engine oil FORD FESTIVA 1991 Owner's Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1991, Model line: FESTIVA, Model: FORD FESTIVA 1991Pages: 454, PDF Size: 9.53 MB

Page 112 of 454

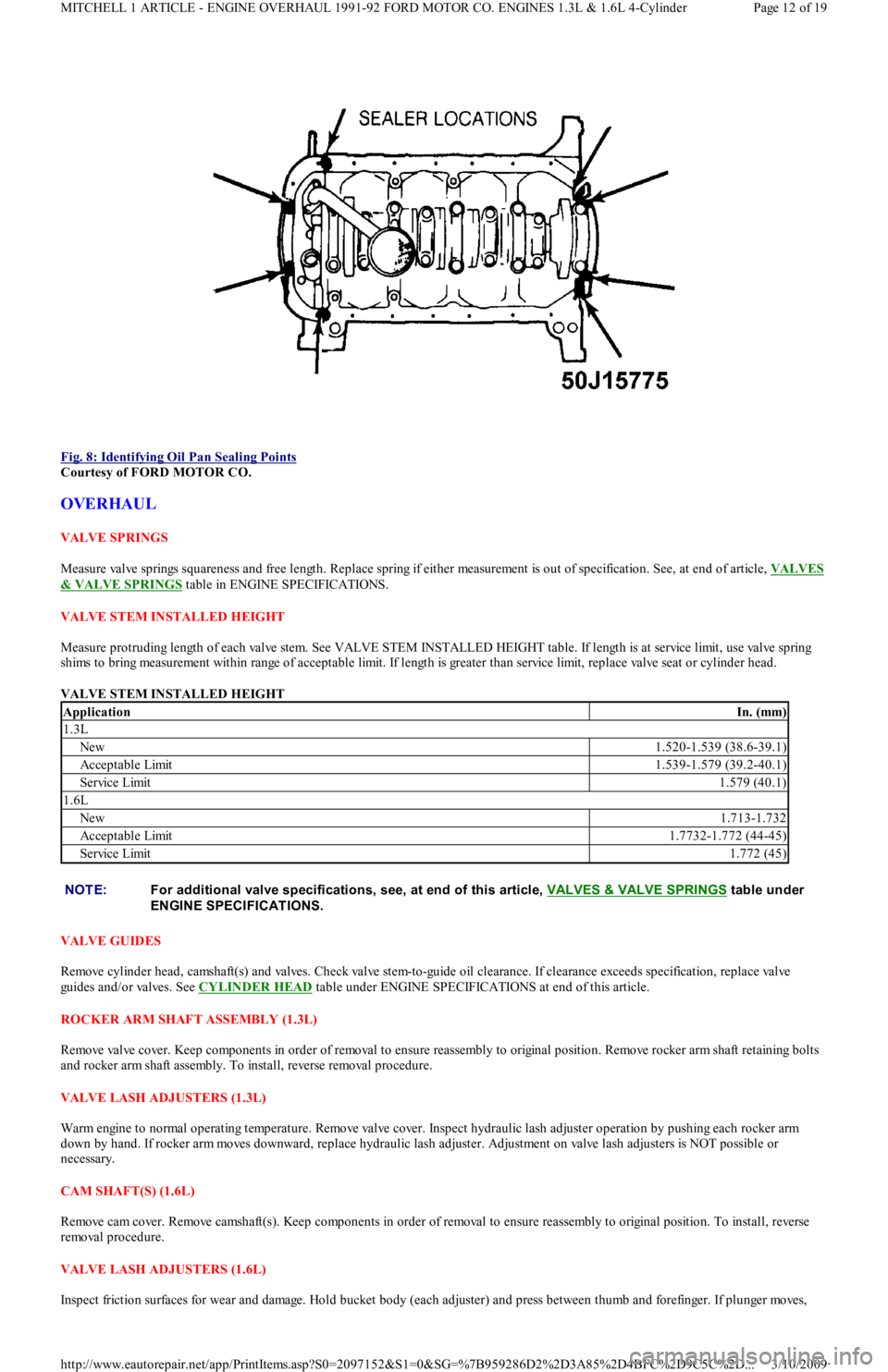

Fig. 8: Identifying Oil Pan Sealing Points

Courtesy of FORD MOTOR CO.

OVERHAUL

VALVE SPRINGS

Measure valve springs squareness and free length. Replace spring if either measurement is out of specification. See, at end of article, VALVES

& VALVE SPRINGS table in ENGINE SPECIFICATIONS.

VALVE STEM INSTALLED HEIGHT

Measure protruding length of each valve stem. See VALVE STEM INSTALLED HEIGHT table. If length is at service limit, use valve spring

shims to bring measurement within range of acceptable limit. If length is greater than service limit, replace valve seat or cylinder head.

VALVE STEM INSTALLED HEIGHT

VALVE GUIDES

Remove cylinder head, camshaft(s) and valves. Check valve stem-to-guide oil clearance. If clearance exceeds specification, replace valve

guides and/or valves. See CYLINDER HEAD

table under ENGINE SPECIFICATIONS at end of this article.

ROCKER ARM SHAFT ASSEMBLY (1.3L)

Remove valve cover. Keep components in order of removal to ensure reassembly to original position. Remove rocker arm shaft retaining bolts

and rocker arm shaft assembly. To install, reverse removal procedure.

VALVE LASH ADJUSTERS (1.3L)

Warm engine to normal operating temperature. Remove valve cover. Inspect hydraulic lash adjuster operation by pushing each rocker arm

down by hand. If rocker arm moves downward, replace hydraulic lash adjuster. Adjustment on valve lash adjusters is NOT possible or

necessary.

CAM SHAFT(S) (1.6L)

Remove cam cover. Remove camshaft(s). Keep components in order of removal to ensure reassembly to original position. To install, reverse

removal procedure.

VALVE LASH ADJUSTERS (1.6L)

Inspect friction surfaces for wear and damage. Hold bucket body (each adjuster) and press between thumb and forefinger. If plunge r mo ve s,

ApplicationIn. (mm)

1.3L

New1.520-1.539 (38.6-39.1)

Acceptable Limit1.539-1.579 (39.2-40.1)

Service Limit1.579 (40.1)

1.6L

New1.713-1.732

Acceptable Limit1.7732-1.772 (44-45)

Service Limit1.772 (45)

NOTE:For additional valve specifications, see, at end of this article, VALVES & VALVE SPRINGS

table under

ENGINE SPECIFICAT IONS.

Page 12 of 19 MITCHELL 1 ARTICLE - ENGINE OVERHAUL 1991-92 FORD MOTOR CO. ENGINES 1.3L & 1.6L 4-Cylinder

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 113 of 454

replace hydraulic lash adjuster. Adjustment on valve lash adjusters is NOT possible or necessary.

PISTON & ROD ASSEMBLY

1. Remove cylinder head assembly. Remove oil pan. Mark connecting rod caps for reassembly reference. Remove rod nuts. Remove lower

rod cap and bearing. Tap piston out top of cylinder block. DO NOT scratch crank journal or cylinder walls during removal.

2. Repeat procedure for remaining pistons. Keep removed parts in order to ensure installation to original position. Position piston assembly

in correct cylinder bore. Align piston mark "F" (1.3L), or notch (1.6L) located at piston pin bore area, and connecting rod oil gr o o ve

toward engine front. To complete installation, reverse removal procedure. Tighten all bolts and nuts to specification. See TORQUE

SPECIFICATIONS table at end of article.

FITTING PISTONS

1. With piston assembly removed, remove piston rings and clean piston. Measure piston outer diameter in thrust direction, below oil ring

groove. Diameter is 2.793-2.794" (70.954-70.974 mm) for 1.3L engines and 3.0690-3.0698 (77.954-77.974) for 1.6L engines.

2. Place piston upside down in cylinder from which it was removed. Using a feeler gauge, measure clearance between piston and cylinder

bore. If clearance is not within specification, bore cylinder and replace piston as necessary. See CYLINDER BLOCK

table in ENGINE

SPECIFICATIONS at end of article.

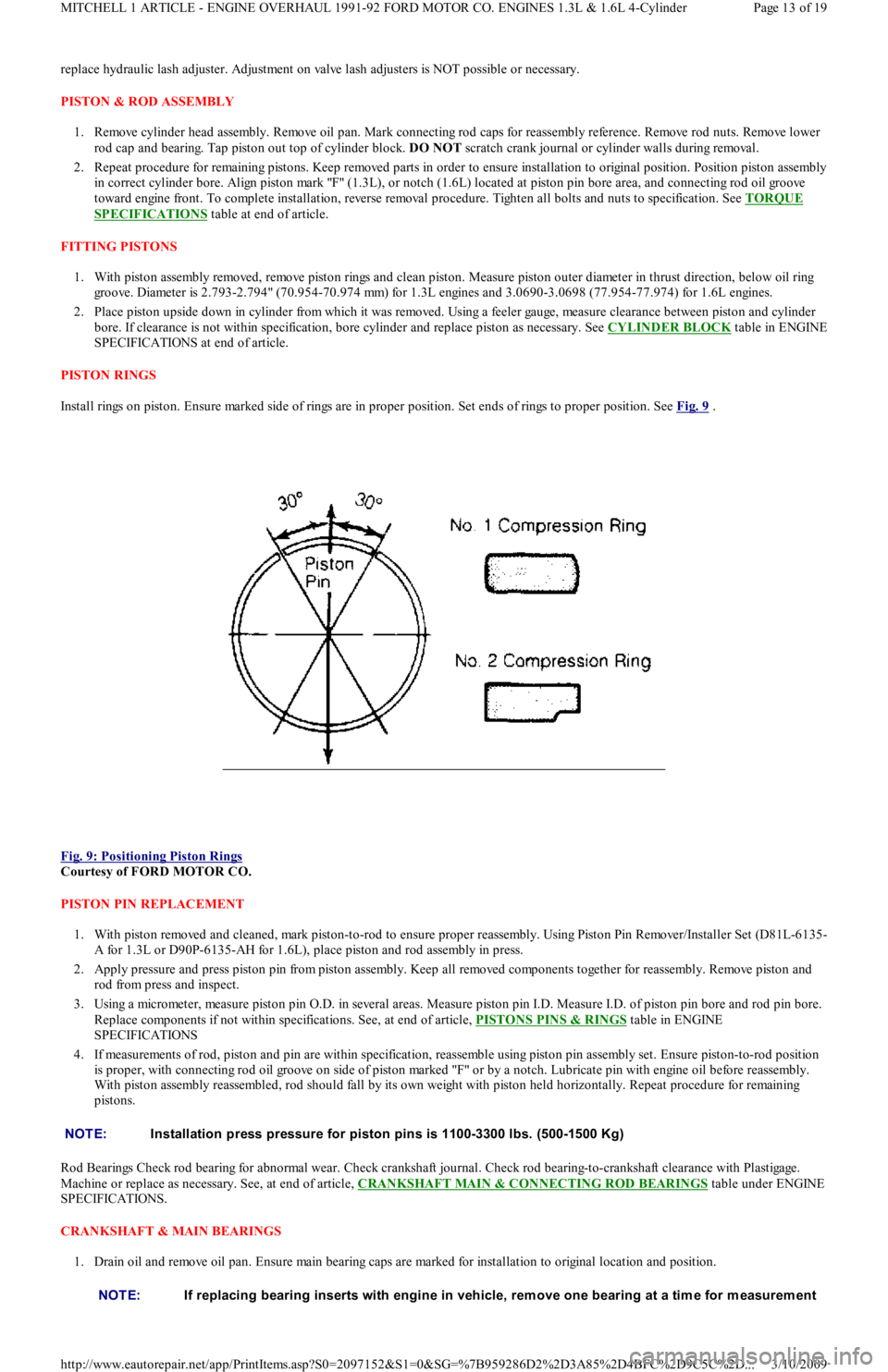

PISTON RINGS

Install rings on piston. Ensure marked side of rings are in proper position. Set ends of rings to proper position. See Fig. 9

.

Fig. 9: Positioning Piston Rings

Courtesy of FORD MOTOR CO.

PISTON PIN REPLACEMENT

1. With piston removed and cleaned, mark piston-to-rod to ensure proper reassembly. Using Piston Pin Remover/Installer Set (D81L-6135-

A for 1.3L or D90P-6135-AH for 1.6L), place piston and rod assembly in press.

2. Apply pressure and press piston pin from piston assembly. Keep all removed components together for reassembly. Remove piston and

rod from press and inspect.

3. Using a micrometer, measure piston pin O.D. in several areas. Measure piston pin I.D. Measure I.D. of piston pin bore and rod pin bore.

Replace components if not within specifications. See, at end of article, PISTONS PINS & RINGS

table in ENGINE

SPECIFICATIONS

4. If measurements of rod, piston and pin are within specification, reassemble using piston pin assembly set. Ensure piston-to-rod position

is proper, with connecting rod oil groove on side of piston marked "F" or by a notch. Lubricate pin with engine oil before reassembly.

With piston assembly reassembled, rod should fall by its own weight with piston held horizontally. Repeat procedure for remaining

pistons.

Rod Bearings Check rod bearing for abnormal wear. Check crankshaft journal. Check rod bearing-to-crankshaft clearance with Plastigage.

Machine or replace as necessary. See, at end of article, CRANKSHAFT MAIN & CONNECTING ROD BEARINGS

table under ENGINE

SPECIFICATIONS.

CRANKSHAFT & MAIN BEARINGS

1. Drain oil and remove oil pan. Ensure main bearing caps are marked for installation to original location and position.

NOTE:Installation press pressure for piston pins is 1100-3300 lbs. (500-1500 Kg)

NOTE:If replacing bearing inserts with engine in vehicle, rem ove one bearing at a tim e for m easurem ent

Page 13 of 19 MITCHELL 1 ARTICLE - ENGINE OVERHAUL 1991-92 FORD MOTOR CO. ENGINES 1.3L & 1.6L 4-Cylinder

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 114 of 454

2. Remove main bearing cap bolts. Remove cap and lower bearing insert. Use bearing remover or fabricated cotter key to remove upper

bearing insert. Insert bearing remover in journal lubrication hole. Rotate crankshaft in normal direction of operation only. Repeat

procedure for remaining main bearings.

3. Check bearings for abnormal wear. Check crankshaft for grooves, scratches and pitting. Using Plastigage method, check clearance of

main bearing-to-crankshaft. Always keep at least 2 bearings and caps tight during clearance check. See, at end of article,

CRANKSHAFT MAIN & CONNECTING ROD BEARINGS

table under ENGINE SPECIFICATIONS.

4. Lubricate and install new bearings in cap and block. Match bearing tangs with notch in cap and block. Position cap in its proper

location and position. Install cap bolts and tighten to specification. See TORQUE SPECIFICATIONS

table at end of article. Repeat

procedure for remaining main bearings.

CRANKSHAFT END PLAY

Check crankshaft end play with dial indicator. End play should be .0031-.0111" (.08-.282 mm). Service limit is .012" (.30 mm). If end play is

not within specification, replace thrust bearings as necessary.

CYLINDER BLOCK

1. Using straightedge and feeler gauge, check entire cylinder head surface of cylinder block. Ensure warpage does not exceed .006" (.15

mm). If warpage exceeds specification, cylinder block surface can be machined a maximum of .008" (.20 mm).

2. Replace cylinder block if it needs to be machined more than .008" (.20 mm). Check cylinder bore for wear, out-of-round, taper and

piston fit. See CYLINDER BORE SPECIFICATIONS

table. Oversize pistons are available in .010" and .020" (.25 mm and .50 mm).

CYLINDER BORE SPECIFICATIONS

LUBRICATION

ENGINE OILING SYSTEM

Oiling system is force-feed type and uses a full-flow oil filter. Oil is retrieved from oil pan by oil pump pick-up tube and distributed to oil

filter. Oil is then filtered and routed throughout engine.

Crankcase Capacity

1.3 L crankcase capacity is 3.2 qts. (3.0 L) without filter change and 3.6 qts. (3.4 L) with filter change. For 1.6 L vehicles, capacity is 3.2 qts

(3.2 L) without filter and 3.72 qts. (3.5 L) with filter.

Normal Oil Pressure (Hot)

Normal oil pressure is 50-64 psi (3.5-4.5 kg/cm2 ) at 3000 RPM.

Pressure Regulator Valve

Pressure regulator valve is located in oil pump body and is nonadjustable.

OIL PUMP

Removal

Remove oil pan, pick-up tube and screen, timing belt and crankshaft sprocket. Remove front engine cover bolts and remove front cover.

R e mo ve b o l t s r e t a in in g p u mp c o ve r t o b a c k sid e o f fr o n t c o ve r h o u sin g.

2) Remove pump cover and inner and outer gears. Pry out front seal from front cover. Remove cotter pin. Remove pressure regulator retainer,

spring and valve.

OIL PUMP SPECIFICATIONS or replacem ent.

ApplicationIn. (mm)

Cylinder Diameter

Standard Bore

1.3L2.7953-2.7960 (71.000-71.019)

1.6L3.0709-3.0716 (78.000-78.019)

Maximu m Bo re

1.3L2.8020 (71.17)

1.6L3.0905-3.0913 (78.500-78.519)

Maximu m Ou t -Of-Ro u n d & Tap er.0007 (.019)

Piston-To-Bore Clearance.006 (.15)

ApplicationIn. (mm)

Inner Gear-To-Outer Gear

1.3L.008 (.20)

1.6L.0008-.0063 (.02-.16)

Outer Gear-To-Housing

1.3L.009 (.22)

1.6L.0035-.0071 (.09-.18)

End Play

1.3L.006 (.14)

Page 14 of 19 MITCHELL 1 ARTICLE - ENGINE OVERHAUL 1991-92 FORD MOTOR CO. ENGINES 1.3L & 1.6L 4-Cylinder

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 115 of 454

Installation

1. Install pressure regulator valve, spring, retainer and new cotter pin. Press a new seal in front cover housing. Install outer and inner gears

in housing. Install pump cover. Coat bolts with Loctite and tighten to specification. See TORQUE SPECIFICATIONS

table at end of

article.

2. Install new gasket and install front cover housing. Install new gasket and install pick-up tube and screen. Tighten all bolts/nuts to

specification. To complete installation, reverse removal procedure.

ENGINE COOLING

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS

1.6L.0012-.0043 (.03-.11)

NOTE:Refer to WAT ER PUMP

under REMOVAL & INSTALLATION in this article.

ApplicationFt. Lbs. (N.m)

"A" Arm Front Bolt72-86 (97-117)

A/C Compressor Bolt29-40 (39-54)

Camshaft Sprocket Bolt36-45 (49-61)

Connecting Rod Nut

Step 111-13 (15-18)

Step 2

1.3L22-25 (30-34)

1.6L35-38 (47-52)

Crankshaft Pulley Bolts9-13 (12-17)

Crankshaft Sprocket Bolt80-87 (108-118)

Crossmember-To-Body Bolt

1.3L47-66 (64-89)

1.6L27-37 (35-50)

Cylinder Head Bolt

Step 135-40 (48-54)

Step 256-60 (76-81)

Exhaust Manifold-To-Cylinder Head

1.3L12-17 (16-23)

1.6L29-42 (39-57)

Exhaust Pipe-To-Manifold29-42 (39-57)

Exhaust Pipe-To-Support Bracket32-45 (43-61)

Flywheel Bolt71-76 (96-103)

Front Cover Housing Bolt (1.3L)14-19 (19-26)

Front Engine Mount Nut32-38 (43-52)

Heater Tube32-45 (43-61)

Intake Manifold-To-Cylinder Head

1.3L14-20 (19-27)

1.6L47-66 (64-89)

Main Bearing Cap Bolts40-44 (54-59)

O2 Sensor27-33 (37-45)

Oil Pump Cover Bolt (1.6L)14-18 (19-25)

P/S Pump Bracket (Nut & Bolt)35-49 (47-66)

P/S Adjusting Nut27-38 (37-52)

P/S Pivot Bolt23-34 (31-46)

Pulse Air Tube Nut23-34 (31-46)

Rear Engine Mount Nut

1.3L21-34 (28-46)

1.6L47-66 (64-89)

Rocker Arm Shaft Bolts16-21 (22-28)

Side Engine Mount Nuts

1.3L29-40 (39-54)

1.6L

RH49-67 (67-91)

LH33-48 (45-65)

Spark Plug11-17 (15-23)

Thermostat Housing Bolt14-22 (19-30)

Timing Belt Tensioner Adjusting Bolt14-19 (19-26)

Turbo Oil Supply Tube

Engine Block Side12-18 (16-24)

Banjo Side(1) 106-159 (12-18)

Turbo-To-Manifold29-42 (39-57)

Water Outlet Bolt14-22 (19-30)

Water Pump Pulley Bolts (1.3L)36-45 (49-61)

Page 15 of 19 MITCHELL 1 ARTICLE - ENGINE OVERHAUL 1991-92 FORD MOTOR CO. ENGINES 1.3L & 1.6L 4-Cylinder

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 116 of 454

ENGINE SPECIFICATIONS

GENERAL SPECIFICATIONS

GENERAL SPECIFICATIONS

CRANKSHAFT, MAIN & CONNECTING ROD BEARINGS

CRANKSHAFT MAIN & CONNECTING ROD BEARINGS

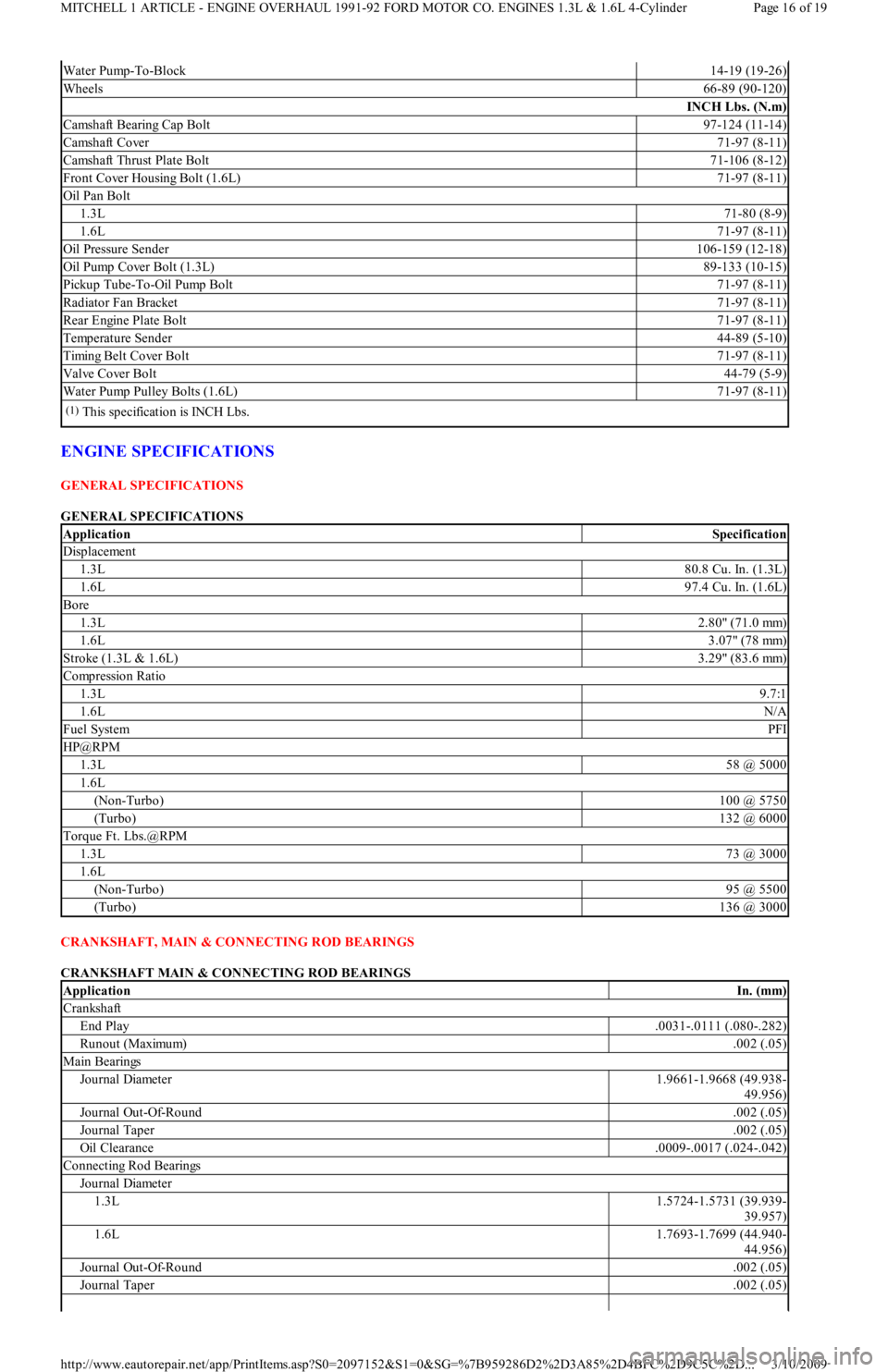

Water Pump-To-Block14-19 (19-26)

Wheels66-89 (90-120)

INCH Lbs. (N.m)

Camshaft Bearing Cap Bolt97-124 (11-14)

Camshaft Cover71-97 (8-11)

Camshaft Thrust Plate Bolt71-106 (8-12)

Front Cover Housing Bolt (1.6L)71-97 (8-11)

Oil Pan Bolt

1.3L71-80 (8-9)

1.6L71-97 (8-11)

Oil Pressure Sender106-159 (12-18)

Oil Pump Cover Bolt (1.3L)89-133 (10-15)

Pickup Tube-To-Oil Pump Bolt71-97 (8-11)

Radiator Fan Bracket71-97 (8-11)

Rear Engine Plate Bolt71-97 (8-11)

Temperature Sender44-89 (5-10)

Timing Belt Cover Bolt71-97 (8-11)

Valve Cover Bolt44-79 (5-9)

Water Pump Pulley Bolts (1.6L)71-97 (8-11)

(1)This specification is INCH Lbs.

ApplicationSpecification

Displacement

1.3L80.8 Cu. In. (1.3L)

1.6L97.4 Cu. In. (1.6L)

Bore

1.3L2.80" (71.0 mm)

1.6L3.07" (78 mm)

Stroke (1.3L & 1.6L)3.29" (83.6 mm)

Compression Ratio

1.3L9.7:1

1.6LN/A

Fuel SystemPFI

HP@RPM

1.3L58 @ 5000

1.6L

(Non-Turbo)100 @ 5750

(Turbo)132 @ 6000

Torque Ft. Lbs.@RPM

1.3L73 @ 3000

1.6L

(Non-Turbo)95 @ 5500

(Turbo)136 @ 3000

ApplicationIn. (mm)

Crankshaft

End Play.0031-.0111 (.080-.282)

Runout (Maximum).002 (.05)

Main Bearings

Journal Diameter1.9661-1.9668 (49.938-

49.956)

Journal Out-Of-Round.002 (.05)

Journal Taper.002 (.05)

Oil Clearance.0009-.0017 (.024-.042)

Connecting Rod Bearings

Journal Diameter

1.3L1.5724-1.5731 (39.939-

39.957)

1.6L1.7693-1.7699 (44.940-

44.956)

Journal Out-Of-Round.002 (.05)

Journal Taper.002 (.05)

Page 16 of 19 MITCHELL 1 ARTICLE - ENGINE OVERHAUL 1991-92 FORD MOTOR CO. ENGINES 1.3L & 1.6L 4-Cylinder

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 117 of 454

CONNECTING RODS

CONNECTING RODS

PISTONS, PINS & RINGS

PISTONS PINS & RINGS

CYLINDER BLOCK

CYLINDER BLOCK

VALVES & VALVE SPRINGS

VALVES & VALVE SPRINGS

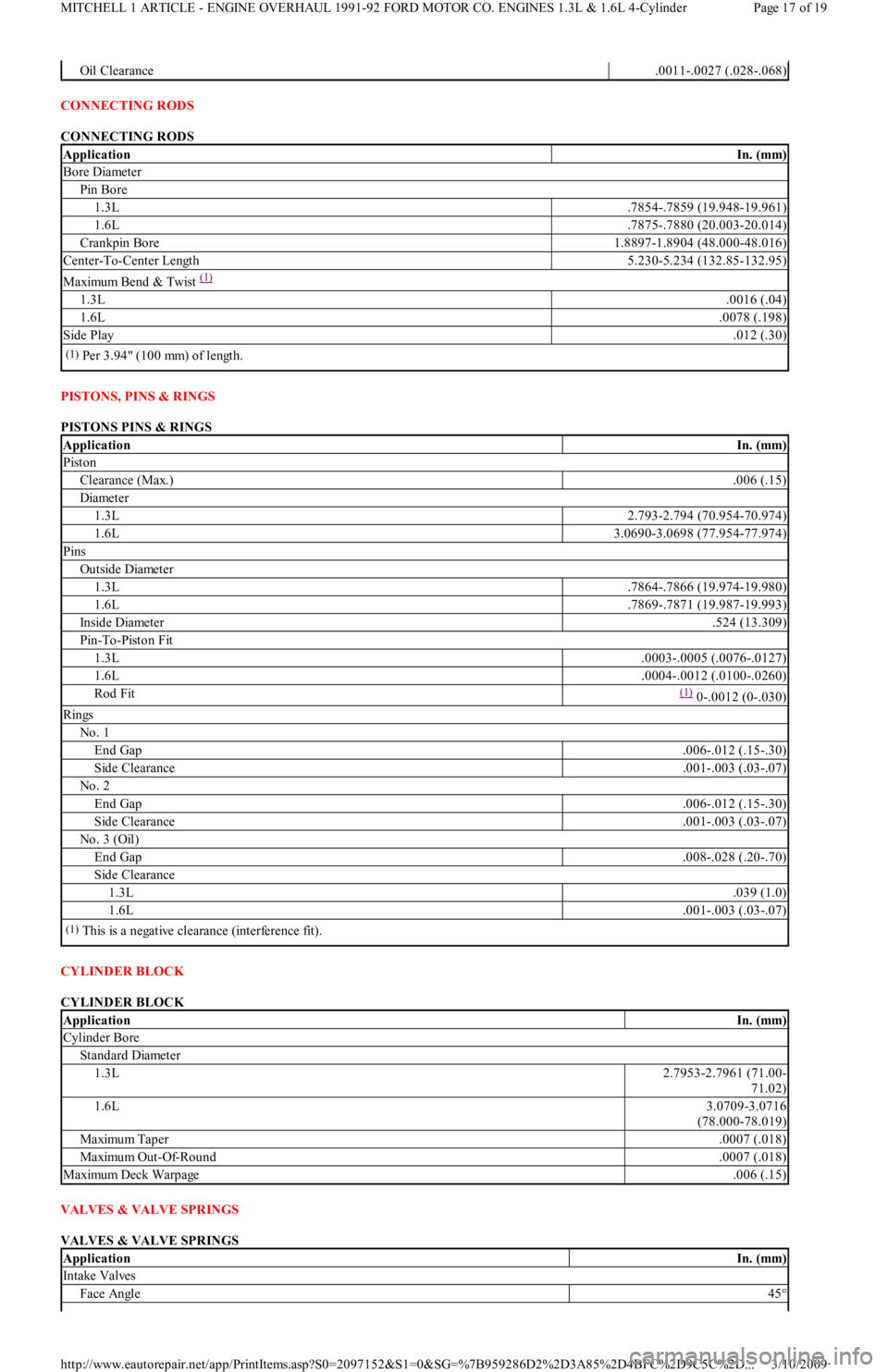

Oil Clearance.0011-.0027 (.028-.068)

ApplicationIn. (mm)

Bore Diameter

Pin Bore

1.3L.7854-.7859 (19.948-19.961)

1.6L.7875-.7880 (20.003-20.014)

Crankpin Bore1.8897-1.8904 (48.000-48.016)

Center-To-Center Length5.230-5.234 (132.85-132.95)

Maximu m Ben d & Twist (1)

1.3L.0016 (.04)

1.6L.0078 (.198)

Side Play.012 (.30)

(1)Per 3.94" (100 mm) of length.

ApplicationIn. (mm)

Piston

Clearance (Max.).006 (.15)

Diameter

1.3L2.793-2.794 (70.954-70.974)

1.6L3.0690-3.0698 (77.954-77.974)

Pins

Outside Diameter

1.3L.7864-.7866 (19.974-19.980)

1.6L.7869-.7871 (19.987-19.993)

Inside Diameter.524 (13.309)

Pin-To-Piston Fit

1.3L.0003-.0005 (.0076-.0127)

1.6L.0004-.0012 (.0100-.0260)

Rod Fit(1) 0-.0012 (0-.030)

Rings

No. 1

End Gap.006-.012 (.15-.30)

Side Clearance.001-.003 (.03-.07)

No. 2

End Gap.006-.012 (.15-.30)

Side Clearance.001-.003 (.03-.07)

No. 3 (Oil)

End Gap.008-.028 (.20-.70)

Side Clearance

1.3L.039 (1.0)

1.6L.001-.003 (.03-.07)

(1)This is a negative clearance (interference fit).

ApplicationIn. (mm)

Cylinder Bore

Standard Diameter

1.3L2.7953-2.7961 (71.00-

71.02)

1.6L3.0709-3.0716

(78.000-78.019)

Maximu m Tap er.0007 (.018)

Maximu m Ou t -Of-Ro u n d.0007 (.018)

Maximu m Deck Warp age.006 (.15)

ApplicationIn. (mm)

In t ake Val ves

Face Angle45°

Page 17 of 19 MITCHELL 1 ARTICLE - ENGINE OVERHAUL 1991-92 FORD MOTOR CO. ENGINES 1.3L & 1.6L 4-Cylinder

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 118 of 454

CYLINDER HEAD

CYLINDER HEAD

CAMSHAFT SPECIFICATIONS

CAMSHAFT SPECIFICATIONS

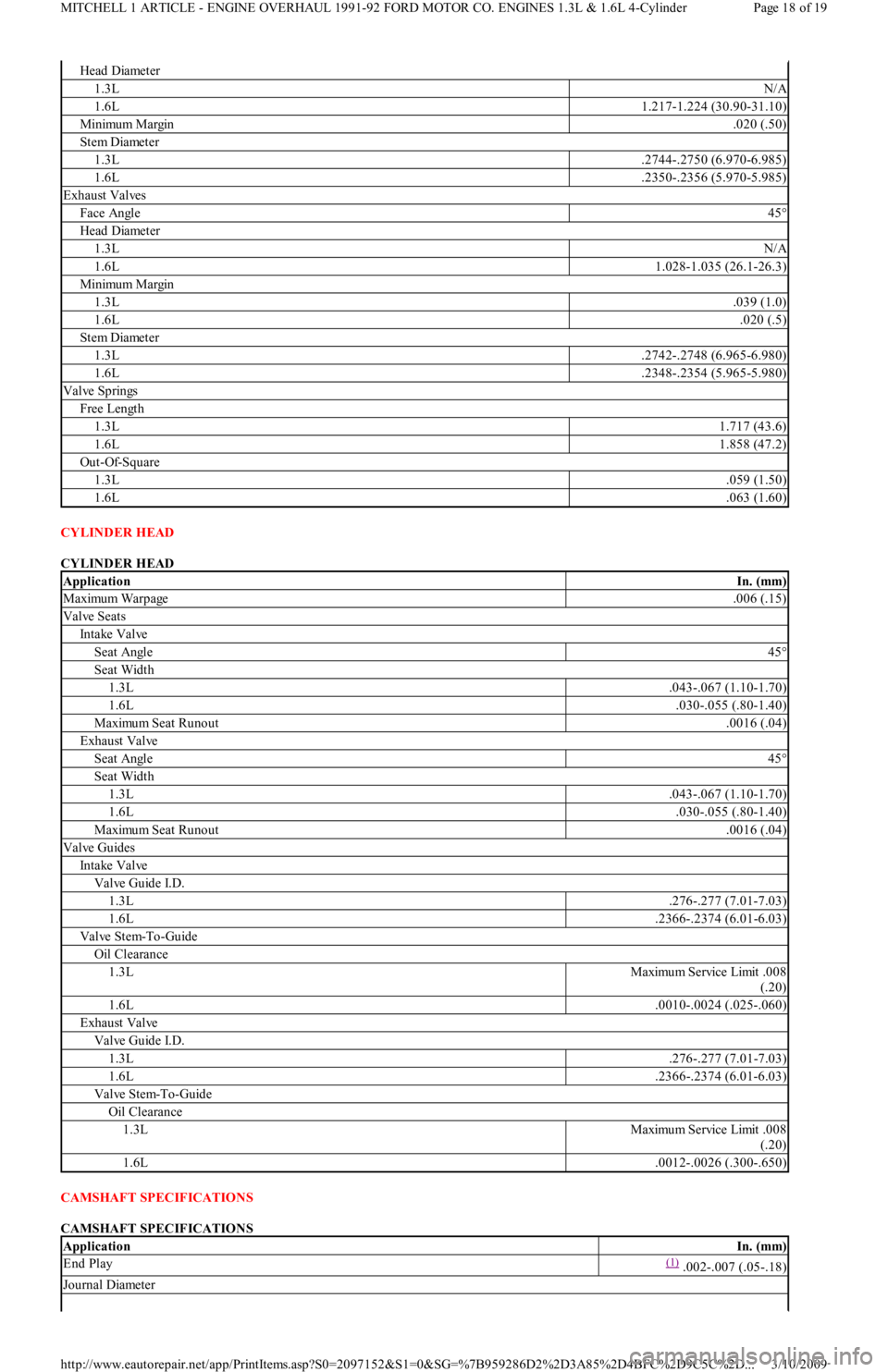

Head Diameter

1.3LN/A

1.6L1.217-1.224 (30.90-31.10)

Min imu m Margin.020 (.50)

Stem Diameter

1.3L.2744-.2750 (6.970-6.985)

1.6L.2350-.2356 (5.970-5.985)

Exhaust Valves

Face Angle45°

Head Diameter

1.3LN/A

1.6L1.028-1.035 (26.1-26.3)

Min imu m Margin

1.3L.039 (1.0)

1.6L.020 (.5)

Stem Diameter

1.3L.2742-.2748 (6.965-6.980)

1.6L.2348-.2354 (5.965-5.980)

Valve Springs

Free Length

1.3L1.717 (43.6)

1.6L1.858 (47.2)

Out-Of-Square

1.3L.059 (1.50)

1.6L.063 (1.60)

ApplicationIn. (mm)

Maximu m Warp age.006 (.15)

Valve Seats

Intake Valve

Seat Angle45°

Seat Width

1.3L.043-.067 (1.10-1.70)

1.6L.030-.055 (.80-1.40)

Maximu m Seat Ru n o u t.0016 (.04)

Exhaust Valve

Seat Angle45°

Seat Width

1.3L.043-.067 (1.10-1.70)

1.6L.030-.055 (.80-1.40)

Maximu m Seat Ru n o u t.0016 (.04)

Valve Guides

Intake Valve

Valve Guide I.D.

1.3L.276-.277 (7.01-7.03)

1.6L.2366-.2374 (6.01-6.03)

Valve Stem-To-Guide

Oil Clearance

1.3LMaximu m Service Limit .0 0 8

(.20)

1.6L.0010-.0024 (.025-.060)

Exhaust Valve

Valve Guide I.D.

1.3L.276-.277 (7.01-7.03)

1.6L.2366-.2374 (6.01-6.03)

Valve Stem-To-Guide

Oil Clearance

1.3LMaximu m Service Limit .0 0 8

(.20)

1.6L.0012-.0026 (.300-.650)

ApplicationIn. (mm)

End Play(1) .002-.007 (.05-.18)

Journal Diameter

Page 18 of 19 MITCHELL 1 ARTICLE - ENGINE OVERHAUL 1991-92 FORD MOTOR CO. ENGINES 1.3L & 1.6L 4-Cylinder

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 119 of 454

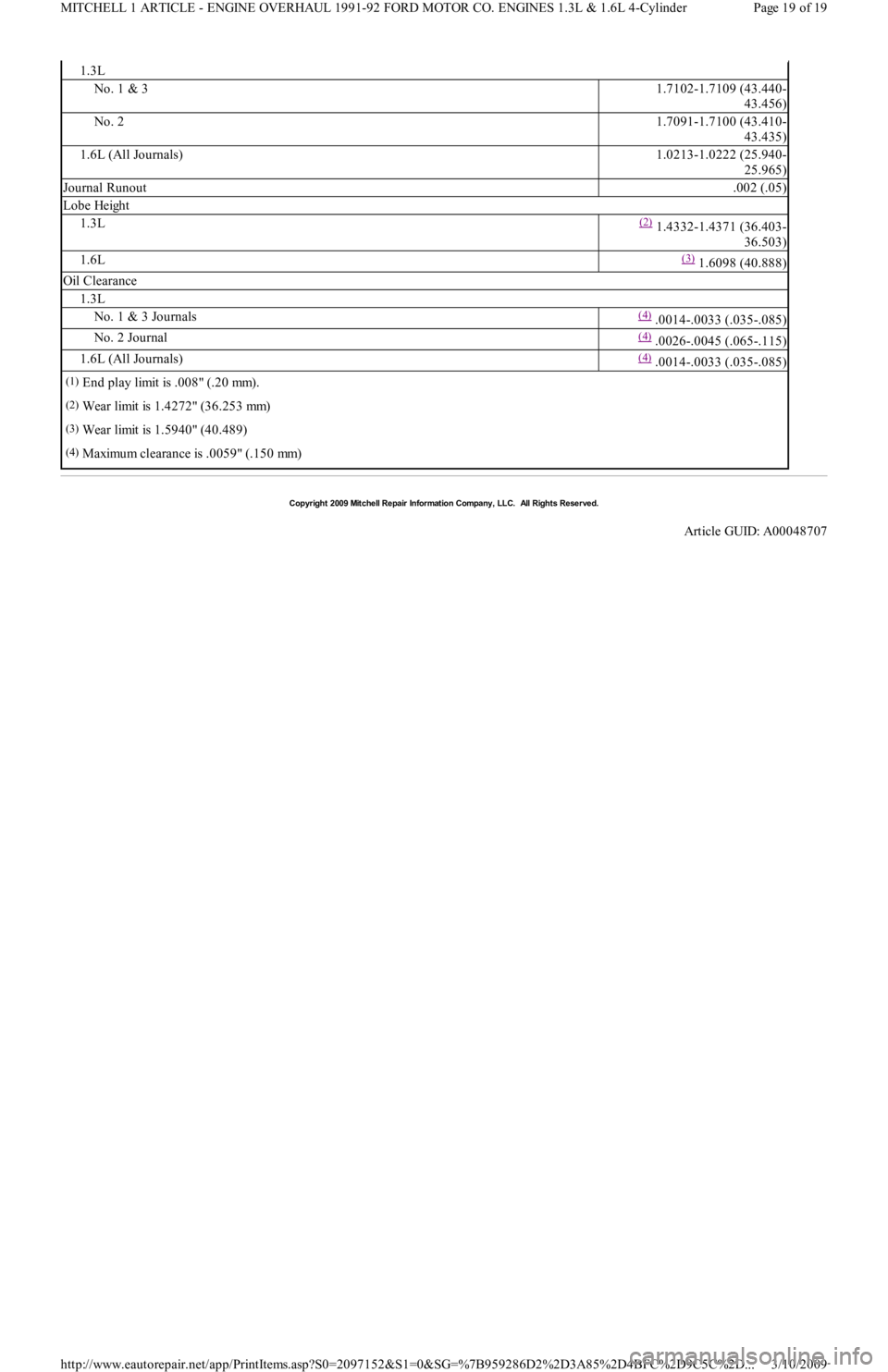

1.3L

No. 1 & 31.7102-1.7109 (43.440-

43.456)

No. 21.7091-1.7100 (43.410-

43.435)

1.6L (All Journals)1.0213-1.0222 (25.940-

25.965)

Journal Runout.002 (.05)

Lobe Height

1.3L(2) 1.4332-1.4371 (36.403-

36.503)

1.6L(3) 1.6098 (40.888)

Oil Clearance

1.3L

No. 1 & 3 Journals(4) .0014-.0033 (.035-.085)

No. 2 Journal(4) .0026-.0045 (.065-.115)

1.6L (All Journals)(4) .0014-.0033 (.035-.085)

(1)End play limit is .008" (.20 mm).

(2)Wear limit is 1.4272" (36.253 mm)

(3)Wear limit is 1.5940" (40.489)

(4)Maximum clearance is .0059" (.150 mm)

Copyr ight 2009 Mitchell Repair Information Company, LLC. All Rights Reserved.

Article GUID: A00048707

Page 19 of 19 MITCHELL 1 ARTICLE - ENGINE OVERHAUL 1991-92 FORD MOTOR CO. ENGINES 1.3L & 1.6L 4-Cylinder

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 121 of 454

3. If voltage is not present or is less than 8 volts at starter solenoid terminal "S", malfunction in circuit to terminal "S" is indicated. Proceed

to the following tests.

IGNITION SWITCH TEST

1. Locate ignition switch connector under dash. Using a 12-volt test light or voltmeter, ensure voltage is present on Black/Yellow wire

when ignition switch is turned to RUN or ON position. This will verify proper operation of ignition switch.

2. If there is no voltage on Black/Yellow wire, the problem is either ignition switch or circuit between battery and ignition switch.

CLUTCH ENGAGE SWITCH (M/T) TEST

Unplug clutch engage switch from main wiring harness. Using an ohmmeter, check for continuity across switch terminals. Continuity should

exist when switch plunger is pushed in and should not exist when switch plunger is released. If clutch engage switch does not operate as

specified, replace switch.

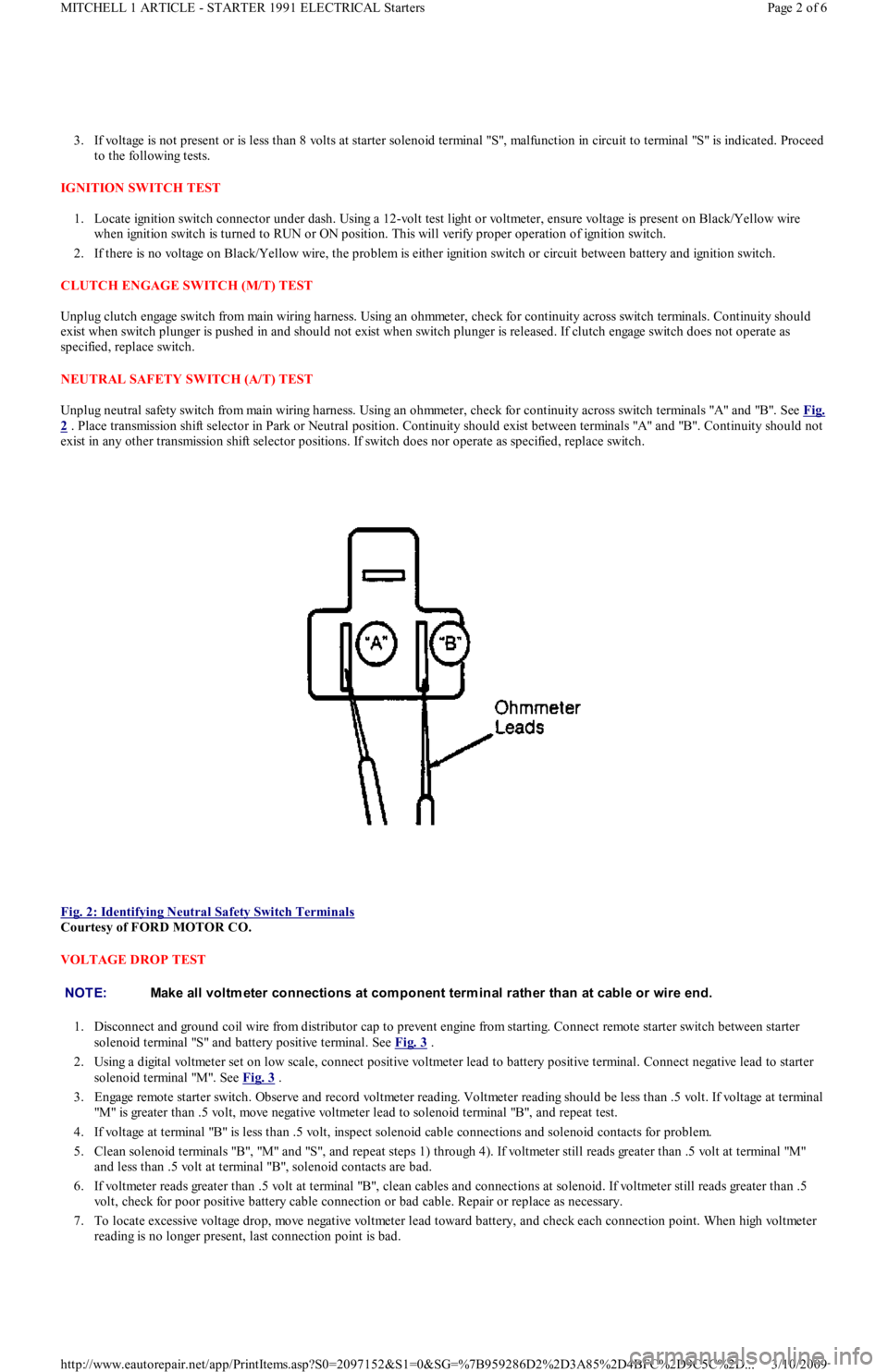

NEUTRAL SAFETY SWITCH (A/T) TEST

Unplug neutral safety switch from main wiring harness. Using an ohmmeter, check for continuity across switch terminals "A" and "B". See Fig.

2 . Place transmission shift selector in Park or Neutral position. Continuity should exist between terminals "A" and "B". Continuity should not

exist in any other transmission shift selector positions. If switch does nor operate as specified, replace switch.

Fig. 2: Identifying Neutral Safety Switch Terminals

Courtesy of FORD MOTOR CO.

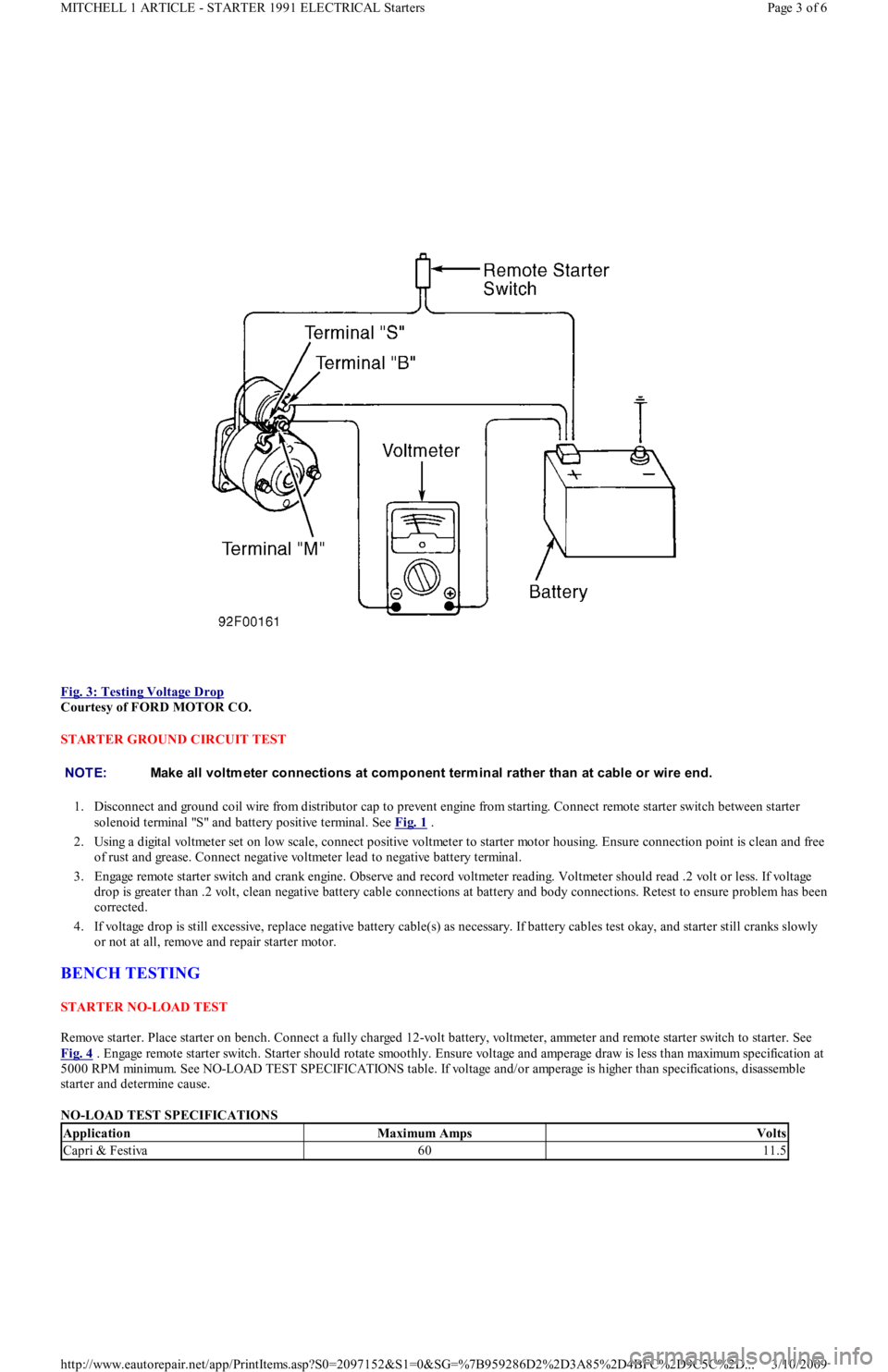

VOLTAGE DROP TEST

1. Disconnect and ground coil wire from distributor cap to prevent engine from starting. Connect remote starter switch between starter

solenoid terminal "S" and battery positive terminal. See Fig. 3

.

2. Using a digital voltmeter set on low scale, connect positive voltmeter lead to battery positive terminal. Connect negative lead to starter

solenoid terminal "M". See Fig. 3

.

3. Engage remote starter switch. Observe and record voltmeter reading. Voltmeter reading should be less than .5 volt. If voltage at terminal

"M" is greater than .5 volt, move negative voltmeter lead to solenoid terminal "B", and repeat test.

4. If voltage at terminal "B" is less than .5 volt, inspect solenoid cable connections and solenoid contacts for problem.

5 . Cl ean so l en o id t ermin al s "B", "M" an d "S", an d rep eat st ep s 1 ) through 4). If voltmeter still reads greater than .5 volt at termin al "M"

and less than .5 volt at terminal "B", solenoid contacts are bad.

6. If voltmeter reads greater than .5 volt at terminal "B", clean cables and connections at solenoid. If voltmeter still reads greater than .5

volt, check for poor positive battery cable connection or bad cable. Repair or replace as necessary.

7. To locate excessive voltage drop, move negative voltmeter lead toward battery, and check each connection point. When high voltmeter

reading is no longer present, last connection point is bad.

NOTE:Make all voltm eter connections at com ponent term inal rather than at cable or wire end.

Page 2 of 6 MITCHELL 1 ARTICLE - STARTER 1991 ELECTRICAL Starters

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 122 of 454

Fig. 3: Testing Voltage Drop

Courtesy of FORD MOTOR CO.

STARTER GROUND CIRCUIT TEST

1. Disconnect and ground coil wire from distributor cap to prevent engine from starting. Connect remote starter switch between starter

solenoid terminal "S" and battery positive terminal. See Fig. 1

.

2. Using a digital voltmeter set on low scale, connect positive voltmeter to starter motor housing. Ensure connection point is clean and free

of rust and grease. Connect negative voltmeter lead to negative battery terminal.

3. Engage remote starter switch and crank engine. Observe and record voltmeter reading. Voltmeter should read .2 volt or less. If voltage

drop is greater than .2 volt, clean negative battery cable connections at battery and body connections. Retest to ensure problem has been

corrected.

4. If voltage drop is still excessive, replace negative battery cable(s) as necessary. If battery cables test okay, and starter still cranks slowly

or not at all, remove and repair starter motor.

BENCH TESTING

STARTER NO-LOAD TEST

Remove starter. Place starter on bench. Connect a fully charged 12-volt battery, voltmeter, ammeter and remote starter switch to starter. See

Fig. 4

. Engage remote starter switch. Starter should rotate smoothly. Ensure voltage and amperage draw is less than maximum specification at

5000 RPM minimum. See NO-LOAD TEST SPECIFICATIONS table. If voltage and/or amperage is higher than specifications, disassemble

starter and determine cause.

NO-LOAD TEST SPECIFICATIONS

NOTE:Make all voltm eter connections at com ponent term inal rather than at cable or wire end.

ApplicationMaximum AmpsVolts

Capri & Festiva6011.5

Page 3 of 6 MITCHELL 1 ARTICLE - STARTER 1991 ELECTRICAL Starters

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...