FORD FIESTA 2007 Workshop Manual

FIESTA 2007

FORD

FORD

https://www.carmanualsonline.info/img/11/56936/w960_56936-0.png

FORD FIESTA 2007 Workshop Manual

Trending: ECU, relay, warning light, DRIVE SHAFT, turn signal, height, steering wheel adjustment

Page 451 of 1226

303-00-29 Engine System - General Information 303-00-29

DIAGNOSIS AND TESTING

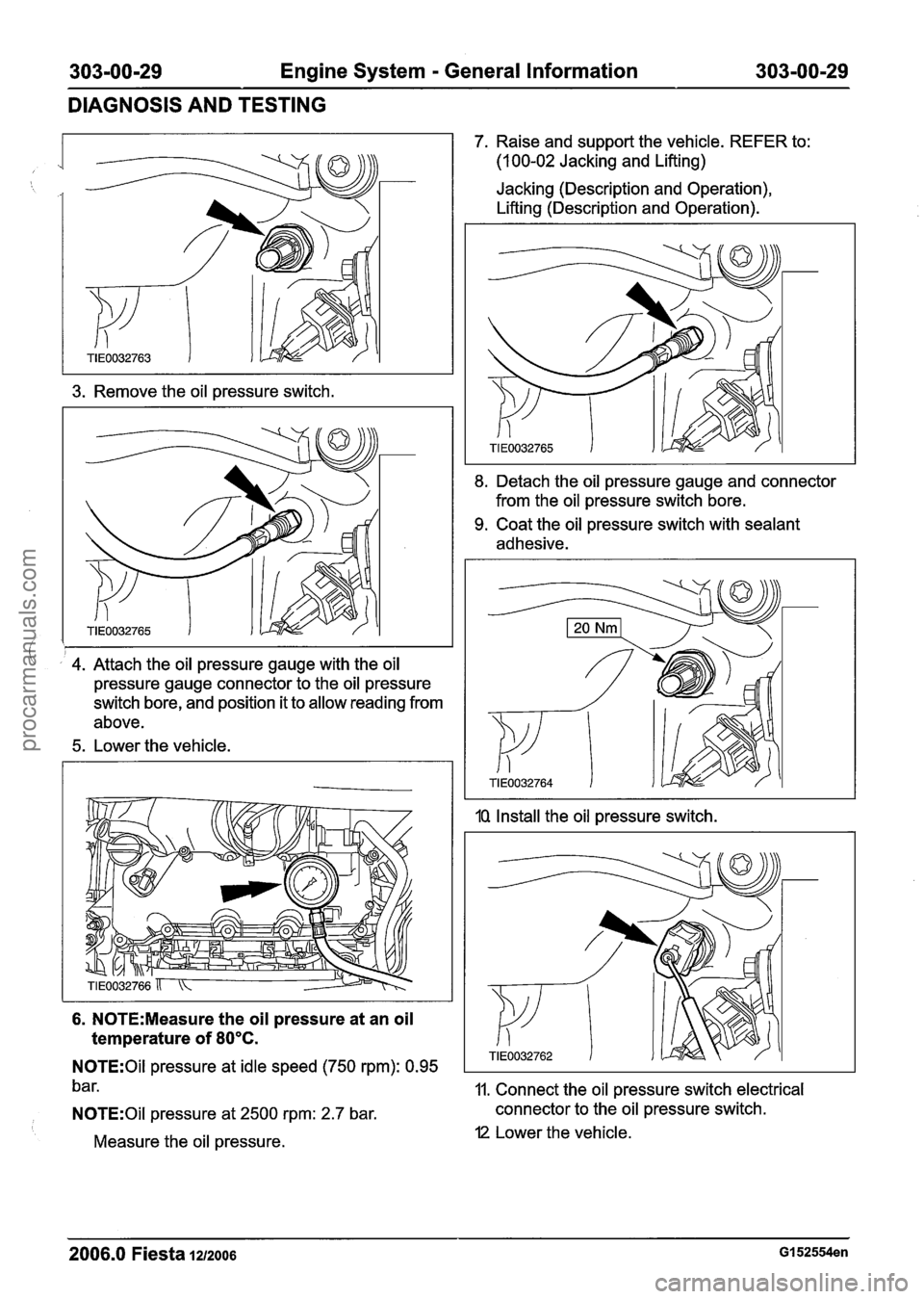

3. Remove the oil pressure switch.

( 4. Attach the oil pressure gauge with the oil

pressure gauge connector to the oil pressure

switch bore, and position it to allow reading from

above.

5. Lower the vehicle. 7.

Raise and support the vehicle. REFER to:

(1 00-02 Jacking and Lifting)

Jacking (Description and Operation),

Lifting (Description and Operation).

8. Detach the oil pressure gauge and connector

from the oil pressure switch bore.

9. Coat the oil pressure switch with sealant

adhesive.

IQ Install the oil pressure switch.

6. N0TE:Measure the oil pressure at an oil

temperature of 80°C.

N0TE:OiI pressure at idle speed (750 rpm): 0.95

bar. 11. Connect the oil pressure switch electrical

N0TE:Oil pressure at 2500 rpm: 2.7 bar. connector to

the oil pressure switch.

Measure the oil pressure.

I2 Lower the vehicle.

2006.0 Fiesta 1212006 GI 52554en

procarmanuals.com

Page 452 of 1226

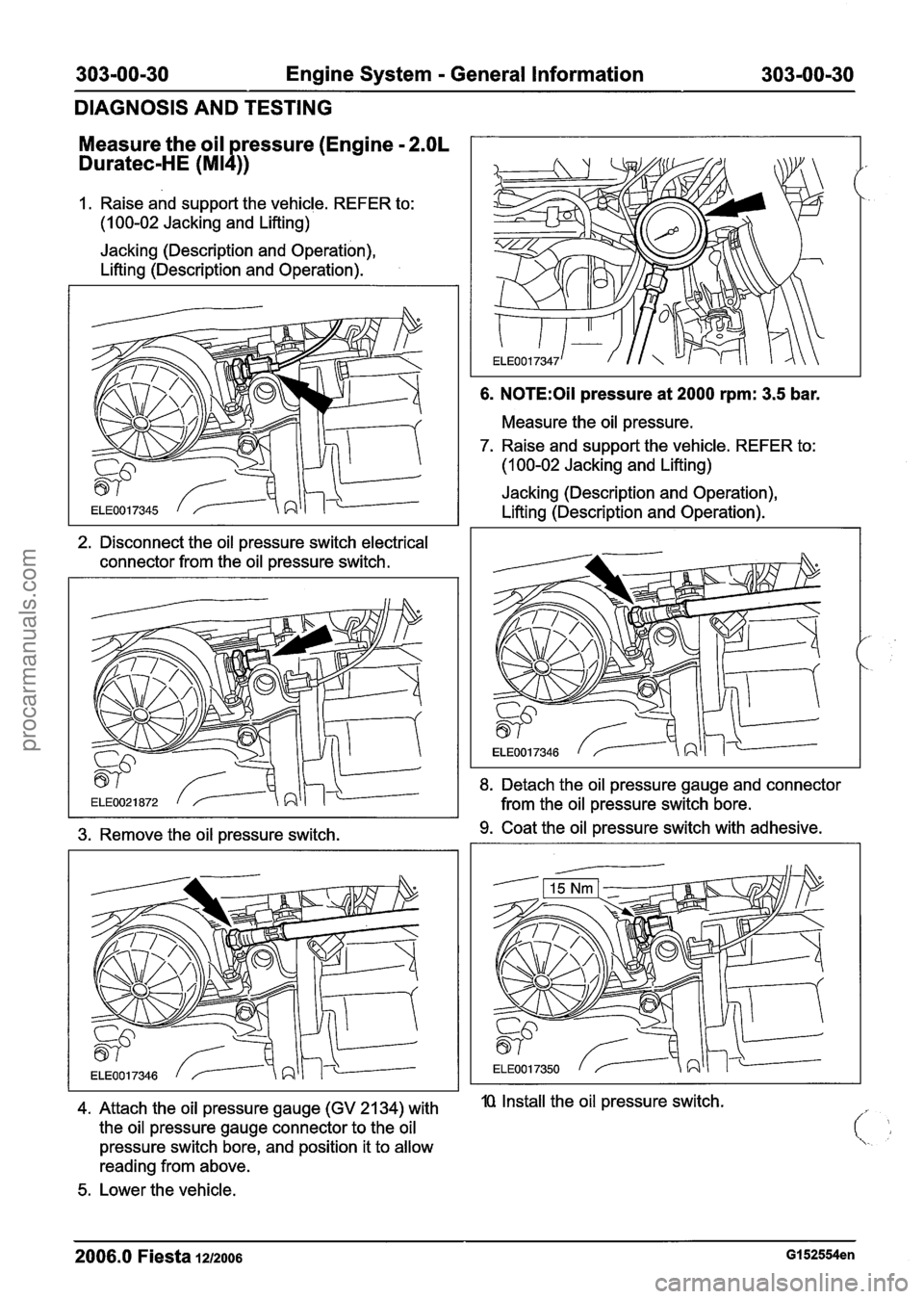

303-00-30 Engine System - General Information 303-00-30

DIAGNOSIS AND TESTING

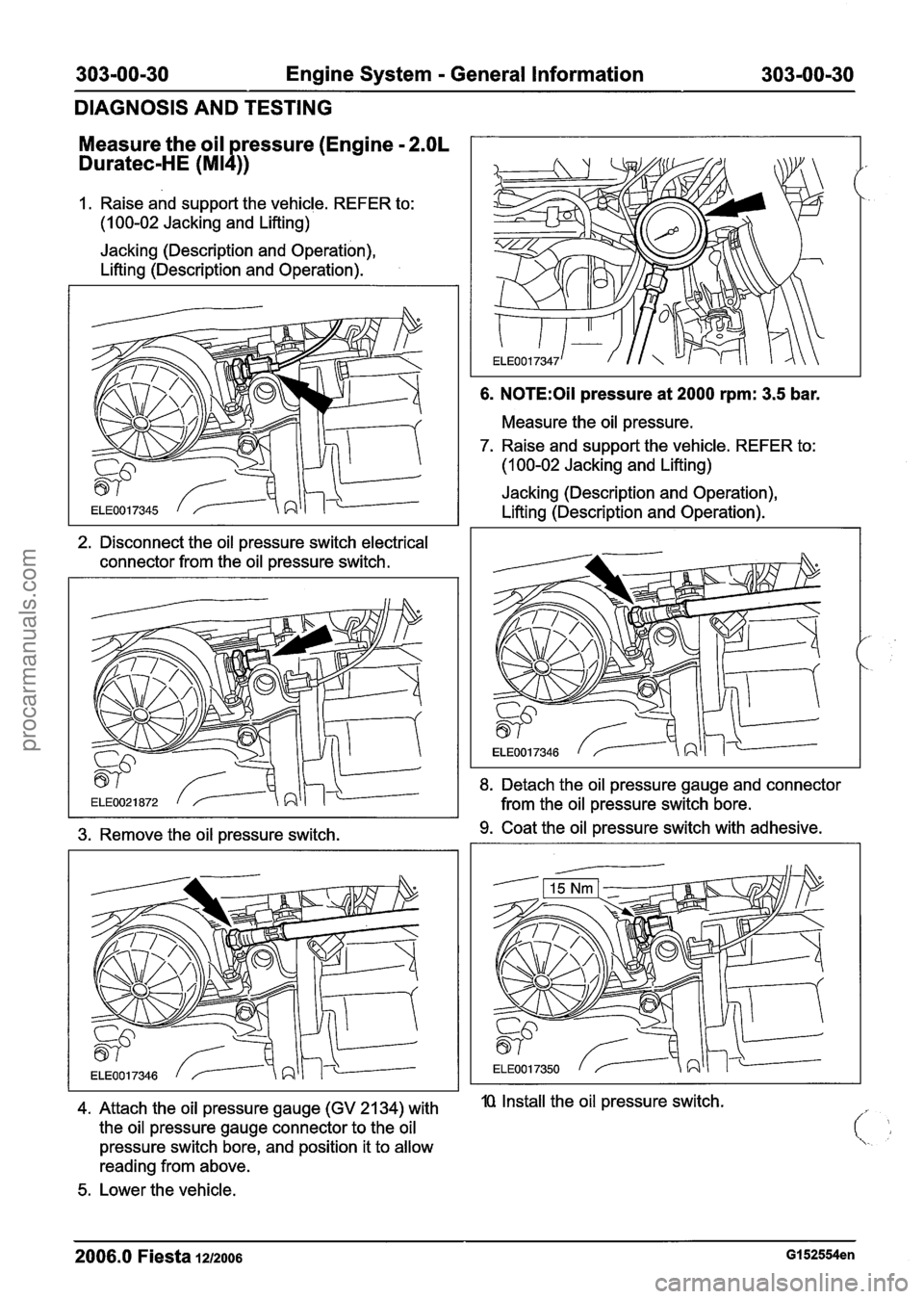

Measure the oil ressure (Engine

- 2.OL

Duratec-HE (MI 1 ))

I. Raise and support the vehicle. REFER to:

(I 00-02 Jacking and Lifting)

Jacking (Description and Operation),

Lifting (Description and Operation).

2. Disconnect the oil pressure switch electrical

connector from the oil pressure switch.

3. Remove the oil pressure switch.

6. N0TE:OiI pressure at 2000 rpm: 3.5 bar.

Measure the oil pressure.

7. Raise and support the vehicle. REFER to:

(1 00-02 Jacking and Lifting)

Jacking (Description and Operation), Lifting (Description and Operation).

8. Detach the oil pressure gauge and connector

from the oil pressure switch bore.

9. Coat the oil pressure switch with adhesive.

4. Attach the oil pressure gauge

(GV 2134) with ICL Install the pressure switch=

the oil pressure gauge connector to the oil

pressure switch bore, and position it to allow

reading from above.

5. Lower the vehicle.

2006.0 Fiesta 1212006 GI 52554en

procarmanuals.com

Page 453 of 1226

303-00-31 Engine System - General Information 303-00-31

DIAGNOSIS AND TESTING

11. Connect the oil pressure switch electrical

connector to the oil pressure switch.

12 Lower the vehicle.

Valve train analysis - static (engine off)

Remove the valve cover.

Check all components of the valve train for damage

and wear. Make sure that only original components

are installed and that all nuts and bolts are

tightened to the specified torque.

2006.0 Fiesta 1212006 GI 52554en

procarmanuals.com

Page 454 of 1226

303-00-32 Engine System - General Information 303-00-32

GENERAL PROCEDURES

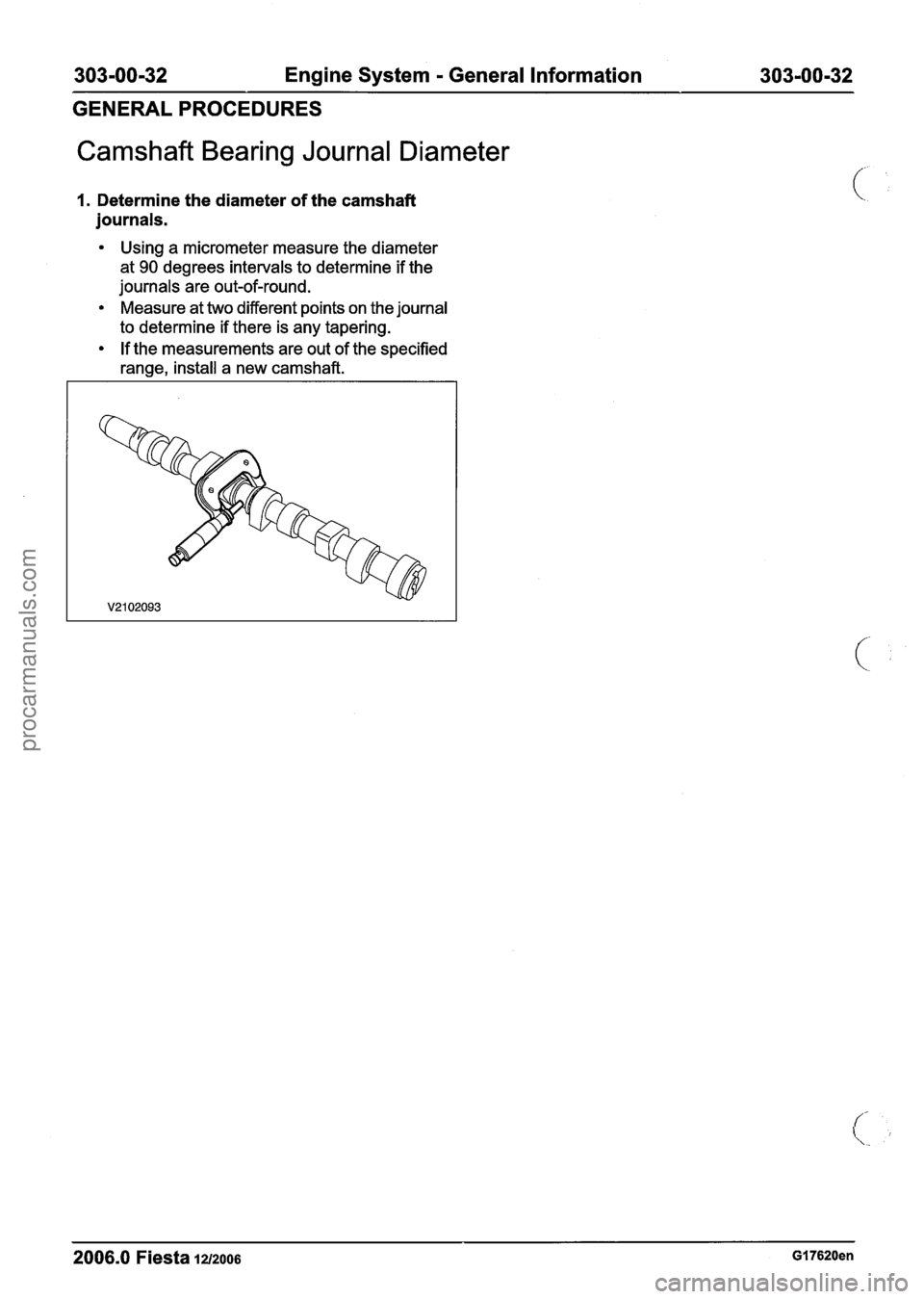

Camshaft Bearing Journal Diameter

1. Determine the diameter of the camshaft

journals.

Using a micrometer measure the diameter

at

90 degrees intervals to determine if the

journals are out-of-round.

Measure at two different points on the journal

to determine if there is any tapering.

If the measurements are out of the specified

range, install a new camshaft.

2006.0 Fiesta 1212006 GI 7620en

procarmanuals.com

Page 455 of 1226

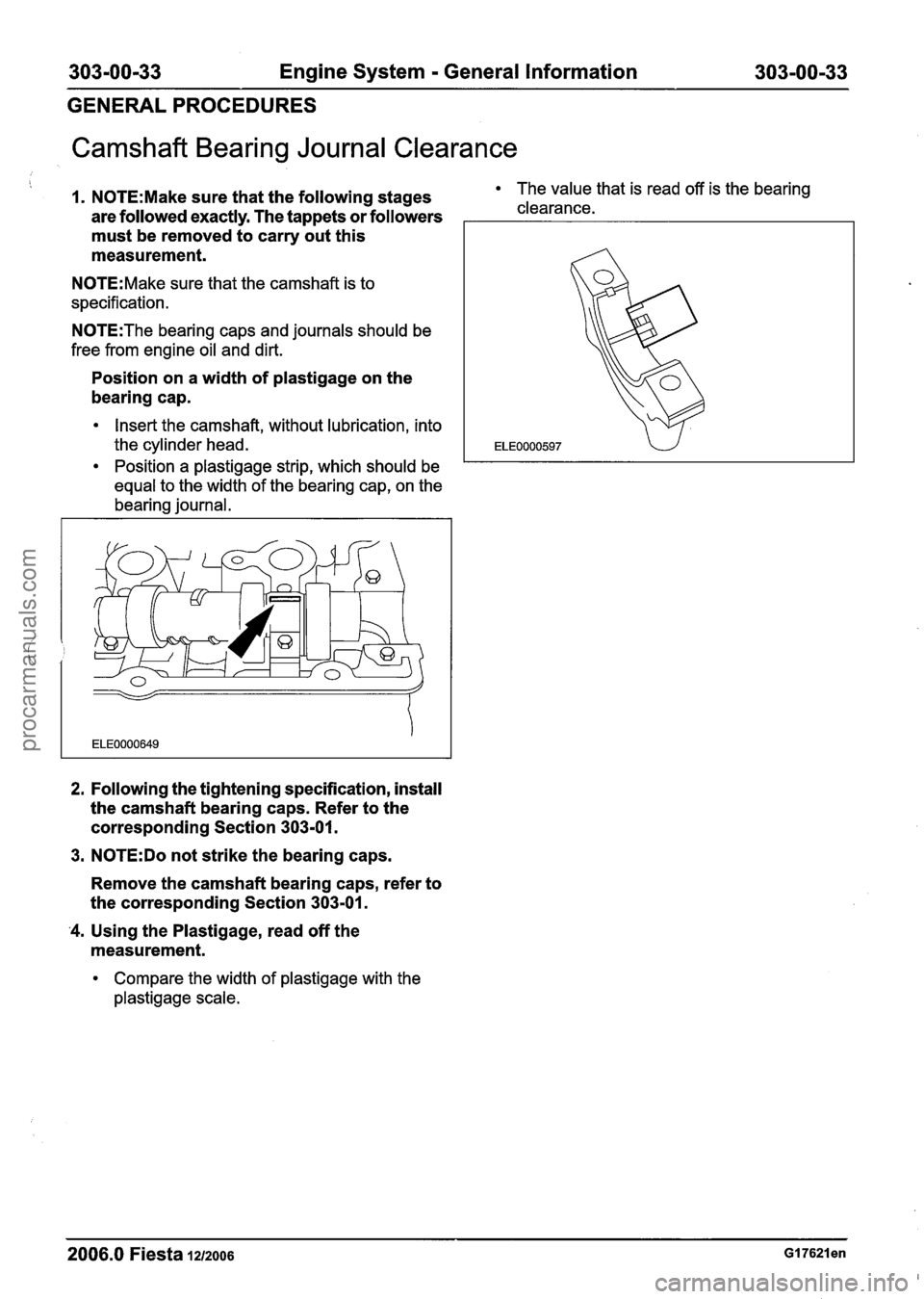

303-00-33 Engine System - General Information 303-00-33

GENERAL PROCEDURES

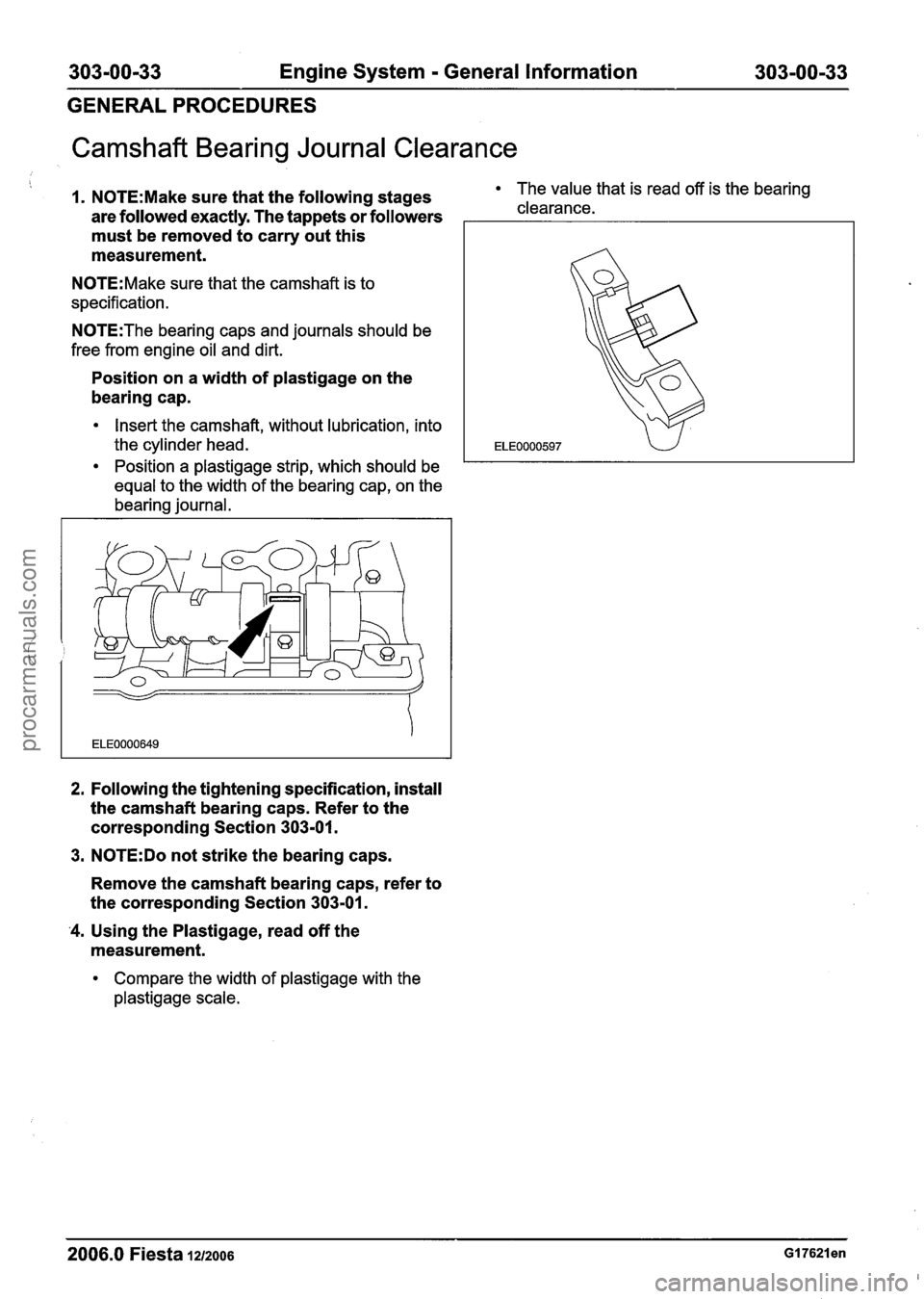

Camshaft Bearing Journal Clearance

1. N0TE:Make sure that the following stages The value that is read off is the bearing

are followed exactly. The tappets or followers clearance.

must be removed to carry out this

measurement.

N0TE:Make sure that the camshaft is to

specification.

N0TE:The bearing caps and journals should be

free from engine oil and dirt.

Position on a width of plastigage on the

bearing cap.

Insert the camshaft, without lubrication, into

the cylinder head.

Position

a plastigage strip, which should be

equal to the width of the bearing cap, on the

bearing journal.

2. Following the tightening specification, install

the camshaft bearing caps. Refer to the

corresponding Section 303-01.

3.

N0TE:Do not strike the bearing caps.

Remove the camshaft bearing caps, refer to

the corresponding Section 303-01.

'4. Using the Plastigage, read off the

measurement.

Compare the width of plastigage with the

plastigage scale.

2006.0 Fiesta 1212006

procarmanuals.com

Page 456 of 1226

303-00-34 Engine System - General Information 303-00-34

GENERAL

PROCEDURES

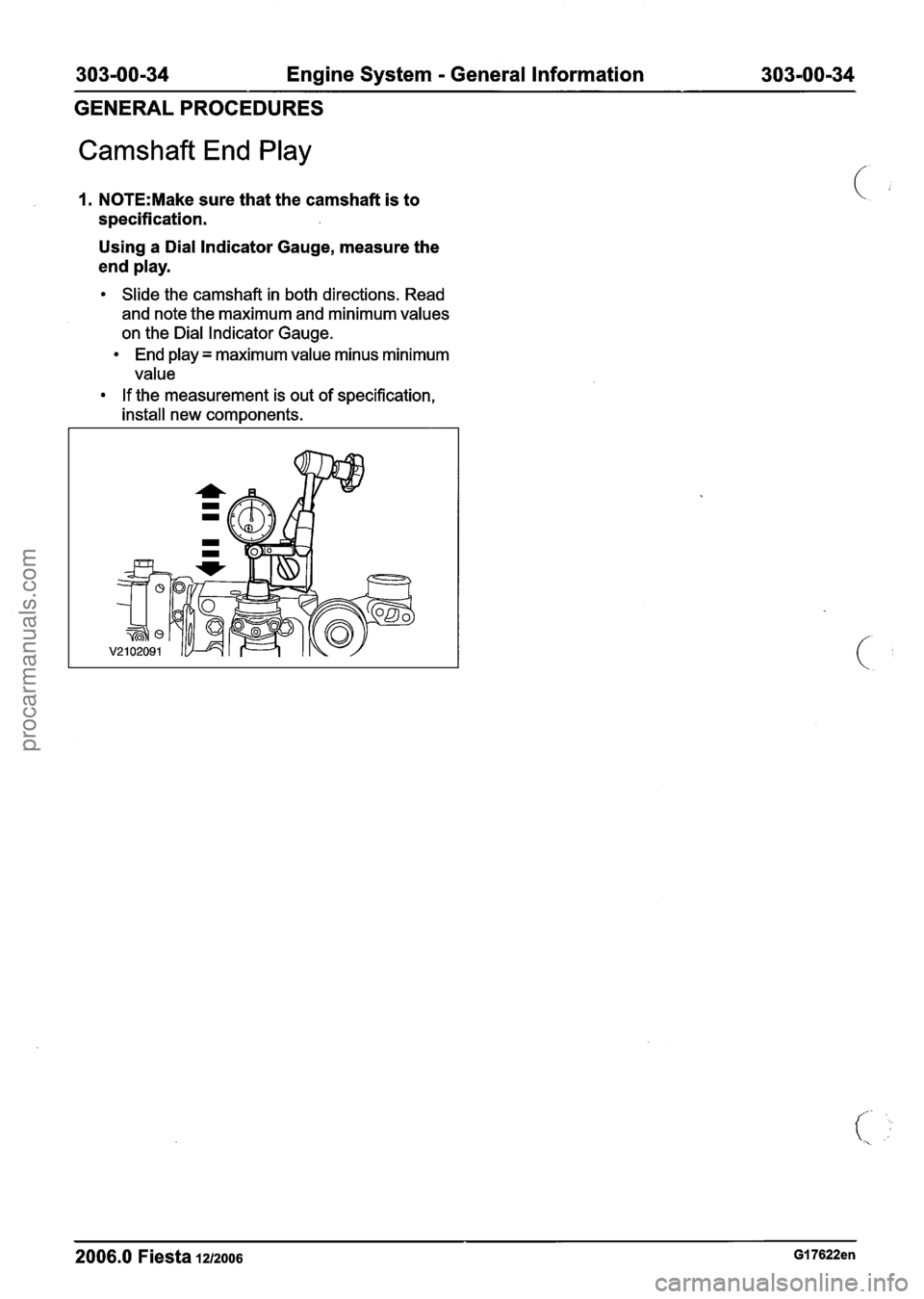

Camshaft End Play

1. N0TE:Make sure that the camshaft is to

specification.

Using a Dial Indicator Gauge, measure the

end play.

Slide the camshaft in both directions. Read

and note the maximum and minimum values

on the Dial lndicator Gauge.

End play = maximum value minus minimum

value

If the measurement is out of specification,

install new components.

2006.0 Fiesta 1212006 GI 7622en

procarmanuals.com

Page 457 of 1226

303-00-35 Engine System - General Information 303-00135

GENERAL PROCEDURES

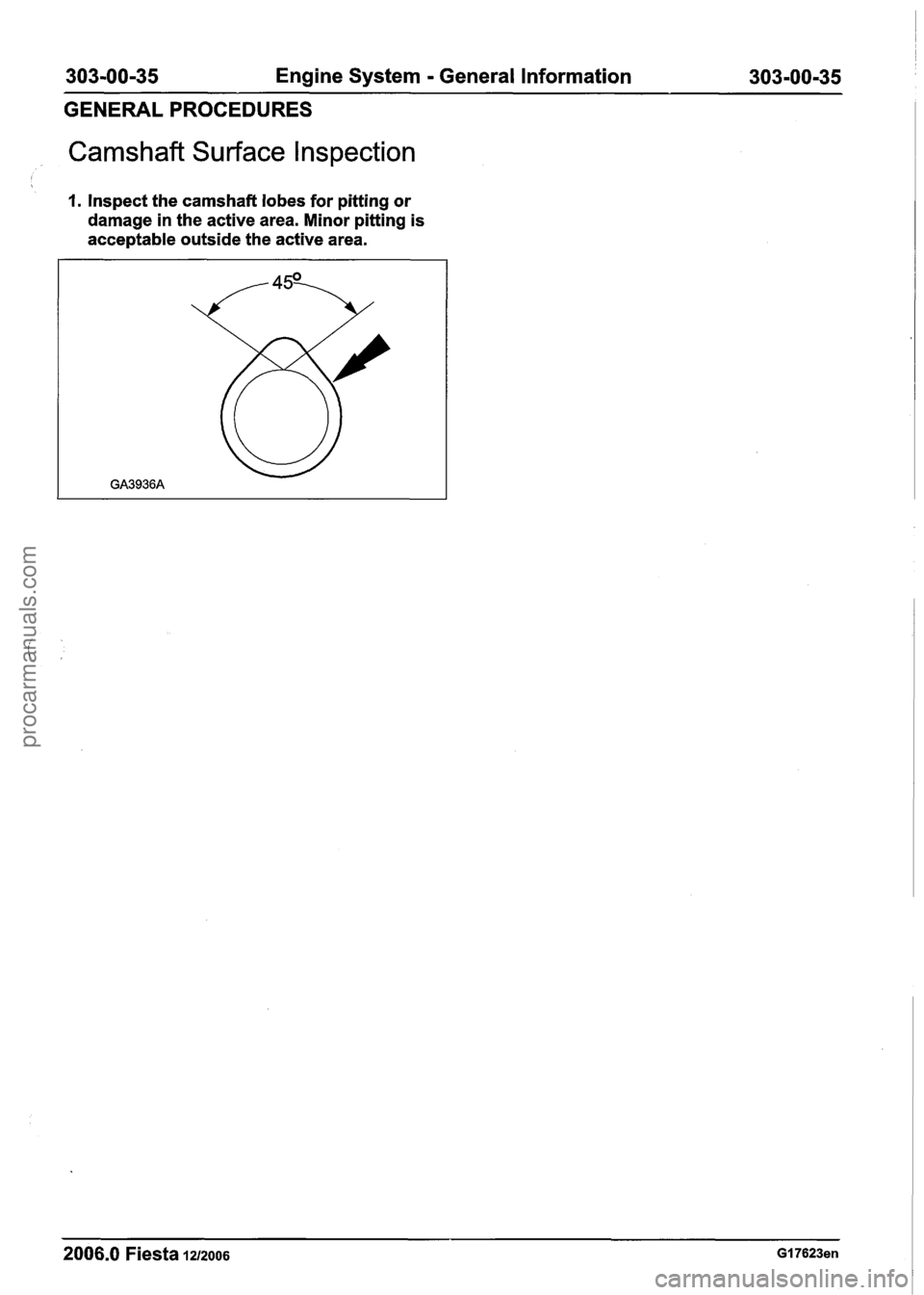

Camshaft Surface l nspection

I

I. Inspect the camshaft lobes for pitting or

damage in the active area. Minor pitting is

acceptable outside the active area.

2006.0 Fiesta 1212006 GI 7623en

procarmanuals.com

Page 458 of 1226

303-00-36 Engine System - General Information 303-00-36

GENERAL PROCEDURES

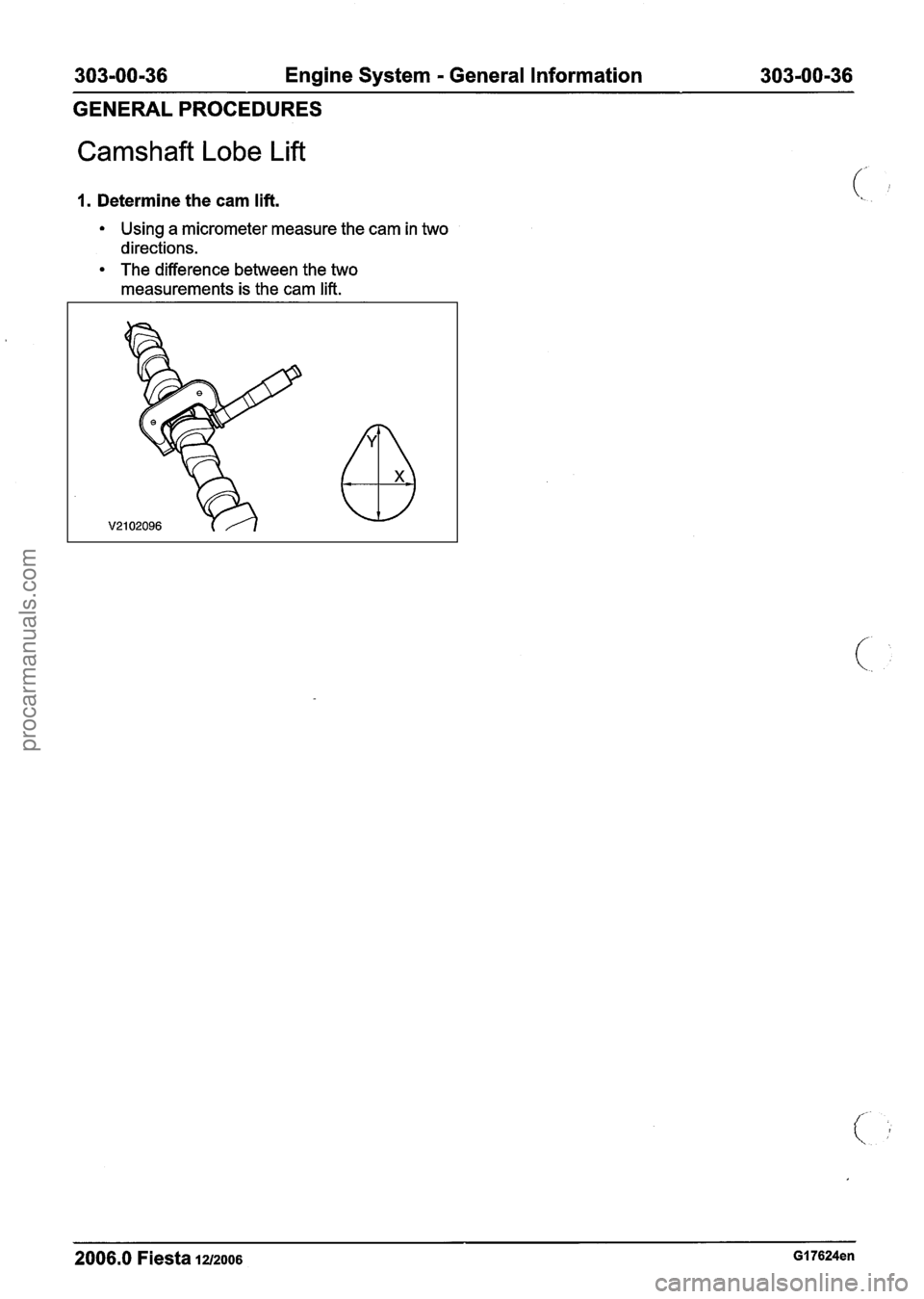

Camshaft Lobe Lift

1. Determine the cam lift.

Using a micrometer measure the cam in two

directions.

The difference between the two

measurements is the cam

lift.

2006.0 Fiesta 1212006 GI 7624en

procarmanuals.com

Page 459 of 1226

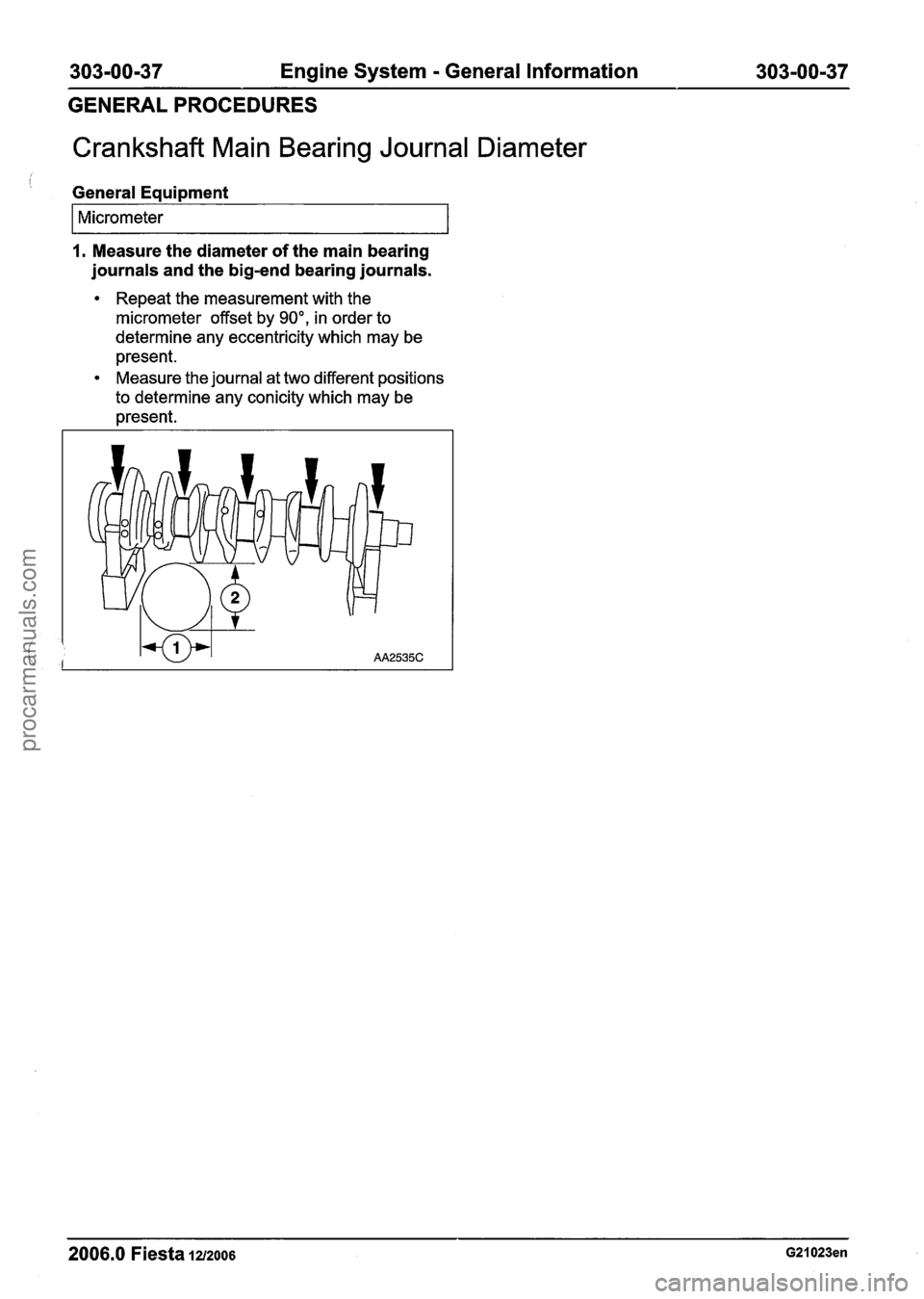

303-00-37 Engine System - General Information 303-00-37

GENERAL PROCEDURES

Crankshaft Main Bearing Journal Diameter

" General Equipment

I Micrometer I

1. Measure the diameter of the main bearing

journals and the big-end bearing journals.

Repeat the measurement with the

micrometer offset by

90°, in order to

determine any eccentricity which may be

present.

Measure the journal at two different positions

to determine any conicity which may be

present.

2006.0 Fiesta 1212006 G21023en

procarmanuals.com

Page 460 of 1226

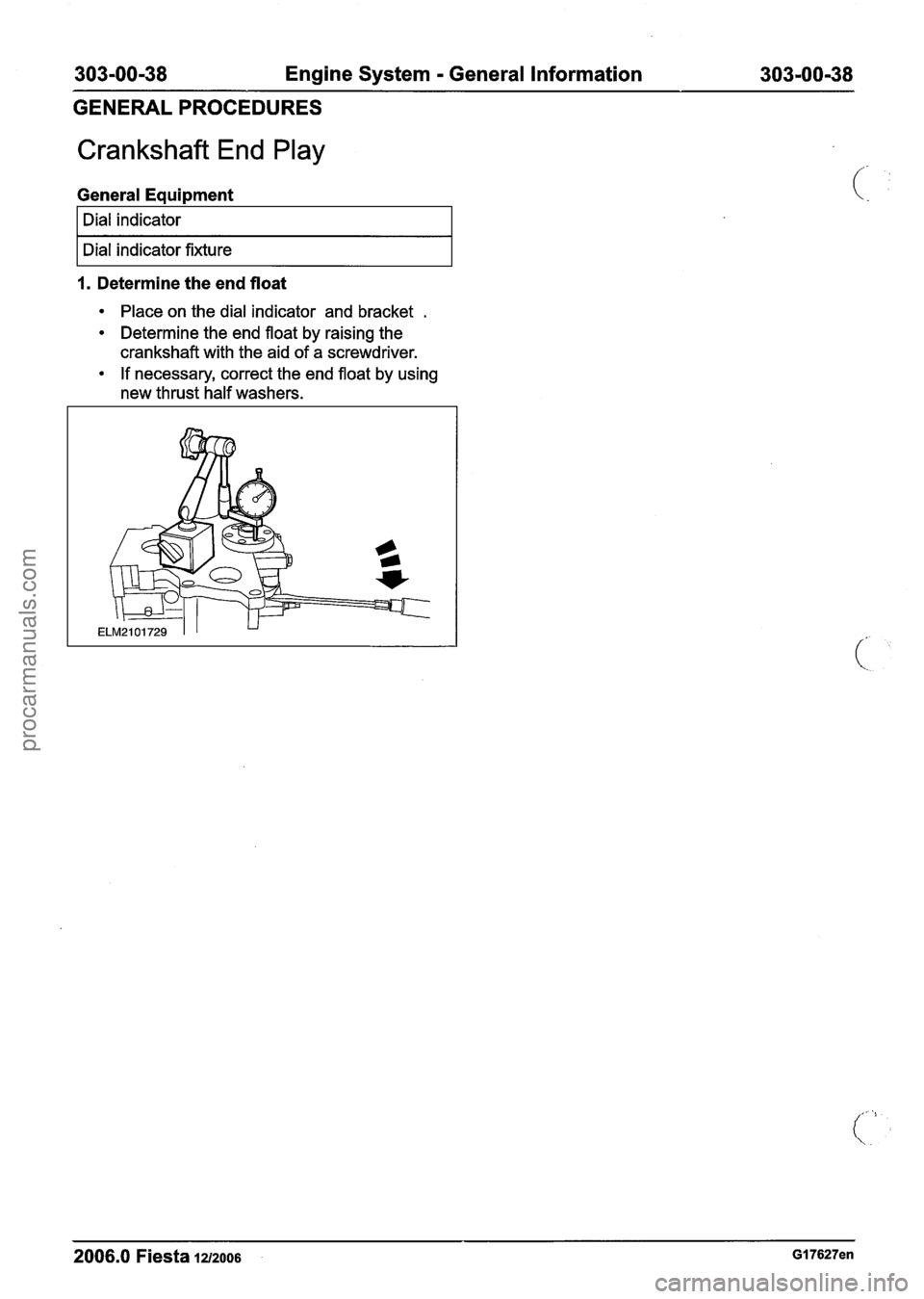

303-00-38 Engine System - General Information 303-00-38

GENERAL PROCEDURES

Crankshaft End Play

General Equipment

I Dial indicator I

I Dial indicator fixture I

1. Determine the end float

Place on the dial indicator and bracket .

Determine the end float by raising the

crankshaft with the aid of a screwdriver.

If necessary, correct the end float by using

new thrust half washers.

2006.0 Fiesta 1212006 GI 7627en

procarmanuals.com

Trending: cylinder head gasket, door lock, wiper fluid, maintenance, CD changer, Breather, liner