heating FORD FESTIVA 1991 User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 1991, Model line: FESTIVA, Model: FORD FESTIVA 1991Pages: 454, PDF Size: 9.53 MB

Page 251 of 454

FUEL INJECTION TROUBLE SHOOTING

Se ve r a l High F ir in g Lin e s

Fuel Mixture UnbalancedCheck Fuel System

EGR Valve Stuck OpenClean/Replace EGR

Valve

High Plug Wire ResistanceReplace Plug Wire

Cracked/Broken PlugsReplace Plugs

Intake Vacuum LeakRepair Leak

Several Low Firing Lines

Fuel Mixture UnbalancedAdjust Fuel Mixture

Plug Wires ArcingReplace Plug Wires

Cracked Coil ArcingReplace Coil

Uneven CompressionCheck/Repair Engine

Faulty Spark PlugsReplace Plugs

Cylinders Not Firing

Cracked Distributor CapReplace Cap

Shorted Plug WiresReplace Plug Wires

Mechanical Engine FaultCheck/Repair Engine

Spark Plugs FouledReplace Plugs

Carbon Track in Distributor CapReplace Cap

Hard Starting

Defective Ignition Coil(s)Replace Coil(s)

Fouled Spark PlugsReplace Plugs

Incorrect TimingReset Ignition Timing

NOTE:T his article is generic in nature and all inform ation does not apply to all vehicles. For vehicle specific

inform ation, see the appropriate articles in the ENGINE PERFORMANCE category.

Problem & Possible CauseAction

Cold Start Valve InoperativeTest Cold Start Valve

Poor Vacuum/Electrical ConnectionRepair Connections

Contaminated FuelTest Fuel for Water/Alcohol

Bad Fuel Pump Relay/CircuitTest Relay/Wiring

Battery Voltage LowCharge/Test Battery

Low Fuel PressureTest Press. Regulator/Pump

No Distributor Reference PulseRepair Ignition System

Coolant Temp. Sensor DefectiveTest Temp. Sensor/Circuit

No Power To InjectorsCheck Injector Fuse/Relay

Hard Starting

Defective Idle Air Control (IAC)Test IAC and Circuit

EGR Valve OpenTest EGR Valve/Control

Circuit

Restricted Fuel LinesInspect/Replace Fuel Lines

Poor MAP Sensor SignalTest MAP Sensor/Circuit

Engine Stalls During Parking ManeuverCheck P.S. Press. Switch

Rough Idle

Dirty Fuel InjectorsClean/Replace Injectors

Poor MAP Sensor SignalTest MAP Sensor/Circuit

Intermittent Fuel Injector OperationCheck Harness Connectors

Erratic Vehicle Speed Sensor InputsHarness Too Close to Plug

Wires

Poor O2 Sensor SignalTest O2 Sensor/Circuit

Faulty PCV SystemCheck PCV Valve and

Hoses

Poor Acceleration

Weak Fuel PumpReplace Fuel Pump

Dirty Fuel InjectorsClean/Replace Injectors

Excessive Intake Valve DepositsClean Intake System

Poor High Speed Operation

Low Fuel Pump VolumeFaulty Fuel Pump/Filter

Poor MAP Sensor SignalTest Speed Sensor/Circuit

Acceleration Ping/Knock

Faulty EGR SystemCheck EGR Valve and

Hoses

Poor Knock Sensor SignalTest Knock Sensor/Circuit

Poor Baro Sensor SignalTest Baro Sensor/Circuit

Improper Ignition TimingAdjust Timing

Engine OverheatingCheck Cooling System

Poor Quality FuelUse Different Fuel

Carbon Build-UpDecarbon Engine

Page 2 of 3 MITCHELL 1 ARTICLE - GENERAL INFORMATION TROUBLE SHOOTING

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 286 of 454

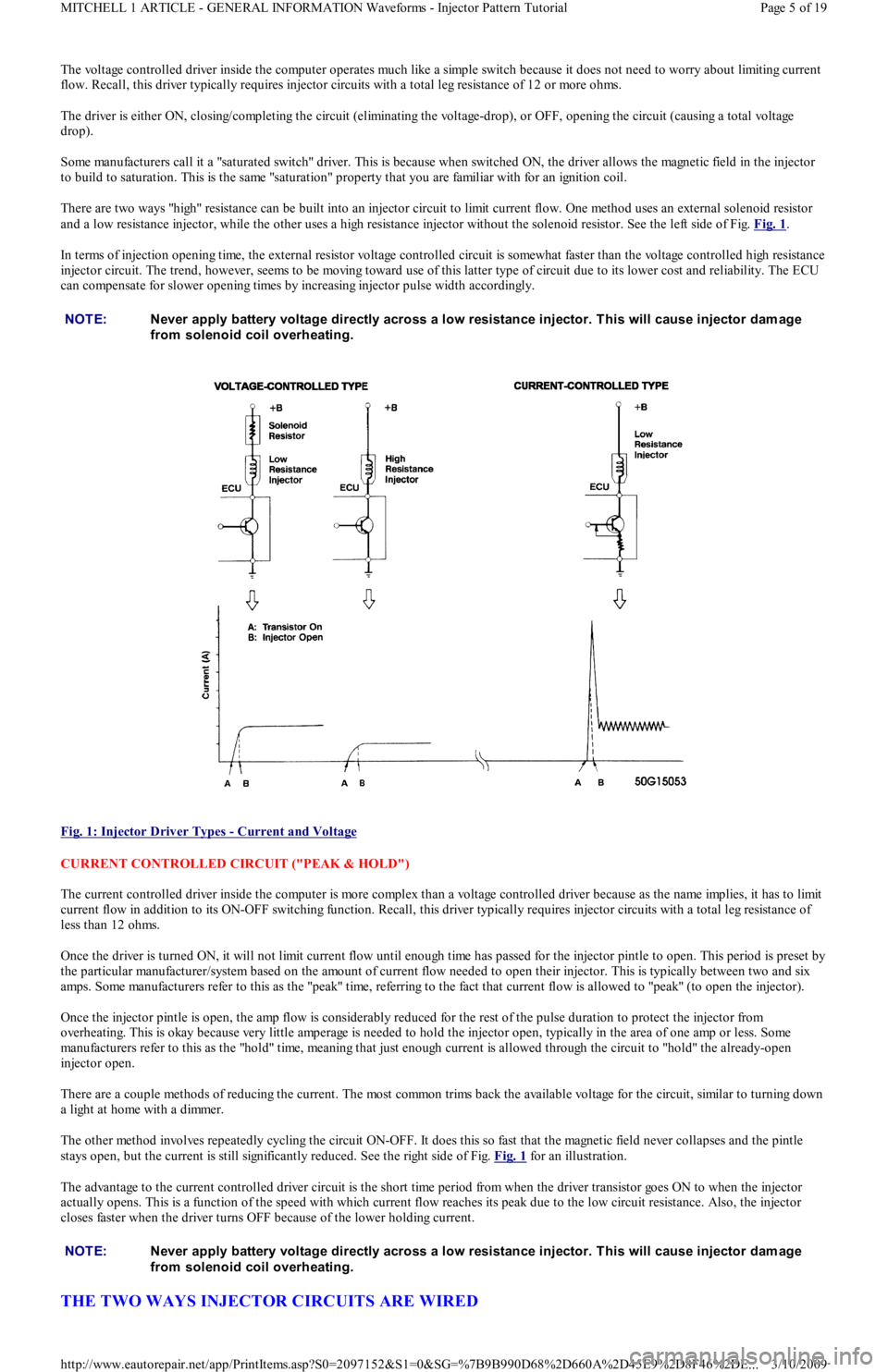

The voltage controlled driver inside the computer operates much like a simple switch because it does not need to worry about limiting current

flow. Recall, this driver typically requires injector circuits with a total leg resistance of 12 or more ohms.

The driver is either ON, closing/completing the circuit (eliminating the voltage-drop), or OFF, opening the circuit (causing a total voltage

drop).

Some manufacturers call it a "saturated switch" driver. This is because when switched ON, the driver allows the magnetic field in the injector

to build to saturation. This is the same "saturation" property that you are familiar with for an ignition coil.

There are two ways "high" resistance can be built into an injector circuit to limit current flow. One method uses an external solenoid resistor

and a low resistance injector, while the other uses a high resistance injector without the solenoid resistor. See the left side of Fig. Fig. 1

.

In terms of injection opening time, the external resistor voltage controlled circuit is somewhat faster than the voltage controlled high resistance

injector circuit. The trend, however, seems to be moving toward use of this latter type of circuit due to its lower cost and reliability. The ECU

can compensate for slower opening times by increasing injector pulse width accordingly.

Fig. 1: Injector Driver Types

- Current and Voltage

CURRENT CONTROLLED CIRCUIT ("PEAK & HOLD")

The current controlled driver inside the computer is more complex than a voltage controlled driver because as the name implies, it has to limit

current flow in addition to its ON-OFF switching function. Recall, this driver typically requires injector circuits with a total leg resistance of

less than 12 ohms.

Once the driver is turned ON, it will not limit current flow until enough time has passed for the injector pintle to open. This period is preset by

the particular manufacturer/system based on the amount of current flow needed to open their injector. This is typically between two and six

amps. Some manufacturers refer to this as the "peak" time, referring to the fact that current flow is allowed to "peak" (to open the injector).

Once the injector pintle is open, the amp flow is considerably reduced for the rest of the pulse duration to protect the injector from

overheating. This is okay because very little amperage is needed to hold the injector open, typically in the area of one amp or less. Some

manufacturers refer to this as the "hold" time, meaning that just enough current is allowed through the circuit to "hold" the already-open

injector open.

There are a couple methods of reducing the current. The most common trims back the available voltage for the circuit, similar to turning down

a light at home with a dimmer.

The other method involves repeatedly cycling the circuit ON-OFF. It does this so fast that the magnetic field never collapses and the pintle

stays open, but the current is still significantly reduced. See the right side of Fig. Fig. 1

for an illustration.

The advantage to the current controlled driver circuit is the short time period from when the driver transistor goes ON to when the injector

actually opens. This is a function of the speed with which current flow reaches its peak due to the low circuit resistance. Also, the injector

closes faster when the driver turns OFF because of the lower holding current.

THE TWO WAYS INJECTOR CIRCUITS ARE WIRED

NOTE:Never apply battery voltage directly across a low resistance injector. T his will cause injector dam age

from solenoid coil overheating.

NOTE:Never apply battery voltage directly across a low resistance injector. T his will cause injector dam age

from solenoid coil overheating.

Page 5 of 19 MITCHELL 1 ARTICLE - GENERAL INFORMATION Waveforms - Injector Pattern Tutorial

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 335 of 454

Back To Article

1991-92 AIR CONDIT IONING & HEAT ING

A/C System General Servicing

HANDLING/SAFETY PRECAUTIONS

1. Always work in a well-ventilated, clean area. Refrigerant R-134a is colorless and is invisible as a gas. Refrigerant (R-12 or R-134a) is

heavier than oxygen and will displace oxygen in a confined area. Avoid breathing refrigerant vapors. Exposure may irritate eyes, nose

and throat.

2. The system's high pressure can cause severe injury to eyes and skin if a hose were to burst. Always wear eye protection when working

around A/C system and refrigerant. If necessary, wear rubber gloves or other protective clothing.

3. Refrigerant evaporates quickly when exposed to atmosphere, freezing anything it contacts. If liquid refrigerant contacts eyes or skin, DO

NOT rub eyes or skin. Immediately flush affected area with cool water for 15 minutes and consult a doctor or hospital.

4. Never use R-134a in combination with compressed air for leak testing. Pressurized R-134a in the presence of oxygen (air concentrations

greater than 60% by volume) may form a combustible mixture. DO NOT introduce compressed air into R-134a containers (full or

empty), A/C system components or service equipment.

5. DO NOT expose A/C system components to high temperatures, steam cleaning for example, as excessive heat will cause

refrigerant/system pressure to increase. Never expose refrigerant directly to open flame. If refrigerant needs to be warmed, place bottom

of refrigerant tank in warm water. Water temperature MUST NOT exceed 125°F (52°C).

6. Use care when handling refrigerant containers. DO NOT drop, strike, puncture or incinerate containers. Use Department Of

Transportation (DOT) approved, DOT 4BW or DOT 4BA, refrigerant containers.

7. Never overfill refrigerant containers. The safe filling level of a refrigerant container MUST NOT exceed 60% of the container's gross

weight rating. Store refrigerant containers at temperature less than 125°F (52°C).

8. R-12 refrigerant (Freon) will be sold and stored in White containers, while R-134a refrigerant will be sold and stored in 30- or 50-

pound Light Blue containers.

9. R-12 and R-134a refrigerants must never be mixed, as their desiccants and lubricants are not compatible. If the refrigerants are mixed,

system cross-contamination or A/C system component failure may occur. Always use separate servicing and refrigerant

recovery/recycling equipment.

10. Follow equipment manufacturer instructions of all service equipment to be used. The Material Safety Data Sheet (MSDS), provided by

refrigerant manufacturer/suppliers, contains valuable information regarding the safe handling of R-12 or R-134a refrigerants.

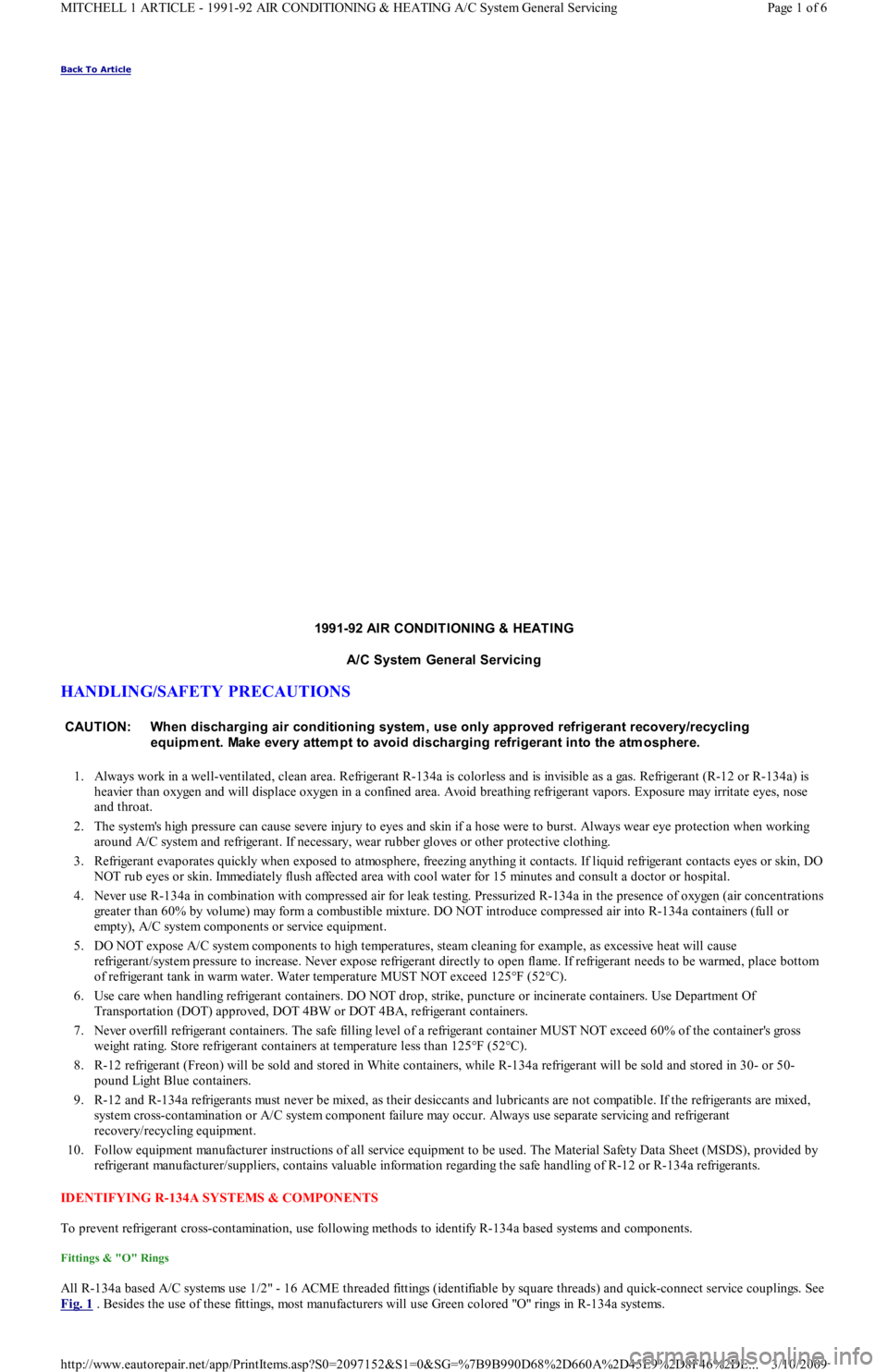

IDENTIFYING R-134A SYSTEMS & COMPONENTS

To prevent refrigerant cross-contamination, use following methods to identify R-134a based systems and components.

Fittings & "O" Rings

All R-134a based A/C systems use 1/2" - 16 ACME threaded fittings (identifiable by square threads) and quick-connect service couplings. See

Fig. 1

. Besides the use of these fittings, most manufacturers will use Green colored "O" rings in R-134a systems. CAUT ION: When discharging air conditioning system , use only approved refrigerant recovery/recycling

equipm ent. Make every attem pt to avoid discharging refrigerant into the atm osphere.

Page 1 of 6 MITCHELL 1 ARTICLE - 1991-92 AIR CONDITIONING & HEATING A/C System General Servicing

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 336 of 454

Fig. 1: Identifying R

-134a Fittings & Quick Connect Service Couplings

Courtesy of AUDI OF AMERICA, INC.

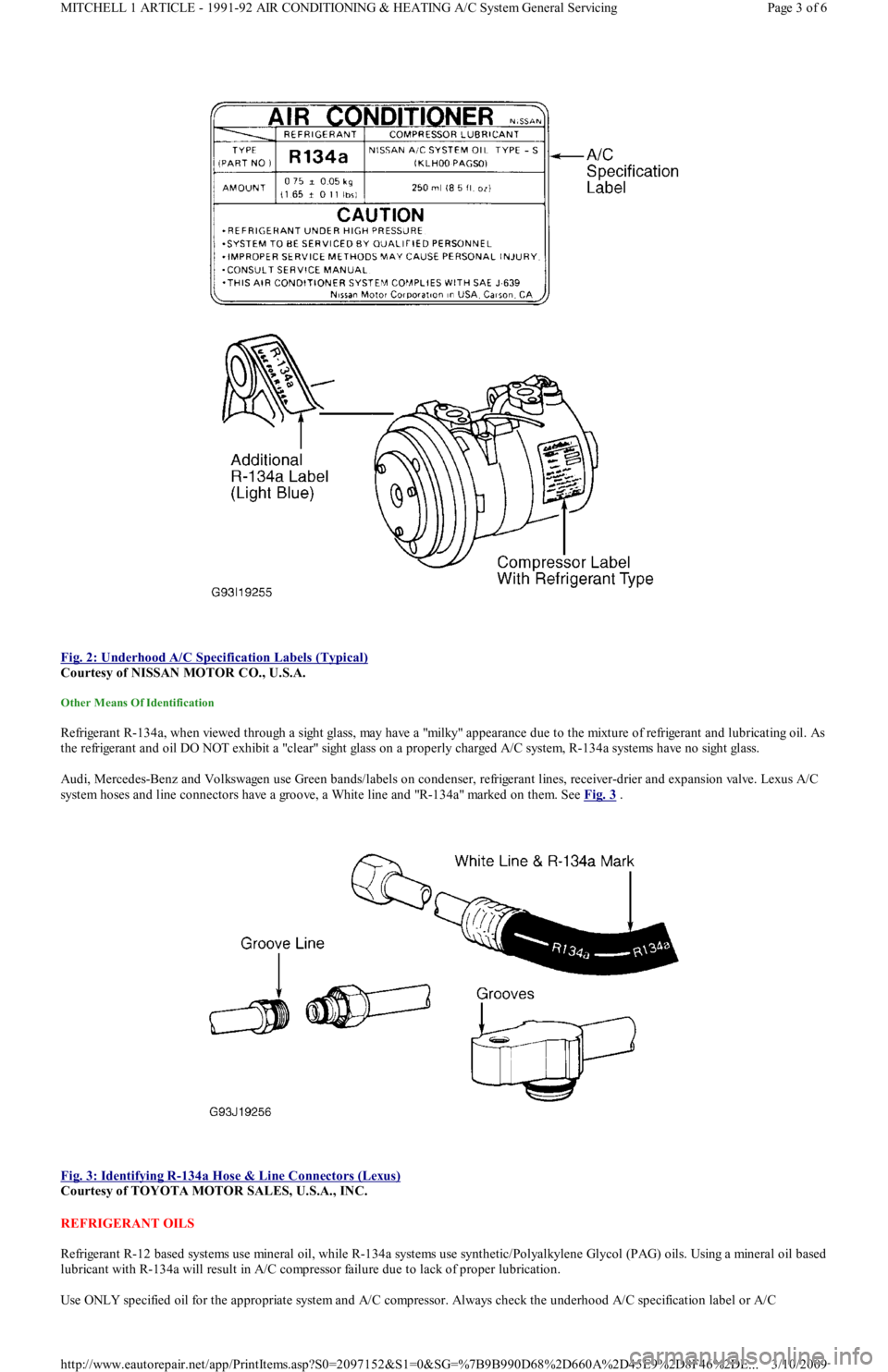

Underhood A/C Specification Labels

Most R-134a based systems will be identified through the use of Green or Light Blue underhood labels, or with R-134a refrigerant clearly

printed on labels. See Fig. 2 . Some manufacturers will identify R-12 based systems with White, Red, Silver or Gold underhood labels. Before

servicing an A/C system, always determine which refrigerant is being used.

Page 2 of 6 MITCHELL 1 ARTICLE - 1991-92 AIR CONDITIONING & HEATING A/C System General Servicing

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 337 of 454

Fig. 2: Underhood A/C Specification Labels (Typical)

Courtesy of NISSAN MOTOR CO., U.S.A.

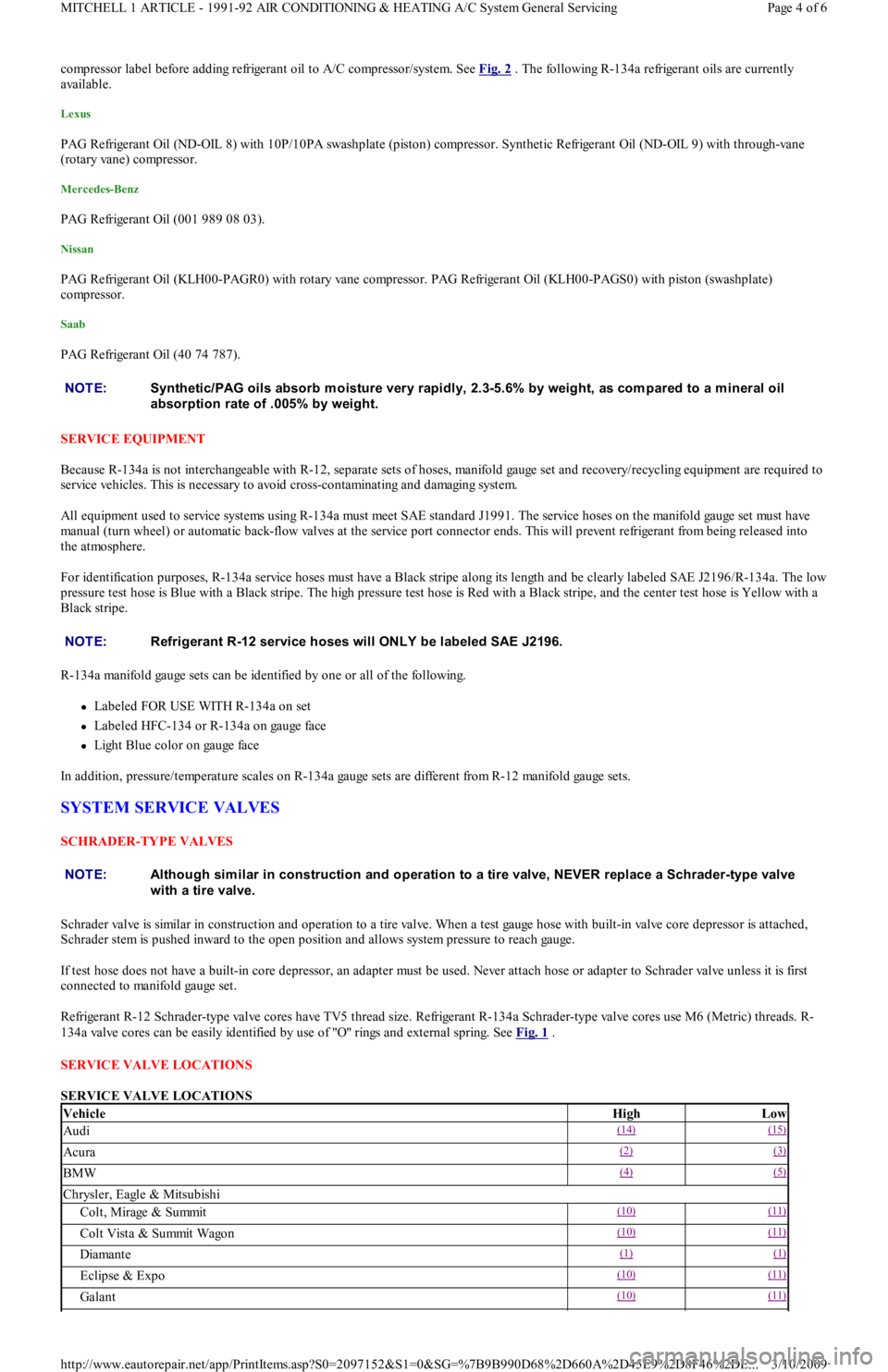

Other Means Of Identification

Refrigerant R-134a, when viewed through a sight glass, may have a "milky" appearance due to the mixture of refrigerant and lubricating oil. As

the refrigerant and oil DO NOT exhibit a "clear" sight glass on a properly charged A/C system, R-134a systems have no sight glass.

Audi, Mercedes-Benz and Volkswagen use Green bands/labels on condenser, refrigerant lines, receiver-drier and expansion valve. Lexus A/C

system hoses and line connectors have a groove, a White line and "R-134a" marked on them. See Fig. 3

.

Fig. 3: Identifying R

-134a Hose & Line Connectors (Lexus)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

REFRIGERANT OILS

Refrigerant R-12 based systems use mineral oil, while R-134a systems use synthetic/Polyalkylene Glycol (PAG) oils. Using a mineral oil based

lubricant with R-134a will result in A/C compressor failure due to lack of proper lubrication.

Use ONLY specified oil for the appropriate system and A/C compressor. Always check the underhood A/C specification label or A/C

Page 3 of 6 MITCHELL 1 ARTICLE - 1991-92 AIR CONDITIONING & HEATING A/C System General Servicing

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 338 of 454

compressor label before adding refrigerant oil to A/C compressor/system. See Fig. 2 . The following R-134a refrigerant oils are currently

available.

Lexus

PAG Refrigerant Oil (ND-OIL 8) with 10P/10PA swashplate (piston) compressor. Synthetic Refrigerant Oil (ND-OIL 9) with through-va n e

(rotary vane) compressor.

Mercedes-Benz

PAG Refrigerant Oil (001 989 08 03).

Nissan

PAG Refrigerant Oil (KLH00-PAGR0) with rotary vane compressor. PAG Refrigerant Oil (KLH00-PAGS0) with piston (swashplate)

compressor.

Saab

PAG Refrigerant Oil (40 74 787).

SERVICE EQUIPMENT

Because R-134a is not interchangeable with R-12, separate sets of hoses, manifold gauge set and recovery/recycling equipment are required to

service vehicles. This is necessary to avoid cross-contaminating and damaging system.

All equipment used to service systems using R-134a must meet SAE standard J1991. The service hoses on the manifold gauge set must have

manual (turn wheel) or automatic back-flow valves at the service port connector ends. This will prevent refrigerant from being released into

the atmosphere.

For identification purposes, R-134a service hoses must have a Black stripe along its length and be clearly labeled SAE J2196/R-134a. The low

pressure test hose is Blue with a Black stripe. The high pressure test hose is Red with a Black stripe, and the center test hose is Yellow with a

Black stripe.

R-134a manifold gauge sets can be identified by one or all of the following.

Labeled FOR USE WITH R-134a on set

Labeled HFC-134 or R-134a on gauge face

Light Blue color on gauge face

In addition, pressure/temperature scales on R-134a gauge sets are different from R-12 manifold gauge sets.

SYSTEM SERVICE VALVES

SCHRADER-TYPE VALVES

Schrader valve is similar in construction and operation to a tire valve. When a test gauge hose with built-in valve core depressor is attached,

Schrader stem is pushed inward to the open position and allows system pressure to reach gauge.

If test hose does not have a built-in core depressor, an adapter must be used. Never attach hose or adapter to Schrader valve unless it is first

connected to manifold gauge set.

Refrigerant R-12 Schrader-type valve cores have TV5 thread size. Refrigerant R-134a Schrader-type valve cores use M6 (Metric) threads. R-

134a valve cores can be easily identified by use of "O" rings and external spring. See Fig. 1

.

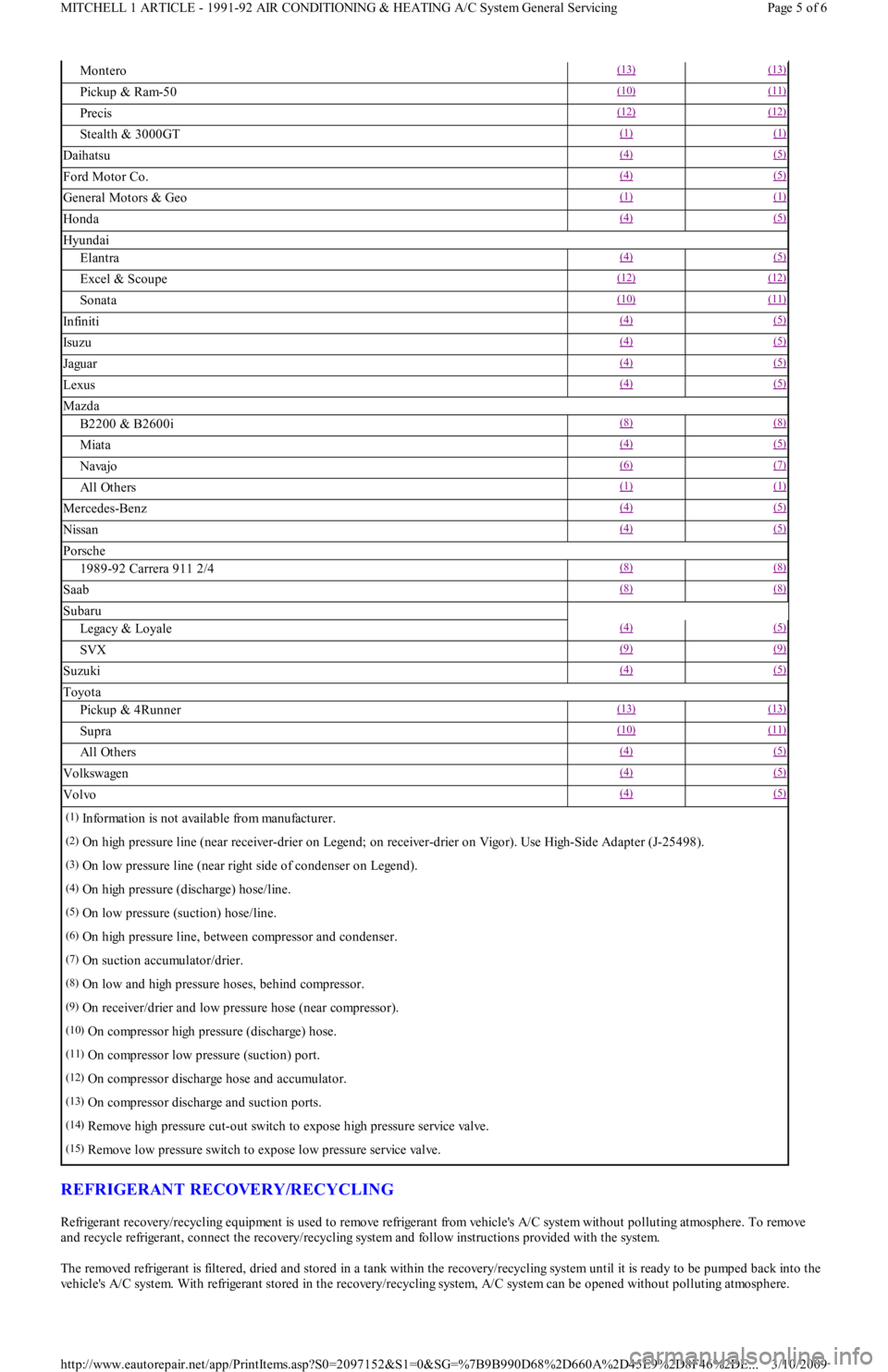

SERVICE VALVE LOCATIONS

SERVICE VALVE LOCATIONS NOTE:Synthetic/PAG oils absorb m oisture very rapidly, 2.3-5.6% by weight, as com pared to a m ineral oil

absorption rate of .005% by weight.

NOTE:Refrigerant R-12 service hoses will ONLY be labeled SAE J2196.

NOTE:Although sim ilar in construction and operation to a tire valve, NEVER replace a Schrader-type valve

with a tire valve.

VehicleHighLow

Audi(14) (15)

Acura(2) (3)

BMW(4) (5)

Chrysler, Eagle & Mitsubishi

Colt, Mirage & Summit(10) (11)

Colt Vista & Summit Wagon(10) (11)

Diamante(1) (1)

Eclipse & Expo(10) (11)

Galant(10) (11)

Page 4 of 6 MITCHELL 1 ARTICLE - 1991-92 AIR CONDITIONING & HEATING A/C System General Servicing

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 339 of 454

REFRIGERANT RECOVERY/RECYCLING

Refrigerant recovery/recycling equipment is used to remove refrigerant from vehicle's A/C system without polluting atmosphere. To remove

and recycle refrigerant, connect the recovery/recycling system and follow instructions provided with the system.

The removed refrigerant is filtered, dried and stored in a tank within the recovery/recycling system until it is ready to be pumped back into the

vehicle's A/C system. With refrigerant stored in the recovery/recycling system, A/C system can be opened without polluting atmosphere.

Montero(13) (13)

Pickup & Ram-50(10) (11)

Precis(12) (12)

Stealth & 3000GT(1) (1)

Daihatsu(4) (5)

Ford Motor Co.(4) (5)

General Motors & Geo(1) (1)

Honda(4) (5)

Hyundai

Elantra(4) (5)

Excel & Scoupe(12) (12)

Sonata(10) (11)

In fin it i(4) (5)

Isu zu(4) (5)

Jaguar(4) (5)

Lexus(4) (5)

Mazda

B2200 & B2600i(8) (8)

Miata(4) (5)

Navajo(6) (7)

All Others(1) (1)

Mercedes-Benz(4) (5)

Nissan(4) (5)

Porsche

1989-92 Carrera 911 2/4(8) (8)

Saab(8) (8)

Subaru

Legacy & Loyale(4) (5)

SVX(9) (9)

Suzuki(4) (5)

Toyota

Pickup & 4Runner(13) (13)

Supra(10) (11)

All Others(4) (5)

Volkswagen(4) (5)

Volvo(4) (5)

(1)Information is not available from manufacturer.

(2)On high pressure line (near receiver-drier on Legend; on receiver-drier on Vigor). Use High-Side Adapter (J-25498).

(3)On low pressure line (near right side of condenser on Legend).

(4)On high pressure (discharge) hose/line.

(5)On low pressure (suction) hose/line.

(6)On high pressure line, between compressor and condenser.

(7)On suction accumulator/drier.

(8)On low and high pressure hoses, behind compressor.

(9)On receiver/drier and low pressure hose (near compressor).

(10)On compressor high pressure (discharge) hose.

(11)On compressor low pressure (suction) port.

(12)On compressor discharge hose and accumulator.

(13)On compressor discharge and suction ports.

(14)Remove high pressure cut-out switch to expose high pressure service valve.

(15)Remove low pressure switch to expose low pressure service valve.

Page 5 of 6 MITCHELL 1 ARTICLE - 1991-92 AIR CONDITIONING & HEATING A/C System General Servicing

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 340 of 454

NOTE:Separate sets of hoses, gauges and refrigerant recovery/recycling equipm ent MUST be used for R-12

and R-134a based system s. DO NOT m ix R-12 and R-134a refrigerants, as their refrigerant oils and

desiccants are NOT com patible. On system s with R-134a refrigerant, use Polyalkylene Glycol (PAG)

wax-free refrigerant oil.

Copyr ight 2009 Mitchell Repair Information Company, LLC. All Rights Reserved.

Article GUID: A00039025

Page 6 of 6 MITCHELL 1 ARTICLE - 1991-92 AIR CONDITIONING & HEATING A/C System General Servicing

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 349 of 454

Back To Article

1991 AIR CONDIT IONING & HEAT

MANUAL A/C

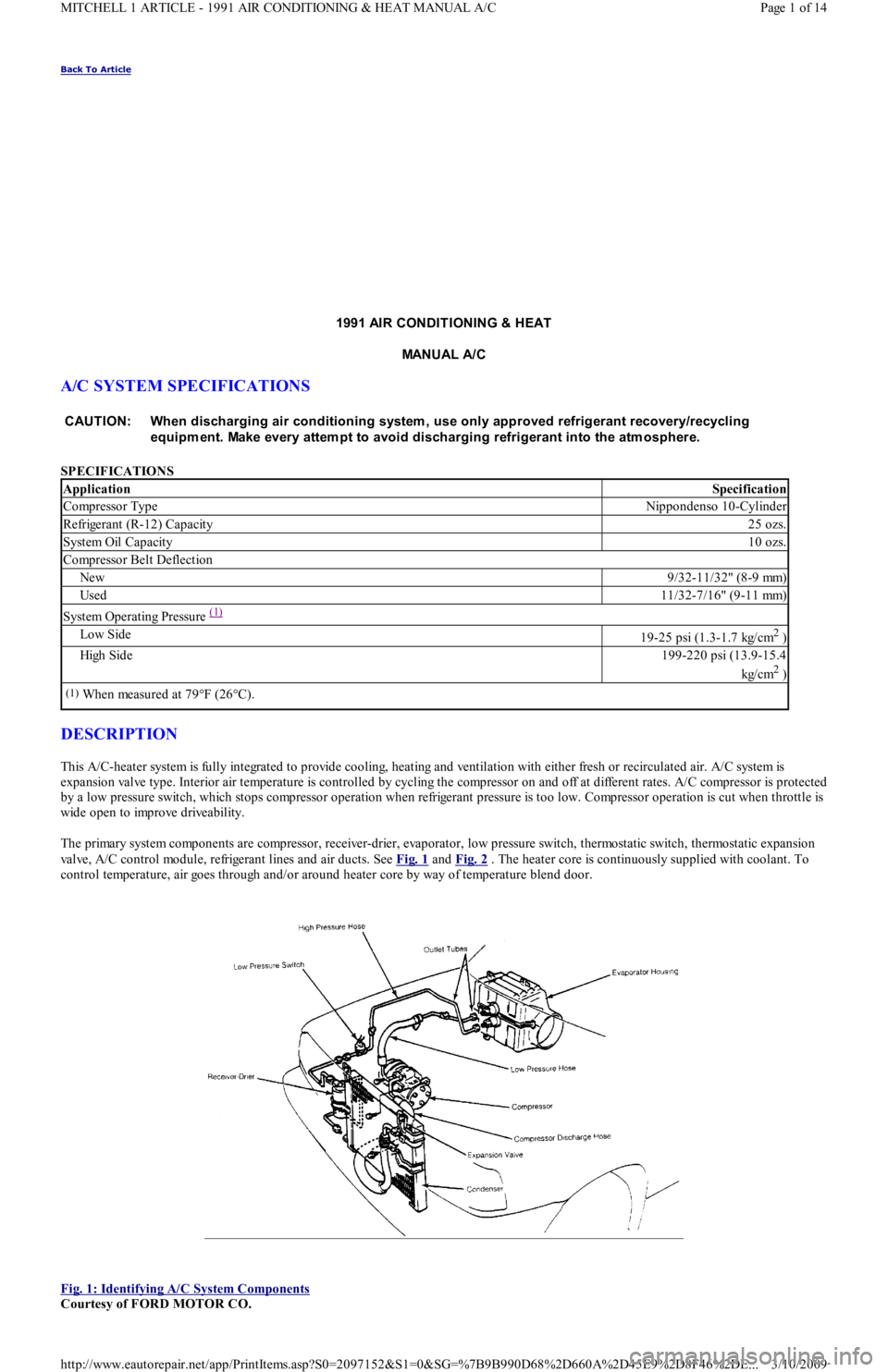

A/C SYSTEM SPECIFICATIONS

SPECIFICATIONS

DESCRIPTION

This A/C-heater system is fully integrated to provide cooling, heating and ventilation with either fresh or recirculated air. A/C system is

expansion valve type. Interior air temperature is controlled by cycling the compressor on and off at different rates. A/C compressor is protected

by a low pressure switch, which stops compressor operation when refrigerant pressure is too low. Compressor operation is cut when throttle is

wide open to improve driveability.

The primary system components are compressor, receiver-drier, evaporator, low pressure switch, thermostatic switch, thermostatic expansion

valve, A/C control module, refrigerant lines and air ducts. See Fig. 1

and Fig. 2 . The heater core is continuously supplied with coolant. To

control temperature, air goes through and/or around heater core by way of temperature blend door.

Fig. 1: Identifying A/C System Components

Courtesy of FORD MOTOR CO. CAUT ION: When discharging air conditioning system , use only approved refrigerant recovery/recycling

equipm ent. Make every attem pt to avoid discharging refrigerant into the atm osphere.

ApplicationSpecification

Compressor TypeNippondenso 10-Cylinder

Refrigerant (R-12) Capacity25 ozs.

System Oil Capacity10 ozs.

Compressor Belt Deflection

New9/32-11/32" (8-9 mm)

Used11/32-7/16" (9-11 mm)

System Operating Pressure (1)

Low Side19-25 psi (1.3-1.7 kg/cm2 )

High Side199-220 psi (13.9-15.4

kg/cm

2 )

(1)When measured at 79°F (26°C).

Page 1 of 14 MITCHELL 1 ARTICLE - 1991 AIR CONDITIONING & HEAT MANUAL A/C

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 439 of 454

1. Inspect wiring and components for shorts, corrosion, overheating, loose connections, or any other damage. Check 10-amp METER fu se.

Disconnect downshift solenoid.

2. With key off, voltage measured at Black/Blue wire should be zero volts. With key on and accelerator pedal fully depressed, voltage

should be greater than 10 volts. If Black/Blue wire is okay, remove downshift solenoid.

3. Apply battery voltage to downshift solenoid connector and ground case. Control rod should move freely when solenoid case is

grounded. If control rod does not move freely, replace downshift solenoid.

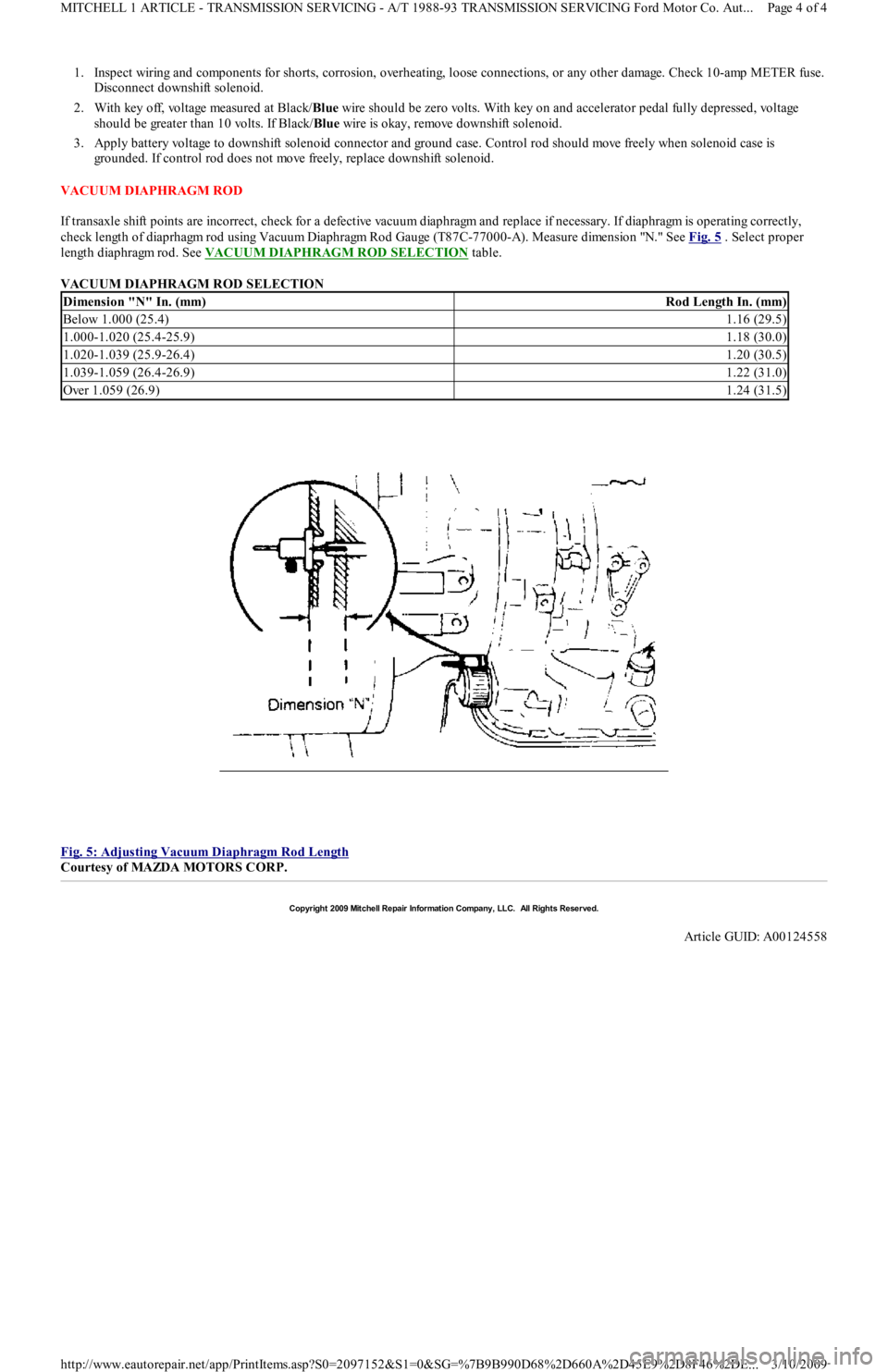

VACUUM DIAPHRAGM ROD

If transaxle shift points are incorrect, check for a defective vacuum diaphragm and replace if necessary. If diaphragm is operating correctly,

check length of diaprhagm rod using Vacuum Diaphragm Rod Gauge (T87C-77000-A). Measure dimension "N." See Fig. 5

. Select proper

length diaphragm rod. See VACUUM DIAPHRAGM ROD SELECTION

table.

VACUUM DIAPHRAGM ROD SELECTION

Fig. 5: Adjusting Vacuum Diaphragm Rod Length

Courtesy of MAZDA MOTORS CORP.

Dimension "N" In. (mm)Rod Length In. (mm)

Below 1.000 (25.4)1.16 (29.5)

1.000-1.020 (25.4-25.9)1.18 (30.0)

1.020-1.039 (25.9-26.4)1.20 (30.5)

1.039-1.059 (26.4-26.9)1.22 (31.0)

Over 1.059 (26.9)1.24 (31.5)

Copyr ight 2009 Mitchell Repair Information Company, LLC. All Rights Reserved.

Article GUID: A00124558

Page 4 of 4 MITCHELL 1 ARTICLE - TRANSMISSION SERVICING - A/T 1988-93 TRANSMISSION SERVICING Ford Motor Co. Aut

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...