light FORD FIESTA 2007 Service Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2007, Model line: FIESTA, Model: FORD FIESTA 2007Pages: 1226, PDF Size: 61.26 MB

Page 618 of 1226

Engine - 1.25L Duratec-1 6V (Sigma)ll.4L

303-01A-I42 Duratec-1 6V (Sigma)/l .6L Duratec-I 6V (Sigma)

INSTALLATION

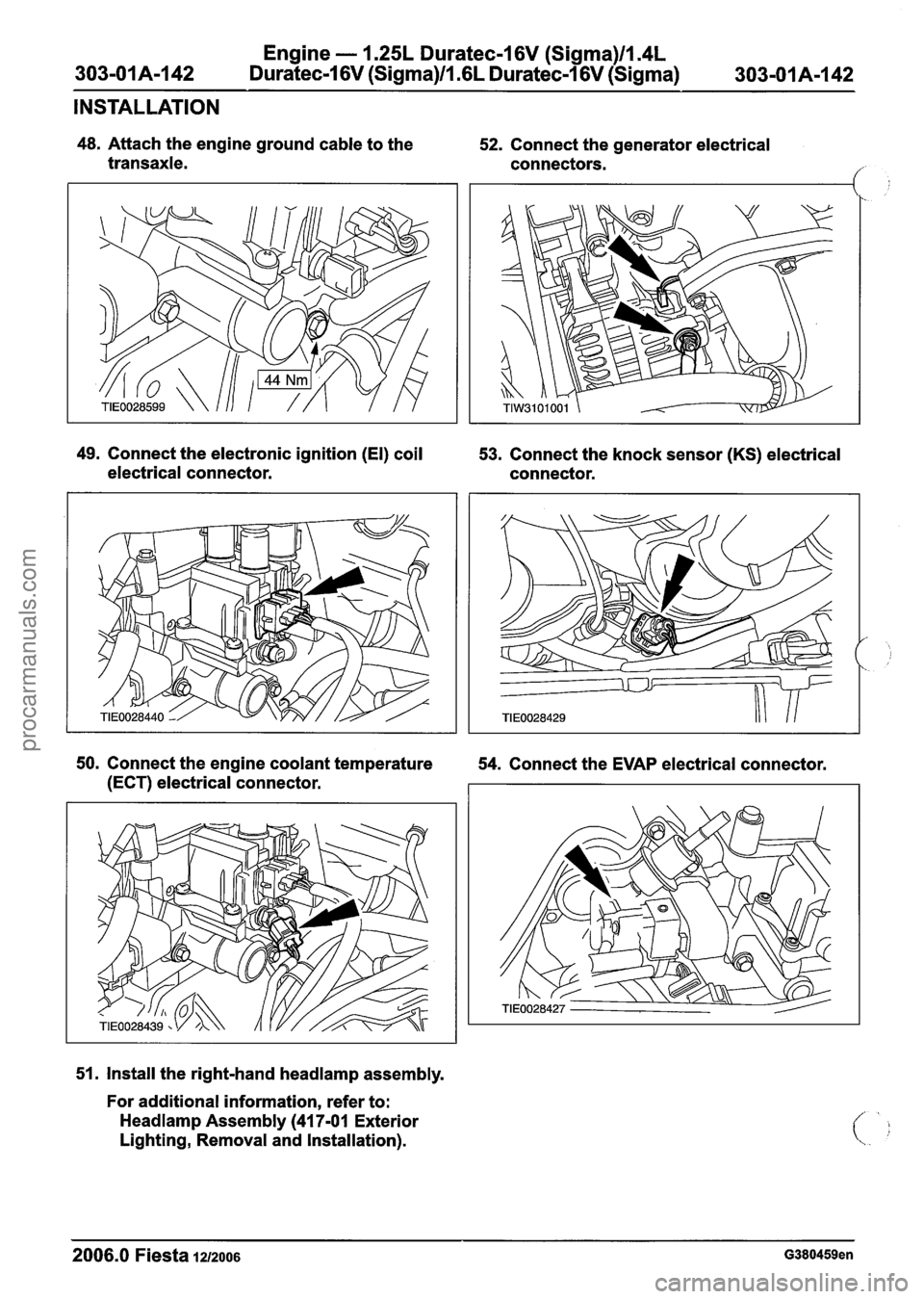

48. Attach the engine ground cable to the

transaxle. 52.

Connect the generator electrical

connectors.

49. Connect the electronic ignition (El) coil

53. Connect the knock sensor

(KS) electrical

electrical connector. connector.

50. Connect the engine coolant temperature

54. Connect the EVAP electrical connector.

(ECT) electrical connector.

51. Install the right-hand

headlamp assembly.

For additional information, refer to:

Headlamp Assembly (41 7-01 Exterior

Lighting, Removal and Installation).

2006.0 Fiesta 1212006 G380459en

procarmanuals.com

Page 631 of 1226

303101 B-9 Engine - 2.OL Duratec-HE (M14) 303-01 B-9

DESCRIPTION AND OPERATION

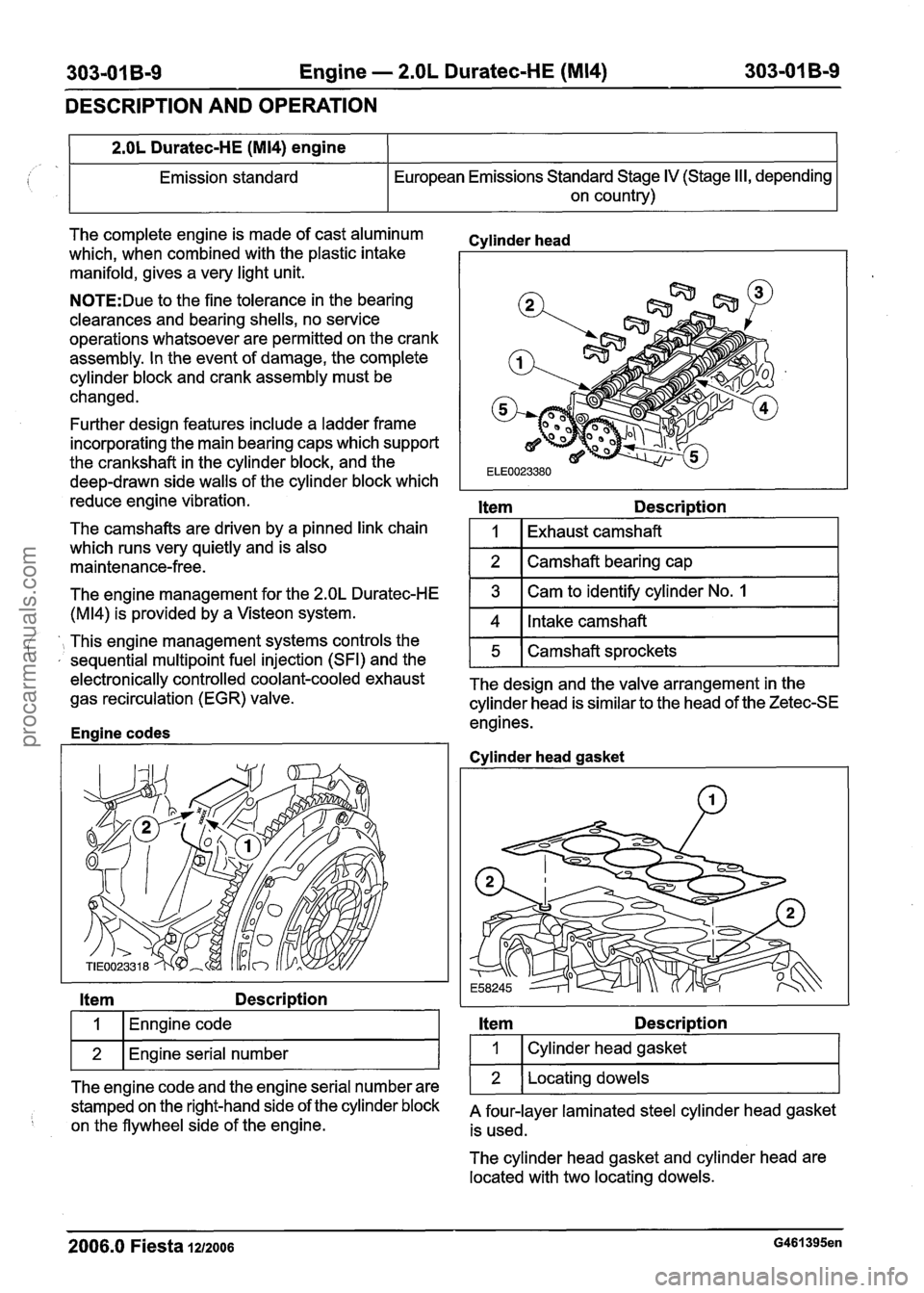

The complete engine is made of cast aluminum

which, when combined with the plastic intake

manifold, gives a very light unit.

2.OL Duratec-HE (M14) engine

Emission standard

N0TE:Due to the fine tolerance in the bearing

clearances and bearing shells, no service

operations whatsoever are permitted on the crank

assembly. In the event of damage, the complete

cylinder block and crank assembly must be

changed. European

Emissions Standard Stage

IV (Stage II I, depending

on country)

Further design features include a ladder frame

incorporating the main bearing caps which support

the crankshaft in the cylinder block, and the

deep-drawn side walls of the cylinder block which

reduce engine vibration.

The camshafts are driven by a pinned link chain

which runs very quietly and is also

maintenance-free.

Cvlinder head

Item Description

1

2

The engine management for the 2.OL Duratec-HE

(M14) is provided by a Visteon system.

Item Description

Exhaust camshaft

Camshaft bearing cap

', This engine management systems controls the ' , sequential multipoint fuel injection (SFI) and the

I 1 (Enngine code I

3

4

wl~n~ine serial number I

Cam to identify cylinder No. 1

Intake camshaft

ele~tronically controlled coolant-cooled exhaust The design and the valve arrangement in the gas recirculation (EGR) valve.

cylinder head is similar to the head of the Zetec-SE

engines.

Enaine codes

5

The engine code and the engine serial number are

stamped on the right-hand side of the cylinder block

on the flywheel side of the engine. Camshaft sprockets

Cvlinder

head gasket

Item Description

I 1 I Cylinder head gasket I

1 2 1 Locating dowels 1

A four-layer laminated steel cylinder head gasket

is used.

The cylinder head gasket and cylinder head are

located with two locating dowels.

2006.0 Fiesta 1212006 G461395en

procarmanuals.com

Page 643 of 1226

303-01 B-21 Engine - 2.OL Duratec-HE (M14) 303-01 B-21

IN-VEHICLE REPAIR

Intake Manifold(21 183 0)

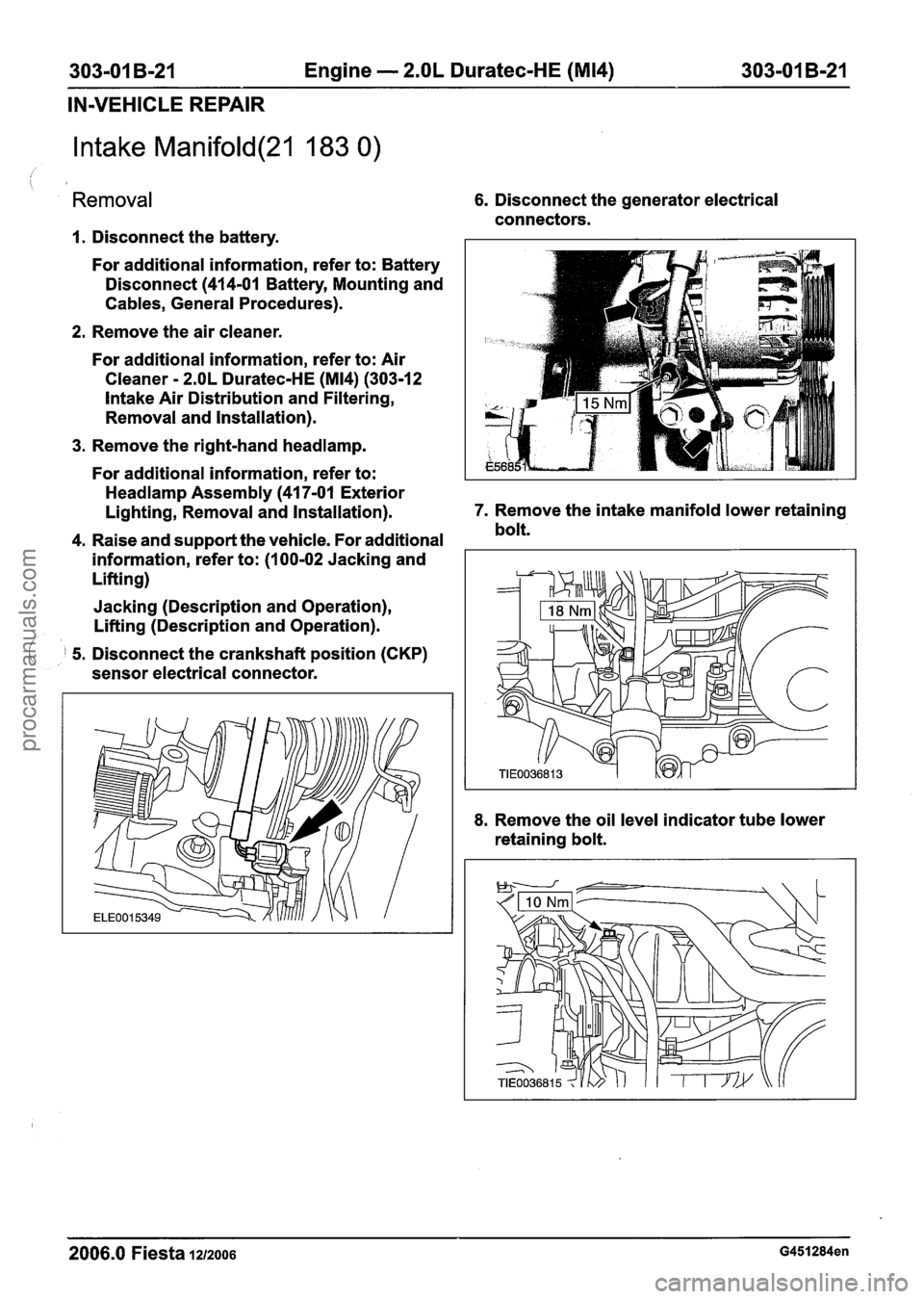

Removal

1. Disconnect the battery.

For additional information, refer to: Battery

Disconnect (414-01 Battery, Mounting and

Cables, General Procedures).

2. Remove the air cleaner.

For additional information, refer to: Air

Cleaner

- 2.OL Duratec-HE (M14) (303-12

lntake Air Distribution and Filtering,

Removal and Installation).

3. Remove the right-hand headlamp.

6. Disconnect the generator electrical

connectors.

For additional information, refer to:

Headlamp Assembly (41 7-01 Exterior

Lighting, Removal and Installation). 7.

Remove the intake manifold lower retaining

4. Raise and support the vehicle. For additional bolt.

information, refer to: (I

00-02 Jacking and

Lifting)

Jacking (Description and Operation),

Lifting (Description and Operation).

( 5. Disconnect the crankshaft position (CKP)

sensor electrical connector.

8. Remove the oil level indicator tube lower

retaining bolt.

2006.0 Fiesta 1212006 G451284en

procarmanuals.com

Page 691 of 1226

303-01 B-69 Engine - 2.OL Duratec-HE (M14) 303-01 B-69

IN-VEHICLE REPAIR

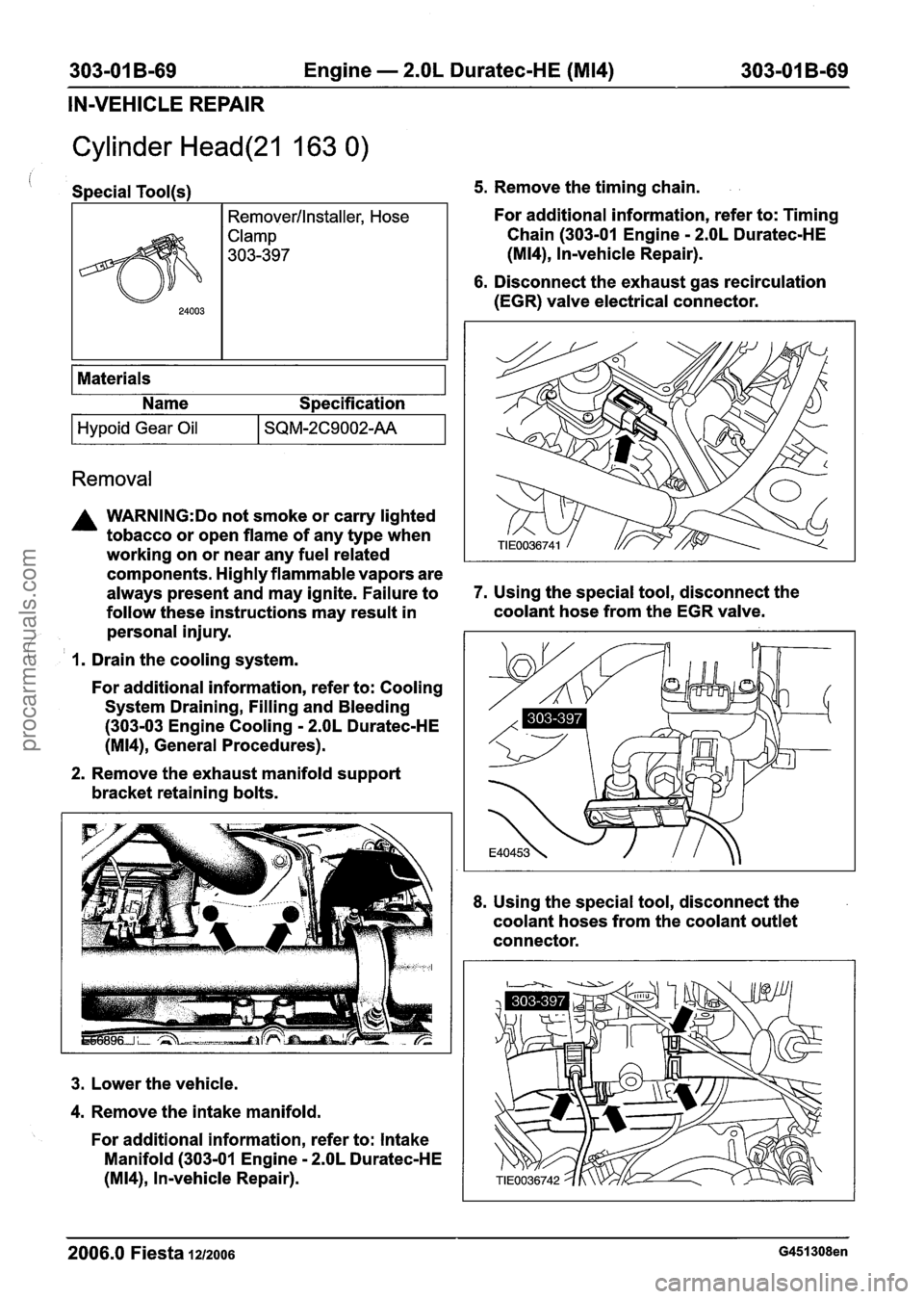

Cylinder Head(21 163 0)

Special Tool(s) 5. Remove the timing chain.

I Materials I

24003

I I Name Specification

Remover/lnstaller, Hose

Clamp

303-397

Removal

For additional information, refer to: Timing

Chain (303-01 Engine

- 2.OL Duratec-HE

(M14), Invehicle Repair).

6. Disconnect the exhaust gas recirculation

(EGR) valve electrical connector.

Hypoid Gear Oil

A WARNING:Do not smoke or carry lighted

tobacco or open flame of any type when

working on or near any fuel related

components. Highly flammable vapors are

always present and may ignite. Failure to

7. Using the special tool, disconnect the

follow these instructions may result in coolant hose

from the EGR valve.

personal injury.

/

SQM-2C9002-AA

( I. Drain the cooling system.

For additional information, refer to: Cooling

System Draining, Filling and Bleeding

(303-03 Engine Cooling

- 2.OL Duratec-HE

(M14), General Procedures).

2. Remove the exhaust manifold support

bracket retaining bolts.

3. Lower the vehicle.

4. Remove the intake manifold.

For additional information, refer to: Intake

Manifold (303-01 Engine

- 2.OL Duratec-HE

(M14), In-vehicle Repair).

8. Using the special tool, disconnect the

coolant hoses from the coolant outlet

connector.

2006.0 Fiesta 1212006 G451308en

procarmanuals.com

Page 696 of 1226

303-01 B-74 Engine - 2.OL Duratec-HE (M14) 303-01 B-74

REMOVAL

Engine

Special Tool(s)

I I Remover, Power Steering I

I I Removerllnstaller, Hose

General Equipment

I Workshop table I

I Engine hoist I

I Securing straps I

Removal

A WARNING:Do not smoke or carry lighted

tobacco or open flame of any type when

working on or near any fuel related

components. Highly flammable vapors are

always present and may ignite. Failure to

follow these instructions may result in

personal injury.

1. Remove the air cleaner. c.

For additional information, refer to: Air

Cleaner

- 2.OL Duratec-HE (M14) (30312

Intake Air Distribution and Filtering,

Removal and Installation).

2. Remove the battery tray.

For additional information, refer to: Battery

Tray

- 2.OL Duratec-HE (M14) (414-01

Battery, Mounting and Cables, Removal

and Installation).

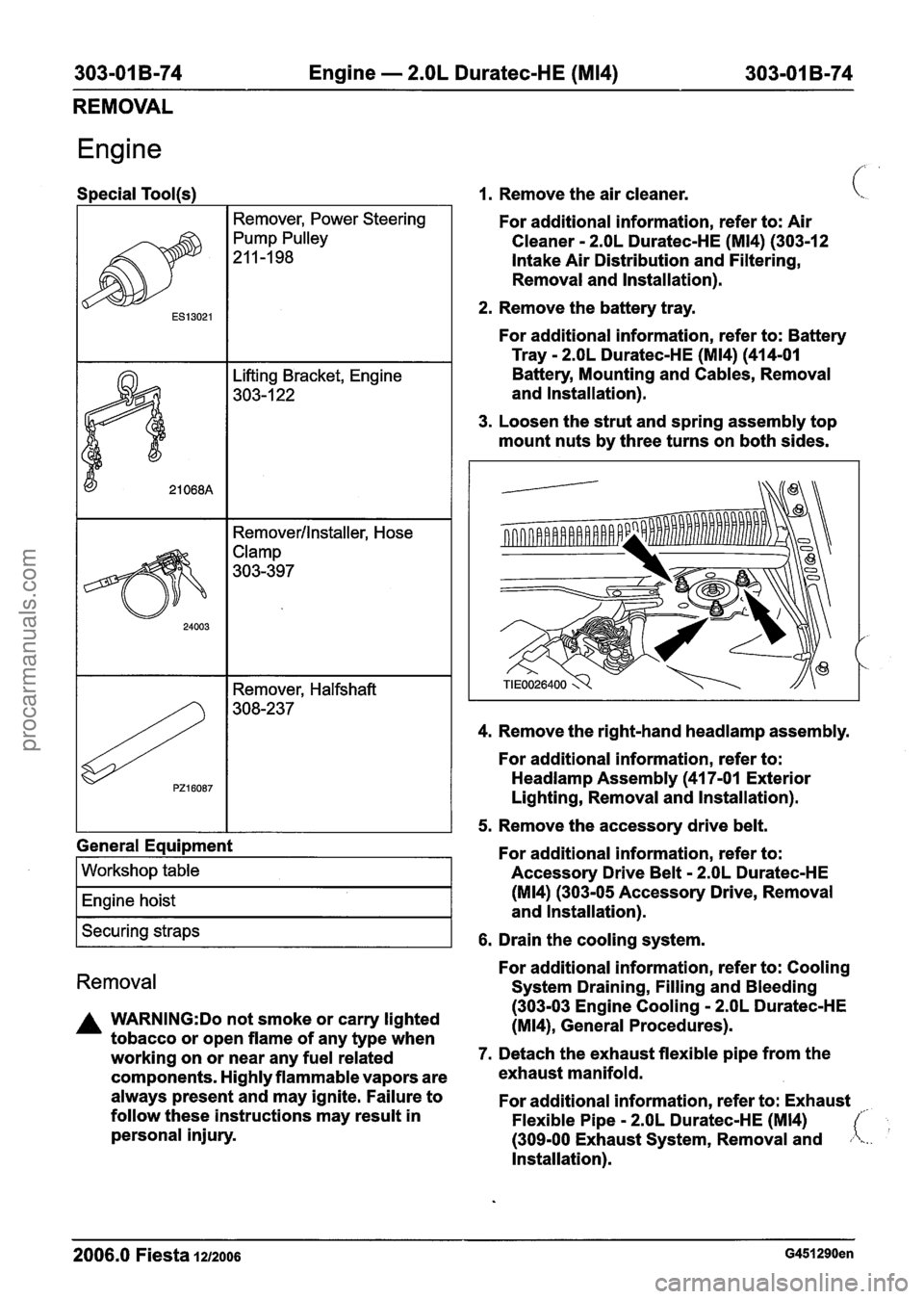

3. Loosen the strut and spring assembly top

mount nuts by three turns on both sides.

4. Remove the right-hand

headlamp assembly.

For additional information, refer to:

Headlamp Assembly (41 7-01 Exterior

Lighting, Removal and Installation).

5. Remove the accessory drive belt.

For additional information, refer to:

Accessory Drive Belt

- 2.OL Duratec-HE

(M14) (303-05 Accessory Drive, Removal

and Installation).

6. Drain the cooling system.

For additional information, refer to: Cooling

System Draining, Filling and Bleeding

(303-03 Engine Cooling

- 2.OL Duratec-HE

(M14), General Procedures).

7. Detach the exhaust flexible pipe from the

exhaust manifold.

For additional information, refer to: Exhaust

Flexible Pipe

- 2.OL Duratec-HE (M14)

(309-00 Exhaust System, Removal and

Installation).

2006.0 Fiesta 1212006 G451290en

procarmanuals.com

Page 733 of 1226

303-01 B-I11 Engine - 2.OL Duratec-HE (M14) 303-01 B-111

INSTALLATION

Engine

i Special Tool(s)

I

I Remover/lnstaller, Hose

General Equipment

I Workshop table 1

I Securing straps I

I Engine hoist I --

A WARNING:Do not smoke or carry lighted

tobacco or open flame of any type when

working on or near any fuel related

components. Highly flammable vapors are

always present and may ignite. Failure to

follow these instructions may result in

personal injury.

1. N0TE:Using suitable retaining straps, secure

the engine on the workshop table.

Support the engine with wooden blocks.

2. Install the transaxle.

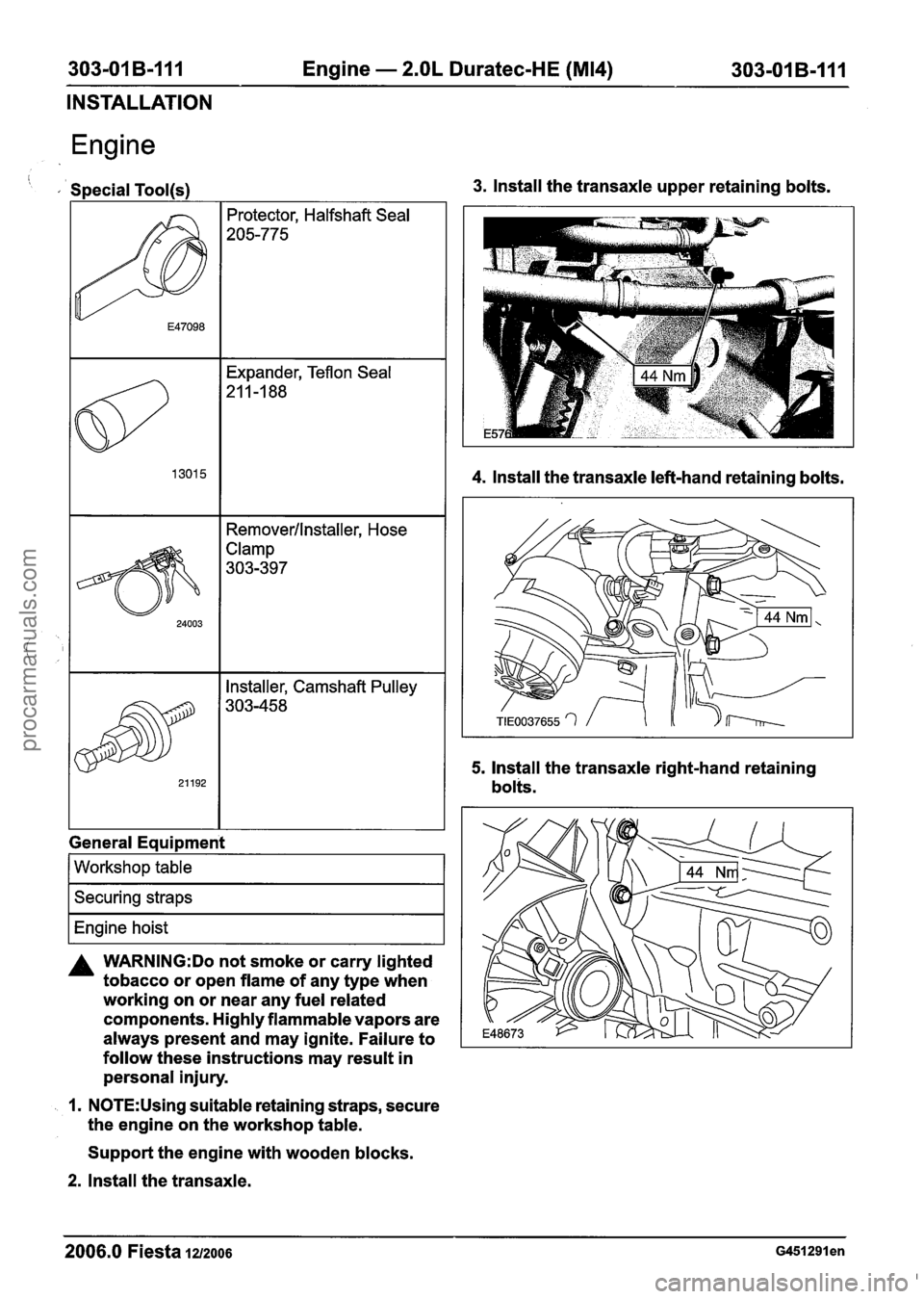

3. Install the transaxle upper retaining bolts.

4. Install the transaxle left-hand retaining bolts.

5. Install the transaxle right-hand retaining

bolts.

2006.0 Fiesta 1212006 ~451291 en

procarmanuals.com

Page 741 of 1226

303-01 B-1/19 Engine - 2.OL Duratec-HE (M14) 303-01 B-119

INSTALLATION

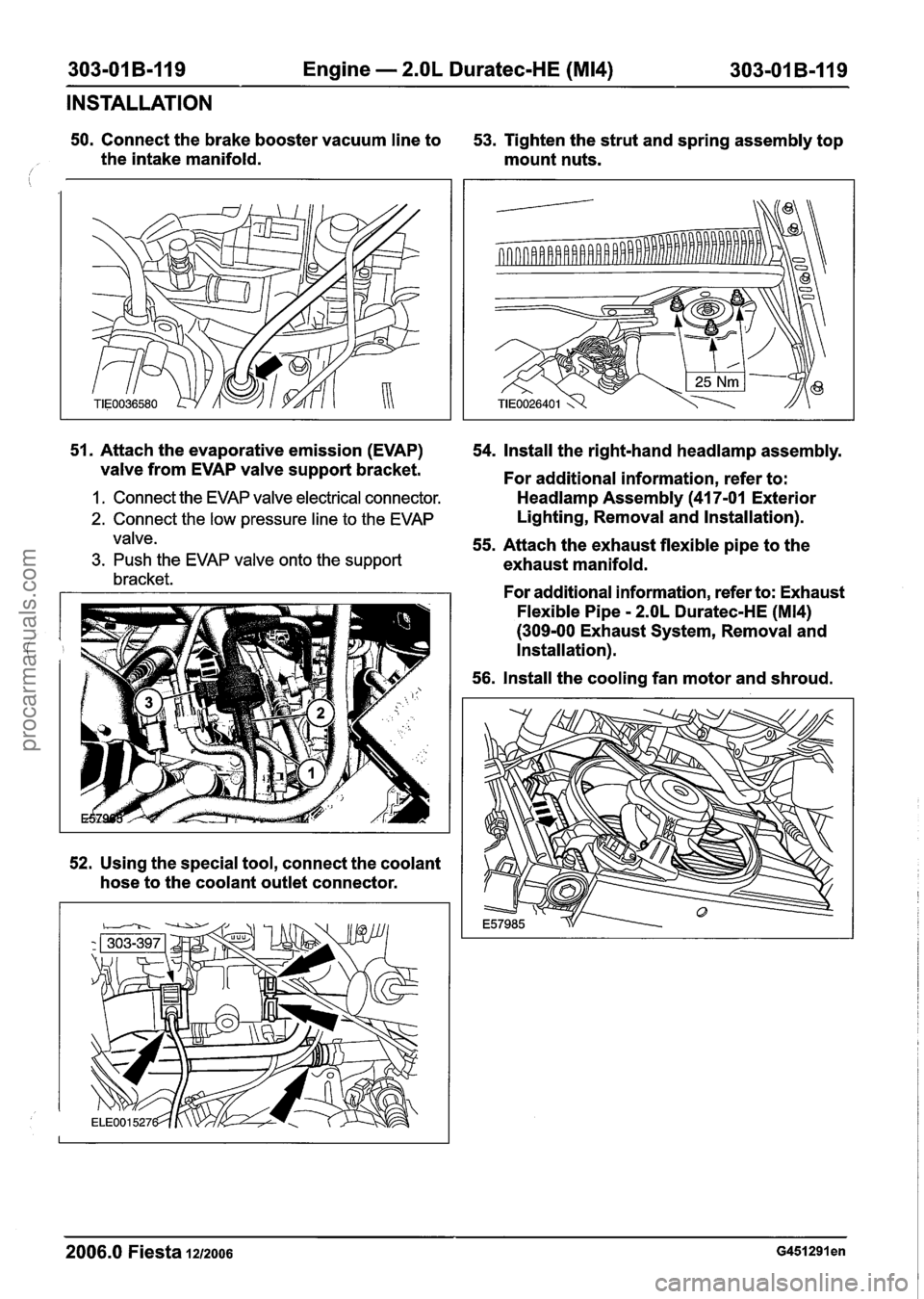

50. Connect the brake booster vacuum line to

53. Tighten the strut and spring assembly top

the intake manifold. mount nuts.

/

51. Attach the evaporative emission (EVAP)

valve from EVAP valve support bracket.

I. Connect the EVAP valve electrical connector.

2. Connect the low pressure line to the EVAP

valve.

3. Push the EVAP valve onto the support

bracket.

52. Using the special tool, connect the coolant

hose to the coolant outlet connector. 54.

Install the right-hand

headlamp assembly.

For additional information, refer to:

Headlamp Assembly (41 7-01 Exterior

Lighting, Removal and Installation).

55. Attach the exhaust flexible pipe to the

exhaust manifold.

For additional information, refer to: Exhaust

Flexible Pipe

- 2.OL Duratec-HE (M14)

(309-00 Exhaust System, Removal and

Installation).

56. Install the cooling fan motor and shroud.

2006.0 Fiesta 1212006 ~451291 en

procarmanuals.com

Page 759 of 1226

Engine Cooling - I .3L Duratec-8V

(Rocam)llm25L Duratec-1 6V (Sigma)ll.4L

303-03A-17 Duratec-1 6V (Sigma)/lm6L Duratec-1 6V (Sigma) 303-03A-17

DIAGNOSIS AND TESTING

RPM - engine speed

i DSRPM - desired engine speed

The IAT sensor output is useful if the engine being

tested is cold or after an over-night cold soak. The

ECT sensor or CHT sensor and the IAT sensor

should either indicate the same value or be within

1 to 2 degrees Celsius of each other.

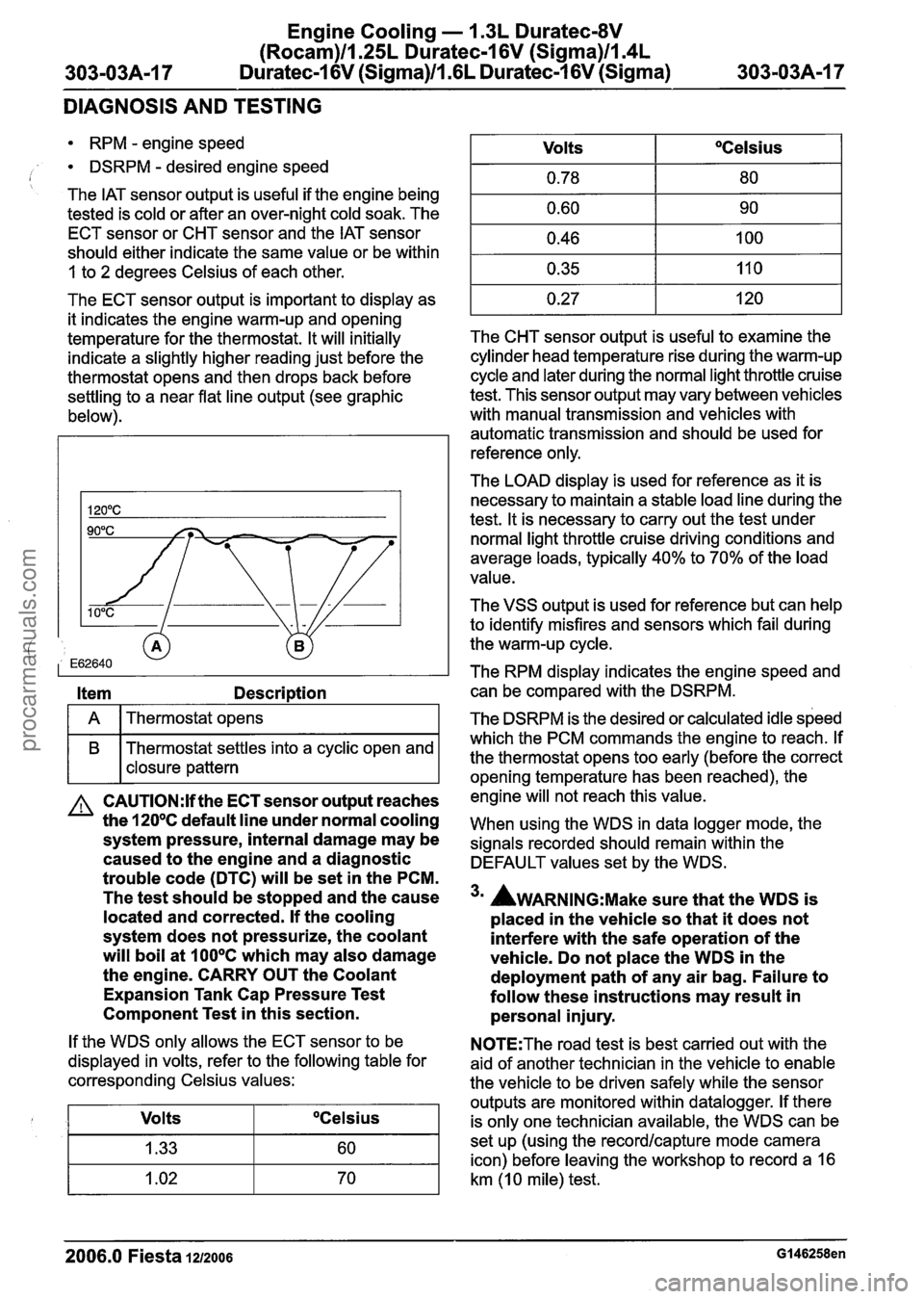

The ECT sensor output is important to display as

it indicates the engine warm-up and opening

temperature for the thermostat. It will initially

indicate a slightly higher reading just before the

thermostat opens and then drops back before

settling to a near flat line output (see graphic

below).

Item Description

I A I Thermostat opens I

B Thermostat settles into a cyclic open and

I I closure pattern

A CAUTI0N:lf the ECT sensor output reaches

the

120°C default line under normal cooling

system pressure, internal damage may be

caused to the engine and a diagnostic

trouble code (DTC) will be set in the PCM.

The test should be stopped and the cause

located and corrected. If the cooling

system does not pressurize, the coolant

will boil at

100°C which may also damage

the engine. CARRY OUT the Coolant

Expansion Tank Cap Pressure Test

Component Test in this section.

If the WDS only allows the ECT sensor to be

displayed in volts, refer to the following table for

corresponding Celsius values:

Volts

OCelsius

The CHT sensor output is useful to examine the

cylinder head temperature rise during the warm-up

cycle and later during the normal light throttle cruise

test. This sensor output may vary between vehicles

with manual transmission and vehicles with

automatic transmission and should be used for

reference only.

Volts

0.78

0.60

0.46

0.35

0.27

The

LOAD display is used for reference as it is

necessary to maintain a stable load line during the

test. It is necessary to carry out the test under

normal light throttle cruise driving conditions and

average loads, typically

40% to 70% of the load

value.

OCelsius

80

90

100

11 0

120

The VSS output is used for reference but can help

to identify misfires and sensors which fail during

the warm-up cycle.

The RPM display indicates the engine speed and can be compared with the DSRPM.

The DSRPM is the desired or calculated idle speed

which the PCM commands the engine to reach. If

the thermostat opens too early (before the correct

opening temperature has been reached), the

engine will not reach this value.

When using the WDS in data logger mode, the

signals recorded should remain within the

DEFAULT values set by the WDS.

3m AWARNING:M~~~ sure that the WDS is

placed in the vehicle so that it does not

interfere with the safe operation of the

vehicle. Do not place the WDS in the

deployment path of any air bag. Failure to

follow these instructions may result in personal injury.

N0TE:The road test is best carried out with the

aid of another technician in the vehicle to enable

the vehicle to be driven safely while the sensor

outputs are monitored within datalogger. If there

is only one technician available, the WDS can be

set up (using the

recordlcapture mode camera

icon) before leaving the workshop to record a

16

km (1 0 mile) test.

2006.0 Fiesta 1212006 GI 46258en

procarmanuals.com

Page 760 of 1226

Engine Cooling - 1.3L Duratec-8V

(Rocam)ll125L Duratec-1 6V (Sigma)ll14L

3-03A-18 Duratec-I 6V (Sigma)ll.GL Duratec-1 6V (Sigma) 303-03A-18

DIAGNOSIS AND TESTING

N0TE:The results from the test are more thermostats may increase the coolant temperature

conclusive if the engine is cold when the test is up to 1

OO°C (212OF) under light engine load

started. conditions.

Carry out a road test. The

engine should start cleanly and the ECT value

REFER to:

RoadlRoller Testing (1 00-00 General

Information, Description and Operation).

4. Drive the vehicle at a constant throttle opening

and set speed until the ECT value settles into

a shallow rise and fall signal, close to a straight

line. This indicates that the thermostat is

functioning correctly.

N0TE:Some thermostats indicate the

temperature(s) in Celsius and Fahrenheit.

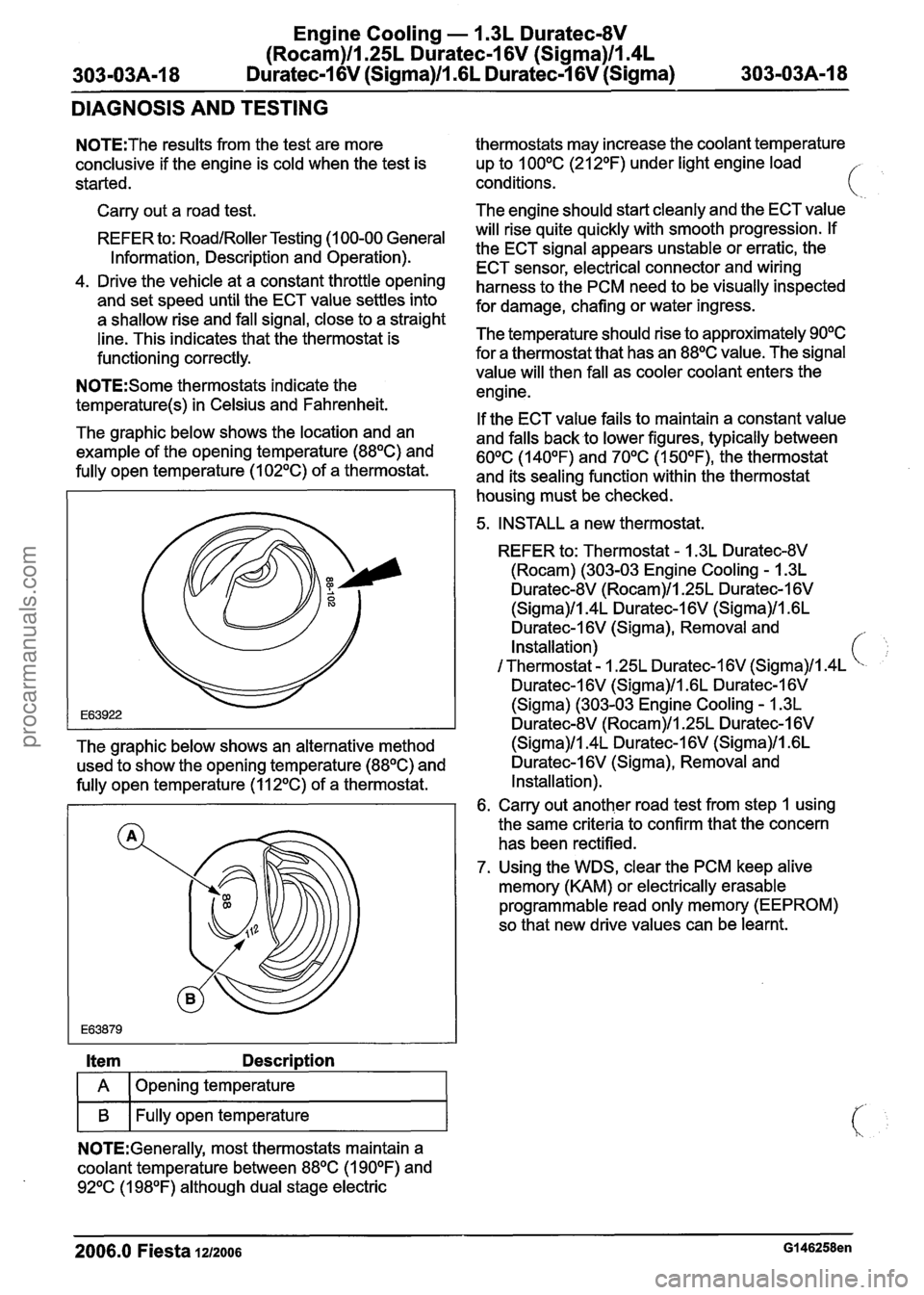

The graphic below shows the location and an

example of the opening temperature

(88OC) and

fully open temperature (1

02OC) of a thermostat. will

risequite quickly with smooth progression.

If

the ECT signal appears unstable or erratic, the

ECT sensor, electrical connector and wiring

harness to the PCM need to be visually inspected

for damage, chafing or water ingress.

The temperature should rise to approximately

90°C

for a thermostat that has an 88OC value. The signal

value will then fall as cooler coolant enters the

engine.

If the ECT value fails to maintain a constant value

and falls back to lower figures, typically between

60°C (140°F) and 70°C (1 50°F), the thermostat

and its sealing function within the thermostat

housing must be checked.

5. INSTALL a new thermostat.

REFER to: Thermostat

- 1.3L Duratec-8V

(Rocam) (303-03 Engine Cooling - 1.3L

Duratec-8V (Rocam)ll.25L Duratec-I 6V

(Sigma)ll.4L Duratec-I 6V (Sigma)ll .6L

Duratec-1

6V (Sigma), Removal and

Installation)

I Thermostat - 1.25L Duratec-I 6V (Sigma)ll.4L

Duratec-1 6V (Sigma)ll .6L Duratec-1 6V

(Sigma) (303-03 Engine Cooling - 1.3L

Duratec-8V (Rocam)ll.25L Duratec-I 6V

The graphic below shows an alternative method (Sigma)/l.4L Duratec-1 6V (Sigma)ll .6L

used to show the opening temperature

(88OC) and Duratec-1 6V (Sigma), Removal

and

fully open temperature (1

12OC) of a thermostat. Installation).

6. Carry out another road test from step 1 using

the same criteria to confirm that the concern

has been rectified.

7. Using the WDS, clear the PCM keep alive

memory (KAM) or electrically erasable

programmable read only memory (EEPROM)

so that new drive values can be learnt.

Item Description

I A 1 Opening temperature I

I B I Fully open temperature I

NOTE:Generally, most thermostats maintain a

coolant temperature between

88OC (1 90°F) and

92OC (1 98OF) although dual stage electric

2006.0 Fiesta 1212006 GI 46258en

procarmanuals.com

Page 784 of 1226

303-03B-14 Engine Cooling - 2.OL Duratec-HE (M14) 303-03B-14

DIAGNOSIS AND TESTING

4. Observe the cooling system pressure tester make sure the pressure test reading

is

gauge reading for approximately two minutes. repeatable

and within acceptable gauge reading

The pressure should not drop during this time. limits of

the coolant expansion tank cap.

( If the system holds Pressure, proceed to Step 5. If the pressure test gauge readings are not 7. If the system does not hold pressure, check

within the acceptable gauge reading limits,

it thoroughly for coolant leaks.

INSTALL a new coolant expansion tank cap.

5. Check the engine for coolant leaks. Drain the

cooling system, repair any coolant leaks found

and fill and bleed the cooling system as

Thermostat Test

necessaw.

REFER to: Cooling System Draining, Filling and

Bleeding (303-03 Engine Cooling

- 2.OL

Duratec-HE (M14), General Procedures).

.Recheck the system by repeating Steps 3 and

4 at least twice.

Radiator Leak Test, Removed From Vehicle

CAUTI0N:Radiator internal pressure must

not exceed

130 kpa (20 psi) or damage may

result.

Clean the radiator thoroughly before leak testing

it, to prevent contamination of the water in the test

tank. Leak test the radiator in clean water with 138

kpa (20 psi) air pressure. Check it thoroughly for

air leaks. INSTALL a new radiator if necessary.

REFER to: Radiator (303-03 Engine Cooling

- 2.OL

Duratec-HE (M14), Removal and Installation).

Coolant Expansion Tank Cap Pressure Test

A WARNING:When releasing the system

pressure, cover the expansion tank cap

with a thick cloth to prevent the possibility

of coolant scalding, Failure to follow this

instruction may result in personal injury.

1. Remove the coolant expansion tank cap.

2. Use water to clean the area of the rubber seal

and pressure relief valve. Install the pressure

tester and adapter and immerse the coolant

-

expansion tank cap in water.

N0TE:lf the plunger of the pump is depressed too

quickly, an erroneous pressure reading will result.

3. Slowly depress the plunger of the pressure test

pump until the pressure gauge reading stops

increasing, and note the highest pressure

reading obtained.

4. Release pressure by turning the pressure relief

screw counterclockwise. Tighten the pressure

relief screw and repeat step 3 at least twice to

I. Connect the WDS to the data link connector

(DLC).

2. Using the WDS datalogger function, SELECT

the following sensors (as applicable to the

application):

IAT

- intake air temperature (IAT) sensor

ECT

- engine coolant temperature (ECT) sensor

CHT

- cylinder head temperature (CHT) sensor

LOAD

- engine load

VSS

- vehicle speed sensor (VSS)

RPM

- engine speed

DSRPM

- desired engine speed

The IAT sensor output is useful if the engine being

tested is cold or after an over-night cold soak. The

ECT sensor or CHT sensor and the IAT sensor

(

should either indicate the same value or be within

1 to 2 degrees Celsius of each other.

The ECT sensor output is important to display as

it indicates the engine warm-up and opening

temperature for the thermostat. It will initially

indicate a slightly higher reading just before the

thermostat opens and then drops back before

settling to a near flat line output (see graphic

below).

Item Description 1'. .

) A 1 Thermostat opens I\

B Thermostat settles into a cyclic open and

I I closure pattern

2006.0 Fiesta 1212006 G426582en

procarmanuals.com