check engine FORD FESTIVA 1991 Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1991, Model line: FESTIVA, Model: FORD FESTIVA 1991Pages: 454, PDF Size: 9.53 MB

Page 161 of 454

Back To Article

I - SYST EM/COMPONENT T EST S

1991 ENGINE PERFORMANCE Ford Motor Co. - Ford/Mercury System & Com ponent T esting

INTRODUCTION

Before testing separate components or systems, perform procedures in BASIC TESTING article in the ENGINE PERFORMANCE Section.

Since many computer-controlled and monitored components set a trouble code if they malfunction, also perform procedures in TESTS

W/CODES article in the ENGINE PERFORMANCE Section.

AIR INDUCTION SYSTEMS

TURBOCHARGERS

Wastegate Actuator

Disconnect air hose from wastegate actuator. Apply 7.0-8.6 psi (.5-.6 kg/cm2 ) regulated air pressure to wastegate inlet fitting. Replace

turbocharger if wastegate actuator rod does not move.

COMPUTERIZED ENGINE CONTROLS

ELECTRONIC CONTROL ASSEMBLY (ECA)

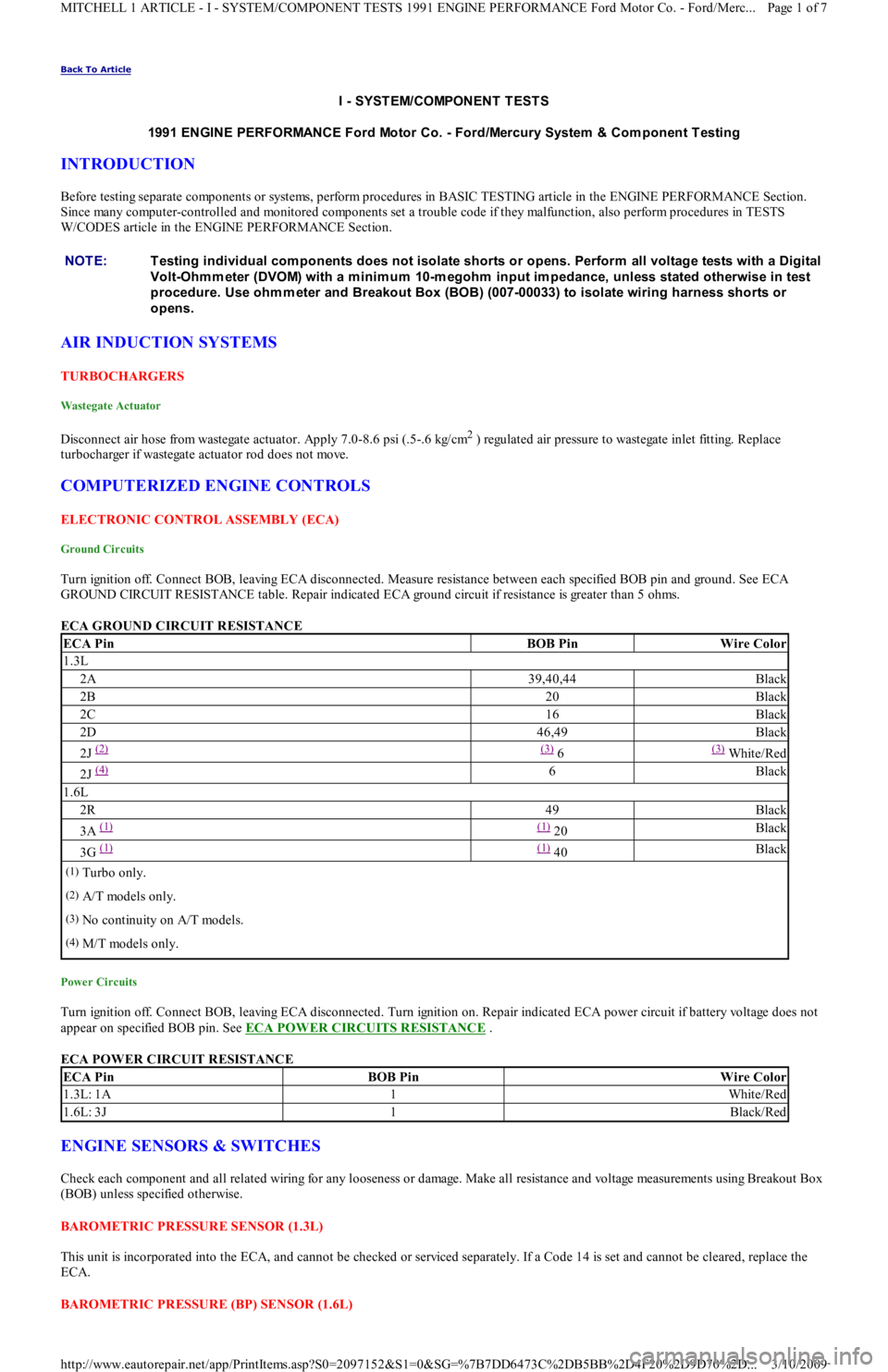

Ground Circuits

Turn ignition off. Connect BOB, leaving ECA disconnected. Measure resistance between each specified BOB pin and ground. See ECA

GROUND CIRCUIT RESISTANCE table. Repair indicated ECA ground circuit if resistance is greater than 5 ohms.

ECA GROUND CIRCUIT RESISTANCE

Power Circuits

Turn ignition off. Connect BOB, leaving ECA disconnected. Turn ignition on. Repair indicated ECA power circuit if battery voltage d o e s n o t

appear on specified BOB pin. See ECA POWER CIRCUITS RESISTANCE

.

ECA POWER CIRCUIT RESISTANCE

ENGINE SENSORS & SWITCHES

Check each component and all related wiring for any looseness or damage. Make all resistance and voltage measurements using Breakout Box

(BOB) unless specified otherwise.

BAROMETRIC PRESSURE SENSOR (1.3L)

This unit is incorporated into the ECA, and cannot be checked or serviced separately. If a Code 14 is set and cannot be cleared, replace the

ECA.

BAROMETRIC PRESSURE (BP) SENSOR (1.6L) NOTE:T esting individual com ponents does not isolate shorts or opens. Perform all voltage tests with a Digital

Volt-Ohm m eter (DVOM) with a m inim um 10-m egohm input im pedance, unless stated otherwise in test

procedure. Use ohm m eter and Breakout Box (BOB) (007-00033) to isolate wiring harness shorts or

opens.

ECA PinBOB PinWire Color

1.3L

2A39,40,44Black

2B20Black

2C16Black

2D46,49Black

2J (2) (3) 6(3) White/Red

2J (4) 6Black

1.6L

2R49Black

3A (1) (1) 20Black

3G (1) (1) 40Black

(1)Turbo only.

(2)A/T models only.

(3)No continuity on A/T models.

(4)M/T models only.

ECA PinBOB PinWire Color

1.3L: 1A1White/Red

1.6L: 3J1Black/Red

Page 1 of 7 MITCHELL 1 ARTICLE - I - SYSTEM/COMPONENT TESTS 1991 ENGINE PERFORMANCE Ford Motor Co. - Ford/Merc

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 162 of 454

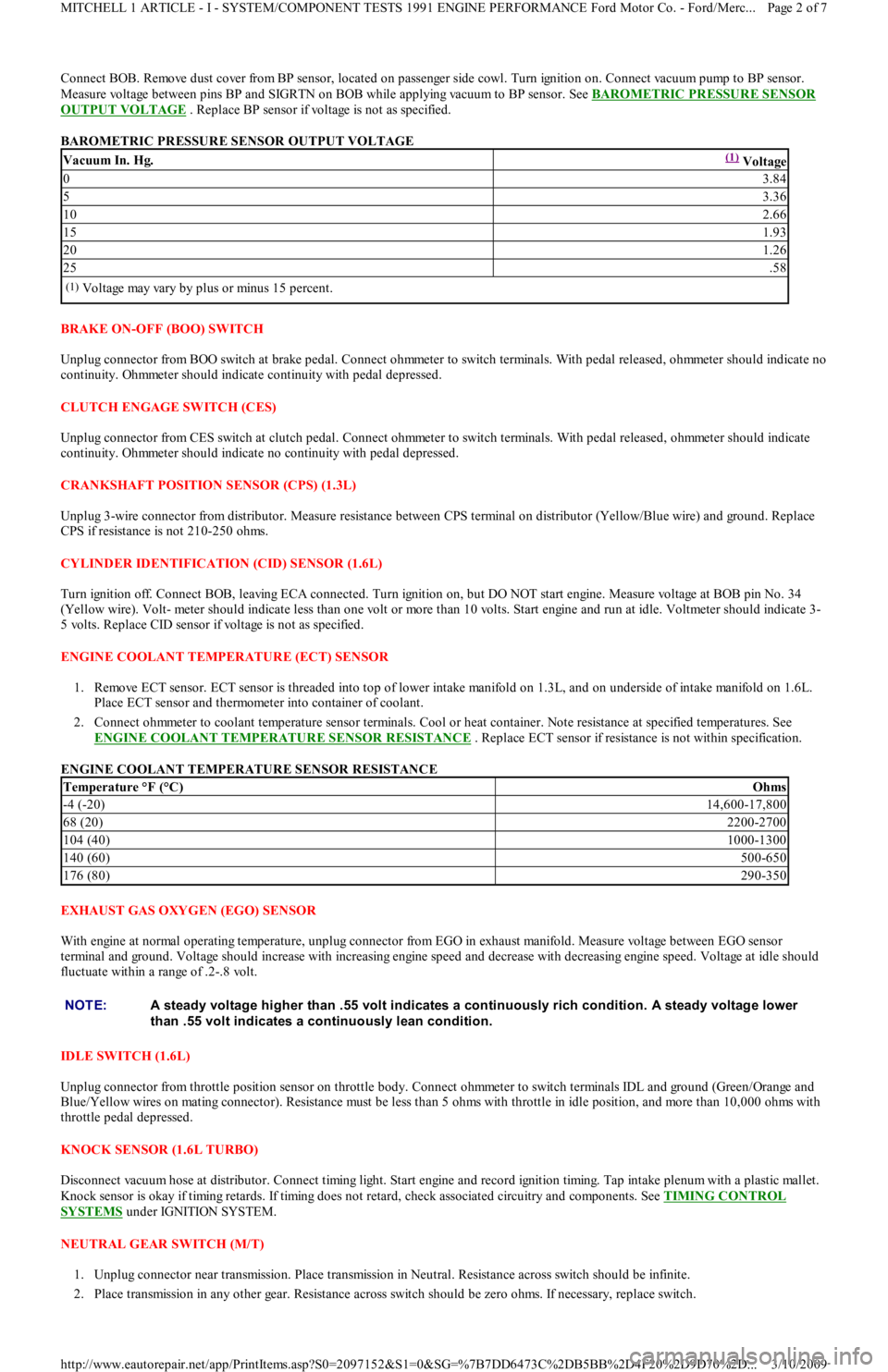

Connect BOB. Remove dust cover from BP sensor, located on passenger side cowl. Turn ignition on. Connect vacuum pump to BP sensor.

Measure voltage between pins BP and SIGRTN on BOB while applying vacuum to BP sensor. See BAROMETRIC PRESSURE SENSOR

OUTPUT VOLTAGE . Replace BP sensor if voltage is not as specified.

BAROMETRIC PRESSURE SENSOR OUTPUT VOLTAGE

BRAKE ON-OFF (BOO) SWITCH

Unplug connector from BOO switch at brake pedal. Connect ohmmeter to switch terminals. With pedal released, ohmmeter should indicate no

continuity. Ohmmeter should indicate continuity with pedal depressed.

CLUTCH ENGAGE SWITCH (CES)

Unplug connector from CES switch at clutch pedal. Connect ohmmeter to switch terminals. With pedal released, ohmmeter should indicate

continuity. Ohmmeter should indicate no continuity with pedal depressed.

CRANKSHAFT POSITION SENSOR (CPS) (1.3L)

Unplug 3-wire connector from distributor. Measure resistance between CPS terminal on distributor (Yellow/Blue wire) and ground. Replace

CPS if resistance is not 210-250 ohms.

CYLINDER IDENTIFICATION (CID) SENSOR (1.6L)

Turn ignition off. Connect BOB, leaving ECA connected. Turn ignition on, but DO NOT start engine. Measure voltage at BOB pin No. 34

(Yellow wire). Volt- meter should indicate less than one volt or more than 10 volts. Start engine and run at idle. Voltmeter should indicate 3-

5 volts. Replace CID sensor if voltage is not as specified.

ENGINE COOLANT TEMPERATURE (ECT) SENSOR

1. Remove ECT sensor. ECT sensor is threaded into top of lower intake manifold on 1.3L, and on underside of intake manifold on 1.6L.

Place ECT sensor and thermometer into container of coolant.

2. Connect ohmmeter to coolant temperature sensor terminals. Cool or heat container. Note resistance at specified temperatures. See

ENGINE COOLANT TEMPERATURE SENSOR RESISTANCE

. Replace ECT sensor if resistance is not within specification.

ENGINE COOLANT TEMPERATURE SENSOR RESISTANCE

EXHAUST GAS OXYGEN (EGO) SENSOR

With engine at normal operating temperature, unplug connector from EGO in exhaust manifold. Measure voltage between EGO sensor

terminal and ground. Voltage should increase with increasing engine speed and decrease with decreasing engine speed. Voltage at idle should

fluctuate within a range of .2-.8 volt.

IDLE SW ITCH (1.6L)

Unplug connector from throttle position sensor on throttle body. Connect ohmmeter to switch terminals IDL and ground (Green/Orange and

Blue/Yellow wires on mating connector). Resistance must be less than 5 ohms with throttle in idle position, and more than 10,000 ohms with

throttle pedal depressed.

KNOCK SENSOR (1.6L TURBO)

Disconnect vacuum hose at distributor. Connect timing light. Start engine and record ignition timing. Tap intake plenum with a plastic mallet.

Knock sensor is okay if timing retards. If timing does not retard, check associated circuitry and components. See TIMING CONTROL

SYSTEMS under IGNITION SYSTEM.

NEUTRAL GEAR SWITCH (M/T)

1. Unplug connector near transmission. Place transmission in Neutral. Resistance across switch should be infinite.

2. Place transmission in any other gear. Resistance across switch should be zero ohms. If necessary, replace switch.

Vacuum In. Hg.(1) Voltage

03.84

53.36

102.66

151.93

201.26

25.58

(1)Voltage may vary by plus or minus 15 percent.

Temperature °F (°C)Ohms

-4 (-20)14,600-17,800

68 (20)2200-2700

104 (40)1000-1300

140 (60)500-650

176 (80)290-350

NOTE:A steady voltage higher than .55 volt indicates a continuously rich condition. A steady voltage lower

than .55 volt indicates a continuously lean condition.

Page 2 of 7 MITCHELL 1 ARTICLE - I - SYSTEM/COMPONENT TESTS 1991 ENGINE PERFORMANCE Ford Motor Co. - Ford/Merc

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 163 of 454

POWER STEERING PRESSURE SWITCH

1. Start engine and run it at idle. Remove connector from switch. Connect ohmmeter to switch terminals. Turn steering wheel from side to

side while observing ohmmeter.

2. Replace power steering switch if continuity does not exist with front wheels turned, or if continuity exists with wheels straight ahead.

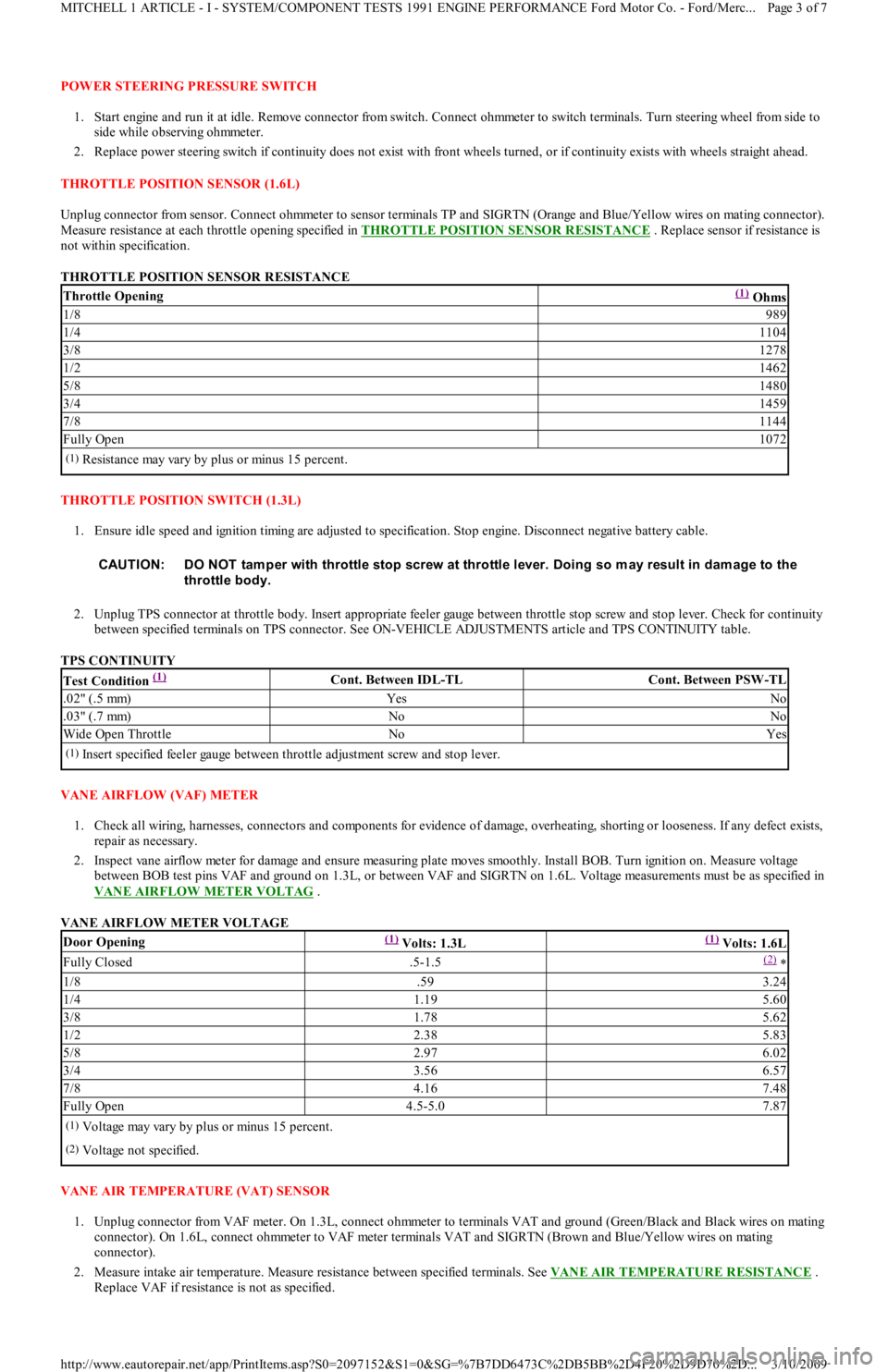

THROTTLE POSITION SENSOR (1.6L)

Unplug connector from sensor. Connect ohmmeter to sensor terminals TP and SIGRTN (Orange and Blue/Yellow wires on mating connector).

Measure resistance at each throttle opening specified in THROTTLE POSITION SENSOR RESISTANCE

. Replace sensor if resistance is

not within specification.

THROTTLE POSITION SENSOR RESISTANCE

THROTTLE POSITION SWITCH (1.3L)

1. Ensure idle speed and ignition timing are adjusted to specification. Stop engine. Disconnect negative battery cable.

2. Unplug TPS connector at throttle body. Insert appropriate feeler gauge between throttle stop screw and stop lever. Check for continuity

between specified terminals on TPS connector. See ON-VEHICLE ADJUSTMENTS article and TPS CONTINUITY table.

TPS CONTINUITY

VANE AIRFLOW (VAF) METER

1. Check all wiring, harnesses, connectors and components for evidence of damage, overheating, shorting or looseness. If any defect exists,

repair as necessary.

2. Inspect vane airflow meter for damage and ensure measuring plate moves smoothly. Install BOB. Turn ignition on. Measure voltage

between BOB test pins VAF and ground on 1.3L, or between VAF and SIGRTN on 1.6L. Voltage measurements must be as specified in

VANE AIRFLOW METER VOLTAG

.

VANE AIRFLOW METER VOLTAGE

VANE AIR TEMPERATURE (VAT) SENSOR

1. Unplug connector from VAF meter. On 1.3L, connect ohmmeter to terminals VAT and ground (Green/Black and Black wires on mating

connector). On 1.6L, connect ohmmeter to VAF meter terminals VAT and SIGRTN (Brown and Blue/Yellow wires on mating

connector).

2. Measure intake air temperature. Measure resistance between specified terminals. See VANE AIR TEMPERATURE RESISTANCE

.

Replace VAF if resistance is not as specified.

Throttle Opening(1) Ohms

1/8989

1/41104

3/81278

1/21462

5/81480

3/41459

7/81144

Fully Open1072

(1)Resistance may vary by plus or minus 15 percent.

CAUT ION: DO NOT tam per with throttle stop screw at throttle lever. Doing so m ay result in dam age to the

throttle body.

Test Condition (1) Cont. Between IDL-TLCont. Between PSW-TL

.02" (.5 mm)YesNo

.03" (.7 mm)NoNo

Wide Open ThrottleNoYes

(1)Insert specified feeler gauge between throttle adjustment screw and stop lever.

Door Opening(1) Volts: 1.3L(1) Volts: 1.6L

Fully Closed.5-1.5(2) *

1/8.593.24

1/41.195.60

3/81.785.62

1/22.385.83

5/82.976.02

3/43.566.57

7/84.167.48

Fully Open4.5-5.07.87

(1)Voltage may vary by plus or minus 15 percent.

(2)Voltage not specified.

Page 3 of 7 MITCHELL 1 ARTICLE - I - SYSTEM/COMPONENT TESTS 1991 ENGINE PERFORMANCE Ford Motor Co. - Ford/Merc

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 164 of 454

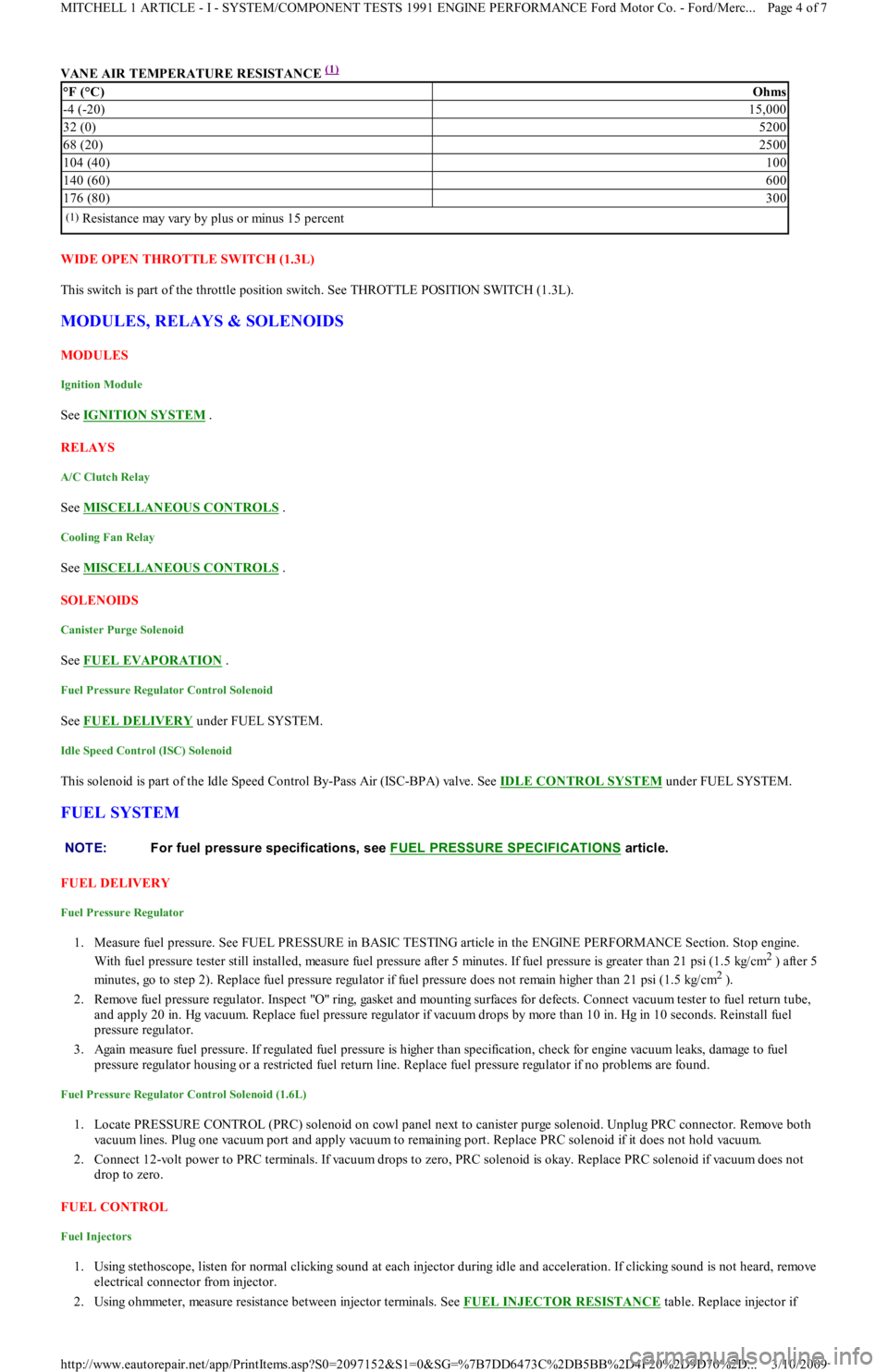

VANE AIR TEMPERATURE RESISTANCE (1)

WIDE OPEN THROTTLE SWITCH (1.3L)

This switch is part of the throttle position switch. See THROTTLE POSITION SWITCH (1.3L).

MODULES, RELAYS & SOLENOIDS

MODULES

Ignition Module

See IGNITION SYSTEM .

RELAYS

A/C Clutch Relay

See MISCELLANEOUS CONTROLS .

Cooling Fan Relay

See MISCELLANEOUS CONTROLS .

SOLENOIDS

Canister Purge Solenoid

See FUEL EVAPORATION .

Fuel Pressure Regulator Control Solenoid

See FUEL DELIVERY under FUEL SYSTEM.

Idle Speed Control (ISC) Solenoid

This solenoid is part of the Idle Speed Control By-Pass Air (ISC-BPA) valve. See IDLE CONTROL SYSTEM under FUEL SYSTEM.

FUEL SYSTEM

FUEL DELIVERY

Fuel Pressure Regulator

1. Measure fuel pressure. See FUEL PRESSURE in BASIC TESTING article in the ENGINE PERFORMANCE Section. Stop engine.

With fuel pressure tester still installed, measure fuel pressure after 5 minutes. If fuel pressure is greater than 21 psi (1.5 kg/cm

2 ) after 5

minutes, go to step 2). Replace fuel pressure regulator if fuel pressure does not remain higher than 21 psi (1.5 kg/cm

2 ).

2. Remove fuel pressure regulator. Inspect "O" ring, gasket and mounting surfaces for defects. Connect vacuum tester to fuel return tube,

and apply 20 in. Hg vacuum. Replace fuel pressure regulator if vacuum drops by more than 10 in. Hg in 10 seconds. Reinstall fuel

pressure regulator.

3. Again measure fuel pressure. If regulated fuel pressure is higher than specification, check for engine vacuum leaks, damage to fuel

pressure regulator housing or a restricted fuel return line. Replace fuel pressure regulator if no problems are found.

Fuel Pressure Regulator Control Solenoid (1.6L)

1. Locate PRESSURE CONTROL (PRC) solenoid on cowl panel next to canister purge solenoid. Unplug PRC connector. Remove both

vacuum lines. Plug one vacuum port and apply vacuum to remaining port. Replace PRC solenoid if it does not hold vacuum.

2. Connect 12-volt power to PRC terminals. If vacuum drops to zero, PRC solenoid is okay. Replace PRC solenoid if vacuum does not

drop to zero.

FUEL CONTROL

Fuel Injectors

1. Using stethoscope, listen for normal clicking sound at each injector during idle and acceleration. If clicking sound is not heard, remove

electrical connector from injector.

2. Using ohmmeter, measure resistance between injector terminals. See FUEL INJECTOR RESISTANCE

table. Replace injector if

°F (°C)Ohms

-4 (-20)15,000

32 (0)5200

68 (20)2500

104 (40)100

140 (60)600

176 (80)300

(1)Resistance may vary by plus or minus 15 percent

NOTE:For fuel pressure specifications, see FUEL PRESSURE SPECIFICAT IONS

article.

Page 4 of 7 MITCHELL 1 ARTICLE - I - SYSTEM/COMPONENT TESTS 1991 ENGINE PERFORMANCE Ford Motor Co. - Ford/Merc

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 165 of 454

resistance is not within specifications. If injector resistance is okay, check for 12 volts at each injector connector. Repair or replace

connector as necessary.

FUEL INJECTOR RESISTANCE

IDLE CONTROL SYSTEM

Idle Speed Control By-pass Air (ISC-BPA) Valve

1. Remove ISC-BPA valve from engine. Connect a hose from a hot water tap to coolant inlet nipple on ISC-BPA valve. Blow through

valve air port. Note resistance to airflow.

2. Supply hot water at 130°F (56°C) minimum to ISC-BPA valve and allow time for valve to respond. Blow through valve again. If

resistance to airflow does not increase when valve is hot, replace ISC-BPA valve.

3. Apply 12 volts to solenoid terminals. If solenoid does not click, replace ISC-BPA valve.

IGNITION SYSTEM

PICK-UP COIL

Check continuity of pick-up coil. If continuity exists, replace igniter unit. If continuity does not exist, replace pick-up coil.

TIMING CONTROL SYSTEMS

Advance Components (1.3L)

Ignition timing advance is controlled by the ECA.

Advance Components (1.6L Non-Turbo)

Ignition advance is controlled by a centrifugal advance mechanism within the distributor, and by a vacuum advance mechanism. If centrifugal

advance is not within specification, service the distributor. Replace the vacuum advance mechanism if vacuum advance is not within

specification. See IGNITION TIMING

. Also see IGNITION TIMING in ADJUSTMENTS article in the ENGINE PERFORMANCE Section.

IGNITION TIMING

Retard Components (1.6L Turbo)

Positive pressure to the vacuum advance cylinder on the distributor retards ignition timing. The ECA also retards ignition timing when it

receives a signal from a Knock Sensor (KS), Knock Control Unit (KC) and related circuitry.

1. Disconnect and plug hoses at distributor. Connect timing light and start engine. Record ignition timing. Tap intake plenum with plastic

mallet while observing ignition timing. If timing retards, knock control circuitry is okay. If timing does not retard, go to step 2).

2. Unplug KC sensor service connector near ECA. Tap intake plenum with plastic mallet while observing ignition timing. If ignition timing

retards, go to step 3). If timing does not retard, go to step 4).

3. Reconnect KC service connector. Tap intake plenum with plastic mallet while observing ignition timing. If ignition timing retards,

replace knock controller. If ignition timing does not retard, go to step 4).

4. Unplug KC service connector near ECA. Temporarily install a known good KS. Tap intake plenum with plastic mallet while observing

ignition timing. If ignition timing retards, replace KS. If ignition timing does not retard, go to step 5).

5. Turn ignition off. Connect BOB. Ensure VPWR and ground wires to KC are okay. Check all KC wiring for shorts or opens. If wiring is

okay, replace KC.

EMISSION SYSTEMS & SUB-SYSTEMS

FUEL EVAPORATION

Canister Purge Solenoid

1. Disconnect vacuum hoses from solenoid. See Fig. 1 . Blow through port "A". Ensure no air exhausts from port "B".

2. Disconnect 2-wire connector from solenoid. Connect 12 volts to one terminal and ground the other terminal of solenoid. Blow air

though port "A". Ensure air exhausts through port "B".

ApplicationOhms

1.3L & 1.6L12-16

NOTE:For basic ignition checks, see BASIC T EST ING article in the ENGINE PERFORMANCE Section.

ApplicationAuto. Trans.Man. Trans.

1.6L Non-Turbo1-3 @ 8500-4 @ 850

1.6L Turbo10-14 @ 8500-4 @ 850

Page 5 of 7 MITCHELL 1 ARTICLE - I - SYSTEM/COMPONENT TESTS 1991 ENGINE PERFORMANCE Ford Motor Co. - Ford/Merc

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 168 of 454

Back To Article

G - T EST S W/CODES

1991-92 ENGINE PERFORMANCE Ford Motor Co. Self-Diagnostics

INTRODUCTION

If no faults were found while performing BASIC TESTING , proceed with self-diagnostics. If no fault codes or only pass codes are present

after entering self-diagnostics, proceed to TESTS W/O CODES article in the ENGINE PERFORMANCE Section for diagnosis by symptom

(i.e., ROUGH IDLE, NO START, etc.).

This article uses many abbreviations for devices, signal names, and wire colors. See SELF

-DIAGNOSTICS ABBREVIATIONS table.

Abbreviations for wire colors used in individual PINPOINT TEST diagrams are as follows:

BLK - Black

BLU - Blue

BRN - Brown

GRN - Green

LT GRN - Light Green

ORG - Orange

PNK - Pink

RED - Red

WHT - White

YEL - Yellow

SELF-DIAGNOSTICS ABBREVIATIONS

SELF-DIAGNOSTIC SYSTEM

Hard Failures

Hard failures cause CHECK ENGINE light (MIL) to come on and remain on until problem is repaired. If MIL comes on and remains on (light

may flash) during vehicle operation, cause of malfunction must be determined using diagnostic (code) charts. If a sensor fails, ECA will use a

substitute value in its calculations to permit continued engine operation. In this condition (limp-in mode), vehicle will run but driveability will

not be optimum.

Intermittent Failures

Intermittent failures may cause MIL to flicker or come on and go off after intermittent defect goes away. Corresponding trouble code, however,

will be retained in ECA memory. If related defect does not reoccur within a certain time frame, related trouble code will be erased from ECA

ApplicationAbbreviation

Analog Volt/OhmmeterVOM

Barometric Pressure SensorBP

Breakout BoxBOB

Canister Purge Control SolenoidCANP

CHECK ENGINE LightMIL

Crankshaft Position SensorCPS

Cylinder Identification SensorCID

Electronic Control AssemblyECA

Electronic Engine ControlEEC

Engine Coolant Temperature SensorECT

Exhaust Gas Oxygen SensorEGO

Idle Speed ControlISC

Ignition Diagnostic MonitorIDM

Keep Alive PowerKAPWR

Key On Engine OffKOEO

Key On Engine RunningKOER

Knock ControlKC

Power & Ground ConnectionsPGC

Fuel Pressure Regulator Control SolenoidPRC

Reference Voltage & Signal ReturnVREF

Self-Test InputSTI

Self-Test OutputSTO

Signal ReturnSIGRTN

Solenoid Controlled By GroundSCG

Switch Monitor LampSML

Switch To GroundSTG

Switch To PowerSTP

Throttle Position SensorTP

Vane Airflow MeterVAF

Vane Air Temperature SensorVAT

Vehicle PowerVPWR

Vehicle Speed SensorVSS

Page 1 of 20 MITCHELL 1 ARTICLE - G - TESTS W/CODES 1991-92 ENGINE PERFORMANCE Ford Motor Co. Self-Diagnostics

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 169 of 454

memory. Intermittent failures may be caused by a sensor, connector, or wiring. See INTERMITTENTS in TESTS W/O CODES article in the

ENGINE PERFORMANCE Section.

VISUAL CHECK & VEHICLE PREPARATION

Before connecting any equipment to diagnose EEC system, perform following preparatory procedures:

Verify condition of air cleaner and air ducts.

Check all vacuum hoses for leaks, restrictions, or improper routing.

Check EEC system wiring harness electrical connections for corrosion, bent or broken pins, loose wires or terminals, or improper

routing.

Check ECA, sensors, and actuators for physical damage.

Check engine oil and coolant level.

Perform all necessary safety precautions to prevent personal injury or vehicle damage.

Set parking brake. Place shift lever in Park for automatic transmissions, or Neutral for manual transmissions. DO NOT move shift lever

during test unless specifically directed.

Turn off all lights and accessories. Ensure vehicle doors are closed when measuring voltage or resistance.

Start engine. Run at idle until upper radiator hose is hot and pressurized and engine is off fast idle. Check for leaks around exhaust

manifold, exhaust gas oxygen sensor, and vacuum hose connections.

Turn ignition off. Service items as required. Go to EQUIPMENT HOOK-UP .

EQUIPMENT HOOK-UP

VOM

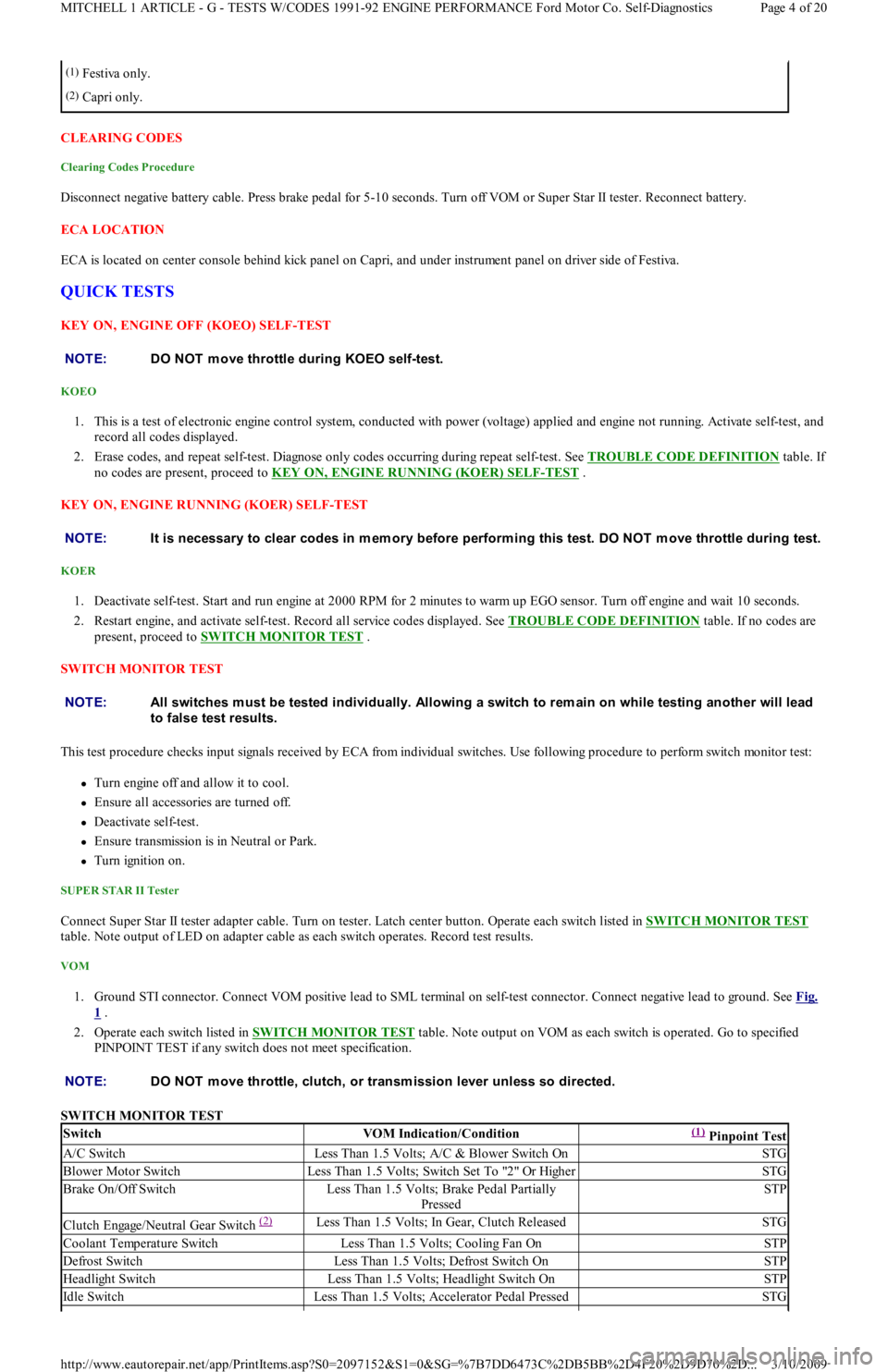

1. Turn ignition off. Connect a jumper wire from STI connector to ground. Refer to SELF-TEST CONNECTOR LOCATION and

SELF

-TEST CONNECTOR WIRE COLORS tables. See Fig. 1 .

2. Connect VOM between STO terminal and engine ground. Set VOM to measure 0-20 volts DC.

CHECK ENGINE Light (MIL)

Connect a jumper wire between STI connector and ground.

SUPER STAR II Tester

Turn ignition off. Connect adapter cable leads to diagnostic tester. Connect service adapter cables to vehicle self-test connectors. Ground

adapter cable.

SELF-TEST CONNECTOR LOCATION

SELF-TEST CONNECTOR WIRE COLORS

Fig. 1: Self

-Test Connector Terminal ID

Courtesy of FORD MOTOR CO.

RETRIEVING CODES

Reading Service Codes

ApplicationLocation

1.3LLeft Rear Corner Of Engine Compartment

1.6LRight Rear Corner Of Engine Compartment

CircuitWire Color

1.3L

SMLBlue/Green

STIYellow/Green

STOYellow/White

1.6L

SMLBlack/Blue

STIYellow

STOGreen/Black

Page 2 of 20 MITCHELL 1 ARTICLE - G - TESTS W/CODES 1991-92 ENGINE PERFORMANCE Ford Motor Co. Self-Diagnostics

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 171 of 454

CLEARING CODES

Clearing Codes Procedure

Disconnect negative battery cable. Press brake pedal for 5-10 seconds. Turn off VOM or Super Star II tester. Reconnect battery.

ECA LOCATION

ECA is located on center console behind kick panel on Capri, and under instrument panel on driver side of Festiva.

QUICK TESTS

KEY ON, ENGINE OFF (KOEO) SELF-TEST

KOEO

1. This is a test of electronic engine control system, conducted with power (voltage) applied and engine not running. Activate self-test, and

record all codes displayed.

2. Erase codes, and repeat self-test. Diagnose only codes occurring during repeat self-test. See TROUBLE CODE DEFINITION

table. If

no codes are present, proceed to KEY ON, ENGINE RUNNING (KOER) SELF

-TEST .

KEY ON, ENGINE RUNNING (KOER) SELF-TEST

KOER

1. Deactivate self-test. Start and run engine at 2000 RPM for 2 minutes to warm up EGO sensor. Turn off engine and wait 10 seconds.

2. Restart engine, and activate self-test. Record all service codes displayed. See TROUBLE CODE DEFINITION

table. If no codes are

present, proceed to SWITCH MONITOR TEST

.

SWITCH MONITOR TEST

This test procedure checks input signals received by ECA from individual switches. Use following procedure to perform switch monitor test:

Turn engine off and allow it to cool.

Ensure all accessories are turned off.

Deactivate self-test.

Ensure transmission is in Neutral or Park.

Turn ignition on.

SUPER STAR II Tester

Connect Super Star II tester adapter cable. Turn on tester. Latch center button. Operate each switch listed in SWITCH MONITOR TEST

table. Note output of LED on adapter cable as each switch operates. Record test results.

VOM

1. Ground STI connector. Connect VOM positive lead to SML terminal on self-test connector. Connect negative lead to ground. See Fig.

1 .

2. Operate each switch listed in SWITCH MONITOR TEST

table. Note output on VOM as each switch is operated. Go to specified

PINPOINT TEST if any switch does not meet specification.

SWITCH MONITOR TEST

(1)Festiva only.

(2)Capri only.

NOTE:DO NOT m ove throttle during KOEO self-test.

NOTE:It is necessary to clear codes in m em ory before perform ing this test. DO NOT m ove throttle during test.

NOTE:All switches m ust be tested individually. Allowing a switch to rem ain on while testing another will lead

to false test results.

NOTE:DO NOT m ove throttle, clutch, or transm ission lever unless so directed.

SwitchVOM Indication/Condition(1) Pinpoint Test

A/C SwitchLess Than 1.5 Volts; A/C & Blower Switch OnSTG

Blower Motor SwitchLess Than 1.5 Volts; Switch Set To "2" Or HigherSTG

Brake On/Off SwitchLess Than 1.5 Volts; Brake Pedal Partially

PressedSTP

Clutch Engage/Neutral Gear Switch (2) Less Than 1.5 Volts; In Gear, Clutch ReleasedSTG

Coolant Temperature SwitchLess Than 1.5 Volts; Cooling Fan OnSTP

Defrost SwitchLess Than 1.5 Volts; Defrost Switch OnSTP

Headlight SwitchLess Than 1.5 Volts; Headlight Switch OnSTP

Id l e Swit chLess Than 1.5 Volts; Accelerator Pedal PressedSTG

Page 4 of 20 MITCHELL 1 ARTICLE - G - TESTS W/CODES 1991-92 ENGINE PERFORMANCE Ford Motor Co. Self-Diagnostics

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 172 of 454

WIGGLE TEST

Checking Circuitry

1. Visually inspect suspected sensor, switch, or solenoid. Enter WIGGLE TEST if using Super Star II tester. If using VOM, connect it to

STO terminal on self-test connector, and ground STI self-test connector terminal. Lightly tap sensor, switch, or solenoid.

2. Push and pull on suspected sensor, switch, or solenoid connector, but DO NOT unplug it. Test and wiggle harness vigorously, working

in small sections, from suspected device toward dash panel, and from dash panel to ECA.

3. If VOM or Super Star II tester does not display a positive indication of an intermittent defect, carefully disconnect suspected device.

Remove terminals from connector.

4. Inspect terminals at both ends for corrosion, bad crimps, or improperly seated terminals. Reconnect after inspection. Unplug harness

fro m E CA.

5. Inspect ECA and harness connector terminals for corrosion, bad crimps, or improperly seated terminals. If VOM does not indicate any

intermittent defect, reconnect wiring and erase codes.

PINPOINT TESTS

HOW TO USE PINPOINT TESTS

1. DO NOT perform any PINPOINT TEST unless directed by a QUICK TESTS procedure. Ensure all non-EEC related defects are

corrected. Follow each test step in order until defect is found. DO NOT replace any part unless so directed. When more than one service

code exists, start with first code displayed.

2. PINPOINT TESTS require ensuring electrical circuits are okay before replacing sensors or any other components. Always test circuits

for continuity between sensor and ECA. Test all circuits for shorts to power, opens, or shorts to ground. VREF and VPWR circuits

should be tested with KOEO or as specified in PINPOINT TESTS.

3. DO NOT measure voltage or resistance at ECA, or connect any test light unless specified in testing procedure. DO NOT pierce wiring.

Isolate both ends of a circuit and turn key off whenever checking for shorts or continuity, unless otherwise specified.

4. Disconnect solenoids and switches before checking circuit continuity or energizing solenoids.

5. An open is defined as any resistance greater than 10,000 ohms, unless otherwise specified.

6. To help diagnose circuits to ECA, turn ignition off and disconnect ECA harness. Connect BOB between ECA and ECA harness to

perform circuit and pinpoint tests.

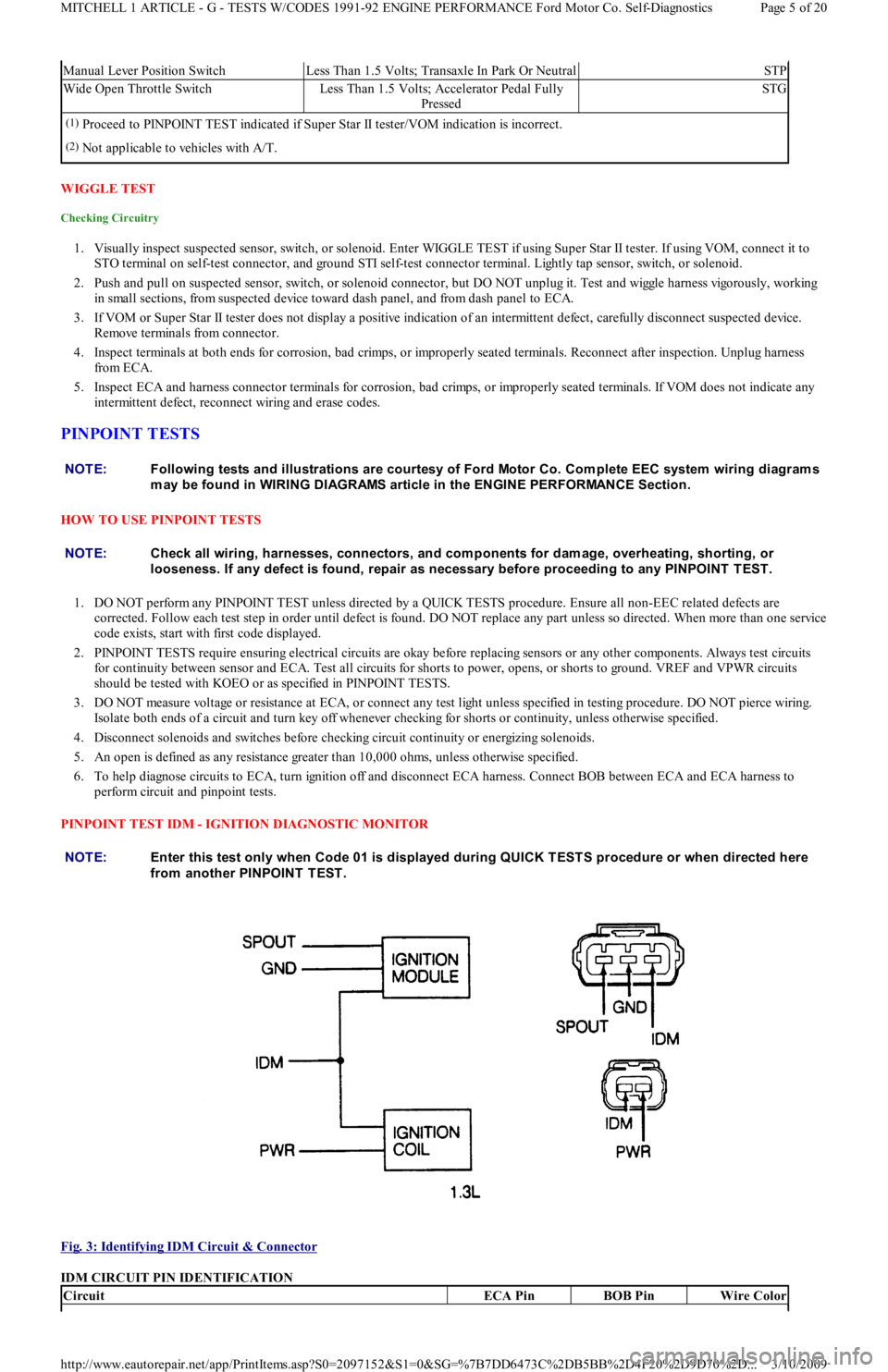

PINPOINT TEST IDM - IGNITION DIAGNOSTIC MONITOR

Fig. 3: Identifying IDM Circuit & Connector

IDM CIRCUIT PIN IDENTIFICATION

Manual Lever Position SwitchLess Than 1.5 Volts; Transaxle In Park Or NeutralSTP

Wide Open Throttle SwitchLess Than 1.5 Volts; Accelerator Pedal Fully

PressedSTG

(1)Proceed to PINPOINT TEST indicated if Super Star II tester/VOM indication is incorrect.

(2)Not applicable to vehicles with A/T.

NOTE:Following tests and illustrations are courtesy of Ford Motor Co. Com plete EEC system wiring diagram s

m ay be found in WIRING DIAGRAMS article in the ENGINE PERFORMANCE Section.

NOTE:Check all wiring, harnesses, connectors, and com ponents for dam age, overheating, shorting, or

looseness. If any defect is found, repair as necessary before proceeding to any PINPOINT T EST .

NOTE:Enter this test only when Code 01 is displayed during QUICK T EST S procedure or when directed here

from another PINPOINT TEST.

CircuitECA PinBOB PinWire Color

Page 5 of 20 MITCHELL 1 ARTICLE - G - TESTS W/CODES 1991-92 ENGINE PERFORMANCE Ford Motor Co. Self-Diagnostics

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 173 of 454

1.3L

1. Connect spark tester between coil secondary wire and ground. Crank engine several times, leaving ignition on between cranking periods.

If continuous sparks jump tester gap, go to next step. If continuous sparks do not jump tester gap, go to step 3).

2. With ignition off, connect BOB, leaving ECA disconnected. Connect test light between test pins IDM and VPWR. Crank engine several

times. If test light flashes each time engine cranks, IDM circuit is okay. Return to QUICK TESTS if directed here from there. If test light

does not flash, repair IDM wire between ECA and coil.

3. Unplug connector from ignition coil. Connect test light between coil IDM wire and PWR wire. Crank engine several times, leaving

ignition on between cranking periods. If test light flashes continuously, go to next step. If test light does not flash continuously, go to

step 6).

4. Turn ignition on. Measure voltage between coil harness PWR wire and ground. If voltage is greater than 10 volts, replace coil. If voltage

is less than 10 volts, repair wire between ignition switch and coil.

5. Connect test light between PWR and ground terminals at coil harness connector. Turn ignition on. If test light glows, replace coil. If test

light does not glow, repair ground wire to coil.

6. Unplug connector from ignition module. Connect jumper wire between SPOUT wire on ignition module harness connector and mating

terminal on ignition module. Connect another jumper wire between ignition module GND wire and mating connector. Leave IDM wire

disconnected. Connect test light between IDM terminal on ignition module and PWR wire. Crank engine several times, leaving ignition

on between cranking periods. If test light flashes each time engine cranks, repair wire between ignition module IDM wire and coil . If t est

light does not flash, go to next step.

7. Turn ignition off. Unplug ignition module connector. Turn ignition on. Measure voltage between ignition module PWR wire and ground.

Turn ignition on. If voltage is not more than 10 volts, repair PWR wire from ignition switch. If voltage is more than 10 volts, go t o n e xt

step.

8. Turn ignition off. Unplug ignition module connector. Turn ignition on. Connect test light between ignition coil PWR wire and ignition

module GND wire. Turn ignition on. If test light glows, go to step 10). If test light does not glow, go to next step.

9. Turn ignition off. Unplug ignition module connector. Connect test light between ignition coil PWR wire and ignition module SPOUT

wire. Crank engine. If test light flashes, check ignition module SPOUT wire for short to ground; if no short exists, replace ignition

module. If test light does not flash, go to next step.

10. Turn ignition off. Unplug ignition module connector. Install BOB, leaving ECA disconnected. Check SPOUT wire for continuity

between BOB test pin and ignition module. If continuity exists, check SPOUT wire for shorts to any other wire. If no short exists,

replace ECA. If continuity does not exist, repair SPOUT wire to ECA.

1.6L

1. Connect spark tester between coil secondary wire and ground. Crank engine several times, leaving ignition on between cranking periods.

If continuous sparks do not jump tester gap, go to step 3). If continuous sparks jump tester gap, go to next step.

2. Turn ignition off. Connect BOB. Leave ECA disconnected. Connect test light between test BOB pins IDM and VPWR. Crank engine

several times. If test light flashes each time engine cranks, IDM circuit is okay. Return to QUICK TESTS if directed here from there. If

test light does not flash, repair IDM wire between ECA and coil.

3. Unplug connector from ignition coil. Connect test light between coil IDM wire and PWR wire. Crank engine several times, leaving

ignition on between cranking periods. If test light does not flash continuously, go to step 6). If test light flashes continuously, go to next

step.

4. Turn ignition on. Measure voltage between coil harness PWR wire and ground. If voltage is greater than 10 volts, replace coil. If voltage

is less than 10 volts, repair wire between ignition switch and coil.

5. Connect test light between PWR and ground terminals at coil harness connector. Turn ignition on. If test light glows, replace coil. If test

light does not glow, repair ground wire to coil.

6. Unplug connector from ignition module. Connect a jumper wire between PWR wire on ignition module harness connector and mating

terminal on ignition module. Leave IDM wire disconnected. Connect test light between IDM terminal on ignition module and PWR

wire. Crank engine several times, leaving ignition on between cranking periods. If test light flashes each time engine cranks, repair wire

between ignition module IDM wire and coil. If test light does not flash. go to next step.

7. Unplug connector from ignition module. Measure voltage between ignition module PWR wire and ground. If voltage is not higher than

10 volts, repair PWR wire from ignition switch. If voltage is higher than 10 volts, go to next step.

8. Turn ignition off. Unplug ignition module connector. Turn ignition on. Connect test light between ignition module PWR wire and

ignition module GND wire. Turn ignition on. If test light glows, replace ignition module. If test light does not glow, repair ignition

module ground wire.

PINPOINT TEST CPS - CRANKSHAFT POSITION SENSOR

1.3L

GND2A39, 40, 44, 60BLK

IDM(1) (1) YEL/GRN

PWR(1) (1) BLK/WHT

SPOUT1G36BLU/ORG

1.6L

IDM1M6YEL/BLU

PWR**********BLK/WHT

(1)ECA and BOB pins not specified.

NOTE:Enter this test only when Code 02 is displayed during QUICK T EST S procedure or when directed here

from another PINPOINT TEST.

Page 6 of 20 MITCHELL 1 ARTICLE - G - TESTS W/CODES 1991-92 ENGINE PERFORMANCE Ford Motor Co. Self-Diagnostics

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...