%27 FORD FESTIVA 1991 Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1991, Model line: FESTIVA, Model: FORD FESTIVA 1991Pages: 454, PDF Size: 9.53 MB

Page 423 of 454

Fig. 14: Exploded View Of Drum Hub Assembly

Courtesy of FORD MOTOR CO.

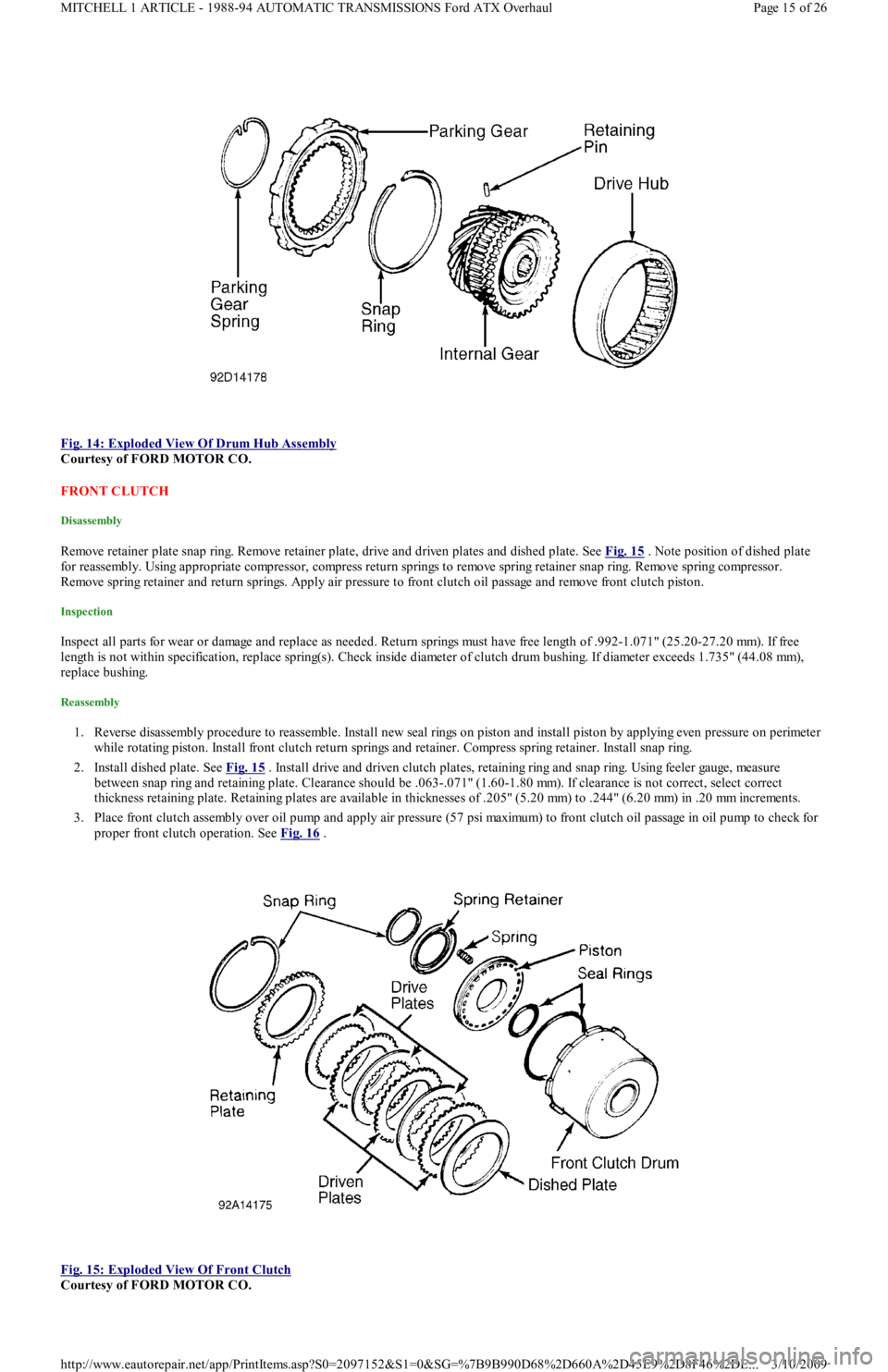

FRONT CLUTCH

Disassembly

Remove retainer plate snap ring. Remove retainer plate, drive and driven plates and dished plate. See Fig. 15 . Note position of dished plate

for reassembly. Using appropriate compressor, compress return springs to remove spring retainer snap ring. Remove spring compressor.

Remove spring retainer and return springs. Apply air pressure to front clutch oil passage and remove front clutch piston.

Inspection

Inspect all parts for wear or damage and replace as needed. Return springs must have free length of .992-1.071" (25.20-27.20 mm). If free

length is not within specification, replace spring(s). Check inside diameter of clutch drum bushing. If diameter exceeds 1.735" (44.08 mm),

replace bushing.

Reassembly

1. Reverse disassembly procedure to reassemble. Install new seal rings on piston and install piston by applying even pressure on perimeter

while rotating piston. Install front clutch return springs and retainer. Compress spring retainer. Install snap ring.

2. Install dished plate. See Fig. 15

. Install drive and driven clutch plates, retaining ring and snap ring. Using feeler gauge, measure

between snap ring and retaining plate. Clearance should be .063-.071" (1.60-1.80 mm). If clearance is not correct, select correct

thickness retaining plate. Retaining plates are available in thicknesses of .205" (5.20 mm) to .244" (6.20 mm) in .20 mm increments.

3. Place front clutch assembly over oil pump and apply air pressure (57 psi maximum) to front clutch oil passage in oil pump to check for

proper front clutch operation. See Fig. 16

.

Fig. 15: Exploded View Of Front Clutch

Courtesy of FORD MOTOR CO.

Page 15 of 26 MITCHELL 1 ARTICLE - 1988-94 AUTOMATIC TRANSMISSIONS Ford ATX Overhaul

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 425 of 454

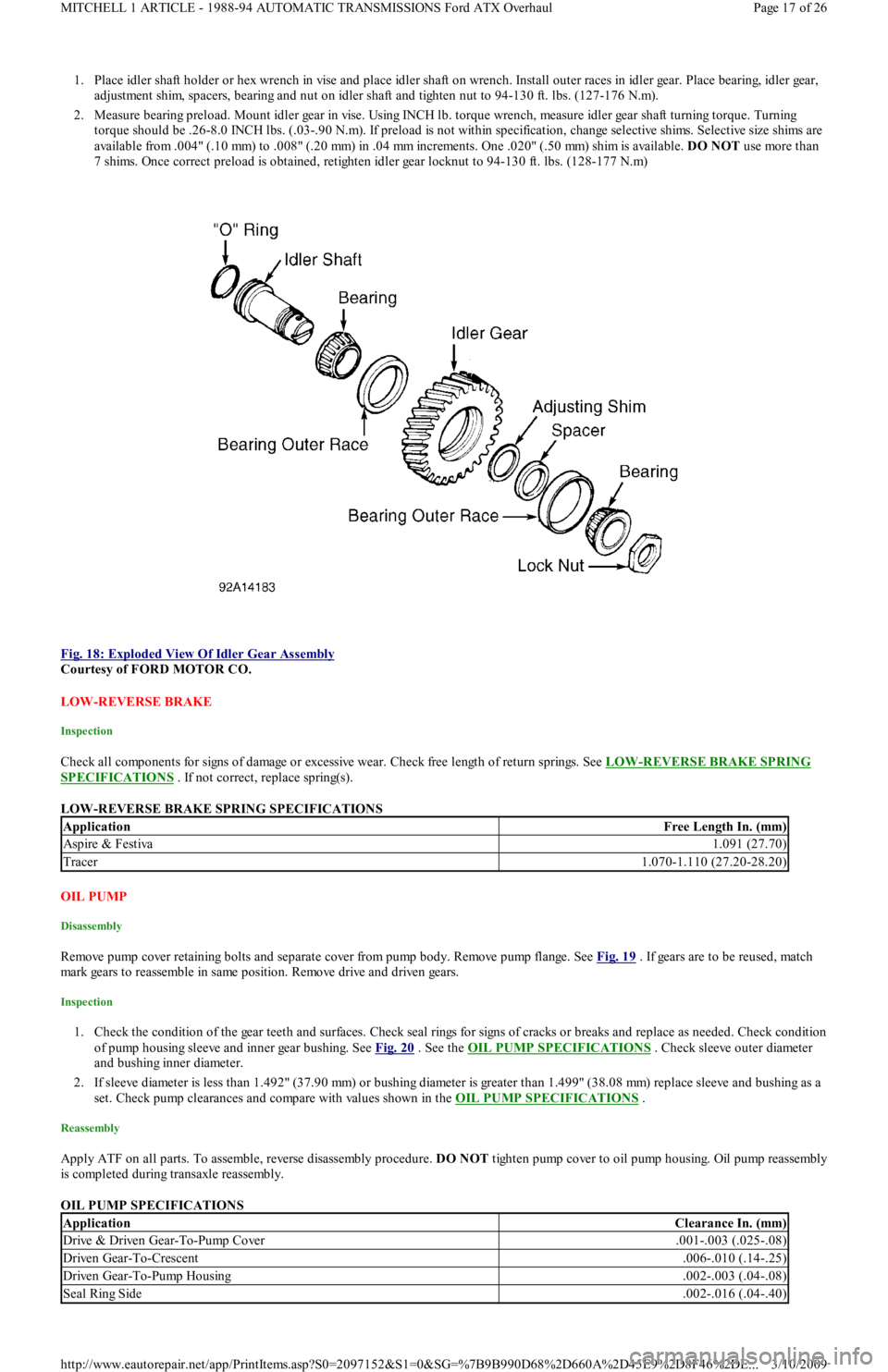

1. Place idler shaft holder or hex wrench in vise and place idler shaft on wrench. Install outer races in idler gear. Place bearing, idler gear,

adjustment shim, spacers, bearing and nut on idler shaft and tighten nut to 94-130 ft. lbs. (127-176 N.m).

2. Measure bearing preload. Mount idler gear in vise. Using INCH lb. torque wrench, measure idler gear shaft turning torque. Turning

torque should be .26-8.0 INCH lbs. (.03-.90 N.m). If preload is not within specification, change selective shims. Selective size shims are

available from .004" (.10 mm) to .008" (.20 mm) in .04 mm increments. One .020" (.50 mm) shim is available. DO NOT use more than

7 shims. Once correct preload is obtained, retighten idler gear locknut to 94-130 ft. lbs. (128-177 N.m)

Fig. 18: Exploded View Of Idler Gear Assembly

Courtesy of FORD MOTOR CO.

LOW-REVERSE BRAKE

Inspection

Check all components for signs of damage or excessive wear. Check free length of return springs. See LOW-REVERSE BRAKE SPRING

SPECIFICATIONS . If not correct, replace spring(s).

LOW-REVERSE BRAKE SPRING SPECIFICATIONS

OIL PUMP

Disassembly

Remove pump cover retaining bolts and separate cover from pump body. Remove pump flange. See Fig. 19 . If gears are to be reused, match

mark gears to reassemble in same position. Remove drive and driven gears.

Inspection

1. Check the condition of the gear teeth and surfaces. Check seal rings for signs of cracks or breaks and replace as needed. Check condition

of pump housing sleeve and inner gear bushing. See Fig. 20

. See the OIL PUMP SPECIFICATIONS . Check sleeve outer diameter

and bushing inner diameter.

2. If sleeve diameter is less than 1.492" (37.90 mm) or bushing diameter is greater than 1.499" (38.08 mm) replace sleeve and bushing as a

set. Check pump clearances and compare with values shown in the OIL PUMP SPECIFICATIONS

.

Reassembly

Apply ATF on all parts. To assemble, reverse disassembly procedure. DO NOTtighten pump cover to oil pump housing. Oil pump reassembly

is completed during transaxle reassembly.

OIL PUMP SPECIFICATIONS

ApplicationFree Length In. (mm)

Aspire & Festiva1.091 (27.70)

Tracer1.070-1.110 (27.20-28.20)

ApplicationClearance In. (mm)

Drive & Driven Gear-To-Pump Cover.001-.003 (.025-.08)

Driven Gear-To-Crescent.006-.010 (.14-.25)

Driven Gear-To-Pump Housing.002-.003 (.04-.08)

Seal Ring Side.002-.016 (.04-.40)

Page 17 of 26 MITCHELL 1 ARTICLE - 1988-94 AUTOMATIC TRANSMISSIONS Ford ATX Overhaul

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 427 of 454

1. Record direction of rotation one-way clutch locks and turns. Remove snap ring and pull out planetary carrier from one-way clutch inner

race. See Fig. 8

. Check for worn or damaged parts. Bushing wear on one-way clutch must not exceed 5.120" (130.06 mm).

2. Check clearance between pinion gears and washers in planetary carrier. If clearance exceeds .031" (.80 mm), replace planetary carrier.

Reverse disassembly procedure to reassemble. Install one-way clutch in inner race and ensure that it will turn in one direction

(clockwise) only.

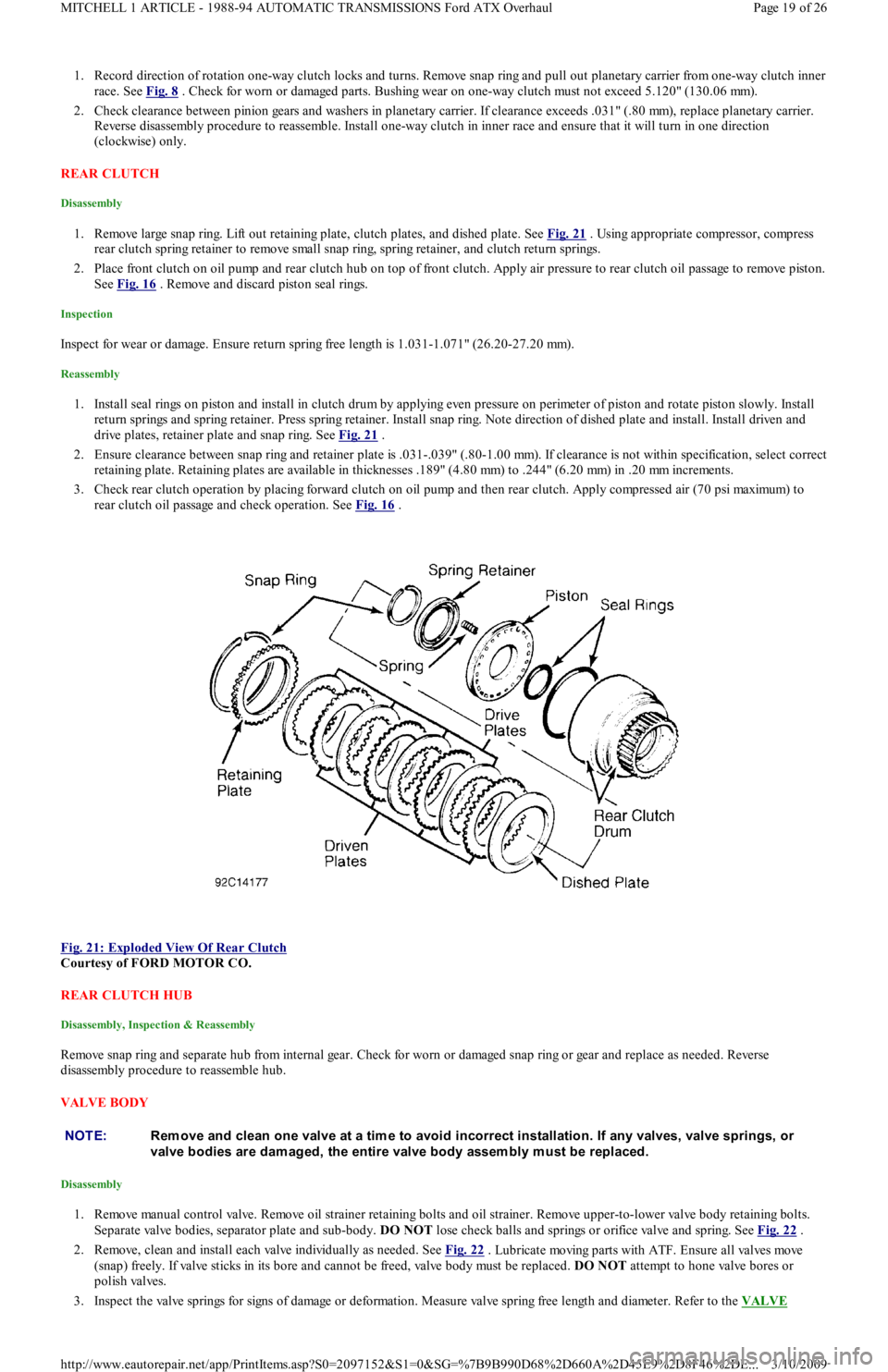

REAR CLUTCH

Disassembly

1. Remove large snap ring. Lift out retaining plate, clutch plates, and dished plate. See Fig. 21 . Using appropriate compressor, compress

rear clutch spring retainer to remove small snap ring, spring retainer, and clutch return springs.

2. Place front clutch on oil pump and rear clutch hub on top of front clutch. Apply air pressure to rear clutch oil passage to remove piston.

See Fig. 16

. Remove and discard piston seal rings.

Inspection

Inspect for wear or damage. Ensure return spring free length is 1.031-1.071" (26.20-27.20 mm).

Reassembly

1. Install seal rings on piston and install in clutch drum by applying even pressure on perimeter of piston and rotate piston slowly. Install

return springs and spring retainer. Press spring retainer. Install snap ring. Note direction of dished plate and install. Install driven and

drive plates, retainer plate and snap ring. See Fig. 21

.

2. Ensure clearance between snap ring and retainer plate is .031-.039" (.80-1.00 mm). If clearance is not within specification, select correct

retaining plate. Retaining plates are available in thicknesses .189" (4.80 mm) to .244" (6.20 mm) in .20 mm increments.

3. Check rear clutch operation by placing forward clutch on oil pump and then rear clutch. Apply compressed air (70 psi maximum) to

rear clutch oil passage and check operation. See Fig. 16

.

Fig. 21: Exploded View Of Rear Clutch

Courtesy of FORD MOTOR CO.

REAR CLUTCH HUB

Disassembly, Inspection & Reassembly

Remove snap ring and separate hub from internal gear. Check for worn or damaged snap ring or gear and replace as needed. Reverse

disassembly procedure to reassemble hub.

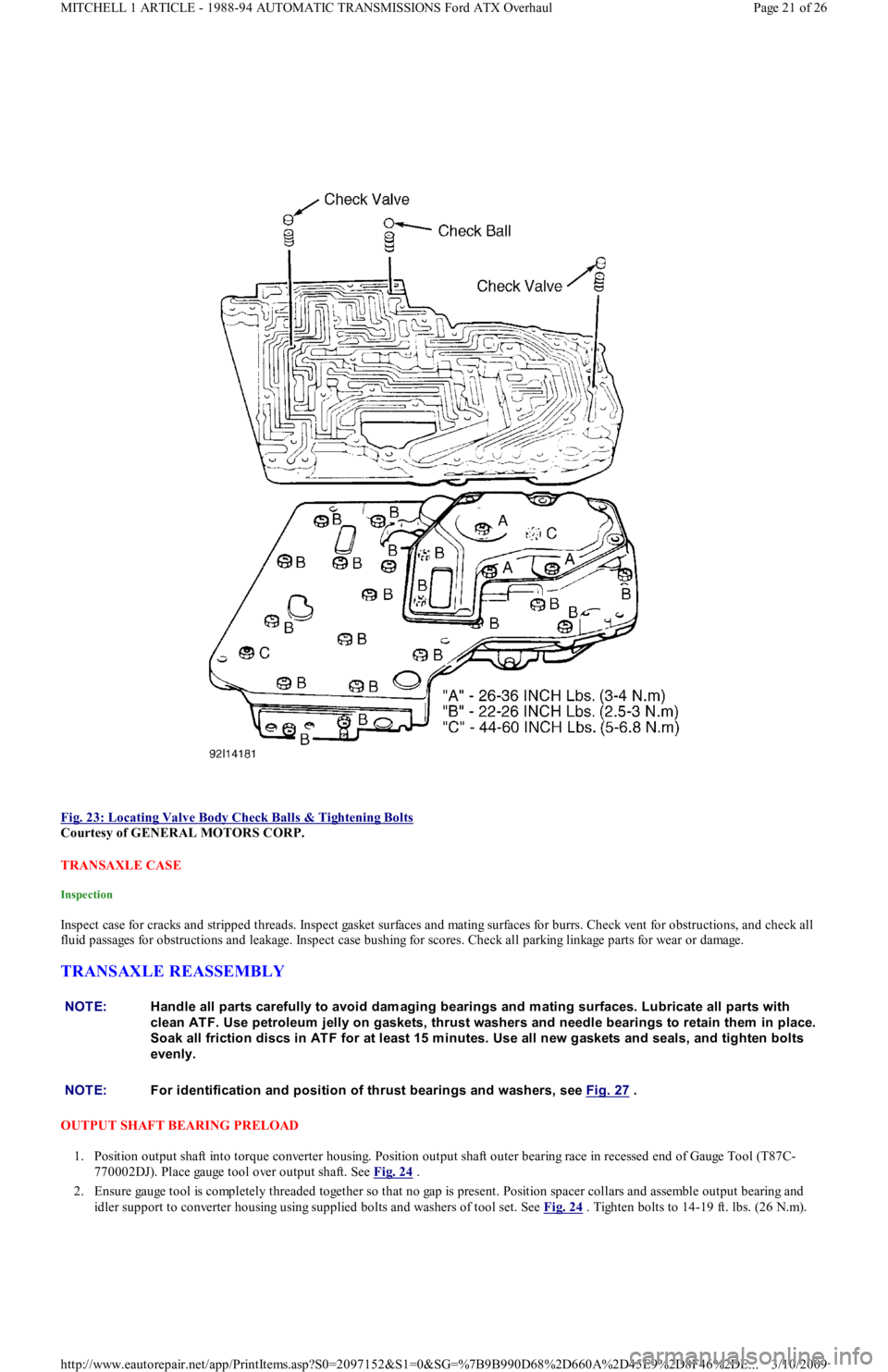

VALVE BODY

Disassembly

1. Remove manual control valve. Remove oil strainer retaining bolts and oil strainer. Remove upper-to-lower valve body retaining bolts.

Separate valve bodies, separator plate and sub-body. DO NOT lose check balls and springs or orifice valve and spring. See Fig. 22

.

2. Remove, clean and install each valve individually as needed. See Fig. 22

. Lubricate moving parts with ATF. Ensure all valves move

(snap) freely. If valve sticks in its bore and cannot be freed, valve body must be replaced. DO NOT attempt to hone valve bores or

polish valves.

3. Inspect the valve springs for signs of damage or deformation. Measure valve spring free length and diameter. Refer to the VALVE

NOTE:Rem ove and clean one valve at a tim e to avoid incorrect installation. If any valves, valve springs, or

valve bodies are dam aged, the entire valve body assem bly m ust be replaced.

Page 19 of 26 MITCHELL 1 ARTICLE - 1988-94 AUTOMATIC TRANSMISSIONS Ford ATX Overhaul

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 429 of 454

Fig. 23: Locating Valve Body Check Balls & Tightening Bolts

Courtesy of GENERAL MOTORS CORP.

TRANSAXLE CASE

Inspection

Inspect case for cracks and stripped threads. Inspect gasket surfaces and mating surfaces for burrs. Check vent for obstructions, and check all

fluid passages for obstructions and leakage. Inspect case bushing for scores. Check all parking linkage parts for wear or damage.

TRANSAXLE REASSEMBLY

OUTPUT SHAFT BEARING PRELOAD

1. Position output shaft into torque converter housing. Position output shaft outer bearing race in recessed end of Gauge Tool (T87C-

770002DJ). Place gauge tool over output shaft. See Fig. 24

.

2. Ensure gauge tool is completely threaded together so that no gap is present. Position spacer collars and assemble output bearing and

idler support to converter housing using supplied bolts and washers of tool set. See Fig. 24

. Tighten bolts to 14-19 ft. lbs. (26 N.m).

NOTE:Handle all parts carefully to avoid dam aging bearings and m ating surfaces. Lubricate all parts with

clean AT F. Use petroleum jelly on gaskets, thrust washers and needle bearings to retain them in place.

Soak all friction discs in AT F for at least 15 m inutes. Use all new gaskets and seals, and tighten bolts

evenly.

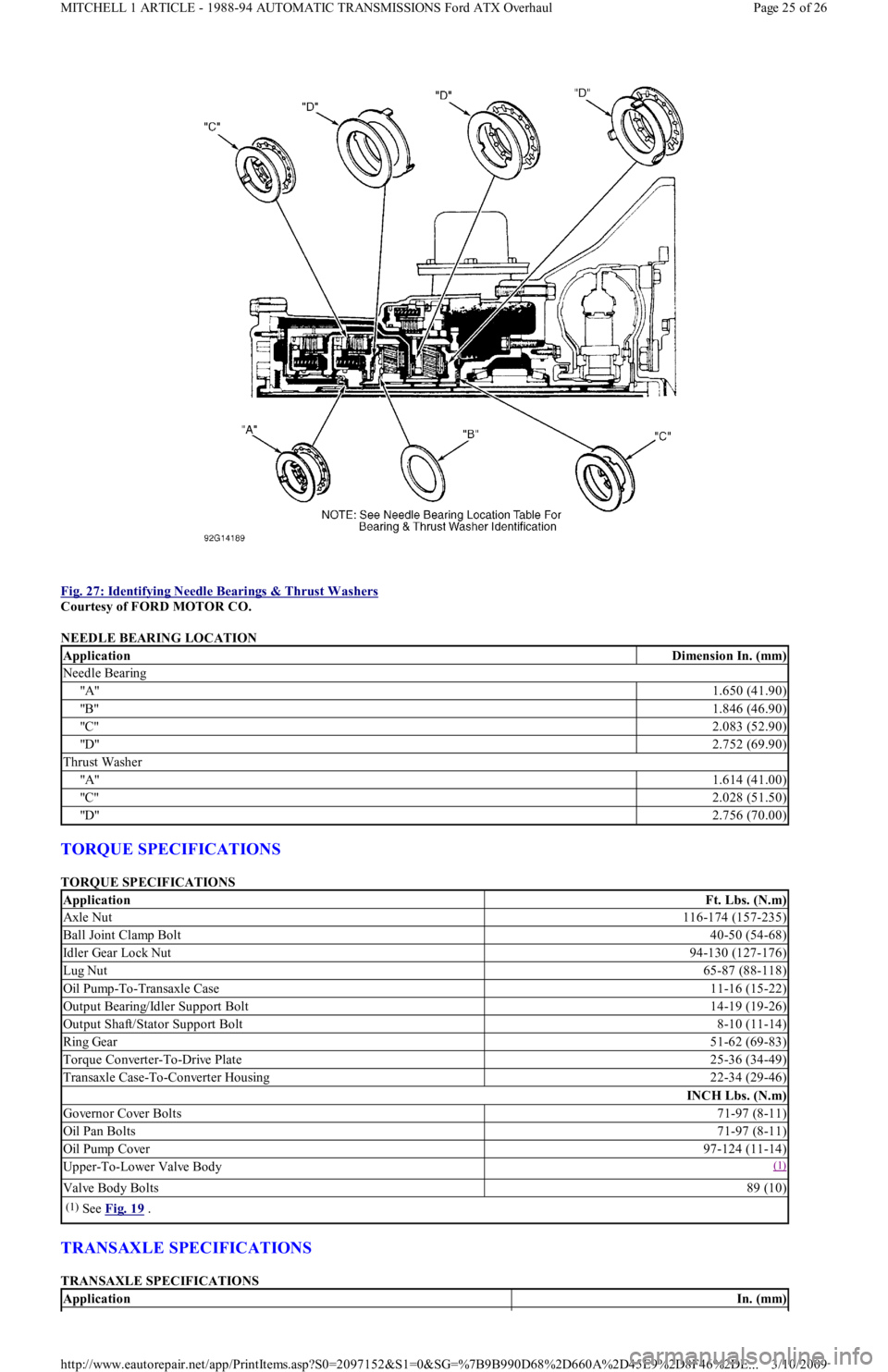

NOTE:For identification and position of thrust bearings and washers, see Fig. 27

.

Page 21 of 26 MITCHELL 1 ARTICLE - 1988-94 AUTOMATIC TRANSMISSIONS Ford ATX Overhaul

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 433 of 454

Fig. 27: Identifying Needle Bearings & Thrust Washers

Courtesy of FORD MOTOR CO.

NEEDLE BEARING LOCATION

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS

TRANSAXLE SPECIFICATIONS

TRANSAXLE SPECIFICATIONS

ApplicationDimension In. (mm)

Needle Bearing

"A"1.650 (41.90)

"B"1.846 (46.90)

"C"2.083 (52.90)

"D"2.752 (69.90)

Thrust Washer

"A"1.614 (41.00)

"C"2.028 (51.50)

"D"2.756 (70.00)

ApplicationFt. Lbs. (N.m)

Axle Nut116-174 (157-235)

Ball Joint Clamp Bolt40-50 (54-68)

Idler Gear Lock Nut94-130 (127-176)

Lug Nut65-87 (88-118)

Oil Pump-To-Transaxle Case11-16 (15-22)

Output Bearing/Idler Support Bolt14-19 (19-26)

Output Shaft/Stator Support Bolt8-10 (11-14)

Ring Gear51-62 (69-83)

Torque Converter-To-Drive Plate25-36 (34-49)

Transaxle Case-To-Converter Housing22-34 (29-46)

INCH Lbs. (N.m)

Go ve r n o r C o ve r B o l t s71-97 (8-11)

Oil Pan Bolts71-97 (8-11)

Oil Pump Cover97-124 (11-14)

Upper-To-Lower Valve Body(1)

Valve Body Bolts89 (10)

(1)See Fig. 19 .

ApplicationIn. (mm)

Page 25 of 26 MITCHELL 1 ARTICLE - 1988-94 AUTOMATIC TRANSMISSIONS Ford ATX Overhaul

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 435 of 454

Back To Article

T RANSMISSION REMOVAL & INST ALLAT ION - A/T

1988-93 T RANSMISSION SERVICING Ford Motor Co. T ransm ission Rem oval & Installation

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS

ApplicationsFt. Lbs. (N.m)

Crossmember Attaching Bolt47-66 (64-89)

Engine-To-Transaxle Bolt41-59 (55-80)

Front Engine Mount-To-Crossmember Nut32-38 (43-52)

Front Wheel Lug Nuts65-87 (88-118)

Gusset Plate-To-Transaxle Bolt27-38 (37-52)

Left Stabilizer Body Bracket Nut/Bolt40-45 (54-61)

Lower Control Arm Clamp Nut/Bolt32-40 (43-54)

Manual Shift Lever Shaft Assembly Nut32-47 (44-64)

Rear Engine Mount-To-Crossmember Nut21-34 (28-46)

Stabilizer Bracket Mounting Nut40-45 (54-61)

Tie Rod End-To-Knuckle Nut26-30 (35-40)

Torque Converter Bolt25-36 (34-49)

INCH Lbs. (N.m)

Flywheel Cover Bolt62-89 (7-10)

Line Pressure Plug44-89 (5-10)

Shift Cable Retainer Bolts71-97 (8-11)

Copyr ight 2009 Mitchell Repair Information Company, LLC. All Rights Reserved.

Article GUID: A00124559

Page 1 of 1 MITCHELL 1 ARTICLE - TRANSMISSION REMOVAL & INSTALLATION - A/T 1988-93 TRANSMISSION SERVICING F

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 443 of 454

Inspection

Check release bearing rotation operation for roughness, sticking and noise. Check release lever and transaxle front bearing retainer for wear or

damage. Ensure bearing slides smoothly on transaxle input shaft. Check release lever shaft for bent, worn or damaged condition. Check all

mating surfaces for wear or damage. Replace worn or defective components.

Installation

Apply light film of grease to transmission front bearing retainer lever-to-bearing surfaces and release lever contact surface. Align bolt hole in

release lever and shaft. Apply Stud/Bearing Sealant (E0AZ-19554-B ) to release lever bolt. Fill grease groove in release bearing hub and

remove any excess grease. Install release lever return spring. To complete installation, reverse removal procedure.

PILOT BEARING

Removal & Installation

Remove transaxle, pressure plate, clutch disc and flywheel. Drive pilot bearing out of flywheel using a driver that makes full contact with

bearing outer race. Reverse procedure for installation.

CLUTCH CABLE

Removal & Installation

1. Disconnect clutch cable from release lever. Remove nuts retaining clutch cable at firewall. Unhook clutch cable at clutch pedal.

2. Remove clutch cable from engine compartment side. To install, apply lithium grease to pedal cable hook and joint between release lever

and pin. Reverse removal procedure to complete installation. See Fig. 2

.

OVERHAUL

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS

TRANSAXLE FLUID LEVELS

TRANSAXLE FLUID LEVELS NOTE:DO NOT rem ove pilot bearing unless necessary.

NOTE:Manufacturer does not provide overhaul inform ation for clutch m aster cylinder and clutch release

cylinder.

ApplicationFt. Lbs. (Nm)

Clutch Cable Bracket Nuts12-17 (16-23)

Clutch Pedal Push Rod Lock Nut9-13 (12-17)

Clutch Pedal Through Bolt Nut15-26 (20-35)

Crossmember

"A" Bo l t s47-66 (64-89)

"B" Bo l t21-34 (28-46)

Crossmember Brace (Front)23-34 (31-46)

Crossmember Brace69-86 (93-117)

Engine Mount Bolt (No. 2)33-48 (45-65)

Engine-To-Transaxle46-66 (63-89)

Flywheel Housing-To-Engine Bolt46-66 (63-89)

Flywheel-To-Crankshaft Bolt71-76 (96-103)

Front Wheel Lug Nut66-89 (90-120)

Lower Ball Joint Pinch Bolt32-40 (43-54)

Master Cylinder Retaining Nuts14-19 (19-26)

Pressure Plate-To-Flywheel Bolt13-20 (18-27)

Rear Engine Cover-To-Housing Bolt28-38 (38-51)

Rear Mount-To-Transmission Bolt50-70 (68-95)

Rear Transmission Mount-To-Body Bolt25-35 (34-48)

Release Fork Attaching Bolt26-30 (35-41)

Slave Cylinder Retaining Bolts12-17 (16-23)

Stabilizer Bracket-To-Body Bolt33-41 (45-56)

Starter Motor-To-Mount Bolt23-34 (31-46)

Transaxle Drain Plug29-40 (39-54)

INCH Lbs. (N.m)

Release Lever Bolt71-97 (8-11)

Speedometer Drive Gear Bolt69-106 (7.8-12)

ApplicationSpecification

Festiva2.6 Qts. (2.5L)

Copyr ight 2009 Mitchell Repair Information Company, LLC. All Rights Reserved.

Page 4 of 5 MITCHELL 1 ARTICLE - CLUTCH 1988-93 Clutch

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...