%27 FORD FESTIVA 1991 Owner's Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 1991, Model line: FESTIVA, Model: FORD FESTIVA 1991Pages: 454, PDF Size: 9.53 MB

Page 324 of 454

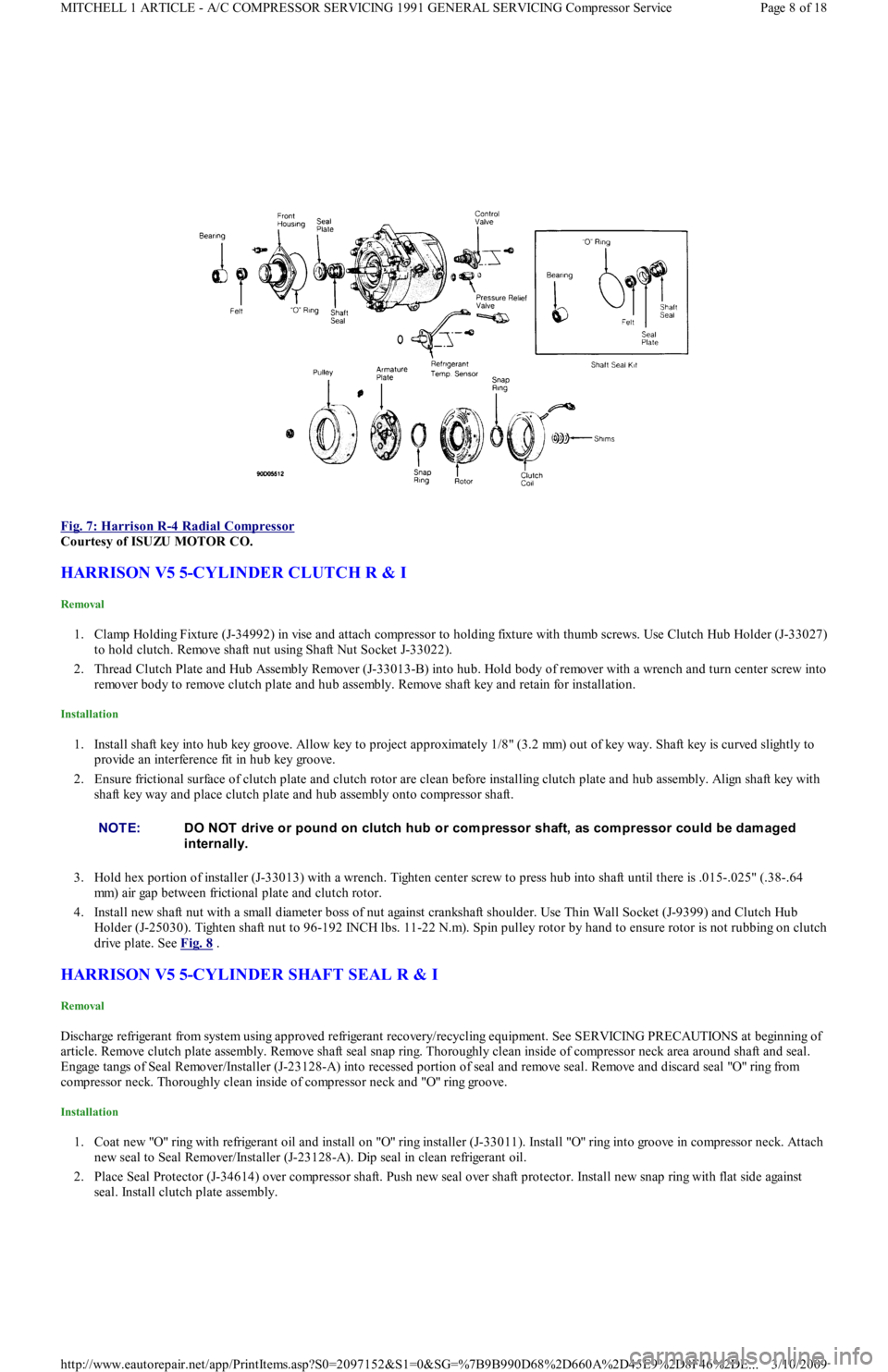

Fig. 7: Harrison R

-4 Radial Compressor

Courtesy of ISUZU MOTOR CO.

HARRISON V5 5-CYLINDER CLUTCH R & I

Removal

1. Clamp Holding Fixture (J-34992) in vise and attach compressor to holding fixture with thumb screws. Use Clutch Hub Holder (J-33027)

to hold clutch. Remove shaft nut using Shaft Nut Socket J-33022).

2. Thread Clutch Plate and Hub Assembly Remover (J-33013-B) into hub. Hold body of remover with a wrench and turn center screw into

remover body to remove clutch plate and hub assembly. Remove shaft key and retain for installation.

Installation

1. Install shaft key into hub key groove. Allow key to project approximately 1/8" (3.2 mm) out of key way. Shaft key is curved slightly to

provide an interference fit in hub key groove.

2. Ensure frictional surface of clutch plate and clutch rotor are clean before installing clutch plate and hub assembly. Align shaft key with

shaft key way and place clutch plate and hub assembly onto compressor shaft.

3. Hold hex portion of installer (J-33013) with a wrench. Tighten center screw to press hub into shaft until there is .015-.025" (.38-.64

mm) air gap between frictional plate and clutch rotor.

4. Install new shaft nut with a small diameter boss of nut against crankshaft shoulder. Use Thin Wall Socket (J-9399) and Clutch Hub

Holder (J-25030). Tighten shaft nut to 96-192 INCH lbs. 11-22 N.m). Spin pulley rotor by hand to ensure rotor is not rubbing on clutch

drive plate. See Fig. 8

.

HARRISON V5 5-CYLINDER SHAFT SEAL R & I

Removal

Discharge refrigerant from system using approved refrigerant recovery/recycling equipment. See SERVICING PRECAUTIONS at beginning of

article. Remove clutch plate assembly. Remove shaft seal snap ring. Thoroughly clean inside of compressor neck area around shaft and seal.

Engage tangs of Seal Remover/Installer (J-23128-A) into recessed portion of seal and remove seal. Remove and discard seal "O" ring from

compressor neck. Thoroughly clean inside of compressor neck and "O" ring groove.

Installation

1. Coat new "O" ring with refrigerant oil and install on "O" ring installer (J-33011). Install "O" ring into groove in compressor neck. Attach

new seal to Seal Remover/Installer (J-23128-A). Dip seal in clean refrigerant oil.

2. Place Seal Protector (J-34614) over compressor shaft. Push new seal over shaft protector. Install new snap ring with flat side against

seal. Install clutch plate assembly.

NOTE:DO NOT drive or pound on clutch hub or com pressor shaft, as com pressor could be dam aged

internally.

Page 8 of 18 MITCHELL 1 ARTICLE - A/C COMPRESSOR SERVICING 1991 GENERAL SERVICING Compressor Service

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 359 of 454

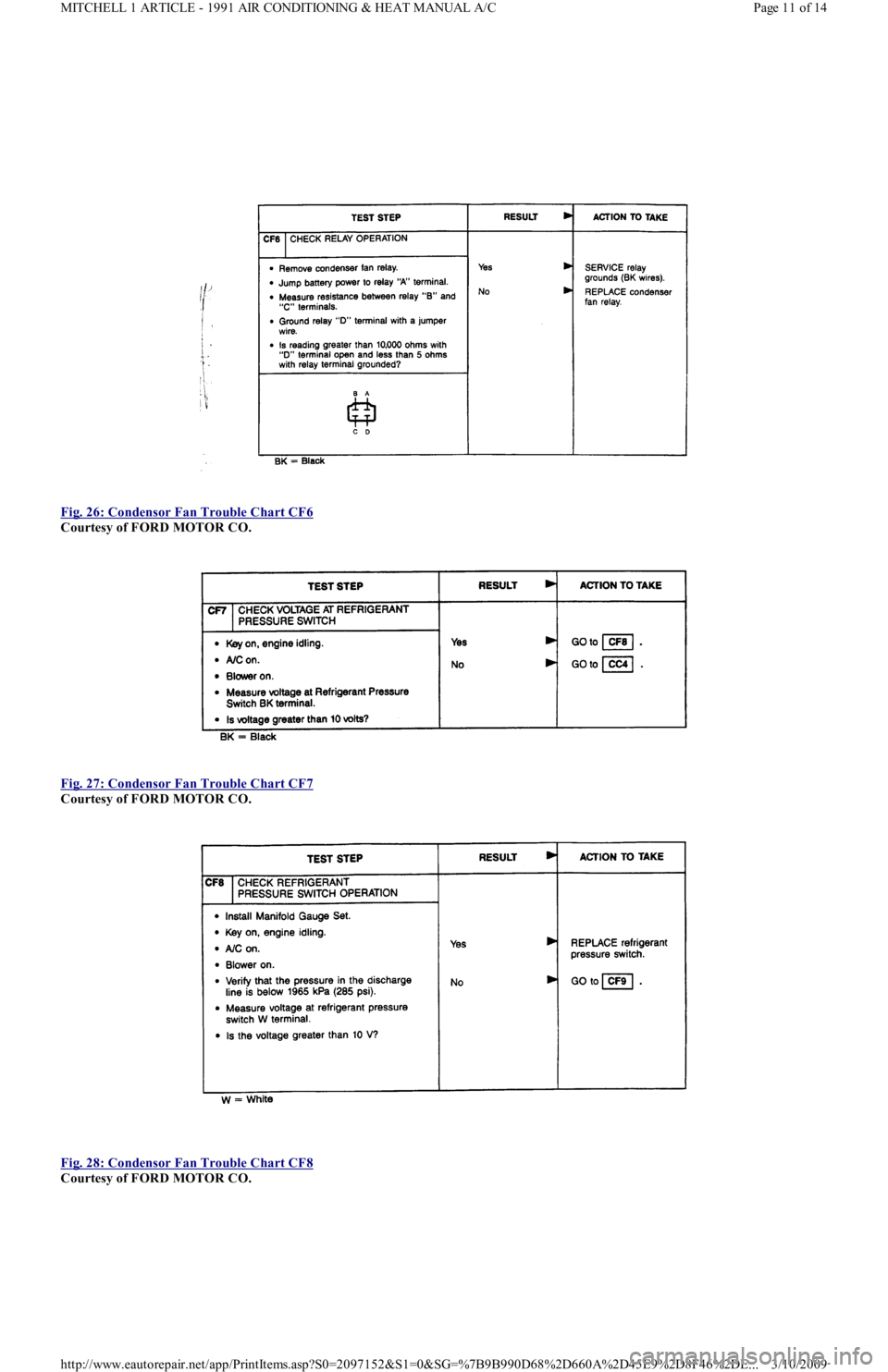

Fig. 26: Condensor Fan Trouble Chart CF6

Courtesy of FORD MOTOR CO.

Fig. 27: Condensor Fan Trouble Chart CF7

Courtesy of FORD MOTOR CO.

Fig. 28: Condensor Fan Trouble Chart CF8

Courtesy of FORD MOTOR CO.

Page 11 of 14 MITCHELL 1 ARTICLE - 1991 AIR CONDITIONING & HEAT MANUAL A/C

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 378 of 454

Back To Article

ST EERING SYST EM - POWER

1991-92 ST EERING Ford Motor Co. - Steering - Power Rack & Pinion

DESCRIPTION & OPERATION

Power steering system consists of a rack and pinion steering gear, valve body, power steering pump, fluid reservoir and interconnecting

hydraulic lines. Pressure and return lines from pump are connected to valve body. A vane-type power steering pump draws fluid from the

steering reservoir. Fluid is compressed by rotor and vanes inside steering pump and sent to steering gear. Pressure is monitored and controlled

by a pressure switch and a control valve located inside of steering pump.

TROUBLE SHOOTING

Refer to TROUBLE SHOOTING - BASIC PROCEDURES article in the GENERAL TROUBLE SHOOTING section.

LUBRICATION

CAPACITY

Information is not available.

FLUID TYPE

Use Dexron-II ATF type fluid.

FLUID LEVEL CHECK

Check fluid level before engine is started, while fluid is still cool. Remove reservoir cap fluid indicator on steering pump. Check fluid level.

Fluid should be between the "L" and "H" marks on the level gauge dipstick. If fluid is needed, fill to the "L" mark on dipstick. Run engine until

warm and turn steering wheel fully in both directions about 10 times. Return steering to straight-ahead position and shut engine off. Ensure

fluid level is between "L" and "H" marks. Add fluid if necessary.

HYDRAULIC FLUID BLEEDING

1. Raise and support front of vehicle. Ensure pump reservoir is filled to specified level. With ignition coil wire disconnected, crank engine

and add fluid to steering pump until fluid level remains constant. While cranking engine, rotate steering from stop to stop. Recheck and

add fluid as necessary.

2. Start engine and allow to idle for several minutes. Turn steering wheel completely lock-to-lock several times. Check fluid level. Add

fluid as necessary. Continue this procedure until there is no bubbling or decrease in fluid level.

ADJUSTMENTS

BELT TENSION

On Festiva, remove air duct and air cleaner. On all models, loosen steering pump mounting pivot bolt and the adjusting bolt lock nut. Using

Belt Tension Gauge (021-0028A), fit gauge to longest available belt span for testing. Adjust belt to specification. See BELT TENSION

SPECIFICATIONS . Tighten adjuster lock nut to 32-45 ft. lbs. (43-61 N.m) on Capri or 27-38 ft. lbs. (37-52 N.m) on Festiva.

BELT TENSION SPECIFICATIONS

REMOVAL & INSTALLATION

STEERING GEAR

Removal

1. Disconnect negative battery cable. On Capri, mark and loosen intermediate lower U-joint. On Festiva, mark and remove steering gear

intermediate shaft connecting steering gear to column shaft. On all models, disconnect high pressure and return lines and plug them.

Loosen front wheel lug nuts.

2. Raise vehicle. Remove front wheels. Remove tie rod end cotter pins and nuts. Separate tie rod ends from steering knuckles using Tie

Rod Remover (T85M-3395-A). Remove tie rod end splash shields. Remove right fender splash shield. Remove front catalytic converter

nuts and separate converter from inlet pipe.

3. Place reference marks on tie rod end and tie rod for reassembly reference. Loosen tie rod jam nut and remove right tie rod end. Remove

steering gear mounting bolts and washers. Slide steering gear to the left and pull right tie rod through fender opening. Remove steering

gear by sliding it to the right.

Installation

Application

(1) Deflection: In.

(mm)Gauge Tension:

Lbs. (kg)

New Belt

Capri & Festiva.31-.35 (8-9)110-132 (50-60)

Used Belt

Capri.31-.35 (8-9)110-132 (50-60)

Festiva.35-.39 (9-10)95-110 (43-50)

(1)Apply approximately 22 lbs. (9.9 kg) of pressure.

Page 1 of 9 MITCHELL 1 ARTICLE - STEERING SYSTEM - POWER 1991-92 STEERING Ford Motor Co. - Steering - Power Rack & Pi

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 385 of 454

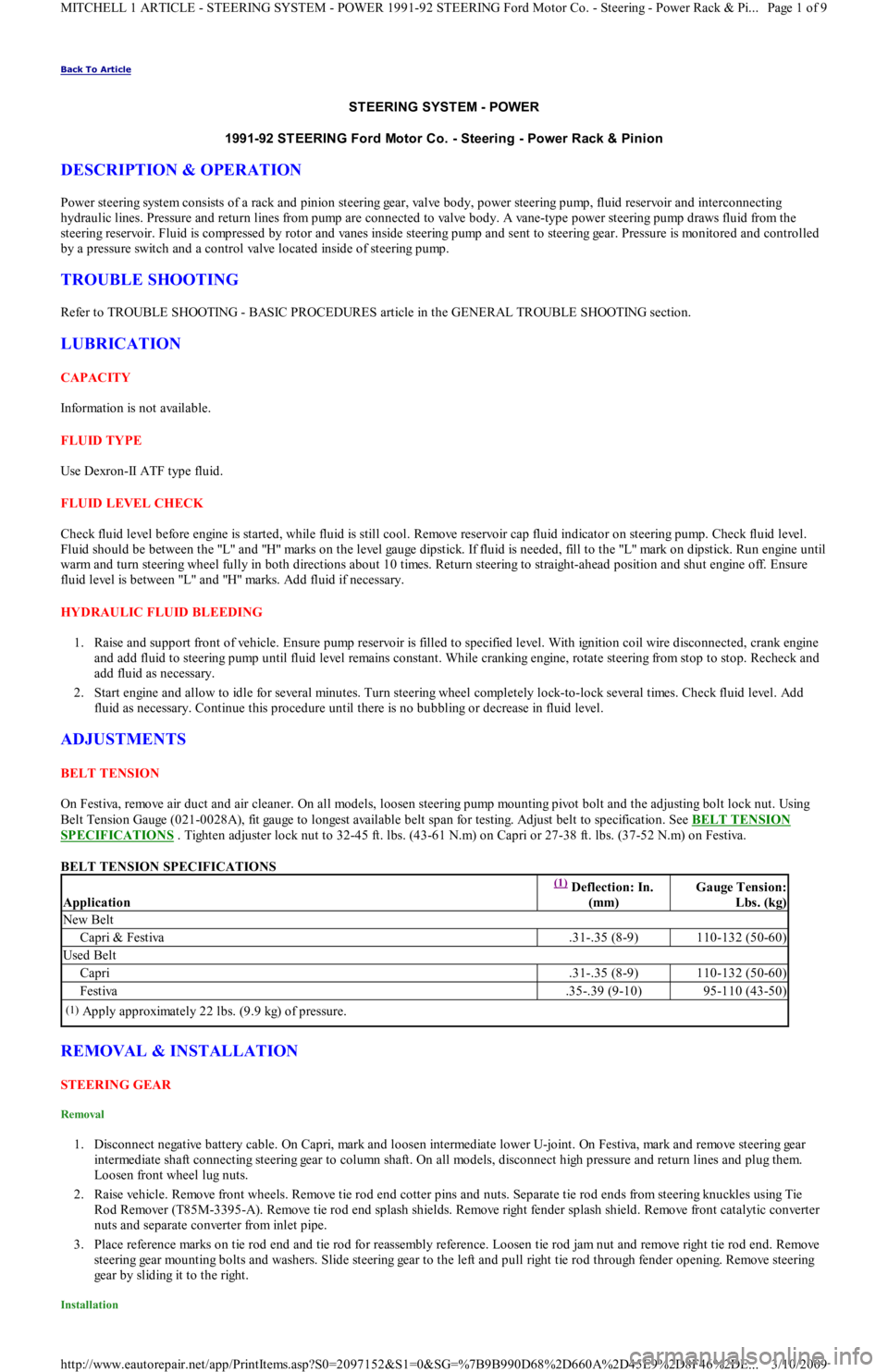

Fig. 7: Power Steering Pump Mounting & Pressure Hose (Festiva)

Courtesy of FORD MOTOR CO.

Fig. 8: Exploded View of Power Steering Pump (Festiva)

Courtesy of FORD MOTOR CO.

2. Remove return line and "O" ring. Remove pulley nut and washer. Remove pulley using Pulley Remover (OTC-1024). Remove keyway,

front bracket bolts and washers. Remove front bracket, rear bracket bolts and washers and rear bracket. Remove rear body bolts and

washers. Remove rear body. Remove shaft retaining ring. Remove shaft and rotor.

3. Remove vanes, "O" ring, and center body. Remove "O" ring and cam ring. Remove seal using Collet (D80L-100-Q) and Slide Hammer

( T5 0 T- 1 0 0 - A) . R e mo ve va l ve fit t in g. R e mo ve 4 "O" r in gs fr o m va l ve fit t in g. R e mo ve c o n t r o l va l ve , sp r in g, p r e ssu r e swit c h fit t ing a n d

spring. Remove "O" ring from pressure switch fitting. Remove spring seat. Remove plunger.

Reassembly (Festiva)

1. Coat pump vanes, rotor and control valve with ATF. Install new "O" ring on pressure switch fitting. Install plunger, spring seat, spring

and pressure switch fitting. Install new "O" rings on valve fitting. Install spring, control valve and valve fitting. Coat lip of new seal with

grease and install seal using suitable installer.

2. Install cam ring, new "O"ring, center body, new "O" ring and rotor. Ensure rounded edge of vanes face toward center of rotor. In st al l

vanes, shaft and retaining ring. Position rear body and install washers and bolts. Position rear bracket and install washers and bolts.

Position front bracket and install washers and bolts.

3. Position key in keyway and install pulley. Install pulley washer and nut. Tighten nut to 22-29 ft. lbs. (29-39 N.m). Install new "O" ring

at return line port. Position high pressure line and install support bracket and cap screw. Install high pressure line attaching washer and

nut. Tighten to 29-36 ft. lbs. (39-49 N.m).

4. Ensure pump rotates freely. If not, disassemble and repair as necessary. Install pump on vehicle. Bleed air from hydraulic system before

starting engine. See HYDRAULIC FLUID BLEEDING

under LUBRICATION.

WHEEL ALIGNMENT

After performing appropriate service procedures, refer to WHEEL ALIGNMENT SPECIFICATIONS & PROCEDURES article in the

WHEEL ALIGNMENT section.

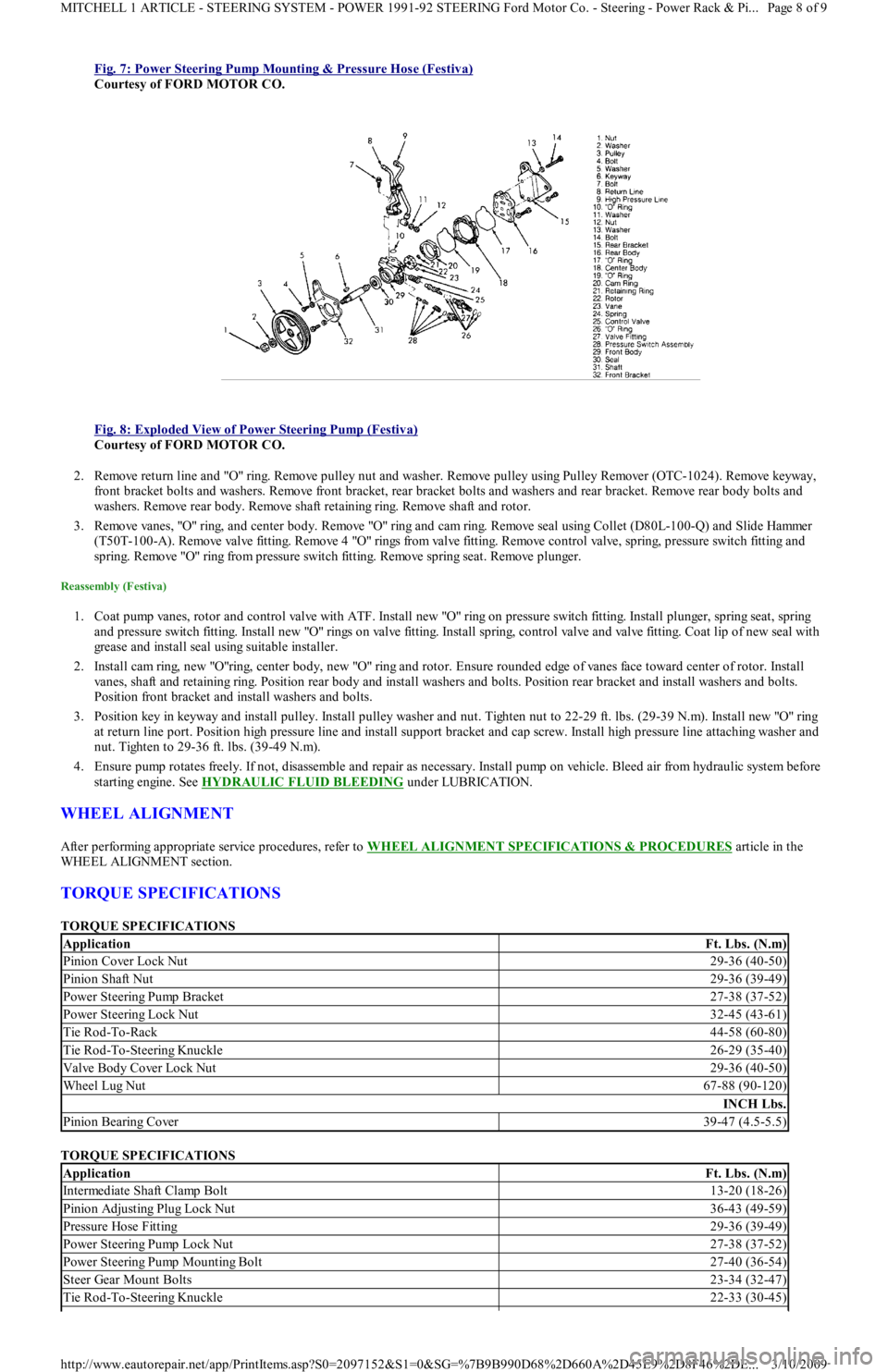

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS

ApplicationFt. Lbs. (N.m)

Pinion Cover Lock Nut29-36 (40-50)

Pinion Shaft Nut29-36 (39-49)

Power Steering Pump Bracket27-38 (37-52)

Power Steering Lock Nut32-45 (43-61)

Tie Rod-To-Rack44-58 (60-80)

Tie Rod-To-Steering Knuckle26-29 (35-40)

Valve Body Cover Lock Nut29-36 (40-50)

Wheel Lug Nut67-88 (90-120)

INCH Lbs.

Pinion Bearing Cover39-47 (4.5-5.5)

ApplicationFt. Lbs. (N.m)

Intermediate Shaft Clamp Bolt13-20 (18-26)

Pinion Adjusting Plug Lock Nut36-43 (49-59)

Pressure Hose Fitting29-36 (39-49)

Power Steering Pump Lock Nut27-38 (37-52)

Power Steering Pump Mounting Bolt27-40 (36-54)

Steer Gear Mount Bolts23-34 (32-47)

Tie Rod-To-Steering Knuckle22-33 (30-45)

Page 8 of 9 MITCHELL 1 ARTICLE - STEERING SYSTEM - POWER 1991-92 STEERING Ford Motor Co. - Steering - Power Rack & Pi

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 393 of 454

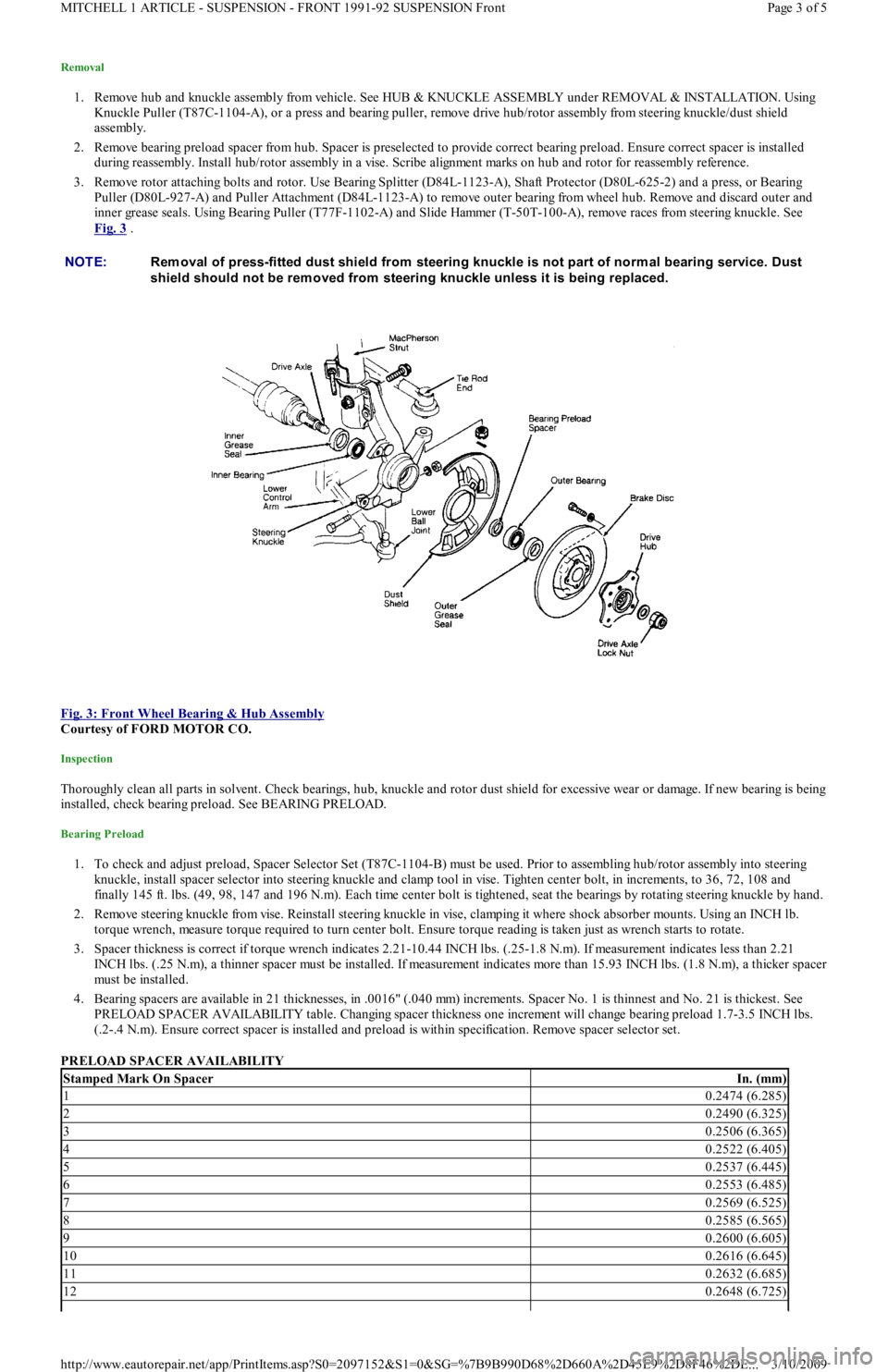

Removal

1. Remove hub and knuckle assembly from vehicle. See HUB & KNUCKLE ASSEMBLY under REMOVAL & INSTALLATION. Using

Knuckle Puller (T87C-1104-A), or a press and bearing puller, remove drive hub/rotor assembly from steering knuckle/dust shield

assembly.

2. Remove bearing preload spacer from hub. Spacer is preselected to provide correct bearing preload. Ensure correct spacer is installed

during reassembly. Install hub/rotor assembly in a vise. Scribe alignment marks on hub and rotor for reassembly reference.

3. Remove rotor attaching bolts and rotor. Use Bearing Splitter (D84L-1123-A), Shaft Protector (D80L-625-2) and a press, or Bearing

Puller (D80L-927-A) and Puller Attachment (D84L-1123-A) to remove outer bearing from wheel hub. Remove and discard outer and

inner grease seals. Using Bearing Puller (T77F-1102-A) and Slide Hammer (T-50T-100-A), remove races from steering knuckle. See

Fig. 3

.

Fig. 3: Front Wheel Bearing & Hub Assembly

Courtesy of FORD MOTOR CO.

Inspection

Thoroughly clean all parts in solvent. Check bearings, hub, knuckle and rotor dust shield for excessive wear or damage. If new bearing is being

installed, check bearing preload. See BEARING PRELOAD.

Bearing Preload

1. To check and adjust preload, Spacer Selector Set (T87C-1104-B) must be used. Prior to assembling hub/rotor assembly into steering

knuckle, install spacer selector into steering knuckle and clamp tool in vise. Tighten center bolt, in increments, to 36, 72, 108 and

finally 145 ft. lbs. (49, 98, 147 and 196 N.m). Each time center bolt is tightened, seat the bearings by rotating steering knuckle by hand.

2. Remove steering knuckle from vise. Reinstall steering knuckle in vise, clamping it where shock absorber mounts. Using an INCH lb.

torque wrench, measure torque required to turn center bolt. Ensure torque reading is taken just as wrench starts to rotate.

3. Spacer thickness is correct if torque wrench indicates 2.21-10.44 INCH lbs. (.25-1.8 N.m). If measurement indicates less than 2.21

INCH lbs. (.25 N.m), a thinner spacer must be installed. If measurement indicates more than 15.93 INCH lbs. (1.8 N.m), a thicker spacer

must be installed.

4. Bearing spacers are available in 21 thicknesses, in .0016" (.040 mm) increments. Spacer No. 1 is thinnest and No. 21 is thickest. See

PRELOAD SPACER AVAILABILITY table. Changing spacer thickness one increment will change bearing preload 1.7-3.5 INCH lbs.

(.2-.4 N.m). Ensure correct spacer is installed and preload is within specification. Remove spacer selector set.

PRELOAD SPACER AVAILABILITY NOTE:Rem oval of press-fitted dust shield from steering knuckle is not part of norm al bearing service. Dust

shield should not be rem oved from steering knuckle unless it is being replaced.

Stamped Mark On SpacerIn. (mm)

10.2474 (6.285)

20.2490 (6.325)

30.2506 (6.365)

40.2522 (6.405)

50.2537 (6.445)

60.2553 (6.485)

70.2569 (6.525)

80.2585 (6.565)

90.2600 (6.605)

100.2616 (6.645)

110.2632 (6.685)

120.2648 (6.725)

Page 3 of 5 MITCHELL 1 ARTICLE - SUSPENSION - FRONT 1991-92 SUSPENSION Front

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 394 of 454

Installation

1. Using Bearing Cup Replacer (D79P-1202-A) and Universal Driver Handle (T80T-4000-W), install bearing races in steering knuckle.

Lubricate bearing races and bearing. Install inner bearing into steering knuckle. Lubricate seal lips and install inner bearing seal into

knuckle. Install original bearing preload spacer in steering knuckle (or spacer selected during bearing preload check). Position outer

bearing in knuckle. Install outer seal. Install hub onto rotor, using reference marks made during removal. Install rotor to hub attaching

bolts.

2. Using a press and adapter from Spacer Selector Set (T87C-1104-B), install knuckle assembly onto hub. To complete installation,

reverse removal procedure.

LOWER CONTROL ARM & BALL JOINT (FESTIVA)

Removal

Remove lower control arm pivot bolt at frame bracket. Remove ball joint clamp bolt and nut from steering knuckle assembly. Remove

stabilizer bushing retaining nut from rear of control arm. Remove rear bushing washer and bushing. Lower the control arm and pry ball joint

stud out of steering knuckle. Disconnect control arm from stabilizer end and remove.

Inspection

Check control arm and bushings for excessive wear or damage. Ensure ball joint stud moves freely but is not loose. Use Ball Joint Rotating

Adapter (T87C-5493-C) to check ball joint rotating torque. Rotating torque should be 16-27 INCH lbs. (1.8-3.1 N.m).

Installation

1. Install front bushing washer with dished side forward. Position bushing stabilizer end and engage control arm with stabilizer. Raise

control arm inner end into pivot bracket on frame. Install pivot bolt to hold it in position.

2. Engage control arm ball joint stud with clamp bore in steering knuckle. Install clamp bolt and nut. Install stabilizer rear bushing and

washer with dished side forward on stabilizer end. Tighten all bolts and nuts to specification.

LOWER CONTROL ARM (CAPRI)

Removal & Installation

Raise and support vehicle. Remove wheel and disconnect stabilizer bar from control arm, if equipped. Remove ball joint clamp bolt. Remove

control arm front mount bolt. Remove control arm rear bracket and mount bolts. Remove control arm. To install, reverse removal procedure.

BALL JOINT (CAPRI)

Removal & Installation

1. Raise and support vehicle. Remove wheel. Remove ball joint clamp bolt from steering knuckle. Use small pry bar to pull down on lower

control arm to separate it from steering knuckle. Remove 2 ball joint retaining bolts and pry ball joint off control arm. To install, reverse

removal procedure.

LOWER CONTROL ARM BUSHING

Removal & Installation (Capri)

1. Remove control arm from vehicle. See LOWER CONTROL ARM. Use Bushing Receiver Cup (T87C-5493-B1), Bushing Driver (T87C-

5493-B2) and vise to remove control arm bushing.

2. To install, press bushing into control arm using same tools used for removal. Refit control arm to chassis.

Removal & Installation (Festiva)

1. Remove control arm from vehicle. See LOWER CONTROL ARM & BALL JOINT. Use Bushing Receiver Cup (T88C-5493-E), Bushing

Pilot (T81P-5493-B2) and "C" Clamp Assembly (T74P-3044-A1) to remove control arm bushing.

2. To install, press bushing into control arm using same tools used for removal. Refit control arm to chassis.

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS

130.2663 (6.765)

140.2679 (6.805)

150.2695 (6.845)

160.2711 (6.885)

170.2726 (6.925)

180.2742 (6.965)

190.2758 (7.005)

200.2774 (7.045)

210.2789 (7.085)

NOTE:Insert bushing quickly and sm oothly. Bushing should only be distorted for a short tim e.

ApplicationFt. Lbs. (N.m)

Capri

Ball Joint Pinch Bolt32-40 (43-54)

Brake Rotor-To-Hub33-40 (44-54)

Page 4 of 5 MITCHELL 1 ARTICLE - SUSPENSION - FRONT 1991-92 SUSPENSION Front

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 395 of 454

Caliper Attaching Bolts29-36 (39-49)

Control Arm Bolt-To-Ball Joint69-86 (93-117)

Control Arm Bracket Bolt44-54 (59-74)

Control Arm Front Bolt69-86 (93-117)

Control Arm Rear Bolt55-69 (75-93)

Drive Axle Nut116-174 (157-236)

Shock Absorber Bolt-To-Knuckle69-72 (93-97)

Stabilizer Bracket Nuts40-50 (54-68)

Steering Knuckle-To-Strut69-86 (93-117)

Steering Knuckle-To-Tie Rod22-33 (29-44)

Strut Assembly-To-Strut Tower17-22 (23-29)

Strut Rod Nut22-27 (29-36)

Wheel Lug Nut65-88 (90-120)

Festiva

Ball Joint Pinch Bolt32-40 (43-54)

Brake Rotor-To-Hub33-40 (44-54)

Caliper Attaching Bolts29-36 (39-49)

Control Arm Bushing Nuts47-57 (64-77)

Control Arm Pivot Bolt32-40 (43-54)

Stabilizer Bar Nuts-To-Control Arm47-57 (64-77)

Stabilizer Mounting Bracket Nuts40-50 (54-68)

Steering Knuckle-To-Strut69-86 (93-117)

Steering Knuckle-To-Tie Rod22-33 (29-44)

Strut Assembly-To-Strut Tower22-27 (29-36)

Wheel Lug Nut65-88 (90-120)

Copyr ight 2009 Mitchell Repair Information Company, LLC. All Rights Reserved.

Article GUID: A00121554

Page 5 of 5 MITCHELL 1 ARTICLE - SUSPENSION - FRONT 1991-92 SUSPENSION Front

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 410 of 454

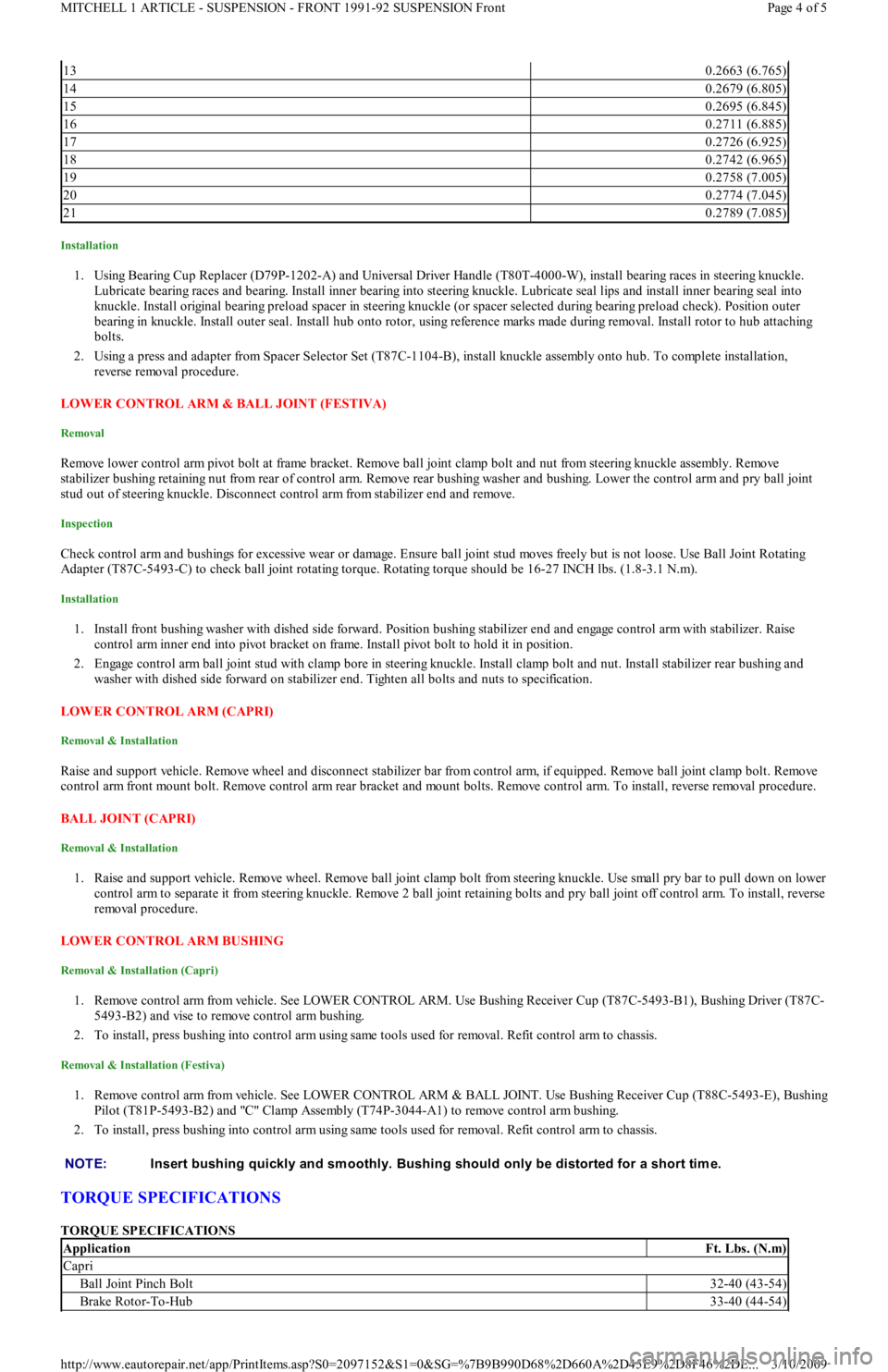

Fig. 2: Compressing Band Apply Servo

Courtesy of FORD MOTOR CO.

DIFFERENTIAL OIL SEALS R & I

Removal

1. Raise and support vehicle. Drain transaxle fluid. Carefully raise staked portion of axle nut. Apply brakes and loosen, but DO NOT

remove, axle nut. Remove lower control arm ball joint clamp bolt. Pry downward on lower control arm to separate control arm from

knuckle.

2. Insert pry bar between transaxle case and axle flange. Carefully apply force to pry bar until axle circlip is disengaged. Slide knuckle

assembly off axle shaft, and remove axle from vehicle. Quickly install appropriate plug in transaxle. Using appropriate puller, remove

seal.

Installation

1. Apply lubrication to new seal. Using appropriate driver, install seal. Install new circlip on transaxle end of axle. Remove transaxle plug,

and carefully install axle into transaxle. Ensure circlip snaps into retaining groove.

2. Install axle into hub. Install NEW axle nut. Tighten bolts to specifications. See TORQUE SPECIFICATIONS

. Stake NEW axle nut

with blunt nose chisel. To complete installation, reverse removal procedure. Fill transaxle fluid to correct level.

OIL COOLER FLUSHING

Contaminates MUST be removed from oil cooler before transmission is put back into service. Replace cooler supply tubes if leaking.

Thoroughly flush oil cooler and lines if a major service or transaxle removal has occurred. It is recommended that a mechanically agitated

cleaner, such as Rotunda (014-00028), be used.

VACUUM THROTTLE VALVE DIAPHRAGM (MODULATOR) R & I

Removal

1. Drain transaxle fluid. Disconnect vacuum hose from modulator. Unscrew modulator from transaxle. Remove control rod. With beveled

side out, insert Vacuum Diaphragm Rod Gauge (T87C-77000-A) into mounting hole until gauge bottoms out.

2. Place gauge rod through opening of gauge until rod bottoms out against vacuum throttle valve. Tighten lock knob on gauge and remove

tool. Using depth gauge, measure distance from flat surface of gauge to end of rod. See Fig. 3

. Select proper length throttle valve rod.

See THROTTLE VALVE ROD DIMENSION CHART

.

THROTTLE VALVE ROD DIMENSION CHART

Installation

Install selected throttle valve rod. Coat threads of modulator with appropriate sealant. To install, reverse removal procedures.

NOTE:If replacing m odulator, it is necessary to replace throttle control valve rod.

Measurement In. (mm)Applicable Rod Length In. (mm)

1.0 (25.4)1.16 (29.5)

1.0-1.02 (25.4-25.9)1.18 (30.0)

1.02-1.04 (25.9-26.4)1.20 (30.5)

1.04-1.06 (25.9-26.4)1.22 (31.0)

1.06-1.08 (26.9-27.4)1.24 (31.5)

Page 2 of 26 MITCHELL 1 ARTICLE - 1988-94 AUTOMATIC TRANSMISSIONS Ford ATX Overhaul

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 415 of 454

inspect and repair circuit between switch harness connector and fuse panel.

5.Check Kickdown Switch

Turn ignition off. Check continuity between kickdown switch terminals. Continuity should only exist with accelerator fully depressed. I

f

switch is functioning correctly, go to next step. Replace switch if it failed testing. Road test vehicle to verify repair.

6.Check Circuit Between Kickdown Switch & Kickdown Solenoid

Ensure ignition is off. Disconnect kickdown switch harness connector. Disconnect kickdown solenoid harness connector. Check

continuity of White/Black wire between switch harness connector and solenoid harness connector. If continuity does not exist, inspect

and repair open circuit as needed. If continuity exists, check continuity between White/Black wire terminal at solenoid harness

connector and ground. If continuity exists, inspect and repair short circuit as needed. If continuity does not exist, replace kickdown

solenoid.

VACUUM THROTTLE VALVE DIAPHRAGM (MODULATOR) TEST

1.Check System Integrity

Inspect all vacuum hoses and connections for leaks or damage. Disconnect vacuum hose at diaphragm connection and inspect for

leaking ATF. Repair as needed. Go to next step.

2.Check Vacuum At Modulator

Ensure ignition is off. Disconnect vacuum hose at modulator valve and connect vacuum gauge to hose. Start and run engine at idle.

Vacuum should be 15-22 In. Hg. If vacuum is not within specification, inspect and repair vacuum hose. If vacuum is within specification,

go to next step.

3.Check Modulator Valve Function

Turn ignition off. Remove modulator valve from transaxle. Connect hand-held vacuum pump to valve. Apply 16-20 In. Hg of vacuum.

Ensure vacuum is held by valve. Release vacuum and verify that valve moves freely. If valve is functioning correctly, go to next step.

Replace valve if it fails testing.

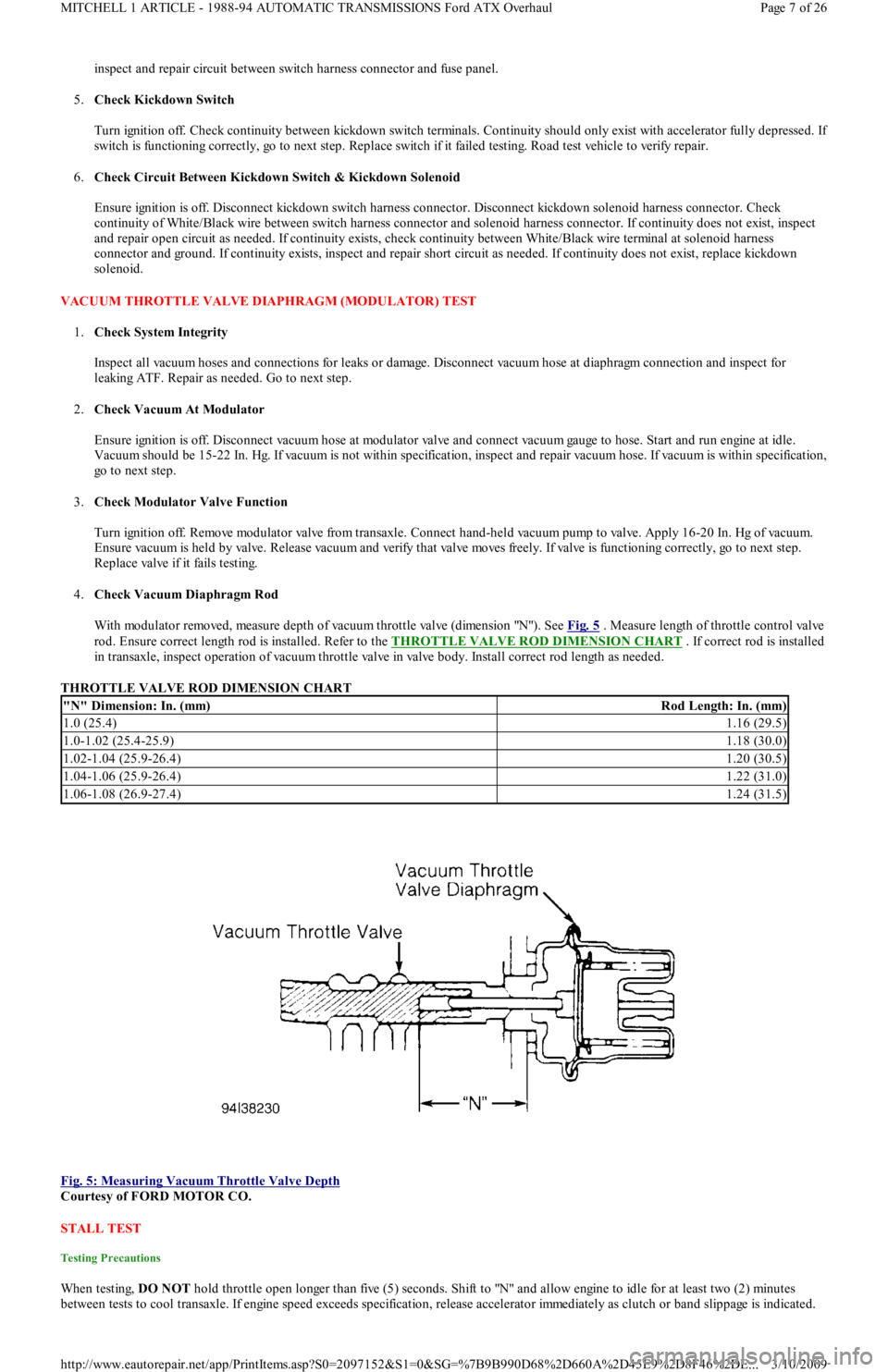

4.Check Vacuum Diaphragm Rod

With modulator removed, measure depth of vacuum throttle valve (dimension "N"). See Fig. 5

. Measure length of throttle control valve

rod. Ensure correct length rod is installed. Refer to the THROTTLE VALVE ROD DIMENSION CHART

. If correct rod is installed

in transaxle, inspect operation of vacuum throttle valve in valve body. Install correct rod length as needed.

THROTTLE VALVE ROD DIMENSION CHART

Fig. 5: Measuring Vacuum Throttle Valve Depth

Courtesy of FORD MOTOR CO.

STALL TEST

Testing Precautions

When testing, DO NOT hold throttle open longer than five (5) seconds. Shift to "N" and allow engine to idle for at least two (2) minutes

between tests to cool transaxle. If engine speed exceeds specification, release accelerator immediately as clutch or band slippage is indicated.

"N" Dimension: In. (mm)Rod Length: In. (mm)

1.0 (25.4)1.16 (29.5)

1.0-1.02 (25.4-25.9)1.18 (30.0)

1.02-1.04 (25.9-26.4)1.20 (30.5)

1.04-1.06 (25.9-26.4)1.22 (31.0)

1.06-1.08 (26.9-27.4)1.24 (31.5)

Page 7 of 26 MITCHELL 1 ARTICLE - 1988-94 AUTOMATIC TRANSMISSIONS Ford ATX Overhaul

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 418 of 454

LINE PRESSURE TEST SPECIFICATIONS (ASPIRE)

LINE PRESSURE TEST SPECIFICATIONS (ALL EXCEPT ASPIRE)

LINE PRESSURE CUT-BACK TEST

1. Connect oil pressure gauges to line pressure and governor pressure ports. See Fig. 6

. Position gauges so they can be seen from driver's

seat.

2. Connect a hand-held vacuum pump to vacuum modulator. See Fig. 6

. Position vacuum pump so it can be operated from driver's seat.

With shift lever in "D", gradually increase engine RPM and observe pressure gauge readings. Record results.

3. With shift lever in "D", gradually increase engine RPM, and apply 8 in. Hg to vacuum modulator. When line pressure reading suddenly

decreases, observe the governor pressure gauge. Refer to LINE PRESSURE CUT

-BACK TEST SPECIFICATIONS .

4. If governor pressure gauge readings are not within specifications, ensure rod in vacuum modulator is installed. If a rod is installed, rod

length may be incorrect or vacuum throttle valve is sticking. See VACUUM THROTTLE VALVE DIAPHRAGM (MODULATOR)

under TESTING.

LINE PRESSURE CUT-BACK TEST SPECIFICATIONS

GOVERNOR PRESSURE TEST

1. Attach oil pressure gauge to governor pressure check port. See Fig. 6

. Position gauge so that it may be seen from driver's seat. Shift

transaxle into "D" and road test vehicle.

2. Accelerate vehicle smoothly and record governor pressure readings at 20, 35 and 55 MPH. See GOVERNOR PRESSURE

SPECIFICATIONS . If pressure gauge readings are not within specifications, check for fluid leakage in line pressure hydraulic circuit

and/or governor pressure hydraulic circuit. Also check for a faulty governor.

GOVERNOR PRESSURE SPECIFICATIONS

REMOVAL & INSTALLATION

See the appropriate TRANSMISSION REMOVAL & INSTALLATION - A/T article in this section. Refer to the following menu:

TORQUE CONVERTER

The torque converter is a sealed unit and cannot be serviced. Check for cracked or worn ring in seal area. Measure bushing in converter boss.

If I.D. is larger than 2.090" (53.08 mm) on Aspire, 1.302" (33.075 mm) on Festiva and Tracer, replace torque converter. If metal particles are

found in ATF, replace torque converter. To clean torque converter, flush with solvent, drain and flush with ATF and drain ATF.

TRANSAXLE DISASSEMBLY

1. Remove torque converter. Attach transaxle to appropriate holding fixture. Remove park/neutral switch, kickdown solenoid and vacuum

modulator with rod. Remove oil dipstick and tube. Remove speedometer driven gear retaining bolt and lift out gear assembly. Remove

oil pump drive shaft and turbine shaft.

2. Remove oil pan. Remove valve body. DO NOT lose check ball and spring. Position transaxle with oil pump facing downward. With

flat-blade screwdriver inserted in wide slot between front clutch drum and sun shell, pry down on front clutch drum. Do this seve r a l

times as you rotate assembly 2 complete revolutions.

3. Using a feeler gauge, measure front clutch drum end play. See Fig. 7

. Check clearance of small slot between front clutch drum tabs and

Applicationpsi (kg/cm2 )

At Idle

"D"46-54 (3.2-3.8)

"2 "150-166 (10.5-11.7)

"R"76-95 (5.3-6.7)

At Stall Speed

"D"141-157 (9.9-11.0)

"2 "150-166 (10.5-11.7)

"R"251-262 (17.6-18.4)

Applicationpsi (kg/cm2 )

At Idle

"D"43-57 (3.0-4.0)

"2 "114-171 (8.0-12.0)

"R"57-110 (4.0-7.0)

At Stall Speed

"D"128-156 (9.0-11.0)

"2 "114-171 (8.0-12.0)

"R"228-270 (16.0-19.0)

Vacuum Pump ReadingGovernor Pressure psi (kg/cm2 )

0 in. Hg (Atmosphere)14-23 (.98-1.6)

8 in. Hg6-14 (.42-.98)

Applicationpsi (kg/cm2 )

Aspire & Festiva

20 MPH13-21 (.9-1.5)

35 MPH25-35 (1.8-2.5)

55 MPH58-70 (4.0-4.8)

Page 10 of 26 MITCHELL 1 ARTICLE - 1988-94 AUTOMATIC TRANSMISSIONS Ford ATX Overhaul

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...