FORD FIESTA 1989 Service Repair Manual

Manufacturer: FORD, Model Year: 1989, Model line: FIESTA, Model: FORD FIESTA 1989Pages: 296, PDF Size: 10.65 MB

Page 111 of 296

container which can be sealed (see

illustration) . Where quick-release couplings

are used on the fuel hoses, release the

protruding locking lugs on each union, by

squeezing them together and carefully pulling

the coupling apart. Note that the fuel supply

hose couplings are identified by a white

colour band and the return hose couplings by

a yellow colour band.

6 Disconnect the filler neck sensing pipe

connection from the rear of the tank (see

illustration) .

7 Support beneath the tank to hold it in

position and remove its four securing bolts

(see illustration) .

8 Partially lower the fuel tank and disconnect

the ventilation tube from the tank top surface

and also disconnect the sender unit multi-

plug. The filler pipe should release from its

fuel tank seal location as the tank is

withdrawn.

Inspection

9 Whilst removed, the fuel tank can be

inspected for damage or deterioration.

Removal of the sender unit (see Section 9) will

allow a partial inspection of the interior. If the

tank is contaminated with sediment or water,

swill it out with clean petrol. Do not under any

circumstances undertake any repairs on a

leaking or damaged fuel tank; this work must

be carried out by a professional who has

experience in this critical and potentially-

dangerous work.

10 Whilst the fuel tank is removed from the

vehicle, it should not be placed in an area

where sparks or open flames could ignite the

fumes coming out of the tank. Be especially

careful inside garages where a natural-gas

type appliance is located, because the pilot

light could cause an explosion.

11 Check the condition of the filler pipe seal

in the fuel tank, and renew it if necessary.

Refitting

All models

12 Refitting is a reversal of the removal

procedure. Apply a light smear of grease to the

filler pipe seal, to ease fitting. Ensure that all

connections are securely fitted. Where quick-

release fuel couplings are fitted, press them together until the locking lugs snap into their

groove. If evidence of contamination was

found, do not return any previously-drained

fuel to the tank unless it is carefully filtered first.

9

Fuel gauge sender unit -

removal and refitting

3

Note: Ford specify the use of their service tool

23-014 (a large box spanner with projecting

teeth to engage the fuel gauge sender unit

retaining ring’s slots) for this task. While

alternatives are possible, in view of the difficulty

experienced in removing and refitting the

sender unit, owners are strongly advised to

obtain the correct tool before starting work. The

help of an assistant will be required. Refer to the

warning note in Section 1 before proceeding.

Removal

1 Remove the fuel tank as described in

Section 8.

2 Engage the special tool into the sender unit

then carefully turn the sender unit and release

it from the top of the tank.

Refitting

3 Refit the sender unit in the reverse order of

removal. Be sure to fit a new seal, and

lubricate it with a smear of grease to prevent it

from distorting when fitting the sender unit.

10 Fuel tank ventilation tube -

removal and refitting

3

Note: Refer to the warning note in Section 1

before proceeding.

Removal

1 The fuel tank ventilation tube runs from the

top surface of the fuel tank to the combined roll-

over/anti-trickle-fill valve assembly mounted in

the left-hand rear wheelarch (see illustration).

Its purpose is to eliminate any possibility of

vacuum or pressure build-up in the fuel tank.

2 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

3 Chock the front wheels then jack up the

rear of the car and support it on axle stands

(see “Jacking and vehicle support” ). Remove

the left-hand rear roadwheel.

4 Support the fuel tank from underneath on a

suitable jack, using a large thick sheet of

board to spread the weight, then undo and

remove the four fuel tank securing bolts.

5 Lower the fuel tank slightly in such a manner

so as to allow access to disconnect the

ventilation tube from the tank top surface.

Ensure that the fuel tank does not foul or strain

any adjacent components as it is lowered;

take appropriate action, as necessary.

6 Disconnect the ventilation tube from the

combined roll-over/anti-trickle-fill valve, release

the tube from its retaining clips and remove.

Refitting

7 Refitting is a reversal of the removal

procedure, ensuring that the fuel tank filler

pipe is located correctly with the tank.

11 Fuel tank filler pipe -

removal and refitting

3

Note: Refer to the warning note in Section 1

before proceeding.

Removal

1 Remove the fuel tank as described in

Section 8.

4A•6 Fuel system – carburettor engines

10.1 Combined roll-over anti-trickle-fill valve assembly

A Tube ventilating to atmosphere

B Ventilation tube from fuel tank

8.7 Fuel tank securing bolts (arrowed)8.6 Filler neck sensing pipe connection at the rear of the fuel tank

1595Ford Fiesta Remake

8.5 Fuel feed and return pipe connections

(arrowed)procarmanuals.com

http://vnx.su

Page 112 of 296

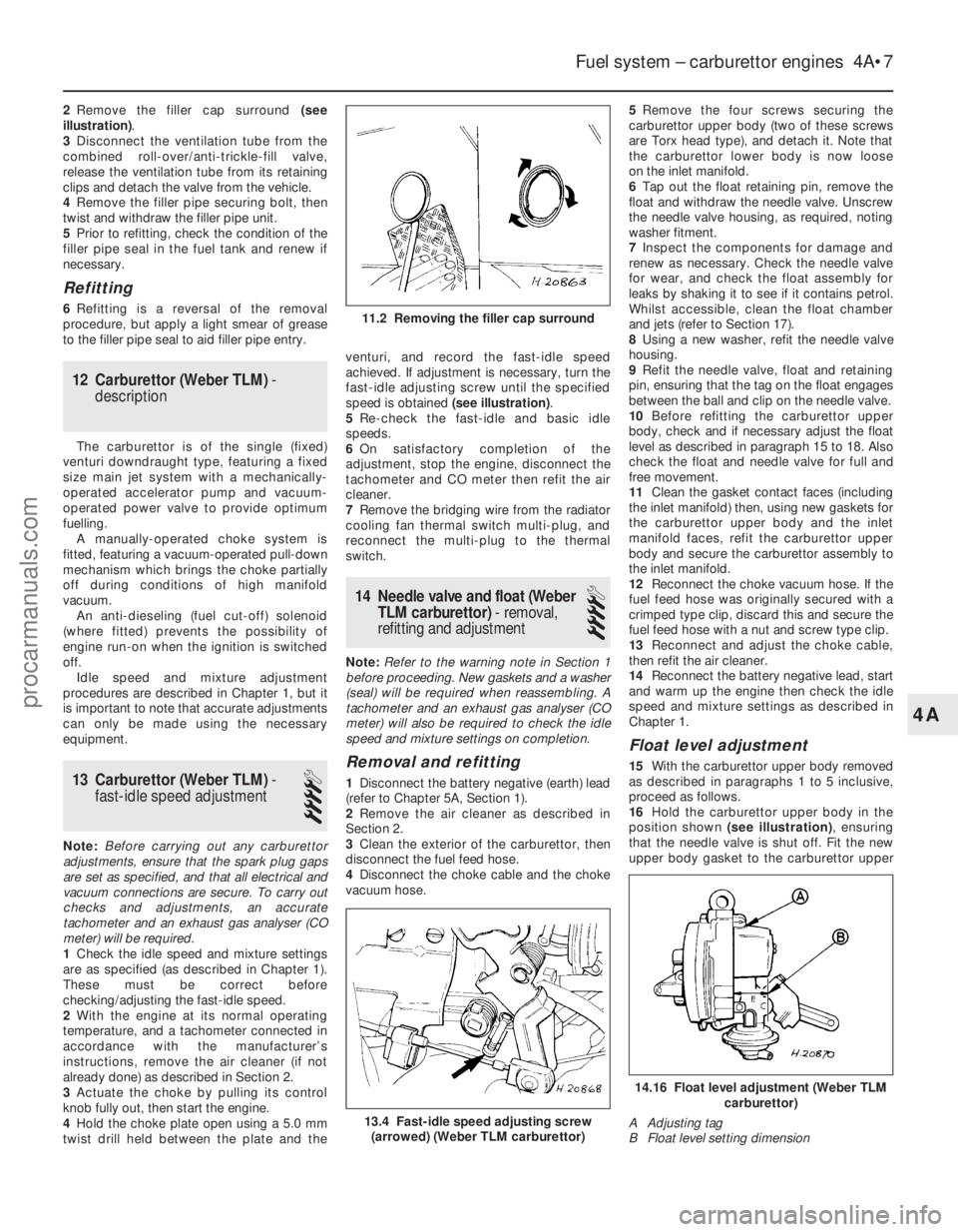

2Remove the filler cap surround (see

illustration) .

3 Disconnect the ventilation tube from the

combined roll-over/anti-trickle-fill valve,

release the ventilation tube from its retaining

clips and detach the valve from the vehicle.

4 Remove the filler pipe securing bolt, then

twist and withdraw the filler pipe unit.

5 Prior to refitting, check the condition of the

filler pipe seal in the fuel tank and renew if

necessary.

Refitting

6 Refitting is a reversal of the removal

procedure, but apply a light smear of grease

to the filler pipe seal to aid filler pipe entry.

12 Carburettor (Weber TLM) -

description

The carburettor is of the single (fixed)

venturi downdraught type, featuring a fixed

size main jet system with a mechanically-

operated accelerator pump and vacuum-

operated power valve to provide optimum

fuelling. A manually-operated choke system is

fitted, featuring a vacuum-operated pull-down

mechanism which brings the choke partially

off during conditions of high manifold

vacuum. An anti-dieseling (fuel cut-off) solenoid

(where fitted) prevents the possibility of

engine run-on when the ignition is switched

off. Idle speed and mixture adjustment

procedures are described in Chapter 1, but it

is important to note that accurate adjustments

can only be made using the necessary

equipment.

13 Carburettor (Weber TLM) -

fast-idle speed adjustment

4

Note: Before carrying out any carburettor

adjustments, ensure that the spark plug gaps

are set as specified, and that all electrical and

vacuum connections are secure. To carry out

checks and adjustments, an accurate

tachometer and an exhaust gas analyser (CO

meter) will be required.

1 Check the idle speed and mixture settings

are as specified (as described in Chapter 1).

These must be correct before

checking/adjusting the fast-idle speed.

2 With the engine at its normal operating

temperature, and a tachometer connected in

accordance with the manufacturer’s

instructions, remove the air cleaner (if not

already done) as described in Section 2.

3 Actuate the choke by pulling its control

knob fully out, then start the engine.

4 Hold the choke plate open using a 5.0 mm

twist drill held between the plate and the venturi, and record the fast-idle speed

achieved. If adjustment is necessary, turn the

fast-idle adjusting screw until the specified

speed is obtained

(see illustration).

5 Re-check the fast-idle and basic idle

speeds.

6 On satisfactory completion of the

adjustment, stop the engine, disconnect the

tachometer and CO meter then refit the air

cleaner.

7 Remove the bridging wire from the radiator

cooling fan thermal switch multi-plug, and

reconnect the multi-plug to the thermal

switch.

14 Needle valve and float (Weber

TLM carburettor) - removal,

refitting and adjustment

4

Note: Refer to the warning note in Section 1

before proceeding. New gaskets and a washer

(seal) will be required when reassembling. A

tachometer and an exhaust gas analyser (CO

meter) will also be required to check the idle

speed and mixture settings on completion.

Removal and refitting

1 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

2 Remove the air cleaner as described in

Section 2.

3 Clean the exterior of the carburettor, then

disconnect the fuel feed hose.

4 Disconnect the choke cable and the choke

vacuum hose. 5

Remove the four screws securing the

carburettor upper body (two of these screws

are Torx head type), and detach it. Note that

the carburettor lower body is now loose

on the inlet manifold.

6 Tap out the float retaining pin, remove the

float and withdraw the needle valve. Unscrew

the needle valve housing, as required, noting

washer fitment.

7 Inspect the components for damage and

renew as necessary. Check the needle valve

for wear, and check the float assembly for

leaks by shaking it to see if it contains petrol.

Whilst accessible, clean the float chamber

and jets (refer to Section 17).

8 Using a new washer, refit the needle valve

housing.

9 Refit the needle valve, float and retaining

pin, ensuring that the tag on the float engages

between the ball and clip on the needle valve.

10 Before refitting the carburettor upper

body, check and if necessary adjust the float

level as described in paragraph 15 to 18. Also

check the float and needle valve for full and

free movement.

11 Clean the gasket contact faces (including

the inlet manifold) then, using new gaskets for

the carburettor upper body and the inlet

manifold faces, refit the carburettor upper

body and secure the carburettor assembly to

the inlet manifold.

12 Reconnect the choke vacuum hose. If the

fuel feed hose was originally secured with a

crimped type clip, discard this and secure the

fuel feed hose with a nut and screw type clip.

13 Reconnect and adjust the choke cable,

then refit the air cleaner.

14 Reconnect the battery negative lead, start

and warm up the engine then check the idle

speed and mixture settings as described in

Chapter 1.

Float level adjustment

15 With the carburettor upper body removed

as described in paragraphs 1 to 5 inclusive,

proceed as follows.

16 Hold the carburettor upper body in the

position shown (see illustration) , ensuring

that the needle valve is shut off. Fit the new

upper body gasket to the carburettor upper

Fuel system – carburettor engines 4A•7

13.4 Fast-idle speed adjusting screw (arrowed) (Weber TLM carburettor)

11.2 Removing the filler cap surround

14.16 Float level adjustment (Weber TLM carburettor)

A Adjusting tag

B Float level setting dimension

4A

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 113 of 296

body, then measure the distance between the

gasket and the step on the float.

17If the measurement is not as specified,

adjust by bending the tag on the float, then re-

check.

18 Refitting should be carried out in

accordance with paragraphs 11 to 14

inclusive.

15 Carburettor (Weber TLM) -

removal and refitting

4

Note: Refer to the warning note in Section 1

before proceeding. New gaskets will be

required when reassembling. A tachometer

and an exhaust gas analyser (CO meter) will

also be required to check the idle speed and

mixture settings on completion.

Removal

1 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

2 Remove the air cleaner as described in

Section 2.

3 Disconnect the accelerator inner and outer

cable from the carburettor (Section 3).

4 Disconnect the choke inner and outer cable

from the carburettor (Section 6).

5 Disconnect the fuel feed hose from the

carburettor, and plug its end to avoid spillage

and prevent dirt ingress. If a crimped type

hose clip is fitted, cut this free taking care to

avoid damage to the hose.

6 Where applicable, disconnect the electrical

lead from the anti-dieseling (fuel cut-off)

solenoid, and all relevant carburettor vacuum

pipes (having labelled them for correct

subsequent refitting).

7 Remove the two Torx head screws securing

the carburettor to the inlet manifold, then

withdraw it from the vehicle (see illustration).

Refitting

8Clean the inlet manifold and carburettor

gasket mating faces.

9 Refit in the reverse order of removal. Fit a

new gasket, and tighten the retaining screws

securely. Ensure that the fuel supply hose

connection to the carburettor is securely fitted, using a new screw type retaining clip.

10

Reconnect the accelerator cable, and

adjust it as described in Section 3.

11 Reconnect the choke cable, and adjust it

as described in Section 6.

12 Refer to Section 2 and refit the air cleaner.

13 When the battery is reconnected, start

and warm up the engine then check the idle

speed and mixture settings as described in

Chapter 1.

16 Accelerator pump diaphragm (Weber TLM carburettor) -

removal and refitting

4

Note: Refer to the warning note in Section 1

before proceeding.

Removal

1 Remove the carburettor as described in

Section 15 and place it on a clean flat work

surface.

2 Remove the accelerator pump cover

retaining screws and detach the cover.

3 Withdraw the diaphragm and spring. Check

the diaphragm for damage, and renew if

evident.

Refitting

4 Clean the carburettor and cover mating

faces. 5

Refit the spring and diaphragm to the

carburettor, aligning the diaphragm with its

cover retaining screw holes. Position the

actuating lever on its cam, then carefully

press the cover against the diaphragm and

secure with its retaining screws.

6 Refit the carburettor as described in

Section 15.

17 Carburettor (Weber TLM) -

dismantling, cleaning,

inspection and reassembly

4

Note: Refer to the warning note in Section 1

before proceeding. Check parts avail-

ability before dismantling. If possible, obtain

an overhaul kit containing all the relevant

gaskets, seals, etc, required for reassembly

prior to dismantling the carburettor.

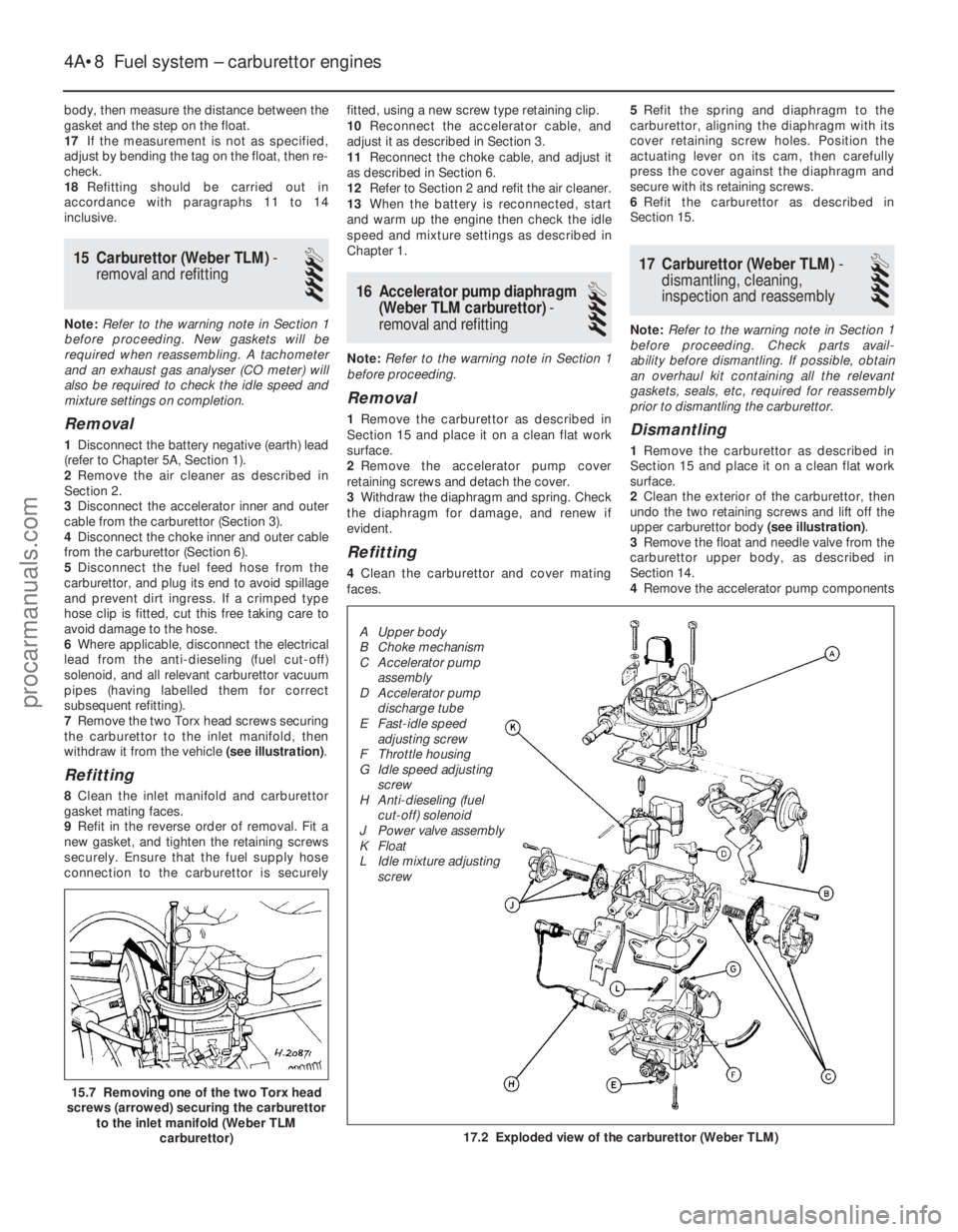

Dismantling

1 Remove the carburettor as described in

Section 15 and place it on a clean flat work

surface.

2 Clean the exterior of the carburettor, then

undo the two retaining screws and lift off the

upper carburettor body (see illustration).

3 Remove the float and needle valve from the

carburettor upper body, as described in

Section 14.

4 Remove the accelerator pump components

4A•8 Fuel system – carburettor engines

17.2 Exploded view of the carburettor (Weber TLM)

15.7 Removing one of the two Torx head

screws (arrowed) securing the carburettor to the inlet manifold (Weber TLM

carburettor)

1595Ford Fiesta Remake

A Upper body

B Choke mechanism

C Accelerator pump

assembly

D Accelerator pump discharge tube

E Fast-idle speed adjusting screw

F Throttle housing

G Idle speed adjusting screw

H Anti-dieseling (fuel cut-off) solenoid

J Power valve assembly

K Float

L Idle mixture adjusting screwprocarmanuals.com

http://vnx.su

Page 114 of 296

as described in Section 16. The power valve

assembly can also be removed in a similar

fashion.

5Prise free the accelerator pump discharge

tube, but take care not to damage it or the

carburettor body.

6 Remove the jets and emulsion tubes as

required, making careful notes of their

respective locations for reassembly.

Cleaning and inspection

7 Soak out the fuel in the float chamber using

a clean rag; this must be safely disposed of.

Clean the float chamber, jets, drillings and

passages with clean petrol. The careful use of

an air line (or footpump) is ideal to blow out

the upper and lower bodies. Never use a

piece of wire for cleaning purposes.

8 Examine all of the carburettor components

for signs of damage or wear, paying particular

attention to the diaphragms, throttle spindle

and plates, and needle valve. Renew all

diaphragms, sealing washers and gaskets as

a matter of course.

Reassembly

9 Refit the emulsion tubes and jets to their

locations as noted during dismantling.

10 Refit the accelerator pump discharge

tube.

11 Refit the accelerator pump and power

valve assemblies as described in Section 16.

12 Refit the needle valve and the float, and

adjust the float setting as described in Sec-

tion 14.

13 Locate a new gasket onto the mating

face, then refit the carburettor upper body to

the main body. As they are reassembled, take

care not to snag the float on the carburettor

main body. Fit and tighten the retaining

screws to secure.

14 On completion, refit the carburettor as

described in Section 15.

18 Carburettor (Weber TLDM) -

description

The carburettor is of twin venturi,

downdraught type, featuring a fixed size main

jet system, adjustable idle system, a

mechanically-operated accelerator pump, and

a vacuum-operated power valve. A manually-

operated cold start choke is fitted, and a

throttle kicker is used on certain models.

In order to comply with emission control

regulations and maintain good fuel

consumption, the main jets are calibrated to

suit the 1/4 to 3/4 throttle range. The power

valve is therefore only used to supply

additional fuel during full-throttle conditions. The accelerator pump is fitted to ensure a

smooth transmission from the idle circuit to

the main jet system. As the accelerator pedal

is depressed, a linkage moves the diaphragm

within the accelerator pump, and a small quantity of fuel is injected into the venturi, to

prevent a momentary weak mixture and

resultant engine hesitation.

The manually-operated choke features a

vacuum-operated pull-down mechanism

which controls the single choke plate under

certain vacuum conditions. On CTX automatic transmission models,

the throttle kicker acts as an idle speed

compensator for when the transmission shift

lever positions R, D or L are selected. The

throttle kicker is operated by vacuum supplied

from the inlet manifold. When the appropriate

transmission shift lever position is selected,

the throttle kicker control solenoid allows the

vacuum to pass to the throttle kicker which

maintains the idle speed by means of a

diaphragm and mechanical linkage. On manual transmission models, the

throttle kicker (when fitted) acts as a damper

by slowing down the closing action of the

throttle plate. Under deceleration, this

maintains the combustion of the air/fuel

mixture entering the cylinders, thus improving

the exhaust emission levels. A vacuum

sustain valve controls the carburettor-sourced

vacuum applied to the throttle kicker unit; this

allows the vacuum slowly to decay, allowing

normal engine idling speed to be achieved. An anti-dieseling (fuel cut-off) solenoid is

fitted to prevent the possibility of the engine

running on after the ignition is switched off. Idle speed and mixture adjustment

procedures are described in Chapter 1, but it

is important to note that accurate adjustments

can only be made using the necessary

equipment.

19 Carburettor (Weber TLDM) -

fast-idle speed adjustment

4

Note: Before carrying out any carburettor

adjustments, ensure that the spark plug gaps

are set as specified, and that all electrical and

vacuum connections are secure. To carry out

checks and adjustments, an accurate

tachometer and an exhaust gas analyser (CO

meter) will be required.

1 Check the idle speed and mixture settings are as specified (as described in Chapter 1).

These must be correct before

checking/adjusting the fast-idle speed.

2

With the engine at its normal operating

temperature, and a tachometer connected in

accordance with the manufacturer’s

instructions, switch the engine off, then

remove the air cleaner (if not already done) as

described in Section 2.

3 Actuate the choke by pulling the control

knob fully out, then start the engine and note

the engine fast-idle speed. Compare it with

the specified speed.

4 If adjustment is required, turn the fast-idle

adjusting screw clockwise to decrease, or

anti-clockwise to increase, the fast-idle speed

(see illustration) .

5 Recheck the fast-idle and basic idle

speeds.

6 On completion of the adjustment, stop the

engine, detach the tachometer and CO meter,

reconnect the radiator cooling fan lead, and

refit the air cleaner.

20 Needle valve and float (Weber

TLDM carburettor) - removal,

refitting and adjustment

4

Note: Refer to the warning note in Section 1

before proceeding. New gaskets and a washer

(seal) will be required when reassembling. A

tachometer and an exhaust gas analyser (CO

meter) will also be required to check the

idle speed and mixture settings on

completion.

Removal and refitting

1 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

2 Remove the air cleaner as described in

Section 2.

3 Clean the exterior of the carburettor, then

disconnect the fuel supply hose and the anti-

dieseling solenoid wiring.

4 Disconnect the choke control cable.

5 Undo and remove the six retaining screws

(four of which are Torx type) and carefully lift

the carburettor upper body clear (see

illustrations) .

6 Invert and support the upper body of the

carburettor for access to the float and pivot.

Fuel system – carburettor engines 4A•9

19.4 Fast-idle speed adjusting screw (arrowed) (Weber TLDM carburettor)

4A

1595Ford Fiesta Remake

20.5a Remove the carburettor upper body securing screws . . .

procarmanuals.com

http://vnx.su

Page 115 of 296

Lightly tap out the float pivot pin, then

withdraw the float, taking care not to distort

the arms of the float (see illustrations).

7 Unscrew the needle valve housing, and

extract it from the carburettor upper body.

Collect the washer from the threads of the

needle valve housing.

8 Clean and inspect the components for

signs of damage or wear, particularly the pivot

holes in the float arm. Check the float for signs

of leakage, by shaking it to see if it contains

fuel. Clean the float chamber and jets (refer to

Section 24 for details). Renew any

components as necessary.

9 Fit a new washer over the needle valve

housing threads, and then carefully screw the

valve unit into position in the upper body.

10 Refit the needle valve, float and retaining

pin, ensuring that the tag on the float engages

with the ball and clip of the needle valve.

11 Before refitting the upper body to the

carburettor, check and if necessary adjust the

float level as described in paragraphs 16

to 18. Also check the float and needle valve

for free movement.

12 Clean the gasket contact faces, then

locate a new gasket and refit the upper body

to the carburettor.

13 Reconnect the fuel supply hose, anti-

dieseling solenoid wiring and the choke cable.

Adjust the choke cable as described in

Section 6. If the fuel hose was originally

secured with a crimped type clip, discard it

and fit a screw type clip. 14

Refit the air cleaner as described in

Section 2.

15 Reconnect the battery earth lead, then

restart the engine and check the idle speed

and mixture settings. Adjust if necessary as

described in Chapter 1.

Float level adjustment

16 With the carburettor upper body removed

as described in paragraphs 1 to 5 inclusive,

proceed as follows.

17 Support the carburettor upper body

vertically, ensuring that the needle valve is

shut off. Locate the new upper body gasket

onto the carburettor upper body, then

measure the distance between the gasket and

the bottom of the float (see illustration).

18 If the measurement is not as specified,

adjust the setting by carefully bending the tag

on the float as required, then recheck.

19 Refit with reference to paragraphs 12

to 15 inclusive.

21 Throttle kicker unit (Weber TLDM carburettor) - removal,

refitting and adjustment

4

Note: A tachometer and exhaust gas analyser

(CO meter) will be required to check and make

any adjustment necessary.

Removal and refitting

1 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

2 Refer to Section 2 and remove the air

cleaner.

3 Detach the vacuum hose from the kicker

unit. Undo the two retaining screws, detach

the linkage and remove the kicker unit (see

illustration) .

4 Refitting the kicker unit is a reversal of the

removal procedure. If the unit is to be

checked for adjustment, loosely locate the air

cleaner, reconnect the inlet air temperature

sensor multi-plug and the battery earth lead,

then proceed as follows.

Adjustment

5 Start and run the engine up to its normal

operating temperature (at which point the

cooling fan will start to operate) then switch

the engine off.

6 Remove the air cleaner again, then detach

the wiring connector of the cooling fan

thermostatic switch. Bridge the terminals in

the connector with a suitable piece of wire to

actuate the cooling fan and keep it running.

Start the engine and run it at 3000 rpm for

30 seconds to stabilise it, then release the

throttle and check (and if necessary adjust)

the idle speed and mixture settings as

described in Chapter 1. Stop the engine.

4A•10 Fuel system – carburettor engines

21.3 General view of throttle kicker

arrangement (Weber TLDM carburettor)

A Tamperproof plug covering adjusting point

B Throttle kicker securing screws

C Vacuum supply pipe20.17 Float level adjustment (Weber TLDM carburettor)

A Float level setting dimension

B Adjusting tag

20.6c Remove the needle valve housing and its washer

20.6b . . . then detach the float and needle valve20.6a Slide out the float retaining pin . . .20.5b . . . then detach the carburettorupper body

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 116 of 296

7Detach the vacuum hose between the

throttle kicker and the inlet manifold at source

(but not the vacuum supply to the ignition

module). Connect a new length of vacuum

hose directly between the manifold and the

kicker unit.

8 Restart the engine and check the engine

speed. The throttle kicker should increase the

engine speed above its normal idle. Check the

speed registered against the specified throttle

kicker operating speed.

9 If required, the throttle kicker speed can be

adjusted by prising free the tamperproof plug

and the adjustment screw turned as

necessary (see illustration 21.3) .

10 When the adjustment is complete, stop

the engine, fit a new tamperproof plug,

disconnect the temporary vacuum hose

(between the manifold and the kicker unit) and

reconnect the original hose (between the

carburettor and the kicker unit).

11 Remove the bridging wire, and reconnect

the cooling fan thermostatic switch multi-

plug. Refit and secure the air cleaner, and

disconnect the tachometer and CO meter to

complete.

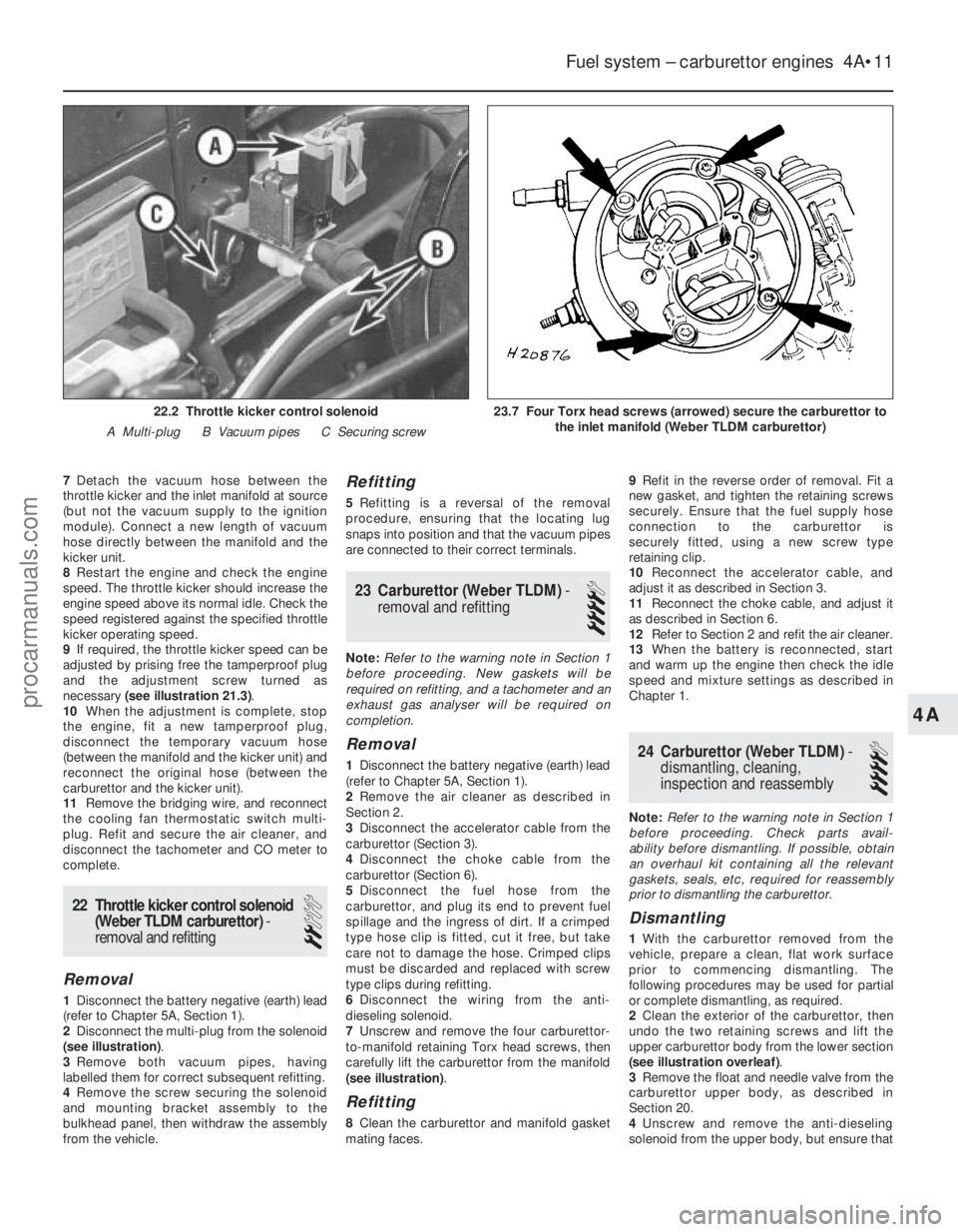

22 Throttle kicker control solenoid

(Weber TLDM carburettor) -

removal and refitting

2

Removal

1 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

2 Disconnect the multi-plug from the solenoid

(see illustration) .

3 Remove both vacuum pipes, having

labelled them for correct subsequent refitting.

4 Remove the screw securing the solenoid

and mounting bracket assembly to the

bulkhead panel, then withdraw the assembly

from the vehicle.

Refitting

5 Refitting is a reversal of the removal

procedure, ensuring that the locating lug

snaps into position and that the vacuum pipes

are connected to their correct terminals.

23 Carburettor (Weber TLDM) -

removal and refitting

4

Note: Refer to the warning note in Section 1

before proceeding. New gaskets will be

required on refitting, and a tachometer and an

exhaust gas analyser will be required on

completion.

Removal

1 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

2 Remove the air cleaner as described in

Section 2.

3 Disconnect the accelerator cable from the

carburettor (Section 3).

4 Disconnect the choke cable from the

carburettor (Section 6).

5 Disconnect the fuel hose from the

carburettor, and plug its end to prevent fuel

spillage and the ingress of dirt. If a crimped

type hose clip is fitted, cut it free, but take

care not to damage the hose. Crimped clips

must be discarded and replaced with screw

type clips during refitting.

6 Disconnect the wiring from the anti-

dieseling solenoid.

7 Unscrew and remove the four carburettor-

to-manifold retaining Torx head screws, then

carefully lift the carburettor from the manifold

(see illustration) .

Refitting

8Clean the carburettor and manifold gasket

mating faces. 9

Refit in the reverse order of removal. Fit a

new gasket, and tighten the retaining screws

securely. Ensure that the fuel supply hose

connection to the carburettor is

securely fitted, using a new screw type

retaining clip.

10 Reconnect the accelerator cable, and

adjust it as described in Section 3.

11 Reconnect the choke cable, and adjust it

as described in Section 6.

12 Refer to Section 2 and refit the air cleaner.

13 When the battery is reconnected, start

and warm up the engine then check the idle

speed and mixture settings as described in

Chapter 1.

24 Carburettor (Weber TLDM) -

dismantling, cleaning,

inspection and reassembly

4

Note: Refer to the warning note in Section 1

before proceeding. Check parts avail-

ability before dismantling. If possible, obtain

an overhaul kit containing all the relevant

gaskets, seals, etc, required for reassembly

prior to dismantling the carburettor.

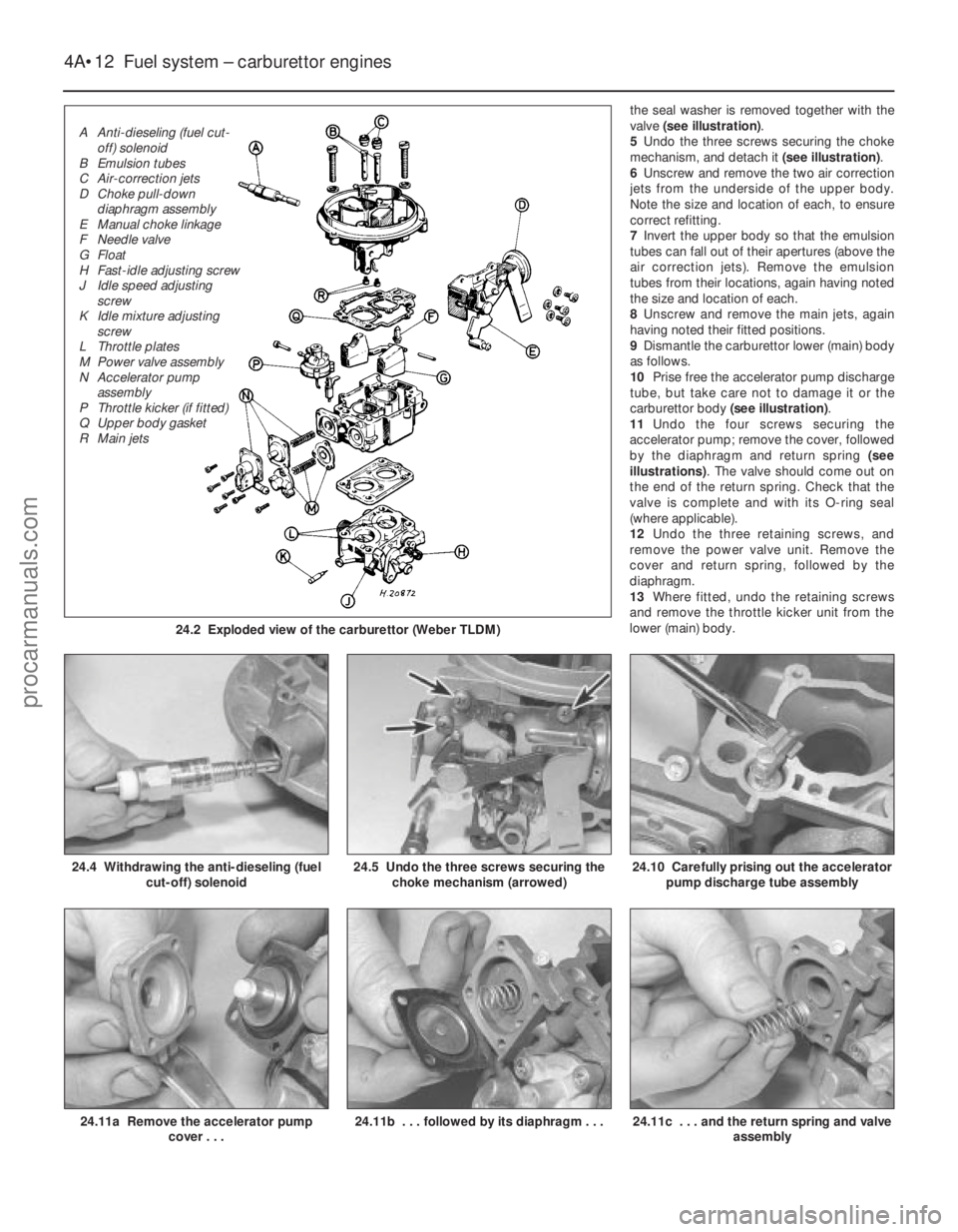

Dismantling

1 With the carburettor removed from the

vehicle, prepare a clean, flat work surface

prior to commencing dismantling. The

following procedures may be used for partial

or complete dismantling, as required.

2 Clean the exterior of the carburettor, then

undo the two retaining screws and lift the

upper carburettor body from the lower section

(see illustration overleaf) .

3 Remove the float and needle valve from the

carburettor upper body, as described in

Section 20.

4 Unscrew and remove the anti-dieseling

solenoid from the upper body, but ensure that

Fuel system – carburettor engines 4A•11

23.7 Four Torx head screws (arrowed) secure the carburettor to the inlet manifold (Weber TLDM carburettor)22.2 Throttle kicker control solenoid

A Multi-plug B Vacuum pipes C Securing screw

4A

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 117 of 296

the seal washer is removed together with the

valve (see illustration) .

5 Undo the three screws securing the choke

mechanism, and detach it (see illustration).

6 Unscrew and remove the two air correction

jets from the underside of the upper body.

Note the size and location of each, to ensure

correct refitting.

7 Invert the upper body so that the emulsion

tubes can fall out of their apertures (above the

air correction jets). Remove the emulsion

tubes from their locations, again having noted

the size and location of each.

8 Unscrew and remove the main jets, again

having noted their fitted positions.

9 Dismantle the carburettor lower (main) body

as follows.

10 Prise free the accelerator pump discharge

tube, but take care not to damage it or the

carburettor body (see illustration).

11 Undo the four screws securing the

accelerator pump; remove the cover, followed

by the diaphragm and return spring (see

illustrations) . The valve should come out on

the end of the return spring. Check that the

valve is complete and with its O-ring seal

(where applicable).

12 Undo the three retaining screws, and

remove the power valve unit. Remove the

cover and return spring, followed by the

diaphragm.

13 Where fitted, undo the retaining screws

and remove the throttle kicker unit from the

lower (main) body.

4A•12 Fuel system – carburettor engines

24.11c . . . and the return spring and valve assembly24.11b . . . followed by its diaphragm . . .24.11a Remove the accelerator pumpcover . . .

24.10 Carefully prising out the accelerator

pump discharge tube assembly24.5 Undo the three screws securing the choke mechanism (arrowed)24.4 Withdrawing the anti-dieseling (fuel cut-off) solenoid

1595Ford Fiesta Remake

24.2 Exploded view of the carburettor (Weber TLDM)

A Anti-dieseling (fuel cut-off) solenoid

B Emulsion tubes

C Air-correction jets

D Choke pull-down diaphragm assembly

E Manual choke linkage

F Needle valve

G Float

H Fast-idle adjusting screw

J Idle speed adjusting screw

K Idle mixture adjusting screw

L Throttle plates

M Power valve assembly

N Accelerator pump assembly

P Throttle kicker (if fitted)

Q Upper body gasket

R Main jets

procarmanuals.com

http://vnx.su

Page 118 of 296

14Prise free and remove the tamperproof

seal, then unscrew and remove the idle

mixture adjustment screw.

15 Undo the retaining screws, and remove

the throttle housing from the carburettor main

body.

Cleaning and inspection

16 Wash the carburettor components,

drillings and passages with clean petrol, then

blow them dry using a low-pressure air line. A

high-pressure air line must not be applied to

the accelerator pump discharge assembly or

the pump supply valve, as they each contain a

rubber Vernay valve, and these can easily be

damaged under high pressure. Never use a

piece of wire for cleaning purposes.

17 Examine all of the carburettor

components for signs of damage or wear,

paying particular attention to the diaphragms,

throttle spindle and plates, needle valve and

mixture screw; the power valve jet is adjacent

to the primary main jet. Renew all

diaphragms, sealing washers and gaskets as

a matter of course.

Reassembly

18 Refit the throttle housing to the

carburettor main body (fitting a new gasket),

and secure with its retaining screws.

19 Refit the idle mixture adjustment screw.

Make an initial adjustment by screwing it fully

in (but do not overtighten or screw it onto its

seat), then unscrew it two full turns.

20 Where fitted, reassemble the throttle

kicker, ensuring that its diaphragm lies flat,

and that the relative position of the operating

link to the kicker cover is correct.

21 Fit the power valve, ensuring that its

diaphragm lies flat and the vacuum

gallery aligns with the diaphragm and

housing.

22 Refit the accelerator pump. Take care not

damage the valve as it is inserted, and check

that the O-ring seal is correctly located on the

end of the valve. Check that the valve is not

trapped by the spring.

23 Refit the accelerator pump discharge jet.

Take care not to damage the valve and/or the

O-ring seal, and ensure that they are correctly

located.

24 Commence reassembly of the upper body

by inserting the emulsion tubes and the air

correction jets into their respective ports (as

noted during removal).

25 Screw the anti-dieseling solenoid into

position. Ensure that the aluminium washer is

fitted, and take care not to overtighten the

valve.

26 Refit the needle valve and the float, and

adjust the float setting as described in Sec-

tion 20.

27 Refit the choke control mechanism, and

secure with its three retaining screws.

28 Locate a new gasket onto the mating

face, then refit the carburettor upper body to

the main body. As they are reassembled, take

care not to snag the float on the carburettor main body. Fit and tighten the retaining

screws to secure.

29

On completion, refit the carburettor as

described in Section 23. Where applicable,

check and adjust the throttle kicker setting

(Section 21) after adjusting the idle speed and

mixture settings.

25 Carburettor (Weber DFTM) -

description

The carburettor operates in essentially the

same manner as TLDM instrument described

in Section 18, but the following features

should be noted. A throttle kicker is fitted to both manual

transmission, and CTX automatic trans-

mission models, the operation of the unit is

described in Section 18. The secondary venturi (barrel) is vacuum-

operated on manual transmission models. On

CTX automatic transmission equipped models

it is operated sequentially. A bleed back solenoid (if fitted) is used to

control the amount of fuel being delivered to

the venturi by the action of the accelerator

pump. Idle speed and mixture adjustment

procedures are described in Chapter 1, but it

is important to note that accurate adjustments

can only be made using the necessary

equipment.

26 Carburettor (Weber DFTM) -

fast-idle speed adjustment

4

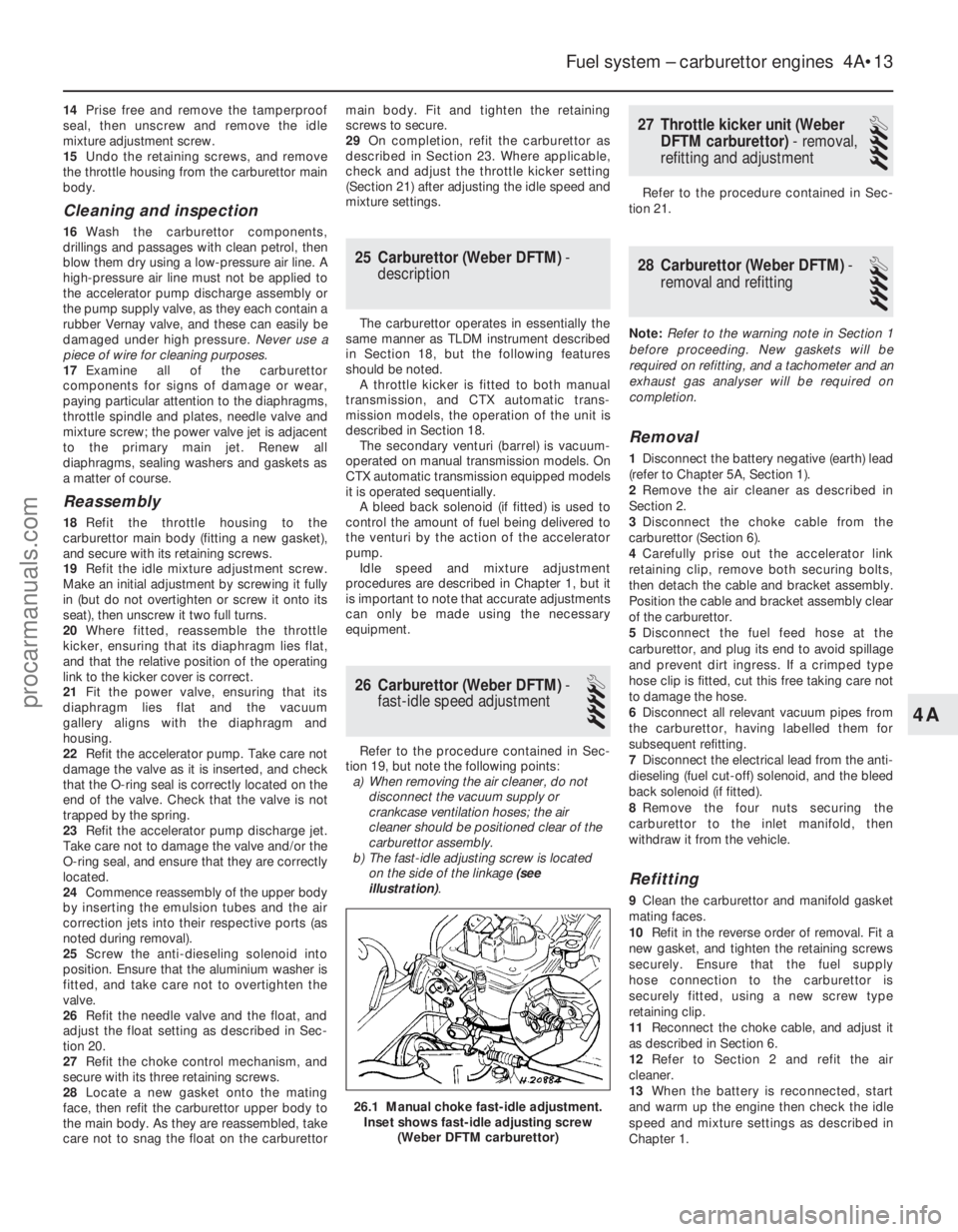

Refer to the procedure contained in Sec-

tion 19, but note the following points:

a) When removing the air cleaner, do not disconnect the vacuum supply or

crankcase ventilation hoses; the air

cleaner should be positioned clear of the

carburettor assembly.

b) The fast-idle adjusting screw is located

on the side of the linkage (see

illustration) .

27 Throttle kicker unit (Weber

DFTM carburettor) - removal,

refitting and adjustment

4

Refer to the procedure contained in Sec-

tion 21.

28 Carburettor (Weber DFTM) -

removal and refitting

4

Note: Refer to the warning note in Section 1

before proceeding. New gaskets will be

required on refitting, and a tachometer and an

exhaust gas analyser will be required on

completion.

Removal

1 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

2 Remove the air cleaner as described in

Section 2.

3 Disconnect the choke cable from the

carburettor (Section 6).

4 Carefully prise out the accelerator link

retaining clip, remove both securing bolts,

then detach the cable and bracket assembly.

Position the cable and bracket assembly clear

of the carburettor.

5 Disconnect the fuel feed hose at the

carburettor, and plug its end to avoid spillage

and prevent dirt ingress. If a crimped type

hose clip is fitted, cut this free taking care not

to damage the hose.

6 Disconnect all relevant vacuum pipes from

the carburettor, having labelled them for

subsequent refitting.

7 Disconnect the electrical lead from the anti-

dieseling (fuel cut-off) solenoid, and the bleed

back solenoid (if fitted).

8 Remove the four nuts securing the

carburettor to the inlet manifold, then

withdraw it from the vehicle.

Refitting

9 Clean the carburettor and manifold gasket

mating faces.

10 Refit in the reverse order of removal. Fit a

new gasket, and tighten the retaining screws

securely. Ensure that the fuel supply

hose connection to the carburettor is

securely fitted, using a new screw type

retaining clip.

11 Reconnect the choke cable, and adjust it

as described in Section 6.

12 Refer to Section 2 and refit the air

cleaner.

13 When the battery is reconnected, start

and warm up the engine then check the idle

speed and mixture settings as described in

Chapter 1.

Fuel system – carburettor engines 4A•13

26.1 Manual choke fast-idle adjustment. Inset shows fast-idle adjusting screw (Weber DFTM carburettor)

4A

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 119 of 296

29 Carburettor (Weber DFTM)-

dismantling, cleaning,

inspection and reassembly

4

Note: Refer to the warning note in Section 1

before proceeding. Check parts avail-

ability before dismantling. If possible, obtain

an overhaul kit containing all the relevant

gaskets, seals, etc, required for reassembly

prior to dismantling the carburettor.

Dismantling

1 With the carburettor removed from the vehicle, prepare a clean, flat work surface

prior to commencing dismantling. The

following procedures may be used for partial

or complete dismantling, as required.

2

Clean the exterior of the carburettor and

detach all vacuum pipes (where applicable),

having noted their fitted location for correct

subsequent reassembly.

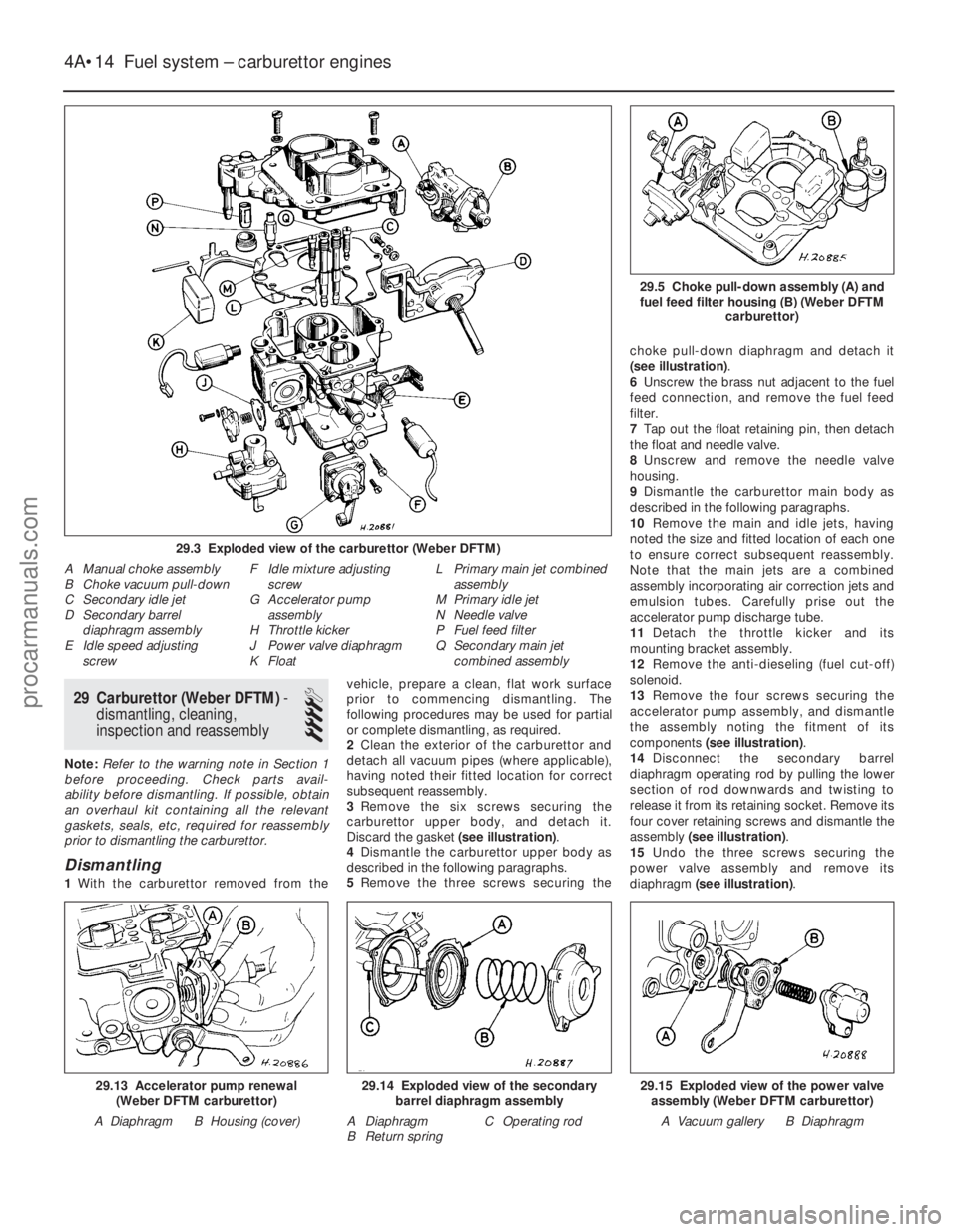

3 Remove the six screws securing the

carburettor upper body, and detach it.

Discard the gasket (see illustration).

4 Dismantle the carburettor upper body as

described in the following paragraphs.

5 Remove the three screws securing the choke pull-down diaphragm and detach it

(see illustration)

.

6 Unscrew the brass nut adjacent to the fuel

feed connection, and remove the fuel feed

filter.

7 Tap out the float retaining pin, then detach

the float and needle valve.

8 Unscrew and remove the needle valve

housing.

9 Dismantle the carburettor main body as

described in the following paragraphs.

10 Remove the main and idle jets, having

noted the size and fitted location of each one

to ensure correct subsequent reassembly.

Note that the main jets are a combined

assembly incorporating air correction jets and

emulsion tubes. Carefully prise out the

accelerator pump discharge tube.

11 Detach the throttle kicker and its

mounting bracket assembly.

12 Remove the anti-dieseling (fuel cut-off)

solenoid.

13 Remove the four screws securing the

accelerator pump assembly, and dismantle

the assembly noting the fitment of its

components (see illustration) .

14 Disconnect the secondary barrel

diaphragm operating rod by pulling the lower

section of rod downwards and twisting to

release it from its retaining socket. Remove its

four cover retaining screws and dismantle the

assembly (see illustration) .

15 Undo the three screws securing the

power valve assembly and remove its

diaphragm (see illustration) .

4A•14 Fuel system – carburettor engines

29.15 Exploded view of the power valve

assembly (Weber DFTM carburettor)

A Vacuum gallery B Diaphragm29.14 Exploded view of the secondary barrel diaphragm assembly

A Diaphragm C Operating rod

B Return spring29.13 Accelerator pump renewal (Weber DFTM carburettor)

A Diaphragm B Housing (cover)

29.5 Choke pull-down assembly (A) and fuel feed filter housing (B) (Weber DFTM carburettor)

29.3 Exploded view of the carburettor (Weber DFTM)

A Manual choke assembly

B Choke vacuum pull-down

C Secondary idle jet

D Secondary barreldiaphragm assembly

E Idle speed adjusting

screw F Idle mixture adjusting

screw

G Accelerator pump

assembly

H Throttle kicker

J Power valve diaphragm

K Float L Primary main jet combined

assembly

M Primary idle jet

N Needle valve

P Fuel feed filter

Q Secondary main jet

combined assembly

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 120 of 296

16Prise out the tamperproof seal covering

the fuel mixture screw, then undo and remove

the mixture screw.

Cleaning and inspection

17 Wash the carburettor components,

drillings and passages with clean petrol, then

blow them dry using a low-pressure air line. A

high-pressure air line must not be applied to

the accelerator pump discharge assembly or

the pump supply valve, as they each contain a

rubber Vernay valve, and these can easily be

damaged under high pressure. Never use a

piece of wire for cleaning purposes.

18 Examine all of the carburettor

components for signs of damage or wear,

paying particular attention to the diaphragms,

throttle spindle and plates, needle valve and

mixture screw; the power valve jet is adjacent

to the primary main jet. Renew all

diaphragms, sealing washers and gaskets as

a matter of course.

Reassembly

19 Refit the fuel mixture screw by fully

winding the screw in, then unwinding three

turns to give an approximate setting.

20 Refit the power valve assembly ensuring

that the diaphragm lies flat, and that the

vacuum gallery lines up correctly with the

diaphragm and housing.

21 Reassemble the secondary barrel

diaphragm into its housing, ensuring that

the diaphragm lies flat and that the vacuum

gallery lines up with the diaphragm and

housing. Also, to assist with installation, do

not reconnect its operating rod until the cover

has been secured.

22 Refit the throttle kicker mounting bracket.

23 Refit the anti-dieseling (fuel cut-off)

solenoid, using a new sealing washer.

24 Refit the accelerator pump assembly,

ensuring that the diaphragm lies flat and is not

kinked.

25 Reassemble the throttle kicker, ensuring

that the diaphragm lies flat and that the relative position of the diaphragm operating

link to the throttle kicker cover is correct. Fully

attach the throttle kicker assembly.

26

Refit the main and idle jets, making

reference to the notes taken during

dismantling to ensure correct fitted locations.

27 Reassemble the carburettor upper body

as described in the following paragraphs.

28 Refit the needle valve housing (using a

new washer if applicable).

29 Refit the needle valve and float assembly,

having ensured that the float tag locates

below the spring clip on the needle valve.

Insert the float retaining pin to secure.

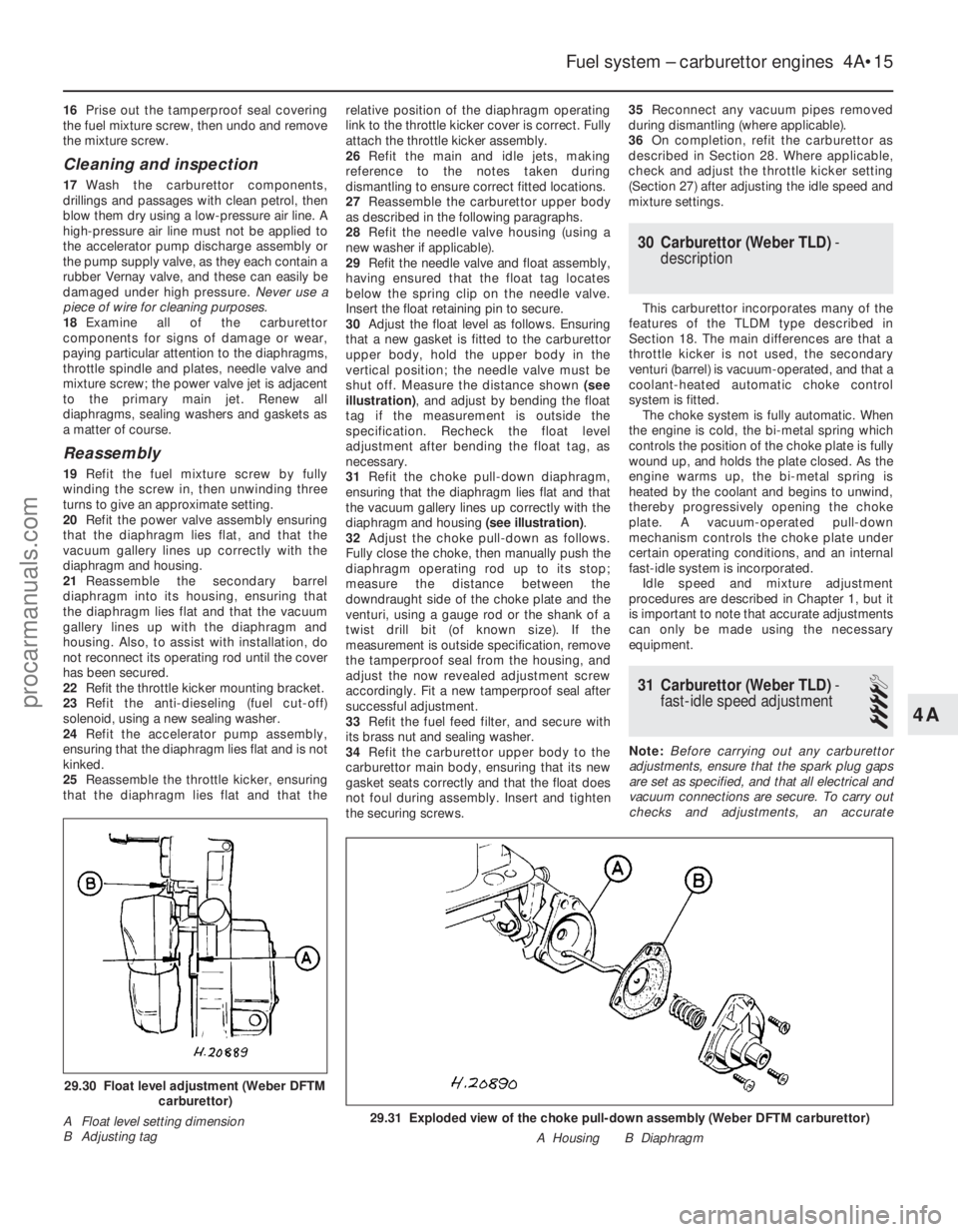

30 Adjust the float level as follows. Ensuring

that a new gasket is fitted to the carburettor

upper body, hold the upper body in the

vertical position; the needle valve must be

shut off. Measure the distance shown (see

illustration) , and adjust by bending the float

tag if the measurement is outside the

specification. Recheck the float level

adjustment after bending the float tag, as

necessary.

31 Refit the choke pull-down diaphragm,

ensuring that the diaphragm lies flat and that

the vacuum gallery lines up correctly with the

diaphragm and housing (see illustration).

32 Adjust the choke pull-down as follows.

Fully close the choke, then manually push the

diaphragm operating rod up to its stop;

measure the distance between the

downdraught side of the choke plate and the

venturi, using a gauge rod or the shank of a

twist drill bit (of known size). If the

measurement is outside specification, remove

the tamperproof seal from the housing, and

adjust the now revealed adjustment screw

accordingly. Fit a new tamperproof seal after

successful adjustment.

33 Refit the fuel feed filter, and secure with

its brass nut and sealing washer.

34 Refit the carburettor upper body to the

carburettor main body, ensuring that its new

gasket seats correctly and that the float does

not foul during assembly. Insert and tighten

the securing screws. 35

Reconnect any vacuum pipes removed

during dismantling (where applicable).

36 On completion, refit the carburettor as

described in Section 28. Where applicable,

check and adjust the throttle kicker setting

(Section 27) after adjusting the idle speed and

mixture settings.

30 Carburettor (Weber TLD) -

description

This carburettor incorporates many of the

features of the TLDM type described in

Section 18. The main differences are that a

throttle kicker is not used, the secondary

venturi (barrel) is vacuum-operated, and that a

coolant-heated automatic choke control

system is fitted. The choke system is fully automatic. When

the engine is cold, the bi-metal spring which

controls the position of the choke plate is fully

wound up, and holds the plate closed. As the

engine warms up, the bi-metal spring is

heated by the coolant and begins to unwind,

thereby progressively opening the choke

plate. A vacuum-operated pull-down

mechanism controls the choke plate under

certain operating conditions, and an internal

fast-idle system is incorporated. Idle speed and mixture adjustment

procedures are described in Chapter 1, but it

is important to note that accurate adjustments

can only be made using the necessary

equipment.

31 Carburettor (Weber TLD) -

fast-idle speed adjustment

4

Note: Before carrying out any carburettor

adjustments, ensure that the spark plug gaps

are set as specified, and that all electrical and

vacuum connections are secure. To carry out

checks and adjustments, an accurate

Fuel system – carburettor engines 4A•15

29.31 Exploded view of the choke pull-down assembly (Weber DFTM carbur\

ettor)

A Housing B Diaphragm

29.30 Float level adjustment (Weber DFTMcarburettor)

A Float level setting dimension

B Adjusting tag

4A

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su