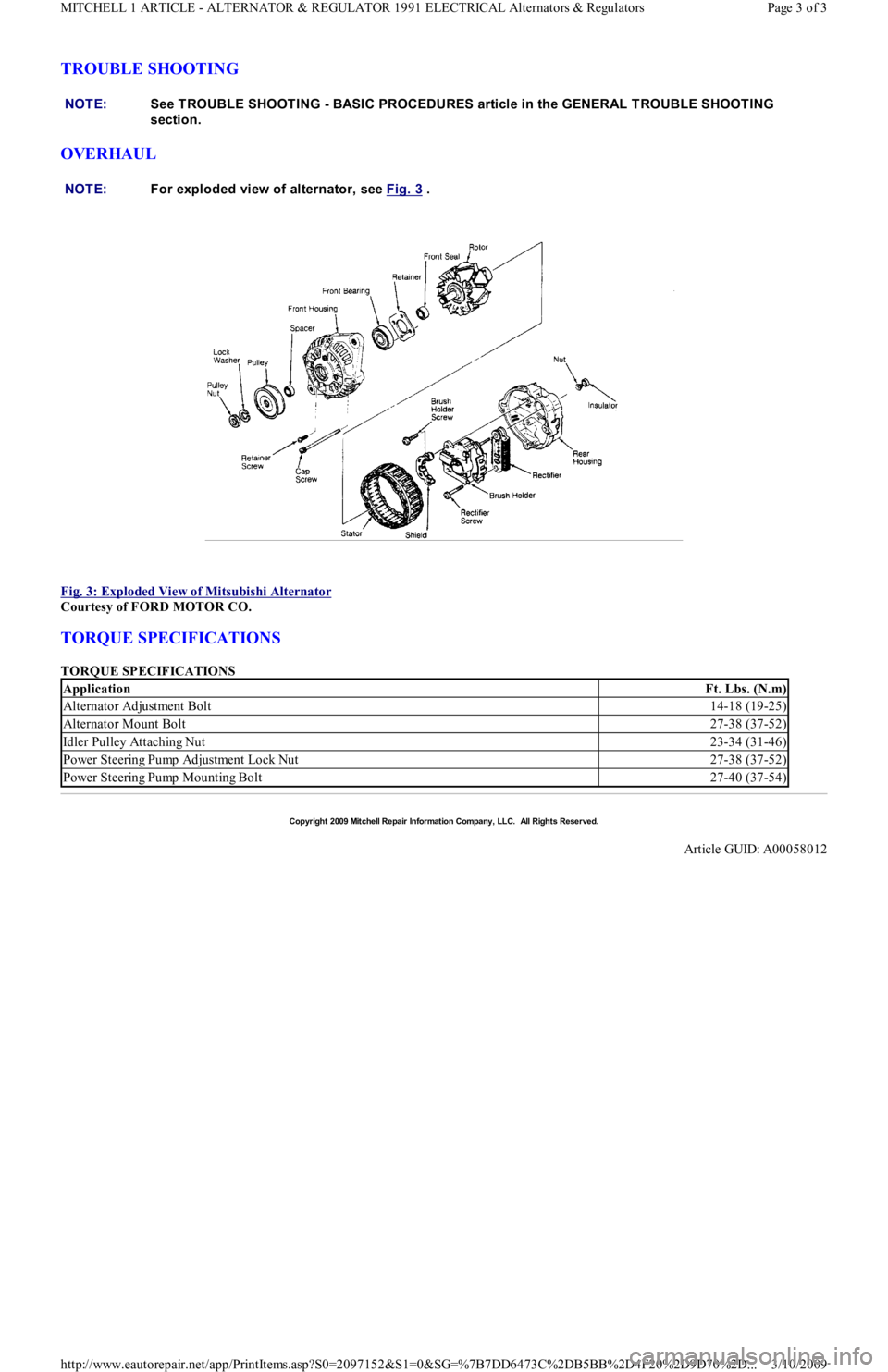

OVERHAUL

Fig. 3: Exploded View of Mitsubishi Alternator

Courtesy of FORD MOTOR CO.

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS NOTE:See T ROUBLE SHOOT ING - BASIC PROCEDURES article in the GENERAL T ROUBLE SHOOT ING

section.

NOTE:For exploded view of alternator, see Fig. 3

.

ApplicationFt. Lbs. (N.m)

Alternator Adjustment Bolt14-18 (19-25)

Alternator Mount Bolt27-38 (37-52)

Idler Pulley Attaching Nut23-34 (31-46)

Power Steering Pump Adjustment Lock Nut27-38 (37-52)

Power Steering Pump Mounting Bolt27-40 (37-54)

Copyr ight 2009 Mitchell Repair Information Company, LLC. All Rights Reserved.

Article GUID: A00058012

Page 3 of 3 MITCHELL 1 ARTICLE - ALTERNATOR & REGULATOR 1991 ELECTRICAL Alternators & Regulators

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 75 of 454

Back To Article

DRIVE BELT ROUTING

1991-92 ENGINE COOLING BELT ROUT ING

BELT ADJUSTMENT

Tensioners may be used to automatically adjust belt tension to specification. Check belt for fraying. If fraying exists, ensure both belt and

tensioner are properly aligned. See Fig. 1

. Tensioners may contain a belt-wear indicator. See Fig. 2 . If tensioner reaches travel limit, as

indicated by marks on tensioner, replace belt. Ensure serpentine belts are properly installed. See Fig. 3

-Fig. 7 . On models without

tensioners, ensure belt tension is within specification. See BELT ADJUSTMENT SPECIFICATIONS table.

BELT TENSION ADJUSTMENT SPECIFICATIONS

(1)

ApplicationNew Belt(2) Used Belt

Continental(3) (3)

Cougar & Thunderbird(3) (3)

Crown Victoria & Grand Marquis

5.0L & 5.8L

1/4" "V" Belt70 (32)50 (23)

6 Rib Belt170 (77)150 (68)

Escort & Tracer

1.8L(4) (5) (4) (5)

1.9L(3) (3)

Mark VII(3) (3)

Mustang(3) (3)

Probe

2.2L & 2.2L Turbo

Alternator(4) (6) (4) (6)

A/C90 (41)90 (41)

Sable & Taurus

2.5L(3) (3)

3.0L (7)

Alternator140-160 (63-67)110-130 (50-59)

P/S & A/C(3) (3)

3.0L SHO

A/C & Alt.220-265(100-120) 148-192 (67-

87)

P/S & W/P154-198 (70-90)112-157 (51-71)

3.8L(3) (3)

Tempo & Topaz

2.3L

Alternator150-170 (68-77)130-150 (59-68)

W/P150-90 (23-41)40-60 (18-27)

Town Car(3) (3)

(1)Tension is measured in Lbs. (kg) using tension gauge.

(2)Used belt is a belt in operation for at least 10 minutes.

(3)Belt tension is automatically adjusted by tensioner.

(4)Manufacturer lists only belt deflection with 22 lbs. applied on belt.

(5)Belt deflection on new belt is .31-.35" (7.9-8.9 mm) or .35-.39" (8.9-9.9 mm) on used belt.

(6)Belt deflection on new belt is .24-.31" (6.1-7.9 mm) or .27-.35" (6.9-8.9 mm) on used belt.

(7)Specification is for models without belt tensioner.

Page 1 of 11 MITCHELL 1 ARTICLE - DRIVE BELT ROUTING 1991-92 ENGINE COOLING BELT ROUTING

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 90 of 454

Back To Article

DRIVE BELT ROUTING

1991-92 ENGINE COOLING BELT ROUT ING

BELT ADJUSTMENT

Tensioners may be used to automatically adjust belt tension to specification. Check belt for fraying. If fraying exists, ensure both belt and

tensioner are properly aligned. See Fig. 1

. Tensioners may contain a belt-wear indicator. See Fig. 2 . If tensioner reaches travel limit, as

indicated by marks on tensioner, replace belt. Ensure serpentine belts are properly installed. See Fig. 3

-Fig. 7 . On models without

tensioners, ensure belt tension is within specification. See BELT ADJUSTMENT SPECIFICATIONS table.

BELT TENSION ADJUSTMENT SPECIFICATIONS

(1)

ApplicationNew Belt(2) Used Belt

Continental(3) (3)

Cougar & Thunderbird(3) (3)

Crown Victoria & Grand Marquis

5.0L & 5.8L

1/4" "V" Belt70 (32)50 (23)

6 Rib Belt170 (77)150 (68)

Escort & Tracer

1.8L(4) (5) (4) (5)

1.9L(3) (3)

Mark VII(3) (3)

Mustang(3) (3)

Probe

2.2L & 2.2L Turbo

Alternator(4) (6) (4) (6)

A/C90 (41)90 (41)

Sable & Taurus

2.5L(3) (3)

3.0L (7)

Alternator140-160 (63-67)110-130 (50-59)

P/S & A/C(3) (3)

3.0L SHO

A/C & Alt.220-265(100-120) 148-192 (67-

87)

P/S & W/P154-198 (70-90)112-157 (51-71)

3.8L(3) (3)

Tempo & Topaz

2.3L

Alternator150-170 (68-77)130-150 (59-68)

W/P150-90 (23-41)40-60 (18-27)

Town Car(3) (3)

(1)Tension is measured in Lbs. (kg) using tension gauge.

(2)Used belt is a belt in operation for at least 10 minutes.

(3)Belt tension is automatically adjusted by tensioner.

(4)Manufacturer lists only belt deflection with 22 lbs. applied on belt.

(5)Belt deflection on new belt is .31-.35" (7.9-8.9 mm) or .35-.39" (8.9-9.9 mm) on used belt.

(6)Belt deflection on new belt is .24-.31" (6.1-7.9 mm) or .27-.35" (6.9-8.9 mm) on used belt.

(7)Specification is for models without belt tensioner.

Page 1 of 11 MITCHELL 1 ARTICLE - DRIVE BELT ROUTING 1991-92 ENGINE COOLING BELT ROUTING

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 108 of 454

front oil seal. Carefully slide camshaft out front of cylinder head. DO NOT d a ma ge b e a r in g b o r e s.

Inspection (1.3L)

1. Check cylinder head for warpage. See INSPECTION under CYLINDER HEAD under REMOVAL & INSTALLATION. Measure

camshaft lobes across their maximum dimensions. Inspect for scoring and wear. Replace camshaft if not within specification. See, in this

article, CAMSHAFT LOBE SPECIFICATIONS

table.

2. Measure camshaft bearing journals and cylinder head bores. See Fig. 6

and Fig. 7 . Subtract camshaft bearing journal O.D. from

cylinder head bore I.D. to obtain oil clearance. If clearance is not within specification, replace head and/or camshaft. See, in this article,

CAMSHAFT SPECIFICATIONS

table under ENGINE SPECIFICATIONS tables.

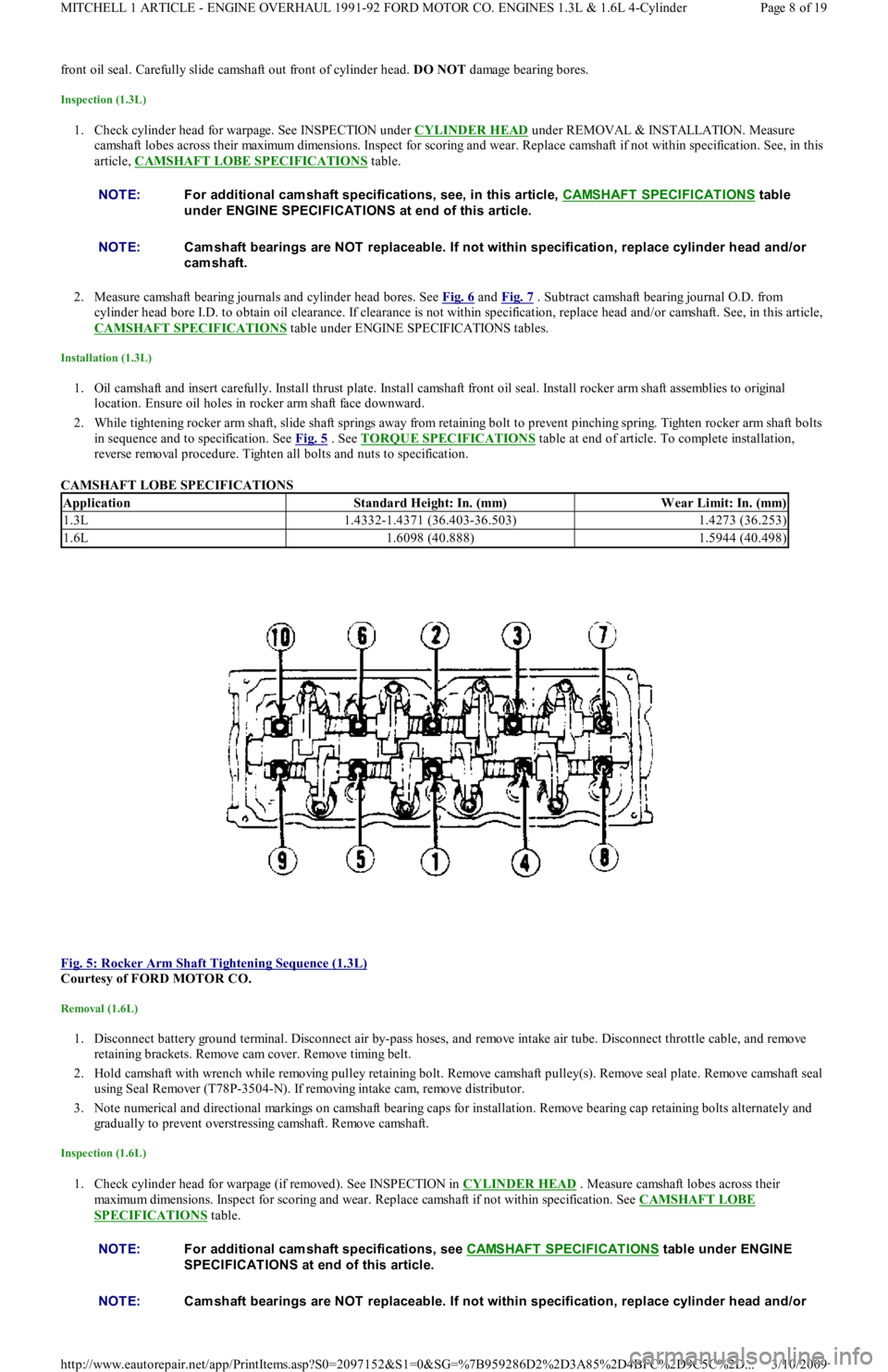

Installation (1.3L)

1. Oil camshaft and insert carefully. Install thrust plate. Install camshaft front oil seal. Install rocker arm shaft assemblies to original

location. Ensure oil holes in rocker arm shaft face downward.

2. While tightening rocker arm shaft, slide shaft springs away from retaining bolt to prevent pinching spring. Tighten rocker arm shaft bolts

in sequence and to specification. See Fig. 5

. See TORQUE SPECIFICATIONS table at end of article. To complete installation,

reverse removal procedure. Tighten all bolts and nuts to specification.

CAMSHAFT LOBE SPECIFICATIONS

Fig. 5: Rocker Arm Shaft Tightening Sequence (1.3L)

Courtesy of FORD MOTOR CO.

Removal (1.6L)

1. Disconnect battery ground terminal. Disconnect air by-pass hoses, and remove intake air tube. Disconnect throttle cable, and remove

ret ain in g b racket s. Remo ve cam co ver. Remo ve t imin g b el t .

2. Hold camshaft with wrench while removing pulley retaining bolt. Remove camshaft pulley(s). Remove seal plate. Remove camshaft seal

using Seal Remover (T78P-3504-N). If removing intake cam, remove distributor.

3. Note numerical and directional markings on camshaft bearing caps for installation. Remove bearing cap retaining bolts alternately and

gradually to prevent overstressing camshaft. Remove camshaft.

Inspection (1.6L)

1. Check cylinder head for warpage (if removed). See INSPECTION in CYLINDER HEAD . Measure camshaft lobes across their

maximum dimensions. Inspect for scoring and wear. Replace camshaft if not within specification. See CAMSHAFT LOBE

SPECIFICATIONS table. NOTE:For additional cam shaft specifications, see, in this article, CAMSHAFT SPECIFICAT IONS

table

under ENGINE SPECIFICATIONS at end of this article.

NOTE:Cam shaft bearings are NOT replaceable. If not within specification, replace cylinder head and/or

cam shaft.

ApplicationStandard Height: In. (mm)W ear Limit: In. (mm)

1.3L1.4332-1.4371 (36.403-36.503)1.4273 (36.253)

1.6L1.6098 (40.888)1.5944 (40.498)

NOTE:For additional cam shaft specifications, see CAMSHAFT SPECIFICAT IONS table under ENGINE

SPECIFICAT IONS at end of this article.

NOTE:Cam shaft bearings are NOT replaceable. If not within specification, replace cylinder head and/or

Page 8 of 19 MITCHELL 1 ARTICLE - ENGINE OVERHAUL 1991-92 FORD MOTOR CO. ENGINES 1.3L & 1.6L 4-Cylinder

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 115 of 454

Installation

1. Install pressure regulator valve, spring, retainer and new cotter pin. Press a new seal in front cover housing. Install outer and inner gears

in housing. Install pump cover. Coat bolts with Loctite and tighten to specification. See TORQUE SPECIFICATIONS

table at end of

article.

2. Install new gasket and install front cover housing. Install new gasket and install pick-up tube and screen. Tighten all bolts/nuts to

specification. To complete installation, reverse removal procedure.

ENGINE COOLING

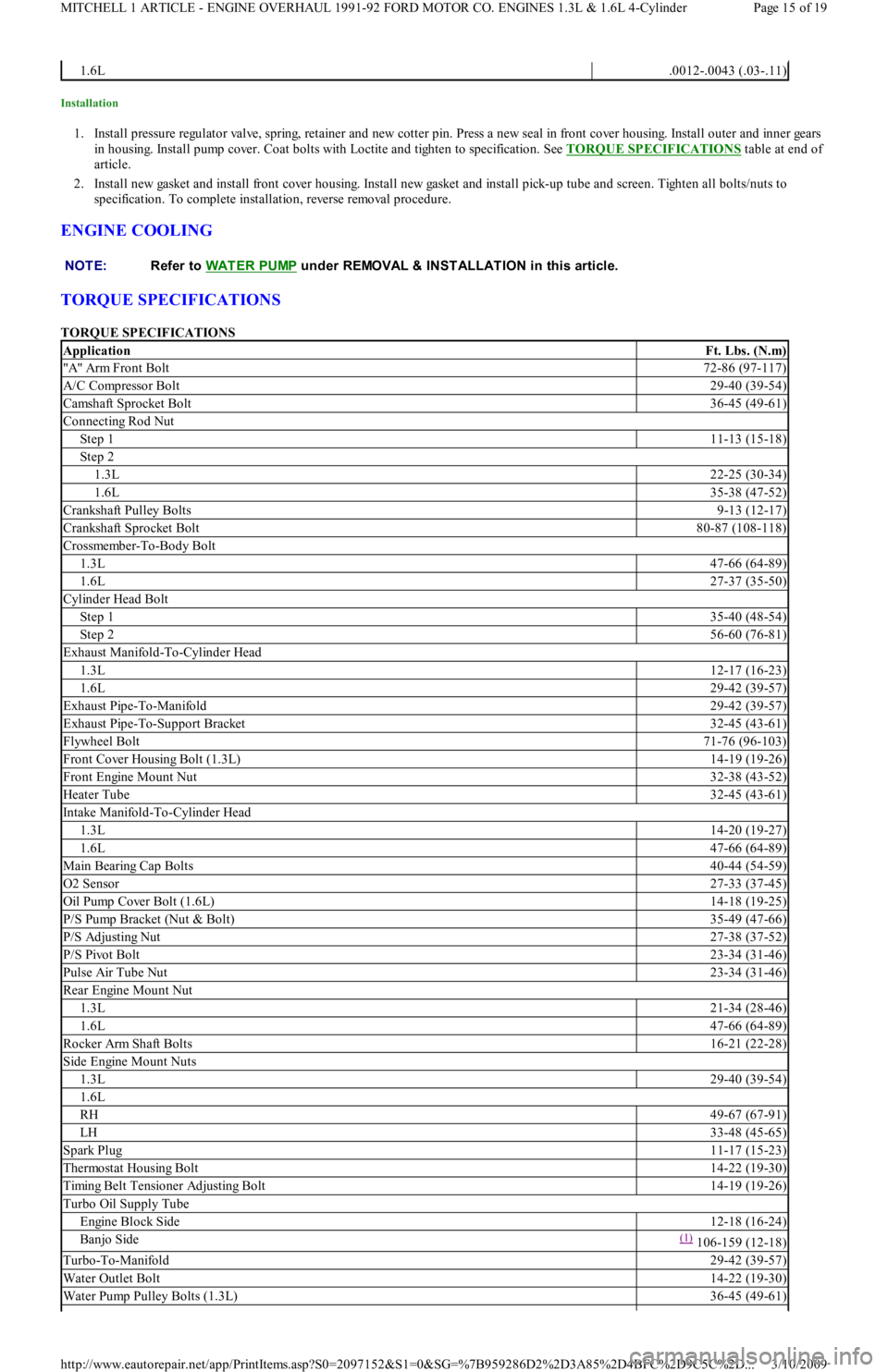

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS

1.6L.0012-.0043 (.03-.11)

NOTE:Refer to WAT ER PUMP

under REMOVAL & INSTALLATION in this article.

ApplicationFt. Lbs. (N.m)

"A" Arm Front Bolt72-86 (97-117)

A/C Compressor Bolt29-40 (39-54)

Camshaft Sprocket Bolt36-45 (49-61)

Connecting Rod Nut

Step 111-13 (15-18)

Step 2

1.3L22-25 (30-34)

1.6L35-38 (47-52)

Crankshaft Pulley Bolts9-13 (12-17)

Crankshaft Sprocket Bolt80-87 (108-118)

Crossmember-To-Body Bolt

1.3L47-66 (64-89)

1.6L27-37 (35-50)

Cylinder Head Bolt

Step 135-40 (48-54)

Step 256-60 (76-81)

Exhaust Manifold-To-Cylinder Head

1.3L12-17 (16-23)

1.6L29-42 (39-57)

Exhaust Pipe-To-Manifold29-42 (39-57)

Exhaust Pipe-To-Support Bracket32-45 (43-61)

Flywheel Bolt71-76 (96-103)

Front Cover Housing Bolt (1.3L)14-19 (19-26)

Front Engine Mount Nut32-38 (43-52)

Heater Tube32-45 (43-61)

Intake Manifold-To-Cylinder Head

1.3L14-20 (19-27)

1.6L47-66 (64-89)

Main Bearing Cap Bolts40-44 (54-59)

O2 Sensor27-33 (37-45)

Oil Pump Cover Bolt (1.6L)14-18 (19-25)

P/S Pump Bracket (Nut & Bolt)35-49 (47-66)

P/S Adjusting Nut27-38 (37-52)

P/S Pivot Bolt23-34 (31-46)

Pulse Air Tube Nut23-34 (31-46)

Rear Engine Mount Nut

1.3L21-34 (28-46)

1.6L47-66 (64-89)

Rocker Arm Shaft Bolts16-21 (22-28)

Side Engine Mount Nuts

1.3L29-40 (39-54)

1.6L

RH49-67 (67-91)

LH33-48 (45-65)

Spark Plug11-17 (15-23)

Thermostat Housing Bolt14-22 (19-30)

Timing Belt Tensioner Adjusting Bolt14-19 (19-26)

Turbo Oil Supply Tube

Engine Block Side12-18 (16-24)

Banjo Side(1) 106-159 (12-18)

Turbo-To-Manifold29-42 (39-57)

Water Outlet Bolt14-22 (19-30)

Water Pump Pulley Bolts (1.3L)36-45 (49-61)

Page 15 of 19 MITCHELL 1 ARTICLE - ENGINE OVERHAUL 1991-92 FORD MOTOR CO. ENGINES 1.3L & 1.6L 4-Cylinder

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...