clock FORD FIESTA 2007 User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2007, Model line: FIESTA, Model: FORD FIESTA 2007Pages: 1226, PDF Size: 61.26 MB

Page 518 of 1226

Engine - 1.25L Duratec-1 6V (Sigma)ll.4L

303-01 A-42 Duratec-1 6V (Sigma)/lm6L Duratec-1 6V (Sigma) 303-01 A-42

IN-VEHICLE REPAIR

Stage 2: 90 degrees.

Engines with eccentric cam timing belt

tensioner

Tension the timing belt by turning the

tensioner clockwise until the arrow points in

line with the center of the rectangular hole

and tighten the bolt.

9. Install the timing belt tensioner. Vehicles built 0912003 onwards

10. Tension the timing belt.

Tension the timing belt by turning the

tensioner counterclockwise until the arrow

points at the mark and tighten the bolt.

I*' AWARNING:D~ not remove the special

tool, until the timing belt is correctly

positioned. Failure to follow this instruction

may result in personal injury, or may

damage the timing belt tensioner.

Install the timing belt tensioner.

/--

13. Tension the timing belt.

Remove the special tool.

Engines with slotted bracket timing belt

tensioner

I I. Install the timing belt tensioner and tension

the timing belt.

Screw in the bolts finger tight.

2006.0 Fiesta 1212006 GI 83738en

procarmanuals.com

Page 555 of 1226

Engine - 1.25L Duratec-I 6V (Sigma)llm4L

303-01A-79 Duratec-1 6V (Sigma)/l .6L Duratec-1 6V (Sigma) 303-01 A-79

REMOVAL

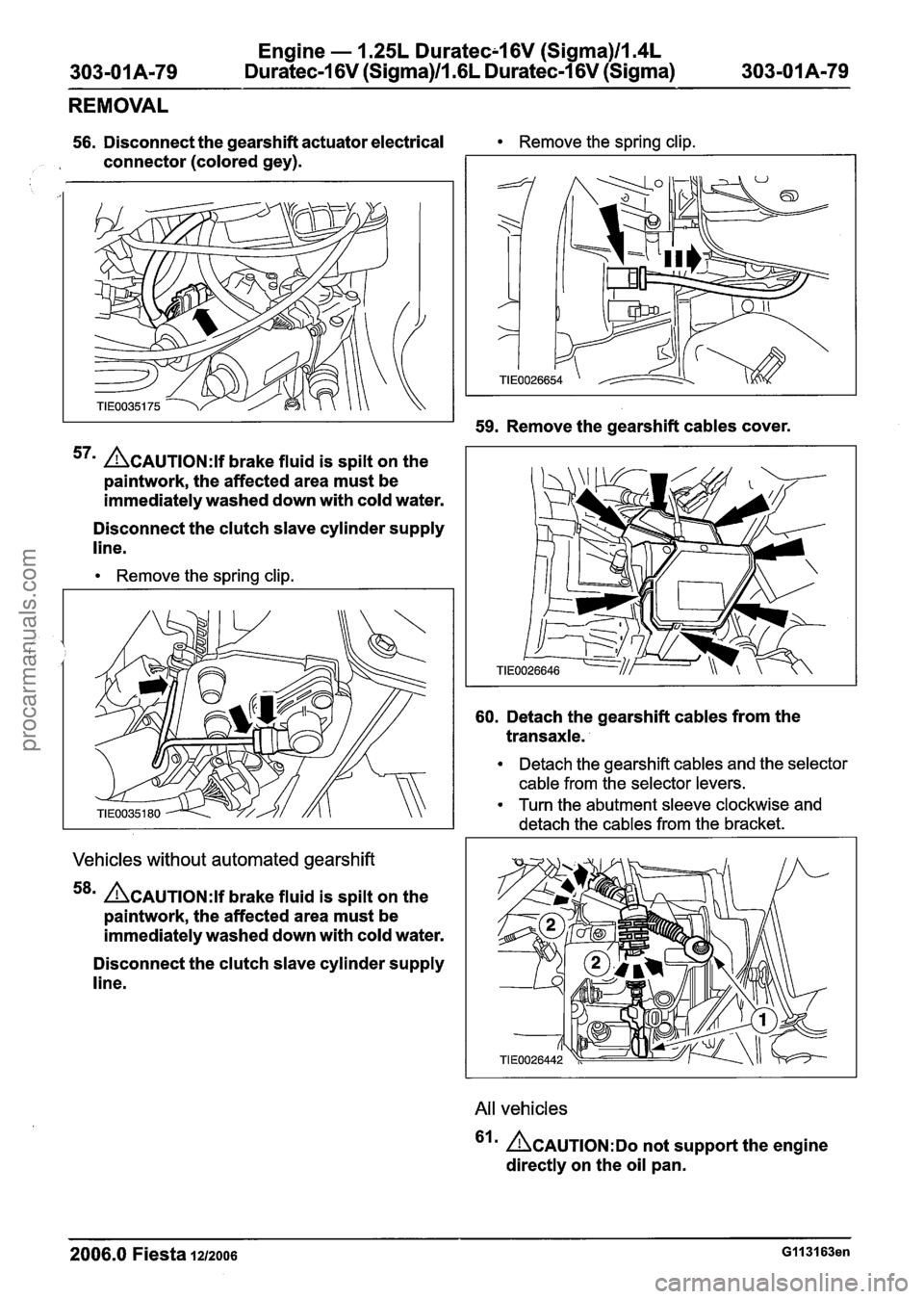

56. Disconnect the gearshift actuator electrical Remove the spring clip.

, connector (colored gey).

59. Remove the gearshift cables cover.

57m ACAUTION:I brake fluid is spilt on the

paintwork, the affected area must be

immediately washed down with cold water.

Disconnect the clutch slave cylinder supply

line.

Remove the spring clip.

Vehicles without automated gearshift

58' ACAUTION:~ brake fluid is spilt on the

paintwork, the affected area must be

immediately washed down with cold water.

Disconnect the clutch slave cylinder supply

line.

60. Detach the gearshift cables from the

transaxle.

Detach the gearshift cables and the selector

cable from the selector levers.

Turn the abutment sleeve clockwise and

detach the cables from the bracket.

All vehicles

'Irn ~CAUTION:DO not support the engine

directly on the oil pan.

2006.0 Fiesta 12/2oo6 G113163en

procarmanuals.com

Page 588 of 1226

303-01 A-I 12

Engine - 1.25L Duratec-1 6V (Sigma)ll.4L

Duratec-1 6V (Sigma)/lm6L Duratec-1 6V (Sigma)

ASSEMBLY

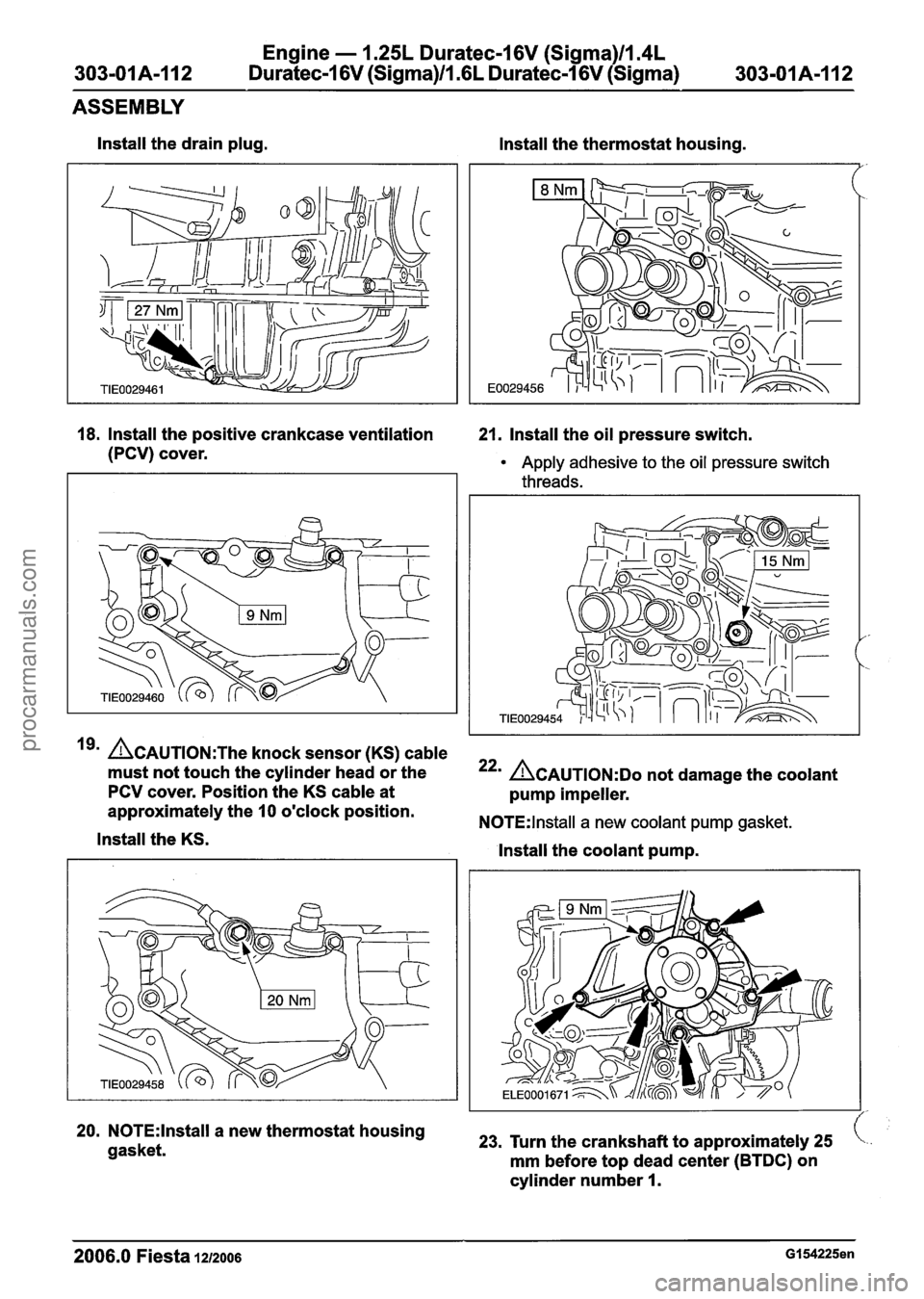

lnstall the drain plug.

lnstall the thermostat housing.

18. Install the positive crankcase ventilation 21. Install the oil pressure switch.

(PCV) cover.

Apply adhesive to the oil pressure switch

threads.

19' ~CAUTION:T~~ knock sensor (KS) cable

must not touch the cylinder head or the

PCV cover. Position the KS cable at

approximately the

10 o'clock position.

lnstall the KS.

20. N0TE:lnstall a new thermostat housing

gasket.

22' ACAUTION:D~ not damage the coolant

pump impeller.

N0TE:lnstall a new coolant pump gasket.

lnstall the coolant pump.

23, Turn the crankshaft to approximately 25

mm before top dead center (BTDC) on

cylinder number

I.

2006.0 Fiesta 1212006 GI 54225en

procarmanuals.com

Page 591 of 1226

Engine - 1.25L Dura

303-01A-115 Duratec-1 6V (Sigma)ll.(

tec-16V (Sigma)ll.4L

iL Duratec-1 6V (Sigma) 303-01A-I15

ASSEMBLY

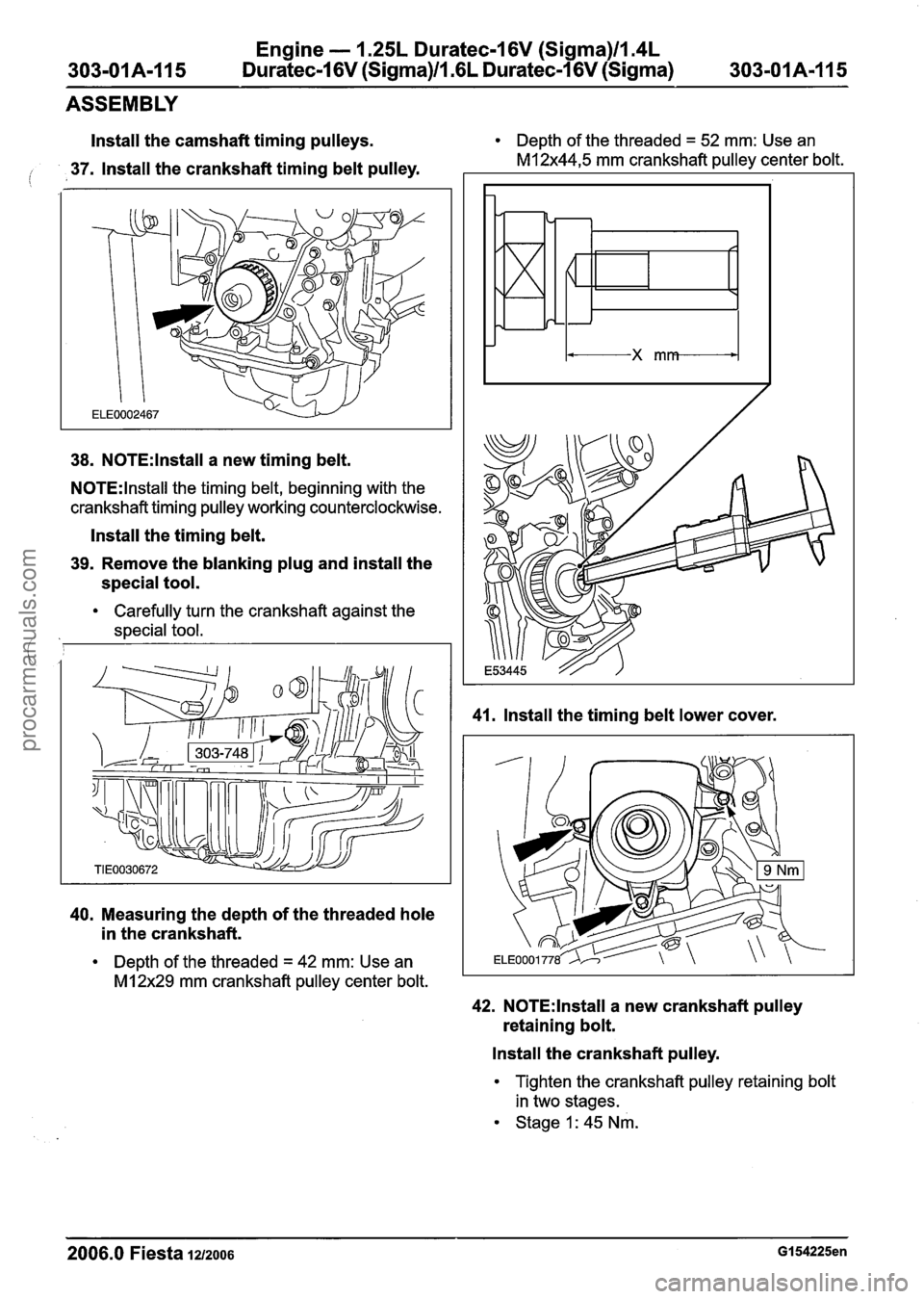

Install the camshaft timing pulleys.

io 37. Install the crankshaft timing belt pulley.

38. N0TE:lnstall a new timing belt.

N0TE:lnstall the timing belt, beginning with the

crankshaft timing pulley working counterclockwise.

Install the timing belt.

39. Remove the blanking plug and install the

special tool.

Carefully turn the crankshaft against the

,I special tool.

40. Measuring the depth of the threaded hole

in the crankshaft.

Depth of the threaded = 42 mm: Use an

MI 2x29 mm crankshaft pulley center bolt. Depth

of the threaded

= 52 mm: Use an

M12x44,5 mm crankshaft pulley center bolt.

41. Install the timing belt lower cover.

42. N0TE:lnstall a new crankshaft pulley

retaining bolt.

Install the crankshaft pulley.

Tighten the crankshaft pulley retaining bolt

in two stages.

Stage 1: 45 Nm.

2006.0 Fiesta 1212006 GI 54225en

procarmanuals.com

Page 592 of 1226

Engine - 1.25L Duratec-1 6V (Sigma)ll.4L

303-01 A-I 16 Duratec-1 6V (Sigma)/l .6L Duratec-1 6V (Sigma)

303-01 A-1 16

ASSEMBLY

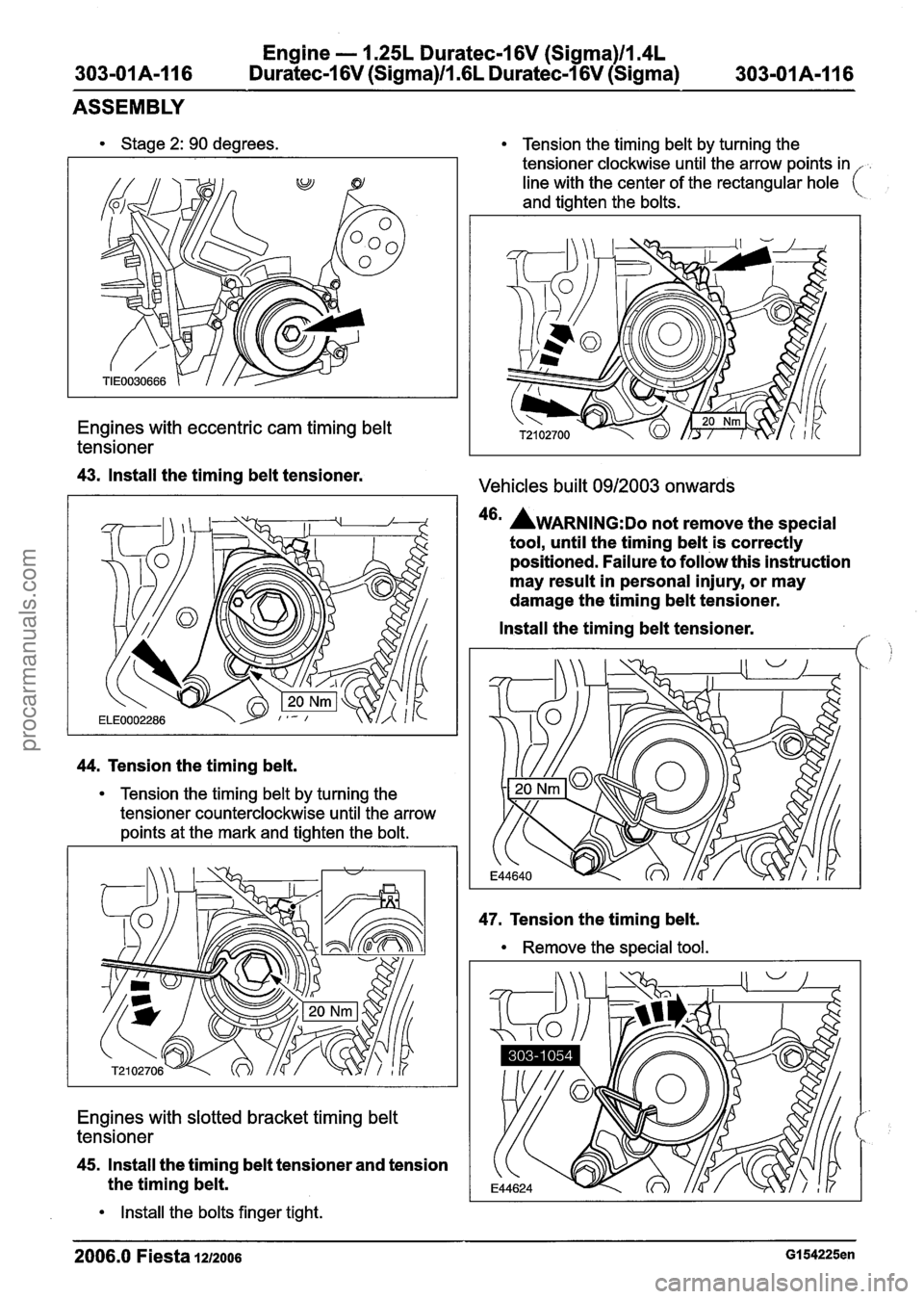

Stage 2: 90 degrees.

Engines with eccentric cam timing belt

tensioner

43. Install the timing belt tensioner.

44. Tension the timing belt.

Tension the timing belt by turning the

tensioner counterclockwise until the arrow

points at the mark and tighten the bolt.

Engines with slotted bracket timing belt

tensioner

45. Install the timing belt tensioner and tension

the timing belt.

Install the bolts finger tight.

Tension the timing belt by turning the

tensioner clockwise until the arrow points in

line with the center of the rectangular hole

(

and tighten the bolts.

Vehicles built 0912003 onwards

46' AWARNING:D~ not remove the special

tool, until the timing belt is correctly

positioned. Failure to follow this instruction

may result in personal injury, or may

damage the timing belt tensioner.

Install the timing belt tensioner.

f,

47. Tension the timing belt.

Remove the special tool.

2006.0 Fiesta 1212006 GI 54225en

procarmanuals.com

Page 603 of 1226

Engine - 1.25L Duratec-1 6V (Sigma)ll.4L

303-01 A-I 27 Duratec-1 6V (Sigma)ll .6L Duratec-1 6V (Sigma)

303-01 A-I 27

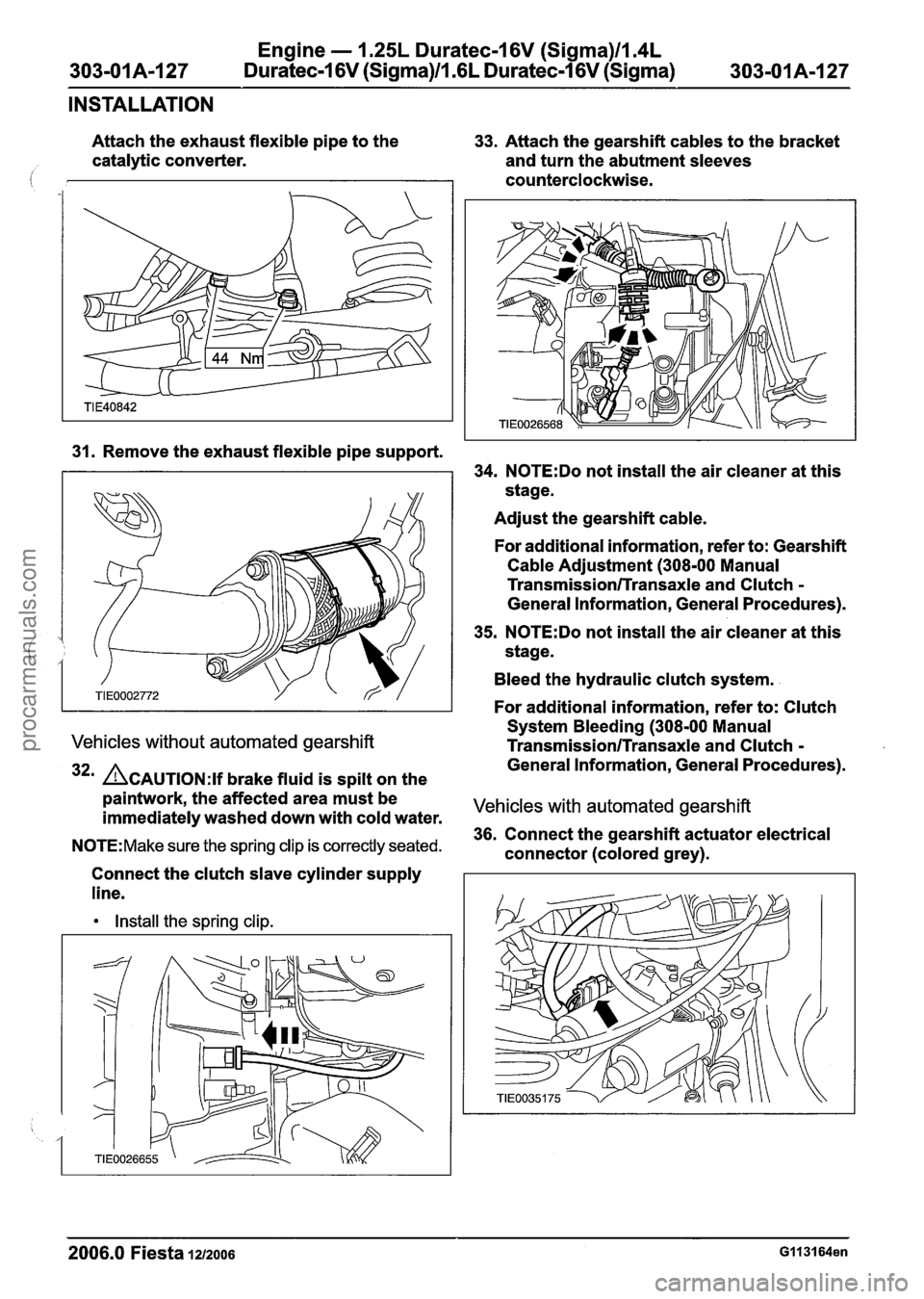

INSTALLATION

Attach the exhaust flexible pipe to the

33. Attach the gearshift cables to the bracket

catalytic converter.

and turn the abutment sleeves

counterclockwise.

31. Remove the exhaust flexible pipe support.

Vehicles without automated gearshift

32m ACAUTION:H brake fluid is spilt on the

paintwork, the affected area must be

immediately washed down with cold water.

N0TE:Make sure the spring clip is correctly seated.

Connect the clutch slave cylinder supply

line.

Install the spring clip.

34. N0TE:Do not install the air cleaner at this

stage.

Adjust the gearshift cable.

For additional information, refer to: Gearshift Cable Adjustment (308-00 Manual

Transmission/Transaxle and Clutch

General Information, General Procedures).

35.

N0TE:Do not install the air cleaner at this

stage.

Bleed the hydraulic clutch system.

For additional information, refer to: Clutch

System Bleeding (308-00 Manual

Transmission/Transaxle and Clutch -

General Information, General Procedures).

Vehicles with automated gearshift

36. Connect the gearshift actuator electrical

connector (colored grey).

2006.0 Fiesta 1212006

procarmanuals.com

Page 702 of 1226

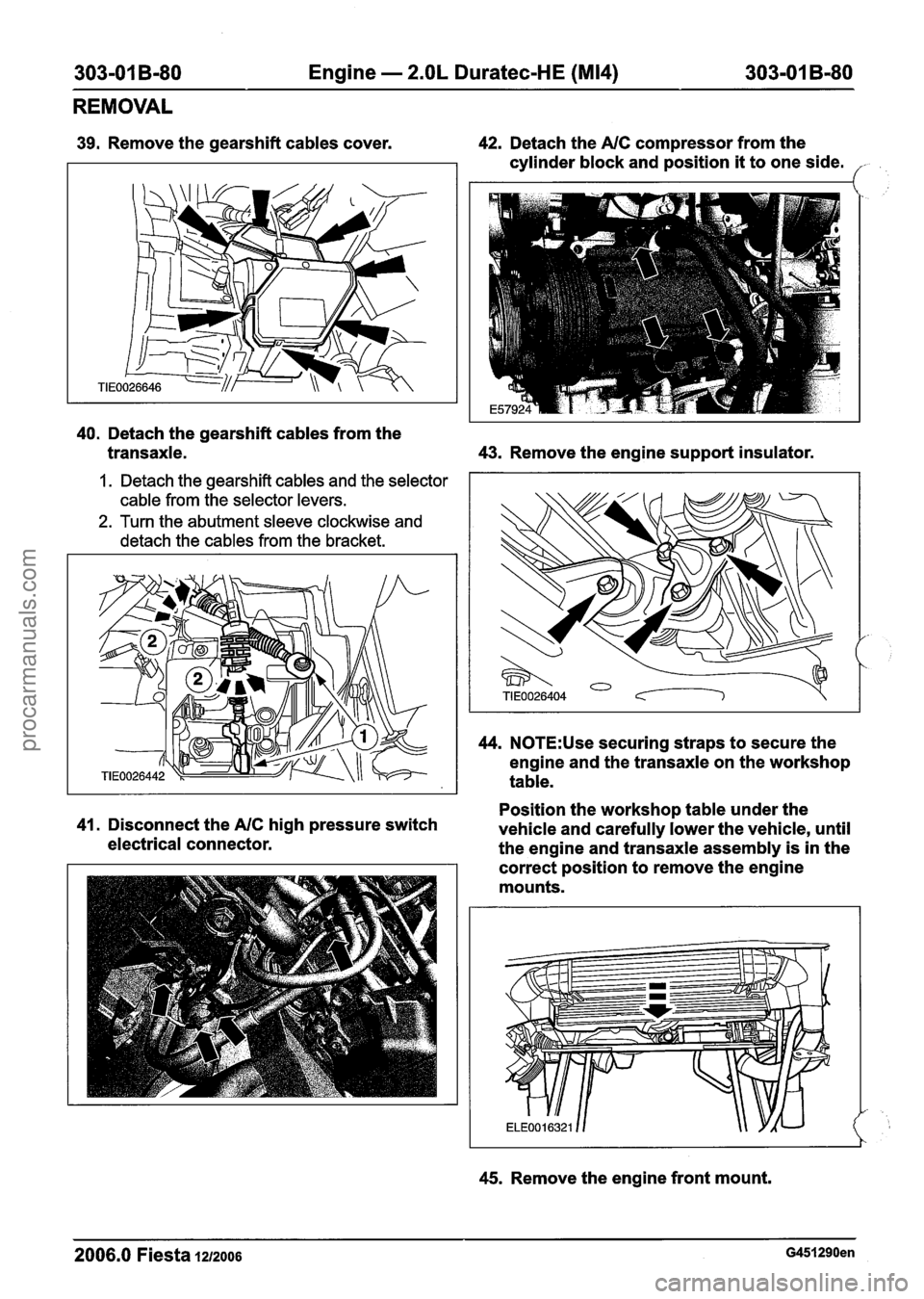

303-01 B-80 Engine - 2.OL Duratec-HE (M14) 303-01 B-80

REMOVAL

39. Remove the gearshift cables cover. 42. Detach the NC compressor from the

cylinder block and position

it to one side. /-

40. Detach the gearshift cables from the

transaxle. 43.

Remove the engine support insulator.

1. Detach the gearshift cables and the selector

cable from the selector levers.

2. Turn the abutment sleeve clockwise and

detach the cables from the bracket.

44. N0TE:Use securing straps to secure the

engine and the transaxle on the workshop

table.

Position the workshop table under the

41. Disconnect the NC high pressure switch

vehicle and carefully lower the vehicle, until

electrical connector.

the engine and transaxle assembly is in the

correct position to remove the engine

mounts.

45. Remove the engine front mount.

2006.0 Fiesta 1212006 G451290en

procarmanuals.com

Page 719 of 1226

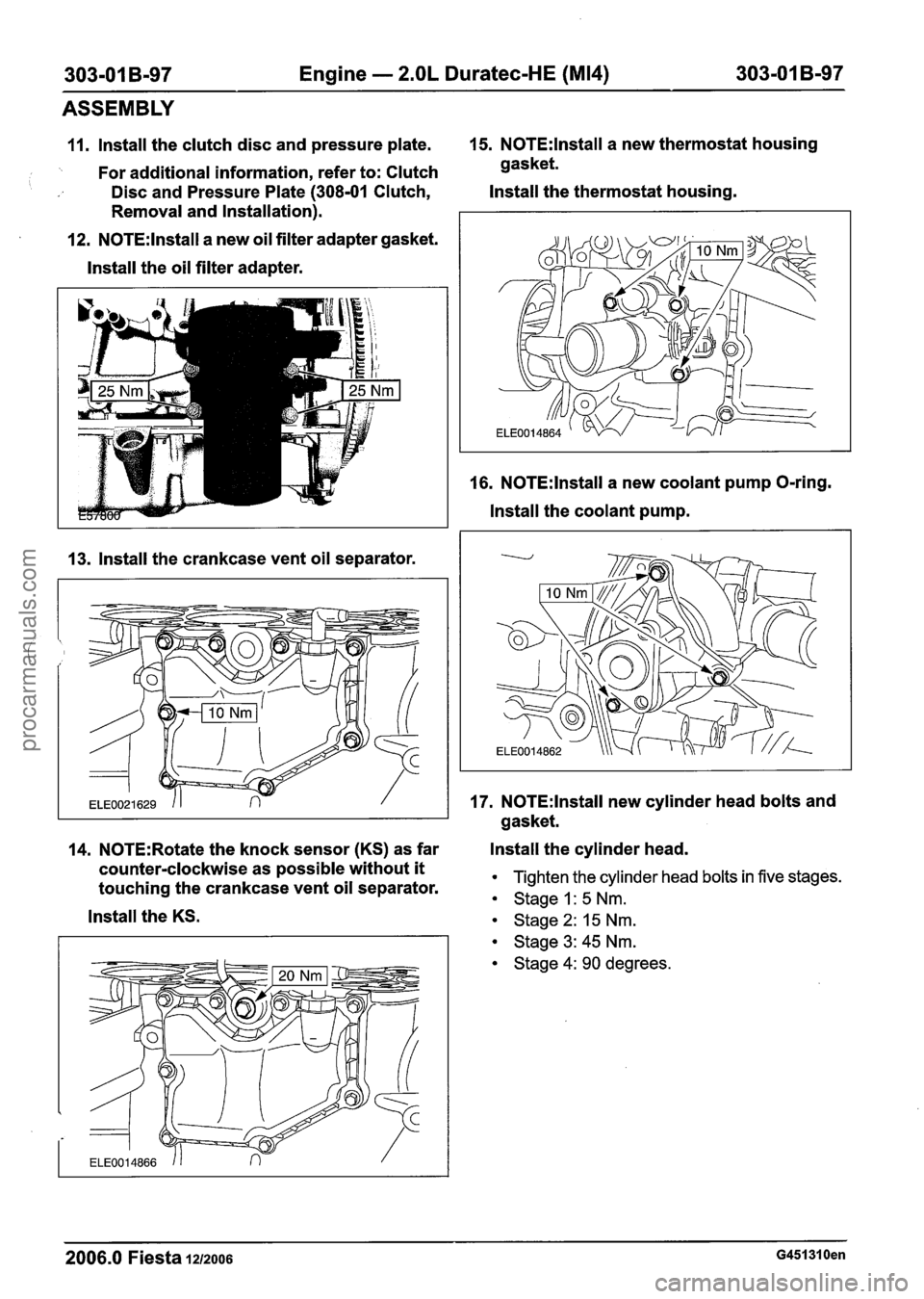

303-01 B-97 Engine - 2.OL Duratec-HE (M14) 303-01 B-97

ASSEMBLY

11. lnstall the clutch disc and pressure plate. 15. N0TE:lnstall a

new thermostat housing

'. For additional information, refer to: Clutch gasket.

Disc and Pressure Plate (308-01 Clutch, Install

the thermostat housing.

Removal and Installation).

12.

N0TE:lnstall a new oil filter adapter gasket.

lnstall the oil filter adapter.

13. lnstall the crankcase vent oil separator. 16.

N0TE:lnstall a

new coolant pump O-ring.

lnstall the coolant pump.

17.

N0TE:lnstall new cylinder head bolts and

gasket.

14.

N0TE:Rotate the knock sensor (KS) as far Install

the cylinder head.

counter-clockwise as possible without

it Tighten the cylinder head bolts in five stages. touching the crankcase vent oil separator. Stage I: 5 Nm.

lnstall the KS. stage 2: 15 Nm.

Stage 3: 45 Nm.

Stage 4: 90 degrees.

2006.0 Fiesta 1212006 G451310en

procarmanuals.com

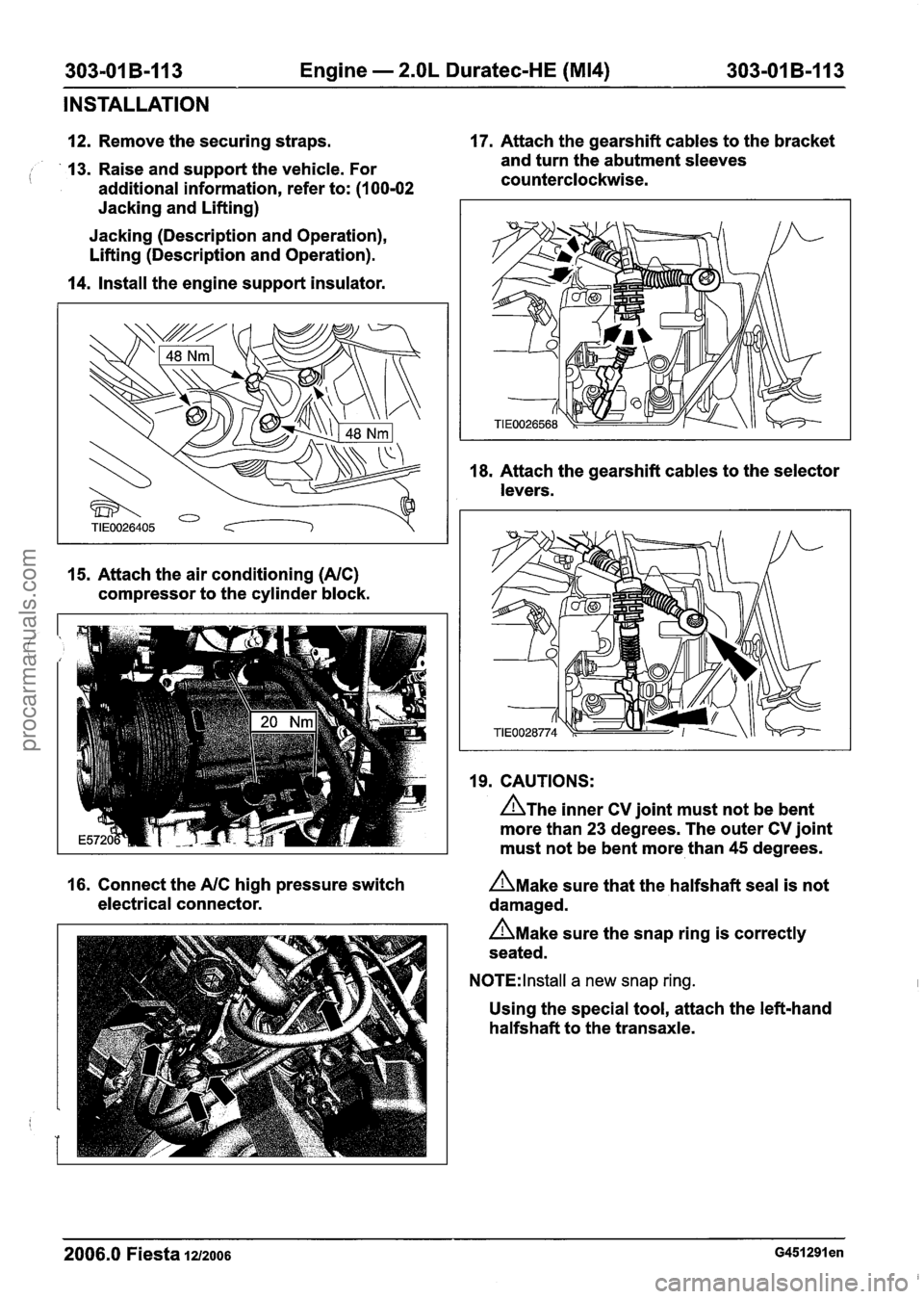

Page 735 of 1226

303-01 B-I 13 Engine - 2.OL Duratec-HE (M14) 303-01 B-113

INSTALLATION

12. Remove the securing straps. 17.

Attach the gearshift cables to the bracket

13. Raise and support the vehicle. For and

turn the abutment sleeves

( additional information, refer to: (I 00-02 counterclockwise.

Jacking and Lifting)

Jacking (Description and Operation),

Lifting (Description and Operation).

14. Install the engine support insulator.

15. Attach the air conditioning (NC)

compressor to the cylinder block. 18.

Attach the gearshift cables to the selector

levers.

19. CAUTIONS:

A~he inner CV joint must not be bent

more than 23 degrees. The outer CV joint

must not be bent more than 45 degrees.

16. Connect the

NC high pressure switch n~ake sure that the halfshaft seal is not

electrical connector. damaged.

n~ake sure the snap ring is correctly

seated.

N0TE:lnstall a new snap ring.

Using the special tool, attach the left-hand

halfshaft to the transaxle.

2006.0 Fiesta 1212006 ~451291 en

procarmanuals.com

Page 758 of 1226

Engine Cooling - 1.3L Duratec-8V

(Rocam)ll.25L Duratec-I 6V (Sigma)ll.4L

303-03A-16 Duratec-1 6V (Sigma)/l .6L Duratec-1 6V (Sigma) 303-03A-16

DIAGNOSIS AND TESTING

Component Tests

Pressure Test

A WARNING:When releasing the system

pressure, cover the expansion tank cap

with a thick cloth to prevent the possibility

of coolant scalding, Failure to follow this

instruction may result in personal injury.

1. Remove the coolant expansion tank cap.

2.

Install the special tools to the coolant expansion

tank.

3. Pressurize the system to the

coolant expansion

tank cap

release pressure.

REFER to: Specifications (303-03 Engine

Cooling - 1.3L Duratec-8V (Rocam)/l.25L

Duratec-I 6V (Sigma)/l.4L Duratec-1 6V

(Sigma)/l .6L Duratec-1 6V (Sigma),

Specifications).

4. Observe the

cooling system pressure tester

gauge reading for

approximately two minutes.

The pressure

should not drop during this time.

If the system holds pressure, proceed to step

6.

If the system does not hold pressure, check

it

thoroughly for coolant leaks.

5. Check the engine for coolant leaks. Drain the

cooling system, repair any coolant leaks found

and

fill and bleed the cooling system as

necessary.

REFER to:

Cooling System Draining, Filling and

Bleeding - 1.3L Duratec-8V (Rocam)/l.25L

Duratec-I 6V (Sigma)/l.4L Duratec-1 6V

(Sigma)/l .6L Duratec-1 6V (Sigma) (303-03

Engine

Cooling - 1.3L Duratec-8V

(Rocam)/l.25L Duratec-1 6V (Sigma)/l.4L

Duratec-1 6V (Sigma)/l .6L Duratec-1 6V

(Sigma), General Procedures).

Clean the radiator thoroughly before leak testing

it, to prevent contamination of the water in the test

tank. Leak test the radiator in

clean water with 138(

kpa (20 psi) air pressure. Check it thoroughly for

air

leaks. INSTALL a new radiator if necessary.

REFER to: Radiator (303-03 Engine

Cooling - 1.3L

Duratec-8V (Rocam)/l.25L Duratec-I 6V

(Sigma)/l.4L Duratec-I 6V (Sigma)ll .6L

Duratec-I 6V (Sigma), Removal and Installation).

Coolant Expansion Tank Cap Pressure Test

A WARNING:When releasing the system

pressure, cover the expansion tank cap

with a thick cloth to prevent the possibility

of coolant scalding, Failure to follow this

instruction may result in personal injury.

1. Remove the coolant expansion tank cap.

2. Use water to clean the area of the rubber seal

and pressure relief valve. Install the pressure

tester and adapter and immerse the

coolant

expansion tank cap in water .

N0TE:lf the plunger of the pump is depressed too

quickly, an erroneous pressure reading will result. l-

3. Slowly depress the plunger of the pressure test

pump until the pressure gauge reading stops

increasing, and note the highest pressure

reading obtained.

4.

Release pressure by turning the pressure relief

screw counterclockwise. Tighten the pressure

relief screw and repeat step 3 at least twice to

make sure the pressure test reading is

repeatable and within acceptable gauge reading

limits of the coolant expansion tank cap.

5.

If the pressure test gauge readings are not

within the

acceptable gauge reading limits,

INSTALL a new coolant expansion tank cap.

6. Recheck the system by repeating steps 3 and

4 at least twice.

Thermostat Test

Radiator Leak Test, Removed From Vehicle

A CAUTI0N:Radiator internal pressure must

not exceed

130 kpa (20 psi) or damage may

result.

1. Connect the WDS to the data link connector

(DLC).

2. Using the WDS

datalogger function, SELECT

the

following sensors (as applicable to the

application):

IAT - intake air temperature (IAT) sensor

ECT

- engine coolant temperature (ECT) sensort

CHT - cylinder head temperature (CHT) sensori

LOAD - engine load

VSS - vehicle speed sensor (VSS)

2006.0 Fiesta 1212006 GI 46258en

procarmanuals.com