engine coolant FORD FESTIVA 1991 Owner's Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1991, Model line: FESTIVA, Model: FORD FESTIVA 1991Pages: 454, PDF Size: 9.53 MB

Page 170 of 454

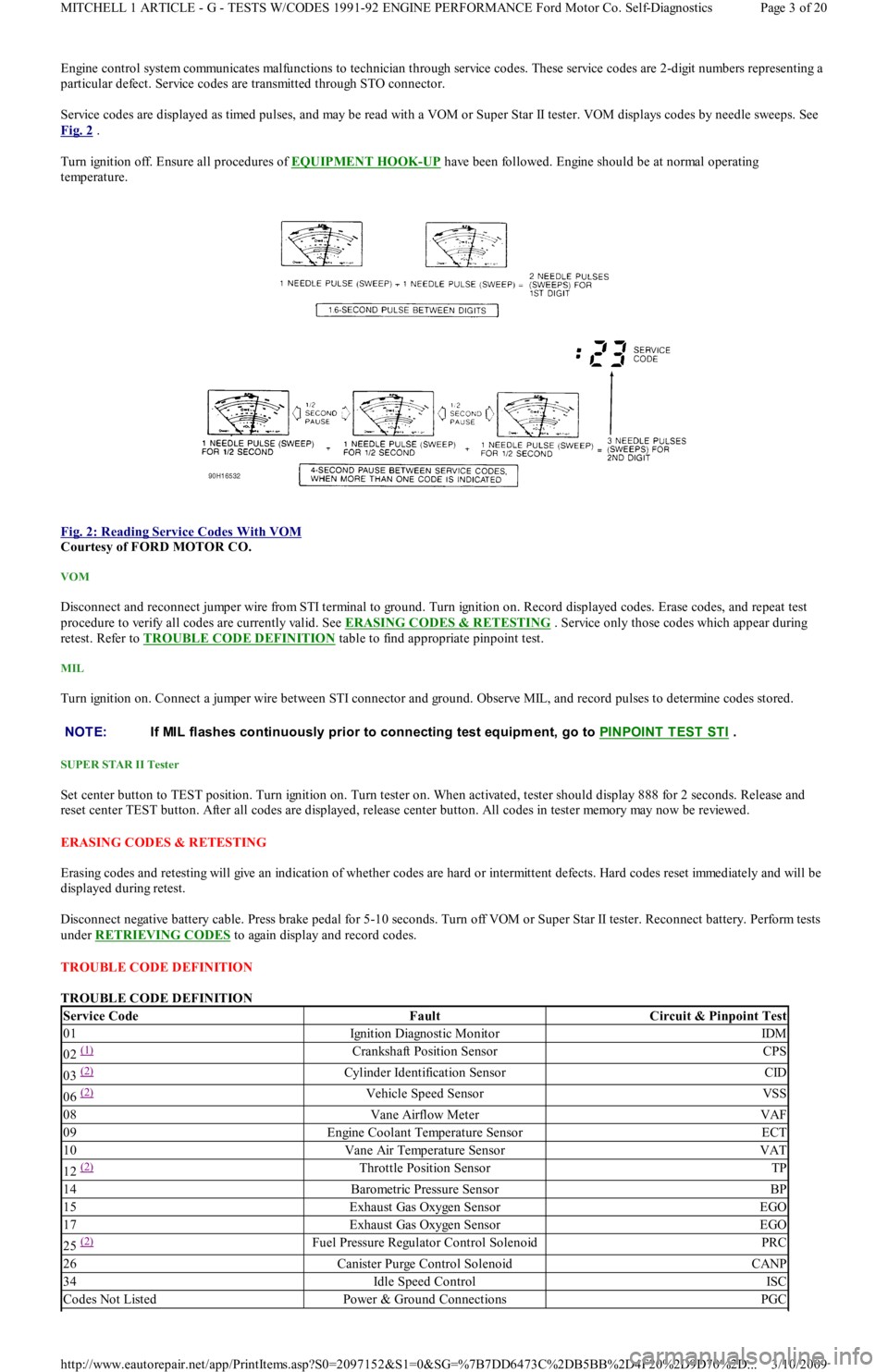

Engine control system communicates malfunctions to technician through service codes. These service codes are 2-digit numbers representing a

particular defect. Service codes are transmitted through STO connector.

Service codes are displayed as timed pulses, and may be read with a VOM or Super Star II tester. VOM displays codes by needle sweeps. See

Fig. 2

.

Turn ignition off. Ensure all procedures of EQUIPMENT HOOK

-UP have been followed. Engine should be at normal operating

temperature.

Fig. 2: Reading Service Codes With VOM

Courtesy of FORD MOTOR CO.

VOM

Disconnect and reconnect jumper wire from STI terminal to ground. Turn ignition on. Record displayed codes. Erase codes, and repeat test

procedure to verify all codes are currently valid. See ERASING CODES & RETESTING . Service only those codes which appear during

retest. Refer to TROUBLE CODE DEFINITION

table to find appropriate pinpoint test.

MIL

Turn ignition on. Connect a jumper wire between STI connector and ground. Observe MIL, and record pulses to determine codes stored.

SUPER STAR II Tester

Set center button to TEST position. Turn ignition on. Turn tester on. When activated, tester should display 888 for 2 seconds. Release and

reset center TEST button. After all codes are displayed, release center button. All codes in tester memory may now be reviewed.

ERASING CODES & RETESTING

Erasing codes and retesting will give an indication of whether codes are hard or intermittent defects. Hard codes reset immediately and will be

displayed during retest.

Disconnect negative battery cable. Press brake pedal for 5-10 seconds. Turn off VOM or Super Star II tester. Reconnect battery. Perform tests

under RETRIEVING CODES

to again display and record codes.

TROUBLE CODE DEFINITION

TROUBLE CODE DEFINITION

NOTE:If MIL flashes continuously prior to connecting test equipm ent, go to PINPOINT T EST ST I .

Service CodeFaultCircuit & Pinpoint Test

01Ignition Diagnostic MonitorIDM

02 (1) Crankshaft Position SensorCPS

03 (2) Cylinder Identification SensorCID

06 (2) Vehicle Speed SensorVSS

08Vane Airflow MeterVAF

09Engine Coolant Temperature SensorECT

10Vane Air Temperature SensorVAT

12 (2) Throttle Position SensorTP

14Barometric Pressure SensorBP

15Exhaust Gas Oxygen SensorEGO

17Exhaust Gas Oxygen SensorEGO

25 (2) Fuel Pressure Regulator Control SolenoidPRC

26Canister Purge Control SolenoidCANP

34Idle Speed ControlISC

Codes Not ListedPower & Ground ConnectionsPGC

Page 3 of 20 MITCHELL 1 ARTICLE - G - TESTS W/CODES 1991-92 ENGINE PERFORMANCE Ford Motor Co. Self-Diagnostics

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 171 of 454

CLEARING CODES

Clearing Codes Procedure

Disconnect negative battery cable. Press brake pedal for 5-10 seconds. Turn off VOM or Super Star II tester. Reconnect battery.

ECA LOCATION

ECA is located on center console behind kick panel on Capri, and under instrument panel on driver side of Festiva.

QUICK TESTS

KEY ON, ENGINE OFF (KOEO) SELF-TEST

KOEO

1. This is a test of electronic engine control system, conducted with power (voltage) applied and engine not running. Activate self-test, and

record all codes displayed.

2. Erase codes, and repeat self-test. Diagnose only codes occurring during repeat self-test. See TROUBLE CODE DEFINITION

table. If

no codes are present, proceed to KEY ON, ENGINE RUNNING (KOER) SELF

-TEST .

KEY ON, ENGINE RUNNING (KOER) SELF-TEST

KOER

1. Deactivate self-test. Start and run engine at 2000 RPM for 2 minutes to warm up EGO sensor. Turn off engine and wait 10 seconds.

2. Restart engine, and activate self-test. Record all service codes displayed. See TROUBLE CODE DEFINITION

table. If no codes are

present, proceed to SWITCH MONITOR TEST

.

SWITCH MONITOR TEST

This test procedure checks input signals received by ECA from individual switches. Use following procedure to perform switch monitor test:

Turn engine off and allow it to cool.

Ensure all accessories are turned off.

Deactivate self-test.

Ensure transmission is in Neutral or Park.

Turn ignition on.

SUPER STAR II Tester

Connect Super Star II tester adapter cable. Turn on tester. Latch center button. Operate each switch listed in SWITCH MONITOR TEST

table. Note output of LED on adapter cable as each switch operates. Record test results.

VOM

1. Ground STI connector. Connect VOM positive lead to SML terminal on self-test connector. Connect negative lead to ground. See Fig.

1 .

2. Operate each switch listed in SWITCH MONITOR TEST

table. Note output on VOM as each switch is operated. Go to specified

PINPOINT TEST if any switch does not meet specification.

SWITCH MONITOR TEST

(1)Festiva only.

(2)Capri only.

NOTE:DO NOT m ove throttle during KOEO self-test.

NOTE:It is necessary to clear codes in m em ory before perform ing this test. DO NOT m ove throttle during test.

NOTE:All switches m ust be tested individually. Allowing a switch to rem ain on while testing another will lead

to false test results.

NOTE:DO NOT m ove throttle, clutch, or transm ission lever unless so directed.

SwitchVOM Indication/Condition(1) Pinpoint Test

A/C SwitchLess Than 1.5 Volts; A/C & Blower Switch OnSTG

Blower Motor SwitchLess Than 1.5 Volts; Switch Set To "2" Or HigherSTG

Brake On/Off SwitchLess Than 1.5 Volts; Brake Pedal Partially

PressedSTP

Clutch Engage/Neutral Gear Switch (2) Less Than 1.5 Volts; In Gear, Clutch ReleasedSTG

Coolant Temperature SwitchLess Than 1.5 Volts; Cooling Fan OnSTP

Defrost SwitchLess Than 1.5 Volts; Defrost Switch OnSTP

Headlight SwitchLess Than 1.5 Volts; Headlight Switch OnSTP

Id l e Swit chLess Than 1.5 Volts; Accelerator Pedal PressedSTG

Page 4 of 20 MITCHELL 1 ARTICLE - G - TESTS W/CODES 1991-92 ENGINE PERFORMANCE Ford Motor Co. Self-Diagnostics

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 177 of 454

connector while moving vane in VAF meter. Voltage should be as specified in VAF METER VOLTAGE table. If voltage is okay,

repair VAF wire to ECA. If voltage is not okay, go to next step.

VAF METER VOLTAGE

4. Unplug connector from VAF. Using jumper wires, connect VPWR and SIGRTN terminals on VAF connector to corresponding terminals

on VAF meter. Leave VAF and VMREF wires disconnected. Measure voltage between VAF terminal at VAF meter, and SIGRTN pin at

harness connector while moving vane in VAF meter. Voltage should be as specified in VAF METER VOLTAGE

table. If voltage is

okay, repair VMREF wire to ECA. If voltage is not okay, go to next step.

5. Unplug connector from VAF meter. Turn ignition on. Measure voltage between SIGRTN and VPWR wire. If voltage is more than 10

volts, replace VAF meter. If voltage is not more than 10 volts, go to next step.

6. Unplug VAF meter connector. Turn ignition on. Measure voltage between VAF meter VPWR wire and ground. If voltage is more than

10 volts, repair VAF wire to ECA. If voltage is not more than 10 volts, go to PINPOINT TEST VPWR.

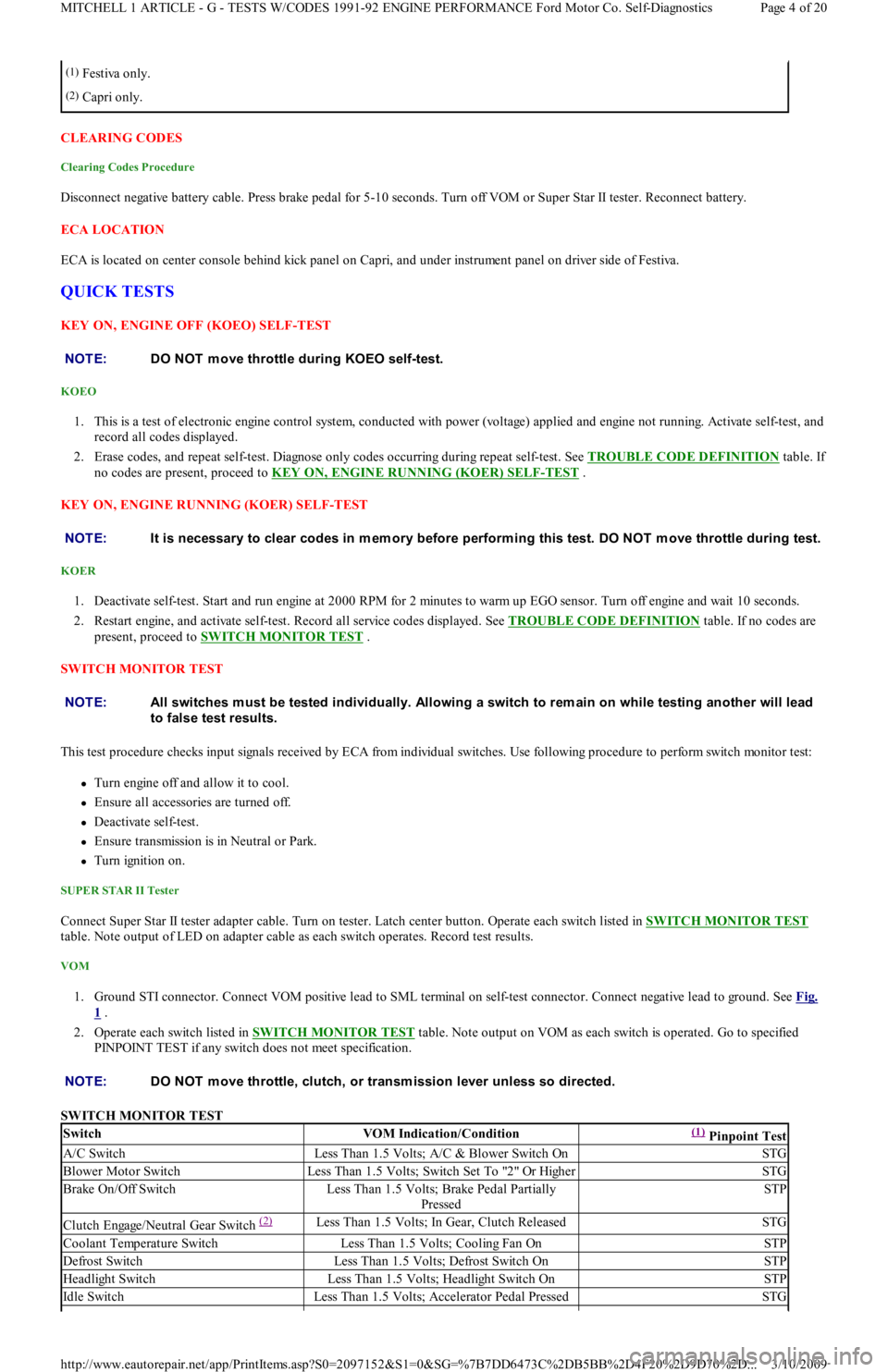

PINPOINT TEST ECT - ENGINE COOLANT TEMPERATURE SENSOR

Fig. 9: Identifying ECT Sensor Circuits

ECT CIRCUIT PIN IDENTIFICATION

1.3L

1. Turn ignition off. Install BOB. Leave ECA disconnected. Unplug ECT connector. Check for continuity between ECT test pin and ECT

terminal (Red/Blue wire) on ECT harness connector. If continuity does not exist, repair ECT wire between ECA and ECT sensor. If

continuity exists, go to next step.

2. Unplug ECT sensor. Check for continuity between Black wire at ECT sensor and ground. If continuity does not exist, repair Black wire

between ECT sensor and ground. If continuity exists, go to next step.

3. Reconnect ECA. Measure resistance between BOB ECT test pin and ground pin. If resistance is 500-1000 ohms, replace ECA. If

resistance is not 500-1000 ohms, replace ECT sensor.

1.6L

1. Turn ignition off. Install BOB. Leave ECA disconnected. Unplug ECT connector. Check for continuity between ECT test pin and ECT

terminal (Blue/Red wire) on ECT harness connector. If continuity does not exist, repair ECT wire between ECA and ECT sensor. If

Door PositionVolts

1/8 Open3.24

1/4 Open5.60

3/8 Open5.62

1/2 Open5.83

5/8 Open6.02

3/4 Open6.57

7/8 Open7.46

Full Open7.87

NOTE:Enter this test only when a Code 09 is displayed during QUICK T EST S procedure or when directed here

from another PINPOINT T EST . T o prevent unnecessary diagnosis, inspect coolant level, oil level,

cooling fan, therm ostat, and airflow to radiator before testing.

CircuitECA PinBOB PinWire Color

1.3L

ECT2Q7RED/BLU

GND(1) (1) BLK

1.6L

ECT2I7BLU/RED

SIGRTN2C46BLU/YEL

(1)Not specified.

Page 10 of 20 MITCHELL 1 ARTICLE - G - TESTS W/CODES 1991-92 ENGINE PERFORMANCE Ford Motor Co. Self-Diagnostics

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 189 of 454

Check vane airflow meter.

Check idle speed control solenoid.

Check pressure regulator control solenoid.

Check heated exhaust gas oxygen sensor.

Check engine coolant temperature sensor.

Check A/C load control solenoid.

STUMBLE/HESITATION DURING ACCELERATION

Check throttle position switch.

Check vane airflow meter.

Check canister purge solenoid.

Check heated exhaust gas oxygen sensor.

Check wide open throttle A/C (WAC) relay.

Check A/C thermostatic switch.

MISSES/SURGES

Check exhaust gas oxygen sensor.

Check throttle position switch.

Check vane airflow meter.

Check wide open throttle vacuum switch.

Check A/C load control solenoid.

Check engine coolant temperature sensor.

IDLE IS FAST/SLOW RETURN TO IDLE

Check idle speed control solenoid.

Check by-pass air control valve.

Check engine coolant temperature sensor.

Check A/C load control solenoid.

IDLE IS ROUGH

Check idle speed control solenoid.

Check A/C load control solenoid.

Check by-pass air control valve.

Check throttle position switch.

Check vane airflow meter.

Check vane air temperature sensor.

Check canister purge solenoid.

Check engine cooling fan.

Check headlight switch.

Check blower control switch.

Check A/C thermostatic switch.

Check neutral safety switch.

Check neutral gear switch or clutch engage switch.

Check heated exhaust gas oxygen sensor.

ENGINE SPEEDS UP

Check idle speed control solenoid.

Check heated exhaust gas oxygen sensor.

Check by-pass air control valve.

CRANKS NORMALLY/NO START

Verify secondary ignition spark is present.

Verify fuel pressure is within specification.

Check vane airflow meter.

Check engine coolant temperature sensor.

CRANKS NORMALLY/SLOW TO START

Check ignition module.

Check engine coolant temperature sensor.

Check vane airflow meter.

Check evaporative emission control components.

Page 2 of 3 MITCHELL 1 ARTICLE - H - TESTS W/O CODES 1991-92 ENGINE PERFORMANCE Ford Motor Co. Trouble Shooting -

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 192 of 454

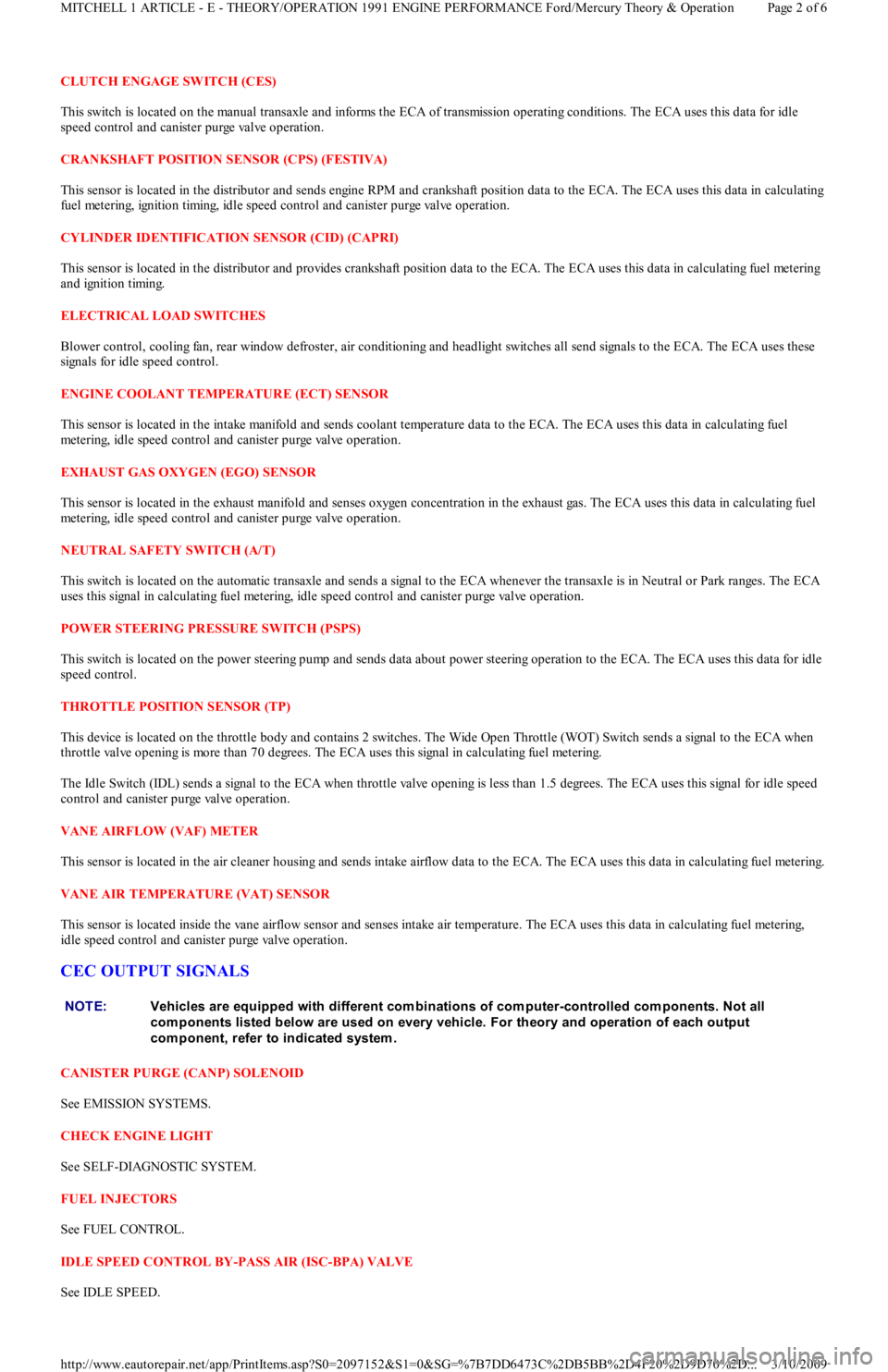

CLUTCH ENGAGE SWITCH (CES)

This switch is located on the manual transaxle and informs the ECA of transmission operating conditions. The ECA uses this data fo r id l e

speed control and canister purge valve operation.

CRANKSHAFT POSITION SENSOR (CPS) (FESTIVA)

This sensor is located in the distributor and sends engine RPM and crankshaft position data to the ECA. The ECA uses this data in calculating

fuel metering, ignition timing, idle speed control and canister purge valve operation.

CYLINDER IDENTIFICATION SENSOR (CID) (CAPRI)

This sensor is located in the distributor and provides crankshaft position data to the ECA. The ECA uses this data in calculating fuel metering

and ignition timing.

ELECTRICAL LOAD SWITCHES

Blower control, cooling fan, rear window defroster, air conditioning and headlight switches all send signals to the ECA. The ECA uses these

signals for idle speed control.

ENGINE COOLANT TEMPERATURE (ECT) SENSOR

This sensor is located in the intake manifold and sends coolant temperature data to the ECA. The ECA uses this data in calculating fuel

metering, idle speed control and canister purge valve operation.

EXHAUST GAS OXYGEN (EGO) SENSOR

This sensor is located in the exhaust manifold and senses oxygen concentration in the exhaust gas. The ECA uses this data in calculating fuel

metering, idle speed control and canister purge valve operation.

NEUTRAL SAFETY SWITCH (A/T)

This switch is located on the automatic transaxle and sends a signal to the ECA whenever the transaxle is in Neutral or Park ranges. The ECA

uses this signal in calculating fuel metering, idle speed control and canister purge valve operation.

POWER STEERING PRESSURE SWITCH (PSPS)

This switch is located on the power steering pump and sends data about power steering operation to the ECA. The ECA uses this data for idle

speed control.

THROTTLE POSITION SENSOR (TP)

This device is located on the throttle body and contains 2 switches. The Wide Open Throttle (WOT) Switch sends a signal to the ECA when

throttle valve opening is more than 70 degrees. The ECA uses this signal in calculating fuel metering.

The Idle Switch (IDL) sends a signal to the ECA when throttle valve opening is less than 1.5 degrees. The ECA uses this signal for idle speed

control and canister purge valve operation.

VANE AIRFLOW (VAF) METER

This sensor is located in the air cleaner housing and sends intake airflow data to the ECA. The ECA uses this data in calculating fuel metering.

VANE AIR TEMPERATURE (VAT) SENSOR

This sensor is located inside the vane airflow sensor and senses intake air temperature. The ECA uses this data in calculating fu el met erin g,

idle speed control and canister purge valve operation.

CEC OUTPUT SIGNALS

CANISTER PURGE (CANP) SOLENOID

See EMISSION SYSTEMS.

CHECK ENGINE LIGHT

See SELF-DIAGNOSTIC SYSTEM.

FUEL INJECTORS

See FUEL CONTROL.

IDLE SPEED CONTROL BY-PASS AIR (ISC-BPA) VALVE

See IDLE SPEED. NOTE:Vehicles are equipped with different com binations of com puter-controlled com ponents. Not all

com ponents listed below are used on every vehicle. For theory and operation of each output

com ponent, refer to indicated system .

Page 2 of 6 MITCHELL 1 ARTICLE - E - THEORY/OPERATION 1991 ENGINE PERFORMANCE Ford/Mercury Theory & Operation

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 202 of 454

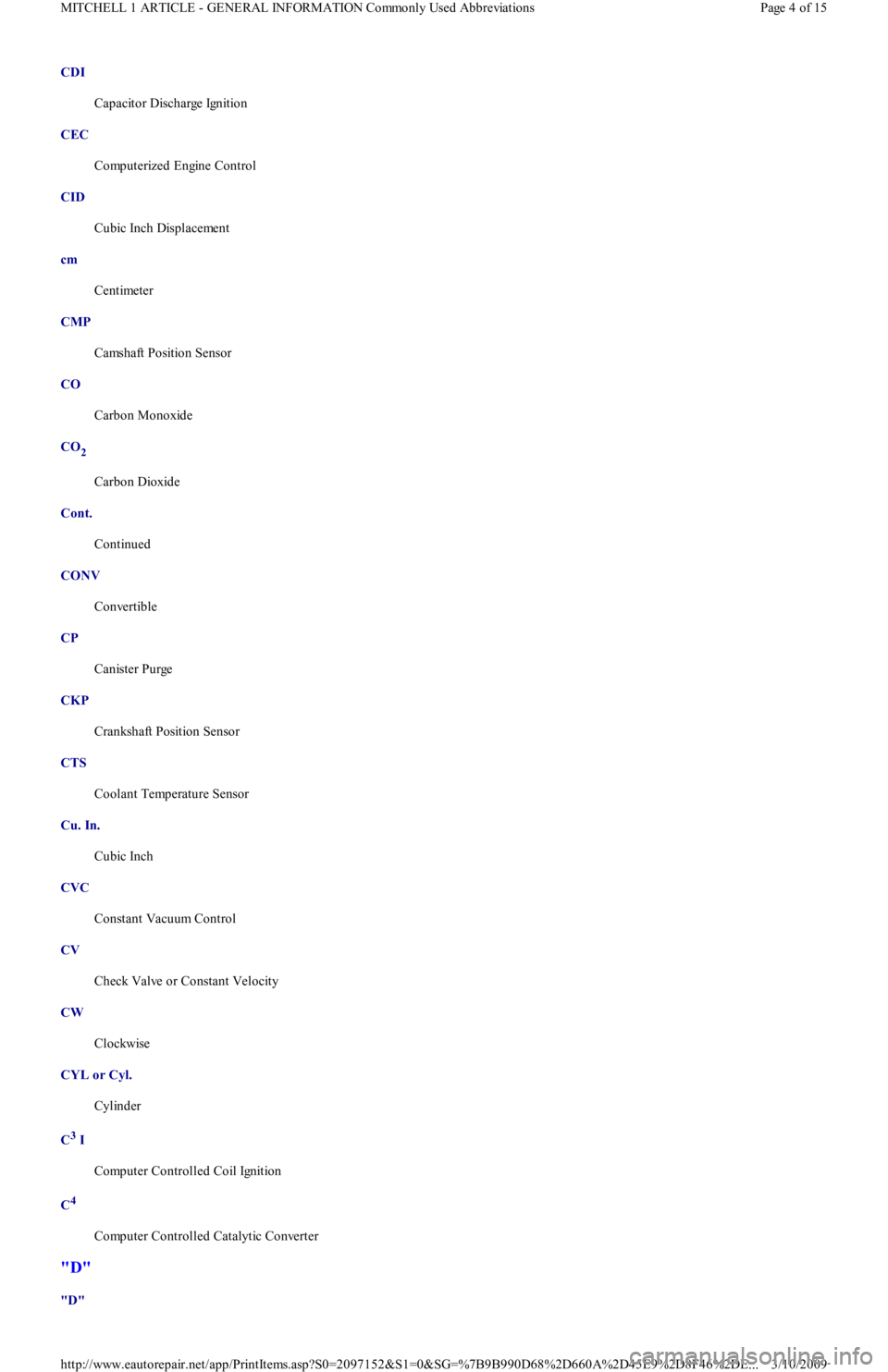

CDI

Capacitor Discharge Ignition

CEC

Computerized Engine Control

CID

Cubic Inch Displacement

cm

Centimeter

CMP

Camshaft Position Sensor

CO

Carbon Monoxide

CO

2

Carbon Dioxide

Cont.

Continued

CONV

Convertible

CP

Canister Purge

CKP

Crankshaft Position Sensor

CTS

Coolant Temperature Sensor

Cu. In.

Cubic Inch

CVC

Constant Vacuum Control

CV

Check Valve or Constant Velocity

CW

Clockwise

CYL or Cyl.

Cylinder

C

3 I

Computer Controlled Coil Ignition

C

4

Computer Controlled Catalytic Converter

"D"

"D"

Page 4 of 15 MITCHELL 1 ARTICLE - GENERAL INFORMATION Commonly Used Abbreviations

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 204 of 454

EBL

Electronic Back Light

ECM

Engine Control Module

ECT

Engine Coolant Temperature Sensor

EDIS

Electronic Distributorless Ignition System

EEC

Electronic Engine Control

EECS

Evaporative Emission Control System

EEPROM

Electronically Erasable PROM

EFE

Early Fuel Evaporation

EGO

Exhaust Gas Oxygen Sensor

EGR

Exhaust Gas Recirculation

ESA

Electronic Spark Advance

ESC

Electronic Spark Control

EST

Electronic Spark Timing

EVAP

Fuel Evaporative System

EVIC

Electronic Vehicle Information Center

EVP

EGR Valve Position Sensor

Exc.

Except

"F"

° F

Fahrenheit (Degrees)

F/B

Fuse Block

Fed.

Page 6 of 15 MITCHELL 1 ARTICLE - GENERAL INFORMATION Commonly Used Abbreviations

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 222 of 454

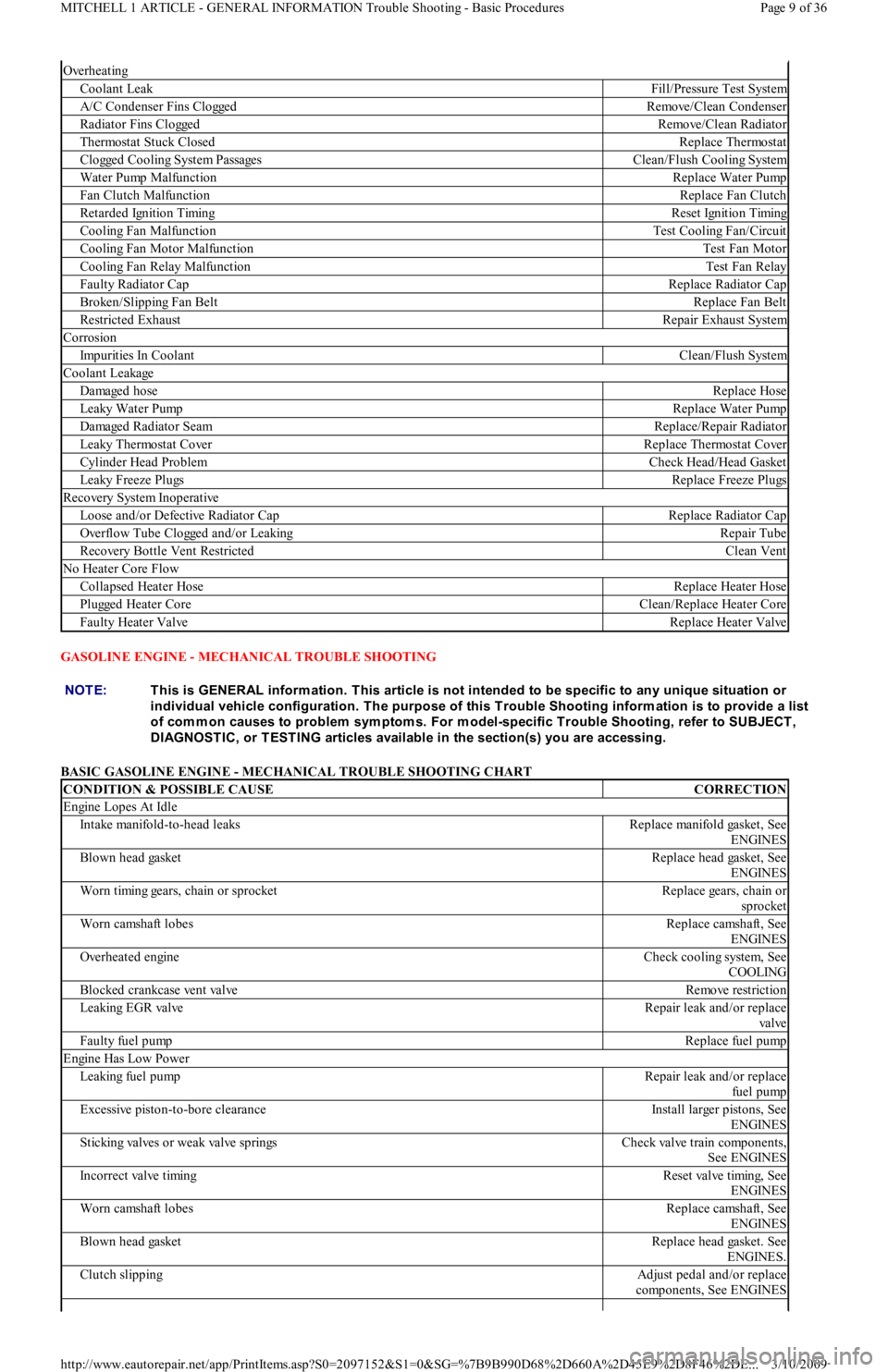

GASOLINE ENGINE - MECHANICAL TROUBLE SHOOTING

BASIC GASOLINE ENGINE - MECHANICAL TROUBLE SHOOTING CHART

Overheating

Coolant LeakFill/Pressure Test System

A/C Condenser Fins CloggedRemove/Clean Condenser

Radiator Fins CloggedRemove/Clean Radiator

Thermostat Stuck ClosedReplace Thermostat

C l o gge d C o o l in g S yst e m P a ssa ge sClean/Flush Cooling System

Water Pump MalfunctionReplace Water Pump

Fan Clutch MalfunctionReplace Fan Clutch

Retarded Ignition TimingReset Ignition Timing

Cooling Fan MalfunctionTest Cooling Fan/Circuit

Cooling Fan Motor MalfunctionTest Fan Motor

Cooling Fan Relay MalfunctionTest Fan Relay

Faulty Radiator CapReplace Radiator Cap

Broken/Slipping Fan BeltReplace Fan Belt

Restricted ExhaustRepair Exhaust System

Corrosion

Impurities In CoolantClean/Flush System

Coolant Leakage

Damaged hoseReplace Hose

Leaky Water PumpReplace Water Pump

Damaged Radiator SeamReplace/Repair Radiator

Leaky Thermostat CoverReplace Thermostat Cover

Cylinder Head ProblemCheck Head/Head Gasket

Leaky Freeze PlugsReplace Freeze Plugs

Recovery System Inoperative

Loose and/or Defective Radiator CapReplace Radiator Cap

Overflow Tube Clogged and/or LeakingRepair Tube

Recovery Bottle Vent RestrictedClean Vent

No Heater Core Flow

Collapsed Heater HoseReplace Heater Hose

Pl u gge d He a t e r C o r eClean/Replace Heater Core

Faulty Heater ValveReplace Heater Valve

NOTE:This is GENERAL inform ation. This article is not intended to be specific to any unique situation or

individual vehicle configuration. T he purpose of this T rouble Shooting inform ation is to provide a list

of com m on causes to problem sym ptom s. For m odel-specific T rouble Shooting, refer to SUBJECT ,

DIAGNOST IC, or T EST ING articles available in the section(s) you are accessing.

CONDITION & POSSIBLE CAUSECORRECTION

Engine Lopes At Idle

In t ake man ifo l d -t o -h ead l eaksReplace manifold gasket, See

ENGINES

Blown head gasketReplace head gasket, See

ENGINES

Worn timing gears, chain or sprocketReplace gears, chain or

sprocket

Worn camshaft lobesReplace camshaft, See

ENGINES

Overheated engineCheck cooling system, See

COOLING

Blocked crankcase vent valveRemove restriction

Le a kin g E GR va l veRepair leak and/or replace

va l ve

Faulty fuel pumpReplace fuel pump

Engine Has Low Power

Leaking fuel pumpRepair leak and/or replace

fu el p u mp

Excessive piston-to-bore clearanceInstall larger pistons, See

ENGINES

Sticking valves or weak valve springsCheck valve train components,

See ENGINES

Incorrect valve timingReset valve timing, See

ENGINES

Worn camshaft lobesReplace camshaft, See

ENGINES

Blown head gasketReplace head gasket. See

ENGINES.

Clutch slippingAdjust pedal and/or replace

components, See ENGINES

Page 9 of 36 MITCHELL 1 ARTICLE - GENERAL INFORMATION Trouble Shooting - Basic Procedures

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 230 of 454

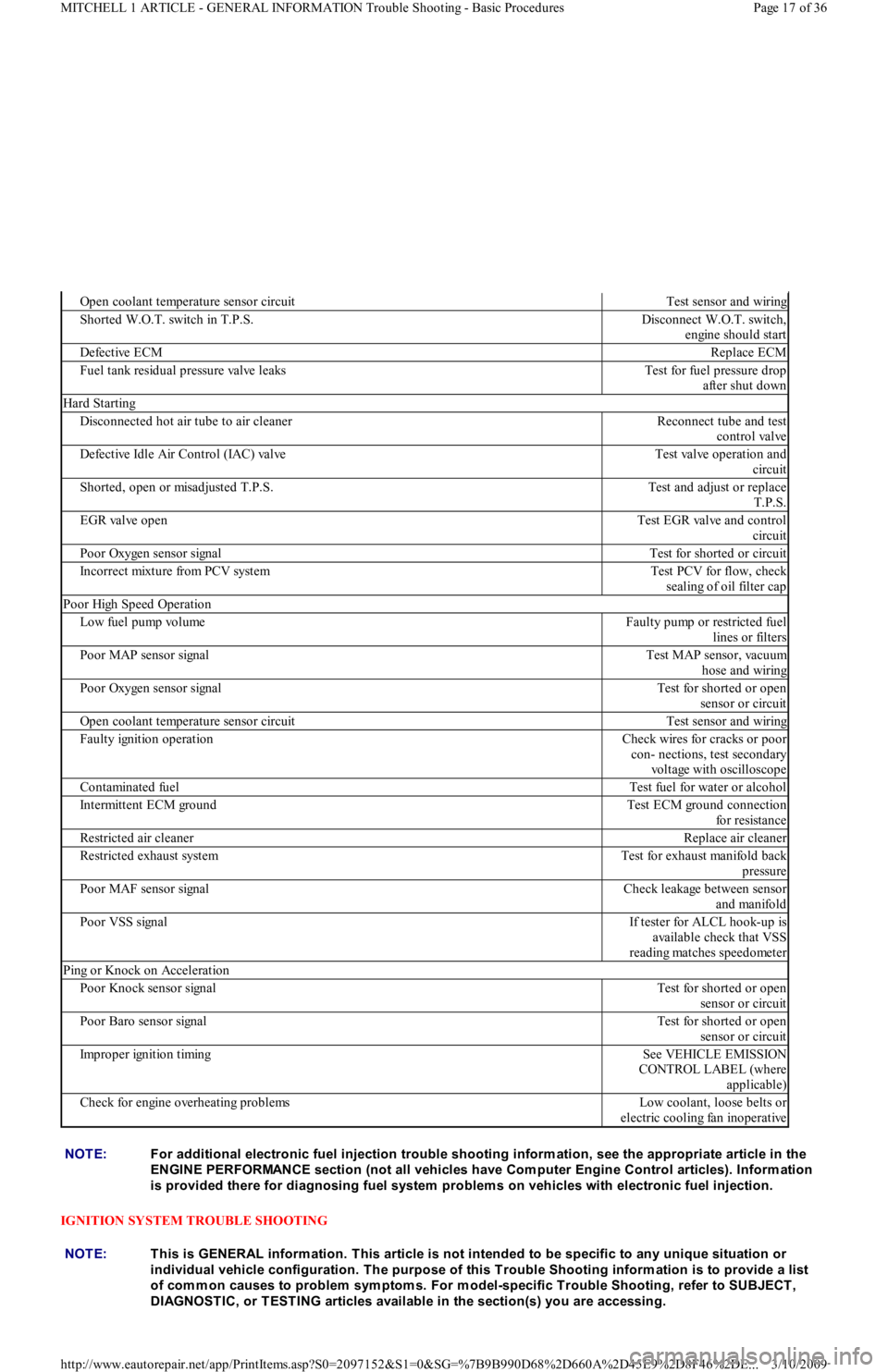

IGNITION SYSTEM TROUBLE SHOOTING

Open coolant temperature sensor circuitTest sensor and wiring

Shorted W.O.T. switch in T.P.S.Disconnect W.O.T. switch,

engine should start

Defective ECMReplace ECM

Fuel tank residual pressure valve leaksTest for fuel pressure drop

after shut down

Hard Starting

Disconnected hot air tube to air cleanerReconnect tube and test

control valve

Defective Idle Air Control (IAC) valveTest valve operation and

circuit

Shorted, open or misadjusted T.P.S.Test and adjust or replace

T.P.S.

EGR valve openTest EGR valve and control

circuit

Poor Oxygen sensor signalTest for shorted or circuit

Incorrect mixture from PCV systemTest PCV for flow, check

sealing of oil filter cap

Poor High Speed Operation

Low fuel pump volumeFaulty pump or restricted fuel

lines or filters

Poor MAP sensor signalTest MAP sensor, vacuum

hose and wiring

Poor Oxygen sensor signalTest for shorted or open

sensor or circuit

Open coolant temperature sensor circuitTest sensor and wiring

Faulty ignition operationCheck wires for cracks or poor

con- nections, test secondary

voltage with oscilloscope

Contaminated fuelTest fuel for water or alcohol

Intermittent ECM groundTest ECM ground connection

for resistance

Restricted air cleanerReplace air cleaner

Restricted exhaust systemTest for exhaust manifold back

pressure

Poor MAF sensor signalCheck leakage between sensor

and manifold

Poor VSS signalIf tester for ALCL hook-up is

available check that VSS

reading matches speedometer

Ping or Knock on Acceleration

Poor Knock sensor signalTest for shorted or open

sensor or circuit

Poor Baro sensor signalTest for shorted or open

sensor or circuit

Improper ignition timingSee VEHICLE EMISSION

CONTROL LABEL (where

applicable)

Check for engine overheating problemsLow coolant, loose belts or

electric cooling fan inoperative

NOTE:For additional electronic fuel injection trouble shooting inform ation, see the appropriate article in the

ENGINE PERFORMANCE section (not all vehicles have Com puter Engine Control articles). Inform ation

is provided there for diagnosing fuel system problem s on vehicles with electronic fuel injection.

NOTE:This is GENERAL inform ation. This article is not intended to be specific to any unique situation or

individual vehicle configuration. T he purpose of this T rouble Shooting inform ation is to provide a list

of com m on causes to problem sym ptom s. For m odel-specific T rouble Shooting, refer to SUBJECT ,

DIAGNOST IC, or T EST ING articles available in the section(s) you are accessing.

Page 17 of 36 MITCHELL 1 ARTICLE - GENERAL INFORMATION Trouble Shooting - Basic Procedures

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 251 of 454

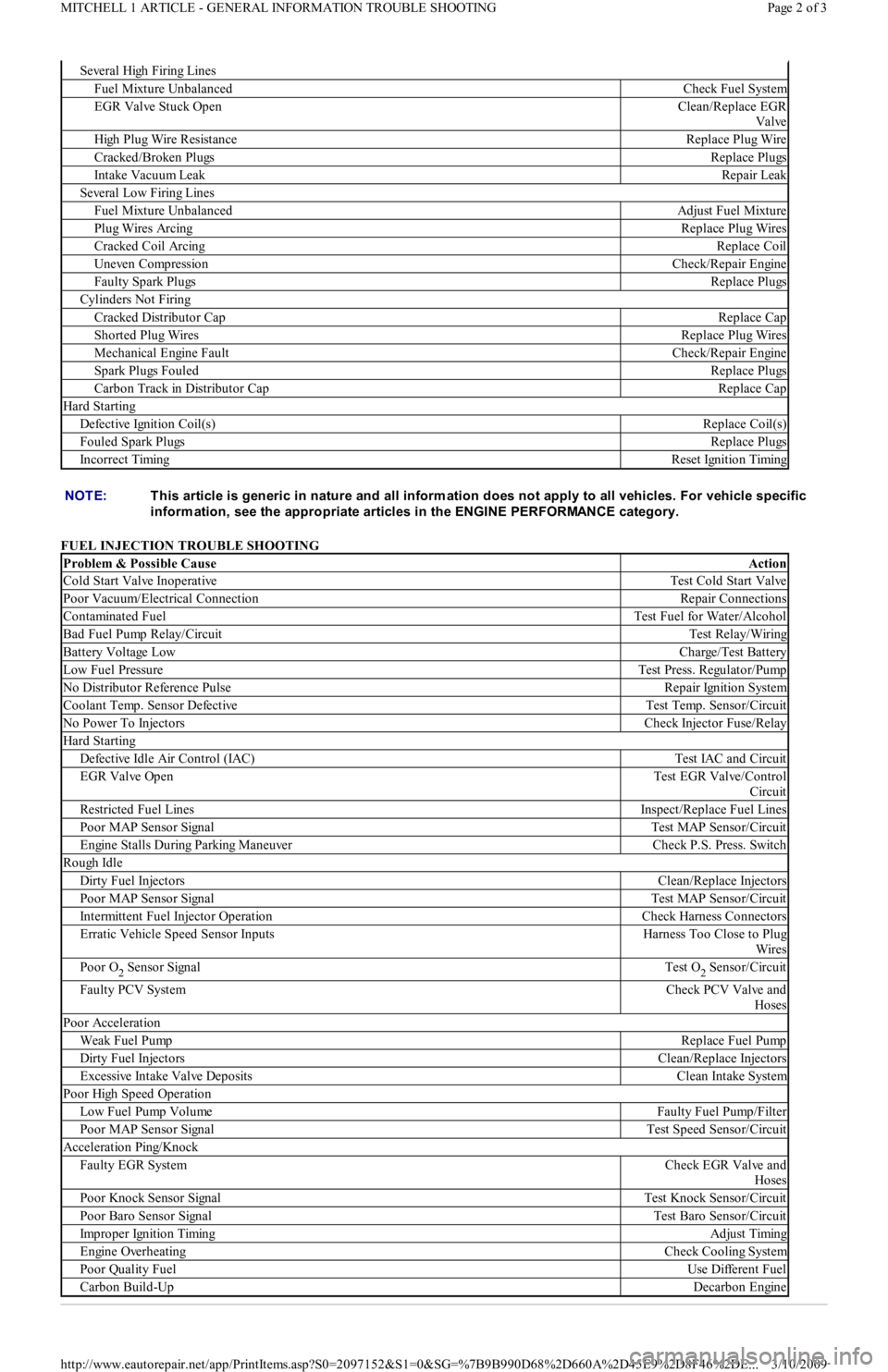

FUEL INJECTION TROUBLE SHOOTING

Se ve r a l High F ir in g Lin e s

Fuel Mixture UnbalancedCheck Fuel System

EGR Valve Stuck OpenClean/Replace EGR

Valve

High Plug Wire ResistanceReplace Plug Wire

Cracked/Broken PlugsReplace Plugs

Intake Vacuum LeakRepair Leak

Several Low Firing Lines

Fuel Mixture UnbalancedAdjust Fuel Mixture

Plug Wires ArcingReplace Plug Wires

Cracked Coil ArcingReplace Coil

Uneven CompressionCheck/Repair Engine

Faulty Spark PlugsReplace Plugs

Cylinders Not Firing

Cracked Distributor CapReplace Cap

Shorted Plug WiresReplace Plug Wires

Mechanical Engine FaultCheck/Repair Engine

Spark Plugs FouledReplace Plugs

Carbon Track in Distributor CapReplace Cap

Hard Starting

Defective Ignition Coil(s)Replace Coil(s)

Fouled Spark PlugsReplace Plugs

Incorrect TimingReset Ignition Timing

NOTE:T his article is generic in nature and all inform ation does not apply to all vehicles. For vehicle specific

inform ation, see the appropriate articles in the ENGINE PERFORMANCE category.

Problem & Possible CauseAction

Cold Start Valve InoperativeTest Cold Start Valve

Poor Vacuum/Electrical ConnectionRepair Connections

Contaminated FuelTest Fuel for Water/Alcohol

Bad Fuel Pump Relay/CircuitTest Relay/Wiring

Battery Voltage LowCharge/Test Battery

Low Fuel PressureTest Press. Regulator/Pump

No Distributor Reference PulseRepair Ignition System

Coolant Temp. Sensor DefectiveTest Temp. Sensor/Circuit

No Power To InjectorsCheck Injector Fuse/Relay

Hard Starting

Defective Idle Air Control (IAC)Test IAC and Circuit

EGR Valve OpenTest EGR Valve/Control

Circuit

Restricted Fuel LinesInspect/Replace Fuel Lines

Poor MAP Sensor SignalTest MAP Sensor/Circuit

Engine Stalls During Parking ManeuverCheck P.S. Press. Switch

Rough Idle

Dirty Fuel InjectorsClean/Replace Injectors

Poor MAP Sensor SignalTest MAP Sensor/Circuit

Intermittent Fuel Injector OperationCheck Harness Connectors

Erratic Vehicle Speed Sensor InputsHarness Too Close to Plug

Wires

Poor O2 Sensor SignalTest O2 Sensor/Circuit

Faulty PCV SystemCheck PCV Valve and

Hoses

Poor Acceleration

Weak Fuel PumpReplace Fuel Pump

Dirty Fuel InjectorsClean/Replace Injectors

Excessive Intake Valve DepositsClean Intake System

Poor High Speed Operation

Low Fuel Pump VolumeFaulty Fuel Pump/Filter

Poor MAP Sensor SignalTest Speed Sensor/Circuit

Acceleration Ping/Knock

Faulty EGR SystemCheck EGR Valve and

Hoses

Poor Knock Sensor SignalTest Knock Sensor/Circuit

Poor Baro Sensor SignalTest Baro Sensor/Circuit

Improper Ignition TimingAdjust Timing

Engine OverheatingCheck Cooling System

Poor Quality FuelUse Different Fuel

Carbon Build-UpDecarbon Engine

Page 2 of 3 MITCHELL 1 ARTICLE - GENERAL INFORMATION TROUBLE SHOOTING

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...