FORD FIESTA 1989 Service Repair Manual

Manufacturer: FORD, Model Year: 1989, Model line: FIESTA, Model: FORD FIESTA 1989Pages: 296, PDF Size: 10.65 MB

Page 151 of 296

Unplug the electrical connectors at the

camshaft position sensor and the coolant

temperature sensor, then unclip the wiring

from the ignition coil bracket, and secure it to

the manifold.

17Remove the three screws securing the

wiring “rail” to the rear of the manifold.

Releasing its wire clip, unplug the large

electrical connector (next to the fuel pressure

regulator) to disconnect the wiring of the

manifold components from the engine wiring

loom.

18 Marking or labelling them as they are

unplugged, disconnect the vacuum hoses at

the manifold and throttle housing.

19 Undo the fuel feed and return lines

connecting the engine to the chassis. Plug or

cap all open fittings. 20

Unbolt the earth lead from the cylinder

head rear support plate/engine lifting eye,

then unscrew the bolt securing the support

plate/lifting eye.

21 Unscrew the nuts and bolts securing the

manifold to the cylinder head, and withdraw it.

Take care not to damage vulnerable

components as the manifold assembly is

manoeuvred out of the engine compartment.

22 With the manifold removed, clean all

traces of the old gasket from the mating

surfaces of the manifold and the cylinder head.

Refitting

All engines

23 Refitting is the reverse of the removal

procedure, noting the following points: a) Fit a new gasket, then locate the manifold on the head and install the nuts and bolts.

b) Tighten the nuts/bolts in three or four

equal steps to the specified torque,

working from the centre outwards, to

avoid warping the manifold.

c) Refit the remaining parts in the reverse order of removal - tighten all fasteners to

the torque wrench settings specified

(where given).

d) Where drained, refill the cooling system

as described in Chapter 1.

e) Before starting the engine, check the accelerator cable for correct adjustment

and the throttle linkage for smooth

operation (Section 5).

f) When the engine is fully warmed-up,

check for signs of fuel, inlet and/or

vacuum leaks.

4D•8 Fuel system - sequential electronic fuel injection engines

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 152 of 296

4E

1595Ford Fiesta Remake

Torque wrench settingsNmlbf ft

Pulse-air system piping sleeve nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32 24

Exhaust manifold to cylinder head: HCS engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . 23 17

CVH engines (non turbocharged) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 12

CVH engines (turbocharged) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28 to 31 21 to 23

PTE engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . 16 12

Zetec engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . 16 12

Chapter 4 Part E:

Exhaust and emission control systems

Catalytic converter - general information and precautions . . . . . . . . 4

Emission control system check . . . . . . . . . . . . . . . . . . . .See Chapter 1

Evaporative emissions control system - checking and component

renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . 6

Exhaust manifold - removal and refitting . . . . . . . . . . . . . . . . . . . . . 3

Exhaust system - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 Exhaust system check . . . . . . . . . . . . . . . . . . . . . . . . . . .See Chapter 1

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . 1

Positive crankcase ventilation system - checking and component

renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . 5

Pulse-air system - checking and component renewal . . . . . . . . . . . 7

Underbonnet check for fluid leaks and hose condition . .See Chapter 1

4E•1

Specifications Contents

Easy, suitable for

novice with little

experience Fairly easy,

suitable

for beginner with

some experience Fairly difficult,

suitable for competent

DIY mechanic

Difficult,

suitable for

experienced DIY

mechanic Very difficult,

suitable for expert DIY

or professional

Degrees of difficulty

54321

1 General information

Exhaust system

The exhaust system is composed of an

exhaust manifold, the front downpipe and

catalytic converter (where fitted), and a main

section incorporating two silencers. The

service replacement exhaust system consists

of three sections: the front downpipe/catalytic

converter, the intermediate pipe and front

silencer, and the tailpipe and rear silencer.

The system is suspended throughout its entire

length by rubber mountings.

Emission control systems

To minimise pollution of the atmosphere

from incompletely-burned and evaporating

gases, and to maintain good driveability and fuel economy, a number of emissions control

systems are used on these vehicles. They

include the following:

a) The engine management system

(comprising both fuel and ignition sub-

systems) itself.

b) Positive Crankcase Ventilation (PCV) system.

c) Evaporative emissions control (EVAP) system.

d) Pulse-air (PAIR) system.

e) Catalytic converter. The operation of the systems is described

in the following paragraphs.

Positive crankcase ventilation system

The function of the crankcase ventilation

system is to reduce the emissions of

unburned hydrocarbons from the crankcase,

and to minimise the formation of oil sludge. By

ensuring that a depression is created in the

crankcase under most operating conditions,

particularly at idle, and by positively inducing fresh air into the system, the oil vapours and

“blow-by” gases collected in the crankcase

are drawn from the crankcase, through the air

cleaner or oil separator, into the inlet tract, to

be burned by the engine during normal

combustion.

On HCS engines, the system consists of a

vented oil filler cap (with an integral mesh

filter) and a hose connecting it to a connector

on the underside of the air cleaner housing. A

further hose leads from the adapter/filter to

the inlet manifold. Under conditions of idle

and part-load, the emissions gases are

directed into the inlet manifold, and dispensed

with in the combustion process. Additional air

is supplied through two small orifices next to

the mushroom valve in the air cleaner

housing, the object of which is to prevent high

vacuum build-up. Under full-load conditions,

when the inlet manifold vacuum is weak, the

mushroom valve opens, and the emissions

are directed through the air cleaner housing

procarmanuals.com

http://vnx.su

Page 153 of 296

into the engine induction system and thence

into the combustion chambers. This

arrangement eliminates any fuel mixture

control problems. The operating principles for

the system used on the Endura-E engine are

basically the same as just described with

revisions to the component locations and

hose arrangement.On CVH and PTE engines, a closed-circuit

type crankcase ventilation system is used, the

function of which is basically the same as that

described for the HCS engine type, but the

breather hose connects directly to the rocker

cover. The oil filler cap incorporates a

separate filter in certain applications. On Zetec engines, the crankcase ventilation

system main components are the oil

separator mounted on the front (radiator) side

of the cylinder block/crankcase, and the

Positive Crankcase Ventilation (PCV) valve set

in a rubber grommet in the separator’s left-

hand upper end. The associated pipework

consists of a crankcase breather pipe and two

flexible hoses connecting the PCV valve to a

union on the left-hand end of the inlet

manifold, and a crankcase breather hose

connecting the cylinder head cover to the air

cleaner assembly. A small foam filter in the air

cleaner prevents dirt from being drawn

directly into the engine.

Evaporative emissions control system

This system is fitted to minimise the escape

of unburned hydrocarbons into the

atmosphere. Fuel evaporative emissions

control systems are limited on vehicles

meeting earlier emissions regulations;

carburettor float chambers are vented

internally, whilst fuel tanks vent to atmosphere

through a combined roll-over/anti-trickle-fill

valve. On vehicles meeting the more stringent

emissions regulations, the fuel tank filler cap

is sealed, and a charcoal canister is used to

collect and store petrol vapours generated in

the tank when the vehicle is parked. When the

engine is running, the vapours are cleared

from the canister (under the control of the

EEC IV engine management module via the

canister-purge solenoid valve) into the inlet

tract, to be burned by the engine during

normal combustion. To ensure that the engine runs correctly

when it is cold and/or idling, and to protect

the catalytic converter from the effects of an

over-rich mixture, the canister-purge solenoid

valve is not opened by the EEC IV module

until the engine is fully warmed-up and

running under part-load; the solenoid valve is

then switched on and off, to allow the stored

vapour to pass into the inlet tract.

Pulse-air system

This system consists of the pulse-air

solenoid valve, the pulse-air valve itself, the

delivery tubing, a pulse-air filter, and on some

models, a check valve. The system injects

filtered air directly into the exhaust ports,

using the pressure variations in the exhaust

gases to draw air through from the filter housing; air will flow into the exhaust only

when its pressure is below atmospheric. The

pulse-air valve can allow gases to flow only

one way, so there is no risk of hot exhaust

gases flowing back into the filter.

The system’s primary function is raise

exhaust gas temperatures on start-up, thus

reducing the amount of time taken for the

catalytic converter to reach operating

temperature. Until this happens, the system

reduces emissions of unburned hydrocarbon

particles (HC) and carbon monoxide (CO) by

ensuring that a considerable proportion of

these substances remaining in the exhaust

gases after combustion are burned up, either

in the manifold itself or in the catalytic

converter.

To ensure that the system does not upset

the smooth running of the engine under

normal driving conditions, it is linked by the

pulse-air solenoid valve to the EEC IV module,

so that it only functions during engine warm-

up, when the oxygen sensor is not influencing

the fuel/air mixture ratio.

Catalytic converter

Catalytic converters have been introduced

progressively on all models in the range, to

meet the various emissions regulations.

The catalytic converter is located in the

exhaust system, and operates in conjunction

with an exhaust gas oxygen sensor to reduce

exhaust gas emissions. The catalytic

converter uses precious metals (platinum and

palladium or rhodium) as catalysts to speed

up the reaction between the pollutants and

the oxygen in the vehicle’s exhaust gases, CO

and HC being oxidised to form H

2O and CO2and (in the three-way type of catalytic

converter) NO

xbeing reduced to N2. Note :

The catalytic converter is not a filter in the

physical sense; its function is to promote a

chemical reaction, but it is not itself affected

by that reaction. The converter consists of an element (or

“substrate”) of ceramic honeycomb, coated

with a combination of precious metals in such

a way as to produce a vast surface area over

which the exhaust gases must flow; the whole

being mounted in a stainless-steel box. A

simple “oxidation” (or “two-way”) catalytic

converter can deal with CO and HC only,

while a “reduction” (or “three-way”) catalytic

converter can deal with CO, HC and NO

x.

Three-way catalytic converters are further

sub-divided into “open-loop” (or

“unregulated”) converters, which can remove

50 to 70% of pollutants and “closed-loop”

(also known as “controlled” or “regulated”)

converters, which can remove over 90% of

pollutants.

In order for a closed-loop catalytic

converter to operate effectively, the air/fuel

mixture must be very accurately controlled,

and this is achieved by measuring the oxygen

content of the exhaust gas. The oxygen

sensor transmits information on the exhaust

gas oxygen content to the EEC IV engine management module, which adjusts the

air/fuel mixture strength accordingly.

The sensor has a built-in heating element

which is controlled by the EEC IV module, in

order to bring the sensor’s tip to an efficient

operating temperature as rapidly as possible.

The sensor’s tip is sensitive to oxygen, and

sends the module a varying voltage

depending on the amount of oxygen in the

exhaust gases; if the inlet air/fuel mixture is

too rich, the sensor sends a high-voltage

signal. The voltage falls as the mixture

weakens. Peak conversion efficiency of all

major pollutants occurs if the inlet air/fuel

mixture is maintained at the chemically-

correct ratio for the complete combustion of

petrol - 14.7 parts (by weight) of air to 1 part

of fuel (the “stoichiometric” ratio). The sensor

output voltage alters in a large step at this

point, the module using the signal change as

a reference point, and correcting the inlet

air/fuel mixture accordingly by altering the fuel

injector pulse width (injector opening time). Removal and refitting procedures for

the oxygen sensor are given in Parts B, C

and D of this Chapter according to fuel

system type.

2 Exhaust system - renewal

2

Warning: Inspection and repair

of exhaust system components

should be done only after

enough time has elapsed after

driving the vehicle to allow the system

components to cool completely. This

applies particularly to the catalytic

converter, which runs at very high

temperatures. Also, when working under

the vehicle, make sure it is securely

supported on axle stands.

If the exhaust system components are

extremely corroded or rusted together, they

will probably have to be cut from the exhaust

system. The most convenient way of

accomplishing this is to have a quick-fit

exhaust repair specialist remove the corroded

sections. Alternatively, you can simply cut off

the old components with a hacksaw. If you do

decide to tackle the job at home, be sure to

wear eye protection, to protect your eyes from

metal chips, and work gloves, to protect your

hands. If the production-fit system is still

fitted, it must be cut for the service-

replacement system sections to fit. The best

way of determining the correct cutting point is

to obtain the new centre or rear section first

then, with the old system removed, lay the

two side by side on the ground. It should now

be relatively easy to determine where the old

system needs to be cut, and it can be marked

accordingly. Remember to allow for the

overlap where the two sections will plug

together.

4E•2 Exhaust and emission control systems

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 154 of 296

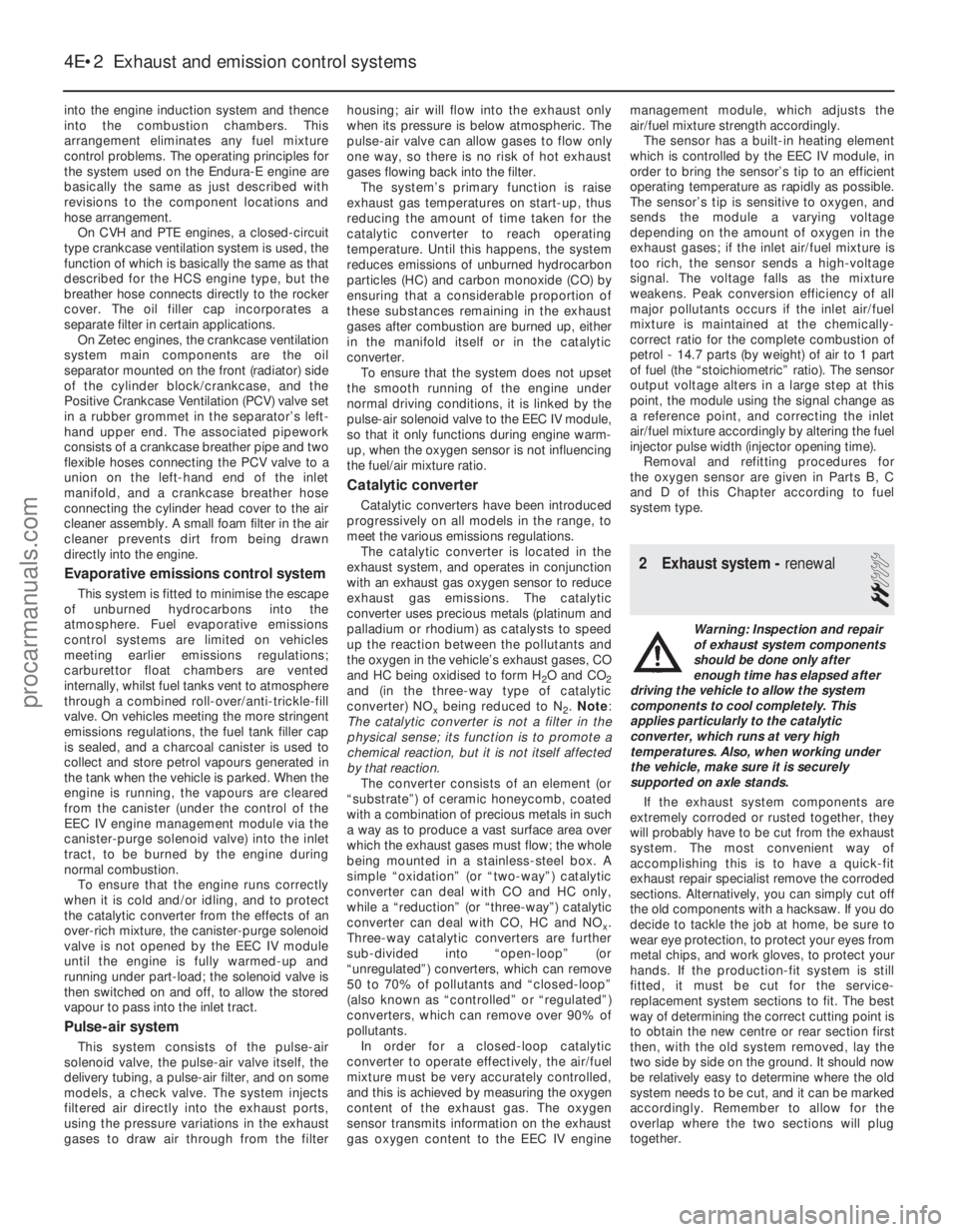

Here are some simple guidelines to apply

when repairing the exhaust system: a) Work from the back to the front when

removing exhaust system components

(see illustration) .

b) Apply penetrating fluid to the exhaust

system component fasteners, to make

them easier to remove.

c) Use new gaskets, rubber mountings and clamps.

d) Apply anti-seize compound to the threads

of all exhaust system fasteners

e) Note that on some models, the downpipe is secured to the manifold by two bolts,

with a coil spring, spring seat and self-

locking nut on each. On refitting, tighten

the nuts until they stop on the bolt

shoulders; the pressure of the springs will

then suffice to make a gastight joint. Do

not overtighten the nuts to cure a leak -

the bolts will shear. Renew the gasket and

the springs if a leak is found

(see

illustrations) .

f) Be sure to allow sufficient clearance between newly-installed parts and all

points on the underbody, to avoid overheating the floorpan, and possibly

damaging the interior carpet and

insulation. Pay particularly close attention

to the catalytic converter and its heat

shield.

Warning: The catalytic converter

operates at very high

temperatures, and takes a long

time to cool. Wait until it’s

completely cool before attempting to

remove the converter. Failure to do so

could result in serious burns.

3 Exhaust manifold - removal and refitting

3

Removal

Note: Never work on or near the exhaust

system and in particular, the catalytic

converter (where fitted), while it is still hot. If

this is unavoidable, wear thick gloves, and

protect yourself from burns should you

accidentally touch a hot exhaust component.

All engines except Zetec

Note: On turbocharged engines, removal and

refitting procedures for the exhaust manifold,

complete with turbocharger are given in

Part C, Section 20.

1 Disconnect the battery negative (earth) lead

- see Chapter 5A, Section 1.

Exhaust and emission control systems 4E•3

2.2b Exhaust system downpipe-to- manifold securing nuts (arrowed)

2.2a Typical exhaust system and heat shield arrangement (1.4 litre CVH CFi model shown)

2.2e Release the spring clip to extract thesecuring bolt from the manifold, when

required2.2d Renew the exhaust system

downpipe-to-manifold gasket to prevent

leaks2.2c Showing securing bolts - note coilspring, and shoulder on bolt

4E

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 155 of 296

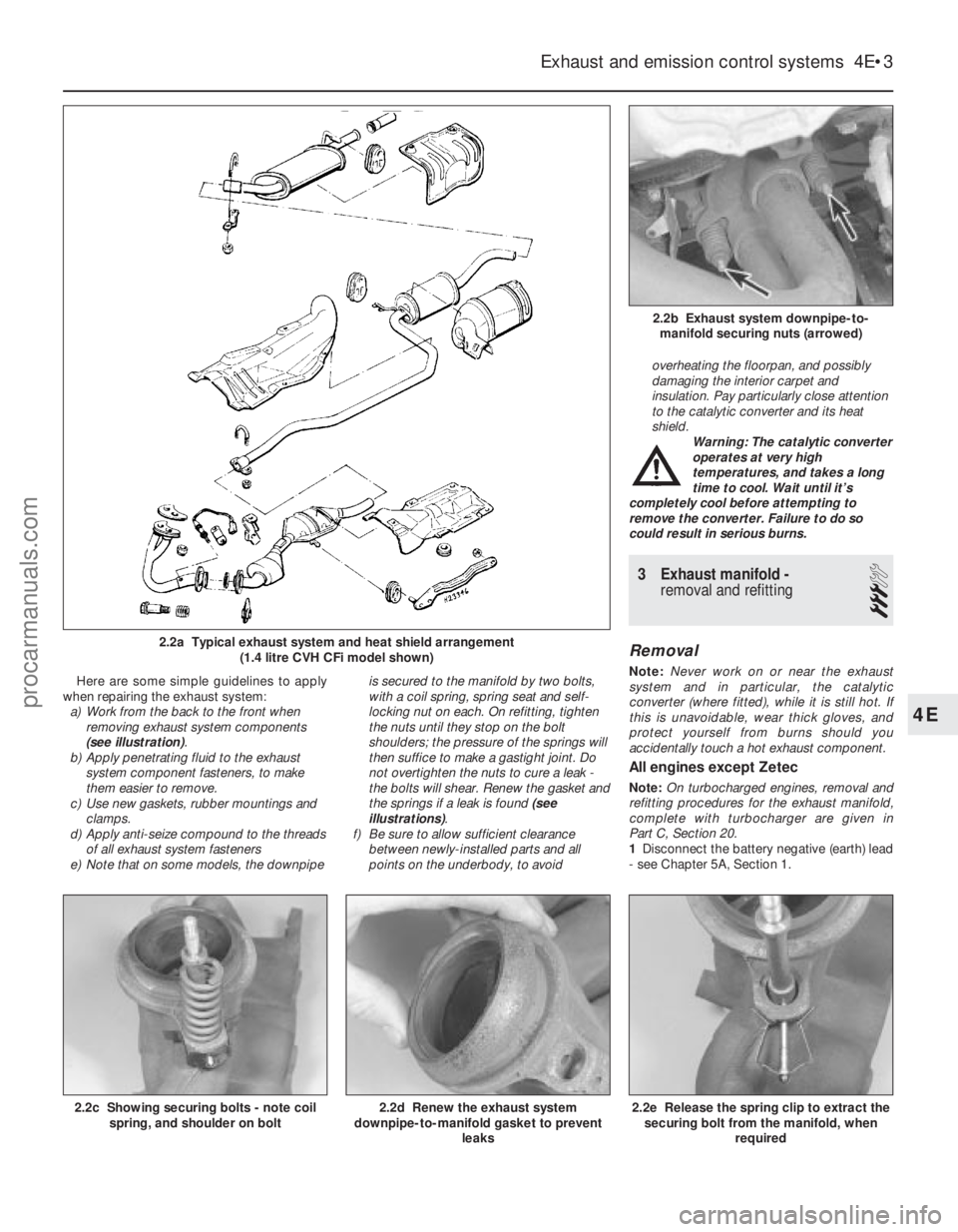

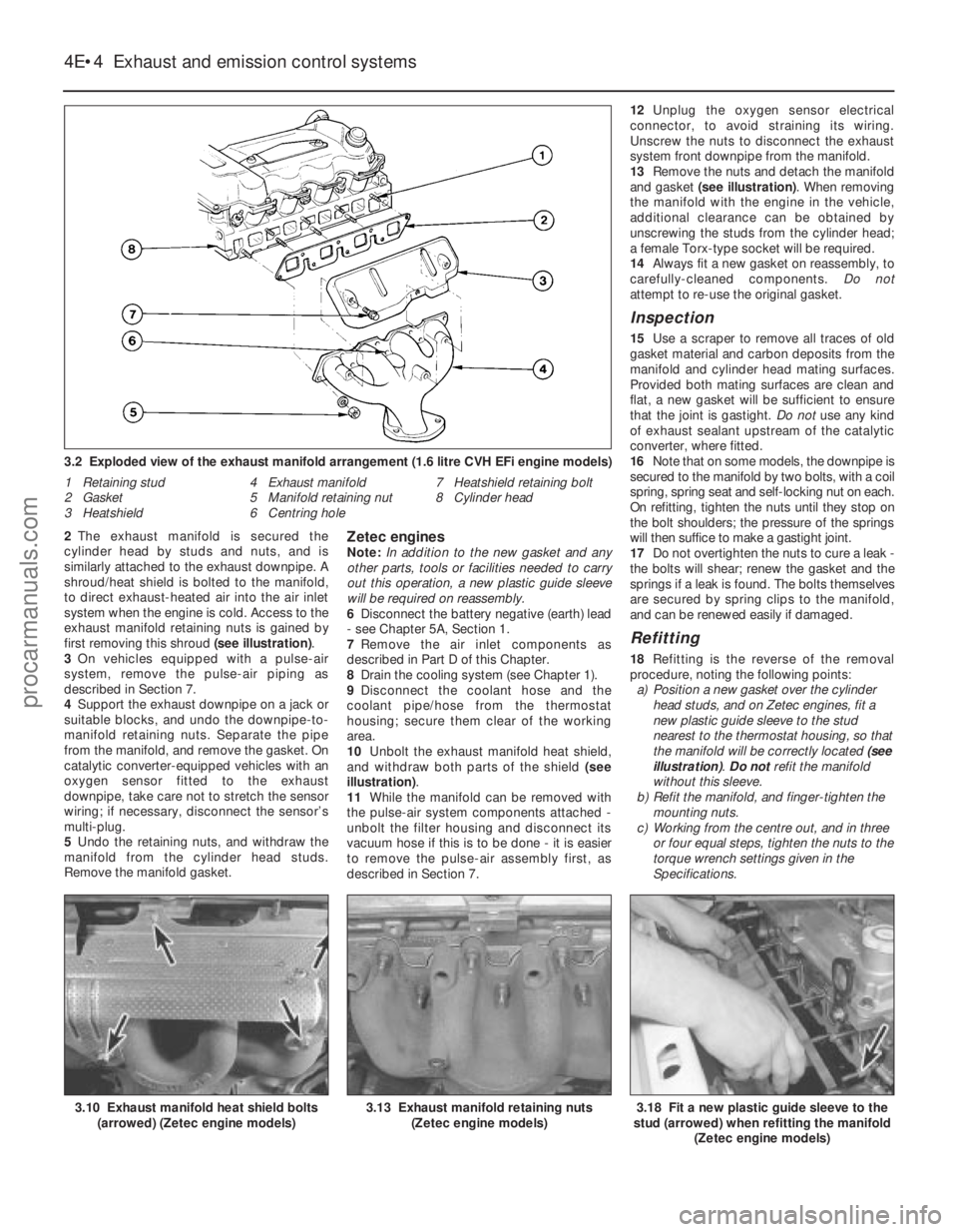

2The exhaust manifold is secured the

cylinder head by studs and nuts, and is

similarly attached to the exhaust downpipe. A

shroud/heat shield is bolted to the manifold,

to direct exhaust-heated air into the air inlet

system when the engine is cold. Access to the

exhaust manifold retaining nuts is gained by

first removing this shroud (see illustration).

3 On vehicles equipped with a pulse-air

system, remove the pulse-air piping as

described in Section 7.

4 Support the exhaust downpipe on a jack or

suitable blocks, and undo the downpipe-to-

manifold retaining nuts. Separate the pipe

from the manifold, and remove the gasket. On

catalytic converter-equipped vehicles with an

oxygen sensor fitted to the exhaust

downpipe, take care not to stretch the sensor

wiring; if necessary, disconnect the sensor’s

multi-plug.

5 Undo the retaining nuts, and withdraw the

manifold from the cylinder head studs.

Remove the manifold gasket.Zetec enginesNote: In addition to the new gasket and any

other parts, tools or facilities needed to carry

out this operation, a new plastic guide sleeve

will be required on reassembly.

6 Disconnect the battery negative (earth) lead

- see Chapter 5A, Section 1.

7 Remove the air inlet components as

described in Part D of this Chapter.

8 Drain the cooling system (see Chapter 1).

9 Disconnect the coolant hose and the

coolant pipe/hose from the thermostat

housing; secure them clear of the working

area.

10 Unbolt the exhaust manifold heat shield,

and withdraw both parts of the shield (see

illustration) .

11 While the manifold can be removed with

the pulse-air system components attached -

unbolt the filter housing and disconnect its

vacuum hose if this is to be done - it is easier

to remove the pulse-air assembly first, as

described in Section 7. 12

Unplug the oxygen sensor electrical

connector, to avoid straining its wiring.

Unscrew the nuts to disconnect the exhaust

system front downpipe from the manifold.

13 Remove the nuts and detach the manifold

and gasket (see illustration) . When removing

the manifold with the engine in the vehicle,

additional clearance can be obtained by

unscrewing the studs from the cylinder head;

a female Torx-type socket will be required.

14 Always fit a new gasket on reassembly, to

carefully-cleaned components. Do not

attempt to re-use the original gasket.

Inspection

15 Use a scraper to remove all traces of old

gasket material and carbon deposits from the

manifold and cylinder head mating surfaces.

Provided both mating surfaces are clean and

flat, a new gasket will be sufficient to ensure

that the joint is gastight. Do not use any kind

of exhaust sealant upstream of the catalytic

converter, where fitted.

16 Note that on some models, the downpipe is

secured to the manifold by two bolts, with a coil

spring, spring seat and self-locking nut on each.

On refitting, tighten the nuts until they stop on

the bolt shoulders; the pressure of the springs

will then suffice to make a gastight joint.

17 Do not overtighten the nuts to cure a leak -

the bolts will shear; renew the gasket and the

springs if a leak is found. The bolts themselves

are secured by spring clips to the manifold,

and can be renewed easily if damaged.

Refitting

18 Refitting is the reverse of the removal

procedure, noting the following points: a) Position a new gasket over the cylinder head studs, and on Zetec engines, fit a

new plastic guide sleeve to the stud

nearest to the thermostat housing, so that

the manifold will be correctly located (see

illustration) . Do notrefit the manifold

without this sleeve.

b) Refit the manifold, and finger-tighten the

mounting nuts.

c) Working from the centre out, and in three or four equal steps, tighten the nuts to the

torque wrench settings given in the

Specifications.

4E•4 Exhaust and emission control systems

3.18 Fit a new plastic guide sleeve to the

stud (arrowed) when refitting the manifold

(Zetec engine models)3.13 Exhaust manifold retaining nuts(Zetec engine models)3.10 Exhaust manifold heat shield bolts(arrowed) (Zetec engine models)

3.2 Exploded view of the exhaust manifold arrangement (1.6 litre CVH E\

Fi engine models)

1 Retaining stud

2 Gasket

3 Heatshield 4 Exhaust manifold

5 Manifold retaining nut

6 Centring hole 7 Heatshield retaining bolt

8 Cylinder head

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 156 of 296

d)Refit the remaining parts in the reverse

order of removal. Tighten all fasteners to

the specified torque wrench settings

where given.

e) Where drained, refill the cooling system (see Chapter 1).

f) Run the engine, and check for exhaust

leaks. Check the coolant level when fully

warmed-up to normal operating

temperature.

4 Catalytic converter - general

information and precautions

The catalytic converter is a reliable and

simple device, which needs no maintenance

in itself, but there are some facts of which an

owner should be aware if the converter is to

function properly for its full service life. a) DO NOT use leaded petrol in a vehicle equipped with a catalytic converter - the

lead will coat the precious metals,

reducing their converting efficiency, and

will eventually destroy the converter.

b) Always keep the ignition and fuel systems

well-maintained in accordance with the

manufacturer’s schedule (see Chapter 1).

c) If the engine develops a misfire, do not drive the vehicle at all (or at least as little

as possible) until the fault is cured.

d) DO NOT push - or tow-start the vehicle -

this will soak the catalytic converter in

unburned fuel, causing it to overheat

when the engine does start.

e) DO NOT switch off the ignition at high engine speeds, ie do not “blip” the

throttle immediately before switching off.

f) DO NOT use fuel or engine oil additives - these may contain substances harmful to

the catalytic converter.

g) DO NOT continue to use the vehicle if the

engine burns oil to the extent of leaving a

visible trail of blue smoke.

h) Remember that the catalytic converter

operates at very high temperatures. DO

NOT, therefore, park the vehicle in dry

undergrowth, over long grass or piles of

dead leaves, after a long run.

I) Remember that the catalytic converter is FRAGILE. Do not strike it with tools

during servicing work.

j) In some cases, a sulphurous smell (like

that of rotten eggs) may be noticed from

the exhaust. This is common to many

catalytic converter-equipped vehicles.

Once the vehicle has covered a few

thousand miles, the problem should

disappear. Low quality fuel with a high

sulphur content will exacerbate this effect.

k) The catalytic converter used on a well-

maintained and well-driven vehicle should

last for between 50 000 and

100 000 miles. If the converter is no

longer effective, it must be renewed.

5 Positive crankcase ventilation system - checking

and component renewal

2

Checking

1 Checking procedures for the system

components are included in Chapter 1.

Component renewal - all

engines except Zetec

Air cleaner components

2 See Chapter 1.

Filter/oil separator and hoses

3All the components relating to the positive

crankcase ventilation system, with the

exception of the HCS engine filter/adapter

located on the underside of the air cleaner,

may be removed by simple disconnection and

withdrawal (having noted all connections for

subsequent refitting).

4 The refitting of all components is a reversal

of the removal procedure, ensuring that the

connections are correctly made.

Component renewal - Zetec

engines

Air cleaner components

5 See Chapter 1.

Positive Crankcase Ventilation (PCV)

valve

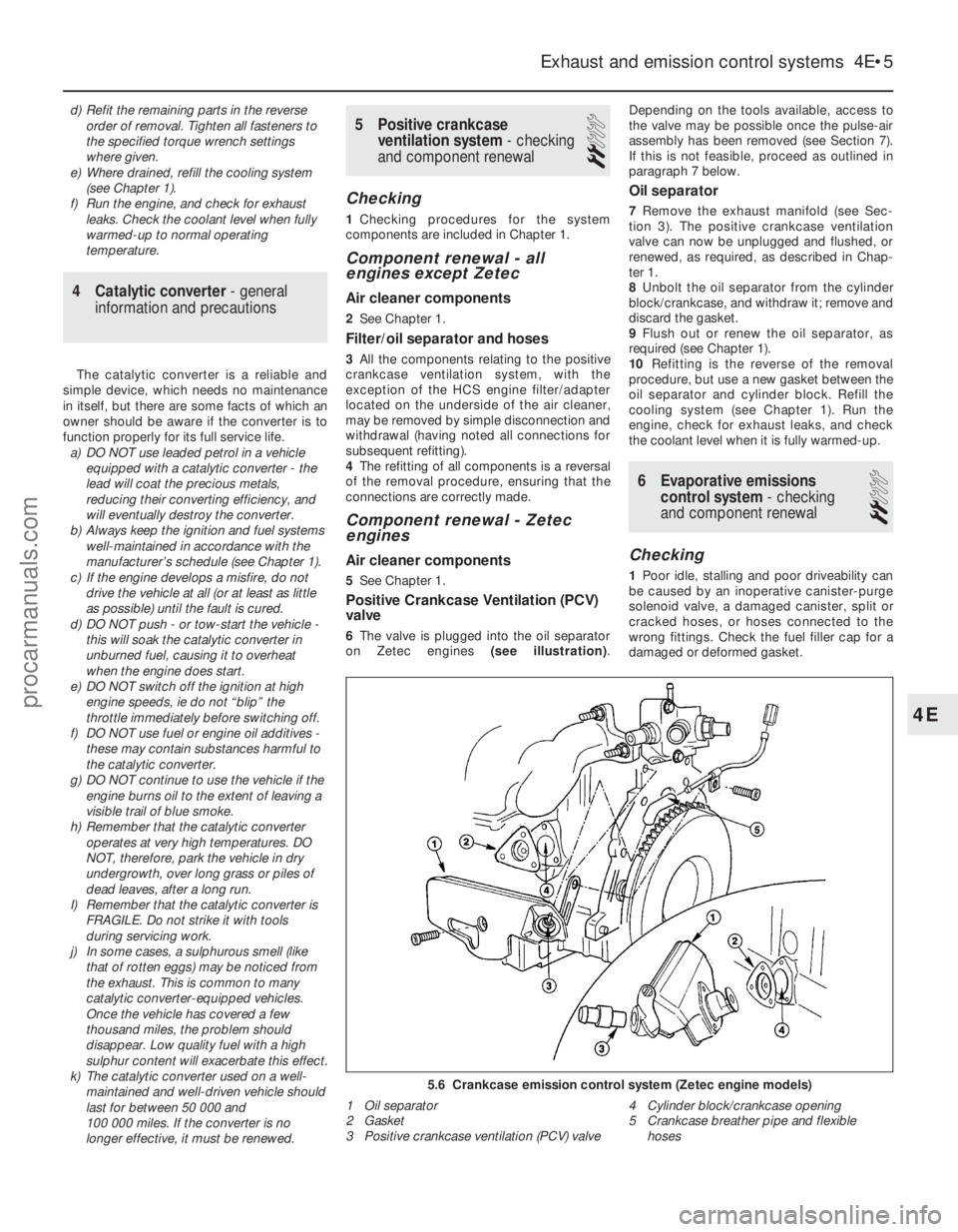

6The valve is plugged into the oil separator

on Zetec engines (see illustration).Depending on the tools available, access to

the valve may be possible once the pulse-air

assembly has been removed (see Section 7).

If this is not feasible, proceed as outlined in

paragraph 7 below.

Oil separator

7

Remove the exhaust manifold (see Sec-

tion 3). The positive crankcase ventilation

valve can now be unplugged and flushed, or

renewed, as required, as described in Chap-

ter 1.

8 Unbolt the oil separator from the cylinder

block/crankcase, and withdraw it; remove and

discard the gasket.

9 Flush out or renew the oil separator, as

required (see Chapter 1).

10 Refitting is the reverse of the removal

procedure, but use a new gasket between the

oil separator and cylinder block. Refill the

cooling system (see Chapter 1). Run the

engine, check for exhaust leaks, and check

the coolant level when it is fully warmed-up.

6 Evaporative emissions control system - checking

and component renewal

2

Checking

1 Poor idle, stalling and poor driveability can

be caused by an inoperative canister-purge

solenoid valve, a damaged canister, split or

cracked hoses, or hoses connected to the

wrong fittings. Check the fuel filler cap for a

damaged or deformed gasket.

Exhaust and emission control systems 4E•5

5.6 Crankcase emission control system (Zetec engine models)

1 Oil separator

2 Gasket

3 Positive crankcase ventilation (PCV) valve 4 Cylinder block/crankcase opening

5 Crankcase breather pipe and flexible

hoses

4E

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 157 of 296

2Fuel loss or fuel odour can be caused by

liquid fuel leaking from fuel lines, a cracked or

damaged canister, an inoperative canister-

purge solenoid valve, or disconnected,

misrouted, kinked or damaged vapour or

control hoses.

3 Inspect each hose attached to the canister

for kinks, leaks and cracks along its entire

length. Repair or renew as necessary.

4 Inspect the canister. If it is cracked or

damaged, renew it. Look for fuel leaking from

the bottom of the canister. If fuel is leaking,

renew the canister, and check the hoses and

hose routing.

5 If the canister-purge solenoid valve is

thought to be faulty, unplug its electrical

connector and disconnect its vacuum hoses.

Connect a battery directly across the valve

terminals. Check that air can flow through the

valve passages when the solenoid is thus

energised, and that nothing can pass when

the solenoid is not energised.

6 Further testing should be left to a dealer

service department.

Component renewal

Charcoal canister-purge solenoid

valve

7 The solenoid is located at or near to the

bulkhead, behind the engine on the right-hand

side (see illustrations) . Locate the solenoid,

then remove any components as necessary to

improve access. 8

Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1), then unplug

the valve’s electrical connector. Unclip the

valve from its location, then disconnect its

vacuum hoses and withdraw it.

9 Refitting is the reverse of the removal

procedure.

Charcoal canister

10 Disconnect the battery negative (earth)

lead (refer to Chapter 5A, Section 1).

11 The canister is located in the front right-

hand corner of the engine compartment.

12 Disconnect the vapour pipe from the unit,

and plug it to prevent the ingress of dirt (see

illustrations)

13 Undo the retaining screw and withdraw

the unit upwards, releasing it from its bracket

(see illustration) .

14 Refit in the reverse order of removal.

Unplug the vapour pipe before reconnecting

it, and ensure that it is clean and securely

connected.

7 Pulse-air system - checking

and component renewal

2

Checking

1 Poor idle, stalling, backfiring and poor

driveability can be caused by a fault in the

pulse-air system. 2

Inspect the vacuum pipe/hose for kinks,

leaks and cracks along its entire length.

Repair or renew as necessary.

3 Inspect the filter housing and piping. If

either is cracked or damaged, renew it.

4 If the pulse-air solenoid valve is thought to

be faulty, unplug its electrical connector and

disconnect its vacuum hoses. Connect a

battery directly across the valve terminals,

and check that air can flow through the valve

passages when the solenoid is thus

energised, and that nothing can pass when

the solenoid is not energised.

5 Further testing should be left to a dealer

service department.

Component renewal

Pulse-air valve, filter and housing

(HCS engines)

6 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

7 Disconnect the vacuum hose from the rear

of the pulse-air valve assembly (see

illustration) .

8 Undo the retaining screws, and withdraw

the air-valve, filter and housing assembly from

the mounting bracket.

9 To dismantle the filter housing, undo the

four screws and separate the top from the

base of the housing; extract the foam filter,

and clean it in a suitable solvent. If any of the

housing’s components are worn or damaged,

the assembly must be renewed.

4E•6 Exhaust and emission control systems

7.7 Location of pulse-air valve (arrowed) (1.3 litre HCS CFi engine models)6.13 Undo the retaining screw and

withdraw the canister upwards, releasing

the tag (arrowed) from its bracket6.12b Canister location and fuel vapourpipe (arrowed) (Zetec engine models)

6.12a Fuel vapour pipe (A) and canister retaining screw (B) (1.4 litre CVH CFi engine models)6.7b Canister purge solenoid valve(arrowed) (Zetec engine models)6.7a Canister purge solenoid valve (A) and multi-plug (B) (1.4 litre CVH CFi engine models)

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 158 of 296

10Refitting is the reverse of the removal

procedure.

Pulse-air valve, filter and housing

(Zetec engines)

11 Disconnect the battery negative (earth)

lead (refer to Chapter 5A, Section 1).

12 Chock the rear wheels then jack up the

front of the car and support it on axle stands

(see “Jacking and vehicle support” ).

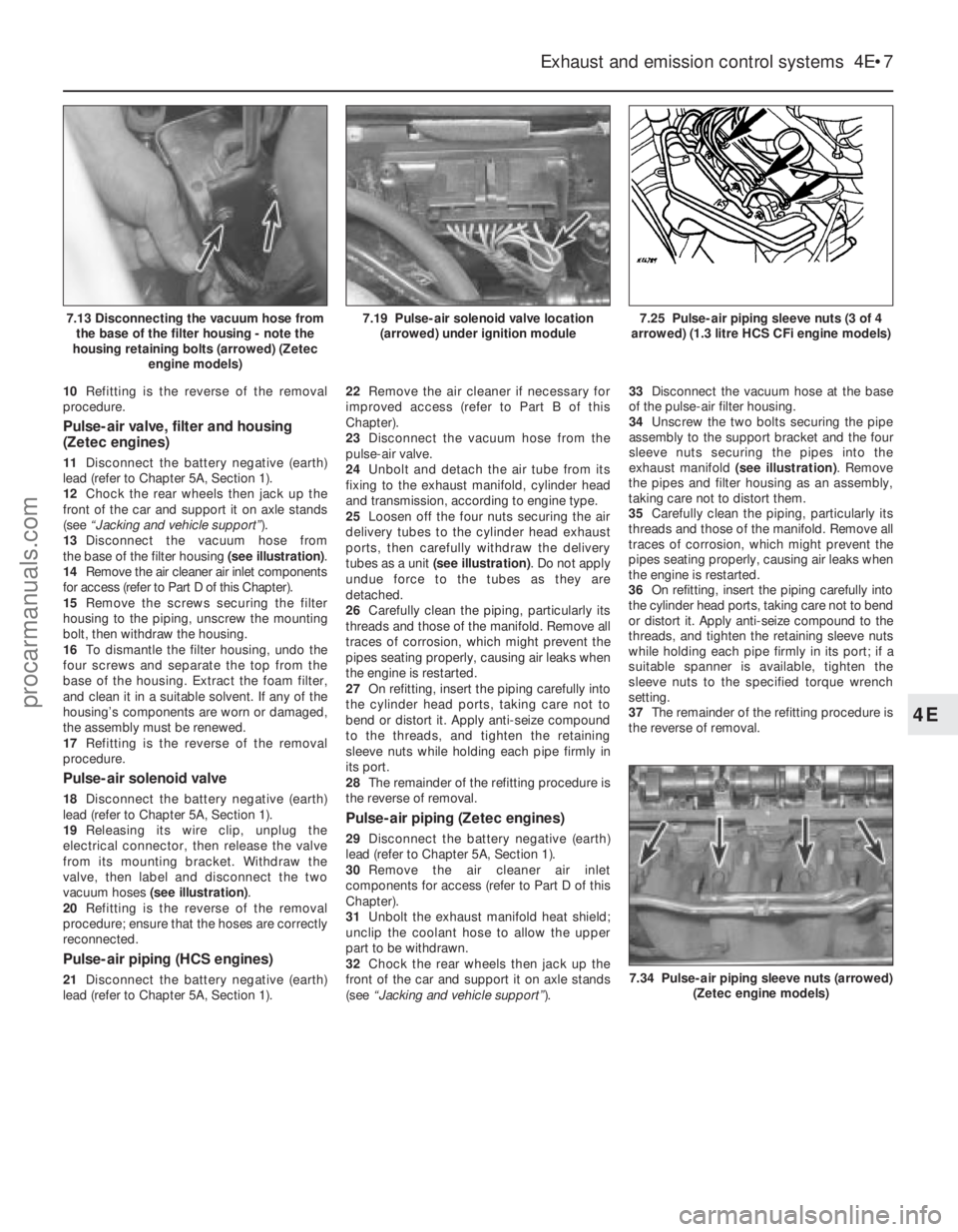

13 Disconnect the vacuum hose from

the base of the filter housing (see illustration).

14 Remove the air cleaner air inlet components

for access (refer to Part D of this Chapter).

15 Remove the screws securing the filter

housing to the piping, unscrew the mounting

bolt, then withdraw the housing.

16 To dismantle the filter housing, undo the

four screws and separate the top from the

base of the housing. Extract the foam filter,

and clean it in a suitable solvent. If any of the

housing’s components are worn or damaged,

the assembly must be renewed.

17 Refitting is the reverse of the removal

procedure.

Pulse-air solenoid valve

18 Disconnect the battery negative (earth)

lead (refer to Chapter 5A, Section 1).

19 Releasing its wire clip, unplug the

electrical connector, then release the valve

from its mounting bracket. Withdraw the

valve, then label and disconnect the two

vacuum hoses (see illustration) .

20 Refitting is the reverse of the removal

procedure; ensure that the hoses are correctly

reconnected.

Pulse-air piping (HCS engines)

21 Disconnect the battery negative (earth)

lead (refer to Chapter 5A, Section 1). 22

Remove the air cleaner if necessary for

improved access (refer to Part B of this

Chapter).

23 Disconnect the vacuum hose from the

pulse-air valve.

24 Unbolt and detach the air tube from its

fixing to the exhaust manifold, cylinder head

and transmission, according to engine type.

25 Loosen off the four nuts securing the air

delivery tubes to the cylinder head exhaust

ports, then carefully withdraw the delivery

tubes as a unit (see illustration) . Do not apply

undue force to the tubes as they are

detached.

26 Carefully clean the piping, particularly its

threads and those of the manifold. Remove all

traces of corrosion, which might prevent the

pipes seating properly, causing air leaks when

the engine is restarted.

27 On refitting, insert the piping carefully into

the cylinder head ports, taking care not to

bend or distort it. Apply anti-seize compound

to the threads, and tighten the retaining

sleeve nuts while holding each pipe firmly in

its port.

28 The remainder of the refitting procedure is

the reverse of removal.

Pulse-air piping (Zetec engines)

29 Disconnect the battery negative (earth)

lead (refer to Chapter 5A, Section 1).

30 Remove the air cleaner air inlet

components for access (refer to Part D of this

Chapter).

31 Unbolt the exhaust manifold heat shield;

unclip the coolant hose to allow the upper

part to be withdrawn.

32 Chock the rear wheels then jack up the

front of the car and support it on axle stands

(see “Jacking and vehicle support” ).33

Disconnect the vacuum hose at the base

of the pulse-air filter housing.

34 Unscrew the two bolts securing the pipe

assembly to the support bracket and the four

sleeve nuts securing the pipes into the

exhaust manifold (see illustration). Remove

the pipes and filter housing as an assembly,

taking care not to distort them.

35 Carefully clean the piping, particularly its

threads and those of the manifold. Remove all

traces of corrosion, which might prevent the

pipes seating properly, causing air leaks when

the engine is restarted.

36 On refitting, insert the piping carefully into

the cylinder head ports, taking care not to bend

or distort it. Apply anti-seize compound to the

threads, and tighten the retaining sleeve nuts

while holding each pipe firmly in its port; if a

suitable spanner is available, tighten the

sleeve nuts to the specified torque wrench

setting.

37 The remainder of the refitting procedure is

the reverse of removal.

Exhaust and emission control systems 4E•7

7.25 Pulse-air piping sleeve nuts (3 of 4

arrowed) (1.3 litre HCS CFi engine models)7.19 Pulse-air solenoid valve location (arrowed) under ignition module7.13 Disconnecting the vacuum hose fromthe base of the filter housing - note the

housing retaining bolts (arrowed) (Zetec engine models)

7.34 Pulse-air piping sleeve nuts (arrowed)

(Zetec engine models)

4E

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 159 of 296

4E•8 Exhaust and emission control systems

1595Ford Fiesta Remake

Notes

procarmanuals.com

http://vnx.su

Page 160 of 296

5A

1595Ford Fiesta Remake

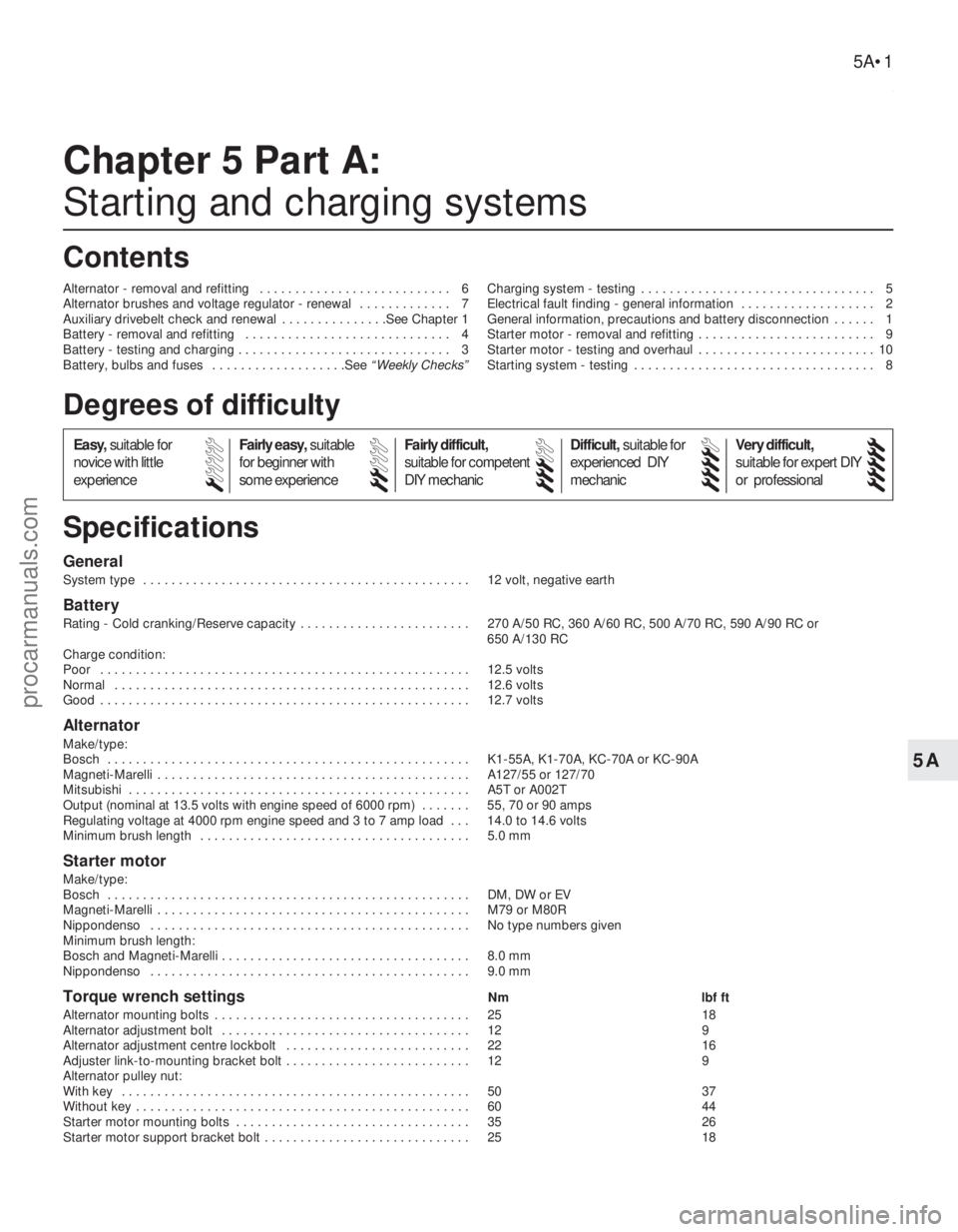

General

System type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . 12 volt, negative earth

Battery

Rating - Cold cranking/Reserve capacity . . . . . . . . . . . . . . . . . . . . . . . . 270 A/50 RC, 360 A/60 RC, 500 A/70 RC, 590 A/90 RC or 650 A/130 RC

Charge condition:

Poor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . . . . . . 12.5 volts

Normal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . . . . 12.6 volts

Good . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . . . . . . 12.7 volts

Alternator

Make/type:

Bosch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . . . . . K1-55A, K1-70A, KC-70A or KC-90A

Magneti-Marelli . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . A127/55 or 127/70

Mitsubishi . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . . A5T or A002T

Output (nominal at 13.5 volts with engine speed of 6000 rpm) . . . . . . . 55, 70 or 90 amps

Regulating voltage at 4000 rpm engine speed and 3 to 7 amp load . . . 14.0 to 14.6 volts

Minimum brush length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . 5.0 mm

Starter motor

Make/type:

Bosch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . . . . . DM, DW or EV

Magneti-Marelli . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . M79 or M80R

Nippondenso . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . No type numbers given

Minimum brush length:

Bosch and Magneti-Marelli . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.0 mm

Nippondenso . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . 9.0 mm

Torque wrench settingsNm lbf ft

Alternator mounting bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

25 18

Alternator adjustment bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 9

Alternator adjustment centre lockbolt . . . . . . . . . . . . . . . . . . . . . . . . . . 22 16

Adjuster link-to-mounting bracket bolt . . . . . . . . . . . . . . . . . . . . . . . . . . 12 9

Alternator pulley nut:

With key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . . . 50 37

Without key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . 60 44

Starter motor mounting bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35 26

Starter motor support bracket bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 18

Chapter 5 Part A:

Starting and charging systems

Alternator - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Alternator brushes and voltage regulator - renewal . . . . . . . . . . . . . 7

Auxiliary drivebelt check and renewal . . . . . . . . . . . . . . .See Chapter 1

Battery - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Battery - testing and charging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Battery, bulbs and fuses . . . . . . . . . . . . . . . . . . .See

“Weekly Checks” Charging system - testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Electrical fault finding - general information . . . . . . . . . . . . . . . . . . . 2

General information, precautions and battery disconnection . . . . . . 1

Starter motor - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . 9

Starter motor - testing and overhaul . . . . . . . . . . . . . . . . . . . . . . . . . 10

Starting system - testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5A•1

Specifications Contents

Easy,

suitable for

novice with little

experience Fairly easy,

suitable

for beginner with

some experience Fairly difficult,

suitable for competent

DIY mechanic

Difficult,

suitable for

experienced DIY

mechanic Very difficult,

suitable for expert DIY

or professional

Degrees of difficulty

54321

procarmanuals.com

http://vnx.su