check engine FORD FESTIVA 1991 Owner's Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 1991, Model line: FESTIVA, Model: FORD FESTIVA 1991Pages: 454, PDF Size: 9.53 MB

Page 138 of 454

CEC

Computerized Engine Controls

DOHC

Dual Overhead Cam

DPFE

Differential Pressure Feedback EGR Valve

EAIR

Electric Air Injection System

EAIR DV

Electric Air Injection System Diverter Valve

ECM

Electronic Control Module

ECU

Electronic Control Unit

EGR

Exhaust Gas Recirculation

EVRS

EGR Vacuum Regulator Solenoid

EVAP

Fuel Evaporative System

EVAP-AAC

EVAP Auxiliary Air Control

EVAP-BPSV

EVAP By-Pass Solenoid Valve

EVAP-BVSV

EVAP Bimetallic Vacuum Switching Valve

EVAP-CAV

EVAP Canister Air Valve

EVAP-CCV

EVAP Control Canister Close Valve

EVAP-CCVSV

EVAP Control Canister Vent Shut Valve

EVAP-CCVVSV

EVAP Closed Canister Valve Vacuum Switching Valve

EVAP-CDCV

EVAP Canister Drain Cut Valve

EVAP-CKV

EVAP Check Valve

EVAP-CPCS

EVAP Canister Purge Control Solenoid

Page 6 of 9 MITCHELL 1 ARTICLE - EMISSION CONTROL APPLICATIONS Emission Applications - Ford Motor Co. - Imports (1968-

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 142 of 454

Back To Article

J - PIN VOLT AGE CHART S

1991 ENGINE PERFORMANCE Ford/Mercury Pin Voltage Charts

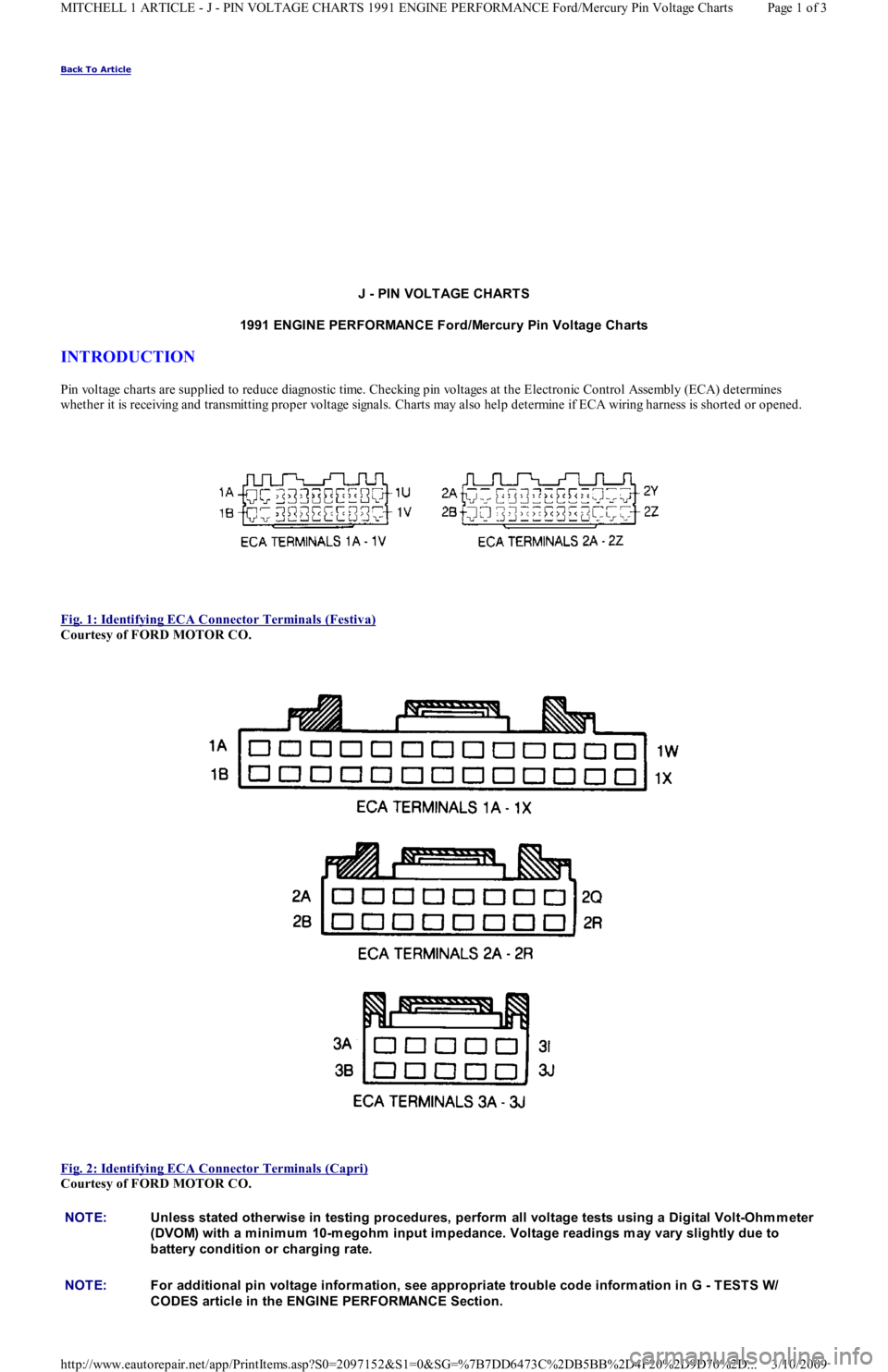

INTRODUCTION

Pin voltage charts are supplied to reduce diagnostic time. Checking pin voltages at the Electronic Control Assembly (ECA) determin es

whether it is receiving and transmitting proper voltage signals. Charts may also help determine if ECA wiring harness is shorted or opened.

Fig. 1: Identifying ECA Connector Terminals (Festiva)

Courtesy of FORD MOTOR CO.

Fig. 2: Identifying ECA Connector Terminals (Capri)

Courtesy of FORD MOTOR CO.

NOTE:Unless stated otherwise in testing procedures, perform all voltage tests using a Digital Volt-Ohm m eter

(DVOM) with a m inim um 10-m egohm input im pedance. Voltage readings m ay vary slightly due to

battery condition or charging rate.

NOTE:For additional pin voltage inform ation, see appropriate trouble code inform ation in G - T EST S W/

CODES article in the ENGINE PERFORMANCE Section.

Page 1 of 3 MITCHELL 1 ARTICLE - J - PIN VOLTAGE CHARTS 1991 ENGINE PERFORMANCE Ford/Mercury Pin Voltage Charts

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 143 of 454

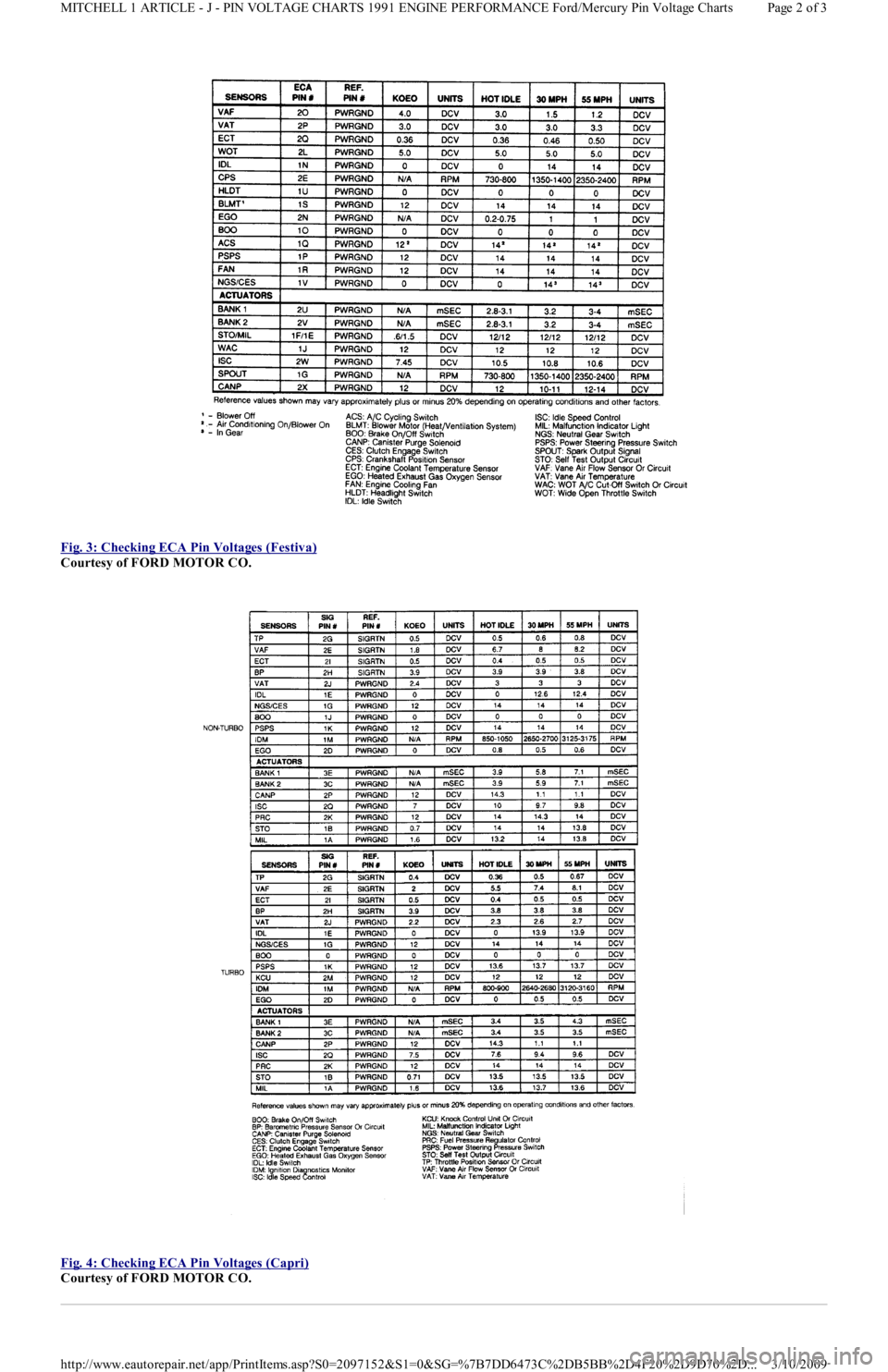

Fig. 3: Checking ECA Pin Voltages (Festiva)

Courtesy of FORD MOTOR CO.

Fig. 4: Checking ECA Pin Voltages (Capri)

Courtesy of FORD MOTOR CO.

Page 2 of 3 MITCHELL 1 ARTICLE - J - PIN VOLTAGE CHARTS 1991 ENGINE PERFORMANCE Ford/Mercury Pin Voltage Charts

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 145 of 454

Back To Article

N - REMOVE/INST ALL/OVERHAUL

1991 ENGINE PERFORMANCE Ford/Mercury Rem oval, Overhaul & Installation

INTRODUCTION

Removal, overhaul and installation procedures are covered in this article. If component removal and installation is primarily an unbolt and

bolt-on procedure, only a torque specification may be furnished.

IGNITION SYSTEM

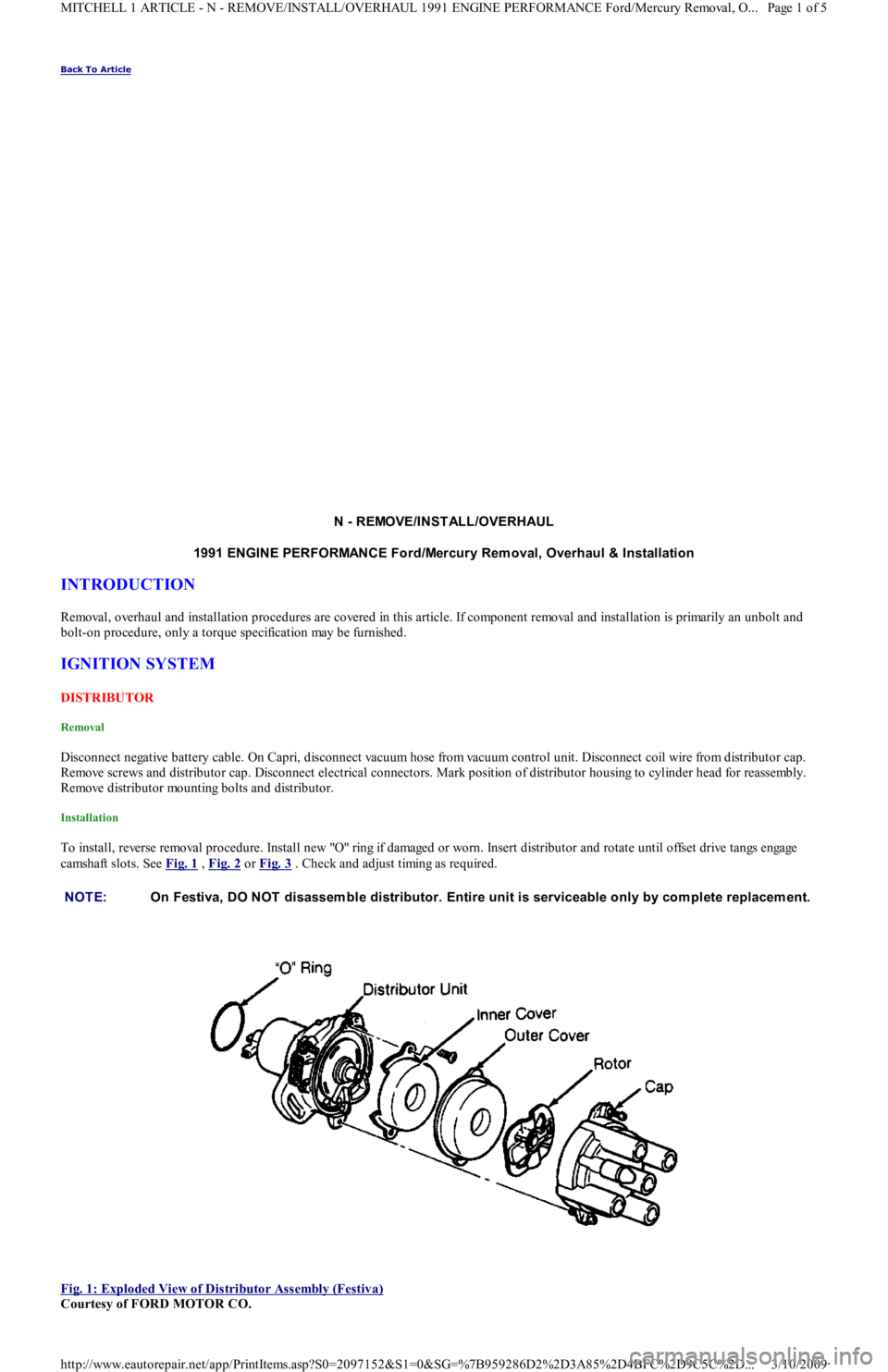

DISTRIBUTOR

Removal

Disconnect negative battery cable. On Capri, disconnect vacuum hose from vacuum control unit. Disconnect coil wire from distributor cap.

Remove screws and distributor cap. Disconnect electrical connectors. Mark position of distributor housing to cylinder head for reassembly.

Remove distributor mounting bolts and distributor.

Installation

To install, reverse removal procedure. Install new "O" ring if damaged or worn. Insert distributor and rotate until offset drive tangs engage

camshaft slots. See Fig. 1

, Fig. 2 or Fig. 3 . Check and adjust timing as required.

Fig. 1: Exploded View of Distributor Assembly (Festiva)

Courtesy of FORD MOTOR CO. NOTE:On Festiva, DO NOT disassem ble distributor. Entire unit is serviceable only by com plete replacem ent.

Page 1 of 5 MITCHELL 1 ARTICLE - N - REMOVE/INSTALL/OVERHAUL 1991 ENGINE PERFORMANCE Ford/Mercury Removal, O

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 147 of 454

ELECTRONIC CONTROL ASSEMBLY (ECA)

REMOVAL & INSTALLATION

Disconnect negative battery cable. On Festiva, from under instrument panel, remove heater duct. On Capri, disengage push-pin retainers by

pulling back on front edges of both center carpet panels. Remove carpet panel retaining screws and panels. Disconnect ECA wire harness

connector. Remove ECA bolts and ECA. To install, reverse removal procedure. On Festiva, ensure mounting clip is inserted into bulkhead

recess.

FUEL SYSTEM

FUEL SYSTEM PRESSURE RELEASE

Remove rear seat assembly. With engine running, disconnect fuel pump connector. Run engine until it stalls to relieve fuel line pressure.

FUEL INJECTORS

Removal

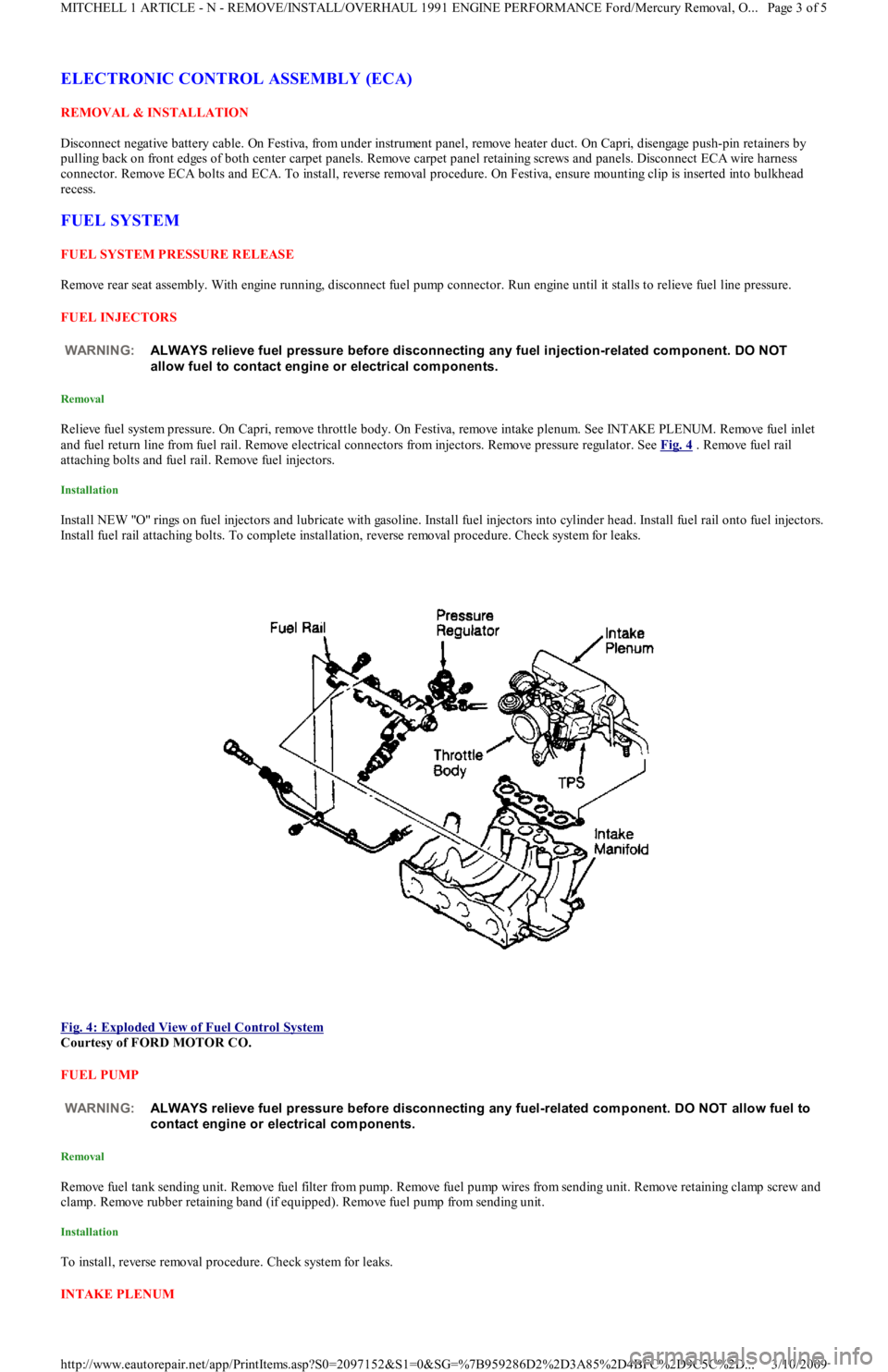

Relieve fuel system pressure. On Capri, remove throttle body. On Festiva, remove intake plenum. See INTAKE PLENUM. Remove fuel inlet

and fuel return line from fuel rail. Remove electrical connectors from injectors. Remove pressure regulator. See Fig. 4

. Remove fuel rail

attaching bolts and fuel rail. Remove fuel injectors.

Installation

Install NEW "O" rings on fuel injectors and lubricate with gasoline. Install fuel injectors into cylinder head. Install fuel rail onto fuel injectors.

Install fuel rail attaching bolts. To complete installation, reverse removal procedure. Check system for leaks.

Fig. 4: Exploded View of Fuel Control System

Courtesy of FORD MOTOR CO.

FUEL PUMP

Removal

Remove fuel tank sending unit. Remove fuel filter from pump. Remove fuel pump wires from sending unit. Remove retaining clamp screw and

clamp. Remove rubber retaining band (if equipped). Remove fuel pump from sending unit.

Installation

To install, reverse removal procedure. Check system for leaks.

INTAKE PLENUM WARNING:ALWAYS relieve fuel pressure before disconnecting any fuel injection-related com ponent. DO NOT

allow fuel to contact engine or electrical com ponents.

WARNING:ALWAYS relieve fuel pressure before disconnecting any fuel-related com ponent. DO NOT allow fuel to

contact engine or electrical com ponents.

Page 3 of 5 MITCHELL 1 ARTICLE - N - REMOVE/INSTALL/OVERHAUL 1991 ENGINE PERFORMANCE Ford/Mercury Removal, O

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 153 of 454

Back To Article

C - SPECIFICATIONS

1991 ENGINE PERFORMANCE Ford/Mercury - Service & Adjustm ent Specifications

INTRODUCTION

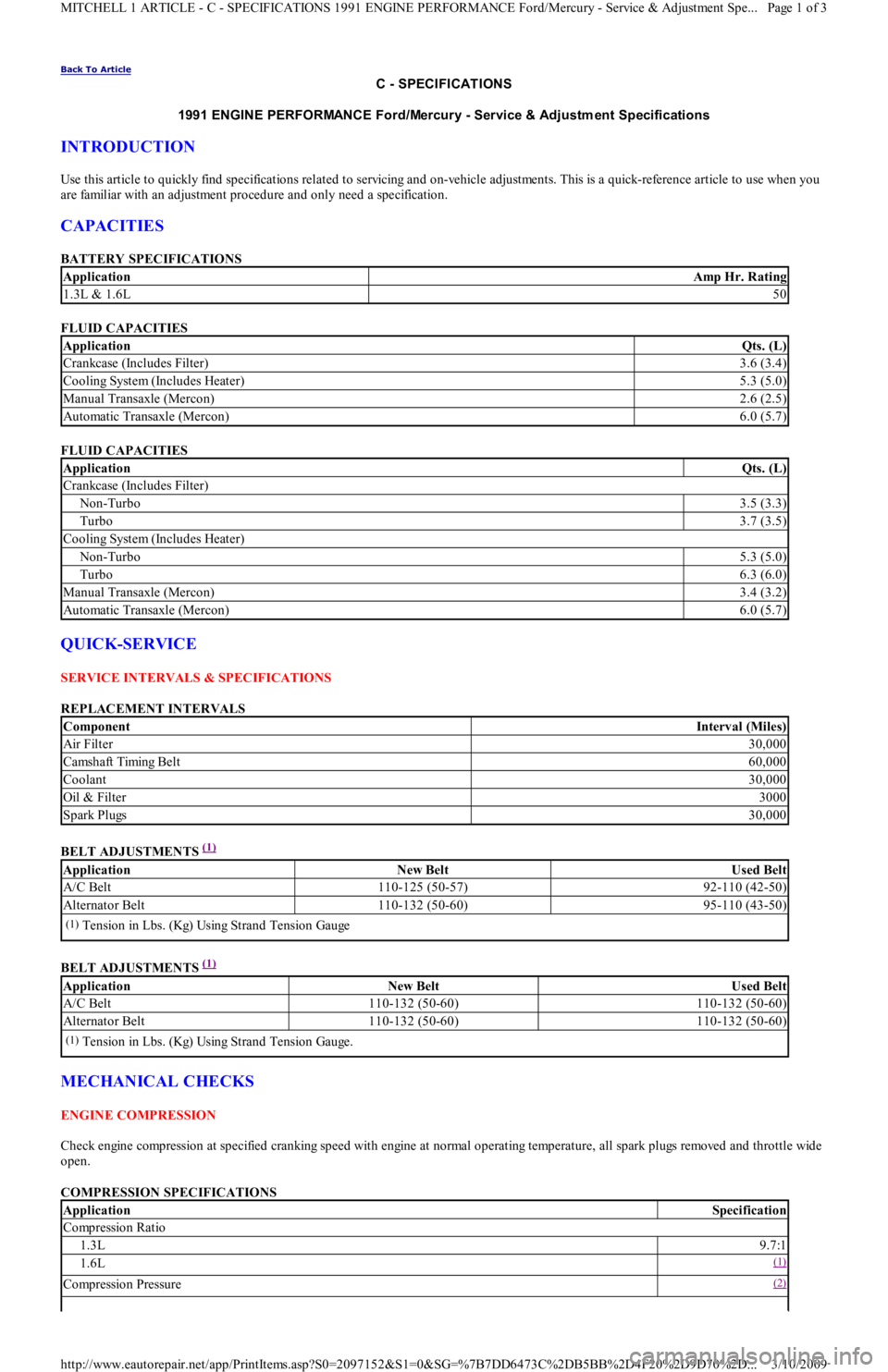

Use this article to quickly find specifications related to servicing and on-vehicle adjustments. This is a quick-reference article to use when you

are familiar with an adjustment procedure and only need a specification.

CAPACITIES

BATTERY SPECIFICATIONS

FLUID CAPACITIES

FLUID CAPACITIES

QUICK-SERVICE

SERVICE INTERVALS & SPECIFICATIONS

REPLACEMENT INTERVALS

BELT ADJUSTMENTS

(1)

BELT ADJUSTMENTS

(1)

MECHANICAL CHECKS

ENGINE COMPRESSION

Check engine compression at specified cranking speed with engine at normal operating temperature, all spark plugs removed and throttle wide

open.

COMPRESSION SPECIFICATIONS

ApplicationAmp Hr. Rating

1.3L & 1.6L50

ApplicationQts. (L)

Crankcase (Includes Filter)3.6 (3.4)

Cooling System (Includes Heater)5.3 (5.0)

Manual Transaxle (Mercon)2.6 (2.5)

Automatic Transaxle (Mercon)6.0 (5.7)

ApplicationQts. (L)

Crankcase (Includes Filter)

Non-Turbo3.5 (3.3)

Turbo3.7 (3.5)

Cooling System (Includes Heater)

Non-Turbo5.3 (5.0)

Turbo6.3 (6.0)

Manual Transaxle (Mercon)3.4 (3.2)

Automatic Transaxle (Mercon)6.0 (5.7)

ComponentInterval (Miles)

Air Filter30,000

Camsh aft Timin g Bel t60,000

Coolant30,000

Oil & Filter3000

Spark Plugs30,000

ApplicationNew BeltUsed Belt

A/C Belt110-125 (50-57)92-110 (42-50)

Alternator Belt110-132 (50-60)95-110 (43-50)

(1)Tension in Lbs. (Kg) Using Strand Tension Gauge

ApplicationNew BeltUsed Belt

A/C Belt110-132 (50-60)110-132 (50-60)

Alternator Belt110-132 (50-60)110-132 (50-60)

(1)Tension in Lbs. (Kg) Using Strand Tension Gauge.

ApplicationSpecification

Compression Ratio

1.3L9.7:1

1.6L(1)

Compression Pressure(2)

Page 1 of 3 MITCHELL 1 ARTICLE - C - SPECIFICATIONS 1991 ENGINE PERFORMANCE Ford/Mercury - Service & Adjustment Spe

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 156 of 454

Back To Article

F - BASIC TESTING

1991-92 ENGINE PERFORMANCE Ford Motor Co. Basic Diagnostic Procedures

INTRODUCTION

The following diagnostic steps help prevent overlooking simple problems and begin diagnosis for a no-start condition.

The first step in diagnosing any driveability problem is to verify the complaint. Test drive the vehicle under the conditions in which the

problem reportedly occurred.

Before entering self-diagnostics, perform a careful and complete visual inspection. Most engine control problems result from mechanical

breakdowns, poor electrical connections or damaged/misrouted vacuum hoses. Before condemning the computerized system, perform each test

listed in this article.

PRELIMINARY INSPECTION & ADJUSTMENTS

VISUAL INSPECTION

Perform a visual inspection of all electrical wiring. Look for chafed, stretched, cut or pinched wiring. Ensure electrical connections fit tightly

and are not corroded. Ensure vacuum hoses are properly routed and are not cut or pinched. If necessary, see VACUUM DIAGRAMS article in

the ENGINE PERFORMANCE Section to verify routing and connections. Inspect air induction system for possible vacuum leaks.

MECHANICAL INSPECTION

Compression

Engine mechanical condition can be checked using a compression gauge, vacuum gauge or engine analyzer. See engine analyzer instruction

manual for specific instructions. Lowest compression reading must be not less than 75 percent of highest reading.

Exhaust System Backpressure

Exhaust system can be checked with a vacuum gauge or a 0-5 psi pressure gauge. If a pressure gauge is used, remove O2 sensor. Connect gauge

to O2 sensor port. Start engine, and run at 2500 RPM. If exhaust system backpressure is more than 2 psi, exhaust system or catalytic converter

is plugged.

If a vacuum gauge is used, connect it to intake manifold vacuum. Start engine. Observe vacuum gauge. Open throttle part way and hold steady.

If vacuum gauge drops slowly after stabilizing, check exhaust system for a restriction.

FUEL PRESSURE

Fuel Pressure Release

Start engine (if possible), and unplug VAF meter connector. When engine stalls, turn ignition off and reconnect VAF meter wiring. Usin g sh o p

towel, cover fitting to absorb leakage when opening fuel system.

Fuel Pressure Check

1. Connect fuel pressure gauge between fuel filter and fuel rail. Open main valve, and close drain valve. Locate fuel pump check connector

in engine compartment, near left strut. Connect jumper wire between fuel pump test terminals (Black and Green/White wires on Capri

or Black and Green/Red wires on Festiva).

2. Turn ignition on to activate fuel pump. If pump does not run, check fuel pump circuit. If possible, start engine. Measure and record fuel

pressure. For fuel pressure specifications, see FUEL PRESSURE SPECIFICATIONS

article. Disconnect vacuum from pressure

regulator. Turn engine off. Wait 5 minutes and ensure residual pressure is at least 21 psi (1.5 kg/cm

2 ).

3. Operate fuel pump by reconnecting jumper wire at fuel pump check connector. Check fuel pump performance. Pinch hose between

pressure gauge and fuel filter. Do not hold longer than necessary to check pressure.For fuel pressure specifications, see FUEL

PRESSURE SPECIFICATIONS article. If pump does not meet specifications, check fuel pump circuit, fuel pump, fuel tank and fuel

filter or replace fuel pump.

FUEL PUMP PERFORMANCE NOTE:Unless stated otherwise in test procedure, perform all voltage tests with a Digital Volt-Ohm m eter

(DVOM) with a m inim um 10-m egohm input im pedance.

CAUT ION: DO NOT use ignition switch during com pression tests on fuel injected vehicles. Fuel injectors are

triggered by ignition switch during cranking m ode. Use a rem ote starter to crank engine to prevent fire

hazard and catalytic converter and engine oiling system contam ination.

WARNING:ALWAYS relieve fuel pressure before disconnecting any fuel injection system com ponent. DO NOT

allow fuel to contact engine or electrical com ponents.

NOTE:For 1991 fuel pressure specifications, see FUEL PRESSURE SPECIFICAT IONS

article. For 1992 fuel

pressure specifications, see FUEL PRESSURE SPECIFICAT IONS

article.

ApplicationPressure psi (kg/cm2 )Min. Vol. in 10 sec. Ozs. (cc)

Capri(1) 5.5 (167)

Festiva(1) 7.4 (220)

Page 1 of 4 MITCHELL 1 ARTICLE - F - BASIC TESTING 1991-92 ENGINE PERFORMANCE Ford Motor Co. Basic Diagnostic Proced

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 157 of 454

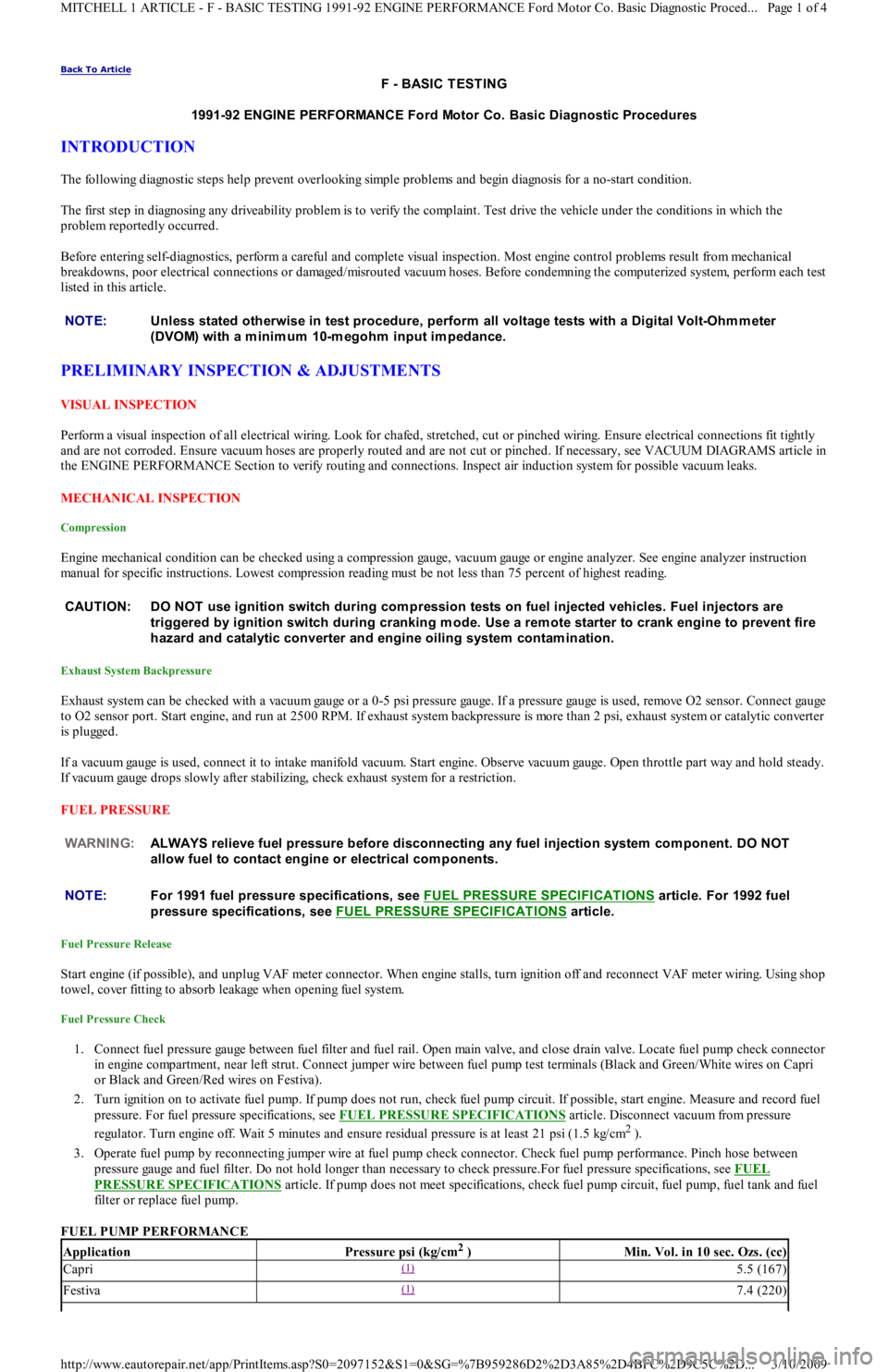

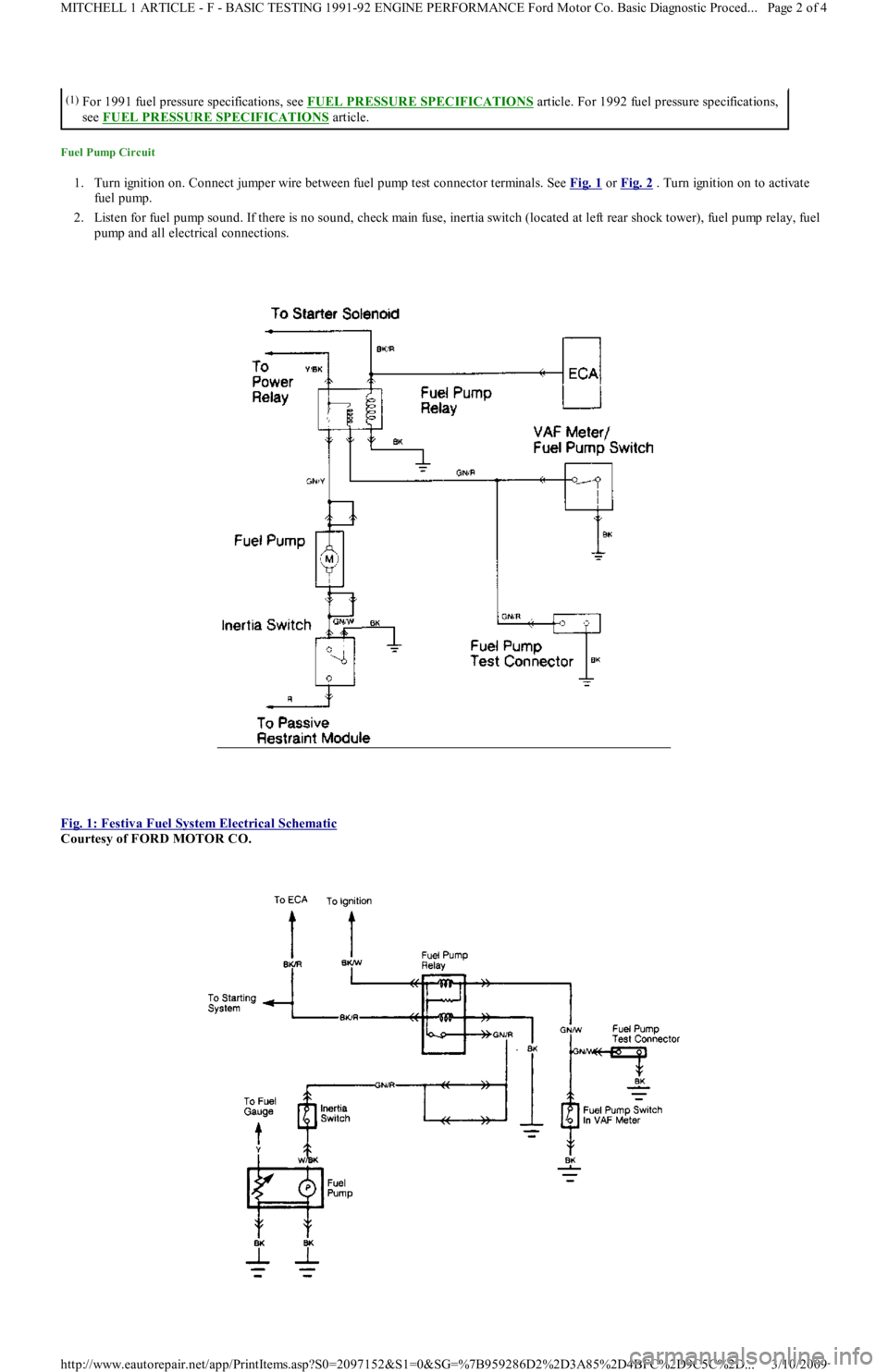

Fuel Pump Circuit

1. Turn ignition on. Connect jumper wire between fuel pump test connector terminals. See Fig. 1 or Fig. 2 . Turn ignition on to activate

fuel pump.

2. Listen for fuel pump sound. If there is no sound, check main fuse, inertia switch (located at left rear shock tower), fuel pump rel ay, fu el

pump and all electrical connections.

Fig. 1: Festiva Fuel System Electrical Schematic

Courtesy of FORD MOTOR CO.

(1)For 1991 fuel pressure specifications, see FUEL PRESSURE SPECIFICATIONS article. For 1992 fuel pressure specifications,

see FUEL PRESSURE SPECIFICATIONS

article.

Page 2 of 4 MITCHELL 1 ARTICLE - F - BASIC TESTING 1991-92 ENGINE PERFORMANCE Ford Motor Co. Basic Diagnostic Proced

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 158 of 454

Fig. 2: Capri Fuel System Electrical Schematic

Courtesy of FORD MOTOR CO.

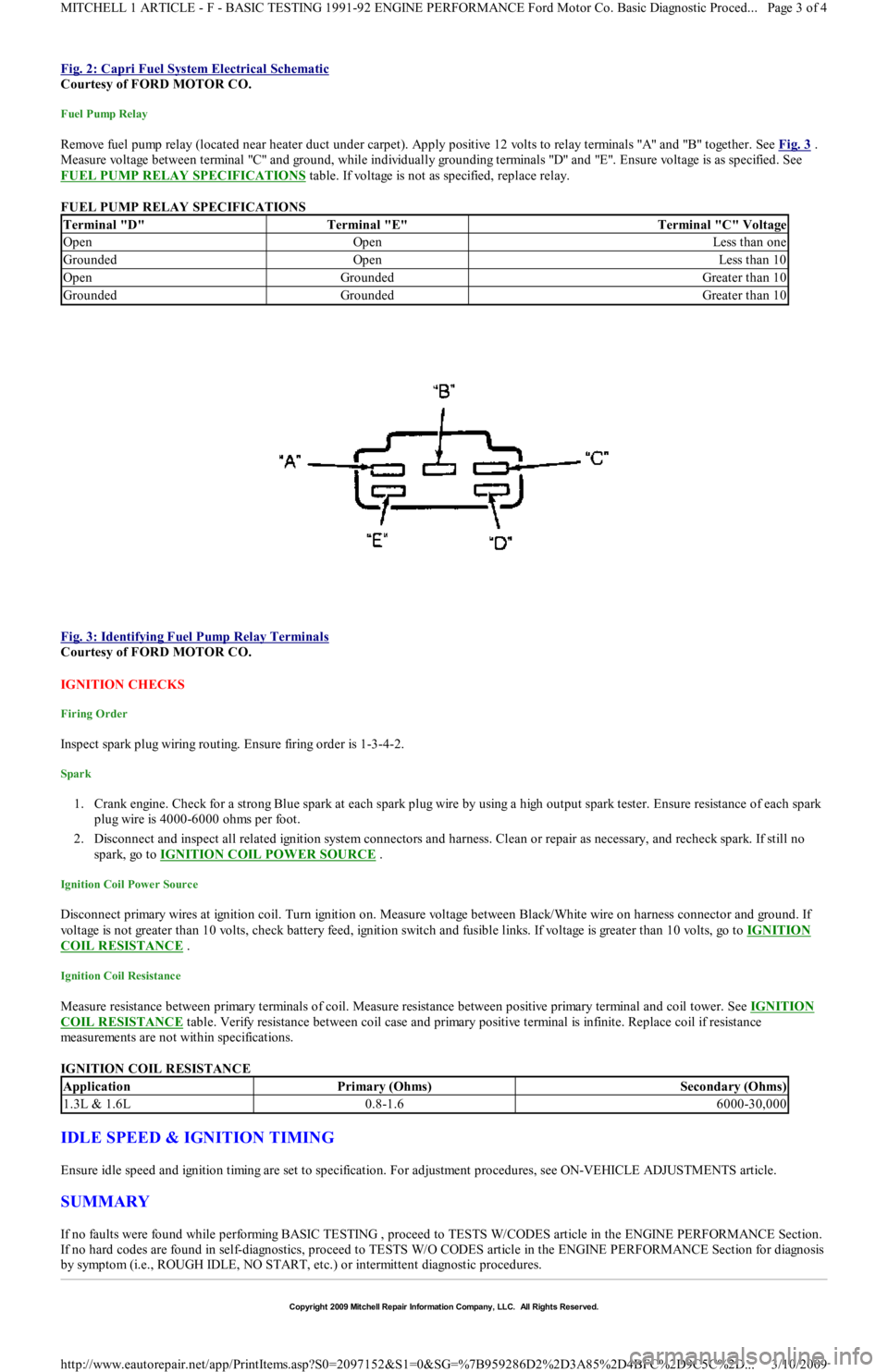

Fuel Pump Relay

Remove fuel pump relay (located near heater duct under carpet). Apply positive 12 volts to relay terminals "A" and "B" together. See Fig. 3 .

Measure voltage between terminal "C" and ground, while individually grounding terminals "D" and "E". Ensure voltage is as specified. See

FUEL PUMP RELAY SPECIFICATIONS

table. If voltage is not as specified, replace relay.

FUEL PUMP RELAY SPECIFICATIONS

Fig. 3: Identifying Fuel Pump Relay Terminals

Courtesy of FORD MOTOR CO.

IGNITION CHECKS

Firing Order

Inspect spark plug wiring routing. Ensure firing order is 1-3-4-2.

Spark

1. Crank engine. Check for a strong Blue spark at each spark plug wire by using a high output spark tester. Ensure resistance of each spark

plug wire is 4000-6000 ohms per foot.

2. Disconnect and inspect all related ignition system connectors and harness. Clean or repair as necessary, and recheck spark. If st il l n o

spark, go to IGNITION COIL POWER SOURCE

.

Ignition Coil Power Source

Disconnect primary wires at ignition coil. Turn ignition on. Measure voltage between Black/White wire on harness connector and ground. If

voltage is not greater than 10 volts, check battery feed, ignition switch and fusible links. If voltage is greater than 10 volts, go to IGNITION

COIL RESISTANCE .

Ignition Coil Resistance

Measure resistance between primary terminals of coil. Measure resistance between positive primary terminal and coil tower. See IGNITION

COIL RESISTANCE table. Verify resistance between coil case and primary positive terminal is infinite. Replace coil if resistance

measurements are not within specifications.

IGNITION COIL RESISTANCE

IDLE SPEED & IGNITION TIMING

Ensure idle speed and ignition timing are set to specification. For adjustment procedures, see ON-VEHICLE ADJUSTMENTS article.

SUMMARY

If no faults were found while performing BASIC TESTING , proceed to TESTS W/CODES article in the ENGINE PERFORMANCE Section.

If no hard codes are found in self-diagnostics, proceed to TESTS W/O CODES article in the ENGINE PERFORMANCE Section for diagnosis

by symptom (i.e., ROUGH IDLE, NO START, etc.) or intermittent diagnostic procedures.

Terminal "D"Terminal "E"Terminal "C" Voltage

OpenOpenLess than one

GroundedOpenLess than 10

OpenGroundedGreater than 10

GroundedGroundedGreater than 10

ApplicationPrimary (Ohms)Secondary (Ohms)

1.3L & 1.6L0.8-1.66000-30,000

Copyr ight 2009 Mitchell Repair Information Company, LLC. All Rights Reserved.

Page 3 of 4 MITCHELL 1 ARTICLE - F - BASIC TESTING 1991-92 ENGINE PERFORMANCE Ford Motor Co. Basic Diagnostic Proced

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 160 of 454

Back To Article

P - EGR FUNCT ION T EST ING

1989-95 ENGINE PERFORMANCE Ford Motor Co. EGR Function T esting

TESTING

EGR VALVE

1989 Merkur & 1991-95 Escort/Tracer 1.9L (Ported EGR Valve)

1. Check vacuum lines for correct routing. Ensure no vacuum is available to EGR valve with engine idling. Disconnect idle air by-pass

valve connector.

2. Disconnect vacuum hose at EGR valve and plug hose end. Connect a vacuum pump to EGR valve. Start engine. Apply 5-10 in. Hg to

vacuum hose. If idle becomes unstable or engine stalls, EGR valve is functioning properly.

3. Reconnect idle air by-pass connector. Connect a vacuum pump to EGR vacuum supply hose. Ensure engine is at normal operating

temperature. Increase engine speed 1500-2000 RPM. Vacuum gauge should read more than 5 in. Hg. If system operates as indicated,

system is functioning properly.

1988-89 Festiva & Tracer (Ported EGR Valve)

1. Ensure engine is at normal operating temperature. Check vacuum lines for correct routing. Ensure no vacuum is available to EGR valve

with engine idling. Start engine. Place finger against EGR diaphragm. Increase engine RPM. Diaphragm should move.

2. Remove EGR vacuum supply hose from EGR valve and plug hose end. Connect a vacuum pump to EGR valve. With engine idling,

apply 6 in. Hg to EGR valve. If vacuum holds and idle becomes unstable or engine stalls, EGR valve is functioning properly.

Copyr ight 2009 Mitchell Repair Information Company, LLC. All Rights Reserved.

Article GUID: A00022693

Page 1 of 1 MITCHELL 1 ARTICLE - P - EGR FUNCTION TESTING 1989-95 ENGINE PERFORMANCE Ford Motor Co. EGR Functio

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...